Combining SWOT with AHP for Analyzing the Adoption of a Circular Economy in the Apparel Industry in Brazil

Abstract

:1. Introduction

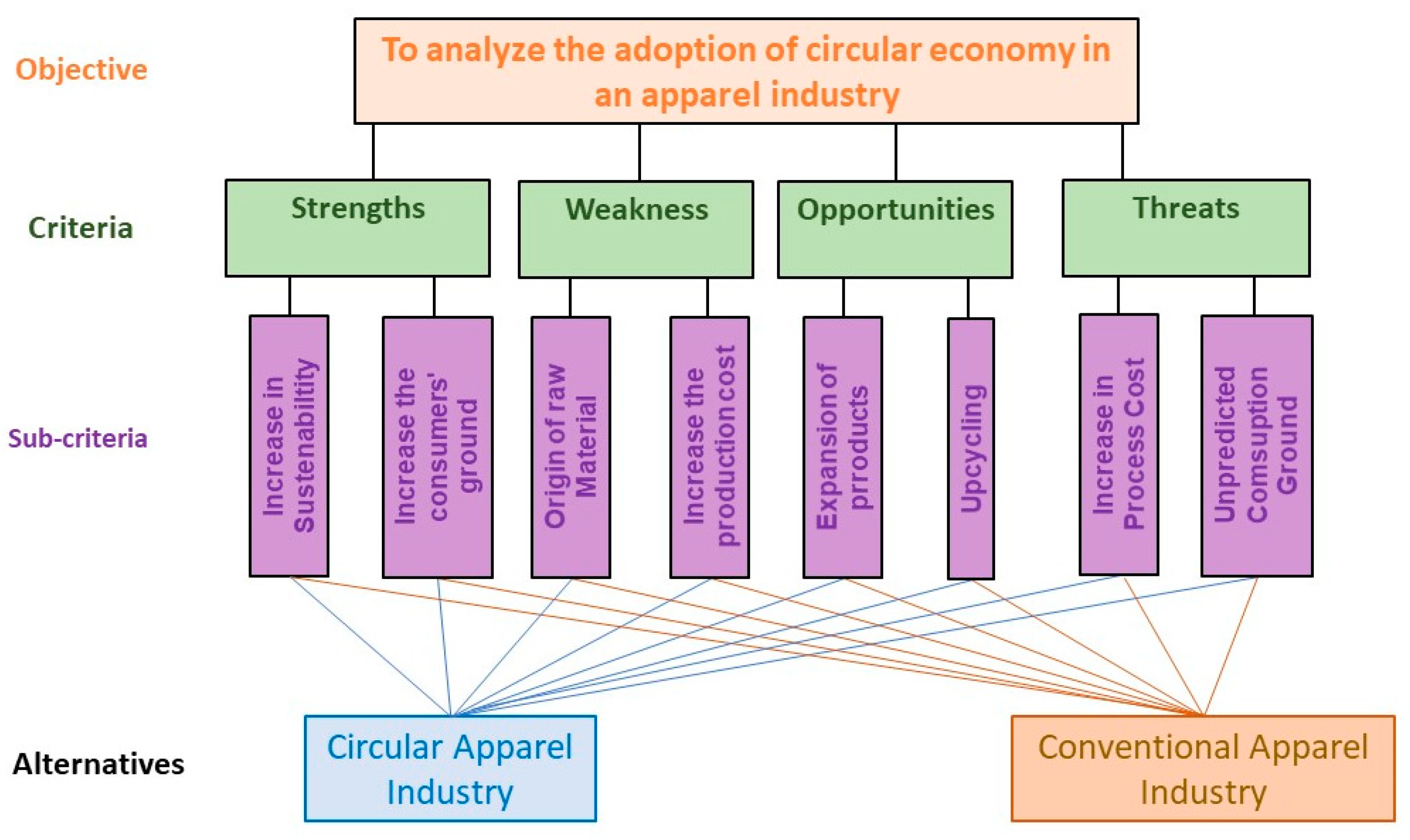

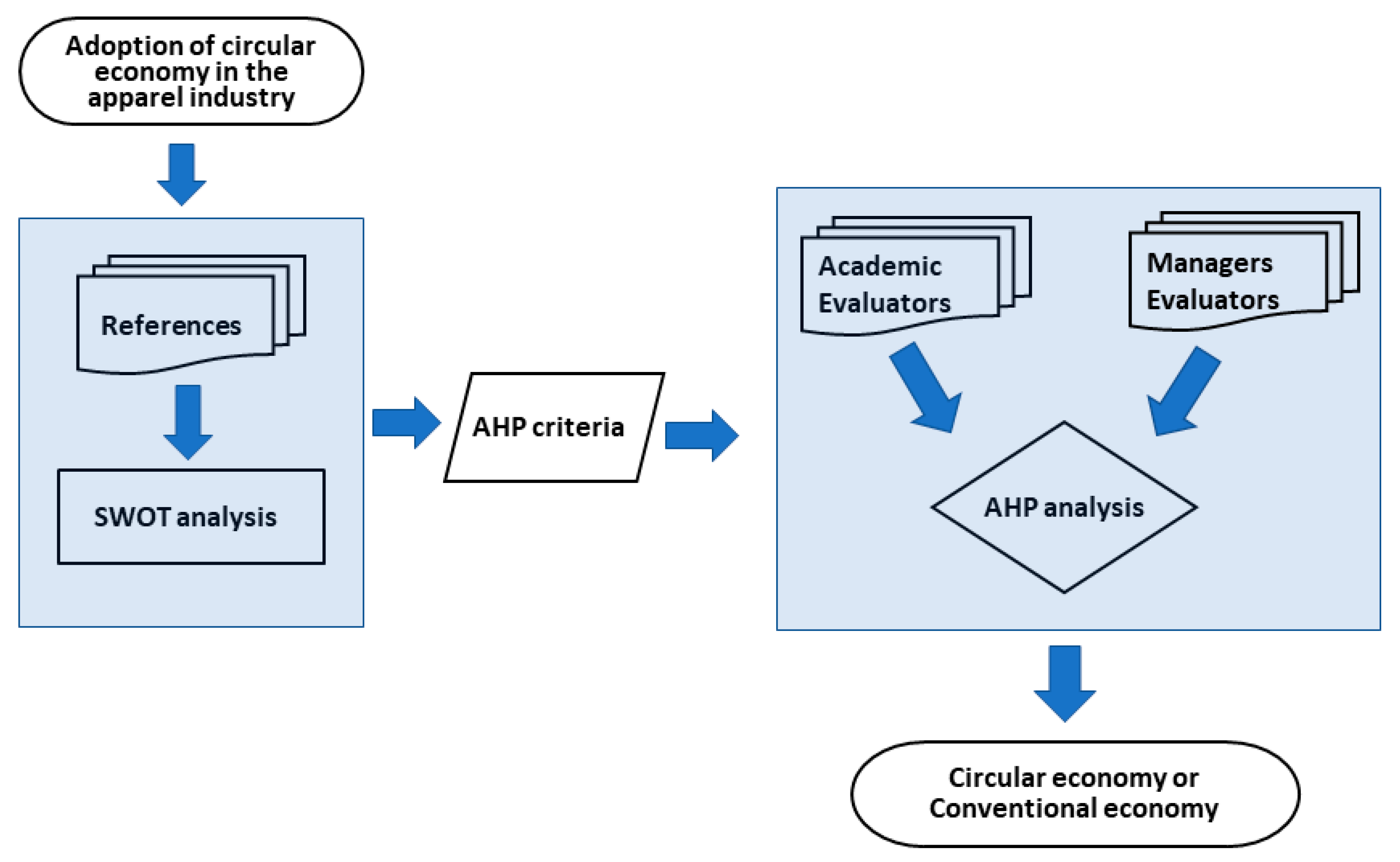

2. Methods

3. Results

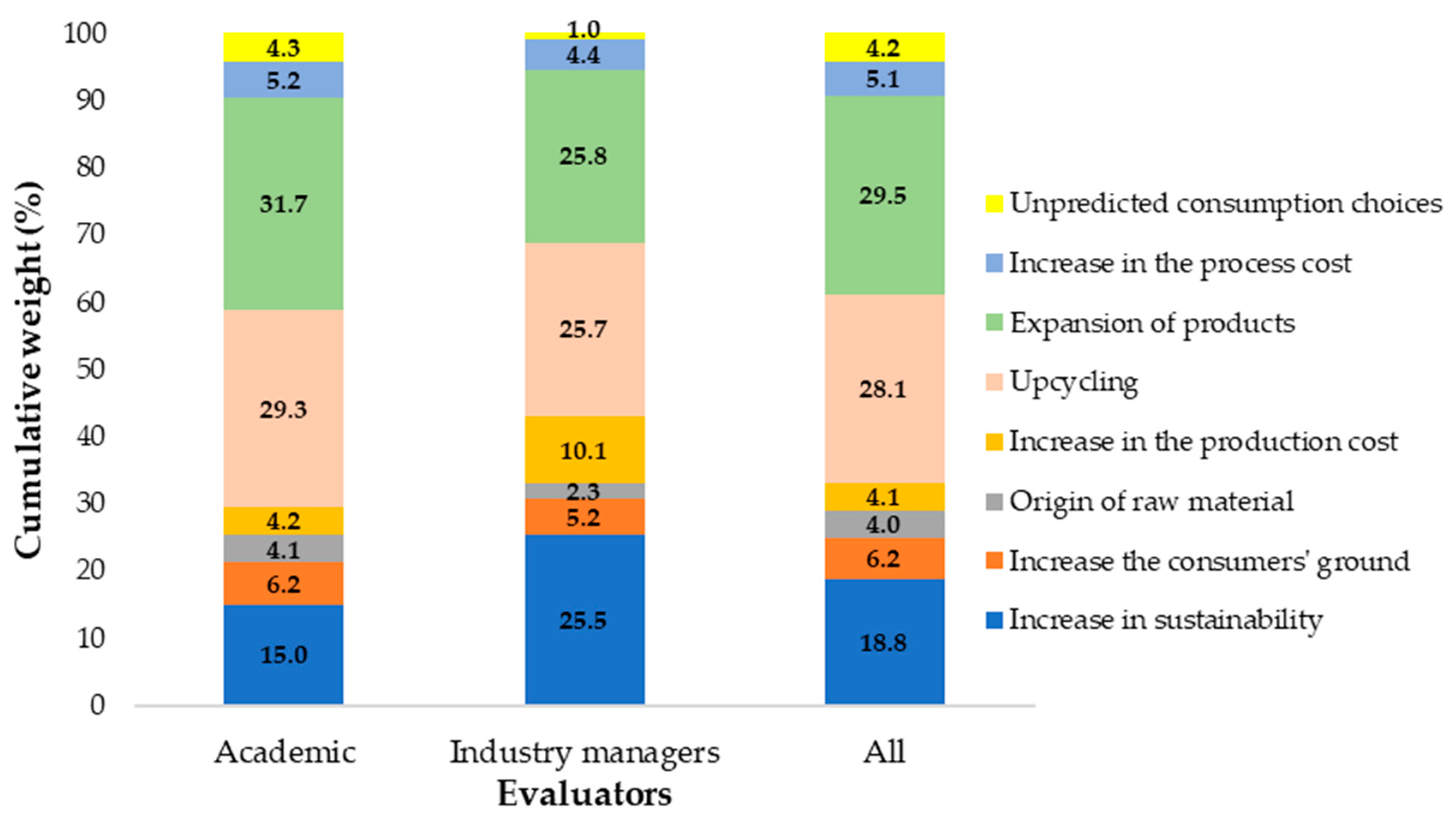

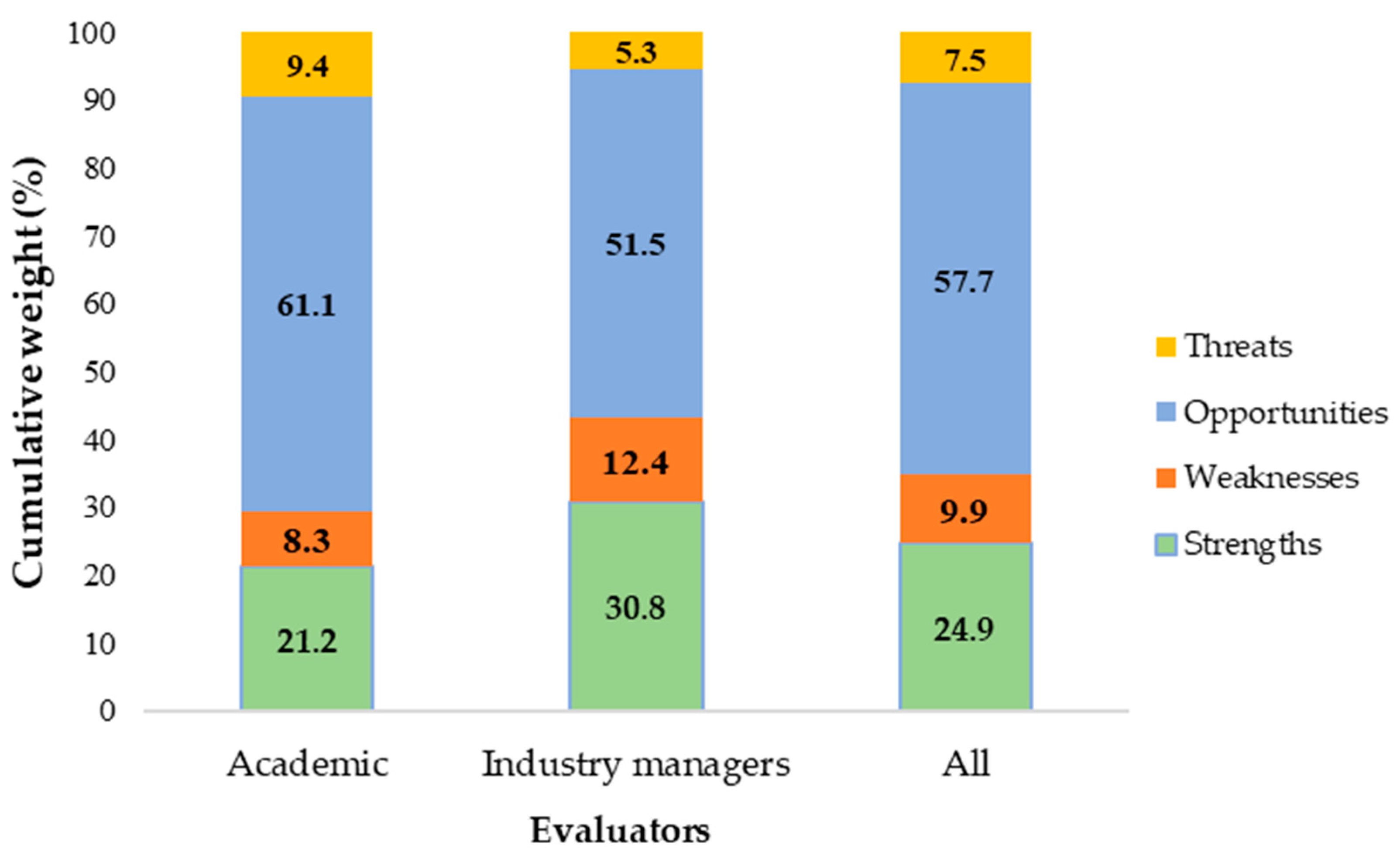

3.1. Academic Evaluators’ Judgment

3.2. Industry Manager Evaluators’ Judgment

3.3. Industry Manager and Academic Evaluators’ Judgment

3.4. Overall Evaluation

3.5. Cluster Analysis

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kozlowski, A.; Searcy, C.; Bardecki, M. The reDesign canvas: Fashion design as a tool for sustainability. J. Clean. Prod. 2018, 183, 194–207. [Google Scholar] [CrossRef]

- Clarke-Sather, A.; Cobb, K. Onshoring fashion: Worker sustainability impacts of global and local apparel production. J. Clean. Prod. 2019, 208, 1206–1218. [Google Scholar] [CrossRef]

- ABIT-Associação Brasileira da Indústria Têxtil e de Confecção. Available online: https://www.abit.org.br/cont/dados-economia (accessed on 10 October 2022).

- Ciasullo, M.V.; Maione, G.; Torre, C.; Troisi, O. What about sustainability? An empirical analysis of consumers’ purchasing behavior in fashion context. Sustainability 2017, 9, 1617. [Google Scholar] [CrossRef]

- Shrivastava, A.; Jain, G.; Kamble, S.S.; Belhadi, A. Sustainability through online renting clothing: Circular fashion fueled by instagram micro-celebrities. J. Clean Prod. 2021, 278, 123772. [Google Scholar] [CrossRef]

- Piontek, F.M.; Müller, M. Literature reviews: Life cycle assessment in the context of product-service systems and the textile industry. Procedia CIRP 2018, 69, 758–763. [Google Scholar] [CrossRef]

- Park, Y.J.; Kim, J. Is Factor Investing Sustainable after Price Impact Costs? The Capacity of Factor Investing in Korea. Sustainability 2019, 11, 4797. [Google Scholar] [CrossRef]

- Ghinea, C.; Ghiuta, O.A. Household food waste generation: Young consumers behaviour, habits and attitudes. IJEST 2019, 16, 2185–2200. [Google Scholar] [CrossRef]

- Da Giau, A.; Macchion, L. Sustainability practices and web-based communication: An analysis of the Italian fashion industry. J. Fash. Mark. 2016, 20, 72–88. [Google Scholar] [CrossRef]

- Garcia-Torres, S.; Rey-Garcia, M.; Albareda-Vivo, L. Effective disclosure in the fast-fashion industry: From sustainability reporting to action. Sustainability 2017, 9, 2256. [Google Scholar] [CrossRef]

- Choudhury, A.K.R. Environmental impacts of denim washing. In The Textile Institute Book Series, Sustainability in Denim; Woodhead Publishing: Sawston, UK, 2017; pp. 49–81. ISBN 9780081020432. [Google Scholar] [CrossRef]

- Luo, Y.; Wu, X.; Ding, X. Carbon and water footprints assessment of cotton jeans using the method based on modularity: A full life cycle perspective. J. Clean Prod. 2022, 332, 130042. [Google Scholar] [CrossRef]

- Turunen, L.L.M.; Halme, M. Communicating actionable sustainability information to consumers: The Shades of Green instrument for fashion. J. Clean Prod. 2021, 297, 126605. [Google Scholar] [CrossRef]

- Nayak, S.S.; Panda, T.K.; Kumar, A.; Jakhar, S.; Luthra, S.; Garza-Reyes, J.A.; Kazancoglu, I. Social and environmental sustainability model on consumers’ altruism, green purchase intention, green brand loyalty and evangelism. J. Clear Prod. 2020, 243, 118575. [Google Scholar]

- Zhang, Q.; Ikram, M.; Ferasso, M.; Sroufe, R. Assessing green technology indicators for cleaner production and sustainable investments in a developing country context. J. Clean Prod. 2021, 322, 129090. [Google Scholar]

- Gwilt, A.; Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T. The environmental price of fast fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the circular economy: Evidence from the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Korhonen, J.; Nuur, C.; Feldmann, A.; Birkie, S.E. Circular economy as an essentially contested concept. J. Clean Prod. 2018, 175, 544–552. [Google Scholar] [CrossRef]

- Borasino, E.; Fuhrmann-Riebel, H. New kids on the recycling block: The role of supermarkets and bodegas for sustainable consumer behaviour in Lima. In Circular Economy and Sustainability; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1–25. [Google Scholar]

- Gruber, M. An evolutionary perspective on adoption-diffusion theory. J. Bus. Res. 2020, 116, 535–541. [Google Scholar] [CrossRef]

- Gadelha, S. Biopolítica, Governamentalidade e Educação: Introdução e Conexões, a Partir de Michel Foucault; AutênticaEd: São Paulo, Brazil, 2016; 240p. [Google Scholar]

- Biava, J.D.O. A Metodologia Canvas e Suas Variações Para o Desenvolvimento do Empreendedorismo. 2017. Available online: http://repositorio.unesc.net/bitstream/1/5617/1/J%C3%B4nata%20de%20Oliveira%20Biava.pdf (accessed on 10 March 2023).

- Sóter, C.M.D.A. O Fator Verde no Design Thinking Canvas: Estudo Inicial da Adaptabilidade da Metodologia Frente aos Desafios Sustentáveis. 2016. Available online: https://repositorio.ufpe.br/bitstream/123456789/23544/4/TESE%20Clarissa%20Menezes%20Azevedo%20Soter.pdf (accessed on 15 March 2023).

- Valle, R.A.B.; Souza, R.G.; Rosenhead, J.; Salhofer, S.P.; Lins, M.P.E. Definition of sustainability impact categories based on stakeholder perspectives. J. Clean Prod. 2015, 105, 41–51. [Google Scholar]

- Saaty, T.L. The Analytic Hierarchy Process; McGrawHill International: New York, NY, USA, 1980; 287p. [Google Scholar]

- Du, Y.; Zheng, Y.; Wu, G.; Tang, Y. Decision-making method of heavy-duty machine tool remanufacturing based on AHP-entropy weight and extension theory. J. Clean Prod. 2020, 252, 119607. [Google Scholar] [CrossRef]

- Bathrinath, S.; Bhalaji, R.K.A.; Saravanasankar, S. Risk analysis in textile industries using AHP-TOPSIS. Mater. Today Proc. 2021, 45, 1257–1263. [Google Scholar] [CrossRef]

- Brandão, L.; de Alencar Nääs, I.; Neto, P.L.D.O.C. Sustainable development of gem production: An application of the Analytical Hierarchy Process. IJAHP 2021, 13. [Google Scholar] [CrossRef]

- Nejad, M.C.; Mansour, S.; Karamipour, A. An AHP-based multicriteria model for assessment of the social sustainability of technology management process: A case study in banking industry. Technol. Soc. 2021, 65, 101602. [Google Scholar] [CrossRef]

- Kim, Y.-J.; Park, J. A Sustainable Development Strategy for the Uzbekistan Textile Industry: The Results of a SWOT-AHP Analysis. Sustainability 2019, 11, 4613. [Google Scholar] [CrossRef]

- Instituto Brasileiro de Geografia e Estatística. Available online: https://censo2021.ibge.gov.br/panorama/?utm_source=ibge&utm_medium=home&utm_campaign=portal (accessed on 10 October 2022).

- Caloête, E.Q.M.; Westin, D.G. SEBRAE—The Brazilian Micro and Small Businesses Support Service-Design in Brazil: Report 2014; Sebrae: Brasília, Brazil, 2014. [Google Scholar]

- Goepel, K.D. Implementation of an Online Software Tool for the Analytic Hierarchy Process (AHP-OS). IJAHP 2018, 10, 469–487. [Google Scholar] [CrossRef]

- Johnstone, L.; Lindh, C. Sustainably sustaining (online) fashion consumption: Using influencers to promote sustainable (un)planned behaviour in Europe’s millennials. J. Retail. Consum. Serv. 2022, 64, 102775. [Google Scholar] [CrossRef]

- Edwards-Jones, G.; Davies, B.; Hussain, S.S. Ecological Economics: An Introduction; John Wiley & Sons: Hoboken, NJ, USA, 2009; 276p. [Google Scholar]

- Kanat, S.; Abbasi, S.A.; Peerzada, M.H.; Atilgan, T. SWOT analysis of Pakistan’s textile and clothing industry. Ind. Textila 2018, 69, 502. [Google Scholar]

- Ishizaka, A.; Labib, A. Review of the main developments in the analytic hierarchy process. Expert Syst. Appl. 2011, 38, 14336–14345. [Google Scholar] [CrossRef]

- Zanirato, S.H.; Rotondaro, T. Consumo, um dos dilemas da sustentabilidade. Estud. Av. 2016, 30, 77–92. [Google Scholar] [CrossRef]

- IBGE. Instituto Brasileiro de Geografia e Estatística (Brazilian Institute of Statistics)—Aplicações e Outros Recursos. 2022. Available online: https://censo2022.ibge.gov.br/panorama/recursos.html (accessed on 12 September 2023).

- Cunha, M.B. O censo demográfico de 2023 e seus possíveis reflexos nas bibliotecas brasileiras. Rev. Ibero-am. Ciênc. Inf. 2023, 16, 307–310. [Google Scholar]

- Leal Filho, W.; Shiel, C.; Paço, A.; Mifsud, M.; Ávila, L.V.; Brandli, L.L.; Molthan-Hill, P.; Pace, P.; Azeiteiro, U.M.; Vargas, V.R.; et al. Sustainable Development Goals and sustainability teaching at universities: Falling behind or getting ahead of the pack. J. Clean Prod. 2019, 232, 285–294. [Google Scholar] [CrossRef]

- Garcia, S.; de Alencar Nääs, I.; de Oliveira Costa Neto, P.L.; dos Reis, J.G.M.; Pólvora, V.N.; de Lima, L.A.; Martinez, A.A.G.; Lessa, V.S. Sustainability in fabric chains and garments for a circular economy. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Novi Sad, Serbia, 30 August 2020. [Google Scholar]

- Bianchi, C.; Birtwistle, G. Sell, give away, or donate: An exploratory study of fashion clothing disposal behaviour in two countries. Int. Rev. Retail. Distrib. Consum. Res. 2010, 20, 353–368. [Google Scholar] [CrossRef]

- Kim, A.J.; Johnson, K.K. Power of consumers using social media: Examining the influences of brand-related user-generated content on Facebook. Comput. Hum. Behav. 2016, 58, 98–108. [Google Scholar] [CrossRef]

- Sinha, P.; Muthu, S.S.; Dissanayake, G. Remanufactured Fashion; Springer: Singapore, 2016; 82p. [Google Scholar]

- Smola, W.K.; Sutton, C.D. Generational differences: Revisiting generational work values for the new millennium. J. Organ. Behav. 2002, 23, 363–382. [Google Scholar] [CrossRef]

| Evaluator | Professional and Commercial Traits | |

|---|---|---|

| Academic | 1 | Researcher with extensive experience in the textile and clothing industry. |

| 2 | Professor and researcher with extensive experience in sustainability and cleaner production. | |

| 3 | Professor and researcher with academic experience in production engineering. | |

| 4 | Teacher and designer with experience in production and factory floors of the clothing industry. | |

| Industrial | 5 | Manager of Industry A. The company is in the under-garment segment, produces more than 200,000 pieces per month, and has been in the market for 25 years. |

| 6 | Manager of Industry B. The company is in the under-garment segment, produces around 180,000 pieces per month, and has been in the market for 20 years. |

| Criteria 1 Strengths | Subcriteria | Criteria 2 Weakness | Subcriteria |

|---|---|---|---|

|

|

|

|

| Criteria 3 Opportunities | Subcriteria | Criteria 4 Threats | Subcriteria |

|

|

| Strength of Importance | Definition |

|---|---|

| 1 | Equal importance |

| 2 | Weak |

| 3 | Moderate importance |

| 4 | Moderate plus importance |

| 5 | Strong importance |

| 6 | Strong plus importance |

| 7 | Very strong importance |

| 8 | Very, very strong importance |

| 9 | Extreme importance |

| Goal | Level 1 Criteria (Weight) | Level 2 Criteria (Weight) | Weight (%) | Rank |

|---|---|---|---|---|

| Comparing the conventional and circular economy | Strengths (0.212) | Increase in sustainability (0.709) | 15.0 | 3rd |

| Increase the consumers’ ground (0.291) | 6.2 | |||

| Weaknesses (0.083) | Origin of raw material (0.496) | 4.1 | ||

| Increase in the production cost (0.504) | 4.2 | |||

| Opportunities (0.611) | Upcycling (0.480) | 29.3 | 2nd | |

| Expansion of products (0.520) | 31.7 | 1st | ||

| Threats (0.094) | Increase in the process cost (0.551) | 5.2 | ||

| Unpredicted consumption choices (0.449) | 4.3 |

| Goal | Level 1 Criteria (Weight) | Level 2 Criteria (Weight) | Weight (%) | Rank |

|---|---|---|---|---|

| Comparing the conventional and circular economy in the apparel industry | Strengths (0.308) | Increase in sustainability (0.830) | 25.5 | 3rd |

| Increase the consumers’ ground (0.170) | 5.2 | |||

| Weakness (0.124) | Origin of raw material (0.183) | 2.3 | ||

| Increase in the production cost (0.817) | 10.1 | |||

| Opportunities (0.515) | Upcycling (0.500) | 25.7 | 2nd | |

| Expansion of products (0.500) | 25.8 | 1st | ||

| Threats (0.053) | Increase in the process cost (0.817) | 4.4 | ||

| Unpredicted consumption choices (0.183) | 1.0 |

| Goal | Level 1 Criteria (Weight) | Level 2 Criteria (Weight) | Weight (%) | Rank |

|---|---|---|---|---|

| Comparing the conventional and circular economy in the apparel industry | Strengths (0.249) | Increase in sustainability (0.754) | 18.8 | 3rd |

| Increase the consumers’ ground (0.246) | 6.2 | |||

| Weakness (0.099) | Origin of raw material (0.375) | 4.0 | ||

| Increase in the production cost (0.625) | 4.1 | |||

| Opportunities (0.577) | Upcycling (0.513) | 28.1 | 2nd | |

| Expansion of products (0.487) | 29.5 | 1st | ||

| Threats (0.075.0) | Increase in the process cost (0.653) | 5.1 | ||

| Unpredicted consumption choices (0.347) | 4.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, R.C.; Nääs, I.d.A.; Garcia, S. Combining SWOT with AHP for Analyzing the Adoption of a Circular Economy in the Apparel Industry in Brazil. Recycling 2023, 8, 73. https://doi.org/10.3390/recycling8050073

Oliveira RC, Nääs IdA, Garcia S. Combining SWOT with AHP for Analyzing the Adoption of a Circular Economy in the Apparel Industry in Brazil. Recycling. 2023; 8(5):73. https://doi.org/10.3390/recycling8050073

Chicago/Turabian StyleOliveira, Rimena Canuto, Irenilza de Alencar Nääs, and Solimar Garcia. 2023. "Combining SWOT with AHP for Analyzing the Adoption of a Circular Economy in the Apparel Industry in Brazil" Recycling 8, no. 5: 73. https://doi.org/10.3390/recycling8050073

APA StyleOliveira, R. C., Nääs, I. d. A., & Garcia, S. (2023). Combining SWOT with AHP for Analyzing the Adoption of a Circular Economy in the Apparel Industry in Brazil. Recycling, 8(5), 73. https://doi.org/10.3390/recycling8050073