Abstract

As the market share of electric vehicles continues to rise, the number of battery systems that are retired after their service life in the vehicle will also increase. This large growth in battery returns will also have a noticeable impact on processes such as battery disassembly. The purpose of this paper is, therefore, to examine the challenges of the battery disassembly process in relation to the required increase in the degree of automation. For this purpose, a survey of various experts along the battery value chain was conducted, and product-side hurdles, such as the wide range of variants, and process-side challenges, such as the opening of the housing cover or the removal of cables and connectors, were identified. Together with an assessment of the potential degree of automation in the context of downstream processes (reuse, repair, remanufacturing, and recycling), this results in a variety of streams for future research in the field of automated battery disassembly. The core aspect in this context is data availability consisting of product and component data as well as process-relevant parameters.

1. Introduction

The transformation in the mobility sector has reached its next phase. With the increasing market share of electrically powered vehicles, electric mobility has now fully arrived in mainstream and among customers. This has not only been recognized by manufacturers, who are now expanding their vehicle portfolios to include more and more purely electrically powered models in addition to an increasing number of hybrid vehicle models [1]. This aspect is also reflected in current political decisions. In addition to the previous financial incentives for electric vehicles, a permanent ban on most vehicles with combustion engines from 2035 onwards, approved by the EU Parliament, has set the course for a complete market diffusion of electric drives in Europe [2].

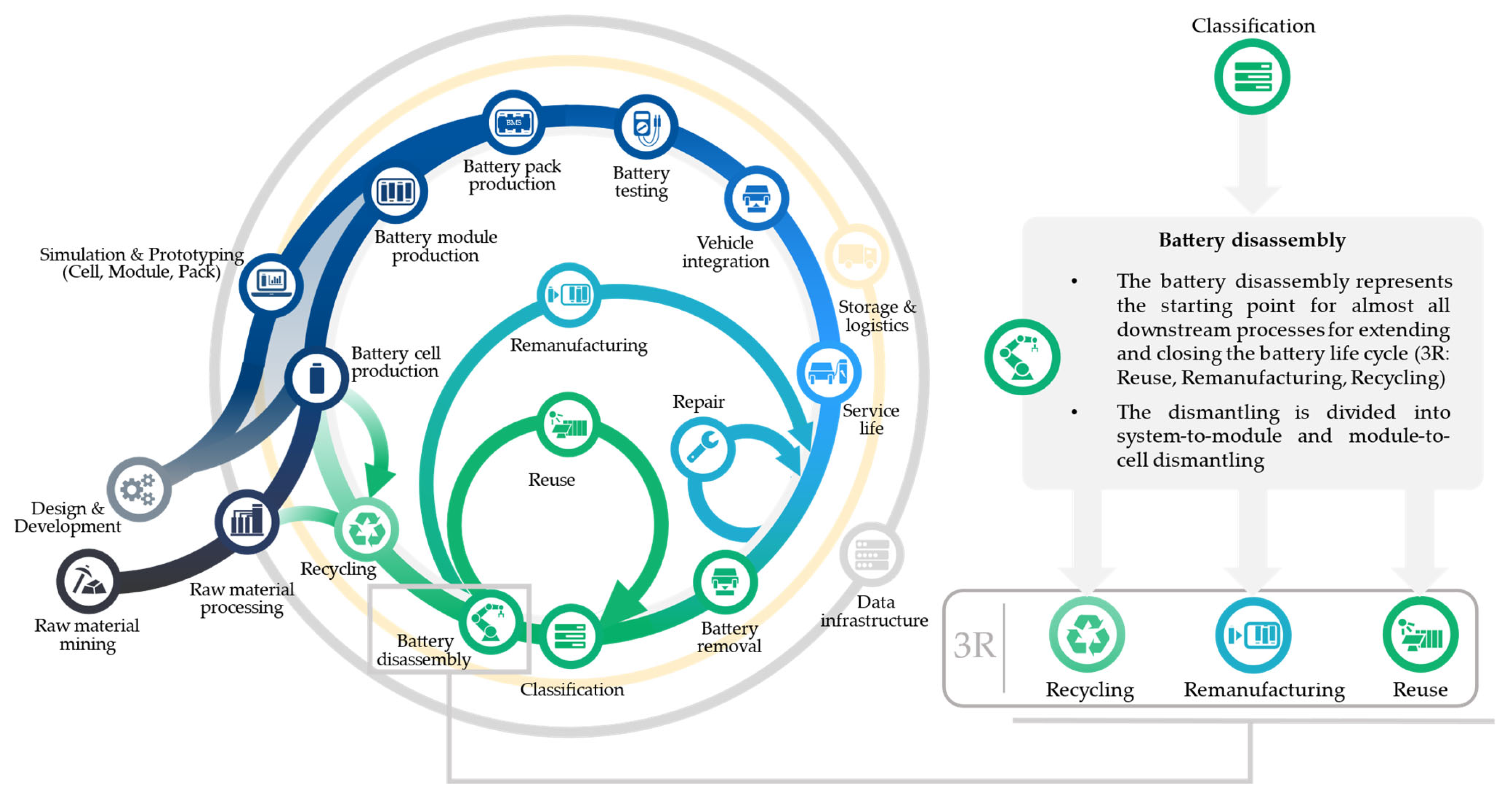

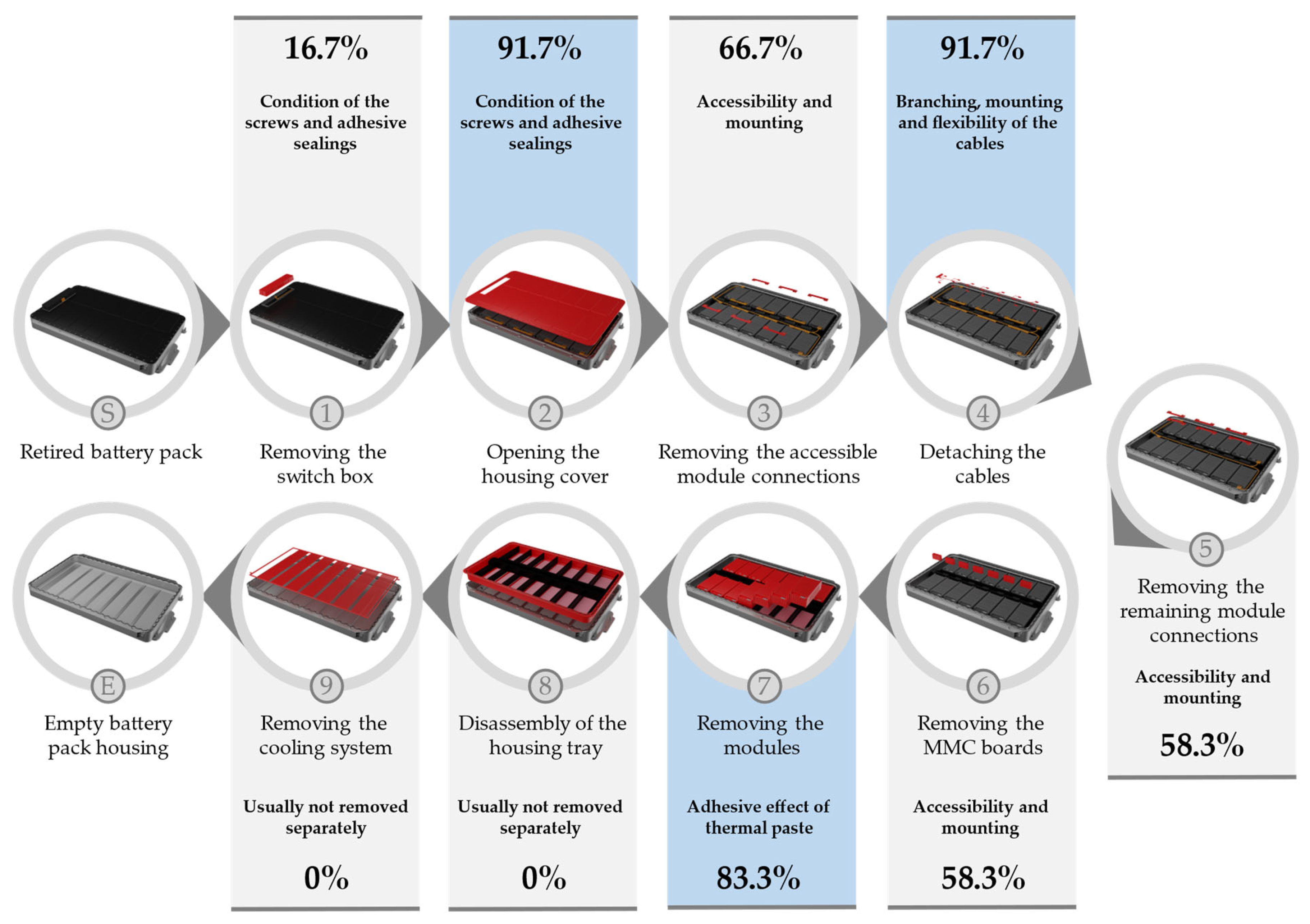

The heart of the electric powertrain is the traction battery. After an initial period in which the focus of electric vehicle and battery manufacturers was on market penetration, along with production and development topics related to increasing capacity and reducing costs of traction batteries [3], growing attention is now being paid to closing the battery lifecycle after the service life in the vehicle. Topics such as further use of traction batteries in stationary storage systems, the repair and remanufacturing of used battery systems, and recycling, including the associated recovery of essential raw materials are becoming increasingly important [4]. All in all, a multitude of paths and phases have been formed here, which the battery passes through, from the extraction of raw materials to a possible recycling. An overview of the most relevant stations is given in Figure 1, which also shows some important side processes such as the topic of logistics and the increasingly required data infrastructure.

Figure 1.

Overview of the closed-loop battery life cycle with disassembly as the central branching point for the 3R paths.

The disassembly of battery systems is a particularly relevant process in the battery cycle. It forms the starting point for reuse, remanufacturing, and recycling paths [5]. These downstream paths and the preceding steps before disassembly can be observed in the bottom section of the cycle in Figure 1. After the battery system has been removed from the vehicle at the end of its service life and a classification of its condition and further possible usage have been determined, it can be dismantled. Battery systems may have spent ten or more years in the vehicle at this point, with their state of health (SOH) typically already down to around 70–80% or less [6,7]. In addition to SOH, factors such as the active material used in the cells and the physical condition are of interest for a classification [8,9].

Due to the central position of battery disassembly in the described pathways, the objective of this work is to examine the future development of battery disassembly. With the help of interviews with experts from various companies along the battery value chain, major challenges in terms of an industrial implementation will be examined.

First, the current state of battery disassembly is described. This is followed by a breakdown of the interview results, particularly with regard to the need for process automation. Finally, the necessary research demand in the field of automated battery disassembly is summarized.

2. State-of-the-Art Battery Disassembly

The present procedure for dismantling traction batteries is still characterized by relatively low return volumes, which will, however, increase significantly in the upcoming years due to the growing market share of electric vehicles. Battery disassembly is, therefore, currently carried out manually and without the support of robots [10]. The disassembly process is usually performed by multiple qualified workers [11].

Due to the manual execution, there is a high-voltage risk to the workers, especially at the beginning of the process, caused by the interconnected cells and modules. For this reason, the workers must have completed high-voltage training before being allowed to work with batteries [12]. In most cases, the battery pack, which is usually in an unknown state of charge, can only be discharged after the housing cover has been removed. The reason for this is that the battery management controller cannot be addressed without the necessary protocols, which are usually not provided by the vehicle manufacturers [13]. The manual energy extraction is done either by discharging at pack level directly at the contactors or by discharging or deactivating the modules at a later stage after removal but before shredding [14]. Deactivation means that cells or modules are placed for example, in a salt bath, whereby the stored energy is dissipated [15].

There are further potential hazards from the toxic electrolyte in the cells [16]. Here, electrolyte can already escape from the cells if the battery pack has been mechanically deformed, for example, due to an accident [17]. In addition, the disassembly operation itself can cause damage, which in turn can lead to a leakage of electrolyte. This hazard potential, as well as the high-voltage hazard, is to be emphasized especially in manual dismantling to the workers carrying out the tasks. But preventive measures should also be implemented for possible future automation.

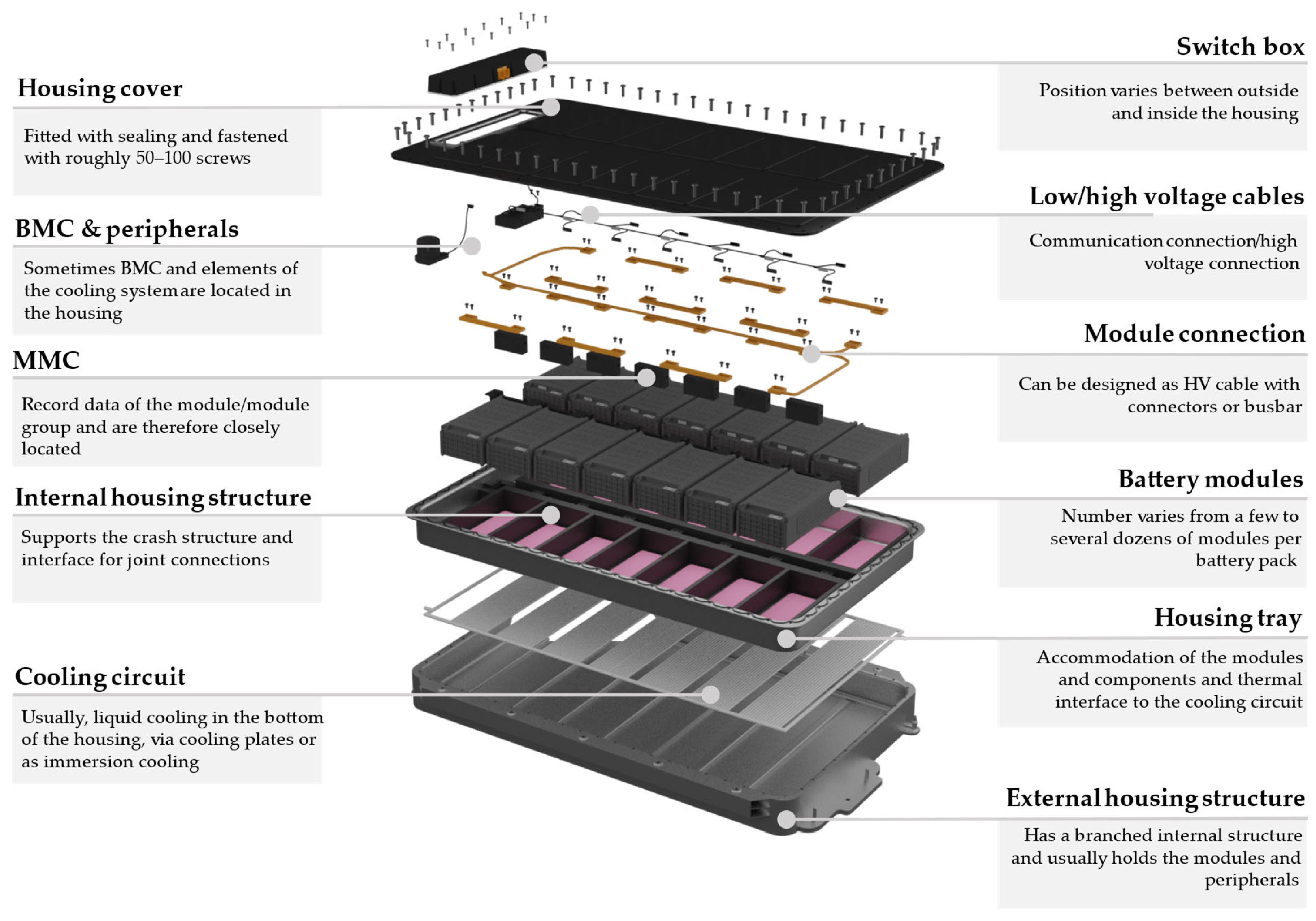

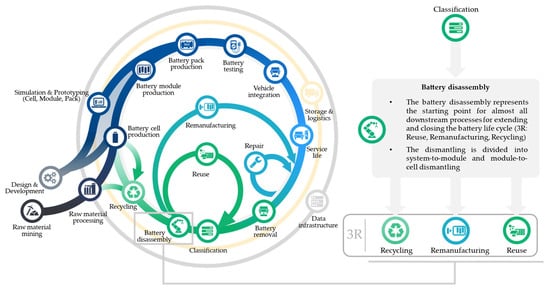

The structural design of the battery system and the joint connections are of decisive importance for the effort required for a disassembly task [18]. Even if battery packs generally have a similar functional design, the number, shape, and position of the individual components, as well as the joints used, can vary greatly [10,19]. Figure 2 shows a general battery pack structure together with details of the individual components.

Figure 2.

Example of a basic battery pack design together with the most relevant components.

In most cases, disassembly begins with opening the battery pack. Either the housing cover or the switch box is removed first, depending on whether the latter is located on the outside of the housing cover. In both cases, this is mostly done by loosening a number of screws [20]. As these screws are located in the outer area of the battery, the condition (deformation, dirt, or corrosion) plays a decisive role in the feasibility of the process step [21]. Another factor is the cover sealing used, which can have very adhesive characteristics, depending on the type and combination of materials selected [20,22].

The opened battery system can now be further processed by first removing the accessible module connections, as well as disconnecting cables and peripherals (e.g., MMCs) [23].

When the modules are completely accessible, they can be removed by loosening screw connections that are usually present [24]. In cases when the system design has integrated a floor cooling below the tray with the modules, a thermal interface material is usually still applied to the bottom of the modules. Together with the very narrow installation space, this can also lead to adhesive-like effects during removal [25].

The variation in design and the number of individual components already mentioned create certain challenges for manual disassembly. Even if this can be mostly handled by the flexibility of human workers, it results in time-consuming activities [26]. For the scaling of the process discussed in the subsequent section, together with an increase in the level of automation, this raises extensive questions.

To underline some concrete differences between functionally equivalent components, Figure 3 shows the module connections, battery/module management controllers, and battery modules from the battery systems of the VW e-Golf, BMW i3, and Audi e-tron vehicle models.

Figure 3.

Differences in the design of functionally equivalent battery components for three different vehicle models.

There are two basic approaches for the module connections. Rigid busbars are used in the Audi e-tron and the VW e-Golf. The busbars differ in shape between the two models, as can be seen on the three images above. But even within one battery pack, there are several different versions of the busbars for interconnecting the total of twenty-seven modules in the Audi e-tron (71 kWh model). They vary in length and shape. In addition to bus bars, HV cables with connectors are used in the e-Golf to connect the battery modules. Those cables are also installed in the BMW i3.

With regard to the battery and module management controller, it should be mentioned that the e-tron has a total of seven Module Management Controllers (MMCs), some of which are located in an enclosure on top of the modules and others in the corners of the pack. In the BMW i3, the MMCs are located directly on the side wall of the respective module housing. Here, there are eight MMCs for the eight installed battery modules. In the VW e-Golf, there is a central control unit that is connected to the modules via a cable network.

The shape and size of the battery modules also differ in all three models. While comparatively smaller modules are installed in the e-Golf and e-tron, the i3 battery modules are significantly larger. In the BMW i3, the modules are also screwed onto cooling pipelines, whereas in the e-tron, thermal interface material is applied to the bottom side of the modules, and an additional screw connection on the four edges of every module attaches them to the inner structure of the housing.

These design variations from conversion to purpose designs, from PHEV to BEV approaches, from an increasing number of models and capacities and the characteristics of their individual components result in very diverse disassembly procedures [26]. In addition to the flexibility required, the disassembly times for different battery models in particular vary due to the numerous components. An overview of these time variations and the associated estimated dismantling costs are shown in Table 1 for various regions. The information shown comprises a mixture of measured and calculated values from the literature.

Table 1.

Overview of disassembly times and costs for different disassembly scenarios.

Even if the individual values are based on different approaches, the dismantling times listed show that each battery model must be considered individually and may be dismantled in a timeframe ranging from about 30 min to several hours. Particularly in regions with high hourly wages, these sometimes very extensive processes result in dismantling costs of several hundred euros for a single battery pack. Compared to China or South Korea, the dismantling process in the European region cannot be economically scaled up with a manual approach for future increases in return volumes. This is particularly caused by the significantly higher labor costs. An increase in the degree of automation in battery disassembly is therefore essential for Europe. In order to achieve shorter cycle times in battery disassembly and to increase the flexibility and robustness, it is necessary to push the use of robots and the development of intelligent and digitized process controls [31,32].

Even though the current standard is the dismantling of systems down to module level, it is worth mentioning that an even deeper dismantling and fractionation is beneficial for the downstream recycling processes in terms of effort and quality of the black mass [33]. The reasons why disassembly down to cell level is often not carried out are due to the similar or greater efforts involved in separating individual components. Modules can contain gap fillers between the cells. The contacting is usually welded and the module housings can often only be separated destructively [34].

3. Methodological Approach and Results

Based on this current state in battery disassembly, an expert survey was conducted. The methodological approach is described before the results are presented and analyzed.

The overall objective of the survey was to highlight the current industrial challenges for increasing the level of automation in battery disassembly in Europe. For this purpose, interviews were conducted with a total of twelve experts from various sectors along the value chain. In addition to two battery experts from the research segment, one OEM, two company representatives from the battery materials industry, and one expert from the automotive aftermarket took part in the interview. In addition, two experts from the field of automation technology and mechanical engineering, as well as four different recycling companies, were interviewed. In addition to product and process engineers, these experts also included strategic decision-makers from senior management. This very comprehensive view of the topic underlines the quality of the results despite the limited number of participants.

The expert interviews were each divided into four subcategories and included various thematic questions. The most relevant findings are presented and classified subsequently. Even though these interviews could only be conducted with an excerpt of the current value chain, it was possible to derive product-related and process-related challenges based on the consistent statements and similar relevance classifications, which together with the market-side boundary conditions currently still result in the fact that the already existing approaches in automated battery disassembly have not yet been industrialized beyond a conceptual level.

3.1. Motivation for an Automated Disassembly

In the course of identifying a motivation for increasing the degree of automation in battery disassembly, the topic of battery return quantities was discussed first. In addition to end-of-life battery returns, another major sub-quantity for recycling is production waste. Currently, this production waste represents the largest share in the battery recycling market [35]. For a future scenario, however, 58% of the experts predicted that end-of-life batteries will exceed production waste in battery manufacturing as the largest material return flow between 2025 and 2030. The other share of respondents (42%) forecasted this scenario for the period between 2030 and 2035. None of the experts expected battery production waste to continue to be the major return stream over the next decade.

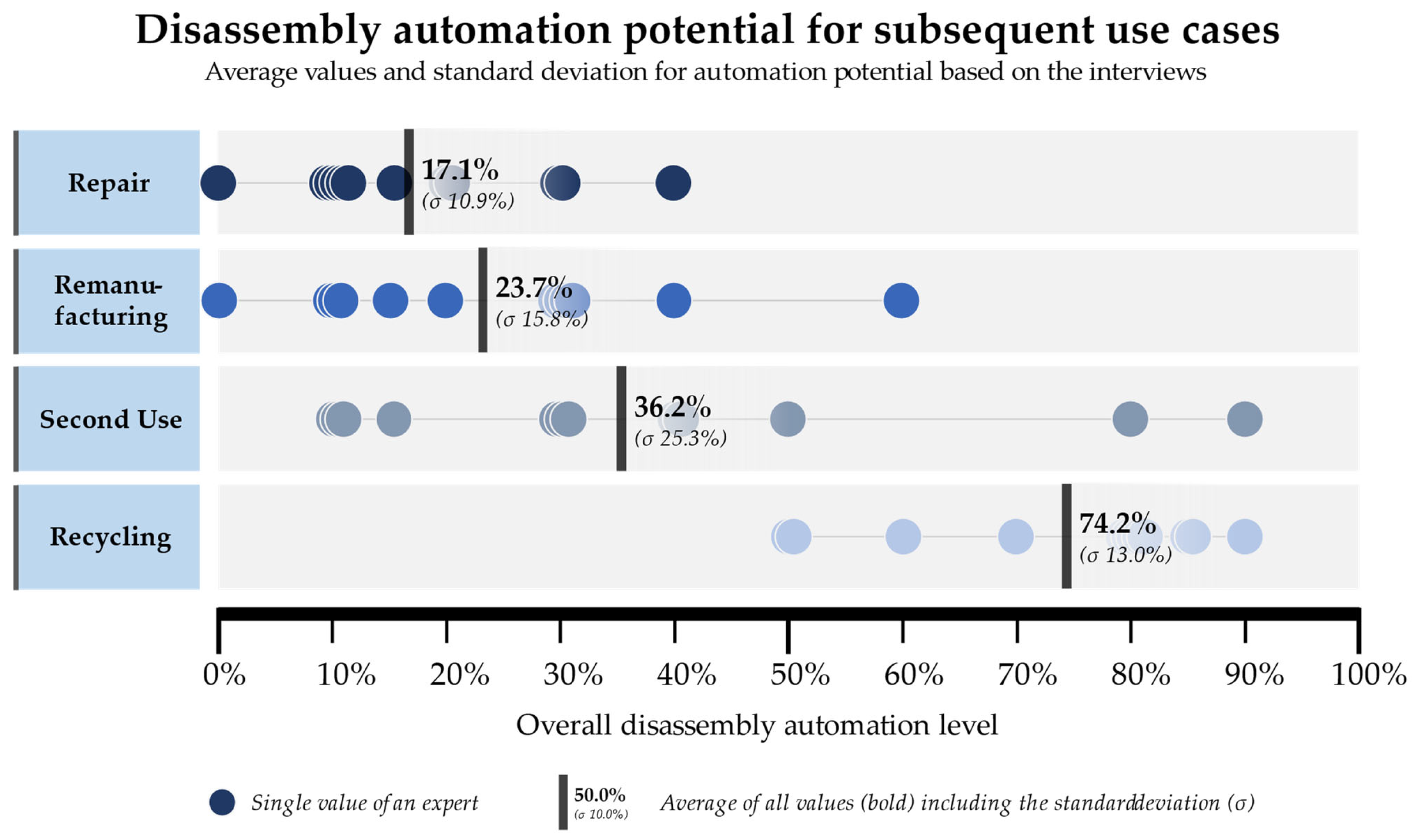

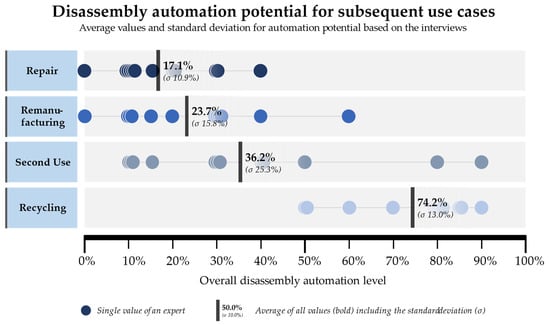

As automation of the battery disassembly process must always be seen in relation to the subsequent purposes, the potential degree of automation according to the respective 3R scenario (Reuse, Remanufacturing/Refurbishment, and Recycling) was also discussed with the experts. The allocation is visualized in Figure 4.

Figure 4.

The forecasted average level of automation for battery disassembly by re-x route.

The classification by the experts basically shows that the greatest potential for automation is seen for a subsequent recycling use case with an average of 74.2%. This is particularly due to the fact that in this scenario the individual process steps of dismantling must not only be carried out non-destructively. In addition, the recycling process routes in scaled stages are significantly more dependent on a continuous supply of input material streams, which in turn increases the need and, therefore, the potential for an automated dismantling process in this constellation [36]. However, the experts do not assume a complete process automation in this use case either, mainly due to the current product design structures and their joint connections.

For the three other use cases, a significantly lower degree of process automation was estimated on average. It should be emphasized that single assessments for the repair and remanufacturing case even assumed no automation, which in turn was attributed to the high degree of individualization. The greatest deviation in the statements, however, was found for the second use scenario. On average, a disassembly automation potential of only 36.2% was noted whereby the statements fluctuated strongly between 10% and 90%.

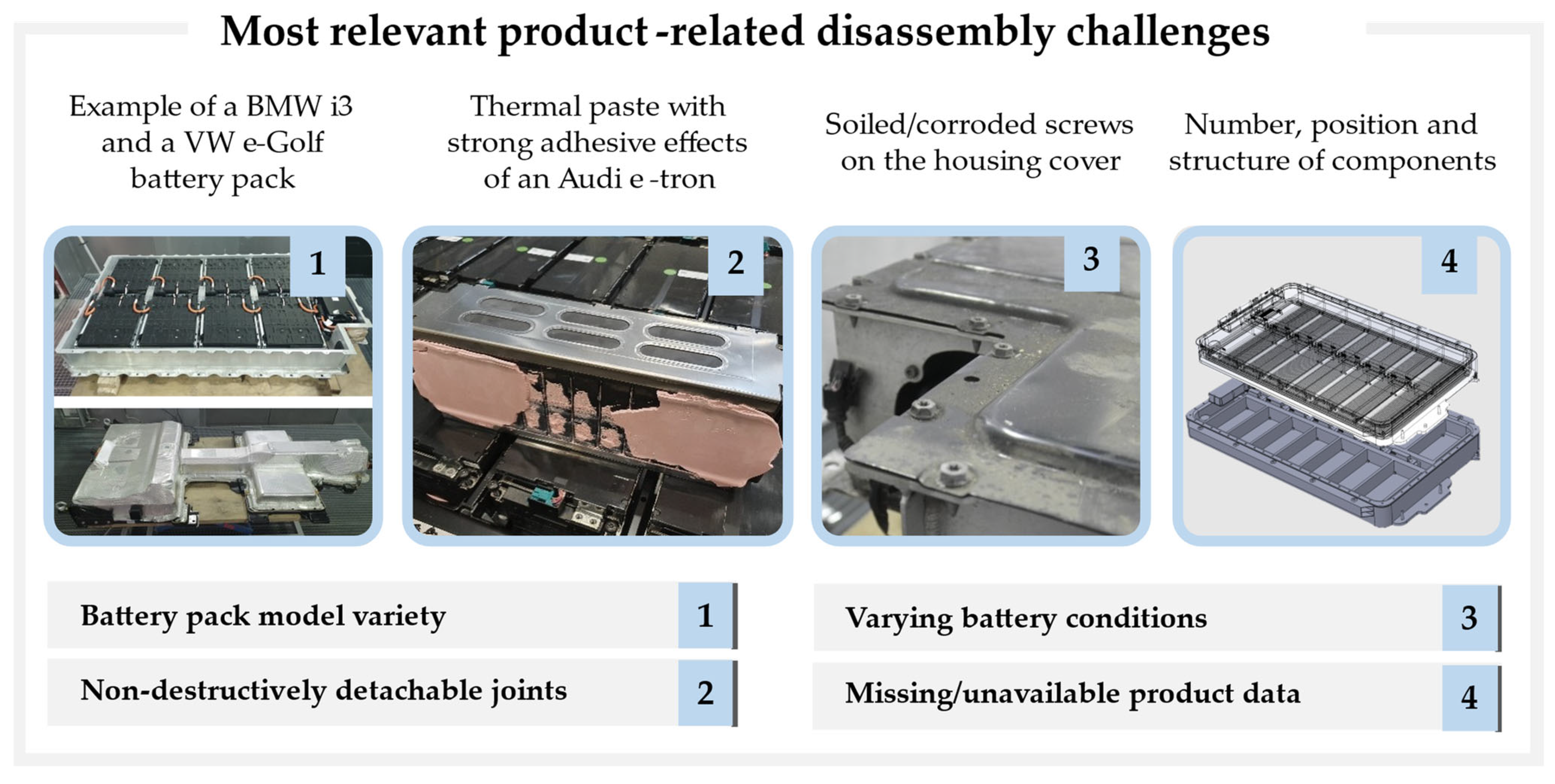

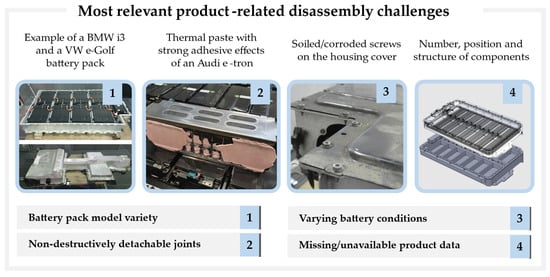

3.2. Product-Related Challenges

When considering the battery disassembly process flow, the product and, above all, its design with various subcomponents play an important role for an automated process control. In the context of product-related challenges, the topic of diversity of variants in battery systems ranked first for the experts interviewed. Not only the differences between various models, but also minimal deviations between the individual battery generations that lead to adjustments in the process [37]. In addition to the diversity of variants, Figure 5 shows the other key challenges posed by the product in automated disassembly.

Figure 5.

Overview of the most relevant product-related challenges for an automated disassembly.

The choice of joints at the interfaces between the components poses further challenges. In particular, welded joints at module level, adhesive joints, or adhesive-like effects—due to interface materials such as thermal conductive pastes on the modules and plug-in connections that are difficult to detach for an automated process—require innovative solutions. But accidents and the associated physical deformations of the battery, as well as dirty and corrosive environmental conditions, also complicate the process control enormously in many cases (e.g., rusted screws) [21]. Finally, in most cases there is a lack of valid data on the battery system and its components for an automated execution of the individual disassembly steps. In addition to the number and position of components, gripping points, required tools, and disassembly sequences are often not initially available.

3.3. Process-Related Challenges

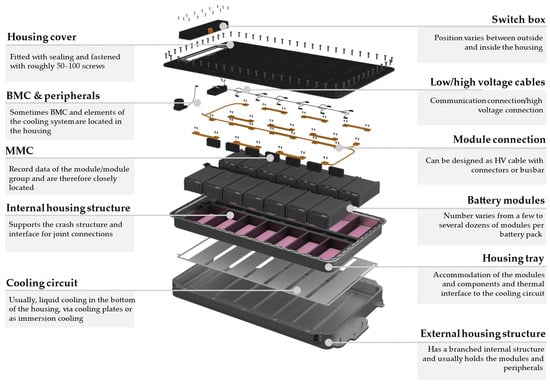

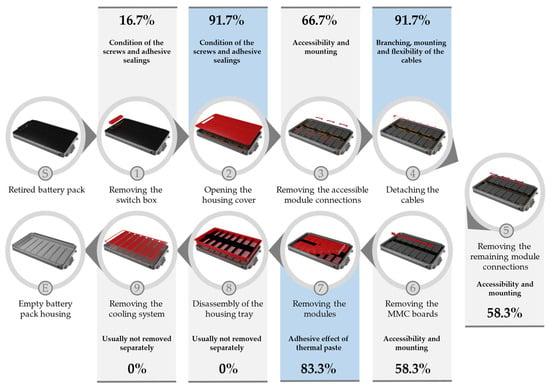

In principle, each dismantling process is individually dependent on the battery model under consideration and can also differ again due to the condition of the individual battery system. Nevertheless, basic dismantling activities can be identified that are available for a large number of battery systems and can be put into a general sequence [10]. On the basis of this process flow shown in Figure 6, the experts’ assessments made it possible to identify individual activities with particularly high difficulties.

Figure 6.

General sequence of the individual disassembly activities and their potential challenges for battery systems.

In the evaluation by the experts interviewed, step 2 (opening the housing cover), step 4 (detaching the cables), and step 7 (removing the modules) turned out to be the most challenging process steps.

When removing the cover, there is a chance that the large number of screws could be dirty, and thus not directly recognizable, or corroded due to their location outside the housing, thus negatively influencing this very repetitive process. Corrosion protection applications would in turn lead to reduced visibility for vision sensor-based methods of automated disassembly which have already been used for screw detection [32,38]. Therefore, this step was considered challenging by 91.7% of the experts.

As non-rigid components, cables are fundamentally more difficult to process in an automated environment. This means that the exact position and, thus, also the defined gripping or cutting points can vary minimally. In addition, there are the often-complicated mechanisms for unplugging connectors, which pose a major challenge in the field of robotics. Here, as well, almost all experts confirmed these circumstances.

The removal of the battery modules is characterized by a combination of steps, starting with loosening the screw connections, finding the exact gripping points, and the hurdle of the highly adhesive effects caused by the heat-conducting paste. Therefore, 83.3% considered this step to be a challenge for automated process control.

3.4. Future Development

With regard to further developments in the field of battery disassembly, the experts were finally asked about the main factors influencing future (partially) automated disassembly, as well as the greatest research and development potentials in this field. The greatest agreement was awarded to the points listed in Table 2. They are therefore of increased relevance in the evaluation of future approaches.

Table 2.

Future influences and potential research and development aspects towards an automated battery disassembly.

In particular, the influence of cell-to-pack approaches and the associated reduction of further structural parts can lead to an increased use of potting materials, which would further increase the hurdles to achieving automated process steps in the disassembly field. In addition to design adaptations towards a more disassembly-friendly design, which were mentioned in many cases in the first place, a more flexible and at the same time more robust process control for automated battery disassembly is necessary. Above all, this requires individual product and process data to be able to reliably identify and dismantle individual components. There was also strong agreement on the concept of using visual sensors to record this data during the process.

4. Conclusions

Due to the significantly increasing return volumes of traction batteries in the near future, a substantial increase in the degree of automation in battery disassembly is required, especially with regard to a stable recycling input flow. The survey of experts along the entire battery value chain presented in this study revealed an average potential level of process automation of 74.2%, which translates into about three out of four steps, particularly in the case of disassembly for downstream recycling. This target value is faced with a multitude of product-related and process-related challenges that need to be solved.

One of the core challenges posed by the product “battery pack” is the huge diversity of variants, which leads to major differences in the positions, shapes, and number of its subcomponents. Together with poorly detachable joints, very individual conditions, and a missing data basis, this results in major hurdles for an automated disassembly process. Therefore, systems are necessary that record data during the process in order to be able to act more robustly in the absence of data and in the presence of deviating conditions. In addition, the data generated in this way must be merged with existing data from preliminary investigations and past disassembly activities to compensate for data gaps in a flexible manner. A robotic execution of disassembly steps, both fully automated and in collaboration with workers down to module or even cell level, is a promising approach in terms of efficiency and cost reduction [39], but can only work as well as the data available to the robotic systems.

On the process side, the experts saw the biggest challenges in opening the housing cover, loosening and removing flexible components such as cables and their plugs, and extracting the modules from the housing’s inner structure. Vision-based sensor systems can be used here to generate the required raw data and—together with robust interpretation approaches such as image-based or point cloud-based object recognition by neural networks—can be beneficial. To move the quality of the results further towards an industrial scale solution, neural networks can be combined in the form of ensembles.

In addition to the ongoing development of the disassembly process, further research must be put into the engineering and production of a design for disassembly so that future battery systems can be disassembled more efficiently and, thus, more economically.

Author Contributions

Conceptualization, D.K. and C.O.; methodology, D.K.; validation, C.O., H.H. and A.K.; formal analysis, D.K.; investigation, D.K.; writing—original draft preparation, D.K.; writing—review and editing, C.O.; visualization, D.K.; supervision, H.H. and A.K. All authors have read and agreed to the published version of the manuscript.

Funding

The project (DemoSens) in the context of which this research was conducted is funded by the German Federal Ministry of Education and Research under the funding code 03XP0314C. The responsibility for the content of this publication lies with the author.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to sensitive manufacturer and company information.

Acknowledgments

A special thanks goes to the twelve company representatives who willingly shared their knowledge and experience during the expert survey and in follow-up discussions. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Barkenbus, J.N. Prospects for Electric Vehicles. Sustainability 2020, 12, 5813. [Google Scholar] [CrossRef]

- García, A.; Monsalve-Serrano, J.; Martinez-Boggio, S.; Golke, D. Energy assessment of the ageing phenomenon in Li-Ion batteries and its impact on the vehicle range efficiency. Energy Convers. Manag. 2023, 276, 116530. [Google Scholar] [CrossRef]

- McGinnis, R. CO2-to-Fuels Renewable Gasoline and Jet Fuel Can Soon Be Price Competitive with Fossil Fuels. Joule 2020, 4, 509–511. [Google Scholar] [CrossRef]

- Rajaeifar, M.; Rajaeifar, M.A.; Ghadimi, P.; Raugei, M.; Wu, Y.; Heidrich, O. Challenges and recent developments in supply and value chains of electric vehicle batteries: A sustainability perspective. Resour. Conserv. Recycl. 2022, 180, 106144. [Google Scholar] [CrossRef]

- Gerlitz, E.; Greifenstein, M.; Kaiser, J.-P.; Mayer, D.; Lanza, G.; Fleischer, J. Systematic Identification of Hazardous States and Approach for Condition Monitoring in the Context of Li-ion Battery Disassembly. Procedia CIRP 2022, 107, 308–313. [Google Scholar] [CrossRef]

- Hua, Y.; Liu, X.; Zhou, S.; Huang, Y.; Ling, H.; Yang, S. Toward Sustainable Reuse of Retired Lithium-ion Batteries from Electric Vehicles. Resour. Conserv. Recycl. 2021, 168, 105249. [Google Scholar] [CrossRef]

- Rallo, H.; Sánchez, A.; Canals, L.; Amante, B. Battery dismantling centre in Europe: A centralized vs decentralized analysis. Resour. Conserv. Recycl. Adv. 2022, 15, 200087. [Google Scholar] [CrossRef]

- Zhou, Z.; Ran, A.; Chen, S.; Zhang, X.; Wei, G.; Li, B.; Kang, F.; Zhou, X.; Sun, H. A fast screening framework for second-life batteries based on an improved bisecting K-means algorithm combined with fast pulse test. J. Energy Storage 2020, 31, 101739. [Google Scholar] [CrossRef]

- Li, R.; Zhang, H.; Li, W.; Zhao, X.; Zhou, Y. Toward Group Applications: A Critical Review of the Classification Strategies of Lithium-Ion Batteries. WEVJ 2020, 11, 58. [Google Scholar] [CrossRef]

- Zorn, M.; Ionescu, C.; Klohs, D.; Zähl, K.; Kisseler, N.; Daldrup, A.; Hams, S.; Zheng, Y.; Offermanns, C.; Flamme, S.; et al. An Approach for Automated Disassembly of Lithium-Ion Battery Packs and High-Quality Recycling Using Computer Vision, Labeling, and Material Characterization. Recycling 2022, 7, 48. [Google Scholar] [CrossRef]

- Hellmuth, J.F.; DiFilippo, N.M.; Jouaneh, M.K. Assessment of the automation potential of electric vehicle battery disassembly. J. Manuf. Syst. 2021, 59, 398–412. [Google Scholar] [CrossRef]

- Shahjalal, M.; Roy, P.K.; Shams, T.; Fly, A.; Chowdhury, J.I.; Ahmed, M.R.; Liu, K. A review on second-life of Li-ion batteries: Prospects, challenges, and issues. Energy 2022, 241, 122881. [Google Scholar] [CrossRef]

- Villagrossi, E.; Dinon, T. Robotics for electric vehicles battery packs disassembly towards sustainable remanufacturing. Res. Sq. 2023. [Google Scholar] [CrossRef]

- Sheth, R.P.; Ranawat, N.S.; Chakraborty, A.; Mishra, R.P.; Khandelwal, M. The Lithium-Ion Battery Recycling Process from a Circular Economy Perspective—A Review and Future Directions. Energies 2023, 16, 3228. [Google Scholar] [CrossRef]

- Mossali, E.; Picone, N.; Gentilini, L.; Rodrìguez, O.; Pérez, J.M.; Colledani, M. Lithium-ion batteries towards circular economy: A literature review of opportunities and issues of recycling treatments. J. Environ. Manag. 2020, 264, 110500. [Google Scholar] [CrossRef]

- Wu, X.; Ma, J.; Wang, J.; Zhang, X.; Zhou, G.; Liang, Z. Progress, Key Issues, and Future Prospects for Li-Ion Battery Recycling. Glob. Chall. 2022, 6, 2200067. [Google Scholar] [CrossRef]

- Christensen, P.A.; Anderson, P.A.; Harper, G.D.J.; Lambert, S.M.; Mrozik, W.; Rajaeifar, M.A.; Wise, M.S.; Heidrich, O. Risk management over the life cycle of lithium-ion batteries in electric vehicles. Renew. Sustain. Energy Rev. 2021, 148, 111240. [Google Scholar] [CrossRef]

- Mossali, E.; Gentilini, L.; Merati, G.; Colledani, M. Methodology and Application of Electric Vehicles Battery Packs Redesign for Circular Economy. Procedia CIRP 2020, 91, 747–751. [Google Scholar] [CrossRef]

- Thompson, D.L.; Hartley, J.M.; Lambert, S.M.; Shiref, M.; Harper, G.D.J.; Kendrick, E.; Anderson, P.; Ryder, K.S.; Gaines, L.; Abbott, A.P. The importance of design in lithium-ion battery recycling—A critical review. Green Chem. 2020, 22, 7585–7603. [Google Scholar] [CrossRef]

- Rosenberg, S.; Huster, S.; Baazouzi, S.; Glöser-Chahoud, S.; Al Assadi, A.; Schultmann, F. Field Study and Multimethod Analysis of an EV Battery System Disassembly. Energies 2022, 15, 5324. [Google Scholar] [CrossRef]

- Blankemeyer, S.; Wiens, D.; Wiese, T.; Raatz, A.; Kara, S. Investigation of the potential for an automated disassembly process of BEV batteries. Procedia CIRP 2021, 98, 559–564. [Google Scholar] [CrossRef]

- Mulcahy, K.R.; Kilpatrick, A.F.R.; Harper, G.D.J.; Walton, A.; Abbott, A.P. Debondable adhesives and their use in recycling. Green Chem. 2022, 24, 36–61. [Google Scholar] [CrossRef]

- Kay, I.; Farhad, S.; Mahajan, A.; Esmaeeli, R.; Hashemi, S.R. Robotic Disassembly of Electric Vehicles’ Battery Modules for Recycling. Energies 2022, 15, 4856. [Google Scholar] [CrossRef]

- Poschmann, H.; Brüggemann, H.; Goldmann, D. Fostering End-of-Life Utilization by Information-driven Robotic Disassembly. Procedia CIRP 2021, 98, 282–287. [Google Scholar] [CrossRef]

- Baazouzi, S.; Rist, F.P.; Weeber, M.; Birke, K.P. Optimization of Disassembly Strategies for Electric Vehicle Batteries. Batteries 2021, 7, 74. [Google Scholar] [CrossRef]

- Hossain, R.; Sarkar, M.; Sahajwalla, V. Technological options and design evolution for recycling spent lithium-ion batteries: Impact, challenges, and opportunities. WIREs Energy Environ. 2023, 161, e481. [Google Scholar] [CrossRef]

- Alfaro-Algaba, M.; Ramirez, F.J. Techno-economic and environmental disassembly planning of lithium-ion electric vehicle battery packs for remanufacturing. Resour. Conserv. Recycl. 2020, 154, 104461. [Google Scholar] [CrossRef]

- Lander, L.; Cleaver, T.; Rajaeifar, M.A.; Nguyen-Tien, V.; Elliott, R.J.R.; Heidrich, O.; Kendrick, E.; Edge, J.S.; Offer, G. Financial viability of electric vehicle lithium-ion battery recycling. iScience 2021, 24, 102787. [Google Scholar] [CrossRef]

- Lander, L.; Tagnon, C.; Nguyen-Tien, V.; Kendrick, E.; Elliott, R.J.R.; Abbott, A.P.; Edge, J.S.; Offer, G.J. Breaking it down: A techno-economic assessment of the impact of battery pack design on disassembly costs. Appl. Energy 2023, 331, 120437. [Google Scholar] [CrossRef]

- Cong, L.; Zhou, K.; Liu, W.; Li, R. Retired Lithium-Ion Battery Pack Disassembly Line Balancing Based on Precedence Graph Using a Hybrid Genetic-Firework Algorithm for Remanufacturing. J. Manuf. Sci. Eng. 2023, 145, 108035. [Google Scholar] [CrossRef]

- Montes, T.; Etxandi-Santolaya, M.; Eichman, J.; Ferreira, V.J.; Trilla, L.; Corchero, C. Procedure for Assessing the Suitability of Battery Second Life Applications after EV First Life. Batteries 2022, 8, 122. [Google Scholar] [CrossRef]

- Choux, M.; Marti Bigorra, E.; Tyapin, I. Task Planner for Robotic Disassembly of Electric Vehicle Battery Pack. Metals 2021, 11, 387. [Google Scholar] [CrossRef]

- Gerlitz, E.; Greifenstein, M.; Hofmann, J.; Fleischer, J. Analysis of the Variety of Lithium-Ion Battery Modules and the Challenges for an Agile Automated Disassembly System. Procedia CIRP 2021, 96, 175–180. [Google Scholar] [CrossRef]

- Graner, M.; Heieck, F.; Fill, A.; Birke, P.; Hammami, W.; Litty, K. Requirements for a Process to Remanufacture EV Battery Packs Down to Cell Level and Necessary Design Modifications. In Proceedings of the Stuttgart Conference on Automotive Production, Stuttgart, Germany, 16–18 November 2022; pp. 376–386. [Google Scholar] [CrossRef]

- Brückner, L.; Frank, J.; Elwert, T. Industrial Recycling of Lithium-Ion Batteries—A Critical Review of Metallurgical Process Routes. Metals 2020, 10, 1107. [Google Scholar] [CrossRef]

- Sommerville, R.; Zhu, P.; Rajaeifar, M.A.; Heidrich, O.; Goodship, V.; Kendrick, E. A qualitative assessment of lithium-ion battery recycling processes. Resour. Conserv. Recycl. 2021, 165, 105219. [Google Scholar] [CrossRef]

- Xiao, J.; Jiang, C.; Wang, B. A Review on Dynamic Recycling of Electric Vehicle Battery: Disassembly and Echelon Utilization. Batteries 2023, 9, 57. [Google Scholar] [CrossRef]

- Liu, Q.; Deng, W.; Pham, D.T.; Hu, J.; Wang, Y.; Zhou, Z. A Two-Stage Screw Detection Framework for Automatic Disassembly Using a Reflection Feature Regression Model. Micromachines 2023, 14, 946. [Google Scholar] [CrossRef]

- Wu, T.; Zhang, Z.; Yin, T.; Zhang, Y. Multi-objective optimization for cell-level disassembly of waste power battery modules in human-machine hybrid mode. Waste Manag. 2022, 144, 513–526. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).