Properties of Rubberized Concrete Prepared from Different Cement Types

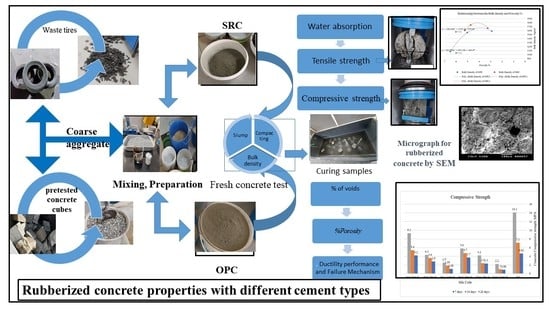

Abstract

:1. Introduction

2. Materials

2.1. The Procedures of Experiment

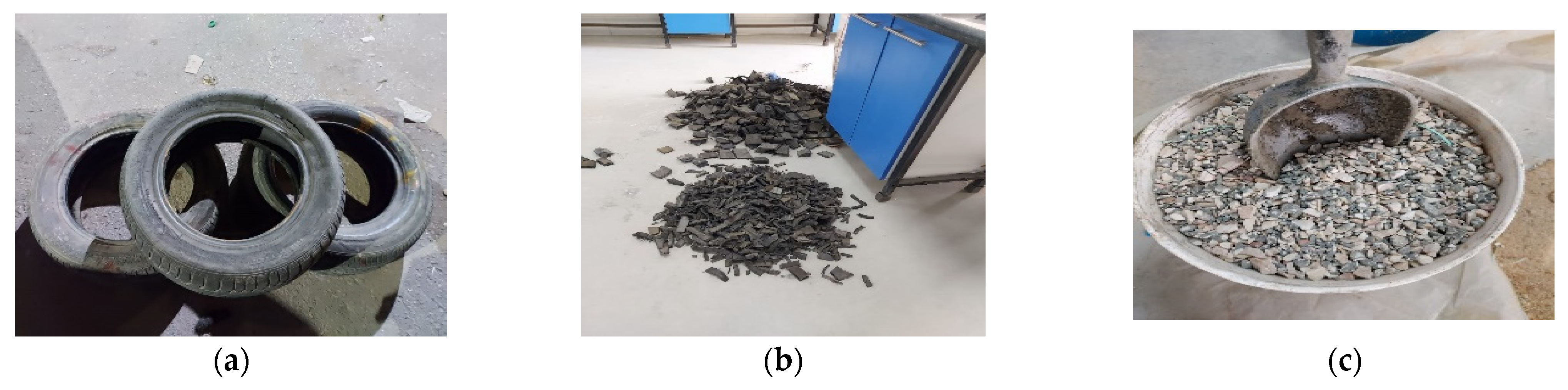

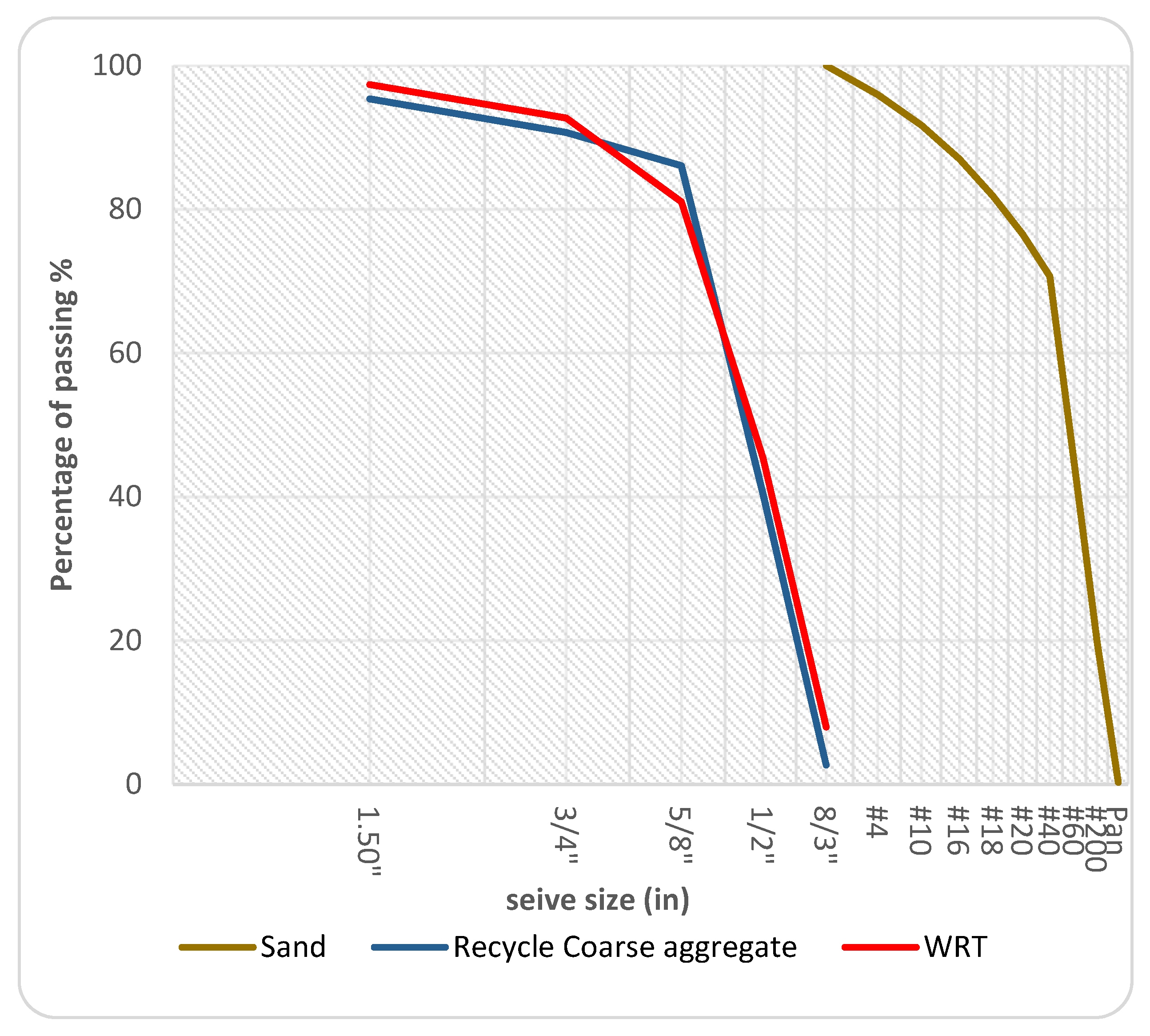

2.2. Aggregate

2.3. Cement

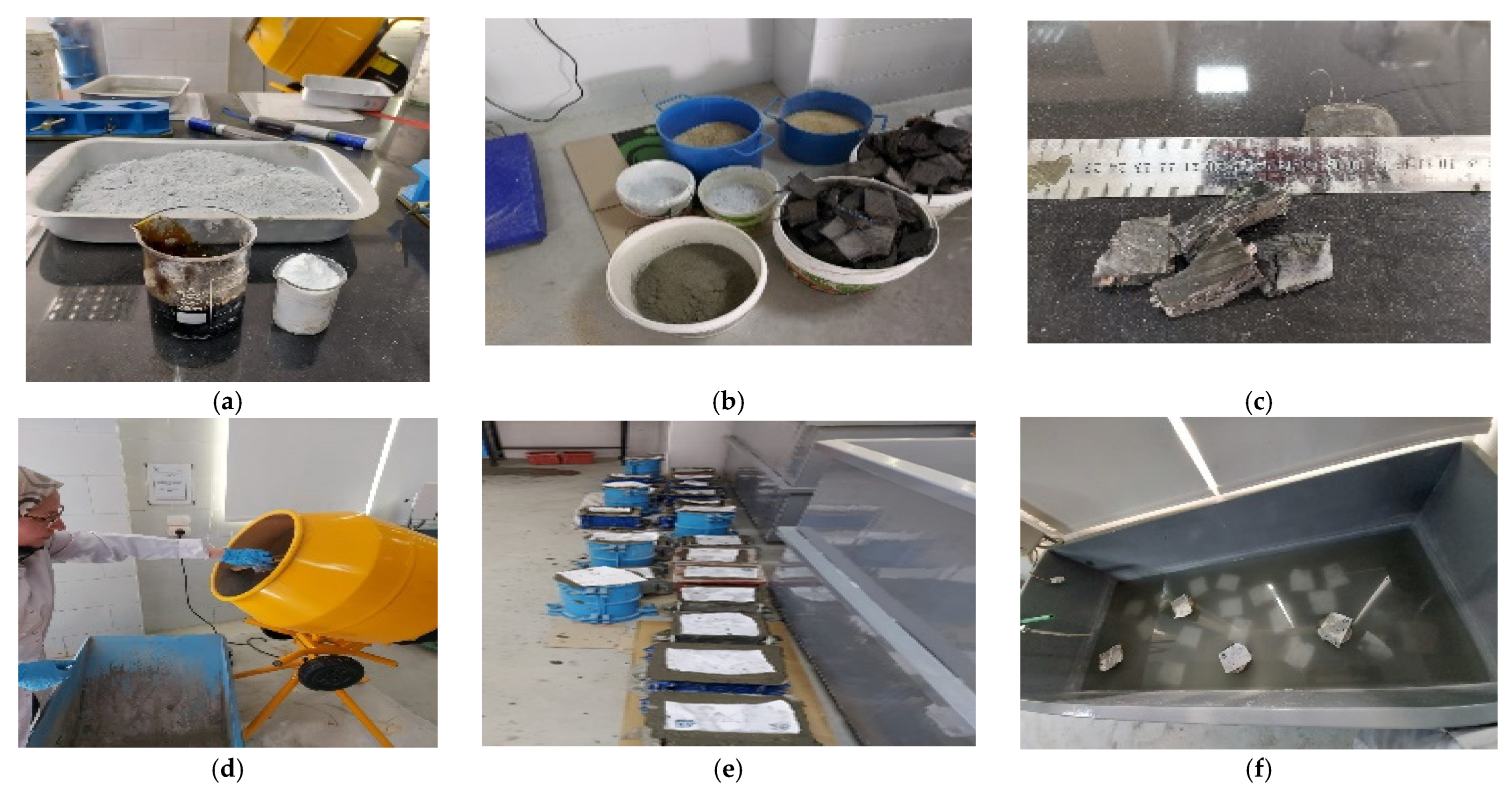

2.4. Preparation of the Specimens

3. Results and Discussion

3.1. Workability

3.2. Bulk Density

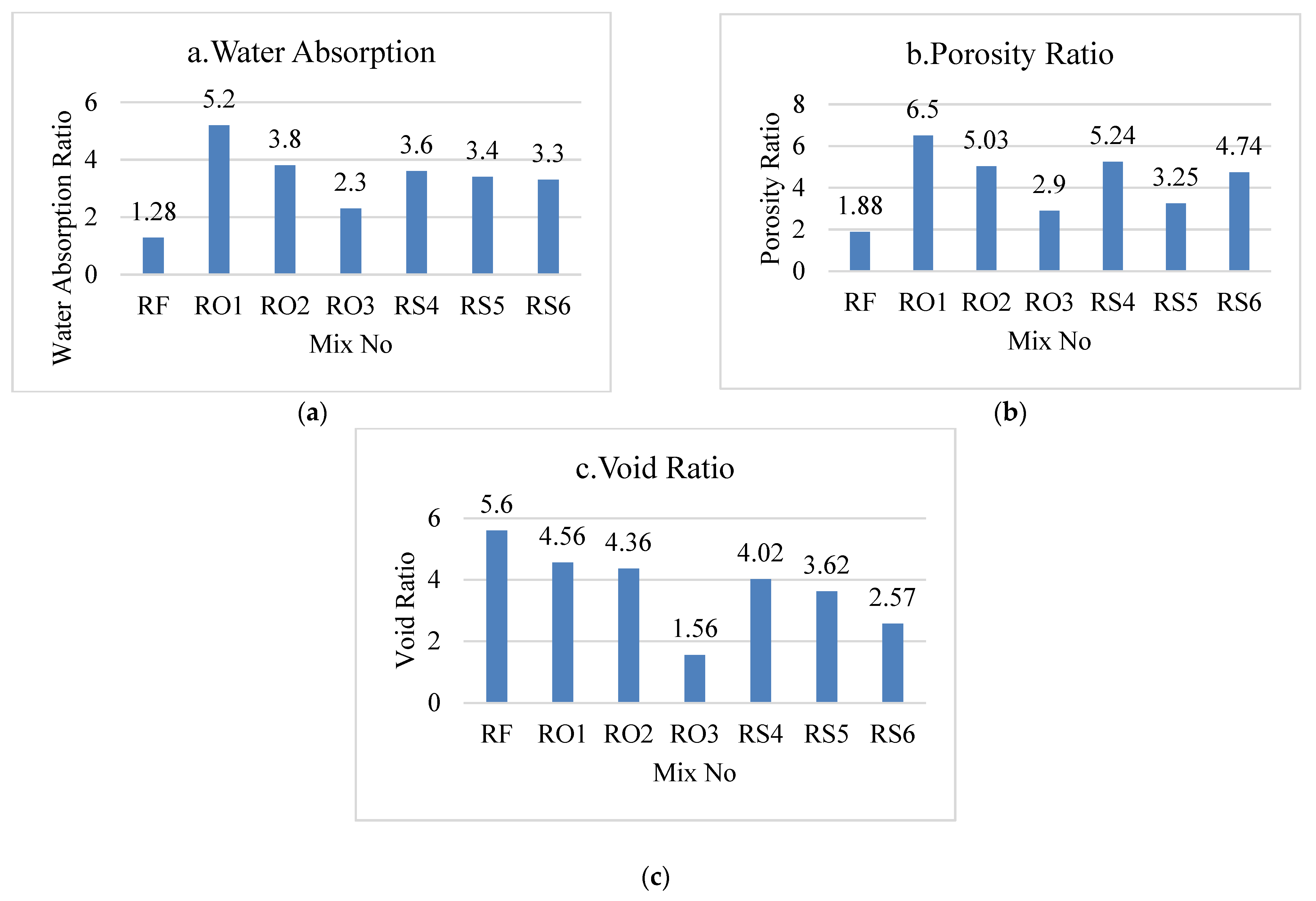

3.3. Water Absorption, Porosity, and Air Content

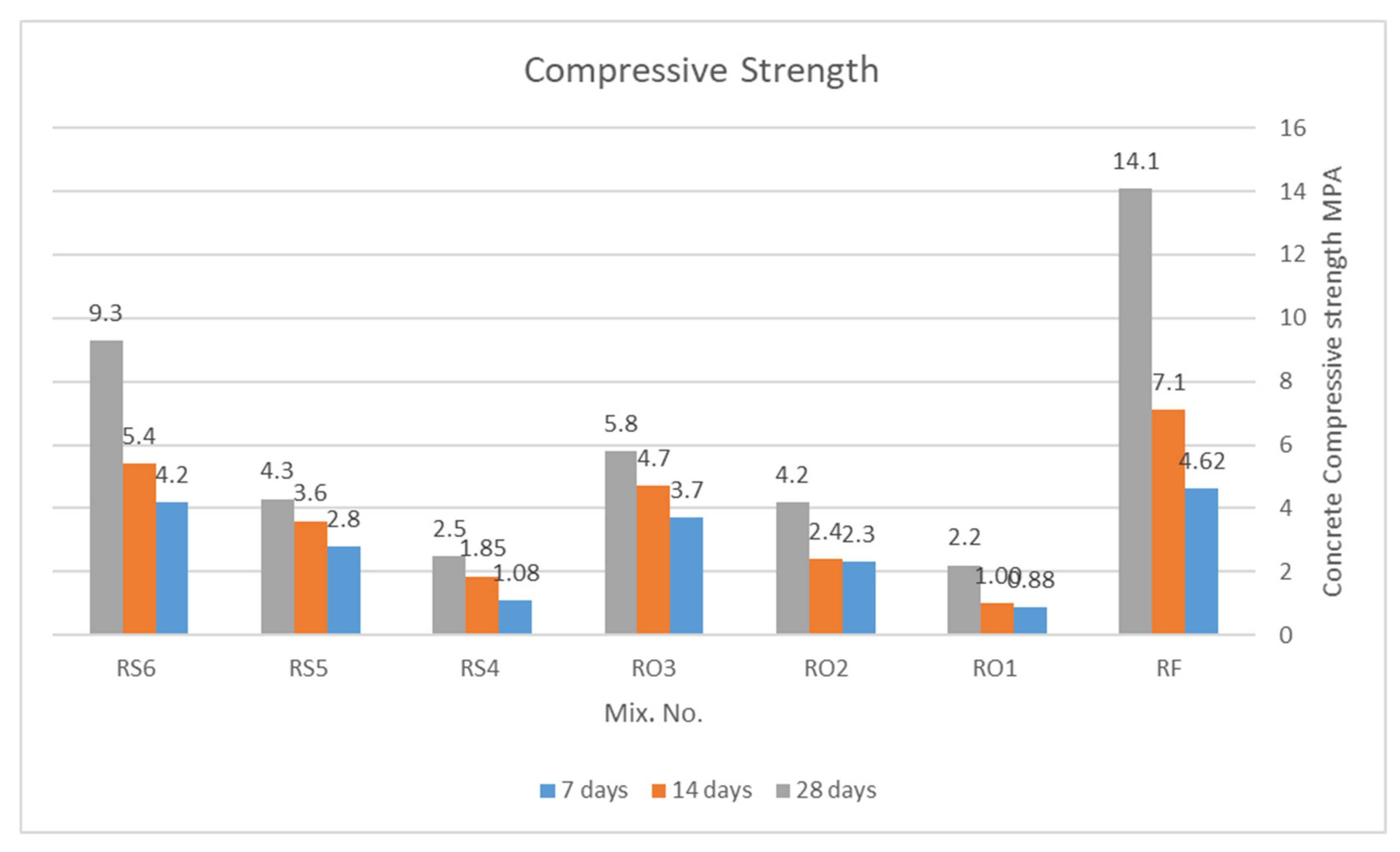

3.4. Compressive Strength

3.5. Tensile Strength

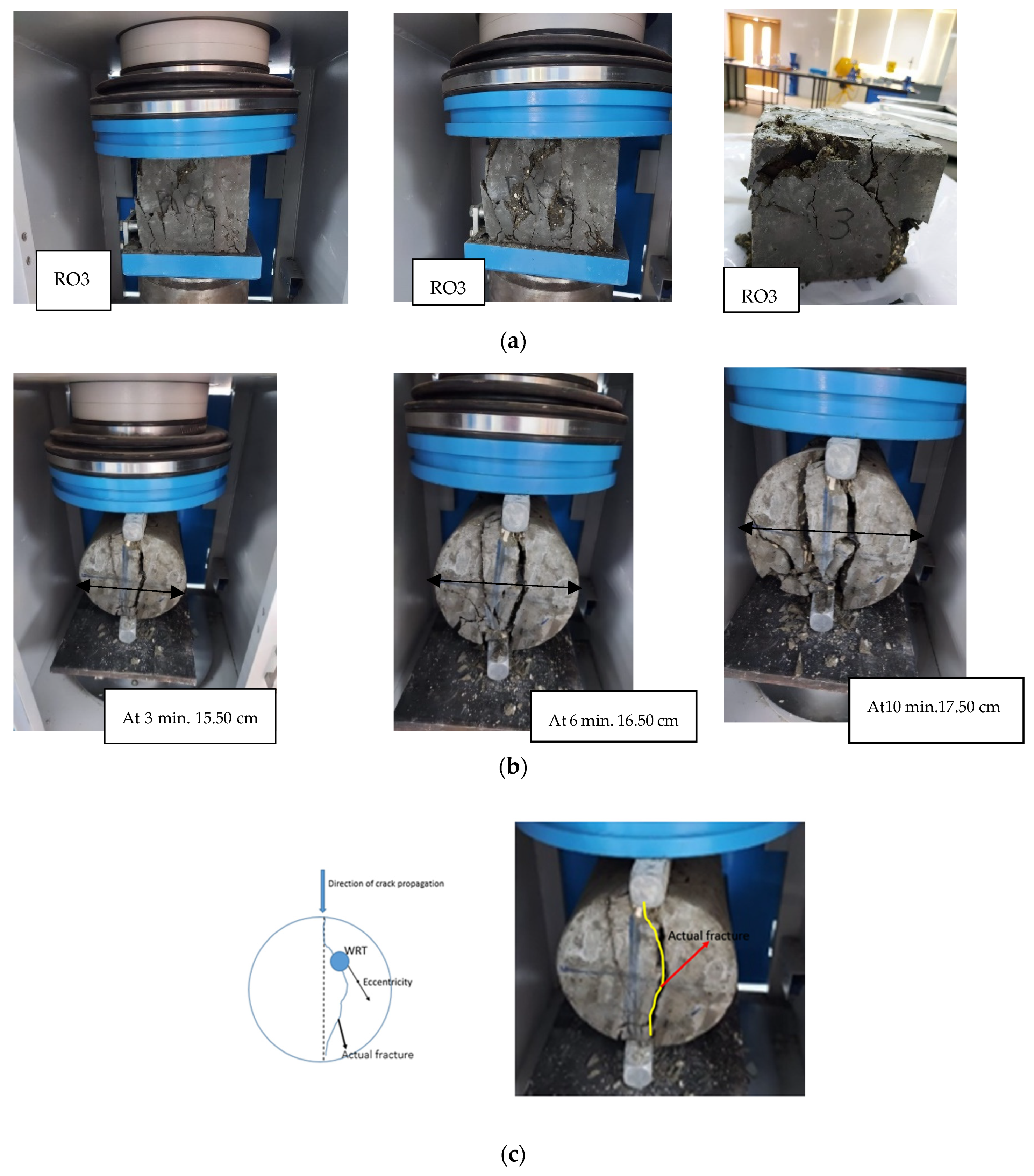

3.6. Ductility Performance and Failure Mechanism

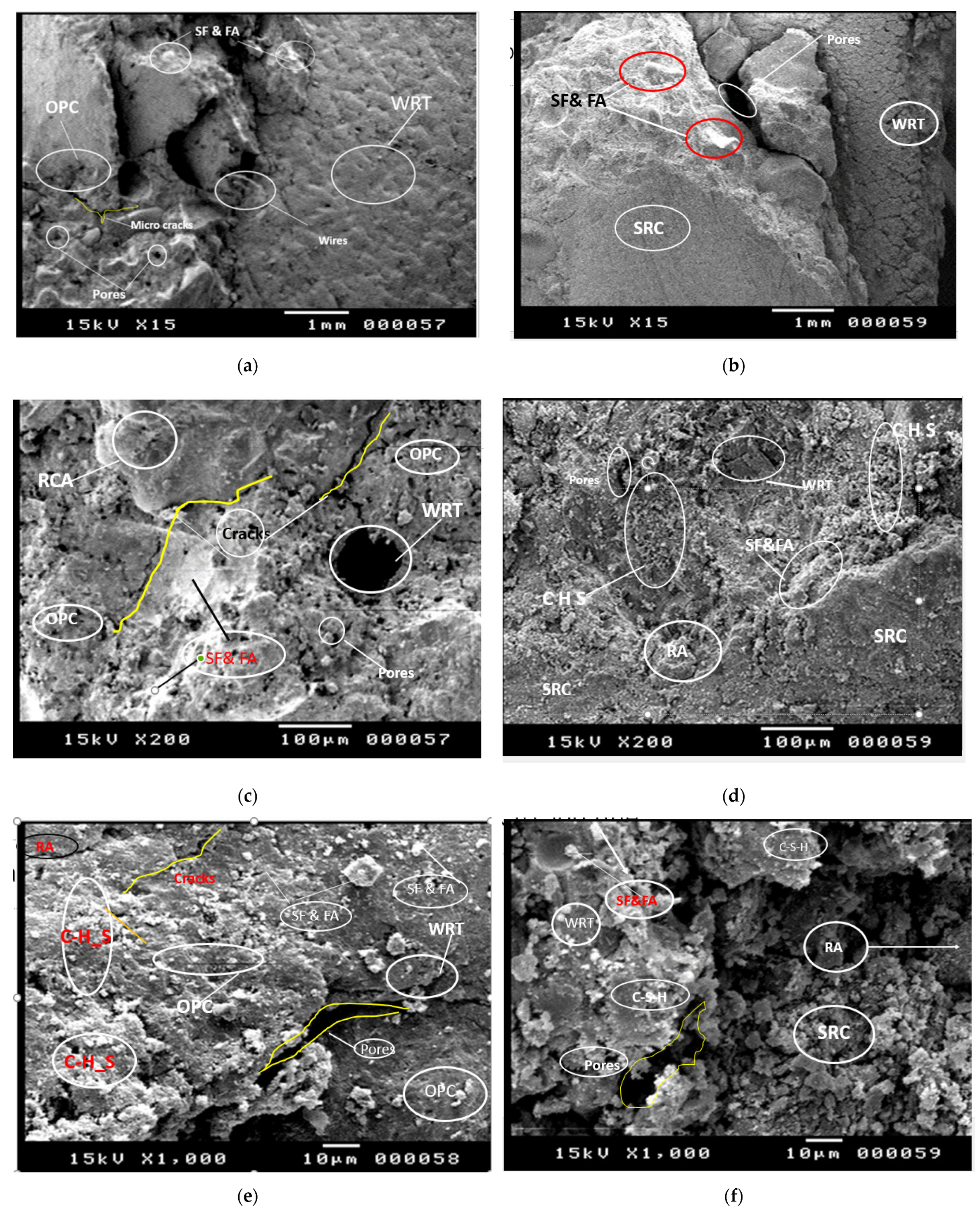

3.7. Scanning Electron Microscopy (SEM)

3.8. Statistical Analysis:

3.8.1. t-Test Independent Method

- Mean 1 and Mean 2 are the average values for groups 1 and 2, respectively;

- var. 1 and var. 2 are the variances for groups 1 and 2, respectively;

- n1 and n2 are the numbers of samples for groups 1 and 2, respectively.

- For concrete compressive strength after 7, 14, and 28 days, the findings of Fcu testing for OPC and SRC cement types show no significant differences.

- For concrete splitting tensile strength after 14 days, the null hypothesis was rejected, and the alternative hypothesis is preferred; therefore, there is a significant difference between the results of tensile strength tests for OPC and SRC.

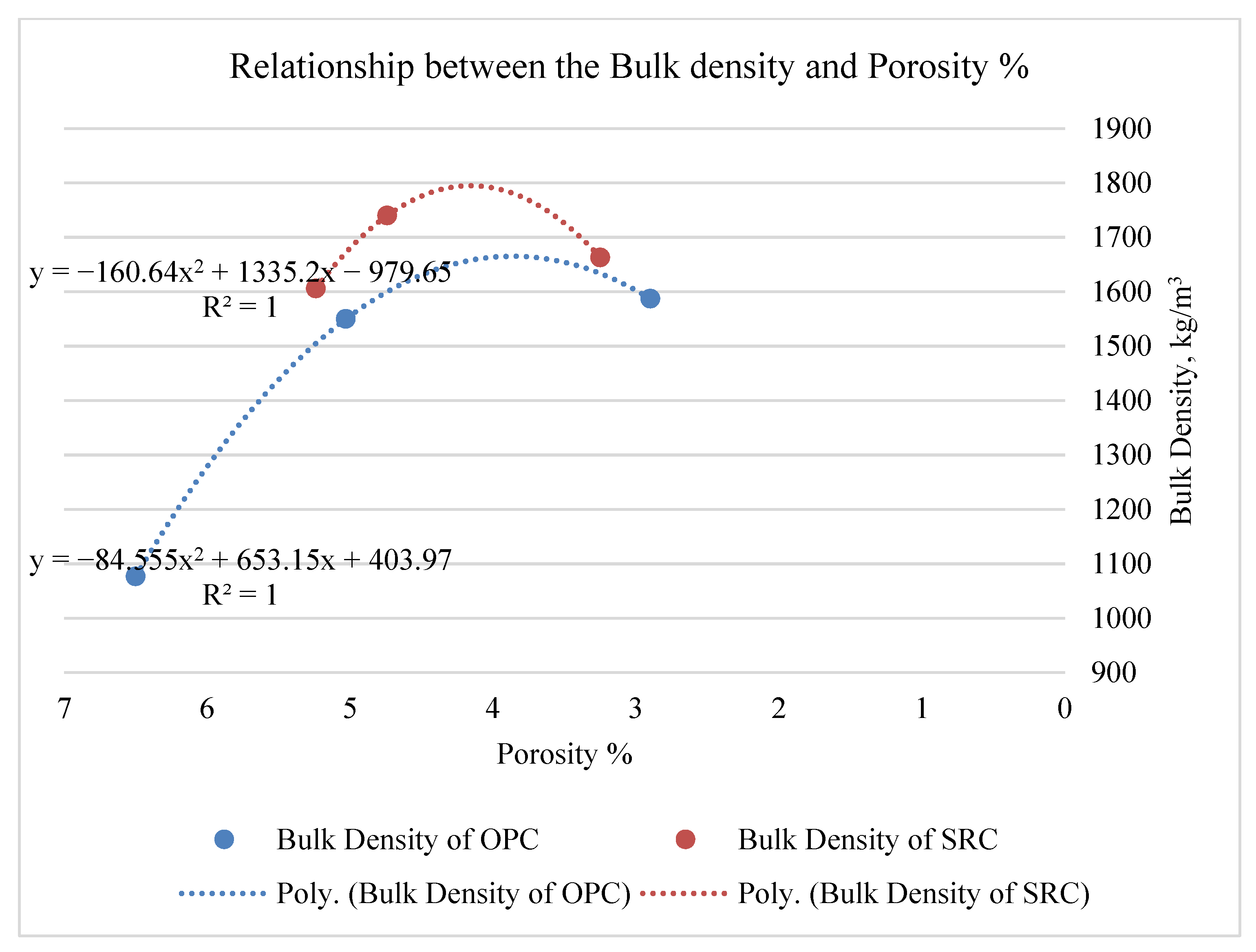

3.8.2. Relationship between Porosity and Bulk Density

- The increase in slump for different percentages of WRT in the samples leads to increased workability for OPC and SRC because the water absorption of WRT increases.

- The density values of WRT for the two types of cement match with the range of densities in lightweight concrete, where LWC is defined according to ACI 213.

- There are noticeable decreases in the void ratios for rubberized concrete prepared from both OPC and SRC mixtures.

- The SRC type can increase the compressive strength of rubberized concrete, which occurs more dramatically than for OPC. However, SRC can also contribute more greatly to improving the characteristic of tensile strength compared with OPC, and this is related to the higher bond stresses between WRT and SRC.

- When the amount of WRT is increased in the mixture, the brittleness of the concrete increases, resulting in smaller cracks when eventually loaded. The specimen with OPC has more brittleness and is eventually destroyed earlier than SRC at the ultimate load.

- SEM images show the presence of pores and voids around the rubber and the polymer composite, whereas uniform dispersion of FA and SF particles is observed in the polymer matrix. However, SEM microstructural analyses suggest a higher proportion of C–S–H intermixed with sulfate reaction phases of SRC rubberized mortar than with OPC. Thus, there is crystal growth in a decreased percentage of air voids, rather than a decrease in internal cracking.

- It is clearly shown that there is a greater increase in the average crack width for OPC mortar than for SRC. More small cracks and microcracks appeared in SRC than OPC specimens. This is partly due to the increased porosity and reduced compressive strength of rubberized cement composites, which gradually expanded and became transfixed.

4. Conclusions

- The workability was higher for fresh rubberized mixtures of SRC than those of OPC.

- Increasing the amount of WRT as a replacement for RCA caused a decrease in the density by approx. 50.5% for OPC and 40% for SRC, although the highest increase in porosity was observed, of approx. 56%, for both types of cement.

- The reductions in WRT as a percentage of RCA led to decreases in water absorption (WAR) and void ratios for both OPC and SRC; in contrast, water absorption and air voids were higher in OPC than in SRC, by 30% and 13%, respectively.

- WRT rubber reduced the compressive and tensile strength by 35% and 60%, respectively, for both SRC and OPC, and the reduction in the amount of WRT used to replace RCA concrete also led to increased compressive and tensile strength. Therefore, the decreasing percentage depends on the amount of recycled rubber in the concrete mixture.

- Recycled rubber positively contributed to the reduction in cracks in the resulting concrete.

- Replacement WRT in concrete 50% from weight of coarse aggregate had the effect of increasing the ductility and subsequently reducing brittleness as a factor of.

- SEM images showed the presence of pores/voids around the rubber and the polymer composite, whereas uniform dispersion of silica fume particles was observed in the polymer matrix.

- The SEM microstructural analysis showed a higher proportion of C–S–H intermixed with the sulfate reaction phases of SRC rubberized mortar than with OPC; thus, crystal growth in a decreased percentage of air voids resulted in a greater increase in the average crack width for OPC mortar than that of SRC.

- The independent t-test was used to compare the average values of compressive and tensile strengths for OPC and SRC, and the findings demonstrate that the differences in Fcu between the OPC and SRC groups were not significant; this means the null hypothesis was accepted according to the statistical analysis. In contrast, for tensile strength (Ft), the null hypothesis was rejected, and the alternative hypothesis was preferred; therefore, there was a significant difference between the results of tensile strength for OPC and SRC.

- For the correlation curve between porosity and bulk densities for both OPC and SRC, the values of R2 for both the OPC and SRC groups were 1.0; therefore, the values were very close in the correlation curves.

- As a recommendation for future work, study should be undertaken of the ductility index evaluation method and the derivation of the energy area ratio, to ensure that ductility evaluation results are based on the brittleness index values of rubberized concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, L.; Huo, X.S.; Yuan, Y. Strength, modulus of elasticity, and brittleness index of rubberized concrete. J. Mater. Civ. Eng. 2008, 20, 692–699. [Google Scholar] [CrossRef]

- Kotresh, K.; Belachew, M.G. Study on waste tyre rubber as concrete aggregates. Int. J. Sci. Eng. Technol. 2014, 3, 433–436. [Google Scholar]

- Copetti, C.M.; Borges, P.M.; Squiavon, J.Z.; da Silva, S.R.; de Oliveira Andrade, J.J. Evaluation of tire rubber surface pre-treatment and silica fume on physical-mechanical behavior and microstructural properties of concrete. J. Clean. Prod. 2020, 256, 120670. [Google Scholar] [CrossRef]

- Martauz, P.; Václavík, V. Review of the use of waste tires in concrete. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; p. 012023. [Google Scholar]

- Fahmy, M.F.; Idriss, L.K. Flexural behavior of large scale semi-precast reinforced concrete T-beams made of natural and recycled aggregate concrete. Eng. Struct. 2019, 198, 109525. [Google Scholar] [CrossRef]

- Gupta, T.; Chaudhary, S.; Sharma, R.K. Assessment of mechanical and durability properties of concrete containing waste rubber tire as fine aggregate. Constr. Build. Mater. 2014, 73, 562–574. [Google Scholar] [CrossRef]

- Ghewa, G.J.P.; Suprobo, P.; Irawan, D.; Wahyuniarsih, S.; Asdam, T. Investigation of Water Absorption for Concrete Using Supplementary Materials. IPTEK J. Technol. Sci. 2020, 31, 309–317. [Google Scholar] [CrossRef]

- Siringi, G.M. Properties of Concrete with Tire Derived Aggregate and Crumb Rubber as a Ligthweight Substitute for Mineral Aggregates in the Concrete Mix. Ph.D. Thesis, The University of Texas, Austin, TX, USA, 2012. [Google Scholar]

- Guo, Y.-C.; Zhang, J.-H.; Chen, G.-M.; Xie, Z.-H. Compressive behaviour of concrete structures incorporating recycled concrete aggregates, rubber crumb and reinforced with steel fibre, subjected to elevated temperatures. J. Clean. Prod. 2014, 72, 193–203. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C. Long term behaviour of cement concrete containing discarded tire rubber. J. Clean. Prod. 2015, 102, 78–87. [Google Scholar] [CrossRef]

- Akinwonmi, A.S.; Seckley, E. Mechanical Strength of Concrete with Crumb and Shredded Tyre As Aggregate Replacement. Int. J. Eng. Res. Appl. 2013, 3, 1098–1101. [Google Scholar]

- Egyptian Organization for Standards & Quality. Cement Part (1) Composition, Specifications and Conformity Criteria for Common Cements; Egyptian Organization for Standards & Quality: Cairo Governorate, Egypt, 2013; Volume 47. [Google Scholar]

- Institution, B.S. BS EN 197-1:2011 Cement. Composition, Specifications and Conformity Criteria for Common Cements; British Standards Institution: London, UK, 2011. [Google Scholar]

- Onuaguluchi, O.; Banthia, N. Long-term sulfate resistance of cementitious composites containing fine crumb rubber. Cem. Concr. Compos. 2019, 104, 103354. [Google Scholar] [CrossRef]

- Aiad, I.; El-Sabbagh, A.; Shafek, S.; Adawy, A.; Abo-EL-Enein, S. Effect of Some Prepared Superplasticizers (Cyclohexanone Based) on Compressive Strength and Physico-chemical Properties of Oil Well Cement Pastes. Egypt. J. Petroleum. 2016, 59, 851–866. [Google Scholar] [CrossRef]

- Center, H.B.N.R. ECP 203-2007 Egyptian Code for Design and Construction of Reinforced Concrete Structures, Design of Concrete Mixes; Housing & Building National Research Center: Giza, Egypt, 2007. [Google Scholar]

- Egyptian Organization for Standards & Quality. Testing of Concrete Part: 2 Properties of Fresh Concrete; Egyptian Organization for Standards & Quality: Cairo Governorate, Egypt, 2008; Volume 66. [Google Scholar]

- Raghavan, D.; Huynh, H.; Ferraris, C. Workability, mechanical properties, and chemical stability of a recycled tyre rubber-filled cementitious composite. J. Mater. Sci. 1998, 33, 1745–1752. [Google Scholar] [CrossRef]

- C09 Committee, A.I. Specification for Lightweight Aggregates for Structural Concrete; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- McCarter, W.J.; Ezirim, H.; Emerson, M. Absorption of water and chloride into concrete. Mag. Concr. Res. 1992, 44, 31–37. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Material design and characterization of high performance pervious concrete. Constr. Build. Mater. 2015, 98, 51–60. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Gbagbo, J.; Russell, M.; Basheer, P. Properties of fly ash concrete modified with hydrated lime and silica fume. Constr. Build. Mater. 2009, 23, 3233–3239. [Google Scholar] [CrossRef]

- Astm, C. Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. 2013. Available online: https://pdfcoffee.com/c642-13-standard-test-method-for-density-absorption-and-voids-in-hardened-concretepdf-pdf-free.html (accessed on 1 June 2022).

- Mushunje, K.; Otieno, M.; Ballim, Y. A review of Waste Tyre Rubber as an Alternative Concrete Constituent Material. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018. [Google Scholar] [CrossRef]

- Wei, Y.; Chai, J.; Qin, Y.; Li, Y.; Xu, Z.; Li, Y.; Ma, Y. Effect of fly ash on mechanical properties and microstructure of cellulose fiber-reinforced concrete under sulfate dry–wet cycle attack. Constr. Build. Mater. 2021, 302, 124207. [Google Scholar] [CrossRef]

- Pelletier-Chaignat, L.; Winnefeld, F.; Lothenbach, B.; Le Saout, G.; Müller, C.J.; Famy, C. Influence of the calcium sulphate source on the hydration mechanism of Portland cement–calcium sulphoaluminate clinker–calcium sulphate binders. Cem. Concr. Compos. 2011, 33, 551–561. [Google Scholar] [CrossRef]

| Properties | Values for WRT | Values for RCA | Values for Sand |

|---|---|---|---|

| Specific gravity | 1.05 | 2.65 | 2.53 |

| Density gm/cm3 | 1.10 | 1.25 | 2.92 gm/cm3 |

| Water absorption (%) | 1.05 | 3.06 | 2.6 |

| Void ratio | - | 0.525 | 0.154 |

| Crushing value (%) | 10 | 21.80 | - |

| Total porosity | - | 0.20 | 0.133 |

| Fineness modulus | - | 7.11 | 2.30 |

| Type of Cement | Specific Gravity kg/m3 | % of Water Consistency | Specific Surface Area (Bline) m2/kg | Bulk Density (kg/m3) | Soundness (Le Chatelier) m |

|---|---|---|---|---|---|

| Ordinary Portland Cement | 3079.288 | 28 | 282.7 | 1140 | 0.00015 |

| Cement Sulfate Resisting | 3079.288 | 28 | 406.6 | 1140 | 0.00015 |

| Type of cement | Initial setting-time (min) | Final setting time (min) | Compressive strength (N/m2) | ||

| 7 Days | 14 Days | 28 Days | |||

| Ordinary Portland Cement | 180 | 230 | 3.8 × 107 | 5.2 × 107 | |

| Cement Sulfate Resisting | 145 | 195 | 3.7 × 107 | 5.0 × 107 | |

| Silica Fume (SF) | ||||||

| Type of Additives | Specific Gravity kg/m3 | Mean Grain Size | Specific Surface Area (Bline) m2/kg | Bulk Density (kg/m3) | Silica Fume Particles | |

| SF | 2200 | 7 | 17,800 | 4300 | 0.50 µm | |

| Fly Ash(FA) | ||||||

| Type of Additives | Specific Gravity kg/m3 | SiO2 | Sulphate SO4 | Al2O3 | CaO | MgO |

| FA | 2120 | 56.88% | 0.27% | 27.65% | 3.6% | 0.34% |

| Properties | Sikament (SP) |

|---|---|

| pH value | 4.3–4.7 |

| Density at 20 °C | 1.20 kg/L |

| Fineness modulus | 3.06 |

| Void ratio | 0.52 |

| Mix No. | Cement (kg/m3) | Fine Aggregate (Sand) (kg/m3) | Coarse Aggregate (kg/ m3) | w/c | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Type | Weight | FA | SF | SP | Type | Weight | RCA | WRT | ||

| RF | OPC | 396 | 0 | 0 | 0 | Siliceous sand | 804 | 846 | 0 | 0.55 |

| RO1 | OPC | 396 | 0.795 | 39.6 | 12 | 804 | 0 | 846 | 0.55 | |

| RO2 | 396 | 0.795 | 39.6 | 12 | 804 | 212 | 634 | 0.55 | ||

| RO3 | 396 | 0.795 | 39.6 | 12 | 804 | 423 | 423 | 0.55 | ||

| RS4 | SRC | 396 | 0.795 | 39.6 | 12 | 804 | 0 | 846 | 0.55 | |

| RS5 | 396 | 0.795 | 39.6 | 12 | 804 | 212 | 634 | 0.55 | ||

| RS6 | 396 | 0.795 | 39.6 | 12 | 804 | 423 | 423 | 0.55 | ||

| Mix. No. | Slump mm | Compact Factor | Bulk Density kg/m3 | Workability |

|---|---|---|---|---|

| RF | 35 | 0.93 | 2800 | low |

| RO1 | 120 | 0.97 | 1077 | High |

| RO2 | 130 | 0.97 | 1550 | High |

| RO3 | 120 | 0.97 | 1587 | High |

| RS4 | 120 | 1.0 | 1606 | High |

| RS5 | 150 | 1.0 | 1663 | High |

| RS6 | 130 | 1.0 | 1740 | High |

| Mix. No. | Compressive Strength (MPa) | Tensile Strength (MPa) | Water Absorption (MPa) | Voids Ratio | Porosity Ratio | ||

|---|---|---|---|---|---|---|---|

| 7 Days | 14 Days | 28 Days | 14 Days | 14 Days | 14 Days | 14 Days | |

| RF | 4.62 | 7.10 | 14.10 | 1.10 | 1.28 | 5.60 | 1.88 |

| RO1 | 0.88 | 1.0 | 2.20 | 0.45 | 5.20 | 4.56 | 6.50 |

| RO2 | 2.30 | 2.40 | 4.20 | 0.65 | 3.8 | 4.36 | 5.03 |

| RO3 | 3.70 | 4.70 | 5.80 | 0.75 | 2.3 | 1.56 | 2.90 |

| RS4 | 1.08 | 1.85 | 2.50 | 0.95 | 3.6 | 4.02 | 5.24 |

| RS5 | 2.80 | 3.60 | 4.30 | 1.25 | 3.4 | 3.62 | 3.25 |

| RS6 | 4.20 | 5.40 | 9.30 | 1.42 | 3.3 | 2.57 | 2.74 |

| Type of Test | Groups | N | Mean | SD |

|---|---|---|---|---|

| Concrete compressive strength after 7 days | OPC group | 3.0 | 2.2933 | 1.41001 |

| SRC group | 3.0 | 2.6933 | 1.56273 |

| Levene’s Test for Equality of Variances | t-Test for Equality of Means | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| F | Sig | t | df | Sig. (2-Tailed) | Mean Difference | Std. Error Difference | 95% Confidence Interval of the Difference | |||

| Lower | Upper | |||||||||

| Concrete compressive strength after 7 Days | Equal variances assumed | 0.039 | 0.853 | −0.329 | 4.0 | 0.759 | −0.40000 | 1.21522 | −3.77399 | 2.97399 |

| Equal variances not assumed | - | - | −0.329 | 3.958 | 0.759 | −0.40000 | 1.21522 | −3.78801 | 2.98801 | |

| Type of Test | Groups | N | Mean | Std. Deviation |

|---|---|---|---|---|

| Concrete compressive strength after 14 days | OPC group | 3.0 | 2.7000 | 1.86815 |

| SRC group | 3.0 | 3.6167 | 1.77506 |

| Levene’s Test for Equality of Variances | t-Test for Equality of Means | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| F | Sig | t | df | Sig. (2-Tailed) | Mean Difference | Std. Error Difference | 95% Confidence Interval of the Difference | |||

| Lower | Upper | |||||||||

| Concrete compressive strength after 14 days | Equal variances assumed | 0.034 | 0.863 | −0.616 | 4.0 | 0.571 | −0.91667 | 1.48782 | −5.04752 | 3.21419 |

| Equal variances not assumed | - | - | −0.616 | 3.990 | 0.571 | −0.91667 | 1.48782 | −5.05177 | 3.21844 | |

| Type of Test | Groups | N | Mean | Std. Deviation |

|---|---|---|---|---|

| Concrete compressive strength after 28 days | OPC group | 3.0 | 4.0667 | 1.80370 |

| SRC group | 3.0 | 5.3667 | 3.52326 |

| Levene’s Test for Equality of Variances | t-Test for Equality of Means | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| F | Sig. | t | df | Sig. (2-Tailed) | Mean Difference | Std. Error Difference | 95% Confidence Interval of the Difference | |||

| Lower | Upper | |||||||||

| Concrete compressive strength after 28 days | Equal variances assumed | 1.880 | 0.242 | −0.569 | 4.0 | 0.600 | −1.30000 | 2.28522 | −7.64478 | 5.04478 |

| Equal variances not assumed | - | - | −0.569 | 2.981 | 0.609 | −1.30000 | 2.28522 | −8.59894 | 5.99894 | |

| Type of Test | Groups | N | Mean | Std. Deviation |

|---|---|---|---|---|

| Splitting tensile strength | OPC group | 3.0 | 0.6167 | 0.15275 |

| SRC group | 3.0 | 1.2067 | 0.23798 |

| Levene’s Test for Equality of Variances | t-Test for Equality of Means | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| F | Sig | t | df | Sig. (2-Tailed) | Mean Difference | Std. Error Difference | 95% Confidence Interval of the Difference | |||

| Lower | Upper | |||||||||

| Splitting tensile strength after 14 days | Equal variances assumed | 0.616 | 0.476 | −3.614 | 4.0 | 0.022 | −0.59000 | 0.16327 | −1.04330 | −0.13670 |

| Equal variances not assumed | - | - | −3.614 | 3.409 | 0.029 | −0.59000 | 0.16327 | −1.07605 | −0.10395 | |

| Type of Test | Significance Level α Versus p-Value | Results |

|---|---|---|

| Concrete compressive strength after 7 days | p-value = 0.759 α = 0.05 p-value > α; The null hypothesis is accepted, and an alternative hypothesis is unable to replace it. | The findings of concrete compressive strength testing for OPC and SRC cement types show no significant differences, and the SRC yielded an average strength of 1.17 of the compressive strength of the OPC group. |

| Concrete compressive strength after 14 days | p-value = 0.571 α = 0.05 p-value > α; The null hypothesis is accepted, and an alternative hypothesis is unable to replace it. | The findings of concrete compressive strength testing for OPC and SRC cement types show no significant differences, and the SRC yielded an average strength of 1.33 of the compressive strength of the OPC group. |

| Concrete compressive strength after 28 days | p-value = 0.600 α = 0.05 p-value > α; The null hypothesis is accepted, and an alternative hypothesis is unable to replace it. | The findings of concrete compressive strength testing for OPC and SRC cement types show no significant differences, and the SRC yielded an average strength of 1.31 of the compressive strength of the OPC group. |

| Concrete splitting tensile strength after 14 days | p-value = 0.022 α = 0.05 p-value < α; The null hypothesis is rejected, and the alternative hypothesis is preferred. | There is a significant difference between the results of tensile strength for OPC and SRC, and the average strength obtained from the SRC is equivalent to 1.95 of the average concrete splitting tensile strength of the OPC group. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Idriss, L.K.; Gamal, Y.A.S. Properties of Rubberized Concrete Prepared from Different Cement Types. Recycling 2022, 7, 39. https://doi.org/10.3390/recycling7030039

Idriss LK, Gamal YAS. Properties of Rubberized Concrete Prepared from Different Cement Types. Recycling. 2022; 7(3):39. https://doi.org/10.3390/recycling7030039

Chicago/Turabian StyleIdriss, Lamiaa K., and Yasser Abdal Shafey Gamal. 2022. "Properties of Rubberized Concrete Prepared from Different Cement Types" Recycling 7, no. 3: 39. https://doi.org/10.3390/recycling7030039

APA StyleIdriss, L. K., & Gamal, Y. A. S. (2022). Properties of Rubberized Concrete Prepared from Different Cement Types. Recycling, 7(3), 39. https://doi.org/10.3390/recycling7030039