Abstract

This review paper shows several sections of bitumen, asphalt mixtures, polymers, and waste plastic in pavement engineering. The paper reviews and evaluates the influence of using waste polymer in improving the rheological and engineering properties of the modified binder and mixtures. Evaluation of properties and design of stone mastic asphalt mixtures are reviewed. Reports and studies had investigated the advantages and importance of using polymer in bitumen modification; however, they yet show a gap in research in terms of the role of waste polymer in improving the durability, aging, and fatigue life in the long term of service.

1. Introduction

The structural stability of the road is usually supplied by the pavement consisting of crushed and carefully selected stone and rock of suitable sizes, which is finally compacted by applying a limited amount of binder. It is known that the standard layers from top to bottom within a pavement are road surface (wearing course), base course (crushed gravel and stone), sub-base course (selected granular material), and sub-grad (natural soil layer). It is noteworthy that it is possible to further strengthen the used granular material with lime, bitumen, or cement. In heavily loaded roads, in the structure of pavements, concrete or asphalt usually substitute the granular material, especially in the base and sub-base layers [,].

Frequently, Portland cement concrete or bitumen base surface are used to form the road surfacing. There are several reasons that necessitate surfacing, some of which are to provide a suitable and safe surface for vehicles to turn on easily, to protect the structure and sub-grade of the pavement from the environmental effects, such as moisture, and to reduce the stress imposed on the pavement to protect it against any possible deformation or destruction [].

This paper reviews the literature related to the data used for analyses and discussions on road surfacing modification in civil engineering. First, the paper will display the background of road engineering and types of hot mix asphalt used in pavement construction. Consideration to the specification and properties of the stone mastic asphalt are illustrated. After that is a comprehensive review on asphalt modification using polymer, waste plastic, and nanomaterials. This paper aims to review the background knowledge and current status of road surfacing in the relevant regions to provide a sympathetic description of the significance of waste-plastic-modified bitumen binder and asphalt mixtures, and its role in providing effective and durable surfacing for heavy-trafficked roads in hot and humid areas. The use of nanomaterials as additive in asphalt are discussed and evaluated. This paper will seek to clarify some of the terms and concepts related to debates to enlighten the readers with the necessary background to better engage with the experiments and discussions alongside the investigator.

2. Background on Road Engineering

Roads and bridges are one of the most crucial components of infrastructure engineering and they play a vital role in our lifetimes. Bituminous mixture is a composite material made up of other distinct materials, employed in a range of civil engineering tasks, such as the construction of roads. It consists of mineral aggregate, bitumen, and air voids, which are the main components of bituminous mixture, blended and then laid and compacted to form the surface of roads [].

Mixing of the aggregate and bitumen is performed using one of the following methods [,]:

- A.

- Hot mix asphalt (HMA) is a mixture of aggregate and bitumen blended through heating. For paving and compaction, the mixture must be hot enough to form the HMA. In cold countries, paving is limited to warm seasons due to the cold weather during winter or autumn, which causes the compacted base to cool down the asphalt mixture too much before it is packed to the desired air void content. Hot mix asphalt is the most common bituminous mix around the world for road pavements with heavy traffic, such as roads and expressways or airport lanes.

- B.

- Warm mix asphalt concrete (WMA) is a mixture created by adding waxes, zeolites, or asphalt emulsions, which are added to the mixture in different stages. This allows a significant reduction in temperature for mixing and laying, which, in turn, leads to more savings in fossil fuels and a reduction in the air pollution and environmental contamination resulting from the emission of CO2, vapours and aerosols. The lower laying temperature not only helps in improving working conditions, but also makes the surface availability faster for utilisation, especially in construction projects with critical tasks and time schedules. Furthermore, the application of such additives in HMA can yield more easily compacted mixes, specifically in cold climates for which the length of the hauls is limited by the temperature.

- C.

- Cold mix asphalt concrete is created by emulsifying the bitumen in water with soap, before being mixed with aggregate, since the viscosity of bitumen emulsion is lower, which renders the mixture easy to work and compact. After the evaporation of a sufficient amount of water, the emulsion breaks, allowing the cold mix to take on the cold HMA properties. Cold mix asphalt concrete is usually used to patch cracked or dug up asphalt parts on roads with lighter traffic services.

- D.

- Cut-back asphalt concrete (CBMA) is created by the dissolution of the binder within kerosene or any other lighter petroleum products before being blended with aggregate. Since the dissolved binder is less viscous, the mixture can be handled and compacted more easily. After the mixture is laid, the lighter petroleum fraction evaporates.

- E.

- Mastic asphalt concrete, sometimes called sheet asphalt, is a mixture of hard grade blown bitumen (oxidised), which is blended in a green cooker while heating to make a liquid of high viscosity, and then the aggregate is added in the mixture. The resulting bitumen aggregate mix is matured through cooking (heating) for approximately 7 h. The thickness of mastic asphalt concrete usually needs to be about 20–30 mm for road, sidewalks, and walker’s lanes and about 10 mm for roof and flooring applications [,].

Hot Mix Asphalt (HMA)

Asphalt pavement or flexible pavement is widely employed throughout the globe. Asphalt pavement has good riding quality, and it is much cheaper to construct, in comparison to concrete or rigid pavements. HMA mixtures for asphalt pavement are divided into three main categories: dense-graded mixture, open-graded mixture, and gap-graded mixture.

Dense-graded mixture is a well-graded mix, which consists of bitumen and aggregate. The distribution of the size of aggregate particles is even and smooth from coarse to fine. Dense-graded HMA is conventionally employed in road construction. One of the disadvantages of the dense-grade mixture is that it does not have high resistance against rutting [].

Open-graded mixture is intended to let in water through its permeability, which makes it considerably different from other kinds of mixture, such as dense-graded or SMA, which are both relatively impermeable by comparison. Crushed gravel or stone with a very small percentage of sand, modified bitumen, and possibly fibres can sometimes be incorporated into the surface mixture of open-graded mixtures. One of the typical disadvantages of this category is its insignificant structural strength, unlike dense-graded mixture or SMA. SMA is a gap-graded mixture, which maximises the durability and rutting resistance by the application of a stone skeleton bound together with a mixture comprising a binder, stabiliser, and mineral filler. SMA is considered to be a premium mixture despite its higher initial cost due to enhanced binder content and application of durable aggregate. Nevertheless, the improved performance makes it suitable for high traffic loadings [].

3. Stone Mastic Asphalt

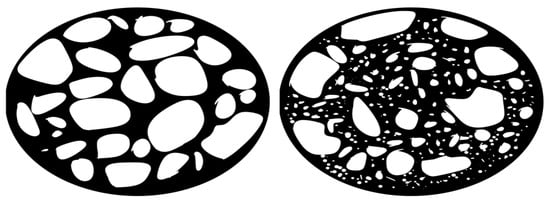

Stone mastic asphalt (SMA) is a mixture of a skeleton of coarse aggregate and a bitumen-binder-rich mortar with 6–8% bitumen. SMA consists of crushed coarse mixture, crushed fine aggregate, asphalt binder, mineral filler, and a stabiliser, such as cellulose, mineral fibres, or a polymer for the binder []. Figure 1 displays a typical SMA mixture and traditional dense-graded mixture. The image on the left shows a higher percentage of bitumen and fractured aggregate, in comparison with the conventional hot mix asphalt shown in the right-hand image. As Figure 1 illustrates, conventional dense-graded mixture contains less bitumen content with a more uniform gradation of the aggregate particles.

Figure 1.

Typical SMA mixture (left) and dense-graded mixture (right).

According to the case studies on using SMA in pavement construction, the application of SMA in road surfacing shows a significant role in enhancing the mixture’s durability, improving rutting resistance and fatigue life. The rutting resistance of SMA is more than that of dense-graded mixtures because of “skeleton coarse aggregate”—this feature offers the contact of stone to stone between the coarse aggregate particles []. The major reason for utilising fully crushed aggregate gap gradation (100%) is the enhancement of the degree of pavement stableness through the interlocking resulting stone-to-stone contact []. This interlock provides the mix with a stronger stone-on-stone skeleton, which is stuck more stably simultaneously as a result of a strong composition of bitumen binder, filler, and other additives in the mixture to enhance its stability [].

SMA is characterised by a mixture of gap-graded aggregate, which minimises the fine and medium-sized aggregate, resulting in a stable and structurally tough mixture. The strength and stability of the SMA is because of the stone portion of the coarse aggregate skeleton, which consequently increases internal friction rate and the resistance of the mixture to shear, thereby enabling it to resist rutting and wearing out caused by repetitive studded tyre contact. However, some weakness is distinguishable in the SMA structure, such as drain down, which ensues from the absence of mid-sized aggregate in the gap-graded mixture, which has a high asphalt binder content instead. Since the SMA is assembled in the silos and then transported by trucks to the construction site, after it is placed, the asphalt binder tends to drain down, which is called mixture drain down. Mix drain down is usually avoided by adding cellulose fibres, mineral fibres, or other modifiers to hold the binder in place, thereby providing the mix with durability [,].

SMA was developed and used in Germany in the mid-1960s to surface pavements to enhance their resistance against rutting, as well as enhance the durability (Ibrahim et al., 2006 []). It was then introduced to the rest of Europe because of its better resistance to damage from studded tyres than other types of HMA []. The abbreviation of SMA is obtained from the German term for slip stone mastic asphalt [].

Because of the indispensable and significant achievements brought about by the utilisation of SMA in Europe, together with the collaboration of the Federal Highway Administration, it found its way to the US in 1991 and has since been used in the construction of road surfacing in some selected states across the country [,]. Nowadays, over 28 states across the US utilise SMA in the construction of asphalt roads. According to reliable sources, the application of SMA has led to a considerable enhancement in pavement durability of up to 20–30 per cent in comparison to the conventional mixes used for such construction before []. These significant results have contributed to the increase in SMA application to various road constructions in the US. Following the US, Japan was the next country to use SMA for road pavement mixtures, which has also been backed by the strong success and achievements in that country.

Successively, Canada and the UK began to employ SMA in the construction industry of road pavements across their states with significant success, using SMA to surface the roads that are prone to heavy traffic to render surface treatment economical and cost-effective. Today, SMA is considered as the top choice in pavement surfacing and resurfacing, where high performance and long durability is an essential requirement in pavement construction throughout the globe. SMA application has recently extended its domain to most of the developing countries, especially in Asia and Latin America.

From the above literature it can be concluded that, currently, SMA is one of the most common mixtures used for road pavement surfacing. SMA is a kind of HMA, which consists of higher binder content with a coarse aggregate skeleton. Briefly, SMA is used to provide a pavement with high resistance to skidding, to restrict the water splash and spray to maintain good visibility on wet days, to provide an even riding surface, and absorb and reduce noise produced by tyres, especially near domestic and urban areas [].

3.1. Advantages and Disadvantages of SMA

In addition, there are several benefits and advantages of application of SMA, mainly including SMA provides a pavement with a durable, textured, and rut-resistant surface; similarly, SMA surface texture features are closer to those of OGA, which reduces the noise to a minimum, even down to a level lower than DGA but slightly higher than or equal to OGA. It is possible to produce, compact, and process SMA using the same equipment and plant used to produce normal HMA (DGA); SMA is especially applicable to intersections and other parts where traffic stress is high and OGA is not suitable; due to the flexible mastic used in SMA, it can reduce reflective cracking brought by underlying cracked pavements; and the SMA durability should be greater than or at least equal to the durability of DGA, but it needs to be significantly greater than that of OGA [,].

Moreover, SMA can also increase skid resistance because of the considerable percentage of fractured aggregates used in it, especially in wet environments. Even though SMA does not let water drain through it, the texture of its surface is like that of open-graded aggregate that absorbs the noise produced by the contact of the tyre with the asphalt surface. Surfaces with coarser texture can absorb not only tyre noise, but also glare and water spray on the pavement. SMA was initially used in asphalt mixes to enhance their level of resistance against studded tyre wear. Another advantage of SMA is that it can increase the resistance of the mixture against plastic deformation, which is one of the common problems that result from heavy traffic loading, which exerts severe stress on the pavement. Moreover, its rough surface provides adequate friction, especially when the asphalt loses its surfacing cement film, which wears out through heavy and frequent vehicle traffic. However, other advantages of SMA make it the most preferred mixture for pavement construction projects around the globe in comparison with other conventional HMA types. Some of these properties are showing improved durability, high resistance to reflective cracking, and improvement against aging [,].

However, some drawbacks and disadvantages that may be relevant to the application of SMA can be summarised as follows: more expensive material due to application of higher filler content and binder; and longer time needed for mixing to inject the extra filler, which may result in lower productivity level. Thus, more time is needed to cool the spread SMA on the roads down to 40 degrees C, which may result in completing road construction or repair to prevent flushing problems. Until removal of the thick binder film off the pavement surface due to traffic, the initial skid resistance is expected to be lower than satisfying level. In urgent cases, tiny grit is needed to be splashed over the surface before launching the road [,].

SMA surfacing generally requires more care and attention; the initial SMA resistance against skid may be low. This is another disadvantage of SMA, which also needs further care during mixing, producing, transporting, and placement on the road. Nevertheless, after achievement of the required capabilities and expertise, SMA is not harder than other mixtures used for pavement surfacing. When polymers are employed, in hot areas or seasons, the distance of the material transportation may be limited [,].

In summary, as the literature reveals, there are many fundamental advantages, such as high durability, improved resistance against fatigue and reflective cracking, and excessive rut resistance, less noise pollution of traffic, and high skid resistance [,]. SMA mixtures also suffer from some disadvantages, including delays in opening (the roads) to traffic, drainage of the binder, and higher initial costs []. Due to the gap-graded structure of SMA mixtures and the high amount of bitumen binder, stabilisation is required to control bitumen drain down [,]. In order to achieve this feature, polymer modifiers or fibres should be added to the SMA mixtures to make the desired modification, reinforcement, and stabilisation in the mixture.

3.2. Characteristics of Materials Used in SMA Mixtures

In this section, the characteristics of aggregate, bitumen, filler, and additive in SMA mixtures will be reviewed. The quality of aggregates employed in SMA needs to be high with a highly rough texture and cubic shape to be able to resist any displacement or rutting. The hardness of the aggregate content helps the pavement to resist breaking under heavy loadings of frequent tyre traffic. The aggregate should also have high resistance to polishing and abrasion [].

The grade of bitumen content employed in SMA usually equals the same grade or slightly stiffer grade than that used in dense-grade mixtures. When bitumen is stiffer, it minimises any potential drain down and helps to reduce rutting, which is usually expected in higher temperatures. Nevertheless, stiffer bitumen might result in thermal cracking. Using high optimum bitumen content and increased film thickness in the SMA, minimises the possibility of thermal cracking, especially in comparison with dense-graded mixture []. The utilisation of binders modified by polymer(s) along with fibre would enhance the resistance of the pavement against problems, such as rutting or fatigue cracking. The modified bitumen can be achieved through incorporating a quantity of stabilising (such as polymers) to conventional bitumen.

The function of filler in the SMA is essentially to stiffen the bitumen-rich SMA. The application of higher amounts of too fine a filler can lead to excessive stiffness of the mixture, rendering it difficult to work, which might result in the mixture being susceptible to cracking. A mineral filler is usually added into the mixture as part of the gradation of the aggregate. The content of the filler (passing the 75 um sieve) in the SMA mixture can range from 8 to 10% of the total amount of aggregate. This high content of mineral filler in the mixture plays a significant role in the properties of SMA, especially relating to the air voids (VIM), optimum bitumen content (OBC), and mineral aggregate voids (VMA). Due to the relatively large amount of the filler, the performance of SMA becomes very different from the other types of HMAs [].

During the last decade, a range of additives have been introduced and developed to help improve the physical properties of the bituminous mixtures. Some additives, e.g., rubbers, fibres, artificial silica, polymers, carbon black, or a combination thereof, have been utilised in the mixtures. The role of these materials is to increase the stiffness and durability of the mastic during production and placement in hot conditions, especially in hot or tropical climates [].

When polymer is used, it is normally mixed with bitumen before being delivered to the plant; however, in some cases, it has been added at the plant. Adding polymer can further stiffen the bitumen and enhance its resistance to drain down. Furthermore, polymer can enhance the adhesion property of the bitumen to the aggregate, especially in wet conditions. The polymers are added to the mixture usually in the range of 3.0–8.0% by weight of the bitumen [].

3.3. SMA Mixtures Design Methods

The methods used for SMA designing, production, and placement are comparable to those applied to the design and production of dense-graded mixtures, normally carried out by Superpave or Marshall procedures. SMA primarily uses gap-graded aggregate, while the standard mixture utilises an aggregate gradation that is smoother and evenly distributed throughout the gradation, resulting in the production of a denser mixture [].

The design of an SMA plays a key role in the provision of an aggregate grading that will accept a high amount of bitumen, which provides a durable mixture, without binder drainage. However, an unsuitable or incorrect SMA design can develop drainage in the truck bodies and fatted areas of the surfacing, particularly in thick surfacing areas. Conversely, the design of an aggregate that requires a low binder content in order to prevent binder drainage may result in a mixture with weak and short durability and having a reduced life.

Unlike an open-graded asphalt mixture, most of the voids among coarse aggregates within an SMA are usually filled with binder and mineral filler. Normally, 3–5% air void content is provided in the designed SMA. Excessive bitumen will push the coarse aggregate particles apart with a sudden reduction in the resistance of the pavement against shear deformation. The application of too little matrix may, however, lead to higher air voids in the mixture, resulting in a reduction in the durability of the pavement, its fast aging, and susceptibility to damage caused by moisture [].

3.4. Marshall Method

The Marshall method is the most conventional and common method employed for making and evaluating trial mixtures in obtaining the optimum bitumen content. This method was initially introduced by a civil engineer collaborating with the Mississippi State Highway Department; his name was Bruce Marshall []. However, the initial features of this method have been improved through time by the American army corps of engineers, and standardised and elaborated in ASTM D1559. Usually, the Marshall method is used in the design of SMA to provide verification of the acceptable number of voids in SMA mixes. Specimens were prepared in the lab using 50 or 75 blows per side produced by a Marshall hammer. It is easier to achieve the compaction of the SMA on the road and the desired density level in comparison to that required by conventional HMA []. The procedures for heating, mixing, and compacting the mixture of aggregates and bitumen are specified by the Marshall method, which is then subjected to a test of stability–flow test and an analysis of density–voids.

A bitumen specification based on climate and traffic loadings, a volumetric mixture design and analysis system, mixture analysis tests, as well as a system of performance prediction including specific software, climatic database, and models of the environment and performance are the three main elements used in the Superpave. Nevertheless, the most important component of Marshall may be its new bitumen grading system, which is designed to link with pavement performance []. Therefore, Marshall can be considered as a system based on performance. It is a system of specifications applicable to asphalt pavement design that is strong enough to successfully tolerate traffic loadings and climactic stresses.

The volumetric properties include the percentage of air voids (VIM), voids in the mineral aggregate (VNA), and voids filled with bitumen (VFB). These properties enable highway engineers to fine-tune the asphalt mixtures to various climates and traffic loads. Therefore, pavements produced this way have proven to be of higher durability and less likely to rut in hot weather or to crack in cold weather.

4. Road Pavement and Modification

Road pavements start experiencing functional deterioration once they are open to heavy traffic or freezing of groundwater during the cold season. Deterioration can include fatigue stripping and rutting. In cold regions, groundwater freezing beneath the surface layer can result in serious cracks in the asphalt mixture even during a single cool season []. One way to increase the service life of road surfaces is using certain additives, such as polymers, to modify and improve the properties of the asphalt mixtures.

As mentioned before in the previous sections, several types of additives have been introduced and developed to help improve the physical properties of the bituminous mixtures. Some additives, e.g., rubbers, fibres, artificial silica, polymers, carbon black, or a combination thereof, have been utilised in the mixtures. The role of these materials is to increase the stiffness and durability of the mastic during production and placement in hot conditions, especially in hot or tropical climates [].

Polymer-modified asphalt mixture is a combination with a wide variety of different uses in civil engineering and construction projects []. Adding polymers to the mixtures expands the bitumen’s stiffness and significantly enhances its susceptibility against temperature fluctuations. This, in turn, enhances the mixture resistance to rutting, which is one of the commonest problems dealt with in pavement project agents and engineers in hot or tropical regions. In these cases, adding polymers to the mixture allows for the application of softer bitumen, which would offer outstanding low temperature performance. The accumulation of polymers to binders results in a significant increase in its cohesiveness and adhesiveness to effectively and strongly bind the mixture of components together. However, polymer plays another important role in the generation of an aggregate coating substance to improve the roughness of the aggregate surfaces and creates an improved asphalt mixture [].

5. Polymer-Modified Asphalt

Different types of modifiers have been used in asphalt modification. These include polymers, which can be categorised as elastomeric and plastomeric, fibres, hydrocarbons, antistripping agents, and waste tyre rubber. Asphalt additives contribute to improvement in stiffness and elasticity []. Modified bituminous mixtures have higher stiffness and resistance against permanent and serious deformations and fatigue cracking [,]. The modifier type and polymer content have the main role of improving the asphalt rheology and, thus, in turn, improve the elastic recovery and reduce the rutting deformation [,,]. A research study [] indicated better binder–aggregate adhesion in asphalt modified mixtures, thus increasing its toughness level. Moreover, addition of polymer significantly improves the fatigue resistance and recovery properties [,,,]. This will result in better resistance to permeant deformation and increase the service life of road pavement []. One of the main advantages of applying polymer technology to bituminous mixtures is to improve the adhesion between the aggregates and binders. A study conducted by Khattak and Baladi [] on the influence of polymer as a modifier revealed that the modification can increase the resistance of bitumen to loading, while making it less susceptible to temperature fluctuations.

Furthermore, some polymers increase the bitumen adhesion to the stones and its resistance to cracking. An ideal binder needs to have optimal cohesion and adhesion properties. The engineering properties of polymer-modified asphalt can be determined by the type of the applied modifier with respect to its content and depend on the type of bitumen employed. However, the main advantage of elastomers, such as styrene butadiene rubber (SBR) and styrene butadiene styrene (SBS), is their capability to increase the strength of the modified bitumen mixtures []. Numerous studies confirm that the application of crumb-rubber-modified binders to pavement mixtures can improve its resistance against fatigue cracking. According to Bahia and Davies [], the impact of crumb rubber on engineering properties of bituminous mixtures is significant in a way that rubberised mixtures display higher resistance to rutting in comparison to the unmodified bituminous mixtures. Two kinds of blending process for bituminous mixtures are the wet and dry processes. In the wet process, the modifier is mixed with the bitumen prior to adding the aggregate, while, in the dry process, the modifier is first added to the aggregate and before the addition of the bitumen [,,].

According to Brule [], normal bitumen may not display tremendous engineering properties under “heavy loads and high or low temperature conditions”. It becomes softer in high temperature and more brittle in cold regions. In order to solve this problem, polymer is usually added to bitumen to improve its engineering effect on the pavement performance, which enhances its resistance against fatigue cracking, permanent deformation, and moisture susceptibility. The stiffer the bituminous mixture, the more resistant it is to permanent deformation. Studies mentioned that polymer added to the mixture increases its elasticity and stiffness in hot climate temperatures [,].

Polymer can be described as a synthetic or natural compound of normally high molecular strength made up of repeated, linked molecules []. The polymers employed for modification purposes in bituminous mixtures are divided into three main categories: plastomers, thermoplastic elastomers, and reactive polymers. The addition of thermoplastic elastomers into binders gives them higher elasticity. However, the application of plastomers and reactive polymers make the binder stronger and more rigid against heavy traffic loadings that usually bring about serious deformation in the surfacing of the pavement []. Furthermore, plastomers increase the stiffness and viscosity of the bitumen in moderate temperatures. Nevertheless, the achieved performance through these modifiers concerning the enhancement of bitumen elasticity in sudden and frequent temperature fluctuations is not considered as satisfactory as expected []. However, some plastomeric polymers commonly employed for modification purposes are ethylene-butyl acrylate (EBA) and polyethylene (PE) [].

Today, asphalt modified by polymer is quite costly in road pavements [,]. Therefore, it is important to analyse cost-effective methods to make the construction projects more economical and feasible before discussing its commercial use. For instance, block styrene-butadiene elastomer—also known as block SBS/SB rubber—is commonly employed by many countries to modify the engineering properties of the asphalt mixture. Nevertheless, even though it has excellent properties, the polymer-modified mixture has one main disadvantage, that is, the high price of the block styrene-butadiene elastomer, which restricts its wide application to most construction and pavement projects, especially in developing countries. One solution for this problem is the application of cheap polymers obtained from waste and disposed materials [].

The first patent for bitumen modification processes with synthetic or natural polymers dates back to 1843, while the initial test projects in this field were launched in Europe as early as the 1930s and employment of neoprene latex was first enacted in North America in the 1950s []. However, 20 years later (1970s), Europe had already overtaken the US in the application of polymer-modified bituminous mixture for road pavement, since, in Europe, the warranties provided by contractors encouraged unprecedented interest in the reduced costs of the life cycle despite the higher costs in the initial phases of the projects. These initial costs restricted the use of polymer-modified bitumen in the United States. However, the mid-1980s witnessed the introduction and use of new types of polymers in Europe and then the US, where a poor economic outlook increasingly prevailed throughout the whole country. The Australian National Asphalt Specification has provided specifications and guides for polymer-modified binders [].

An approach to life cycle cost analysis has been developed by the US Federal Highway Administration (FHWA) to assess and measure the life cycle costs applicable to pavement construction that use asphalt-modified binders and other additive treatments. The results of relevant studies reveal the cost-effective feature of asphalt rubber. A survey by the US States Department of Transportation carried out in 1997 discovered that 47 of the 50 states in the country were interested in the application of modified binders in their future projects, while 35 of the respondents said that they would employ the binders even in greater amounts in future construction projects []. Many studies have been conducted on the evaluation of the performance of polymer-modified pavement mixtures around the world. Furthermore, experiments on binders have been undertaken in various labs in different regions, the results of which are steadily being revealed. Based on a study known as Nevada, in 2003, the viscosity of binders modified by polymer at 60 °C is usually greater in comparison to the viscosity of unmodified binders despite the slight modifications of the penetration rate at all temperatures.

6. General Studies on Using Additives in Road Construction

In pavement construction, conventional asphalt mixtures are susceptible to extreme temperature variations and climatic conditions, which usually lead to problems, such as cracking, that may result in fractures []. Moreover, at higher temperatures during the hot seasons in tropical and hot regions, bitumen mixture suffers from creep or flow. A stable pavement surface should not creep or flow under heavy traffic loadings. With this in mind, many researchers are involved in studies investigating the way they can modify bituminous mixtures by adding various additives to enhance its performance against the aforementioned problems [].

Modification of the bituminous mix with polymers seems to have great potential for the efficient use in flexible pavement design to enhance their active service or minimise the layer thickness of their wearing course or base layer. Modifying and advancing the properties of bitumen and asphalt mix by using certain additives, such as polymers, is one way of boosting the service life of road surfaces [,,]. Several studies performed to categorise bitumen modifiers according to their composition have been categorised into several groups. These include elastomeric polymers, plastomeric polymers, fibre, and crumb rubber, as illustrated in Table 1.

Table 1.

Illustration of the various types of polymers and additives used in asphalt modification.

During a shared study [] conducted an investigation concerning the impact of polyester fibres on fatigue and the rheological properties of bitumen and bituminous mixtures. Their studies reveal that the binder viscosity increases with the addition of more polyester fibre contents into the mixture, particularly at lower temperatures. The results of their research confirm the possibility of an improvement of the mixture fatigue property through adding fibre, specifically where the stress level is low. Huang and White [] also carried out research on asphalt overlays modified with polypropylene fibre. The modified and normal asphalt mixture samples of cores were transferred to the laboratory to be investigated and analysed under controlled conditions. It was revealed that the modified asphalt mixtures were stiffer and displayed improvements in durability and fatigue resistance. However, the main problem with polypropylene fibre was that, due to its low melting point, the fibre was inherently incompatible with hot bitumen. According to Huang and White, further studies were required to rightly perceive the viscoelastic properties of the fibre-modified bituminous mixtures.

In this regard, [] employed starch (ST) and styrene butadiene styrene (SBS) to add to SMA mixes. Then, physiochemical tests were carried out on modified and unmodified bitumen mixtures, including performance tests, such as Marshall stability, tensile strength, tensile strength ratio, and resilient modulus. The test results reveal that damage caused by moisture and susceptibility of the mixture against temperature fluctuations and variations can be reduced through the addition of ST and SBS into the bituminous mix. According to the same results, ST can also play the role of an antistripping agent in the mixture, reduce the plant emissions, save energy by about 30%, and increase its resistance to chemicals and solvents. As per the multi-layer elastic analysis results, pavement mixtures modified by ST and SBS consume less construction materials for the pavement.

Casey et al. [] studied the possibility of using waste polymer to modify asphalt. Tests were conducted to evaluate the impact of the waste polymer on the properties of the bitumen. The results showed that 4% of recycled HDPE is an ideal content and could result in improving the physical-rheological properties of the modified binder. Further research was conducted by Bradley Putman et al., in which they analysed the possibility of applying waste carpet and tyre fibres in the SMA mixture. The added fibres play the role of stabiliser in the SMA to prevent drain down, which is a result of high asphalt binder contents. In this study, the researchers compared the performance of SMA mixtures modified by tyre fibres and carpet with mixtures made with normally used cellulose fibre and other polyester fibres produced specifically for use in HMA. Concerning the permanent deformation and susceptibility to moisture, there was no significant difference between the two fibres in their results. However, carpet and tyre fibres significantly contributed to an improvement in the mixture toughness in contrast to the cellulose ones [].

7. Waste Materials

7.1. Waste Materials and Environment

The construction of hundreds of kilometres of roads around the world every year results in the consumption of tonnes of raw materials and the impoverishment of natural resources in different parts of the globe. In addition, as an outcome of a consuming society, developed countries are currently facing a major problem from the huge waste materials produced daily by their citizens. The disposal of these waste materials has turned into one of the critical issues of municipalities in modern cities. However, disposed waste material is not only limited to civil life, as it also comes from some other sources, such as commercial, industrial, and the like. The worst part is that a major portion of the produced waste materials are left over intact for a long time, which, therefore, results in extended pollution for the environment. This issue is forcing the authorities to find solutions, such as dumping the waste in landfills around cities [].

However, the currently available middens are running out of their capacity, while the establishment of new sites for this purpose have encountered a regulation stalemate, which restricts the conventional way of waste disposal through its burial around living areas. This doubles the problem of waste disposal and finding new solutions and middens adds to the disposal costs that are imposed on the municipal authorities and, ultimately, the taxpayers []. Solid and synthetic waste material consume natural resources for their production, as well as cause serious environmental pollution of the water, land, and air. It is noteworthy to mention that pollution in any form is a kind of waste itself. Therefore, waste middens and landfill can contribute to serious environmental problems, both in the long term and short term. Some of the risks and negative effects of waste dumping in middens and landfills around the domestic area can be summarised as follows:

- i.

- Fire or explosion, which is a threat to the living areas adjacent to middens and landfills, especially with organic (biodegradable) waste materials, since they can easily generate a highly flammable combination of various gases, such as methane, which is known as landfill gas.

- ii.

- Contamination of the ground and surface water neighbouring the landfills and middens as a result of decomposition of waste materials in the landfills, which leads to landfill leachates that are highly risky and dangerous for hygienic purposes.

- iii.

- Pollution of the local amenities available in those areas.

- iv.

- Other environmental pollution brought about by odour, dust, noise, aesthetics, and the like, which result from dumping and landfilling operations [].

However, the impact of landfill on the environment is not at all negative. If landfill is rationally and logically engineered and controlled, it can yield some benefits as well, such as the retrieval of derelict land in the necessary area. However, a serious problem for such projects is finding suitable sites and transportation costs, which finally lead to the high expense of landfills and disposal operations. New municipal regulations exacerbate the previous problems, making waste disposal even more difficult. Some of these recent regulations:

(a) Require high standards of landfill control and management, seeking simultaneously to discourage landfill of certain problematic waste materials.

(b) Attempt to progressively reduce landfilling operations of biodegradable materials, which form the major portion of the waste materials delivered to the disposal sites.

Since Landfill Tax is imposed on all types of waste materials delivered to middens and landfills, the total amount of waste materials heading to these sites has been significantly reduced, resulting in the reduction and recycling of reusable products. There is also evidence that industrial waste is being distributed on agricultural land as fertiliser, which is a good omen for the future of consumer societies.

7.2. Recycling of Waste Materials

Recycling waste materials produced by industrial plants and workshops, especially relating to civil engineering, has seen significant developments in recent decades. Some of the successful examples of these developments include coal fly ash, silica fumes, and blast furnace slag. The reuse of risky waste has also been the subject of much research throughout years. Such research mainly focused on the impact of the residue on the properties of the construction materials, as well as on its effects on the environment. The most recent studies have concentrated on the possibilities of reusing solid waste materials in road construction, which has recently turned into a hot issue. Apparently, this has two main causes, namely, the lack or reduction in natural resources usable for road construction and the existence of solid waste materials that can be reused in many construction projects in civil engineering [].

7.3. Typical Kinds of Waste Materials

During recent decades, there have been a limited number of researchers focusing specifically on the incorporation of selected waste polymers have been among those employed and utilised for such purposes. Certainly, there are some other materials disposed of, which can be utilised in similar ways to be incorporated into HMA as modifiers in future construction projects. The availability of a sufficient quantity of the target material and continuity of its supply can be among the selection criteria [,]. The cost of incorporation of the selected waste material can also be another factor, which enlists it as a candidate for such purpose.

In general, there are different types of waste [] and these include:

- a.

- Solid waste materials: any kind of disposed of household or office furniture, kitchen utensils, harmless industrial waste materials, construction and renovation debris, municipality and agricultural trash, and discarded materials; many other nontoxic/non-hazardous solid waste materials are grouped into this category.

- b.

- Special waste materials: hazardous household or office waste, such as chemicals, paints, and paint thinners, rechargeable batteries used in different devices at home or office, lead-acid batteries used in vehicles, oil, worn-out tyres, etc.

- c.

- Hazardous waste materials: any liquid, solid, gaseous, or hybrid material disposed of by hospitals, clinics, and health centres. These materials, if left uncontrolled, can threaten the health of the residents of that area in which they are discarded.

Collection, transportation, and disposal of solid waste materials have turned into a serious concern around the world in recent years. In most countries, conventional technologies and systems can only remove 30–50 per cent of the produced solid waste materials and these wastes are disposed of in ways detrimental to the environment. Therefore, in order to solve or minimise this problem, the disposed materials can be exposed to recycling, reuse, and accelerated decomposition through economical and environmentally friendly practices [].

8. Waste Plastic

The growing quantity of plastic products, such as containers and bottles, consumed yearly all over the globe from the most developed to the least developed countries has turned the disposal of this material into a serious problem, especially in developing and developed societies. Plastic containers enjoy certain features that make them attractive and the preferred products of consumers. Plastic offers a strong material with low density that is ergonomic, durable, light, and cheap, which is usable in packaging and other industrial, medical, food services, and appliances, artificial implants, land/soil conservation, water desalination, flood prevention, housing, communication, and security applications. The annual consumption of plastic has globally jumped from about 5 million to 100 million tons within the second half of the last century. Hence, plastic has become one of the most important solid waste materials in recent decades [].

However, some plastic items that are used to preserve food are disposable, which have to be discarded after one-time use and only a short time after purchase. Reusable plastic items are preferred since they can help save the resources and money of the consumers [,]. Therefore, multi-trip plastic containers have gained more appeal among manufacturers and consumers. This, in turn, contributes to a reduction in plastic waste materials in the environment.

Along with these solutions, recycling the disposable plastic items, or those that need to be discarded after a lifetime, can yield several advantages [] as follows:

- a.

- Preservation of limited fossil resources, such as oil, of which at least 8% is consumed to produce plastic items in the world, 4% for petrochemical feedstock, and 4% during manufacture, respectively;

- b.

- Reduction in energy consumption;

- c.

- Reduction in disposed and discarded solid materials;

- d.

- Reduction in carbon dioxide (CO2), sulphur dioxide (SO2), and nitrogen oxide (NO) emissions.

Considering the points discussed above, recycling plastic waste materials contributes to a significant reduction in disposed plastic materials in the environment, as well as helping to preserve the natural fossil resources that form the main source of plastic production and manufacturing around the world. Plastic waste is increasing, and the investigation shows lack of the potential of secondary pollution. Thus, future research should be conducted to investigate this topic.

Application of Polyethylene Plastic in Asphalt

During the last decade, there were only a few studies on using a plastic polymer as additive and asphalt modifier, as illustrated in Table 2 and Table 3. The large and uncontrolled amount of PET plastic bottles produced in recent decades has contributed to the creation of serious environmental problems, mostly because of hygienic consideration, in that these plastics are not reusable for refilling. Hence, nearly all the produced bottles are disposed of as waste plastic materials whose decomposition and return to nature is outside of the lifetime of current generations [,,,,,,,]. Recycling these PET bottles can be an effective and immediate solution to this problem in industrial and consumer societies.

Table 2.

Types of plastic used in previous research studies.

Table 3.

Properties of asphalt mix using plastic obtained from previous studies.

The modification of bituminous mixes with waste plastics seems to have great potential for use in flexible pavements to enhance their active service life or minimise the layer thickness of their wearing course or base layer. The application of waste plastic in asphalt modification increases the stability and service life of the pavement, in addition to improving its ability to tolerate high traffic loads, reducing its susceptibility to deformation, and imparting better aging resistance. In addition, waste plastic asphalt can meet the requirement for design, coating, and construction, and seems to be a substantial, practical, and economical alternative to other commercial polymers [,,,,,,,].

In this study, a kind of polyethylene was used as an additive in SMA. The studies specifically concentrating on the modification of asphalt mixtures through the application of polyethylene are inadequate []. The studies covering polyethylene-reinforced asphalt mixture and binders form only a small portion of the current publications and there is still a necessity for further studies focusing specifically on this topic.

Joint research by Awwad and Shbeeb investigated the results of the employment of polyethylene polymers to improve the engineering properties of asphalt mixtures. Their study was conducted to determine the best and the most proper polyethylene type and proportion to be used in the asphalt mixture to obtain the optimal result. Hence, they applied two types of polyethylene to the aggregate coating, namely, low-density polyethylene (LDPE) and high-density polyethylene (HDPE), respectively. The addition of the polymers to the mixture was carried out in two forms, ground and unground. The produced mixture samples displayed that the ground HDPE imparts better engineering properties to the resulting mixture. The most appropriate percentage of the modifier suggested by researchers to be added to the mixture is 12% by the bitumen weight. The results of this experiment further confirm that the introduced HDPE can contribute to the enhancement of mixture stability, slight increase of air voids (VIM), and voids of the mineral aggregate (VMA) in it, as well as the reduction of the asphalt mixture density [].

Another study concentrating on the potential of LDPE prospects was jointly conducted by Al-Hadidy and Tan Yi-qiu to study the engineering properties of this polymer as a modifier that can be applied to asphalt mix modifications and improvements. The obtained outcomes confirm that the softening point of the binders modified by LDPE are comparatively higher, while its ductility values were fixed at the minimum specifications range (100+ cm), which, in turn, resulted in a decrease in loss weight percentage due to heat and air, which means a significant improvement in the overall durability of the original SMA. Furthermore, the results reveal that LDPE-modified SMA mixture can provide the optimal mixture for pavement construction and coating in regions with extreme temperature fluctuations and excessive moisture [].

Sinan Hinishoglu and Emine Agar used other kinds of waste plastic materials with HDPE to modify binders with various blending temperatures, time lengths, and HDPE percentage. For this experiment, they used Marshall stability, Marshall quotient, and Marshall flow. They concluded that 4% of HDPE at 165 °C mixing temperature blended continuously for 30 min is the best condition for Marshall stability, Marshall flow, and Marshall quotient (MQ). As a result, a new condition applied to this experiment, the percentage of the Marshall quotient, was raised by 50% in comparison to the control mixture. Furthermore, the researchers noted that resistance of the HDPE-modified bituminous mix against serious deteriorations and deformation was significantly increased [].

A study by Zoorob and Suparma revealed that using LDPE waste plastic in bituminous mixtures could result in a significant enhancement of its stability, i.e., approximately 2.5 times greater than the stability of the control mixtures, and durability, while decreasingly its density. In addition, the outcomes of the study showed that the plastiphalt fatigue life of the modified mixtures was longer than the control ones []. Furthermore, the adding of polyethylene into the porous asphalt mixture can also result in significant improvements in its oil-resistance properties.

There have also been other studies on the topic, among which some tried to investigate the effects of polyethylene on engineering and rheological properties of bituminous mixtures [,,,]. Based on the results of these experiments, adding the polymer significantly increased the rutting resistance of the asphalt-modified mixture. Moreover, using polyethylene as a polymer to asphalt mixture, the results confirmed that addition of the polymer results in improving the fatigue resistance, workability, and efficiency of the modified mixture [,].

According to investigation reports [,,,], using waste plastic in asphalt modification would essentially help reduce environment contamination and balance the economic system by sparing additional cost. Therefore, using waste plastic in asphalt enhances the temperature susceptibility and stiffness. Thus, waste-plastic-modified bitumen results in an enhancement in rutting and fatigue resistance [,,]. Modifying and advancing the properties of bitumen and asphalt mix by using certain additives, such as plastic polymers, is one way of boosting the service life of road surfaces.

A study by Mashaan et al. [] has investigated the impact of waste PET plastic on the engineering and performance properties of 14 mm dense-graded asphalt, which is widely used in course surfacing in Western Australia. The study emphasises that the 6% and 8% waste PET are the idealistic contents projected to modify and improve the strength, stiffness, durability, elasticity properties, and rutting resistance of asphalt mixtures. In addition, the rutting and fatigue properties of SMA mixture using waste high-density polyethylene (HDPE) have been enhanced as reported []. The study outcome shows that SMA mixtures modified with 4% HDPE have the best fatigue resistance at a fatigue life of 157,090 cycles; however, the 8% HDPE has the better rutting resistance at a rut depth of 1.05 mm.

9. Conclusions

The paper reviews and assesses the influence of using waste polymer in improving the rheological, stiffness, performance properties, and engineering properties of the modified binder and mixtures. Remarkable findings are listed as below:

- The advance of utilising waste plastic as an ecological environmentally friendly modifier in asphalt was performed and examined. The results show the possibility to use waste plastic in modifying bitumen.

- The large and uncontrolled amount of PET bottles produced in recent decades has contributed to the creation of serious environmental problems, mostly because of the hygienic consideration, in that they are not reusable for refilling. Considering the points discussed above, recycling plastic waste materials contributes to a significant reduction in disposed plastic materials in the environment, as well as helping to preserve the natural fossil resources.

- The report emphasises that the 6% and 8% waste PET are the idealistic contents projected to modify and improve the strength, stiffness, durability, elasticity properties, and rutting resistance of asphalt mixtures. However, most of the previous studies show no description of the compositional differences in the PET used; as such, the ideal content could be below or above the 6–8% based on the materials and mixing process. Generally, polyethylene terephthalate (PET, also known as PETE, PETP, or PET-P) belongs to the polyester family and is made of a thermoplastic resin (Mashaan et al. 2021a). PET is one of the most essential raw materials used in making synthesised fibres. The structure of PET is formed of linear saturated thermoplastic polyesters, which have been in use since 1966 (Modarres and Hamedi 2014). The procedure for making these kinds of polymers consists of two phases: (a) esterification of dimethyl terephthalate with ethylene glycol; (b) polycondensation.

- In addition, the rutting and fatigue properties of SMA mixture using waste high-density polyethylene (HDPE) have been enhanced at 2–4%. Another report shows that SMA mixtures modified with 4% HDPE have the best fatigue resistance at a fatigue life of 157,090 cycles; however, the 8% HDPE has the better rutting resistance at a rut depth of 1.05 mm.

- Based on the above results, it can be concluded that PET, as a recycled polymer, can significantly improve the engineering properties of the asphalt mixture. In addition, higher contents, of 6% and 8%, could make the SMA mixtures more stable and durable.

- Results of aging display that nearly all waste plastic samples had longer fatigue life, lower aging index, and, as such, higher resistance to fatigue and cracking in comparison with nonmodified bitumen.

- Considering more research on using different sizes of waste plastic, different shapes of waste plastic, different bitumen types, different blending conditions of time, temperature, and shear velocity are recommended for future research. In addition, using high-advance technology to examine the chemical development and change in plastic–bitumen interaction phase is required for better understanding of the engineering properties.

Funding

The funding support by RTP 2018 Australian government.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The author would like to express deep thanks and acknowledge the funding support by RTP 2018 Australian government.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mahrez, A. Properties and Performance of Stone Mastic Asphalt Reinforced with Glass Fibre. Ph.D. Thesis, Faculty of Engineering, University of Malaya, Kuala Lumpur, Malaysia, 2008. [Google Scholar]

- Troutbeck, R.; Kennedy, C. Review of the Use of Stone Mastic Asphalt (SMA) Surfacing by the Queensland Department of Main Roads; Queensland University of Technology: Brisbane, Australia, 2005. [Google Scholar]

- Hamed, F.K.M. Evaluation of Fatigue Resistance for Modified Asphalt Concrete Mixture Based on Dissipate Energy Concept. Ph.D. Thesis, Technische University Darmstadt, Darmstadt, Germany, 2010. [Google Scholar]

- Ali, A.H.; Mashaan, N.S.; Karim, M.R. Investigations of Physical and Rheological Properties of Aged Rubberised Bitumen. Adv. Mater. Sci. Eng. 2013, 2013. [Google Scholar] [CrossRef]

- Chiu, C.T.; Lu, L.C. A laboratory study on stone matrix asphalt using ground tire rubber. Constr. Build. Mater. 2007, 21, 1027–1033. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Karim, M.R.; Abdelaziz, M. A Review on Fatigue and Rutting Performance of Asphalt Mixes. Sci. Res. Essays 2011, 6, 670–682. [Google Scholar]

- Ibrahim, M.R.; Katman, H.Y.; Karim, M.R.; Mahrez, A. Properties of rubberised bitumen mixes prepared with wet and dry mixing process. In Proceedings of the 8th International Conference of Eastern Asia Society for Transportation Studies, Surabaya, Indonesia, 1 January 2009. [Google Scholar]

- Asi, I.M. Laboratory comparison study for the use of stone mastic asphalt in hot weather climates. Constr. Build. Mater. 2006, 20, 982–989. [Google Scholar] [CrossRef]

- Abdullah, S. A Laboratory Investigation of Modified Binders in Bituminous Mixes. MSc. Dissertation, University of Malaya, Kuala Lumpur, Malaysia, 1996. [Google Scholar]

- Becker, Y.; Mendez, M.P.; Rodriguez, Y. Polymer modified asphalt. Vis. Tecnol. 2001, 9, 39–50. [Google Scholar]

- AI-Hadidy, A.I.; Tan, Y.-q. Mechanistic analysis of ST and SBS-modified flexible pavements. Constr. Build. Mater. 2009, 23, 2941–2950. [Google Scholar] [CrossRef]

- Ali, A.H. Influence of Crumb Rubber Modifier on Performance Characteristics of Stone Mastic Asphalt Mixture. MSc. Dissertation, University of Malaya, Kuala Lumpur, Malaysia, 2013. [Google Scholar]

- Awwad, M.T.; Shbeeb, L. The Use of Polyethylene in Hot Asphalt Mixtures. Am. J. Appl. Sci. 2007, 4, 390–396. [Google Scholar] [CrossRef]

- Xue, Y.; Hou, H.; Zhu, S.; Zha, J. Utilization of municipal solid waste incineration ash in stone mastic asphalt mixture: Pavement performance and environmental impact. Constr. Build. Mater. 2009, 23, 989–996. [Google Scholar] [CrossRef]

- Yildirim, Y. Polymer Modified Asphalt Binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Modarres, A.; Hamedi, H. Effect of waste plastic bottles on the stiffens and fatigue properties of modified asphalt mixes. Mater. Des. 2014, 61, 8–15. [Google Scholar] [CrossRef]

- Aflaki, S.; Memarzadeh, M. Using two-way ANOVA and hypothesis test in evaluating crumb rubber modification (CRM) agitation effects on rheological properties of bitumen. Constr. Build. Mater. 2011, 25, 2094–2106. [Google Scholar] [CrossRef]

- Casey, D.; McNally, C.; Gibney, A.; Gilchrist, M.D. Development of a recycled polymer modified binder for use in stone mastic asphalt. Resour. Conserv. Recycl. 2008, 52, 1167–1174. [Google Scholar] [CrossRef]

- Perez- Lepe, A.; Martinez- Boza, F.J.; Gallegos, C.; Gonzalez, O.; Munoz, M.E.; Santamaria, A. Influence of the processing condition on the rheological behaviour of polymer-m modified bitumen. Fuel 2003, 82, 1339–1348. [Google Scholar] [CrossRef]

- Larsen, H.J.E.; Wohlk, C.J.; Hall, B.A. Modified bitumen. In Proceedings of the 14th ARRB Conference, Canberra, Australia, 28 August–2 September 1988. [Google Scholar]

- Isacsson, U.; Lu, X. Characterization of bitumens modified with SEBS, EVA and EBA polymers. J. Mater. Sci. 1999, 34, 3737–3745. [Google Scholar] [CrossRef]

- Bahia, H.U.; Anderson, D.A. Strategic highway research program binder rheological parameters: Background and comparison with conventional properties. Transp. Res. Rec. 1995, 1488, 32–39. [Google Scholar]

- Airey, G.D.; Singleton, T.M.; Collop, A.C. Properties of polymer modified bitumen after rubber- bitumen interaction. J. Mater. Civ. Eng. 2002, 14, 344–354. [Google Scholar] [CrossRef]

- Ozen, H.; Aksoy, A.; Tayfur, S.; Celik, F. Laboratory performance comparison of the elastomer-modified asphalt mixtures. Build Environ. 2008, 43, 1270–1277. [Google Scholar] [CrossRef]

- Khattak, M.J.; Baladi, G.Y. Fatigue and permanent deformation models for polymer-modified asphalt mixtures. Transp. Res. Rec. 2001, 1767, 135–145. [Google Scholar] [CrossRef]

- Hwang, E.H.; Ko, Y.S. Comparison of mechanical and physical properties of SBR-polymer modified mortars using recycled waste materials. J. Ind. Eng. Chem. 2008, 14, 644–650. [Google Scholar] [CrossRef]

- Bahia, H.U.; Davies, R. Effect of crumb rubber modifiers (CRM) on performance- related Properties of asphalt binders. J. Assoc. Asph. Paving Technol. 1994, 63, 414–449. [Google Scholar]

- Brule, B. Polymer-modified asphalt contents used in the road construction industry: Basic principles. Transp. Res. Rec. J. Transp. Res. Board 1996, 1535, 48–53. [Google Scholar] [CrossRef]

- Mostafa, A.E.A. Examining the Performance of Hot Mix Asphalt Using Nano- Materials. J. Eng. 2016, 6, 25–34. [Google Scholar]

- Tapkın, S.; Cevik, A.; Usar, U. Prediction of Marshall Test Results For Polypropylene Modified Dense Bituminous Mixtures Using Neural Networks. Expert Syst. Appl. 2010, 37, 4660–4670. [Google Scholar] [CrossRef]

- Ahmed, L.A. Improvement of marshall properties of the asphalt concrete mixture using the polyethylene as additive. Eng. Tecnol. 2007, 25, 383–394. [Google Scholar]

- Moreno, F.; Rubio, M.C.; Martinez-Echevarria, M.J. Analysis of digestion time and the crumb rubber percentage in dry-process crumb rubber modified hot bituminous mixes. Constr. Build. Mater. 2011, 25, 2323–2334. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Karim, M.R. Investigating the rheological properties of crumb rubber modified bitumen and its correlation with temperature susceptibility. Mater. Res. 2013, 16, 116–127. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Ali, A.; Karim, M.R.; Mahrez, A. A Review on Using Crumb Rubber in Reinforcement of Asphalt Pavement. Sci. World J. 2014, 2014, 214612. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S. The influence of crumb rubber modifier (CRM) microstructure on the high temperature properties of CRM binder. Int. J. Pavement Eng. 2005, 6, 265–271. [Google Scholar] [CrossRef]

- Al-Hadidy, A. Comparative performance of the SMAC made with the SBS and St- modified binders. J. Mater. Civ. Eng. 2018, 22, 580–587. [Google Scholar] [CrossRef]

- Widyatmoko, I.; Elliott, R. Characteristics of elastomeric and plastomeric binders in contact with natural asphalts. Constr. Build. Mater. 2008, 22, 239–249. [Google Scholar] [CrossRef]

- Wu, S.; Ye, Q.; Li, N. Investigation of rheological and fatigue properties of asphalt mixtures containing polyester fibers. Constr. Build. Mater. 2008, 22, 2111–2115. [Google Scholar] [CrossRef]

- Putman, B.J.; Amirkhanian, S.N. Utilization of waste fibers in stone matrix asphalt mixtures. Resour. Conserv. Recycl. 2003, 42, 265–274. [Google Scholar] [CrossRef]

- Huang, H.W.T. Dynamic properties of fiber-modified overlay mixture. Resour. Conserv. Recycl. 1996, 1545, 98–104. [Google Scholar] [CrossRef]

- Hınıslıoğlu, S.; Ağar, E. Use of waste high density polyethylene as bitumen modifier in asphalt concrete mix. Mater. Lett. 2004, 58, 267–271. [Google Scholar] [CrossRef]

- Ishaq, M.A.; Giustozzi, F. Correlation between Rheological Tests on Bitumen and Asphalt Low Temperature Cracking Tests. Constr. Build. Mater. 2022, 320, 126109. [Google Scholar] [CrossRef]

- Viscione, N.; Veropalumbo, R.; Oreto, C.; Biancardo, S.A.; Abbondati, F.; Russo, F. Additional procedures for characterizing the performance of recycled polymer modified asphalt mixtures. Measurement 2022, 187, 110238. [Google Scholar] [CrossRef]

- Costa, L.M.B.; Silva HM, R.D.; Peralta, J.; Oliveira, J.R.M. Using waste polymers as a reliable alternative for asphalt binder modification – Performance and morphological assessment. Constr. Build. Mater. 2019, 198, 237–244. [Google Scholar] [CrossRef]

- Kalantar, Z.N.; Mahrez, A.; Karim, M.R. Properties of Bituminous Binder Modified with Waste Polyethylene Terephthalate; Malaysian Universities Transportation Research Forum and Conferences (MUTRFC); University Tenaga Nasional: Kajang, Malaysia, 2010. [Google Scholar]

- Zakaria, N.M. Characterisation of Bitumen and Asphalt Mixture with Recycled Waste Plastic (RWP) Modified Binder. Ph.D. Dissertation, University of Nottingham, Nottingham, UK, 2020. [Google Scholar]

- Kassim, T.A.; Bernd, R.; Simoneit, T.; Williamson, K.J. Forensicinvestigation of Leachates from Recycled Solid Wastes: Anenvironmental Analysis Approach. In The Handbook of Environmentalchemistry; Springer: Berlin, Germany, 2005; Volume 5, pp. 321–400. [Google Scholar]

- Aubert, J.E.; Husson, B.; Sarramone, N. Utilization of municipal solid waste incineration (MSWI) fly ash in blended cement: Part 2: Mechanical strength of mortars and environmental impact. J. Hazard. Mater. 2007, 156, 12–19. [Google Scholar] [CrossRef]

- Ameri, M.; Kouchaki, S.; Roshani, H. Laboratory evaluation of the effect of nanoorganosilane anti-stripping additive on the moisture susceptibility of HMA mixtures under freeze–thaw cycles. Constr. Build. Mater. 2013, 48, 1009–1016. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Rezagholilou, A.; Nikraz, H. Waste Polymer as Additive in Asphalt pavement reinforcement: A review. In Proceedings of the 18th AAPA International Flexible Pavements Conference, Sydney, Australia, 18–21 August 2019. [Google Scholar]

- Kalantar, Z.N.; Karim, M.R.; Abdelaziz, M. A review of using waste and virgin polymer in pavement. Constr. Build. Mater. 2012, 33, 55–62. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Chegenizadeh, A.; Nikraz, H.; Rezagholilou, A. Investigating the engineering properties of asphalt binder modified with waste plastic polymer. Ain Shams Eng. J. 2021, 12, 1569–1574. [Google Scholar] [CrossRef]

- Mashaan, N.; Chegenizadeh, A.; Nikraz, H. Laboratory Properties of Waste PET Plastic-Modified Asphalt Mixes. Recycling 2021, 6, 49. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Chegenizadeh, A.; Nikraz, H. Evaluation of the Performance of Two Australian Waste-Plastic-modified Hot Mix asphalt. Recycling 2022, 7, 16. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Chegenizadeh, A.; Nikraz, H. A comparison on physical and rheological properties of three different waste-plastic-modified bitumen. Recycling 2022, 7, 18. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Chegenizadeh, A.; Nikraz, H. Performance of PET and Nano-silica Modified Stone Mastic Asphalt Mixtures. Case Stud. Constr. Mater. 2022, 16, e01044. [Google Scholar] [CrossRef]

- Zoorob, S.; Latif, B.S. Laboratory Design and Investigation of the Properties of Continuously Graded Asphaltic Concrete Containing Recycled Plastics Aggregate Replacement (Plastiphalt). Cem. Concr. Compos. 2000, 22, 233–242. [Google Scholar] [CrossRef]

- Al-Hadidy, A.; Yi-Qiu, T. Effect of polyethylene on life of flexible pavements. Constr. Build. Mater. 2009, 23, 1456–1464. [Google Scholar] [CrossRef]

- Ho, S.; Church, K.; Law, B.; MacLeod, D.; Zanzotto, L. Study of recycled polyethylene materials as asphalt modifiers. Can J. Civ. Eng. 2006, 33, 968–981. [Google Scholar] [CrossRef]

- Al-Hadidy, A.; Yi-Qiu, T. Mechanistic approach for polypropylene-modified flexible pavements. Mater. Des. 2009, 30, 1133–1140. [Google Scholar] [CrossRef]

- Vansudevan, R.; Ramalinga Chandra Sekar, A.; Sundarakannan, B.; Velkennedy, R. A technique to dispose waste plastics in an ecofriendly way-Application in construction of flexible pavement. Constr. Build. Mater. 2012, 28, 311–320. [Google Scholar] [CrossRef]

- Attaelmanan, M.; Cheng, P.F.; Abdul-Rahim, I.A.-H. Laboratory Evaluation of HMA with High Density Polyethylene as a Modifier. Constr. Build. Mater. 2011, 25, 2764–2770. [Google Scholar] [CrossRef]

- Moghddam, T.B.; Soltani, M.; Karim, M.R. Experimental characterization of rutting performance of polyethylene Terephthalate modified asphalt mixtures under static and dynamic loads. Constr. Build. Mater. 2014, 65, 487–494. [Google Scholar] [CrossRef]

- Khan, I.M.; Kabir, S.; Alhussain, M.A.; Almansoor, F.F. Asphalt design using recycled plastic and crumb-rubber waste for sustainable pavement construction. International Conference on Sustainable Design, Engineering and Construction. Procedia Eng. 2016, 145, 1557–1564. [Google Scholar] [CrossRef]

- Ameri, M.; Danial, N. Performance Properties of Devulcanized Waste PET Modified Asphalt Mixtures. Petrol. Sci. Technol. 2017, 35, 99–104. [Google Scholar] [CrossRef]

- Sara, F.; Silva, H.M.R.D.; Oliveira, J.R.M. Mechanical, surface and environmental evaluation of stone mastic asphalt mixtures with advanced asphalt binders using waste materials. Road Mater. Pavement Des. 2017, 20, 316–333. [Google Scholar]

- Asare, P.N.A.; Kuranchie, F.A.; Ofosu, E.A. Evaluation of incorporating plastic wastes into asphalt materials for road construction in Ghana. Cogent Environ. Sci. 2019, 5, 1576373. [Google Scholar] [CrossRef]

- Santos, J.; Pham, A.; Stasinopoulos, P. Recycling waste plastics in roads: A life-cycle assessment study using primary data. Sci. Total Environ. 2020, 751, 141842. [Google Scholar] [CrossRef] [PubMed]

- Jamshidi, A.; White, G. Evaluation of Performance and Challenges of Use of Waste Materials in Pavement Construction: A Critical Review. Appl. Sci. 2020, 10, 226. [Google Scholar] [CrossRef]

- Hake, S.L.; Damgir, R.M.; Awsarmal, P.R. Utilization of Plastic waste in Bitumen Mixes for Flexible Pavement. In Proceedings of the world congress on Transport Research-WCTR 2019, Mumbai, India, 26–30 May 2019. Transp. Res. Proced. 2020, 48, 3779–3785. [Google Scholar] [CrossRef]

- Haider, S.; Hafeez, I.; Jamal, R.U. Sustainable use of waste plastic modifiers to strengthen the adhesion properties of asphalt mixtures. Constr. Build. Mater. 2020, 235, 117496. [Google Scholar] [CrossRef]

- Al-Haydari, I.S.; Al-Haidari, H.S. Mechanical properties of polyethylene terephthalate-modified pavement mixture. Mater. Sci. Eng. 2020, 870, 012073. [Google Scholar] [CrossRef]

- Kumar, R.; Khan, M.A. Use of plastic waste along with bitumen in construction of flexible pavement. Int. J. Eng. Res. Technol. 2020, 9, 153–158. [Google Scholar]

- Chegenizadeh, A.; Bradley, P.; Hamid, N. Mechanical properties of stone mastic asphalt containing high-density polyethene: An Australian case. Case Stud. Constr. Mater. 2021, 15, e00631. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).