The Challenge of Plastic Management for Waste Electrical and Electric Equipment Recycling in the Global South: A Case Comparison between Europe and Latin America

Abstract

:1. Introduction

2. Case Study

3. Materials and Methods

3.1. Samples for Primary Characterization

3.2. Statistical Significance of Selected Sample Size

3.3. Sample Characterisation

3.4. Classification Criteria

3.5. Literature Review

3.5.1. WEEE Scenario

3.5.2. WEEE Management Infrastructure

3.5.3. Treatment Options in the Latin American Region

4. Results

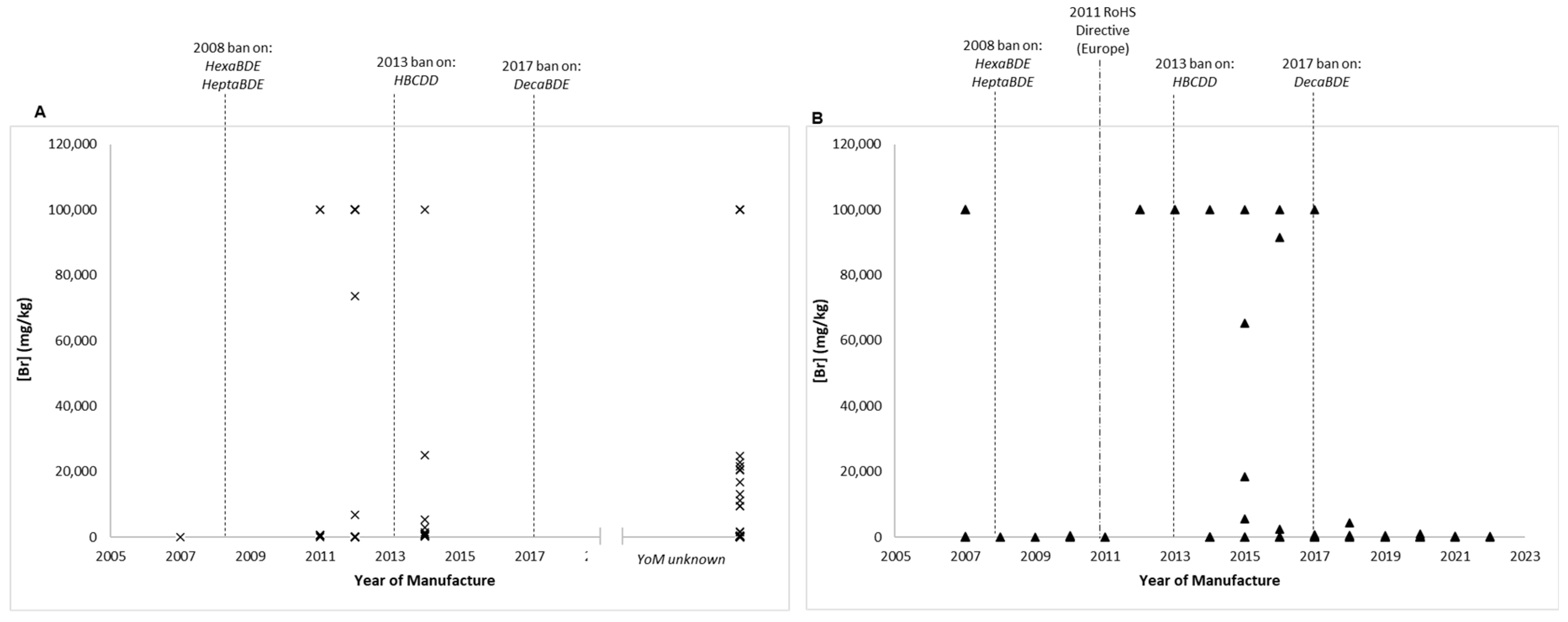

4.1. Bromine and Antimony Content: Classification

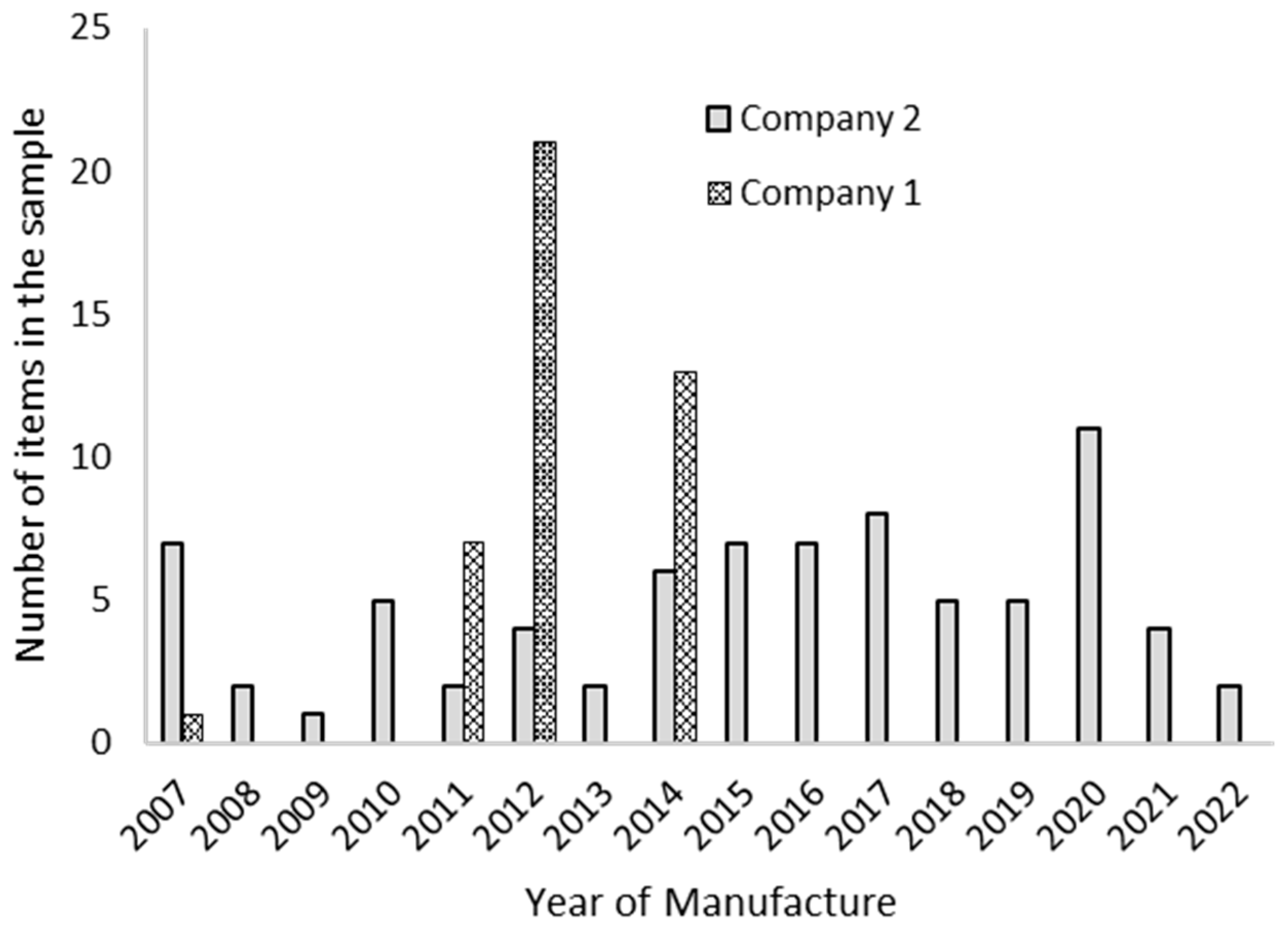

4.2. Year of Manufacture

4.3. Amount of Plastic Generated: An Estimate

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on Waste Electrical and Electronic Equipment (WEEE) (Recast) Text with EEA Relevance. 2012, Volume 197. Available online: http://data.europa.eu/eli/dir/2012/19/oj/eng (accessed on 17 July 2023).

- Charitopoulou, M.A.; Papadopoulou, L.; Achilias, D.S. Microwave-assisted extraction as an effective method for the debromination of brominated flame retarded polymeric blends with a composition that simulates the plastic part of waste electric and electronic equipment (WEEE). Sustain. Chem. Pharm. 2022, 29, 100790. [Google Scholar] [CrossRef]

- Kousaiti, A.; Hahladakis, J.N.; Savvilotidou, V.; Pivnenko, K.; Tyrovola, K.; Xekoukoulotakis, N.; Astrup, T.F.; Gidarakos, E. Assessment of tetrabromobisphenol-A (TBBPA) content in plastic waste recovered from WEEE. J. Hazard. Mater. 2020, 390, 121641. [Google Scholar] [CrossRef]

- Okeke, E.S.; Huang, B.; Mao, G.; Chen, Y.; Zeng, Z.; Qian, X.; Wu, X.; Feng, W. Review of the environmental occurrence, analytical techniques, degradation and toxicity of TBBPA and its derivatives. Environ. Res. 2022, 206, 112594. [Google Scholar] [CrossRef]

- Regulation (EU) 2019/1021 of the European Parliament and of the Council of 20 June 2019 on Persistent Organic Pollutants (Recast) Text with EEA Relevance. 2019, Volume 169. Available online: http://data.europa.eu/eli/reg/2019/1021/oj/eng (accessed on 7 July 2023).

- The Persistent Organic Pollutants Regulations. 2007. Available online: https://www.legislation.gov.uk/uksi/2007/3106/made (accessed on 7 July 2023).

- Bill, A.; Gasser, M.; Haarman, A.; Boni, H. Processing of WEEE plastics. In A Practical Handbook; Solving the E-Waste Problem (StEP) Initiative; Sustainable Electronics Recycling International (SERI): Hastings, MN, USA, 2019. [Google Scholar]

- Keeley-Lopez, P.; Turrell, J.; Vernon, J. An Assessment of the Levels of Persistent Organic Pollutants (POPs) in Waste Electronic and Electrical Equipment in England and Wales, 2020. UC14161.3, March 2020. Available online: https://icer.org.uk/research/ (accessed on 11 July 2023).

- Zhan, F.; Zhang, H.; Cao, R.; Fan, Y.; Xu, P.; Chen, J. Release and Transformation of BTBPE During the Thermal Treatment of Flame Retardant ABS Plastics. Environ. Sci. Technol. 2019, 53, 185–193. [Google Scholar] [CrossRef] [PubMed]

- Aldrian, A.; Ledersteger, A.; Pomberger, R. Monitoring of WEEE plastics in regards to brominated flame retardants using handheld XRF. Waste Manag. 2015, 36, 297–304. [Google Scholar] [CrossRef] [PubMed]

- Yli-Rantala, E.; Bacher, J.; Kaartinen, T.; Vincenti, N.; Zhan, M. Pre-Treatment and Characterisation of WEEE, ELV and C&DW Plastics, Regional Perspectives on Their Recycling, and Testing of Recyclates (Deliverable D1.1 of NONTOX Project). 2021, p. 89. Available online: http://nontox-project.eu/wp-content/uploads/2021/05/NONTOX-D1-1.pdf (accessed on 6 July 2023).

- Strobl, L.; Diefenhardt, T.; Schlummer, M.; Leege, T.; Wagner, S. Recycling Potential for Non-Valorized Plastic Fractions from Electrical and Electronic Waste. Recycling 2021, 6, 33. [Google Scholar] [CrossRef]

- Bonifazi, G.; Fiore, L.; Hennebert, P.; Serranti, S. Development of a selection system based on hyperspectral imaging for plastic waste with brominated flame retardants. Environ. Eng. Manag. J. 2020, 19, 1755–1763. [Google Scholar]

- Bonifazi, G.; Fiore, L.; Hennebert, P.; Serranti, S. An Efficient Strategy Based on Hyperspectral Imaging for Brominated Plastic Waste Sorting in a Circular Economy Perspective. In Advances in Polymer Processing 2020; Hopmann, C., Dahlmann, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 14–27. [Google Scholar] [CrossRef]

- Bonifazi, G.; Fiore, L.; Gasbarrone, R.; Hennebert, P.; Serranti, S. Detection of Brominated Plastics from E-Waste by Short-Wave Infrared Spectroscopy. Recycling 2021, 6, 54. [Google Scholar] [CrossRef]

- Alghamdi, M.; Abdallah, M.A.-E.; Harrad, S. The utility of X-Ray fluorescence spectrometry as a tool for monitoring compliance with limits on concentrations of halogenated flame retardants in waste polymers: A critical review. Emerg. Contam. 2022, 8, 9–20. [Google Scholar] [CrossRef]

- Sharkey, M. Sources, Concentrations, and Screening of Hazardous Brominated Flame Retardants from Waste Streams in Ireland. Ph.D. Thesis, University of Galway, Galway, Ireland, 2019. [Google Scholar] [CrossRef]

- Stockholm Convention–Home Page. Available online: https://www.pops.int/default.aspx (accessed on 9 June 2023).

- Haarman, A.; Magalini, F.; Courtois, J. Study on the Impacts of Brominated Flame Retardants on the Recycling of WEEE Plastics in Europe. November 2020. Available online: https://www.bsef.com/wp-content/uploads/2020/11/Study-on-the-impact-of-Brominated-Flame-Retardants-BFRs-on-WEEE-plastics-recycling-by-Sofies-Nov-2020.pdf (accessed on 25 May 2023).

- Harrad, S.; Drage, D.; Abdallah, M.; Sharkey, M.; Berresheim, H. Evaluation of Hand-Held Xrf for Screening Waste Articles for Exceedances of Limit Values for Brominated Flame Retardants, Environmental Protection Agency, Report, March 2019. Available online: https://aran.library.nuigalway.ie/handle/10379/16246 (accessed on 9 June 2023).

- Alassali, A.; Abis, M.; Fiore, S.; Kuchta, K. Classification of plastic waste originated from waste electric and electronic equipment based on the concentration of antimony. J. Hazard. Mater. 2019, 380, 120874. [Google Scholar] [CrossRef]

- Alassali, A.; Picuno, C.; Samara, H.; Diedler, S.; Fiore, S.; Kuchta, K. Antimony Mining from PET Bottles and E-Waste Plastic Fractions. Sustainability 2019, 11, 4021. [Google Scholar] [CrossRef]

- Pan, X.; Wong, C.; Li, C. Circular economy practices in the waste electrical and electronic equipment (WEEE) industry: A systematic review and future research agendas. J. Clean. Prod. 2022, 365, 132671. [Google Scholar] [CrossRef]

- Forti, V.; Baldé, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020. 2020, p. 120. Available online: https://ewastemonitor.info/wp-content/uploads/2020/11/GEM_2020_def_july1_low.pdf (accessed on 7 August 2023).

- Dias, P.R.; Cenci, M.P.; Bernades, A.M.; Huda, N. What drives WEEE recycling? A comparative study concerning legislation, collection and recycling. Waste Manag. Res. 2022, 40, 1527–1538. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Bello, L.A.; Estupiñán-Escalante, E. The impact of waste of electrical and electronic equipment public police in Latin America: Analysis of the physical, economical, and information flow. In Handbook of Electronic Waste Management; Elsevier: Amsterdam, The Netherlands, 2020; pp. 397–419. [Google Scholar] [CrossRef]

- Weghofer, S.; Mertl, M.; Yao, X.; Strambu, S. Unido Opendata Platform. Available online: https://open.unido.org/projects/M4/projects/140297 (accessed on 14 July 2023).

- Chaine, C.; Hursthouse, A.S.; Jandric, A.; McLean, B.; McLellan, I.; McMahon, B.; McNulty, J.; Miller, J.; Salhofer, S.; Viza, E. Optimized industrial sorting of WEEE plastics: Development of fast and robust h-XRF technique for hazardous components. Case Stud. Chem. Environ. Eng. 2023, 7, 100292. [Google Scholar] [CrossRef]

- Cronin, P.; Ryan, F.; Coughlan, M. Undertaking a literature review: A step-by-step approach. Br. J. Nurs. 2013, 17, 38–43. [Google Scholar] [CrossRef]

- Anuario Estadistico 2022; Instituto Nacional de Estadistica: Montevideo, Uruguay, 2022; ISSN 1688-101X.

- World Bank Open Data (Uruguay GDP), World Bank Open Data. Available online: https://data.worldbank.org (accessed on 11 June 2023).

- Regional E-Waste Monitor for Latin America 2022, E-Waste Monitor. Available online: https://ewastemonitor.info/regional-e-waste-monitor-for-latin-america-2022/ (accessed on 9 June 2023).

- Souteras, F.; Crovetto, M.J.; Guerguerian, G. Residuos de Aparatos Electricos y Electronicos en Uruguay. Cantidades Generadas y Flujos, 2020. Available online: https://residuoselectronicosal.org/wp-content/uploads/2020/12/RAEE-en-Uy-Cantidades-generadas-y-flujos-1.pdf (accessed on 26 May 2023).

- Population Estimates for the UK, England, Wales, Scotland and Northern Ireland–Office for National Statistics. Available online: https://www.ons.gov.uk/peoplepopulationandcommunity/populationandmigration/populationestimates/bulletins/annualmidyearpopulationestimates/mid2021 (accessed on 12 June 2023).

- GDP Quarterly National Accounts, Scotland 2022 Quarter 3 (July to September); Scottish Government Riaghaltas na h-Alba gov.scot: Edinburgh, Scotland, 2023.

- Waste Data|Scottish Environment Protection Agency (SEPA). Available online: https://www.sepa.org.uk/environment/waste/waste-data/ (accessed on 14 July 2023).

- Clausen, J.; Göll, E.; Tappeser, V. Sticky Transformation How path dependencies in socio-technical regimes are impeding the transformation to a Green Economy. J. Innov. Manag. 2017, 2, 110–137. [Google Scholar] [CrossRef]

- Evolución del Alumbrado Público en Uruguay|Opp–Oficina de Planeamiento y Presupuesto de la República. Available online: https://www.opp.gub.uy/es/noticias/evolucion-del-alumbrado-publico-en-uruguay (accessed on 11 June 2023).

- Estrategia Nacional de Iluminación Eficiente y Sostenible; Ministerio de Industria, Energía y Minería: Montevideo, Uruguay, 2013.

- Dell’Onte, H. La Mitad de los Hogares Uruguayos Tiene Aire Acondicionado, Todo El Campo, 18 May 2023. Available online: https://todoelcampo.com.uy/2023/05/la-mitad-de-los-hogares-uruguayos-tiene-aire-acondicionado/ (accessed on 14 July 2023).

- Shepherd, M. Most Homes in the United Kingdom Have No Air Conditioning–Unprecedented Heat Looms, Forbes. Available online: https://www.forbes.com/sites/marshallshepherd/2022/07/15/most-homes-in-the-united-kingdom-have-no-air-conditioningunprecedented-heat-looms/ (accessed on 14 July 2023).

- Directive 2011/65/EU of the European Parliament and of the Council of 8 June 2011 on the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment (Recast) (Text with EEA Relevance). 2016. Available online: https://eur-lex.europa.eu/legal-content/en/ALL/?uri=celex%3A32011L0065 (accessed on 9 June 2023).

- WEEE and RoHS in Latin America and the Caribbean, Compliance & Risks. Available online: https://www.complianceandrisks.com/thank-you/od-webinar/weee-rohs-latin-america-and-caribbean/ (accessed on 9 June 2023).

- Liu, K.; Tan, Q.; Yu, J.; Wang, M. A global perspective on e-waste recycling. Circ. Econ. 2023, 2, 100028. [Google Scholar] [CrossRef]

- MVOTMA. Plan Nacional de Aplicación del Convenio de Estocolmo Sobre Contaminantes Orgánicos Persistentes 2017–2030 Uruguay; MVOTMA: Montevideo, Uruguay, 2017.

- PREAL Project, PREAL. Available online: https://residuoselectronicosal.org/ (accessed on 11 June 2023).

- Hernandez, S.C.A.; Ott, D.; Lora Reyes, N. Transboundary Movement of WEEE in Latin America.pdf, StEP Working Group for Latin America and the Caribbean. 2023. Available online: https://www.step-initiative.org/files/_documents/publications/Movimientos%20Transfronterizos%20de%20RAEE%20en%20Am%C3%A9rica%20Latina.pdf (accessed on 15 May 2023).

- PLAST2bCLEANED: Recycling Process for Waste Electrical & Equipment, PLAST2bCLEANED. Available online: https://plast2bcleaned.eu/ (accessed on 14 July 2023).

- NONTOX Project–NONTOX Project. Available online: http://nontox-project.eu/ (accessed on 14 July 2023).

- POPs Destruction Technologies. UNEP–UN Environment Programme, 15 September 2017. Available online: http://www.unep.org/explore-topics/chemicals-waste/what-we-do/persistent-organic-pollutants/pops-destruction (accessed on 7 July 2023).

- Stubbings, W.A.; Abdallah, M.A.-E.; Misiuta, K.; Onwuamaegbu, U.; Holland, J.; Smith, L.; Parkinson, C.; McKinlay, R.; Harrad, S. Assessment of brominated flame retardants in a small mixed waste electronic and electrical equipment (WEEE) plastic recycling stream in the UK. Sci. Total Environ. 2021, 780, 146543. [Google Scholar] [CrossRef]

- Hennebert, P.; Filella, M. WEEE plastic sorting for bromine essential to enforce EU regulation. Waste Manag. 2018, 71, 390–399. [Google Scholar] [CrossRef]

- Duflou, J.R.; Boudewijn, A.; Cattrysse, D.; Wagner, F.; Accili, A.; Dimitrova, G.; Peeters, J.R. Product clustering as a strategy for enhanced plastics recycling from WEEE. CIRP Ann. 2020, 69, 29–32. [Google Scholar] [CrossRef]

- Sharkey, M.; Abdallah, M.A.-E.; Drage, D.S.; Harrad, S.; Berresheim, H. Portable X-ray fluorescence for the detection of POP-BFRs in waste plastics. Sci. Total Environ. 2018, 639, 49–57. [Google Scholar] [CrossRef] [PubMed]

- Sharkey, M.; Drage, D.; Harrad, S.; Stubbings, W.; Rosa, A.H.; Coggins, M.; Berresheim, H. POP-BFRs in consumer products: Evolution of the efficacy of XRF screening for legislative compliance over a 5-year interval and future trends. Sci. Total Environ. 2022, 853, 158614. [Google Scholar] [CrossRef] [PubMed]

| Sampled Equipment Characteristics | Company 1 (Uruguay) | Company 2 (Scotland) |

|---|---|---|

| Year of recovery | The equipment sampled was received from different Uruguayan companies for replacement, either due to changes in technology or breakage over 2 years (between 2021 and 2022), comprising LED TVs and small display equipment (i.e., tablets). | The equipment sampled was received from different UK Compliance Schemes and UK Councils, from both households and non-household sources. All the equipment was received on site during the year 2022, comprising LED and LCD TVs and monitors. |

| Year of manufacture | 2007–2014 | 2007–2022 |

| Origin | China and Mexico | China, Czech Republic, Poland, Turkey, United Kingdom |

| Bromine (Br) Concentration [mg/kg] | |||

| <830 | ≥830 | ||

| Antimony (Sb) concentration [mg/kg] | <8300 | Recycle | POP waste |

| ≥8300 | Hazardous waste | POP and hazardous waste (POP and HAZ) | |

| Category | Uruguay (Ton/Year) | Scotland (Ton/Year) | Difference |

|---|---|---|---|

| Monitors, screens, and display devices | 5613 | 3563 | Uruguay 36% |

| Large appliances | 7016 | 9421 | Scotland 26% |

| Small appliances (includes small computer and telecommunications equipment) | 14,987 | 12,691 | Uruguay 15% |

| Temperature exchange equipment (including fridges and freezers) | 9313 | 7233 | Uruguay 22% |

| Fluorescent tubes and other light bulbs | 677 | 151.6 | Uruguay 78% |

| Median (mg/kg) | Max (wt%) | Min (mg/kg) | ||

|---|---|---|---|---|

| Bromine (ppm) | Company 1 | 762 | >15% | <LOD |

| Company 2 | 135 | >10% | <LOD | |

| Antimony (ppm) | Company 1 | 2104 | >2.8% | 53.5 |

| Company 2 | <LOD | >6.2% | <LOD |

| Ton/Year (2019) | |||

|---|---|---|---|

| Uruguay | Scotland | Difference | |

| Monitors, screens, and display devices | 5613 | 3563 | 37% |

| Plastic | 1684 | 1069 | 37% |

| Recyclable | 821 | 775 | 6% |

| POPs | 472 | 80 | 83% |

| POPandHAZ | 390 | 214 | 45% |

| Aspect | Uruguay | Scotland |

|---|---|---|

| Material | Technological alternatives must be sought to cope with the higher volumes of POPs and hazardous waste, and greater management costs. The weaker economic development suggests that the availability of the necessary technology will not be immediate, or on an appropriate scale. This results in inefficient waste management or export, losing the opportunity to generate business and economic profit from resource recovery. | With support from the government for the innovation and development of new technologies, technically and economically feasible alternatives for the management of this unique type of waste are being sought. |

| Legislation | It would be key to develop and enforce legislation that regulates the presence and management of POPs in WEEE plastics, in order to protect the environment and public health. Ongoing efforts should be focused on developing regulation that includes control measures and restrictions on the characteristics of the products that are placed on the market. | Regulations put pressure on waste managers who must make large investments to comply with a demanding legislation that does not focus on controlling the problem, and only addresses the solution. |

| Waste management sector | It is necessary to provide support to the waste management sector, so that it can exist even after facing the higher management costs associated with complying with any standards. It is advisable to promote eco-design, to ensure the quality of the equipment placed on the market, as well as to allow users and managers to know what components it contains. It is necessary to ensure the implementation of a system for the collection, reuse, and recycling of end-of-life equipment. | |

| Sorting criteria | The screening of WEEE plastics for hazardous compounds, such as POPs, is a practice that should be widely adopted. One of the keys to the implementation of a screening technique on the industrial level is the speed of processing; thus, it is important to define the criteria (based on tracer elements, i.e., Br/Sb or chemical compounds) that will be used to validate the defined requirements and their implementation. | |

| Sorting technology | With relatively low investment and operating costs, XRF would be a suitable, cost-effective option to consider, with a capacity to determine Br/Sb concentations in less than 10 s, and with an approximate efficiency of 90% [55]. Further research on the effectiveness and efficiency of h-XRF for the identification of hazardous materials is still needed, as manufacturers are migrating the use of POP-BFRs to non-POP-BFRs. | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaine, C.; Hursthouse, A.S.; McLellan, I.; Viza, E.; Miller, J. The Challenge of Plastic Management for Waste Electrical and Electric Equipment Recycling in the Global South: A Case Comparison between Europe and Latin America. Recycling 2023, 8, 71. https://doi.org/10.3390/recycling8050071

Chaine C, Hursthouse AS, McLellan I, Viza E, Miller J. The Challenge of Plastic Management for Waste Electrical and Electric Equipment Recycling in the Global South: A Case Comparison between Europe and Latin America. Recycling. 2023; 8(5):71. https://doi.org/10.3390/recycling8050071

Chicago/Turabian StyleChaine, Cecilia, Andrew S. Hursthouse, Iain McLellan, Evi Viza, and Jan Miller. 2023. "The Challenge of Plastic Management for Waste Electrical and Electric Equipment Recycling in the Global South: A Case Comparison between Europe and Latin America" Recycling 8, no. 5: 71. https://doi.org/10.3390/recycling8050071

APA StyleChaine, C., Hursthouse, A. S., McLellan, I., Viza, E., & Miller, J. (2023). The Challenge of Plastic Management for Waste Electrical and Electric Equipment Recycling in the Global South: A Case Comparison between Europe and Latin America. Recycling, 8(5), 71. https://doi.org/10.3390/recycling8050071