Evaluating the Thermal Behavior of a Sustainable Room and Roof Prototype Using Recycled Waste Materials

Abstract

1. Introduction

2. Materials and Methods

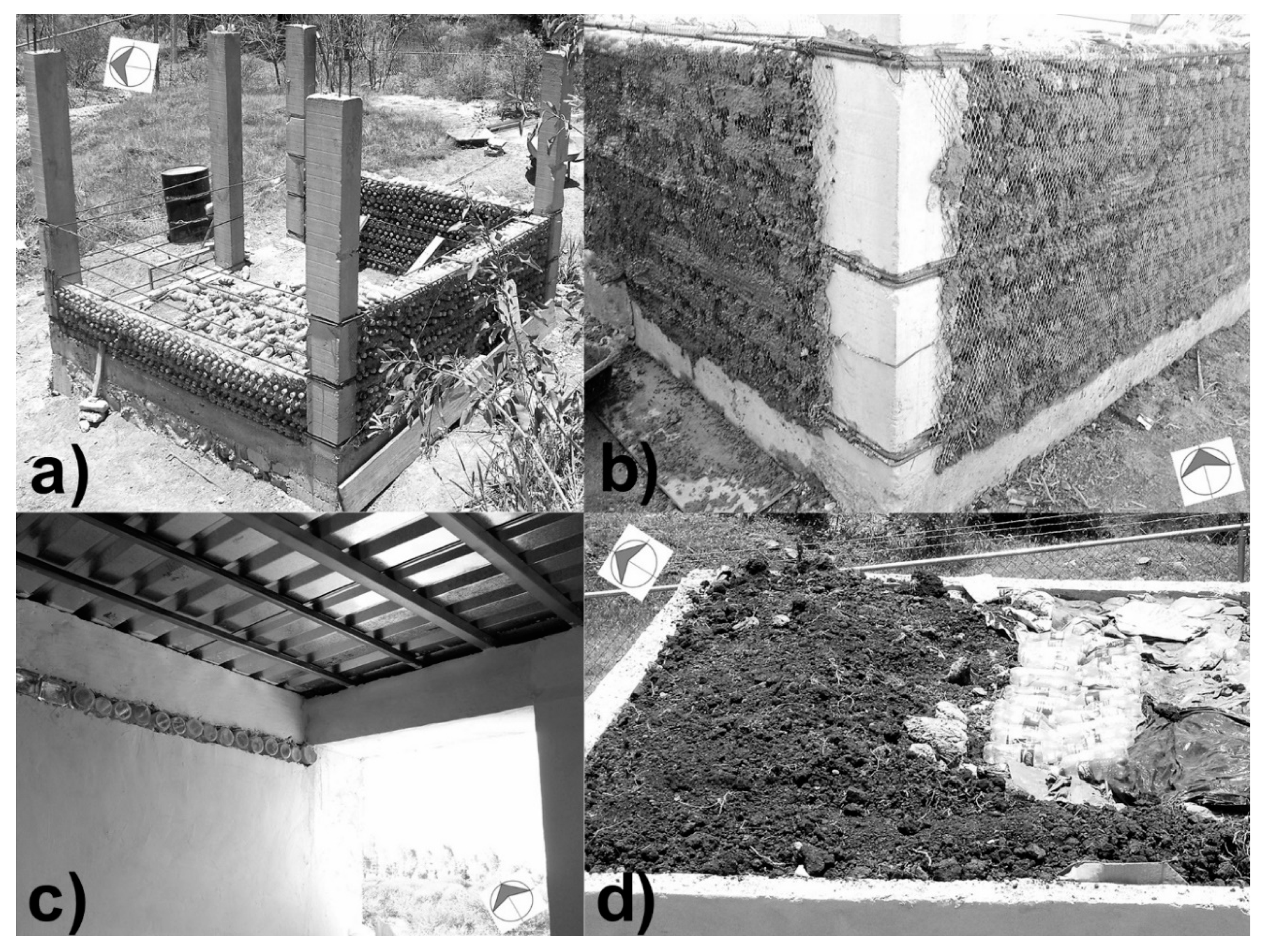

2.1. Construction of Room Prototype

2.1.1. Stone Masonry Foundations and Reinforced Concrete Columns

2.1.2. PET Bottle Filling with Soil

2.1.3. The Construction of PET Bottle Walls

2.1.4. Confinement Perpendicular to the Walls

2.1.5. Wrapping with Galvanized Wire Nets

2.1.6. Covering Walls with Mortar

2.1.7. Area for Skylights

2.1.8. Multi-Layered Roof

2.2. Measuring External and Internal Climatic Conditions: Humidity and Temperature

2.2.1. Internal

2.2.2. External

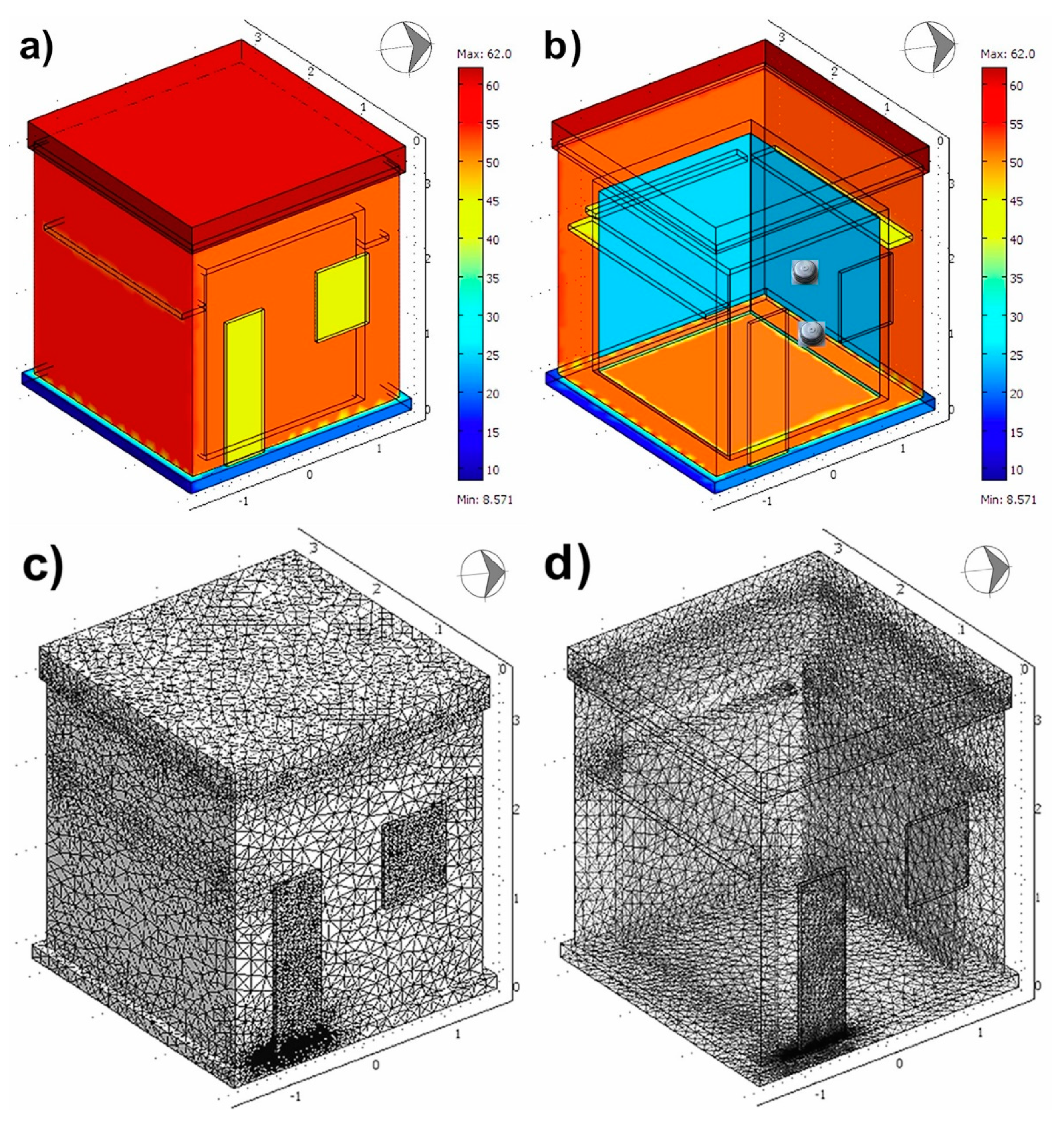

2.3. Simulation of Thermal Transference at the Prototype Building

- Geometrical details of room prototype. This could be drawn within the software or imported from other specialized design software.

- Specification of conditions of each subdomain from the prototype to be evaluated, in this case: walls, windows, doors, roof, and foundations. Table 1A shows each condition used.

- Specification of boundary and initial conditions for the structure. The room was sectioned into parts as necessary to establish different conditions. The specifications are shown in Table 1B. These boundary conditions were chosen in part based on characteristics of the prototype and, in part, based on thermal images and other measured properties or dimensions.

- Setting temperature and average radiation of the areas.

- Solving the simulated system.

3. Results and Discussion

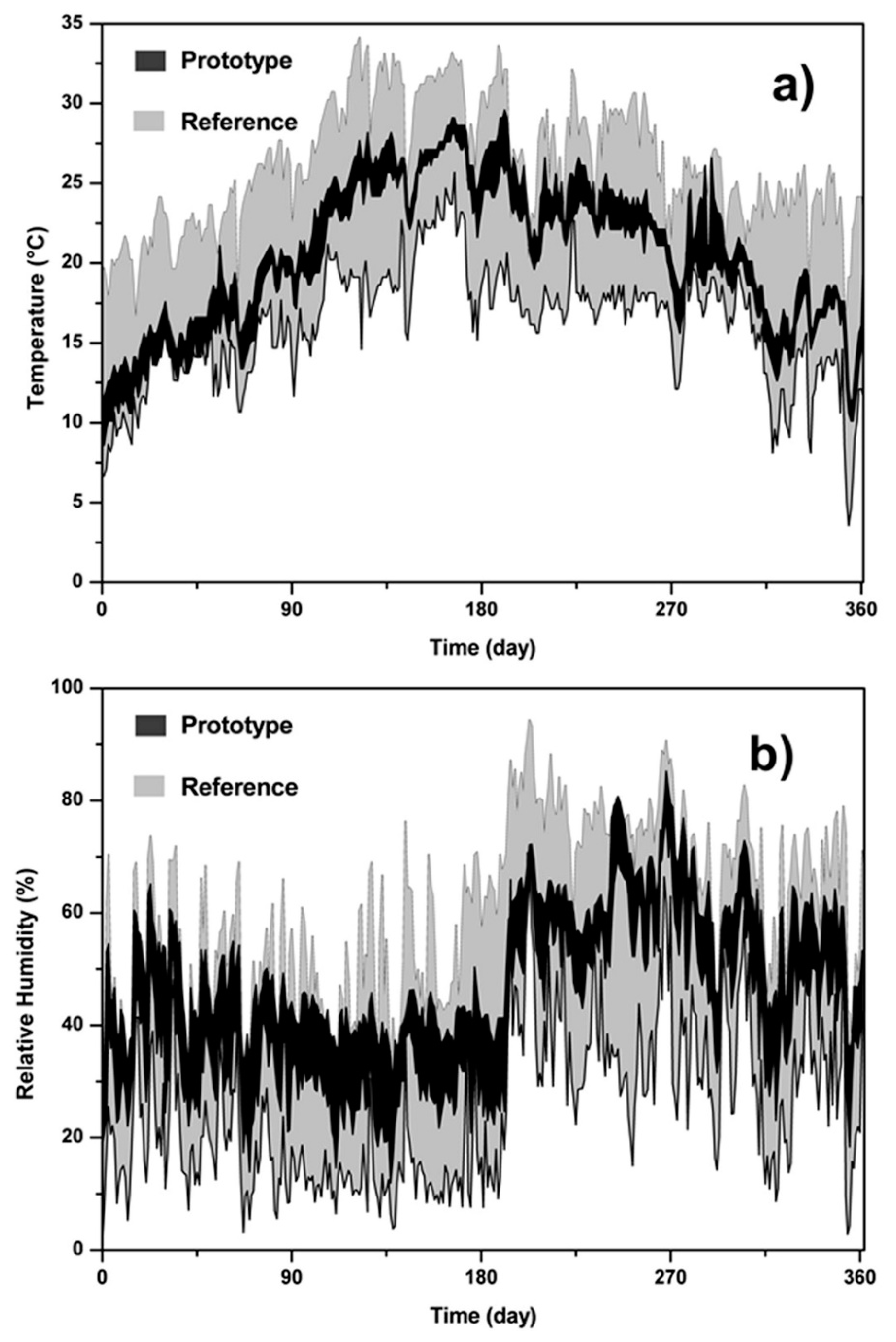

3.1. Temperature and Relative Humidity

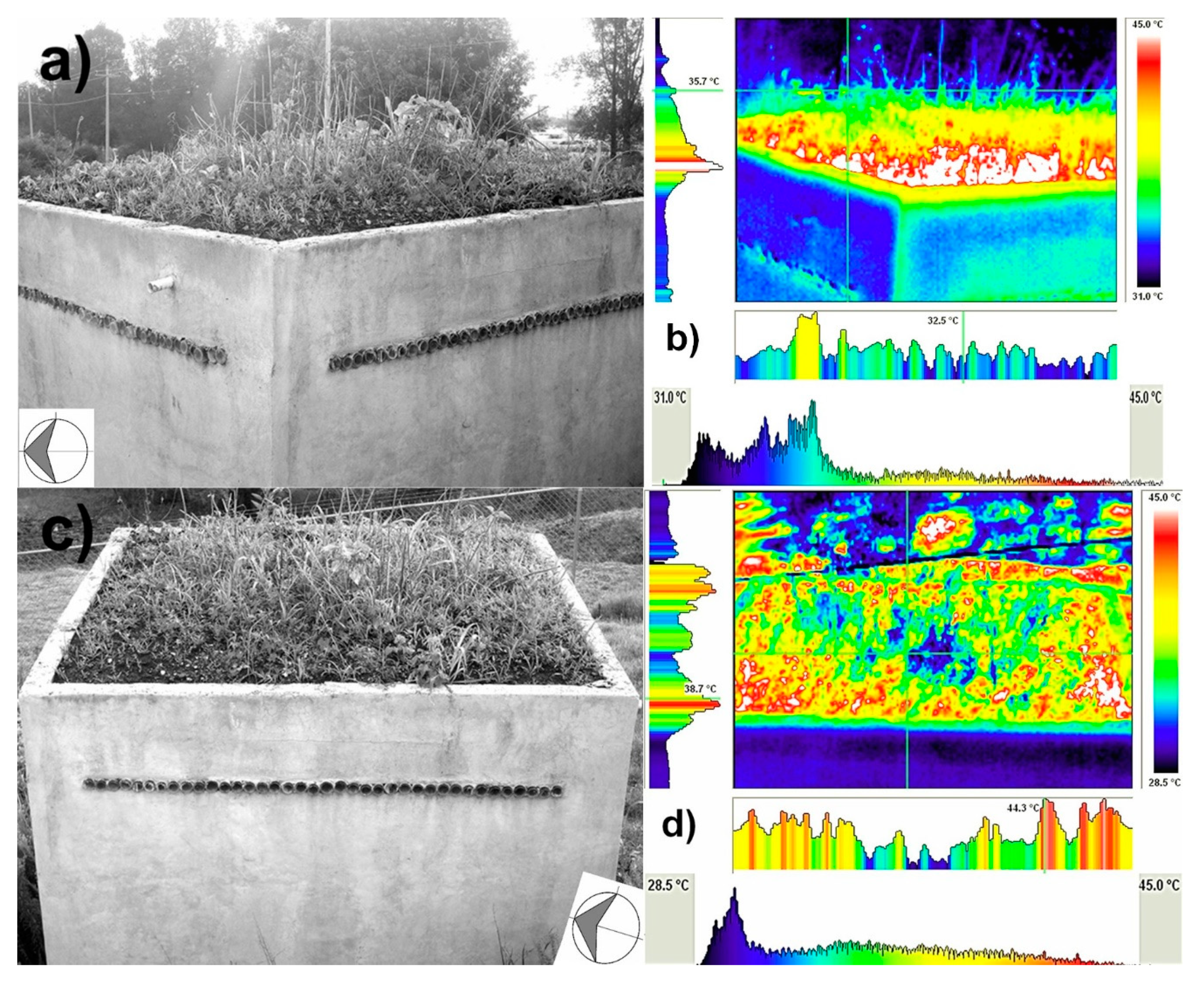

3.2. Thermograph Images and Humidity on Surfaces

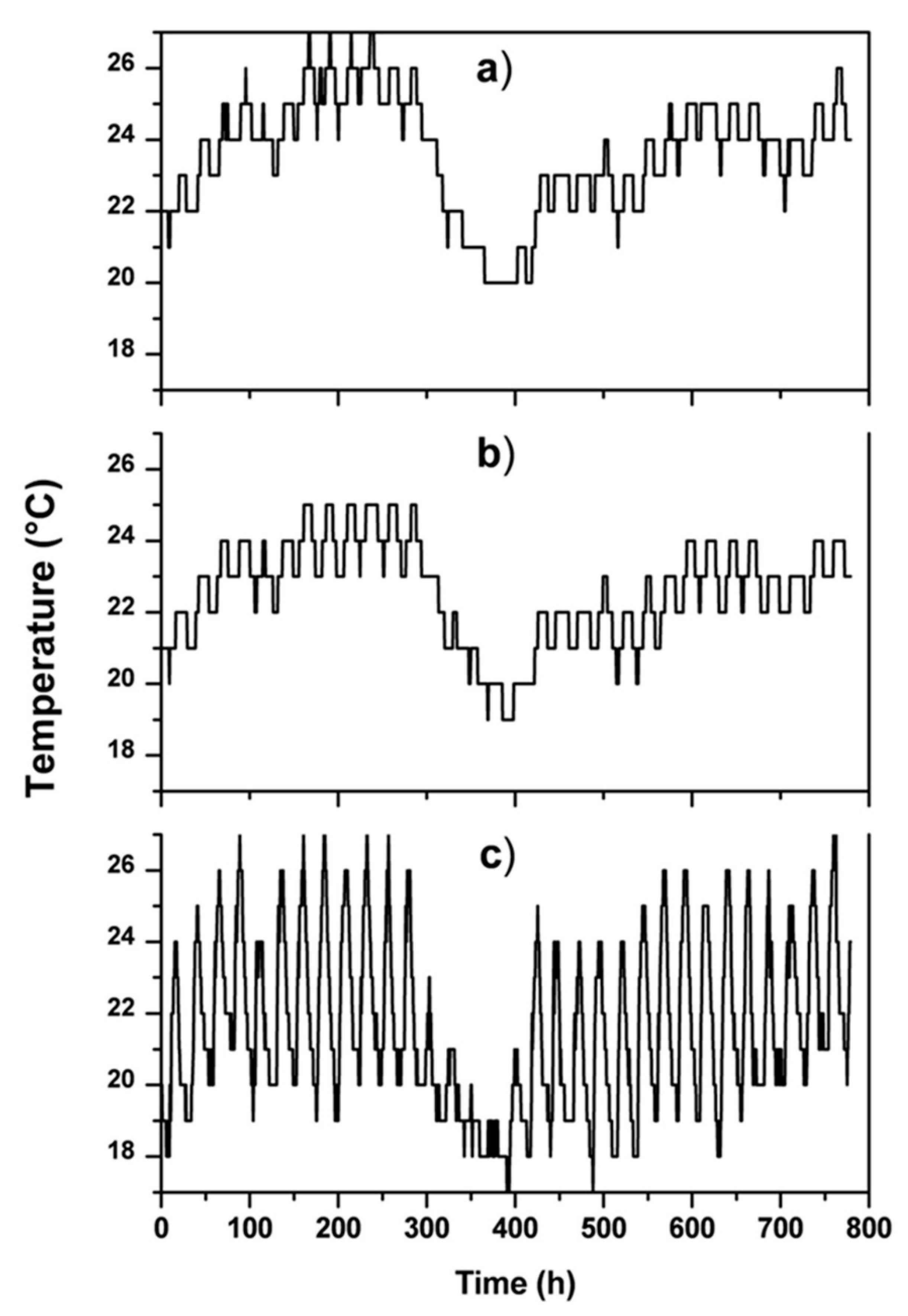

3.3. Heat Transfer Simulation by COMSOL Multiphysics

3.4. Heat Transfer Simulation by COMSOL Multiphysics

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Griffiths, S.; Sovacool, B.K. Rethinking the future low-carbon city: Carbon neutrality, green design, and sustainability tensions in the making of Masdar City. Energ. Res. Soc. Sci. 2020, 62, 101368. [Google Scholar] [CrossRef]

- Saieg, P.; Sotelino, E.D.; Nascimento, D.; Caiado, R.G.G. Interactions of Building Information Modeling, Lean and Sustainability on the Architectural Engineering and Construction industry: A systematic review. J. Clean. Prod. 2018, 174, 788–806. [Google Scholar] [CrossRef]

- Shan, M.; Hwang, B.-G. Green building rating systems: Global reviews of practices and research efforts. Sustain. Cities Soc. 2018, 39, 172–180. [Google Scholar] [CrossRef]

- Khoshnava, S.M.; Rostami, R.; Valipour, A.; Ismail, M.; Rahmat, A.R. Rank of green building material criteria based on the three pillars of sustainability using the hybrid multi criteria decision making method. J. Clean. Prod. 2018, 173, 82–99. [Google Scholar] [CrossRef]

- Al-ajmi, F.F.; Loveday, D.L. Indoor thermal conditions and thermal comfort in air conditioned domestic buildings in the dry-desert climate of Kuwait. Build. Environ. 2010, 45, 704–710. [Google Scholar] [CrossRef]

- Huang, C.; Zou, Z.; Li, M.; Wang, X.; Li, W.; Huang, W.; Yang, J.; Xiao, X. Measurements of indoor thermal environment and energy analysis in a large space building in typical seasons. Build. Environ. 2007, 42, 1869–1877. [Google Scholar] [CrossRef]

- Martín, S.; Mazarrón, F.R.; Cañas, I. Study of thermal environment inside rural houses of Navapalos (Spain): The advantages of reuse buildings of high thermal inertia. Constr. Build. Mater. 2010, 24, 666–676. [Google Scholar] [CrossRef]

- Grigoletti, G.; Sattler, M.A.; Morello, A. Analysis of the thermal behavior of a low cost, single-family, more sustainable house in Porto Alegre, Brazil. Energ. Build. 2008, 40, 1961–1971. [Google Scholar] [CrossRef]

- Santamouris, M. Cooling the cities—A review of reflective and green roof mitigation technologies to fight heat island and improve comfort in urban environments. Sol. Energy 2014, 103, 682–703. [Google Scholar] [CrossRef]

- Pradhan, S.; Al-Ghamdi, S.G.; Mackey, H.R. Greywater recycling in buildings using living walls and green roofs: A review of the applicability and challenges. Sci. Total Environ. 2019, 652, 330–344. [Google Scholar] [CrossRef]

- Pushkar, S. Modeling the substitution of natural materials with industrial byproducts in green roofs using life cycle assessments. J. Clean. Prod. 2019, 227, 652–661. [Google Scholar] [CrossRef]

- Zhang, Z.; Szota, C.; Fletcher, T.D.; Williams, N.S.G.; Farrell, C. Green roof storage capacity can be more important than evapotranspiration for retention performance. J. Environ. Manag. 2019, 232, 404–412. [Google Scholar] [CrossRef] [PubMed]

- Cascone, S.; Coma, J.; Gagliano, A.; Pérez, G. The evapotranspiration process in green roofs: A review. Build. Environ. 2019, 147, 337–355. [Google Scholar] [CrossRef]

- Arnaud, L. Comparative Study of Hygro Thermal Performances of Building Materials. In Proceedings of the 11th International Conference on Non-Conventional Materials and Technologies (NOCMAT 2009), Bath, UK, 6–9 September 2009. [Google Scholar]

- Zhang, H.; Yoshino, H. Analysis of Indoor Humidity Environment in Chinese Residential Buildings. Build. Environ. 2010, 45, 2132–2140. [Google Scholar] [CrossRef]

- Makaka, G.; Meyer, E.L.; McPherson, M. Thermal behavior and ventilation efficiency of a low-cost passive solar energy efficient house. Renew. Energ. 2008, 33, 1959–1973. [Google Scholar] [CrossRef]

- Garzón, B.; Raimondi, G.G. Thermal Simulation for the Improvement of Rural Popular Houses in Tucuman, Argentina. In Proceedings of the 11th International Conference on Non-Conventional Materials and Technologies (NOCMAT 2009), Bath, UK, 6–9 September 2009. [Google Scholar]

- Garzón, B.; Hernández, A.; Mele, E.; de Benito, L. Application of Bioclimatic Strategies, Monitoring and Thermal Simulation in a Social Rural House in Chubut, Argentina. In Proceedings of the 11th International Conference on Non-Conventional Materials and Technologies (NOCMAT 2009), Bath, UK, 6–9 September 2009. [Google Scholar]

- Sailor, D.J. A green roof model for building energy simulation programs. Energ. Build. 2008, 40, 1466–1478. [Google Scholar] [CrossRef]

- Fraternali, F.; Ciancia, V.; Chechile, R.; Rizzano, G.; Feo, L.; Incarnato, L. Experimental study of the thermo-mechanical properties of recycled PET fiber-reinforced concrete. Compos. Struct. 2011, 93, 2368–2374. [Google Scholar] [CrossRef]

- Foty, D. Preliminary analysis of concrete reinforced with waste bottles PET fibers. Constr. Build. Mater. 2011, 25, 1906–1915. [Google Scholar] [CrossRef]

- Reis, J.M.L.; Carneiro, E.P. Evaluation of PET waste aggregates in polymer mortars. Constr. Build. Mater. 2012, 271, 107–111. [Google Scholar] [CrossRef]

- Frigione, M. Recycling of PET bottles as fine aggregate in concrete. Waste Manag. 2010, 30, 1101–1106. [Google Scholar] [CrossRef]

- Spadea, S.; Farina, I.; Berardi, V.P.; Dentale, F.; Fraternali, F. Energy dissipation capacity of concretes reinforced with recycled PET fibers. Ing. Sismica 2014, 31, 61–70. [Google Scholar]

- Colangelo, F.; Forcina, A.; Farina, I.; Petrillo, A. Life cycle assessment (LCA) of different kinds of concrete containing waste for sustainable construction. Buildings 2018, 8, 70. [Google Scholar] [CrossRef]

- Arulrajah, A.; Perera, S.; Wong, Y.C.; Horpibulsuk, S.; Maghool, F. Stiffness and flexural strength evaluation of cement stabilized PET blends with demolition wastes. Constr. Build. Mater. 2020, 239, 117819. [Google Scholar] [CrossRef]

- Chinchillas-Chinchillas, M.J.; Gaxiola, A.; Alvarado-Beltrán, C.G.; Orozco-Carmona, V.M.; Pellegrini-Cervantes, M.J.; Rodríguez-Rodríguez, M.; Castro-Beltrán, A. A new application of recycled-PET/PAN composite nanofibers to cement-based materials. J. Clean. Prod. 2020, 252, 119827. [Google Scholar] [CrossRef]

- Ricardo, J.R.C. Use of Residues of Crushed Pet Bottles in the Form of a Scale as an Addition to the Manufacture of Concrete. In Proceedings of the International Conference of Sustainable Production and Use of Cement and Concrete; RILEM Bookseries; Springer: Cham, Switzerland, 2020; Volume 22, pp. 251–263. [Google Scholar] [CrossRef]

- Taherkhani, H.; Arshadi, M.R. Investigating the mechanical properties of asphalt concrete containing waste polyethylene terephthalate. Road Mater. Pavement Des. 2019, 20, 381–398. [Google Scholar] [CrossRef]

- Hidayat, N.; Pratama, G.N.I.P.; Pramita, I.D. The Effect of PET Plastic Addition (Polyethylene Terephthalate) and Carbide Waste Filler for Asphalt Concrete-Binder Course (AC-BC) on Marshall Characteristics. IOP Conf. Ser. Earth Environ. Sci. 2019, 366, 012024. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Gao, W.-Y.; Duan, Z.-J.; Bai, Y.-L.; Guo, Y.-C.; Ouyang, L.-J. Axial compressive behavior of polyethylene terephthalate/carbon FRP-confined seawater sea-sand concrete in circular columns. Constr. Build. Mater. 2020, 234, 117383. [Google Scholar] [CrossRef]

- Gao, Y.; Romero, P.; Zhang, H.; Huang, M.; Lai, F. Unsaturated polyester resin concrete: A review. Constr. Build. Mater. 2019, 228, 116709. [Google Scholar] [CrossRef]

- Sharma, R.; Bansal, P.P. Use of different forms of waste plastic in concrete—A review. J. Clean. Prod. 2016, 112, 473–482. [Google Scholar] [CrossRef]

- Geyer, B.; Lorenz, G.; Kandelbauer, A. Recycling of poly(ethylene terephthalate)—A review focusing on chemical methods. Express Polym. Lett. 2016, 10, 559–586. [Google Scholar] [CrossRef]

- Alfahdawi, I.H.; Osman, S.A.; Hamid, R.; AL-Hadithi, A.I. Influence of PET wastes on the environment and high strength concrete properties exposed to high temperatures. Constr. Build. Mater. 2019, 225, 358–370. [Google Scholar] [CrossRef]

- Noroozi, R.; Shafabakhsh, G.; Kheyroddin, A.; Mohammadzadeh Moghaddam, A. Investigating the effects of recycled PET particles, shredded recycled steel fibers and Metakaolin powder on the properties of RCCP. Constr. Build. Mater. 2019, 224, 173–187. [Google Scholar] [CrossRef]

- Zhou, S.; Rabczuk, T.; Zhuang, X. Phase field modeling of quasi-static and dynamic crack propagation: COMSOL implementation and case studies. Adv. Eng. Softw. 2018, 122, 31–49. [Google Scholar] [CrossRef]

- Guo, B.; Hong, Y.; Qiao, G.; Ou, J. A COMSOL-PHREEQC interface for modeling the multi-species transport of saturated cement-based materials. Constr. Build. Mater. 2018, 187, 839–853. [Google Scholar] [CrossRef]

- Wei, Y.; Zhou, S.; Han, Z.; Yu, L.; Wei, X. Influence of random aggregates on diffusion behavior of chloride ions in concrete based on comsol simulation. Compos. Mech. Comput. Appl. 2018, 9, 1–16. [Google Scholar] [CrossRef]

- Maliki, M.; Laredj, N.; Bendani, K.; Missoum, H. Two-dimensional transient modeling of energy and mass transfer in porous building components using COMSOL multiphysics. J. Appl. Fluid Mech. 2017, 10, 319–328. [Google Scholar] [CrossRef]

- Sharifi, N.P.; Freeman, G.E.; Sakulich, A.R. Using COMSOL modeling to investigate the efficiency of PCMs at modifying temperature changes in cementitious materials—Case study. Constr. Build. Mater. 2015, 101, 965–974. [Google Scholar] [CrossRef]

- Ceja Soto, F.R.; Pérez Bueno, J.J.; Mendoza López, M.L.; Pérez Ramos, M.E.; Reyes Araiza, J.L.; Ramírez Jiménez, R.; Manzano-Ramírez, A. Sustainability Metrics for Housing and the Thermal Performance Evaluation of a Low-Cost Prototype Made with Poly (Ethylene Terephthalate) Bottles. Recycling 2019, 4, 30. [Google Scholar] [CrossRef]

- NMX-C-414-ONNCCE-2017. Construction Industry-Hydraulic Cementing-Specifications and Test Methods. Available online: https://onncce.org.mx/es/?option=com_merchant&view=category&cid=11 (accessed on 7 February 2020).

- ASTM. C33/C33M-18 Standard Specification for Concrete Aggregates. Available online: https://www.astm.org/Standards/C33.htm (accessed on 7 February 2020).

- ASTM. C109/C109M-16a Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). Available online: https://www.astm.org/Standards/C109.htm (accessed on 7 February 2020).

| A) Thermal Parameters of Subdomains | Internal Air Environment | Foundations | Walls | Door | Green Roof | Windows | Glass Skylights and Ventilation |

|---|---|---|---|---|---|---|---|

| Thermal conductivity, k (W/m K) | 0.0232 | 0.22 | 0.37 | 1.38 | 0.87 | 1.38 | 1.09 |

| Density, ρ (kg/m3) | 1.29 | 2700 | 3500 | 2203 | 2100 | 2203 | 2203 |

| Heat Capacity, cp (J/Kg K) | 1000 | 385 | 320 | 703 | 920 | 703 | 703 |

| Temperature, T (°C) | 25 | 25 | 20 | 47 | 57 | 47 | 57 |

| B) Thermal Boundary Conditions | |||||||

| Emissivity, ϵ | 0.60 | 0.90 | 0.83 | 0.97 | 0.78 | 0.97 | 0.97 |

| Temperature, T (°C) | 25 | 20 | 52 | 45 | 62 | 45 | 52 |

| 1 | 2 | 3 | 4 | |

|---|---|---|---|---|

| P-Tmax | P-Tmin | R-Tmin | R-Tmin | |

| y0 | 7.03 | 5.43 | 17.17 | −25.02 |

| xc | 186.74 | 186.69 | 179.59 | 183.22 |

| w | 246.14 | 241.34 | 220.64 | 515.07 |

| A | 6076.7 | 5862.9 | 3528.1 | 28714.3 |

| Area | 7743.8 | 7028.1 | 9367.1 | 5799.4 |

| Center (day) | 182.8 | 183.0 | 180.3 | 181.6 |

| Height (°C) | 26.7 | 24.8 | 29.9 | 19.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ceja Soto, F.R.; Pérez Bueno, J.d.J.; Mendoza López, M.L.; Pérez Ramos, M.E.; Reyes Araiza, J.L.; Ramírez Jiménez, R.; Manzano-Ramírez, A. Evaluating the Thermal Behavior of a Sustainable Room and Roof Prototype Using Recycled Waste Materials. Recycling 2020, 5, 2. https://doi.org/10.3390/recycling5010002

Ceja Soto FR, Pérez Bueno JdJ, Mendoza López ML, Pérez Ramos ME, Reyes Araiza JL, Ramírez Jiménez R, Manzano-Ramírez A. Evaluating the Thermal Behavior of a Sustainable Room and Roof Prototype Using Recycled Waste Materials. Recycling. 2020; 5(1):2. https://doi.org/10.3390/recycling5010002

Chicago/Turabian StyleCeja Soto, Flavio Roberto, José de Jesús Pérez Bueno, Maria Luisa Mendoza López, Martha Elba Pérez Ramos, José Luis Reyes Araiza, Rubén Ramírez Jiménez, and Alejandro Manzano-Ramírez. 2020. "Evaluating the Thermal Behavior of a Sustainable Room and Roof Prototype Using Recycled Waste Materials" Recycling 5, no. 1: 2. https://doi.org/10.3390/recycling5010002

APA StyleCeja Soto, F. R., Pérez Bueno, J. d. J., Mendoza López, M. L., Pérez Ramos, M. E., Reyes Araiza, J. L., Ramírez Jiménez, R., & Manzano-Ramírez, A. (2020). Evaluating the Thermal Behavior of a Sustainable Room and Roof Prototype Using Recycled Waste Materials. Recycling, 5(1), 2. https://doi.org/10.3390/recycling5010002