Abstract

Efficient packaging waste management systems are essential considering recent revisions of the European legislation on packaging waste management that sets ambitious targets. European rules aim to deal with the increasing quantities of packaging waste, which cause environmental problems. Consequently, it is necessary to identify functional packaging waste management systems to achieve these targets effectively and efficiently. However, given the heterogeneity of the different packaging management systems, policymakers, scholars, and industry operators struggle to have a comparative view. The number of non-harmonized laws in force across countries, autonomous recycling targets, and constant updates are prominent problems that make it difficult to obtain comparable information for research, business, and policymaking. To fill this gap, our research question consists of assigning responsibilities for prevention, collection, recycling, and recovery and an overview of some models at a glance with respect to the general governance and functioning of the system. We base our research on a multiple-case design since more cases are examined using complementary data collection methods, analysis of the previous literature, reports, legislation, and business and institutional websites. Our results provide insights from the following cases: Germany, France, the United Kingdom, the Netherlands, Portugal, Denmark, Spain, and Italy. In addition, policy implications emerge as our insights help overcome barriers in the European market’s development caused by the different rules on packaging management and design serving policymakers that aim to harmonize the management of packaging waste. The paper also contains managerial implications for circular economy business models that can be used by managers who aim to design or upgrade their business models according to both recent legislative upgrades and packaging management systems.

1. Introduction

Environmentally sound management of packaging waste is a prominent topic worldwide due to potential environmental risks deriving from suboptimal management [1]. It is no wonder that the governance of packaging waste management systems is one of the pillars of national strategies for the circular economy since packaging waste has increased with a wide range of direct and indirect environmental consequences [2]. Focusing on the governance mechanism and the main actors involved, we review some European packaging waste management systems, identifying common elements and main differences in order to add pieces of information to design ever more circular-economy-compliant waste management systems [3]. Efficient waste management systems are essential in light of the recent revision of the European legislation on waste that sets higher recycling targets by 2030. Consequently, it is necessary to identify functional packaging waste management systems to achieve these ambitious targets effectively and efficiently. For example, the EU’s circular economy action plan aims to support the reduction in plastic waste, and a key element of it is the improvement of the economics and quality of recycled plastic, establishing the closed-loop recycling of food packaging materials [4].

Given the heterogeneity of the different packaging management systems, policymakers, academics, and industry operators struggle to have a comparative view on different systems [5,6,7]. A comparative vision is significant given the support it could give to national circular economy strategies, the healthy functioning of waste management, the system’s economic efficiency, and social well-being. Since reuse and recycling are two of the most important strategies involved in the development of the circular economy, to define common recycling and reuse targets comparable information is needed; in this respect, a recent paper proposed a waste circularity index that is a valuable approach [8].

Therefore, we intend to provide useful information for analyzing packaging waste management systems from a governance standpoint.

Packaging waste management stakeholders can also use this information to assess the validity of packaging waste management systems by comparing them with systems in place in other countries. This comparison can also be used to define benchmarks and performance assessments, of which importance has surged [9,10,11,12]. The analysis was carried out by observing the systems in Germany, France, the United Kingdom, the Netherlands, Portugal, Denmark, Spain, and Italy. Most of the countries analyzed rely on local authorities or an extended producer responsibility (EPR) policy for the collection and recycling of packaging waste. In some countries, there is no compulsory filing system, although there is a discussion about a possible introduction in the future. Frequently, a coordinating body for managing packaging waste is aimed at ensuring advanced monitoring and control. The document provides a general overview of packaging waste management in the analyzed countries and shows how different countries manage waste in a relatively homogeneous way. The scope of this paper falls within the purpose of the European waste framework and, in particular, Directive 2018/852/EU, which aims to harmonize national measures regarding packaging and waste management to prevent or reduce environmental impacts, as well as distortions of and restrictions on competition in the European Union (EU). The Directive also addresses the polluter pays principle and shared responsibility. The standard is based on the reuse, recycling, and recovery of waste and reducing the production of and dangers associated with waste: disposal is a marginal activity that should be carried out only due to unavoidable technical reasons and not due to economic concerns. The Directive covers all packaging, which is defined as products composed of materials of any kind that are used to contain and protect certain goods, ranging from raw materials to finished products, and allows their handling and delivery from the producer to the consumer or user. In this paper, we review several characteristics of practices regarding the management of packaging waste across various European countries and the United Kingdom (UK). The primary distinctions of the systems of EU member states and the UK are illustrated. Through this comparative analysis of the governance of packaging waste management, we create added value for scholars, businesses, and policymakers. In particular, scholars can have a simplified but comparable framework that is useful for international assessments and firms can have an overview of the market in which they operate, whereas policymakers benefit from information that may be useful for developing policies to make the recycled materials market work smoothly, which is fundamental in light of recent EU legislation updates.

2. Materials and Methods

We based this research on a multiple-case design, since more cases are examined using multiple data collection methods: analysis of the previous literature, reports, legislation, and business and institutional websites. As generally recognized, this approach is more powerful than a single-case design as it guarantees more extensive descriptions of the analyzed phenomenon [13]. In fact, we conducted a cross-case examination in an effort to provide pieces of knowledge on this issue. However, this may yield increased generalizability. We also considered the principle of triangulation that suggests using multiple sources of data to enhance the credibility. There is a wide consensus on the fact that triangulation aligns multiple perspectives and facilitates the comprehension of complex topics [14] and the enhancement of confidence in findings [15]. However, we did not investigate cause-and-effect relationships; instead, we focused on similarities and differences across cases providing a multiple-case analysis. This kind of analysis needs a priori defined research questions, and a clearly designated population from which observations are drawn [16]. In this respect, we aimed to provide scholars and policymakers the groundwork from which comparisons or benchmarks can be built that are useful for policy analysis [17], for performance analysis [18], and market harmonization purposes. In fact, a prominent topic in environmental economics is the need for reducing packaging waste while guaranteeing the free movement of materials in a market economy [19], which is one of the pillars of the development of the European single market.

3. Overview of Packaging Waste Management Models

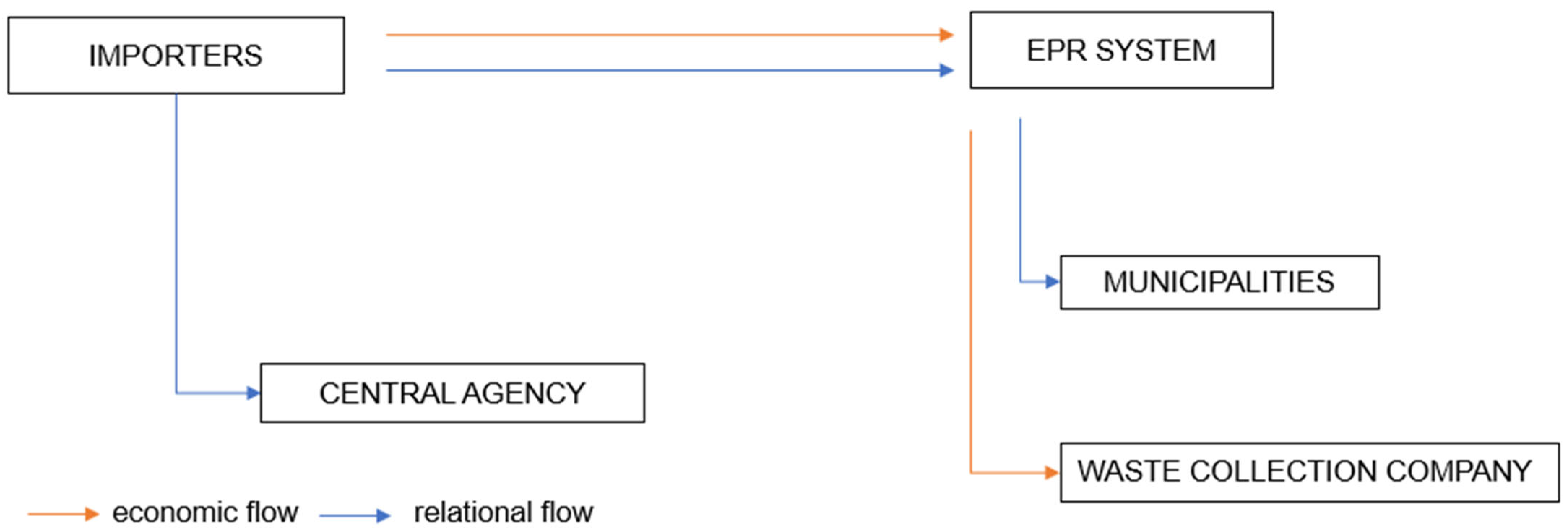

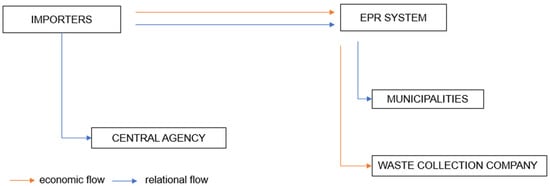

In this section we provide an overview of the packaging waste management systems analyzed: Germany, France, the United Kingdom, the Netherlands, Portugal, Denmark, Spain, and Italy. In Germany, the waste management policy relies on closed cycles and allocates waste disposal responsibilities to manufacturers and distributors of products [20], see Figure 1. Producers or distributors of packaged goods intended for final consumers shall guarantee separate collection through participation in a dual system. In 2019, the new Packaging Act replaced the reference legislation; a recent article shows how German waste legislation has evolved [21]. The recent legislative framework introduced new obligations designed to achieve ever greater transparency, control, and responsibility on the part of manufacturers regarding the packaging market.

Figure 1.

German packaging waste management model. Source: own elaboration based on [22,23].

In 2019, a central agency was established to enhance transparency in granting licenses and support executive institutions that counter licensing omissions. The agency is financed by dual systems and represents all stakeholders in the packaging sector. In addition to data released regarding consumption, the agency certifies recycling data at the national level, whereas the EPR systems offer packaging recyclability certification services. This structure is designed to guarantee greater transparency. The German Packaging Act (VerpackG) is the implementation of the European Packaging Directive into national law. The goal of this act is to prevent or reduce the impact of packaging waste on the environment. In addition to the obligations to participate in a collection system and draft an annual declaration of completeness that certifies the quantity of packaging materials placed on the German market in the previous year, the mentioned act has brought changes to Germany’s packaging disposal and recycling system, among others: an obligation to register and to communicate data related to packaging to both the agency and the chosen disposal system, and an introduction of ecological criteria. Indeed, the ordinance introduces module license fees based on ecological criteria aimed at encouraging greater use of recyclable packaging or packaging from recycled materials that systems will be required to consider when defining the costs of participation. Finally, there are changes to reuse requirements in which the act provides for an increase in packaging reuse quotas to ensure better and more frequent reuse of packaging. Table 1 summarizes Germany’s packaging management model with regard to the scheme of responsibilities adopted. It is important to examine increasingly important phenomenon of prevention policies in the packaging sector [24].

Table 1.

Responsibilities for prevention, collection, recycling, and recovery in Germany.

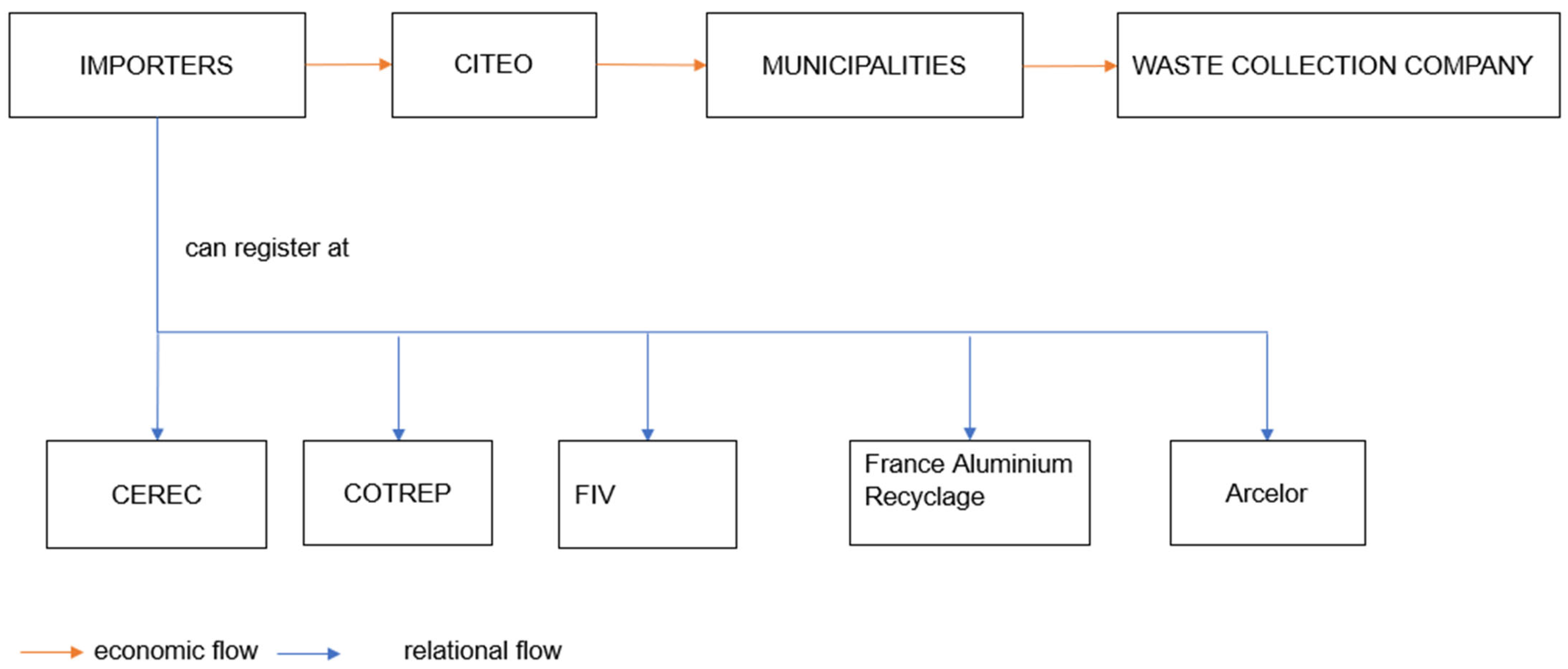

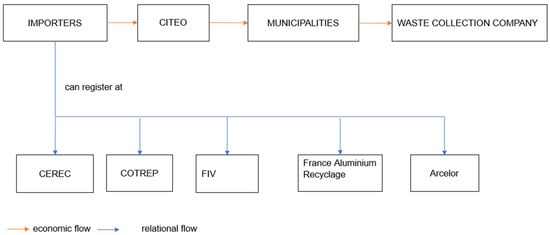

In France, municipalities can choose between three approaches to manage domestic separate waste collection; for an overview of costs and financial transfers see [26]. The first approach foresees separate waste collection via the supply chain where municipalities sign a contract for separate domestic collection with Citeo, a private, not-for-profit company with a view to reduce the environmental impact of packaging and paper.

Citeo organizes, manages, and develops the recycling of packaging placed on the French market under the extended responsibility of the producer. According to a recent study, municipalities appear to seek technical and cost efficiency gains by cooperating via municipal waste partnerships [27].

Alternatively, municipalities sign a contract for separate domestic collection with one of the business federations, as in Figure 2. Citeo proposes modulation of the contribution based on the eco-design of packaging, which has led to the practice of certifying subjects for the recyclability of packaging, specialized by material. Modulation of the environmental contribution is required by law. Modulation of the environmental contribution applies differently depending on whether users adhere to the prevention program. Modulation of the contribution is based on the degree of recyclability, the number of units that make up the packaging, and the information detailed on the label. The modulation mechanism promotes eco-design and considers the user’s innovation with regard to the packaging. Table 2 summarizes the packaging management model used in France at the level of responsibility.

Figure 2.

French packaging waste management model. Source: own elaboration based on [28,29].

Table 2.

Responsibilities for prevention, collection, recycling, and recovery in France.

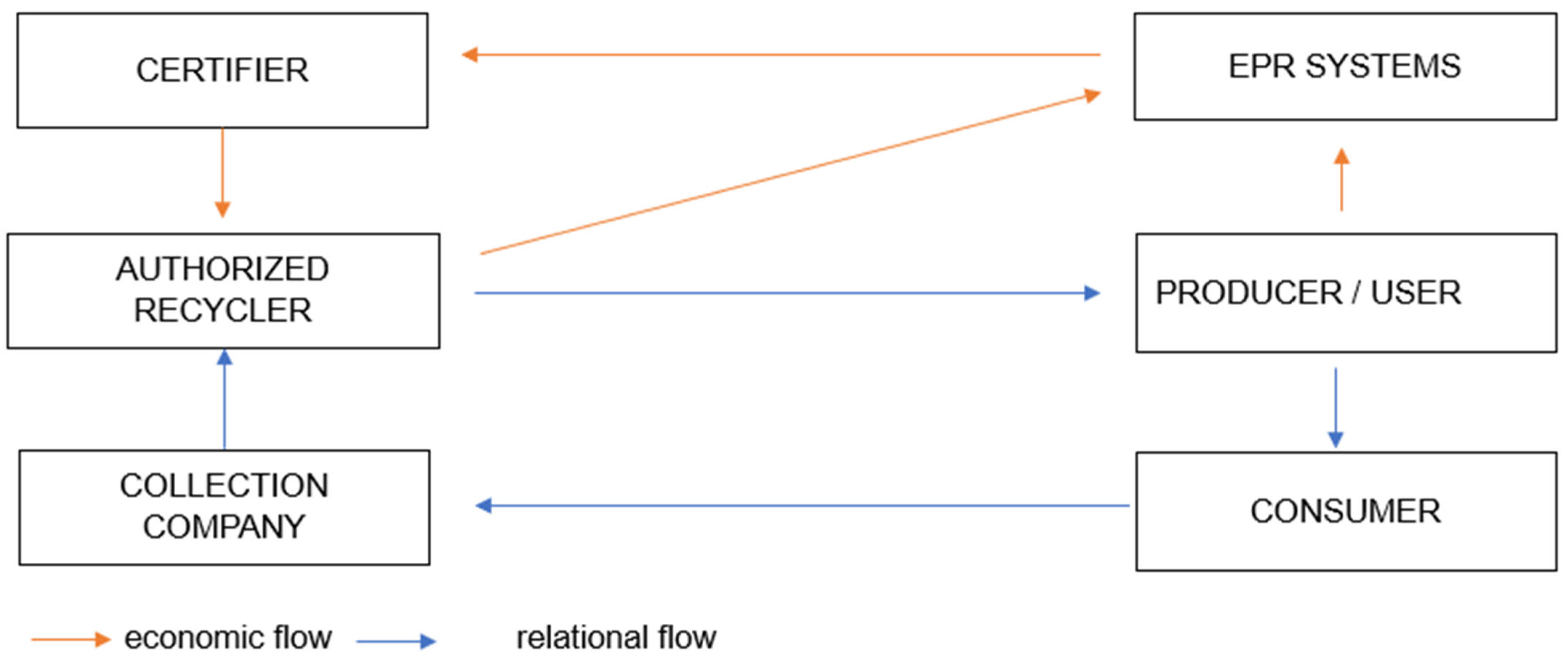

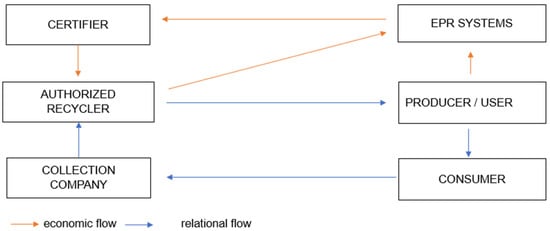

The UK system is based on recycling certificates (PRNs), which represent the amount of packaging recycled by recyclers and sold to EPR systems, see Figure 3. There are three main collection schemes: kerbside collection, household waste recycling centres, and bring sites/banks; a recent paper provides a detailed description of the collection schemes [30]. Broadly speaking, the system is based on certificate trading and is managed by a central authority. Packaging manufacturers and users must comply with the recycling obligations defined by law. To meet these obligations, manufacturers can purchase PRNs from recyclers through EPR systems. Packaging manufacturers and users can sign up for an EPR system, which registers companies and verifies that they comply with packaging recycling targets (through the purchase of recycling certificates).

Figure 3.

UK model. Source: own elaboration based on [31].

The Environment Agency, which controls the EPR systems, conducts final verification of compliance with the objectives and the actual purchase of PRNs. The PRN system relies on market mechanisms. A manufacturer/user can decide whether to self-recycle waste or have third parties recycle and purchase PRNs. Although the annual demand for PRNs is driven by producers, the PRN supply depends on multiple factors, including recycling plants, prices of noble/second raw materials, and exchange rates. Growth in this sector and the achievement of recycling objectives in the UK system depends heavily upon the performance of export markets. This system also performs accreditation of recycling data, and thus, the data are not based on user self-declarations. Table 3 summarizes the UK packaging management model with regard to the scheme of responsibilities adopted.

Table 3.

Responsibilities for prevention, collection, recycling, and recovery in the UK.

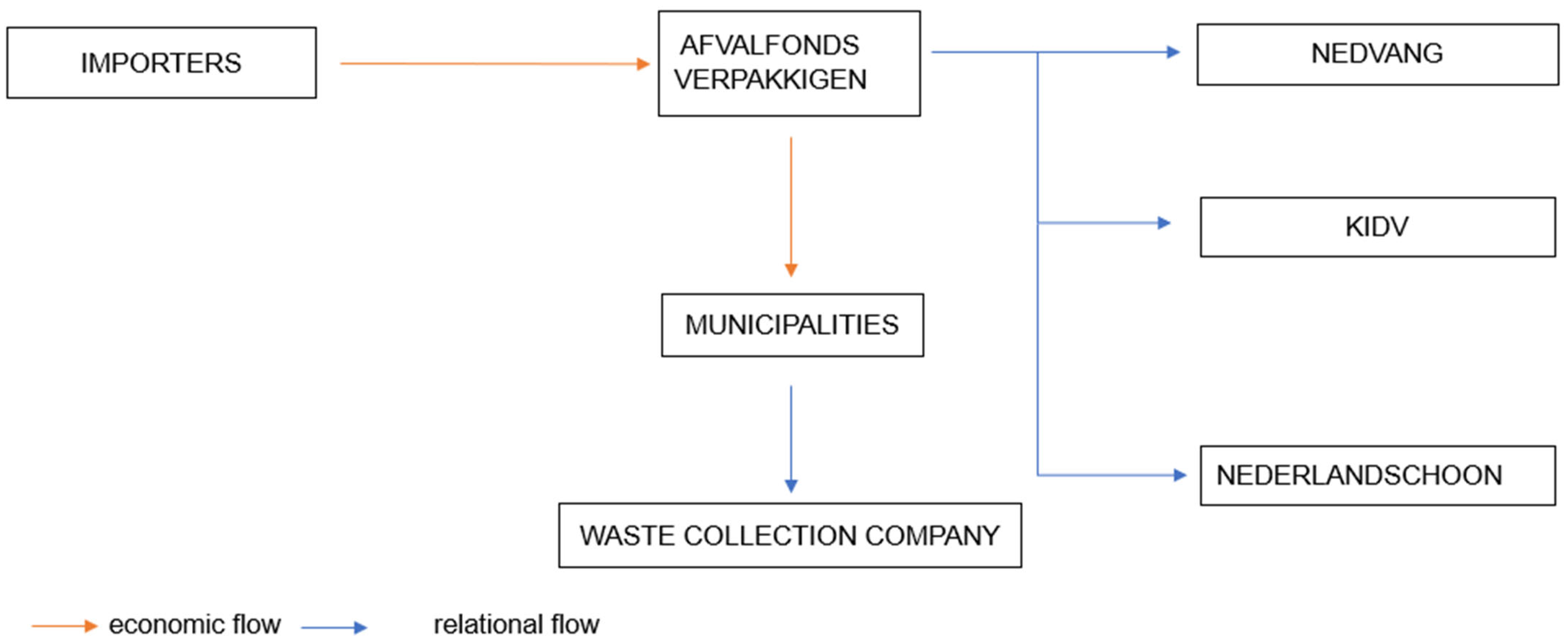

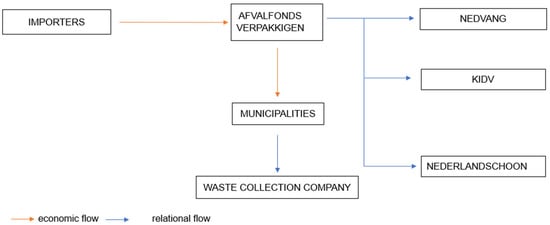

In the Netherlands, the waste management contribution agreement is binding for all manufacturers and importers of packaged products. In the Dutch system, see Figure 4, different actors are responsible for contributions to management, monitoring, and prevention of excess waste generation. Note that several municipalities and waste management companies have researched new ways to enhance the recycling of waste [32]. In addition, the literature suggests that light-weighting is a frequently applied packaging source reduction method [33]. The Waste Management Contribution Agreement is binding for all manufacturers and importers of packaged products. In the Dutch system, different actors are responsible for contributions to management, monitoring, and prevention of excess waste generation. The typical responsibilities of an EPR entity are allocated to different entities, with different legal forms and participation requirements.

Figure 4.

Dutch model. Source: own elaboration based on [34].

Nedvang, a non-profit organization, monitors and stimulates the collection of packaging waste and recommends the level of fees paid to municipalities based on the quality and quantity of separate collections. Afvalfonds Verpakkingen (AF), the Packaging Waste Fund, oversees operational management of the financing of the entire system and ensures recycling targets are achieved. In addition, AF collaborates with municipalities to finance packaging waste collection and selection, establishes contributions, and collects these contributions from obligated entities. The Packaging Waste Fund’s primary aim is to implement the packaging agreement, which is a binding waste management contribution agreement between AF and all producers and importers. AF sets up and collects the contributions for packaging waste management and entrusts other tasks to various organizations through service-level agreements and/or funding. Manufacturers and importers of packaged products are legally obligated to ensure packaging prevention, collection, and recycling. Table 4 summarizes the packaging management model of the Netherlands concerning the scheme of responsibilities.

Table 4.

Responsibilities for prevention, collection, recycling, and recovery in the Netherlands.

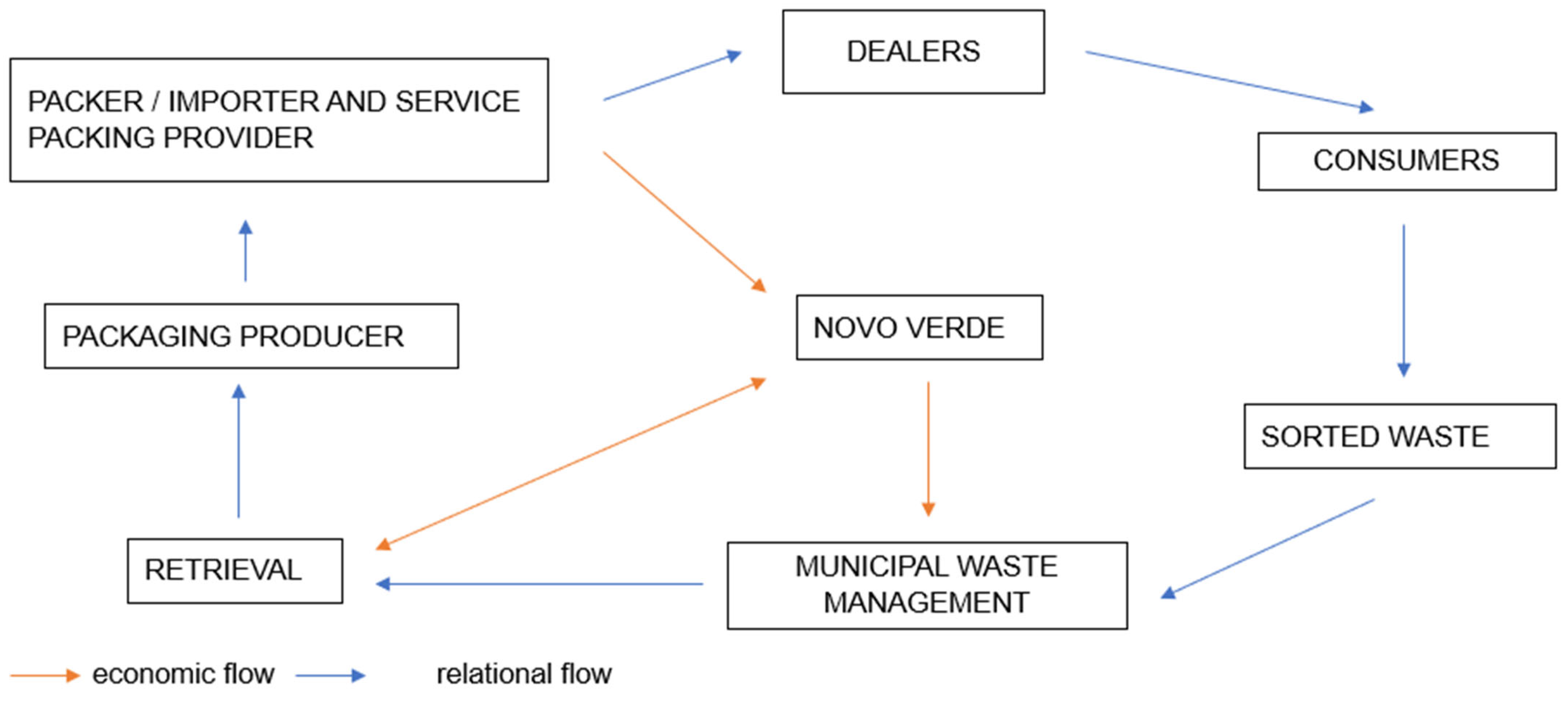

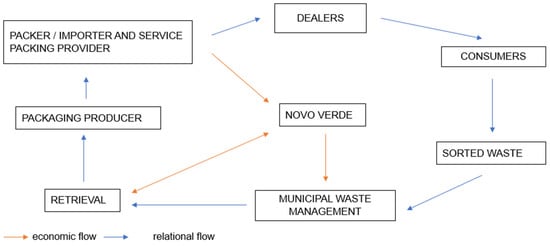

In Portugal, Figure 5 below, the EPR supports separate collection through a so-called waste exchange. The Organized Waste Market (MOR) is an electronic platform for waste trading targeted toward industrial and household wastes not covered by sorting. The MOR allows waste producers/holders to sell waste to management/recycling companies. This mechanism increases the liquidity of the system and reduces bureaucratic constraints. The platform management company validates transactions and interfaces with market participants. In addition, it is responsible for financing the MOR through an annual fee and a percentage of the value transacted. For recycling and recovery of municipal, non-reusable packaging waste, producers and importers of goods packaged in Portugal must alternatively join the Sociedade Ponto Verde (SPV) compliance scheme, which is a non-profit system, adhere to the compliance scheme, which is a for-profit system where membership involves paying a fee to co-finance the collection, recycling, and recovery of packaging materials, or organize their own collection and recycling system (self-compliance). By law, the responsibility for the management and final destination of packaging waste lies with the packaging companies or importers who place packaged products on the market. It is important to recall the functions of the SPV that finances the collection and separation of packaging that enters municipal waste, steers the recycling of separate collections and selling of packaging to recyclers, monitors packaging to ensure that it reaches the correct final destination, and supports research programs.

Figure 5.

Portuguese model. Source: own elaboration based on [35].

Manufacturers and importers pay a fee to co-finance the collection, recycling, and recovery of packaging materials. Novo Verde, in turn, finances the municipal waste management service and waste recovery centers. Table 5 summarizes the packaging management model of Portugal with regard to the scheme of responsibilities.

Table 5.

Responsibilities for prevention, collection, recycling, and recovery in Portugal.

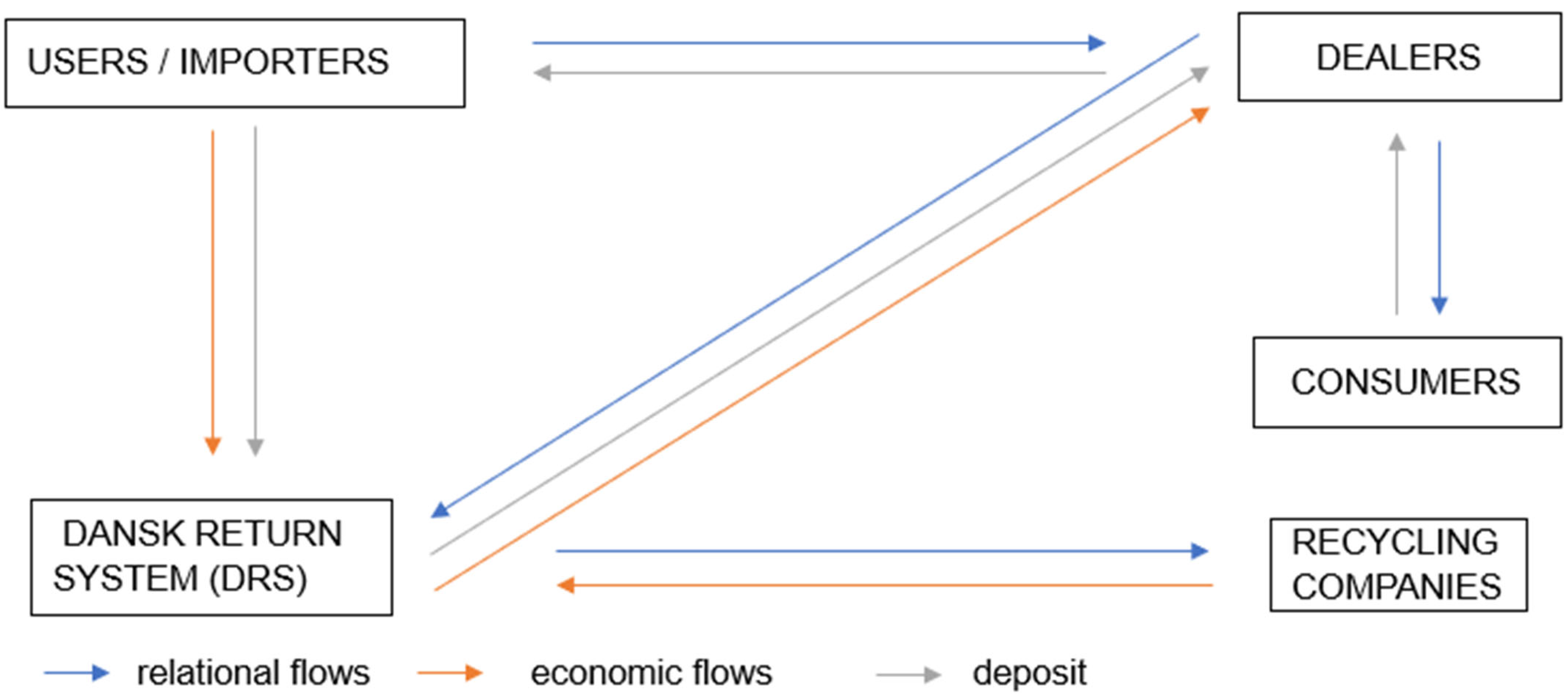

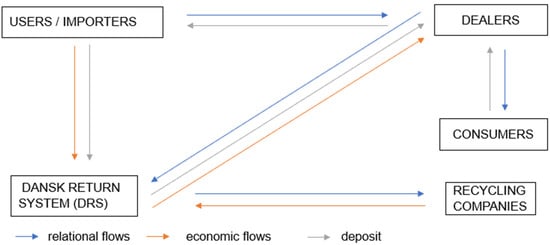

In Denmark, a packaging recycling system with a deposit system operated by the non-profit Dansk Return System (DRS) exists as in Figure 6. Users and importers must register themselves and register their products in the DRS; pay the deposit on packaging to the DRS; and contribute to the DRS to cover logistics and collection costs, proportional to the packaging volume and differentiated by the type of packaging. Distributors can subscribe to the DRS for free; however, they must pay the deposit to the producers and set up collection points for used packaging. Consumers must pay the deposit on the packaging they purchase and return the used packaging to the distributors.

Figure 6.

Danish model. Source: [31,36].

The DRS must collect used packaging free of charge, return the deposit to the distributors and cover their collection management costs, and initiate recycling of the material. To collect and recycle/recover non-reusable beverage packaging waste, domestic producers and beverage importers in Denmark must register with the DRS deposit system. The DRS is a non-profit system that receives revenue from three sources: the sale of material from bottles and cans to companies that process these materials and produce new packaging, and the taxes manufacturers and importers pay for shipping a mortgaged bottle or can on the market. The deposit system involves six actors: Companies that import or produce beverages marketed in Denmark must register with the Danish storage system. Suppliers pay a deposit to the DRS when they send new bottles and cans of beverages to the market. The deposit is held until it is paid to a store or consumer, shop, restaurant, etc.; here, consumers can buy drinks with a mortgage. These establishments must register with the deposit system to collect empty bottles and storage cans. Denmark has a deposit system that guarantees the recycling of disposable packaging of plastic, aluminum, and beverage glass. The DRS operates the Danish deposit system for disposable packaging. Breweries own the system, and the directing board also includes retail representatives and importers. The Ministry oversees the DRS and assesses its performance before a new period of exclusive rights is granted. Finally, when empty bottles and cans leave the DRS, they are taken to facilities that specialize in recycling them for new glass, plastic, and metal products. In this process, the quality of the materials is preserved so that they can become new beverage packaging. Table 6 summarizes the packaging management model of Denmark with regard to the scheme of responsibilities.

Table 6.

Responsibilities for prevention, collection, recycling, and recovery in Denmark.

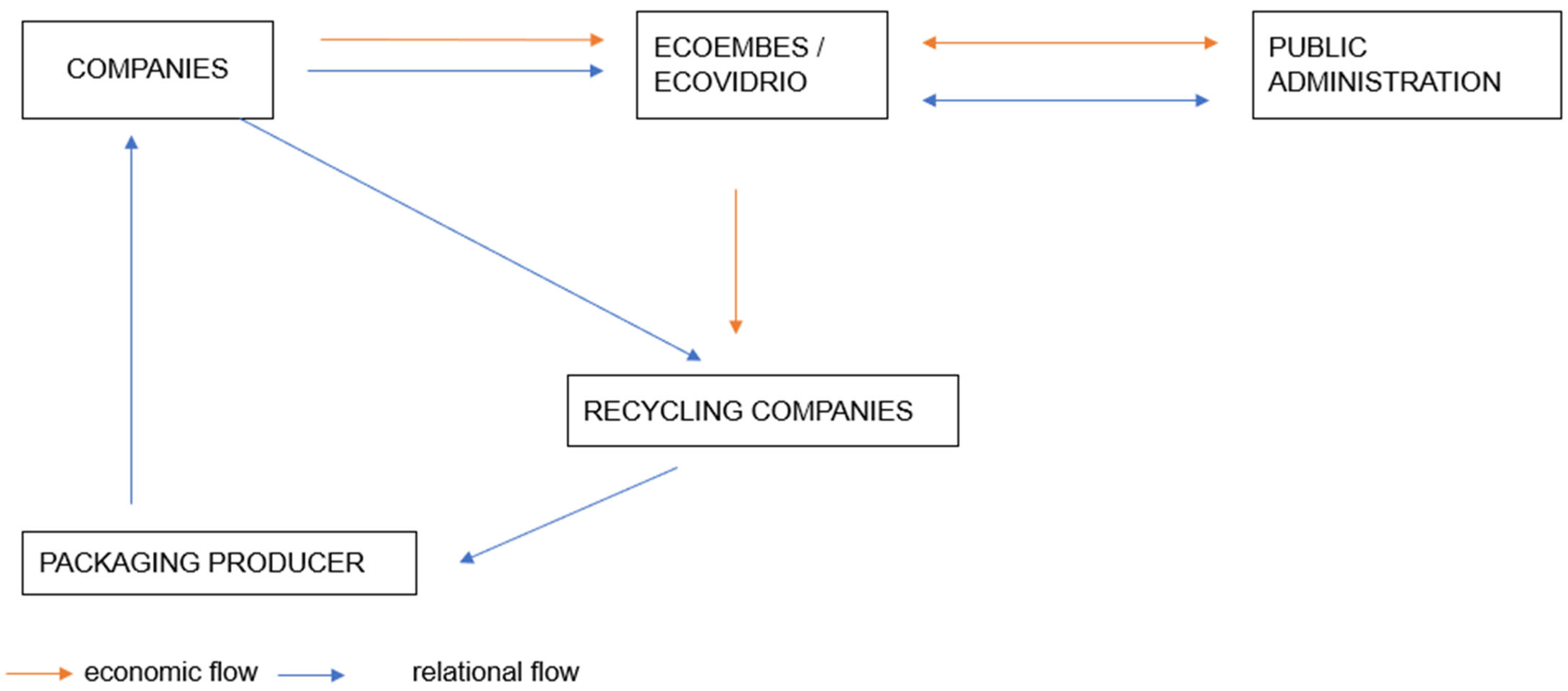

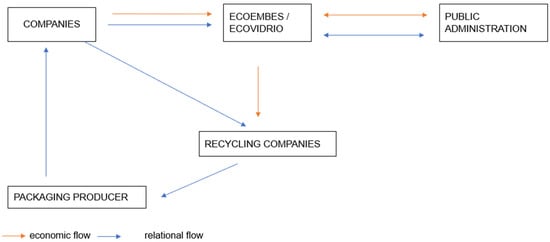

In Spain, to recycle and recover non-glass packaging waste (present in municipal waste), producers or importers of goods packaged must participate in Ecoembes, a non-profit compliance scheme as in Figure 7. For an overview of EPR policies for the packaging waste in Spain and Portugal, as well as the impact throughout the years in both countries, see [37]. For collecting and recycling glass packaging waste, manufacturers or importers of goods packed in glass in Spain must register with the Ecovidrio compliance scheme.

Figure 7.

Spanish model. Source: own elaboration based on [38,39].

To manage packaging and industrial waste assimilated into municipal waste, companies can take advantage of the service offered by Ecoembes or organize themselves independently (self-compliance). The system covers light packaging and paper cardboard. Authorizations for integrated management systems are granted to autonomous communities. Companies rely on Ecoembes to fulfill their legal obligations regarding waste management through the annual declaration of packaging and tax payment. The model is funded through a proportional contribution system involving all participating actors. The tariff is designed so that the income obtained from the system covers the difference between the expected expenses for collecting and sorting packaging waste and the revenues from the sale of recovered materials to recycling companies. At the other end of the recycling chain, Ecoembes compensates local authorities for the additional costs they incur compared to the costs of the ordinary waste collection, transport, and treatment system, within the terms set out in the cooperation agreement. Ecovidrio was established due to the need of companies to fulfill the extended responsibilities of the manufacturers. For the system to function properly, close collaboration is needed between packaging companies, public administrations, the Horeca sector, and citizens. In this sense, every actor has an important role to play. Placement of bins and management of glass packaging waste collection are based on two different management systems: the town hall carrying out the collection and financing the total cost, or directly carrying out the necessary tasks to ensure selective collection using bins. Table 7 summarizes the packaging management model of Spain with regard to the scheme of responsibilities.

Table 7.

Responsibilities for prevention, collection, recycling, and recovery in Spain.

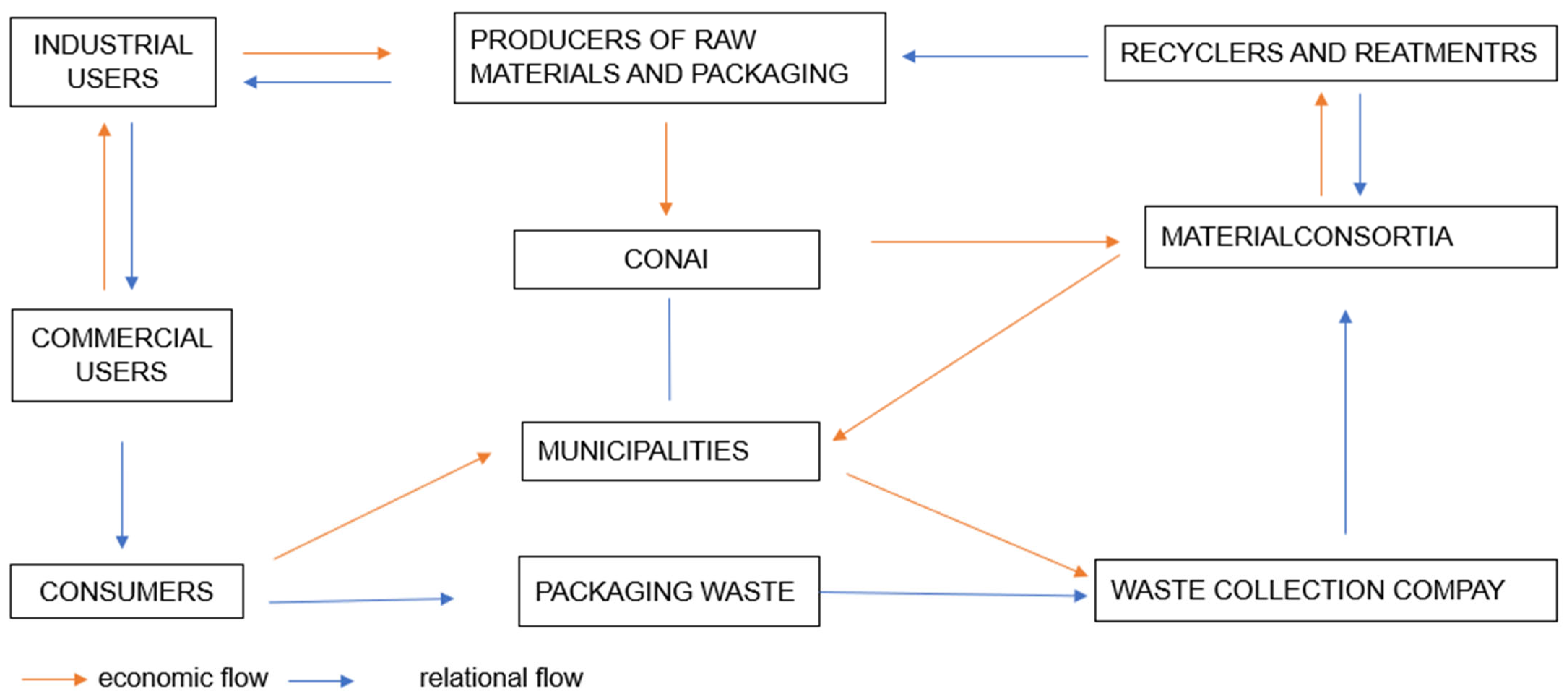

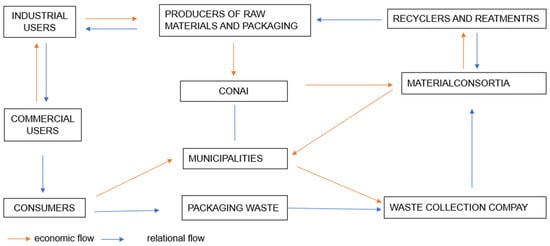

In Italy, packaging manufacturers can independently organize the management of their packaging waste throughout the national territory, or they can join the Conai, a non-profit consortium and compliance scheme, see Figure 8. The consortium system aims to achieve the overall target of recycling and recovering packaging across the country and, at the same time, ensure that targeted management policies are implemented, including prevention policies, through eco-innovation. In addition, Conai guarantees compliance with the principle of extended producer responsibility, allocating the environmental contribution (CAC) among producers and users. Within the system, the producer/user pays the CAC according to the type of packaging, which is given to the specific material consortia; in addition, a share goes to covering running expenses, which, in turn, pays a compensation to municipalities under the agreement between the consortium and the national association of municipalities (ANCI) to cover the additional charges resulting from the separate collection of packaging.

Figure 8.

Italian model. Source: own elaboration based on [40].

Among other functions, Conai promotes, manages, and coordinates the activity of separate collections of packaging waste according to the criteria of efficiency, effectiveness, and cost-effectiveness, ensures the objectives of recovery and recycling of packaging waste as required by law are achieved, supervises cooperation between the consortia and other economic operators, defines the fee for the management of packaging waste be-tween producers and users, i.e., the environmental contribution on consortium members, incentivizes the respect of the waste hierarchy, such as support for research and innovation in advanced recycling technologies, and encourages the recycling and recovery of raw materials. Table 8 summarizes the Italian packaging management model with regard to the scheme of responsibilities.

Table 8.

Responsibilities for prevention, collection, recycling, and recovery in Italy.

4. Discussion

Based on the results presented in the overview of packaging waste management models, we discuss each model hereafter. A dual waste collection system operates in Germany alongside municipal undifferentiated collection. This system was established to ensure the recovery and recycling of packaging waste. Participation in a dual system involves the conclusion of a contract, which is based on estimates of the quantities the producer/distributor plans to export annually. Based on these quantities, the disposal cost of each material is determined. With the new Packaging Act, Germany seeks to increase the recycling rates of the materials that make up the packaging of products. Manufacturers are called upon to take greater responsibility for the reuse, recycling, and disposal of their packaging. The system allows for high-quality recycling; for example, plastic bottles can thus be transformed into new bottles for food use via a process known as “bottle to bottle”, which involves effective and dispersion-free use cycles.

The French model is characterized by a central coordination agency that defines the environmental contribution, which varies according to a malus/bonus system based on the recyclability of packaging. The variation of the contribution favors users and importers who adhere to the prevention program guidelines. Authorities that certify the recyclability of packaging provide support services to users for eco-design activities.

The British system is based on recycling certificates exchanged through a dedicated platform. The PRN system is based on market mechanisms in which a producer/user can decide whether to self-recycle waste or have third parties recycle and purchase PRNs. The sale of PRNs affects the prices of secondary raw materials.

The Dutch system is characterized by companies that have three purposes (i.e., de-termination of the environmental contribution, monitoring to ensure correct management along the supply chain, and communication). AF ensures the achievement of recycling targets, collaborates with municipalities to finance the collection and selection of pack-aging waste, and establishes contributions and collects them from obligated entities. Nedvang monitors and promotes the collection of packaging waste, has the power of sanction, tabulates recycling data, and recommends the fees to be paid to municipalities based on the quality and quantity of the different wastes collected. The Portuguese system is characterized by a platform for buying and selling waste that provides an intersection between supply and demand that favors development of the market. The Portuguese system is a potentially interesting mechanism for the development of secondary raw material markets. The mechanism of waste exchange is complementary to the separate collection on the public surface, increasing the ease of introducing waste exchange in countries with a consolidated separate collection system.

With respect to Denmark, Danish local authorities oversee the collection, transport, and disposal of waste, and many private and public companies separate and pre-treat certain types of waste before it is exported abroad. The Beverage Packaging Deposit Ordinance of 2001 instituted a deposit-return system for beverage packaging that remains one of the most efficient collection systems in the world. The DRS is controlled by the Danish Ministry of Environment and Food and was granted the exclusive right to operate the return and deposit system until 2020. The main activities of the DRS include collecting payments from importers and producers from whom the commission on the deposit is owed.

The Spanish model relies on the payment of environmental contributions to co-finance the separate collection, recycling, and recovery of materials. For non-glass packaging waste, manufacturers/importers participate in the Ecoembes compliance scheme. For glass packaging, they participate in the Ecovidrio compliance scheme.

In Italy, Conai is based on the shared responsibility principle, relying on the involvement of all the players in waste management: from the companies who produce and use packaging, to the public administrations that establish the rules of waste management in the territories, to citizens whose daily actions when separating waste initiate a virtuous process for the environment, all the way to the recycling companies.

Conai is therefore committed to a path of support for local authorities in planning the associated management of the waste cycle. Another topic that Conai faces is the regional differential regarding the collection and treatment of waste. Although there are advantages in the simplifications made to map the governance of different packaging waste management models, some limits are unavoidable. The main limitations of this study are the lack of empirical data on the actual costs of operation of the various systems examined, the different roles the public institutions play in the functioning of the market, and the necessary graphic simplification of the analyzed systems, which therefore causes the loss of some information. Finally, although significant, the number of countries considered should be extended to all 27 EU countries.

5. Conclusions

The circular economy is central to the European Green Deal strategy, and the positive effects in terms of competitiveness and social well-being in rethinking economic models to make them circular are increasingly evident. With this in mind, the European Commission presented an action plan whose main objective is to promote growth by reducing the carbon footprint and the efficient use of resources. Therefore, packaging waste management systems can be considered prominent pillars in national waste management strategies to meet such ambitious recycling targets by 2030. The above is particularly true given that countries are asked to meet higher recycling targets if they want to comply with European legislation and there is evidence demonstrating that increasing quantities of packaging waste, which causes environmental problems, are being produced. Consequently, it is necessary to identify functional packaging waste management systems to achieve these targets effectively and efficiently. Given that for benchmarking purposes, comparable information is needed, one should also consider that packaging waste models across European countries are heterogeneous at the time of this writing. In addition, non-harmonized laws in force across countries, autonomous recycling targets, and constant updates represent barriers to the transition towards a more integrated market. To fill this gap, we compared responsibilities for prevention, collection, recycling, and recovery, and an overview of some models with respect to the general governance and functioning of the systems. Our results provide insights from the following cases: Germany, France, the United Kingdom, the Netherlands, Portugal, Denmark, Spain, and Italy. In addition, policy implications emerge as our insights help overcome barriers in the European market’s development caused by the different rules for packaging management and design, serving policymakers that aim to harmonize the management of packaging waste. To conclude, it is important to highlight the importance of people and future generations that can also play a role in moving towards a more circular economy with respect to packaging waste minimization and recycling. Indeed, this is starting from the idea that one of the most prominent drivers of product design and usage is people’s acceptance of such products.

Author Contributions

Both authors jointly contributed to all sections of the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No empirical data analysis.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jang, Y.-C.; Lee, G.; Kwon, Y.; Lim, J.; Jeong, J. Recycling and Management Practices of Plastic Packaging Waste towards a Circular Economy in South Korea. Resour. Conserv. Recycl. 2020, 158, 104798. [Google Scholar] [CrossRef]

- Pinos, J.; Hahladakis, J.N.; Chen, H. Why Is the Generation of Packaging Waste from Express Deliveries a Major Problem? Sci. Total Environ. 2022, 830, 154759. [Google Scholar] [CrossRef]

- Di Foggia, G.; Beccarello, M. Designing Waste Management Systems to Meet Circular Economy Goals: The Italian Case. Sustain. Prod. Consum. 2021, 26, 1074–1083. [Google Scholar] [CrossRef]

- Franz, R.; Welle, F. Recycling of Post-Consumer Packaging Materials into New Food Packaging Applications—Critical Review of the European Approach and Future Perspectives. Sustainability 2022, 14, 824. [Google Scholar] [CrossRef]

- Rodrigues, A.P.; Fernandes, M.L.; Rodrigues, M.F.F.; Bortoluzzi, S.C.; Gouvea da Costa, S.E.; Pinheiro de Lima, E. Developing Criteria for Performance Assessment in Municipal Solid Waste Management. J. Clean. Prod. 2018, 186, 748–757. [Google Scholar] [CrossRef]

- Jacobsen, R.; Buysse, J.; Gellynck, X. Cost Comparison between Private and Public Collection of Residual Household Waste: Multiple Case Studies in the Flemish Region of Belgium. Waste Manag. 2013, 33, 3–11. [Google Scholar] [CrossRef]

- Simões, P.; Marques, R.C. On the Economic Performance of the Waste Sector. A Literature Review. J. Environ. Manag. 2012, 106, 40–47. [Google Scholar] [CrossRef]

- Colasante, A.; D’Adamo, I.; Morone, P.; Rosa, P. Assessing the Circularity Performance in a European Cross-Country Comparison. Environ. Impact Assess. Rev. 2022, 93, 106730. [Google Scholar] [CrossRef]

- Lavigne, C.; De Jaeger, S.; Rogge, N. Identifying the Most Relevant Peers for Benchmarking Waste Management Performance: A Conditional Directional Distance Benefit-of-the-Doubt Approach. Waste Manag. 2019, 89, 418–429. [Google Scholar] [CrossRef]

- Lu, W.; Chen, X.; Peng, Y.; Shen, L. Benchmarking Construction Waste Management Performance Using Big Data. Resour. Conserv. Recycl. 2015, 105, 49–58. [Google Scholar] [CrossRef] [Green Version]

- Ilić, M.; Nikolić, M. Waste Management Benchmarking: A Case Study of Serbia. Habitat Int. 2016, 53, 453–460. [Google Scholar] [CrossRef]

- Zaman, A.U.; Swapan, M.S.H. Performance Evaluation and Benchmarking of Global Waste Management Systems. Resour. Conserv. Recycl. 2016, 114, 32–41. [Google Scholar] [CrossRef]

- Mills, A.J.; Durepos, G.; Wiebe, E. Multiple-Case Design. Encycl. Case Study Res. 2010, I, 868–870. [Google Scholar]

- Hastings, S.L. Triangulation. Encycl. Res. Des. 2010, I, 1538–1541. [Google Scholar]

- Mueller, C.W. Conceptualization, Operationalization, and Measurement. SAGE Encycl. Soc. Sci. Res. Methods 2004, 162–166. [Google Scholar]

- Santos, F.M.; Eisenhardt, K.M. Multiple Case Study. SAGE Encycl. Soc. Sci. Res. Methods 2004, I, 685–686. [Google Scholar]

- Khandker, S.R.; Koolwal, G.B.; Samad, H.A. Handbook on Impact Evaluation; The World Bank: Washington, DC, USA, 2010; Volume 41, ISBN 9780821380284. [Google Scholar]

- Di Foggia, G.; Beccarello, M. Improving Efficiency in the MSW Collection and Disposal Service Combining Price Cap and Yardstick Regulation: The Italian Case. Waste Manag. 2018, 79, 223–231. [Google Scholar] [CrossRef]

- Ellsworth-Krebs, K.; Rampen, C.; Rogers, E.; Dudley, L.; Wishart, L. Circular Economy Infrastructure: Why We Need Track and Trace for Reusable Packaging. Sustain. Prod. Consum. 2022, 29, 249–258. [Google Scholar] [CrossRef]

- Nelles, M.; Grünes, J.; Morscheck, G. Waste Management in Germany—Development to a Sustainable Circular Economy? In Proceedings of the Procedia Environmental Sciences, 1 January 2016; Elsevier; Volume 35, pp. 6–14. Available online: https://www.sciencedirect.com/science/article/pii/S1878029616300901 (accessed on 3 March 2022).

- Dornack, C. Waste Policy for Source Separation in Germany BT—Source Separation and Recycling: Implementation and Benefits for a Circular Economy; Maletz, R., Dornack, C., Ziyang, L., Eds.; Springer: Cham, Switzerland, 2018; pp. 3–10. ISBN 978-3-319-69072-8. [Google Scholar]

- PREVENT Waste Alliance. How Germany’s EPR System for Packaging Waste Went from a Single PRO to Multiples PROs with a Register; GIZ: Bonn, Germany, 2020. [Google Scholar]

- Zentrale Stelle Essential Questions for Implementing the Verpackungsgesetz (Packaging Act). Available online: https://www.verpackungsregister.org/en (accessed on 3 March 2022).

- Tencati, A.; Pogutz, S.; Moda, B.; Brambilla, M.; Cacia, C. Prevention Policies Addressing Packaging and Packaging Waste: Some Emerging Trends. Waste Manag. 2016, 56, 35–45. [Google Scholar] [CrossRef]

- Italian Packaging Institute Vademecum for Packaging Waste Environmental Management [Vademecum per La Gestione Ambientale Degli Imballaggi]; Milan (IT). 2018. Available online: https://www.certifico.com/ambiente/documenti-ambiente/248-documenti-ambiente-enti/5776-vademecum-per-la-gestione-ambientale-degli-imballaggi (accessed on 7 March 2022).

- Cabral, M.; Ferreira, S.; Simões, P.; da Cruz, N.F.; Marques, R.C. Financial Flows in the Recycling of Packaging Waste: The Case of France. Pol. J. Environ. Stud. 2013, 22, 1637–1647. [Google Scholar]

- De Jaeger, S.; Rogge, N. Cost-Efficiency in Packaging Waste Management: The Case of Belgium. Resour. Conserv. Recycl. 2014, 85, 106–115. [Google Scholar] [CrossRef]

- CITEO. Annual Report [Report Annuel]; CITEO: Paris, France, 2021. [Google Scholar]

- Cotrep. Recyclability of Plastic Packaging. Improving Recycling through Eco-Design; Cotrep: Paris, France, 2022. [Google Scholar]

- Hahladakis, J.N.; Purnell, P.; Iacovidou, E.; Velis, C.A.; Atseyinku, M. Post-Consumer Plastic Packaging Waste in England: Assessing the Yield of Multiple Collection-Recycling Schemes. Waste Manag. 2018, 75, 149–159. [Google Scholar] [CrossRef]

- Marchi, A. European Packaging Waste Systems at Glance [Sintesi Comparativa Di Alcuni Sistemi Di Imballaggio in Europa]; CESISP: Milan, Italy, 2022. [Google Scholar]

- Goorhuis, M.; Reus, P.; Nieuwenhuis, E.; Spanbroek, N.; Sol, M.; van Rijn, J. New Developments in Waste Management in the Netherlands. Waste Manag. Res. 2012, 30, 67–77. [Google Scholar] [CrossRef]

- van Sluisveld, M.A.E.; Worrell, E. The Paradox of Packaging Optimization—A Characterization of Packaging Source Reduction in the Netherlands. Resour. Conserv. Recycl. 2013, 73, 133–142. [Google Scholar] [CrossRef]

- Afvalfonds Verpakkingen Public Report. Recycling in the Circular Economy [Verpakkingen in de Circulaire Economie]. 2021. Available online: https://www.afvalfondsverpakkingen.nl/sites/default/files/2022-03/Publieksverslag2020.pdf (accessed on 26 April 2022).

- Novo Verde Packaging Waste Management Compliance Scheme Chain. Available online: https://novoverde.pt/en/packaging-waste-management-integrated-system/ (accessed on 7 March 2022).

- PwC Reports and Studies: Packaging Management. Available online: https://www.strategyand.pwc.com/it/en/insights/report-search.html (accessed on 4 February 2022).

- Rubio, S.; Ramos, T.R.P.; Leitão, M.M.R.; Barbosa-Povoa, A.P. Effectiveness of Extended Producer Responsibility Policies Implementation: The Case of Portuguese and Spanish Packaging Waste Systems. J. Clean. Prod. 2019, 210, 217–230. [Google Scholar] [CrossRef]

- Ecovidrio Ecovidrio System. Available online: https://www.ecovidrio.es/asi-funciona-el-sistema/el-modelo-en-espana (accessed on 3 March 2022).

- Ecoembres Ecoembres System. Available online: https://www.ecoembes.com/en/node/42 (accessed on 3 February 2022).

- CONAI. Green Economy Report; CONAI: Milan, Italy, 2021. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).