Abstract

Packaging materials play a significant role in the meat, fish, and seafood, pharmaceutical, beverages, and electronics industries. These materials protect the contents during handling and transportation from damage, contamination, and loss of quality, thus enhancing the shelf life of the products being packaged. Several materials, like paper and cardboard, plastics, metals, and glass, have been widely used. However, the vast consumption of these materials leads to high waste generation due to increasing demands globally. This article considers some aspects of recycling waste packaging materials, the need for recycling in terms of environmental impacts, and the energy-saving and economic benefits. It also provides some highlights on the sustainability of the processes of recycling and how the government and public can influence recycling operations. The impact of the COVID-19 pandemic on packaging systems and solid waste management is also highlighted. This study also provides a short note on the possible future methods to be adopted in the recycling process of waste packaging materials.

1. Introduction

Packaging materials are often used to hold and protect products during distribution, sale, storage, delivery, and use [1]. These packaging materials include paper and paperboards, plastics, aluminum, steel cans, glass, etc. The choice and the usage of these packaging materials depend on product classification, price, and packaging drive. Paper and plastics are the most used packaging materials [2]. Paper, plastic, and paperboard have been used alike as primary packaging and secondary packaging for a broad range of foods for decades [3,4]. The weight of paper and paperboard used for packaging materials is roughly equal to the total weight of all other packaging materials [5]. However, packaging materials are unarguably growing in the retail industry, and the demand to reuse post-consumer packaging materials is also growing [6]. Recycling packaging materials has an up-surging role in packaging industries. Over the past two decades, before the development of various recycling approaches and legislation/policies, greater portions of post-consumer packaging waste materials go into landfill sites or incineration [6]. Recycling, however, is the reprocessing of waste products for other purposes or the original purpose [7]. This procedure is made up of chemical and/or physical processes, which transform the amassed and sorted wastes or scraps into secondary basic materials or stocks [7]. The recycling of waste packaging involves four duties, which include collection, separation, reprocessing, and marketing. Presently, a recycling issue is emerging concerning the greater utilization of plastic as a packaging material [8]. Among various packaging materials, plastics have been largely used due to their lower price, light weight, constructional properties, ease of use, resistance to chemicals and corrosion, etc. [1]. The majority of plastic packaging materials are made from petrochemicals. According to the Statista Research Department report in August 2023 [9], plastic production globally was estimated to be 390.7 million metric tons in 2021 compared to 240 million tons per annum in 2013, as reported by [10], of which packaging materials constitute more than 39%.

Plastic packaging is at present influenced by polyolefin, for instance, polyethylene and polypropylene [11]. Around 95% of the paper cardboard boxes and ridged cardboard found in boxes that are used for shipping large goods to the back end of the retail cache are recycled, with the latest one holding up to 38% recycled fibers and 62% new fibers for strength [12]. Due to environmental demands, however, post-consumer plastic packaging materials have been reviewed many times for recycling into new packaging. Single-component recycling for packaging materials is supported by the demands of both the government and public. In many countries of the world, the consumer, government, and packaging industries use packaging materials with an approved eco-balance in the retail outlet [6]. The recycling of packaging materials does not often occur due to environmental impact alone, but rather for other factors too, like political, economic, and social ones [7]. However, the existence of a standard market for products being composed of recycled paper and glass means that the recycling operation of such materials supports the environment [7]. Contradictory situations arise for plastic products, where there is no development in the products recycling market, except for certain materials; thus, the environmental drivers are the most common factors [7]. The components that must be taken into deliberation when the issue is regarding the recycling of packaging materials include superior environmental performance, economic stability of the whole process, which includes the collection, sorting, and transportation of the waste materials, and lastly consumer acceptance of recycled materials (especially in sensitive applications like food packaging) [7].

However, recycling packaging materials has many advantages, including a reduction in environmental impact, creating jobs, saving energy, maintaining a good ecosystem, etc. This section of the paper will concentrate on the need for recycling, sustainable packaging through recycling, innovative recycling ideas for sustainable packaging, and possible future trends.

2. Role of Recycling in Sustainable Packaging

It is believed that recycling is environmentally and economically beneficial [13]. Recycling has lots of advantages, such as creating jobs, saving energy, the possible elimination of an environmental impact, the production of a product that has almost the same quality as its virgin equivalent, economic benefits, reduction in greenhouse gas emissions, etc. Waste picking is either an overriding or a leading part of recovering resources that are recyclable in some countries that have financial limitations, institutional collapse, and backward treatment structures [14]. Through the recycling of waste packaging materials, the waste pickers are important middlemen of the circular economy in materialized economies [15]. However, the appeal is intended to intensify the role of waste pickers in household waste management, while aiding the initiation of a circular economy. Municipalities often do not recognize waste pickers as service providers; often they are discriminated against [16]. In the work of Johnson et al. (2008), it was stated that contemporary recycling applications reduced energy usage by 33% and CO2 emissions by 32%. In the case of stainless-steel wire manufactured wholly from scraps, the energy usage would be 67% shorter than virgin-based production, and CO2 gas emissions would be slashed by 70% [17].

In developing countries, e.g., Nigeria, it was reported that about 1046.43 Gigawatts of energy could be saved annually by recycling recyclable waste materials rather than manufacturing new ones out of virgin materials [18]. The same literature stated that through the recycling of waste products in Nigeria, about USD 11.71 million in economic benefits can be obtained, which is equal to the establishment of approximately 16,562 jobs yearly, and the environmental evaluation results indicated that 307.364 tons of CO2 gas and reductions in the emissions of greenhouse gasses could be attained yearly. The economic advantage of recycling is obtained from the selling of recyclable materials and the creation of job opportunities for waste pickers. The quality of a recycled product is almost the same as that of a virgin product of the same material. It has been verified in the literature that certain recycled materials, occasionally, have the same qualities as virgin materials [19]. However, the utilization of recyclable resources to manufacture new products puts a stop to this energy usage and out-turn into eschewing the emissions of dangerous gases into the airspace. This is because recycling minimizes the utilization of emerging materials to produce consumer goods, and not all the waste processed at the material recycling plants for material recovery is entirely recycled [18].

Recovered products from recycled solid waste can be utilized continually to reduce the usage of virgin materials, leading to energy being saved, the preservation of virgin resources, and the minimization of environmental degeneration [20]. An expansion in the percentage of recycling was noticed to reduce environmental impacts [21]. According to Blengini and Garbarino [22], environmental benefits have been outlined in 13th place among the 14 impact categories for waste packaging recycling. However, waste recycling plants for packaging materials that are powered by electricity were seen to create extremely low environmental impacts in comparison with plants operated using fossil fuels such as diesel [23]. In addition, recycling plants that have no storage operations/facilities and reduced transportation distances were seen to work better harmoniously [21]. The non-recycling of packaging waste materials derives financial disincentives in the United Kingdom, where they instituted a tax on landfill to promote waste recycling. A similar practice was advocated by the India government; it helps to bring down the cost of producing virgin materials and reduces environmental problems [24,25], such as the emission of hazardous gas and disposal via landfill [26]. Thus, the choice of using waste materials as a secondary asset to produce recycled material is necessary due to the high cost and energy intensiveness associated with producing virgin material [25].

3. Sustainable Packaging through Recycling

From a sustainability perspective, the conversion of used packaging waste materials into new useful ones can help to save a significant amount of energy that might be required to produce a product from virgin materials. However, converting plastic waste materials into petrochemical feedstock can help to lessen the depletion of fossil fuels by counterbalancing them with chemically recovered biogas from non-recyclable plastics [27,28]. There are different techniques used to recycle waste materials, which include chemical techniques, mechanical recycling techniques, fluidization techniques, and pyrolysis techniques. Table 1 shows a summary of the different types of techniques used in recycling waste materials. Chemical recycling methods, like gasification and pyrolysis, are prospective techniques used for decreasing the rate of waste plastic packaging materials. This is because it can process many forms of non-recyclable plastics, converting them to usable feedstock, which can be used to create virgin plastics and/or refined into other petrochemicals, like aviation fuel and diesel [27].

Table 1.

Summary of recycling methods. Adopted from: [25].

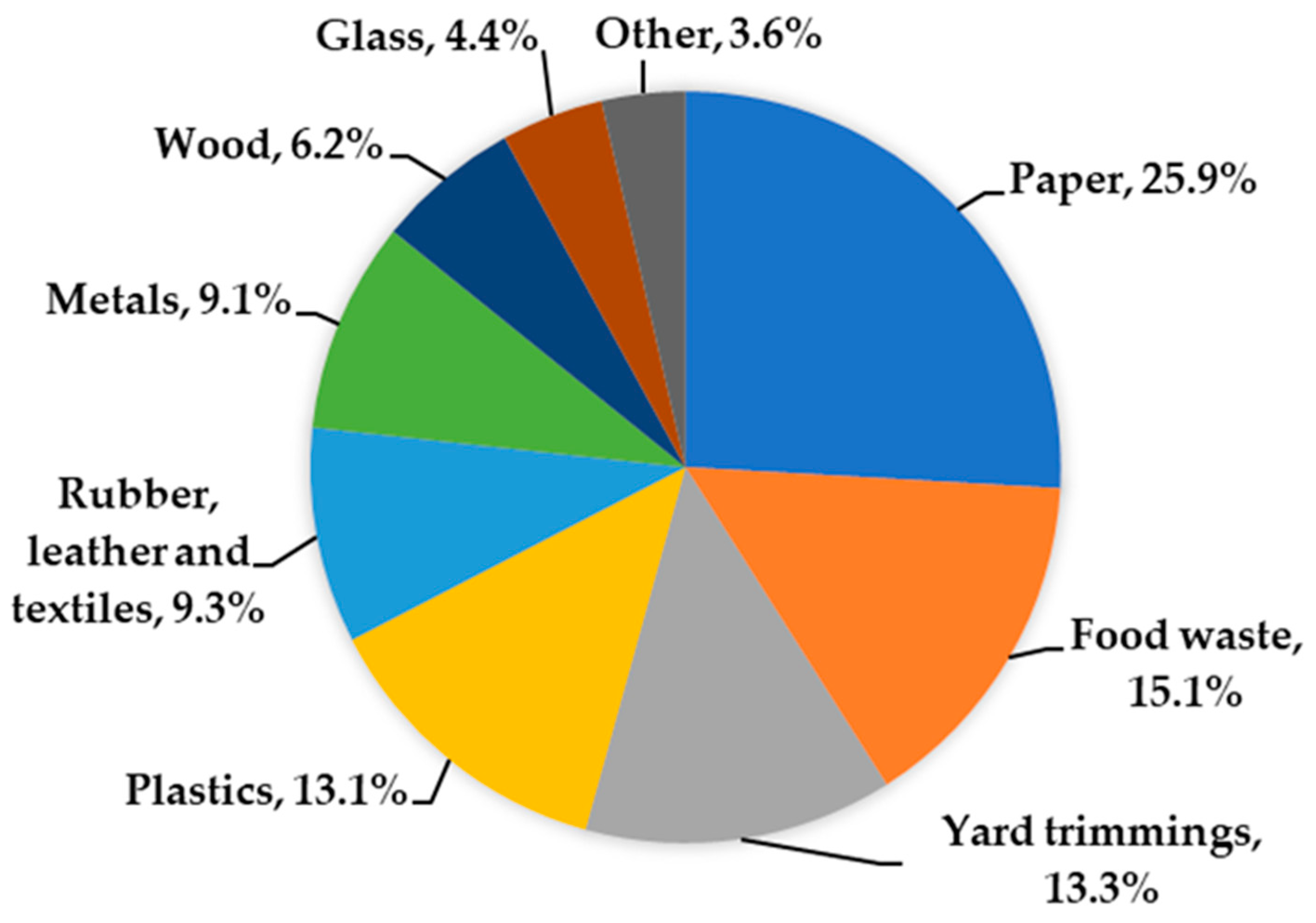

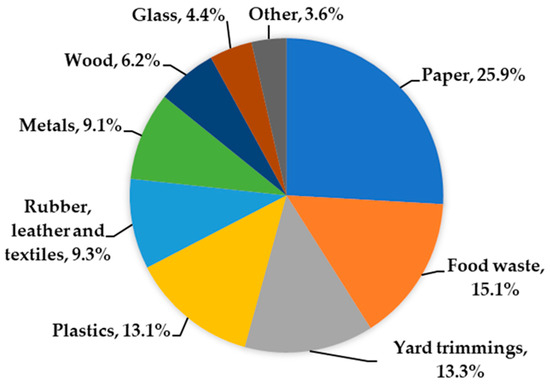

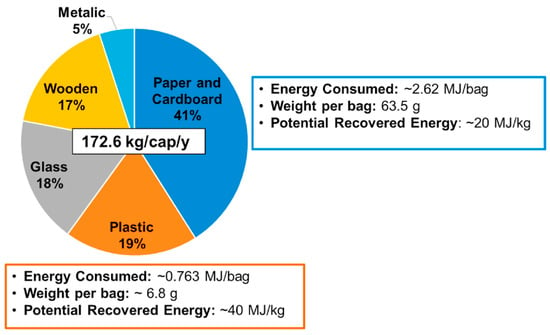

The rates of waste generation and recycling are functions of the economic activities in such an area; thus, this influences the environment in different forms [12]. The nature of the material will also determine the possibility of recycling the extent of waste generated. Similar trends are observed in most developed countries for the ratio of municipal solid wastes that are generated. Among these solid wastes, paper is the highest, as shown in Figure 1. This material (paper) can be recycled and used for various applications such as packaging, cardboard, etc. Another waste material contributing to about 13.1% of the total waste generated is plastics. The innovative recycling of plastic waste will go a long way to reduce deposition at landfills and on water bodies. Of all these solid wastes, only about 25.7% are recycled, while 52.5% end up in landfills [33]. Corrugated cardboard used in the shipping industry and for bulk deliveries is 95% recycled. It was also reported in the literature that 38% of the new boxes used for deliveries are recycled and 62% are new fibers, respectively [12].

Figure 1.

Typical municipal solid waste composition per mass basis. Adopted with permission from Ref. [12].

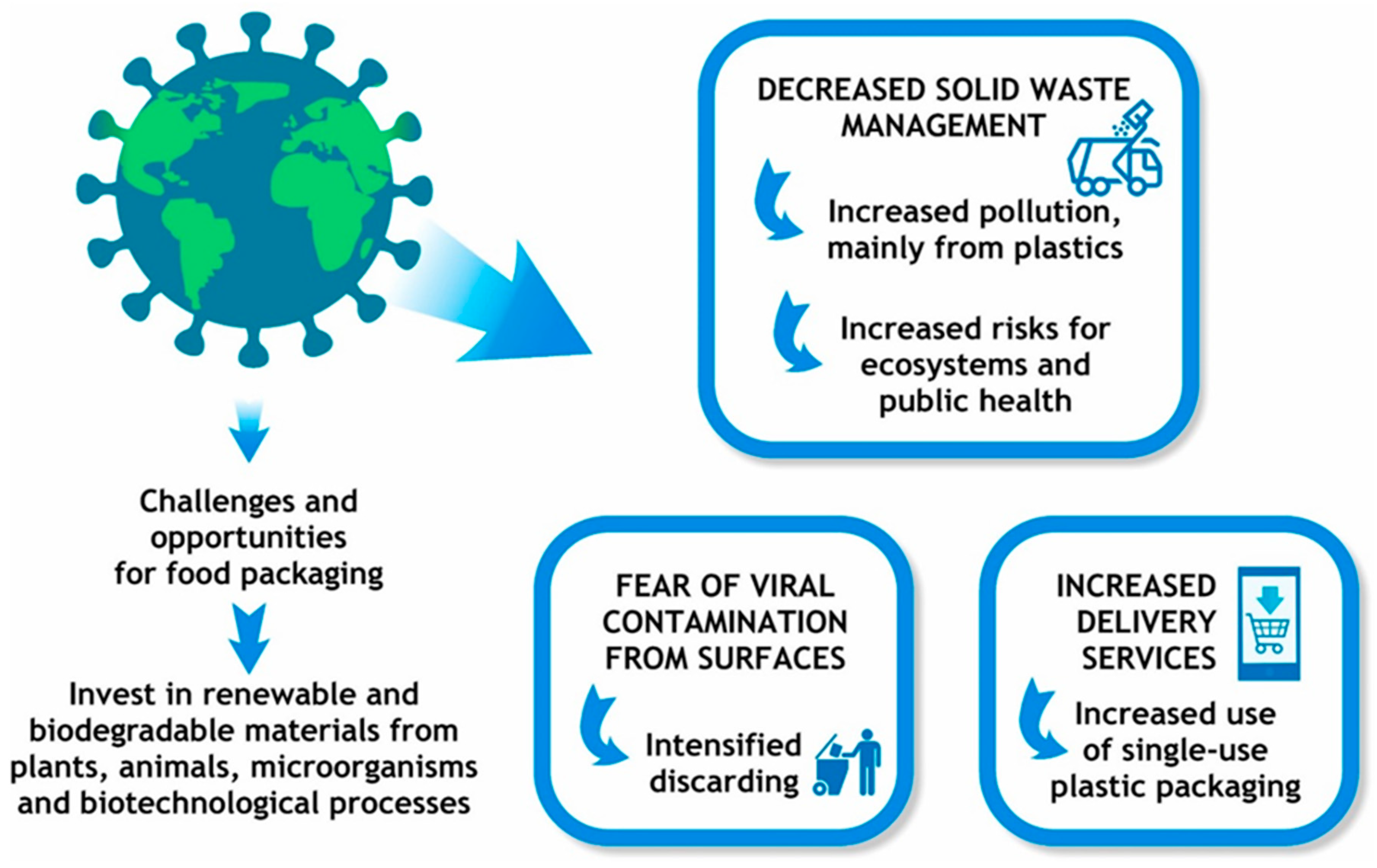

In a study reported by Wang et al. [34], online shopping is growing exponentially worldwide, thereby giving rise to increasing the volume of packaging materials used daily. As reported by the same authors, 50.71 billion orders were recorded for China’s delivery market in 2018, with more than 100 million parcels being delivered daily. The current global COVID-19 pandemic has also contributed to the high number of online orders, leading to high packaging requirements [35]. The risk of contamination with COVID-19 is among the factors that necessitates packaging materials, leading to increased waste materials that can be recycled, thus creating a major setback for waste management systems. The virus can survive on the surfaces of packaging materials, especially in the food industry, for a prolonged period [35,36]. This is the reason for the constant disinfestation of surfaces regularly. The cost of packaged products went up by 20–54% during the period of the pandemic [35].

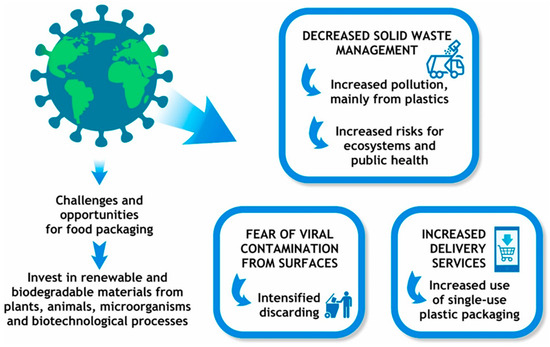

To ensure sustainable recycling, the used packaging materials could be heat-treated prior to handling to remove possible virus contaminations that may be present on its surface. Also, in the plastic recycling chain, a heating process is integrated into the system in the form of an extruder that has various heating temperature zones that could go as high as 300 °C. Alternatively, these materials should be left in the open air for days since the virus can only survive for a few days in the open. If the process of solid waste management is not practiced during this pandemic, there could be a huge crisis, leading to pollution from plastic and paper/paperboard materials [37]. Similar methods were reported by Sharma et al. [38] and Van Fan et al. [39] on how to handle waste management systems during the COVID-19 pandemic. There is no doubt that ever since the COVID-19 pandemic started in 2020, it has greatly affected packaging industries. Figure 2 shows some ways in which this industry and the environment have been severely affected.

Figure 2.

Impact of COVID-19 on the packaging industry and solid waste management. Adopted with permission from Ref. [35].

4. Legal and Systemic Solution for Sustainable Packaging

The community and companies can benefit by recycling their used packaging materials through government incentives and policies that can promote recycling. A literature review has shown that several elements such as government policies and internal psychological elements like rational internalization could well define the public’s waste materials recycling conduct [40]. Based on this logic, the authors brainstormed that the end-users of goods have the desire to be involved in taking out packaging waste for recycling; this readiness is influenced by policies made by the government and normative internalization elements. The United Kingdom introduced a levy on landfills as a financial deterrent, aiming to encourage the re-direction of package waste from dumping onto landfills but to develop different treatment methods in the same manner as recycling. In recycling waste materials, the government’s compensation and punishment actions are mostly divided into three categories, namely incentives, punishment, and government charging fees from stakeholders [40]. However, based on the compensation actions of the government over the recycling of waste materials, the works of Cao et al. [41] and Edwards et al. [42] confirmed that government subsidies on waste recycling can enhance the efficiency of formal processing. As reported in the literature, imposing penalties could solve the recycling problems effectively [43,44].

In a study by Jacobsen et al. [45], where they looked at the most important drivers of sustainable consumers’ plastic packaging waste avoidance and recycling, they discovered that environmental concern, task-specific benefits, lack of knowledge and understanding, lack of opportunities, task difficulty, and inconvenience are the biggest drivers. With this understanding, a sustainable environment can be created, which supports recycling, promotes government efforts toward reducing waste, and provides the needed incentives to the community to achieve a green economy. The works of Lee et al. [46] and Wu et al. [47] revealed that municipal waste charges have become the prime means for waste treatment policies and speculated the success of policies in separate contexts. They further declared that a quantity-based charging system would improve processing efficiency. In Taiwan, packaging materials had no market or unsatisfactory market value; thus, the government imposed an integrated product levy and subsidies policy to supply adequate economic incentives for recycling different classes of packaging vessels, like paper, plastic, aluminum, glass, etc. [48]. The government incentive approach inspired and established the waste packaging vessels’ recycling market, and in a 1998 survey, the recycling system provided about 18,356 employment opportunities, TWD 6.97 billion in real production value, and TWD 3.18 billion in real GDP [49].

5. Drawbacks and Limitations of Recycling

The process of recycling packaging materials has limitations and drawbacks, which often have huge consequences for the environment. Another problem that is common with recycling packaging materials is separation and sorting processes, which are often tedious and time-consuming. Waste pickers mix various types of waste, making it difficult to sort during recycling. An example is plastic waste made from natural and synthetic sources or a combination of both sources for improved properties and performance [49,50,51]. Among the recent methods of packaging is mixed material packaging, which comes with the challenge of recycling due to the difficulty of separating the materials for recycling and reuse [52]. Various packaging materials have different recycling methods and drawbacks.

5.1. Plastic Recycling

Plastic-based materials have been widely used for packaging. Most recently, biodegradable polymers have been largely researched as packaging materials due to their environmentally friendly nature. Recycling these materials is very crucial to protecting and preserving the environment. The cost and process of recycling such materials is economical. In addition, despite being biodegradable polymeric materials, it takes time before bacteria can fully act on it to completely decompose the materials, thus making recycling a necessity. The methods of recycling plastic-based packaging materials and plastics generally range from mechanical to chemical recycling (depolymerization), quaternary, primary, and dissolution–precipitation techniques [53,54,55]. The drawbacks that are common with plastic packaging materials include a high negative environmental footprint and a high cost, which comes from waste collection and transportation to the recycling plant/location. Another common challenge is consumers’ behavioral patterns, such as improper disposal that ends up affecting the environment.

According to Zheng and Suh [56], the negative environmental impact of recycling can be minimized or eradicated by using renewable energy sources. The major drawback of plastics recycling is the fact that they are sometimes manufactured from different polymers in order to improve certain properties of the overall material. This makes recycling difficult due to varying melting and processing temperatures. Furthermore, fillers such as fibers and nanoparticles may be incorporated to strengthen the plastic, making it difficult to recover the base material, thus making recycling a challenge [57]. Impurities or contaminations also limit the quality of recycled plastics. These impurities are introduced during the recycling process or improper treatment methods. Another significant drawback of plastic recycling is the varying life cycle of plastics being recycled. Recycling packaging plastic materials with different life cycles often affects the properties of the new material, thus limiting its areas of applications or usage [53].

5.2. Glass Recycling

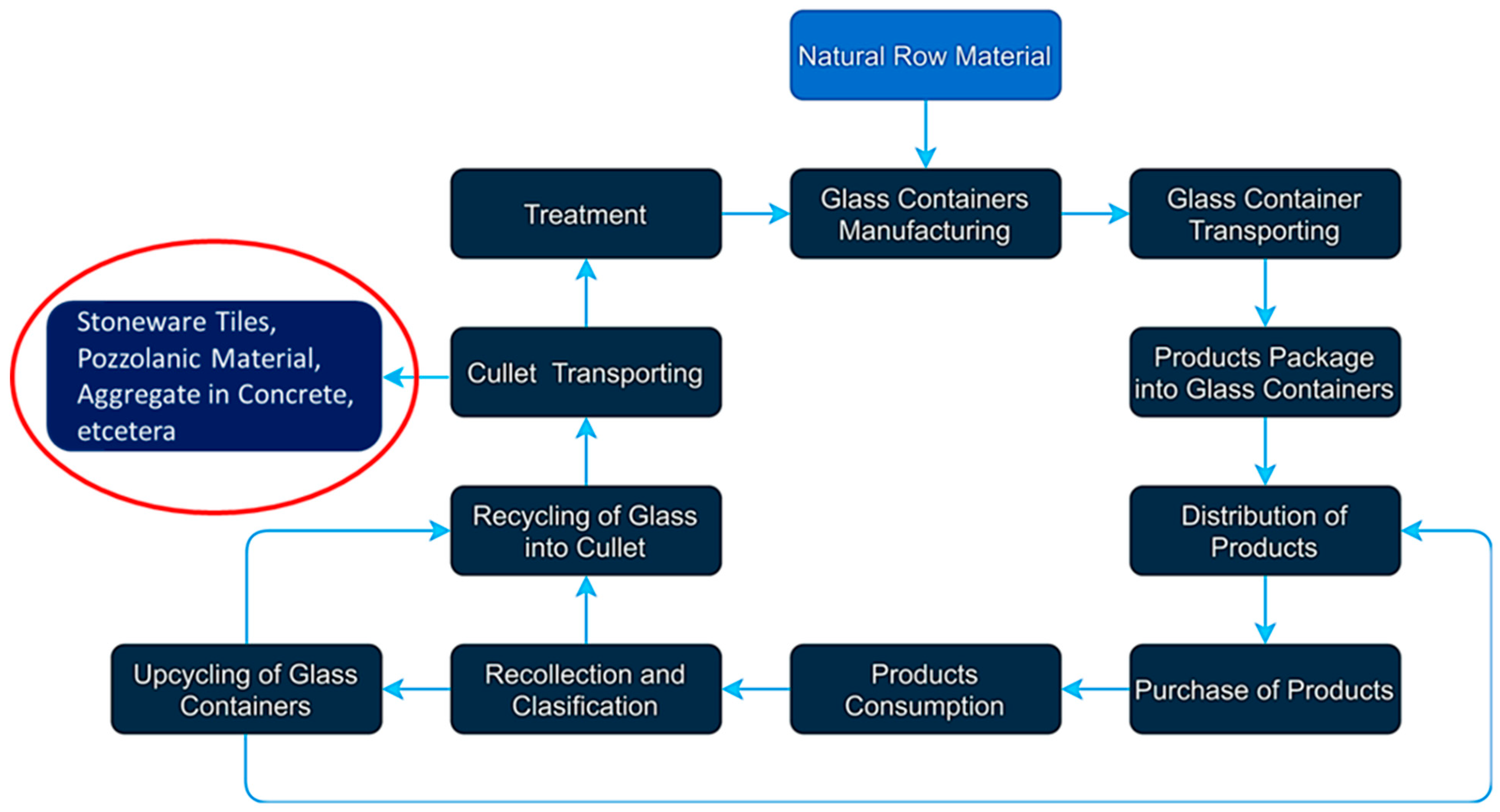

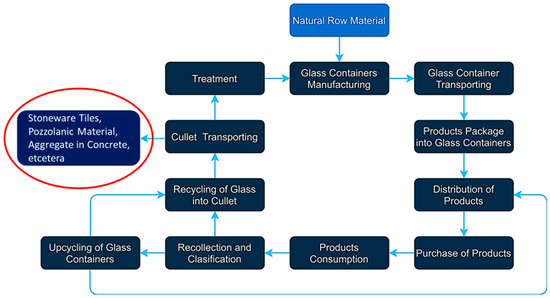

This is an inorganic waste considered to be 100% recyclable without any property loss during the recycling process [58]. Glass can be recycled by washing/cleaning and reusing it or by using them to create new materials, e.g., stoneware tiles [59], pozzolanic material in Portland cement for concrete production [60], partial replacement of fine aggregates (sand) and cement for the production of concrete [61], glass–ceramic materials [62], and porous material manufacturing [63]. The drawbacks associated with recycling glass are a high transportation cost, which is a result of its weight, and the tedious process of separating colored glasses from each other [58]. Another factor limiting the glass recycling industry is the growing demand for plastics and paper/paperboard due to environmental concerns and other facts like the cost of glass waste compared with the effort of collecting them, as shown in Table 2. Another important thing to note when it comes to glass recycling is the other parts of this packaging material, which include caps made from metal, plastic or wood that must be separated, as well as labels made from paper or plastic. To organize these separation processes, it is necessary to reduce the particle size of waste glass to liberate all the non-glass elements or to manually remove the caps and labels on glass bottles. Lastly, to ensure the quality of recycled glass, ceramics and stone particles must be separated, as well as off-color particles. This material can also be used for other purposes. Figure 3 shows the glass recycling process and newly proposed additions, which are circled in red. This provides a broader overview of glass bottles from the manufacturing stage to recycling and other forms of usage.

Table 2.

Prices of waste and scrap materials. Adapted from García Guerrero et al. [64].

Figure 3.

Newly proposed integral glass recycling process. Adapted from García Guerrero et al. [64].

5.3. Paper and Paperboard Recycling

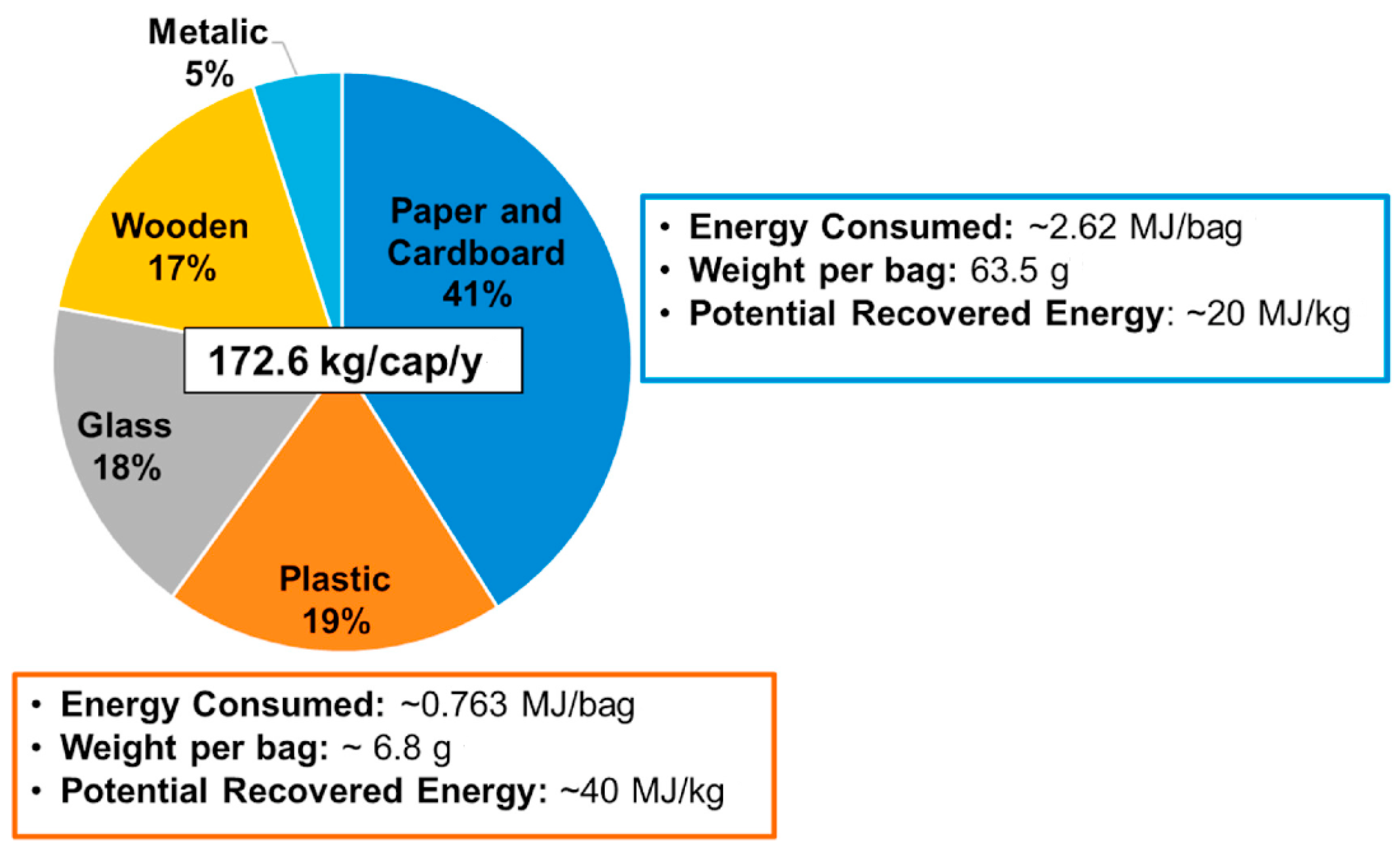

This is a network of interlaced cellulose fibers that are mostly obtained from wood. Paper and paperboard are fast becoming the most used packaging materials due to the biodegradability tendencies of the materials. These materials are often coated, laminated, treated, and impregnated with resins, waxes, and lacquers to improve their protective and functional properties [51]. Paperboards are normally thicker compared to paper because they are in multiple layers, resulting in a higher weight. Paperboards are classified as whiteboard, solid board, chipboard, and fiberboard. According to the Royal Society of Chemistry, UK, as reported by Klemeš et al. [65], paper-based materials have a large water footprint and generate more air pollution compared with plastics. Paper is seen as a perfect replacement for plastics based on the degradation rate, but plastics are superior to paper in terms of environmental sustainability, provided that it is correctly used and disposed of. Figure 4 shows various packaging materials. Comparing papers and plastics, as indicated in Figure 4, the following drawbacks are observed with paper-based materials:

- Higher energy consumption;

- Lower potential energy recovery;

- Higher weight per bag.

Figure 4.

Alternative packaging material showing the drawback of paper and paperboard. Adapted with permission from Ref. [65].

Figure 4.

Alternative packaging material showing the drawback of paper and paperboard. Adapted with permission from Ref. [65].

Recycling uses paper, and paperboards use less energy, less water, and produce less air pollution compared with using virgin materials. The rate of saving energy by recycling paper rather than using virgin materials is a major benefit to the environment [57].

6. Future Trends and Conclusions

The recycling methods of packaging materials, based on the current trends, are set for an upsurge in the recycling of products since both manufacturers and recycling enterprises work jointly and outstretch an evaluative large scale. As soon as this is attained, recycled products will become the standard, with a 100% re-circulating rate, making sure that recycled products are utilized for the production of similar products or closely related. With the help of both existing and future technology, recycling stations will be capable of sorting and separating waste items with ease. Educating the public on how to sort and separate packaging waste items in their various households will help to make recycling more efficient. An individual’s disposable habits must be changed by ensuring that each waste material is disposed of in the bin meant for that particular type of material.

In addition, the government should compel the packaging materials industries to use more biodegradable-based materials in the production of packaging materials. Furthermore, the use of packaging materials with 100% recyclable potential should be encouraged by the packaging industries since little enhancement will be required during the recycling process. Metallic packaging material, e.g., aluminum cans, is a good example of a packaging material that should be encouraged to be adopted in the future by the packaging industries. The recycling rate of cans (made of aluminum) is excellent; they are 100% recyclable and can be made available in different sizes and shapes, just like polyethylene terephthalate (PET), which is 100% recyclable; they are the easiest product to recycle [66]. Germany and other European countries have already targeted a high percentage rate of cans recycling [67].

On the more extensive recycling front, polls from the Metal Packaging Manufacturers Association and cans makers in the United Kingdom pointed out that the metal packaging industry had a target of an 80% recycling rate in 2020 [67]; shortly, they will achieve a recycling rate of 100%. The salient point at this moment is that crucial metal packaging producers, which provide international markets, have acknowledged their designated role in the global sustainability program and are guaranteed to increase the rate of recycling to higher levels. However, the drive for enhanced sustainability is the primary element of the trends and innovations in the global end-user of the goods packaging market. Metal packaging needs to be introduced with niche market changes to extend and innovate the future recycling process. The drive for the extension of polyethylene terephthalate recycling should be encouraged by the beverage and soda industries. The world’s largest plastic bottle recycling plant in Spartanburg, USA, pioneered by Coca-Cola and the United Resources Recovery Corporation (URRC), should be optimized to obtain a higher efficiency.

There were some long-term objectives set by Coca-Cola for all of their plastic bottles to be a combination of plant-based materials and recycled polyethylene terephthalate by the year 2020 [67]. It will be fascinating to see the next phase of this objective and how the entire plastic recycling industry can overcome its recycling challenges in the future. In a 2021 report by Coca-Cola, titled “2020 World Without Waste Report”, it was reported that 90% of their packaging is recyclable, and they aimed for this to be 100% by 2025 globally (where there is infrastructure for recycling). There is also a plan in motion to achieve 50% usage of recycled materials for their packaging products by 2023 globally [68]. Certainly, the drive for greater sustainability in the future recycling of waste packaging materials is dependent on the success of the Spartanburg PET recycling plant or an equivalent.

Based on the findings of this study, it has been revealed that sustainable packaging is possible through the innovative recycling of used packaging materials and other waste materials. In addition, it has been discovered that recycling is a time- and energy-saving exercise, preserves virgin materials, and is cost-effective in some regards. The effective and efficient practice of recycling can protect the environment from the pollution that may arise during the extraction of materials that are used in packaging industries. The impact of COVID-19 on packaging systems and solid waste management has also been highlighted. Based on the findings in this chapter and other chapters of this book, it is, therefore, proposed that more studies should focus on how to attain a 100% recycling rate of waste materials (either packaging or non-packaging materials).

Author Contributions

Conceptualization, I.D.I., A.A.E., E.R.S. and Y.H.; formal analysis, I.D.I., E.R.S., T.J., Y.H., J.M.N., W.K.K., J.S. and A.A.E.; methodology, I.D.I., A.A.E., W.K.K. and Y.H.; project administration, I.D.I.; supervision, T.J., Y.H., J.M.N., W.K.K. and E.R.S.; writing—original draft, I.D.I. and A.A.E.; writing—review and editing, T.J., E.R.S., J.M.N., W.K.K., J.S. and A.A.E. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Research Foundation (NRF), South Africa, (Grant number 138546).

Data Availability Statement

Not applicable.

Acknowledgments

The author would like to thank the Tshwane University of Technology, Pretoria, South Africa, for providing a conducive environment in which to carry out this research work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jang, Y.-C.; Lee, G.; Kwon, Y.; Lim, J.-H.; Jeong, J.-H. Recycling and management practices of plastic packaging waste towards a circular economy in South Korea. Res Conser Recycl. 2020, 158, 104798. [Google Scholar] [CrossRef]

- Deshwal, G.K.; Panjagari, N.R.; Alam, T. An overview of paper and paper based food packaging materials: Health safety and environmental concerns. J. Food Sci. Technol. 2019, 56, 4391–4403. [Google Scholar] [CrossRef] [PubMed]

- Khalid, M.Y.; Arif, Z.U. Novel biopolymer-based sustainable composites for food packaging applications: A narrative review. Food Pac. Shelf Life 2022, 33, 100892. [Google Scholar] [CrossRef]

- Muratore, F.; Barbosa, S.E.; Martini, R.E. Development of bioactive paper packaging for grain-based food products. Food Pac. Shelf Life 2019, 20, 100317. [Google Scholar] [CrossRef]

- Triantafyllou, V.I.; Akrida-Demertzi, K.; Demertzis, P.G. Migration studies from recycled paper packaging materials: Development of an analytical method for rapid testing. Anal. Chimica Acta 2002, 467, 253–260. [Google Scholar] [CrossRef]

- Franz, R.; Welle, F. Recycling packaging materials. In Novel Food Packaging Techniques; Woodhead Publishing Ltd.: Cambridge, UK, 2003; pp. 497–518. [Google Scholar]

- Dainelli, D. Sealed Air Corporation, Milan, Italy. In Global Legislation for Food Contact Materials; Elsevier: Amsterdam, The Netherlands, 2015; p. 183. [Google Scholar]

- Boparai, K.S.; Singh, R. Recyclability of Packaging Materials for Domestic Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 144–148. [Google Scholar]

- Statista Research Department. Global Plastic Production 1950–2021. Available online: https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/ (accessed on 1 September 2023).

- Cooper, T.A. Developments in plastic materials and recycling systems for packaging food, beverages and other fast-moving consumer goods. In Trends in Packaging of Food, Beverages and Other Fast-Moving Consumer Goods; Woodhead Publishing: Cambridge, UK, 2013; pp. 58–107. [Google Scholar]

- Castelvetro, V.; Corti, A.; Bianchi, S.; Giacomelli, G.; Manariti, A.; Vinciguerra, V. Microplastics in fish meal: Contamination level analyzed by polymer type, including polyester (PET), polyolefins, and polystyrene. Enviro. Pollut. 2021, 273, 115792. [Google Scholar] [CrossRef] [PubMed]

- Cushman-Roisin, B.; Cremonini, B.T. Chapter 11—Waste, packaging, and recycling. In Data, Statistics, and Useful Numbers for Environmental Sustainability; Cushman-Roisin, B., Cremonini, B.T., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 163–177. [Google Scholar]

- Moazzem, S.; Wang, L.; Daver, F.; Crossin, E. Environmental impact of discarded apparel landfilling and recycling. Resour. Conserv. Recycl. 2021, 166, 105338. [Google Scholar] [CrossRef]

- Velis, C. Waste Pickers in Global South: Informal Recycling Sector in a Circular Economy Era; SAGE Publications Sage UK: London, UK, 2017.

- Fuss, M.; Barros, R.T.; Poganietz, W.-R. The role of a socio-integrated recycling system in implementing a circular economy–The case of Belo Horizonte, Brazil. Waste Manag. 2021, 121, 215–225. [Google Scholar] [CrossRef]

- Azevedo, B.D.; Scavarda, L.F.; Caiado, R.G.G. Urban solid waste management in developing countries from the sustainable supply chain management perspective: A case study of Brazil’s largest slum. J. Clean. Prod. 2019, 233, 1377–1386. [Google Scholar] [CrossRef]

- Johnson, J.; Reck, B.K.; Wang, T.; Graedel, T.E. The energy benefit of stainless steel recycling. Energy Policy. 2008, 36, 181–192. [Google Scholar] [CrossRef]

- Ayodele, T.; Alao, M.; Ogunjuyigbe, A. Recyclable resources from municipal solid waste: Assessment of its energy, economic and environmental benefits in Nigeria. Res. Conser. Recyc. 2018, 134, 165–173. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E.; Patel, M.K. Open-loop recycling: A LCA case study of PET bottle-to-fibre recycling. Resour. Conserv. Recycl. 2010, 55, 34–52. [Google Scholar] [CrossRef]

- Menikpura, S.N.; Santo, A.; Hotta, Y. Assessing the climate co-benefits from Waste Electrical and Electronic Equipment (WEEE) recycling in Japan. J. Clean. Prod. 2014, 74, 183–190. [Google Scholar] [CrossRef]

- Ram, V.; Kishore, K.C.; Kalidindi, S.N. Environmental benefits of construction and demolition debris recycling: Evidence from an Indian case study using life cycle assessment. J. Clean. Prod. 2020, 255, 120258. [Google Scholar] [CrossRef]

- Blengini, G.A.; Garbarino, E. Resources and waste management in Turin (Italy): The role of recycled aggregates in the sustainable supply mix. J. Clean. Prod. 2010, 18, 1021–1030. [Google Scholar] [CrossRef]

- Borghi, G.; Pantini, S.; Rigamonti, L. Life cycle assessment of non-hazardous Construction and Demolition Waste (CDW) management in Lombardy Region (Italy). J. Clean. Prod. 2018, 184, 815–825. [Google Scholar] [CrossRef]

- Maheshwari, S.; Deswal, S. Role of Waste Management at Landfills in Sustainable Waste Management. Int. J. Emerg. Technol. 2017, 8, 324–328. [Google Scholar]

- Utekar, S.; Suriya, V.K.; More, N.; Rao, A. Comprehensive study of recycling of thermosetting polymer composites–Driving force, challenges and methods. Compos. Part B Eng. 2021, 207, 108596. [Google Scholar] [CrossRef]

- Nkwachukwu, O.I.; Chima, C.H.; Ikenna, A.O.; Albert, L. Focus on potential environmental issues on plastic world towards a sustainable plastic recycling in developing countries. Int. J. Ind. Chem. 2013, 4, 1–13. [Google Scholar] [CrossRef]

- Partridge, C.; Medda, F. Opportunities for chemical recycling to benefit from waste policy changes in the United Kingdom. Res. Conser. Recyc. X 2019, 3, 100011. [Google Scholar] [CrossRef]

- Wong, S.; Ngadi, N.; Abdullah, T.A.T.; Inuwa, I.M. Current state and future prospects of plastic waste as source of fuel: A review. Renew. Sust. Ener. Rev. 2015, 50, 1167–1180. [Google Scholar] [CrossRef]

- Marsh, G. Reclaiming value from post-use carbon composite. Reinf. Plast. 2008, 52, 36–39. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling technologies for thermoset composite materials—Current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Jiang, G.; Pickering, S.J.; Walker, G.S.; Wong, K.H.; Rudd, C.D. Surface characterisation of carbon fibre recycled using fluidised bed. Appl. Surf. Sci. 2008, 254, 2588–2593. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- EPA, U. Facts and Figures about Materials, Waste and Recycling; EPA, Environmental Protection Agency: Washington, DC, USA, 2019; p. 12. [Google Scholar]

- Wang, Q.; Zhang, W.; Tseng, C.P.M.L.; Sun, Y.; Zhang, Y. Intention in use recyclable express packaging in consumers’ behavior: An empirical study. Res. Conser. Recyc. 2021, 164, 105115. [Google Scholar] [CrossRef]

- de Oliveira, W.Q.; de Azeredo, H.M.C.; Neri-Numa, I.A.; Pastore, G.M. Food packaging wastes amid the COVID-19 pandemic: Trends and challenges. Trend. Food Sci. Technol. 2021, 116, 1195–1199. [Google Scholar] [CrossRef]

- Hakovirta, M.; Hakovirta, J. Transmittance and Survival of SARS-CoV-2 in Global Trade: The Role of Supply Chain and Packaging. J. Pack. Technol. Res. 2020, 4, 261–265. [Google Scholar] [CrossRef]

- Ceylan, Z.; Meral, R.; Cetinkaya, T. Relevance of SARS-CoV-2 in food safety and food hygiene: Potential preventive measures, suggestions and nanotechnological approaches. Virus Disease 2020, 31, 154–160. [Google Scholar] [CrossRef]

- Sharma, H.B.; Vanapalli, K.R.; Cheela, V.S.; Ranjan, V.P.; Jaglan, A.K.; Dubey, B.; Goel, S.; Bhattacharya, J. Challenges, opportunities, and innovations for effective solid waste management during and post COVID-19 pandemic. Res. Conser. Recyc. 2020, 162, 105052. [Google Scholar] [CrossRef]

- Van Fan, Y.; Jiang, P.; Hemzal, M.; Klemeš, J.J. An update of COVID-19 influence on waste management. Sci. Total Environ. 2021, 754, 142014. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Long, R.; Chen, H.; Cheng, X. Willingness to participate in take-out packaging waste recycling: Relationship among effort level, advertising effect, subsidy and penalty. Waste Manag. 2021, 121, 141–152. [Google Scholar] [CrossRef]

- Cao, J.; Lu, B.; Chen, Y.; Zhang, X.; Zhai, G.; Zhou, G.; Jiang, B.; Schnoor, J.L. Extended producer responsibility system in China improves e-waste recycling: Government policies, enterprise, and public awareness. Rene. Sust. Ener. Rev. 2016, 62, 882–894. [Google Scholar] [CrossRef]

- Edwards, J.; Burn, S.; Crossin, E.; Othman, M. Life cycle costing of municipal food waste management systems: The effect of environmental externalities and transfer costs using local government case studies. Res. Conser. Recyc. 2018, 138, 118–129. [Google Scholar] [CrossRef]

- Chen, J.; Hua, C.; Liu, C. Considerations for better construction and demolition waste management: Identifying the decision behaviors of contractors and government departments through a game theory decision-making model. J. Clean. Prod. 2019, 212, 190–199. [Google Scholar] [CrossRef]

- Estalaki, S.M.; Abed-Elmdoust, A.; Kerachian, R. Developing environmental penalty functions for river water quality management: Application of evolutionary game theory. Environ. Earth Sci. 2015, 73, 4201–4213. [Google Scholar] [CrossRef]

- Jacobsen, L.F.; Pedersen, S.; Thøgersen, J. Drivers of and barriers to consumers’ plastic packaging waste avoidance and recycling–A systematic literature review. Waste Manag. 2022, 141, 63–78. [Google Scholar] [CrossRef]

- Lee, C.K.M.; Ng, K.K.H.; Kwong, C.K.; Tay, S.T. A system dynamics model for evaluating food waste management in Hong Kong, China. J. Mater. Cycl. Waste Manag. 2019, 21, 433–456. [Google Scholar] [CrossRef]

- Wu, Y.-G.; Chu, Z.-J.; Zhuang, J. Evaluation of optional fee structures for solid waste management in China. Waste Manag. Res. 2018, 36, 513–519. [Google Scholar] [CrossRef]

- Bor, Y.J.; Chien, Y.-L.; Hsu, E. The market-incentive recycling system for waste packaging containers in Taiwan. Environ. Sci. Policy. 2004, 7, 509–523. [Google Scholar] [CrossRef]

- Chen, C.-C.; Dai, L.; Ma, L.; Guo, R.T. Enzymatic degradation of plant biomass and synthetic polymers. Nat. Rev. Chem. 2020, 4, 114–126. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.-D. Biodegradability of plastics: The issues, recent advances, and future perspectives. Environ. Sci. Pollu. Res. 2021, 28, 1278–1282. [Google Scholar] [CrossRef] [PubMed]

- Zarrintaj, P.; Saeb, M.R.; Jafari, S.H.; Mozafari, M. Application of compatibilized polymer blends in biomedical fields. In Compatibilization of Polymer Blends; Elsevier: Amsterdam, The Netherlands, 2020; pp. 511–537. [Google Scholar]

- Singh, A.; Sharma, P.K.; Malviya, R. Eco friendly pharmaceutical packaging material. World Appl. Sci. J. 2011, 14, 1703–1716. [Google Scholar]

- Tshifularo, C.A.; Patnaik, A. Recycling of plastics into textile raw materials and products. In Sustainable Technologies for Fashion and Textiles; Nayak, R., Ed.; Woodhead Publishing: Cambridge, UK, 2020; pp. 311–326. [Google Scholar]

- Schyns, Z.O.; Shaver, M.P. Mechanical recycling of packaging plastics: A review. Macromol. Rapid Commun. 2021, 42, 2000415. [Google Scholar] [CrossRef] [PubMed]

- Kaiser, K.; Schmid, M.; Schlummer, M. Recycling of polymer-based multilayer packaging: A review. Recycling 2018, 3, 1. [Google Scholar] [CrossRef]

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Chang. 2019, 9, 374–378. [Google Scholar] [CrossRef]

- Muzenda, E. Recycling situation in South Africa: A discussion. Int. J. Bio. Ecolog. Environ. Sci. 2013, 2, 79–82. [Google Scholar]

- Pereira da Costa, F.; Rodrigues da Silva Morais, C.; Rodrigues, A.M. Sustainable glass-ceramic foams manufactured from waste glass bottles and bentonite. Cera. Int. 2020, 46, 17957–17961. [Google Scholar] [CrossRef]

- Haque, M.J.; Munna, A.H.; Rahman, S.; Rahman, M.A. Fabrication and Performance Analysis of Porcelain Stoneware Tiles Incorporated with Labware Glass Cullet. Trans. Indian Ceram. Soc. 2021, 80, 64–70. [Google Scholar] [CrossRef]

- Raju, A.S.; Anand, K.; Rakesh, P. Partial replacement of Ordinary Portland cement by LCD glass powder in concrete. Mater. Today Proceed. 2021, 46, 5131–5137. [Google Scholar] [CrossRef]

- Atoyebi, O.; Gana, A.; Longe, J. Strength assessment of concrete with waste glass and bankoro (Morinda Citrifolia) as partial replacement for fine and coarse aggregate. Resul. Eng. 2020, 6, 100124. [Google Scholar] [CrossRef]

- Felisberto, R.; Santos, M.C.; Arcaro, S.; Basegio, T.M.; Bergmann, C.P. Assessment of environmental compatibility of glass–ceramic materials obtained from galvanic sludge and soda–lime glass residue. Proce. Safet. Environ. Protec. 2018, 120, 72–78. [Google Scholar] [CrossRef]

- Liang, S.-X.; Wang, X.; Zhang, W.; Liu, Y.J.; Wang, W.; Zhang, L.C. Selective laser melting manufactured porous Fe-based metallic glass matrix composite with remarkable catalytic activity and reusability. Appl. Mater. Today. 2020, 19, 100543. [Google Scholar] [CrossRef]

- García Guerrero, J.; Rodríguez Reséndiz, J.; Rodríguez Reséndiz, H.; Álvarez-Alvarado, J.M.; Rodríguez Abreo, O. Sustainable Glass Recycling Culture-Based on Semi-Automatic Glass Bottle Cutter Prototype. Sustainability 2021, 13, 6405. [Google Scholar] [CrossRef]

- Klemeš, J.J.; Van Fan, Y.; Tan, R.R.; Jiang, P. Minimising the present and future plastic waste, energy and environmental footprints related to COVID-19. Renew. Sust. Ener. Rev. 2020, 127, 109883. [Google Scholar] [CrossRef]

- Puente-Rueda, C.; Saénz-Nuño, M.A.; Luis-Zamora, J.; Puente-Agueda, C. Solar Energy and Reused Materials in the Recycling of Plastics. In New Materials for a Circular Economy; Garcia-Penas, A., Sharma, G., Eds.; Materials Research Forum LLC: Millersville, PA, USA, 2023; Volume 149, pp. 70–104. [Google Scholar]

- Farmer, N. The future: Global trends and analysis for the international packaging market in relation to the speed of impact of packaging innovation and likely material changes. In Trends in Packaging of Food, Beverages and Other Fast-Moving Consumer Goods (FMCG); Woodhead Publishing: Cambridge, UK, 2013; pp. 288–312. [Google Scholar]

- The Coca-Cola Company. 2020 World without Waste Report. Available online: https://www.coca-colacompany.com/content/dam/company/us/en/reports/coca-cola-world-without-waste-report-2020.pdf (accessed on 31 August 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).