Abstract

Economic and regulatory pressures on the global composites industry have encouraged the research and development of technology for the recycling of fiber reinforced polymer composites. Although significant advancements have been made in the recycling of carbon fiber composites, more progress is needed in the recovery of glass fibers, which make up the overwhelming volume of the composites market. In this study, wind turbine blades and automotive sheet moulding compound (SMC) were subjected to a two temperature step pyrolysis. This multistep process yielded improvements in the recovered E-glass fiber’s tensile strength, by as much as 19%, and strain to failure, by as much as 43%, over a single high temperature step pyrolysis. Despite these gains, pre-pyrolysis fiber measurements indicate that pre-existing damage may inherently limit the quality of glass fiber recoverable from pyrolysis without any post processing.

1. Introduction

Over 9 million tons of glass fiber reinforced polymer composites were produced globally in 2015 [1]. Roughly 70% of these composites are made with thermosets [1]. As such, they are quite resilient in service but do not lend themselves towards recycling like other engineering materials (e.g., metals and thermoplastics). This issue has not stopped attempts at materials recovery, with approaches now built around reclaiming the reinforcing fibers through degrading the resin matrix with some form of mechanical, chemical, or thermal attack [2]. Of the methods developed, one of the simplest options that has achieved some measure of commercial success is pyrolysis. In a low or no oxygen environment, composite scrap is heated to thermally break down the resin phase, resulting in recovered fibers, fillers, char, and hydrocarbon gases and oils [2]. This process has proved fairly successful in the recovery of carbon fiber through a variety of reactor designs and has reached the point that commercial quantities are becoming available on the open market [3,4,5]. The resulting hydrocarbon gases can contain significant portions of hydrogen, methane, carbon monoxide, and carbon dioxide, while the resulting oils tend to be rich in aromatic compounds; however, exact compositions can be quite complex and vary with different resin mixtures, additives, temperatures, and atmospheric compositions [2]. Aside from allowing for recovery of the resin phase as chemical feedstock for reprocessing or energy conversion, the inert atmosphere used for pyrolysis can limit carbon fiber damage through oxidation during recovery [2]. At timescales of relevance to recycling, inert nitrogen atmosphere has also been shown to noticeably reduce damage to glass fiber composites during recovery as well [6].

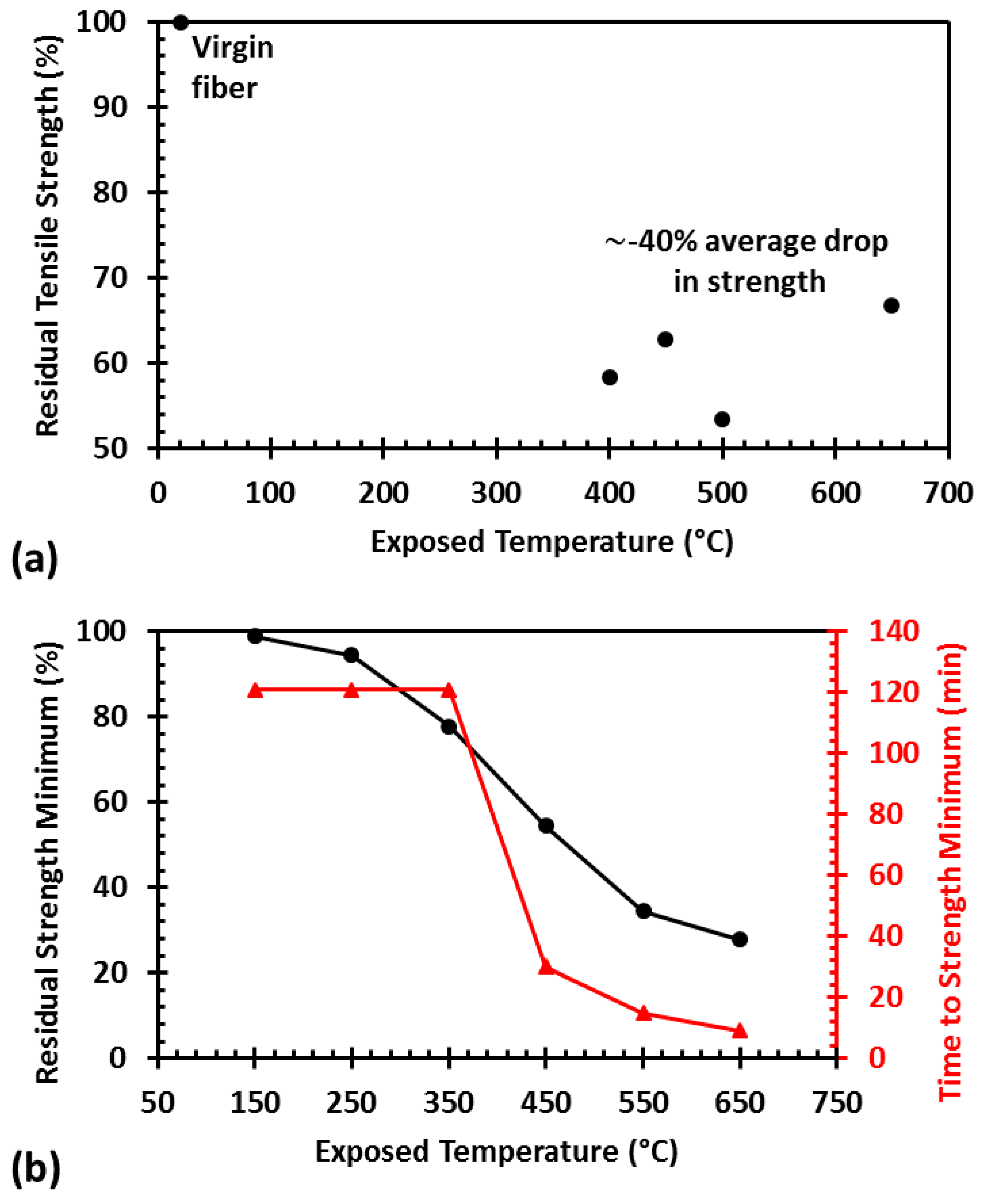

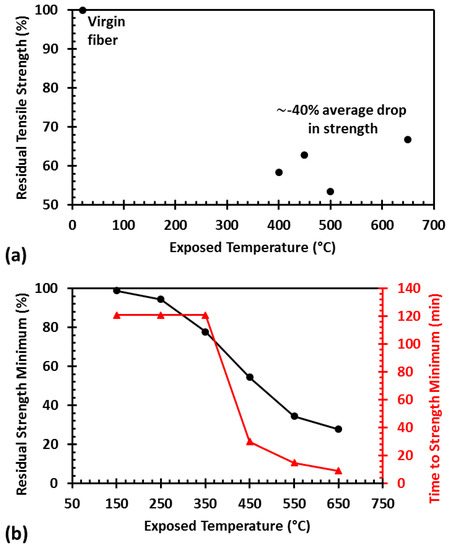

The key to carbon fiber recovery’s success has been both the mechanical quality of the reclaimed fibers and their attractive potential price point versus virgin carbon fiber, which is comparatively quite expensive to produce [2]. Unfortunately, the success of carbon fiber composites recycling has not extended into E-glass fiber composites, which represent the overwhelming volume of the composites market [1]. The lack of any viable glass reinforced composite recycling technology means that almost all composites must still be landfilled for disposal [1]. The problem with E-glass, when compared with carbon, is that glass fibers appear to be significantly more degraded by pyrolysis processing [1,7,8]. For example, Figure 1a shows E-glass filament strengths, recovered through pyrolysis by Cunliffe et al., from an unsaturated polyester based sheet molding compound (SMC) that indicate an approximately 40%–50% average drop in tensile strength [7]. Feih et al. would later conduct several in-depth studies on E-glass degradation under temperatures relevant to pyrolysis [6,9,10]. Their experiments, summarized in Figure 1b, indicate that E-glass filament tensile strength declines over time until hitting a stable minimum value with both minimum residual fiber strength and rate of strength decay dictated by pyrolysis temperature [6].

Figure 1.

(a) Average single filament tensile strength results from pyrolyzed thermoset polyester SMC with calcium carbonate and aluminum trihydrate fillers. Redrawn from data in Cunliffe et al. Tables 8 and 9 in [7]. (b) Minimum residual tensile strengths achieved in E-glass fiber at various pyrolysis temperatures (black circles) versus measured upper bound time limit for reaching said minimum (red triangles). Redrawn from data in Feih et al. Figure 1(a) in [6].

The data in Figure 1b suggests the potential for higher quality E-glass fiber recovery through optimization of a two temperature step pyrolysis process. By using a long, lower temperature step to degrade most of the composite resin phase in conjunction with a brief, higher temperature step to complete resin removal, it would appear possible to reduce a glass reinforced composite’s exposure to high temperatures and yield a stronger reclaimed fiber. Obtaining higher strength glass directly from pyrolysis could aid both efforts to reuse recovered glass fiber material blended with virgin E-glass [11,12] and to regenerate the original glass fiber strength post-pyrolysis [13]. Such a process should also be viable for carbon fiber recovery, allowing for the co-recovery of mixed recyclates at pilot plant scale with final intermediate mechanical properties between E-glass and carbon fiber [14]. To test this concept, a case study was designed and implemented using two representative composite materials used in commerce: E-glass reinforced epoxy wind turbine blades and E-glass reinforced unsaturated polyester and vinyl ester automotive structural SMC.

2. Results

2.1. Thermal Testing

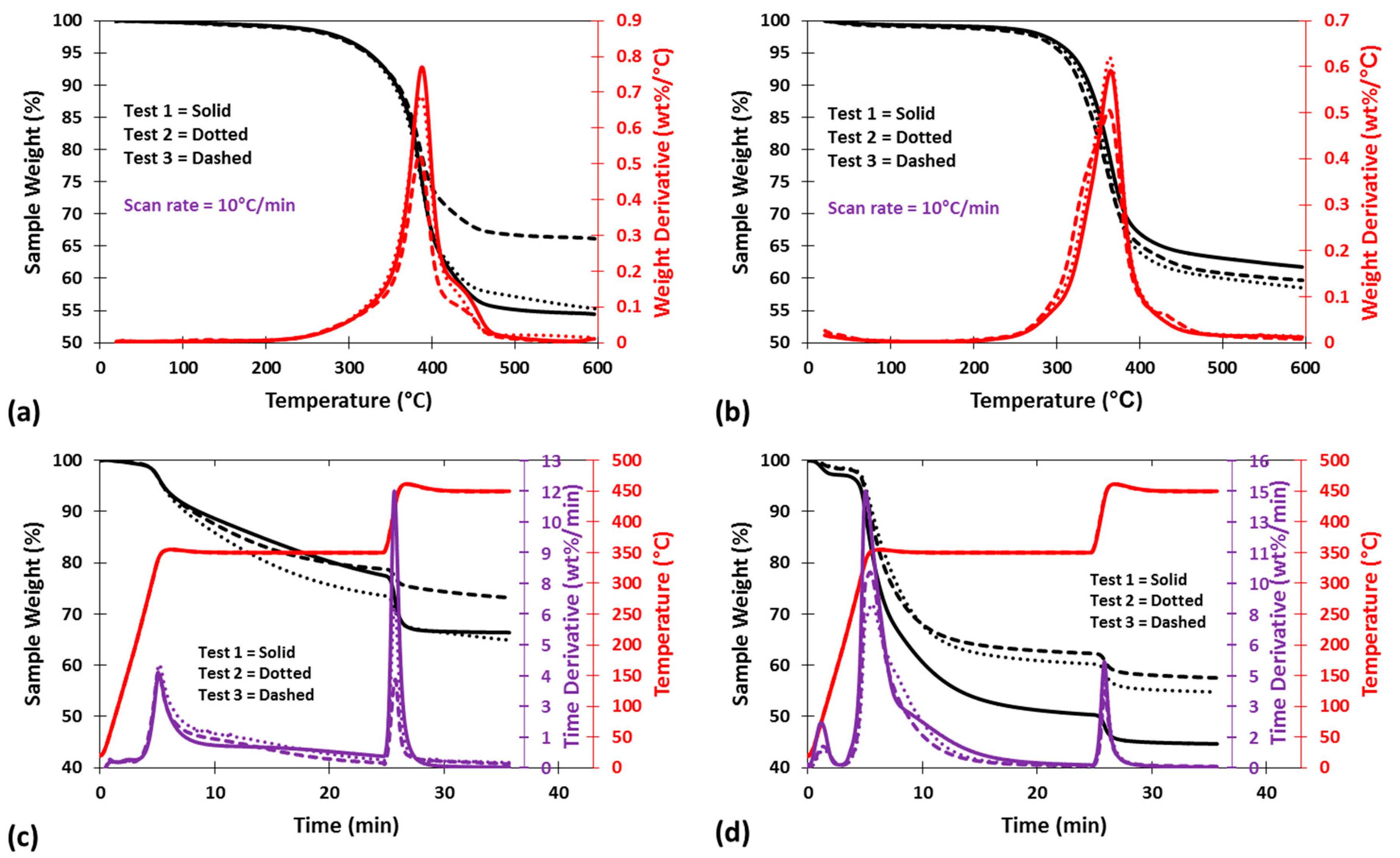

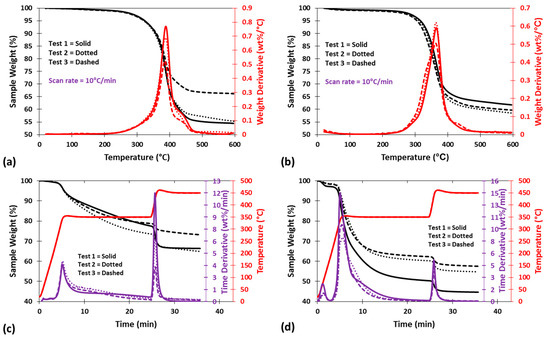

To determine the necessary thermal profile needed for pyrolyzing the selected test materials, each sample material was heated in a TGA at 10 °C/min. From the results presented in Figure 2a,b, the pyrolysis of the organic compounds in both specimens appears to initiate around 250 °C but proceeds very slowly until the mid-300s °C. Figure 2a shows a distortion in the slope to the right of the main peak in the wt%/°C derivative. While not as pronounced, there is also a broadening of the right side of the wt%/°C derivative in Figure 2b. This indicates the presence of both a higher and lower temperature phase being removed in both specimens. This is not altogether surprising as it is likely that the support materials (i.e., balsa wood and PVC foam) and epoxy in the wind blade sample and that the unsaturated polyester and vinyl ester components in the SMC sample begin breaking down at different temperatures.

Figure 2.

Respective TGA results for each of the tested composite waste materials. Three samples scanned at a rate of 10 °C/min for each test material: (a) SMC, (b) wind blade. Three samples during a simulated two temperature step pyrolysis procedure: (c) SMC, (d) wind blade. Data suggests a generic thermal profile capable of being used in large scale pyrolysis recycling [14].

The TGA scan results suggested that a generic thermal profile with a long, low pyrolysis temperature step at 350 °C followed by a short 450 °C high temperature pyrolysis step would be capable of completely pyrolyzing all selected sample materials. Based on the Feih et al. results in Figure 1b, conducting the bulk of the pyrolysis at 350 °C and with limited exposure to 450 °C would be expected to yield glass fibers with improved tensile strength over a single 450 °C step. The suggested thermal profile was therefore tested via TGA using the following sequence: (1) sample heated to 200 °C over 3 min to allow time for the TGA chamber to be fully purged with nitrogen, (2) sample heated over 2 min to 350 °C low temperature pyrolysis setting and held isothermal for 20 min, (3) sample heated to 450 °C high temperature pyrolysis setting over 1 min and then held isothermal for 10 min. The results in Figure 2c,d show that in both sample materials the low temperature 350 °C step was able to begin removing material, as indicated by the progressive sample weight loss with time. These results also show that the 450 °C high temperature step is capable of removing all remaining polymeric materials within a brief exposure window, as indicated by the narrow spikes in time derivatives followed by the leveling off of sample weights. Given the significant inhomogeneity in starting fiber to resin to filler ratio for the shredded specimens tested, assessing whether differences in yield were from starting composition variation or thermal processing was impractical. Using the known bulk composition of the SMC sample and the TGA results, an estimate of overall approximate yield for pyrolysis is ~4–12 wt% residual carbonaceous char on top of the 49 wt% fiber and 12 wt% mineral filler. Larger quantities of material were then processed using this same two temperature step approach in a nitrogen purged tube furnace to obtain sufficient quantities of sample fiber filaments for mechanical testing.

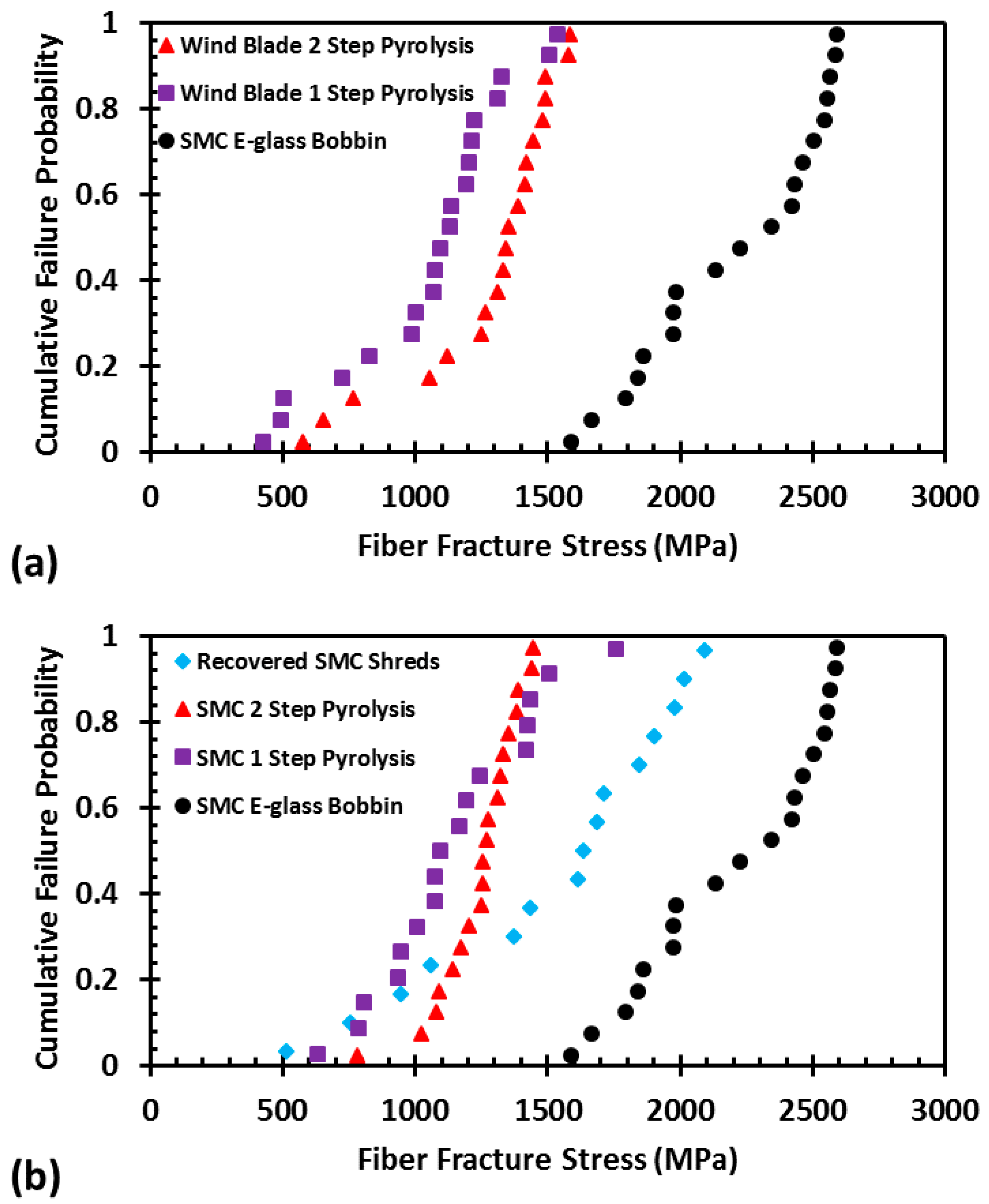

2.2. Post-Pyrolysis Fiber Characterization

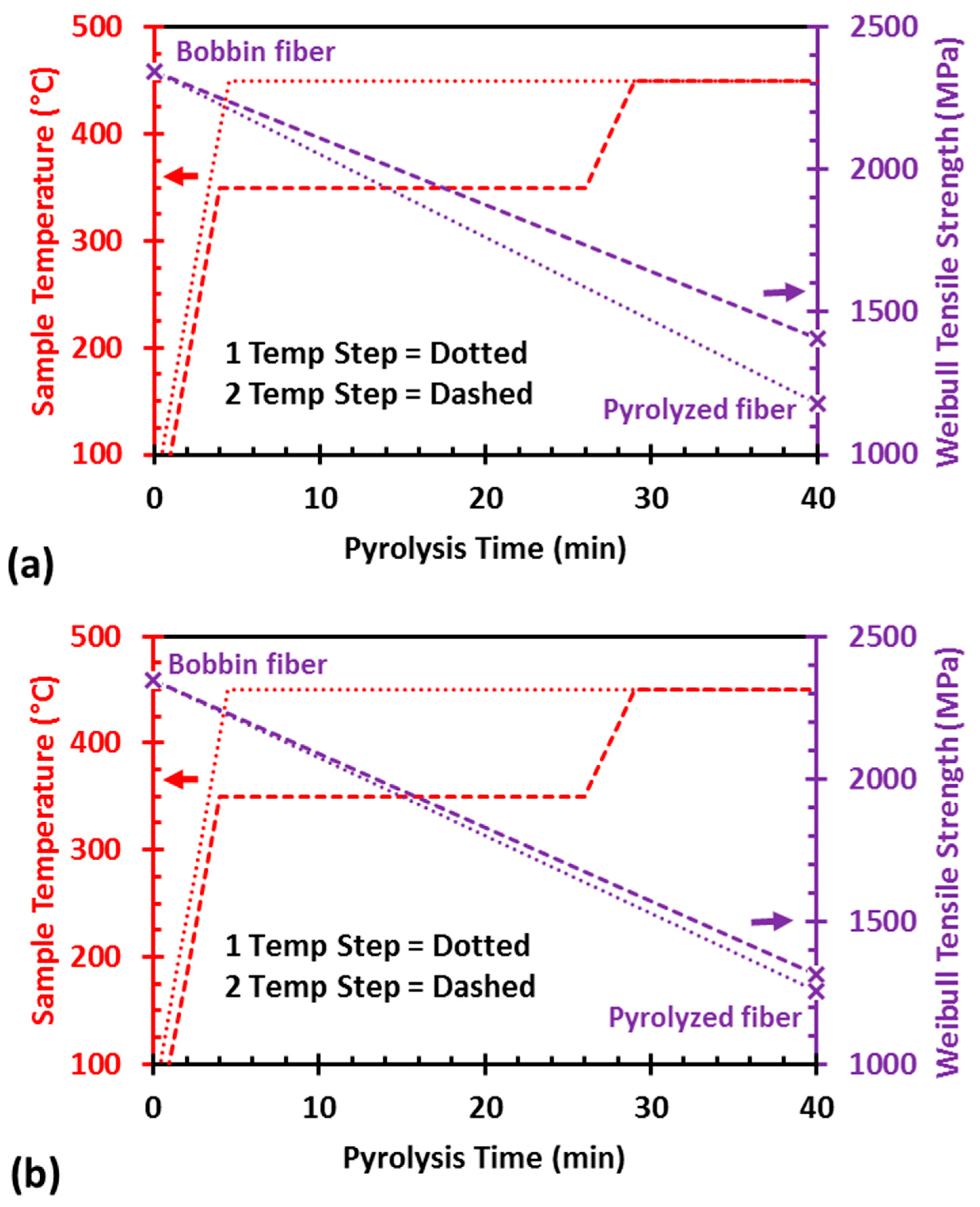

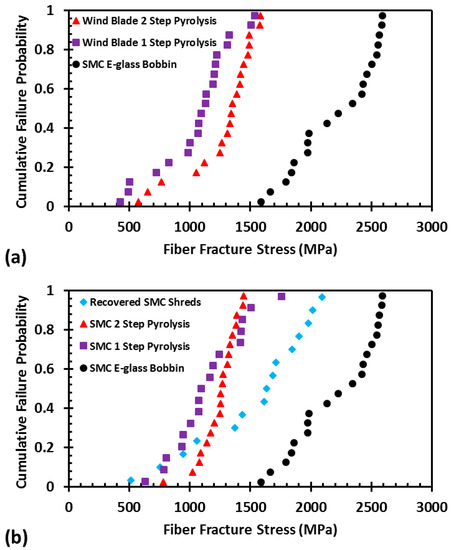

Fibers collected from the single and two-step pyrolysis processes were characterized via single filament tension testing. Sample fibers were tested without any surface char removal procedure in order to isolate the effect of the different pyrolysis procedures. Figure 3 indicates that the two temperature step pyrolysis process yielded a 19% improvement in final Weibull characteristic tensile strength of the wind turbine blade glass fibers and an around 5% improvement in the SMC recovered fibers. This suggests that merely adjusting temperature, without using any additional post processing steps, does have the potential to process glass fiber composite recyclates with higher output mechanical strength. Of interest though is why there appears to be such a large difference in the effect between the wind blade and SMC recovered fibers. This can be understood by closer examination of the Weibull tensile strength plots in Figure 4. While these plots show the expected leftward shift to lower fiber fracture stresses from virgin to pyrolyzed material, Figure 4b also shows single filament tensile strength measurements of glass fibers recovered from the shredded SMC, before pyrolysis recovery, which exhibit reduced strength values as well. This indicates that the glass fibers in the SMC material had already been damaged with a −27% difference in strength before any recycling attempts were made. The two temperature step pyrolysis can therefore only be responsible for the remaining −17% of the total −44% difference in final tensile strength from virgin E-glass. As pyrolysis cannot recover fiber strength that the input material did not possess, these results suggest that pre-existing fiber damage may be more of a limiting factor in the recycling of glass fiber composites than damage introduced during fiber reclamation. This damage may also help explain the trend in Weibull modulus, a non-dimensional measure of the projected spread in fiber tensile strengths within a specimen with larger values indicating a narrower distribution. Table 1 shows that the virgin E-glass bobbin specimens start with the narrowest distribution in tensile strength; however, as some of the fibers are damaged at random through part production, in-service use, and shredding, the distribution in fiber strengths widens. As all the fibers become damaged by the pyrolysis heat treatment though, the distribution in stronger and weaker filaments begins to shrink.

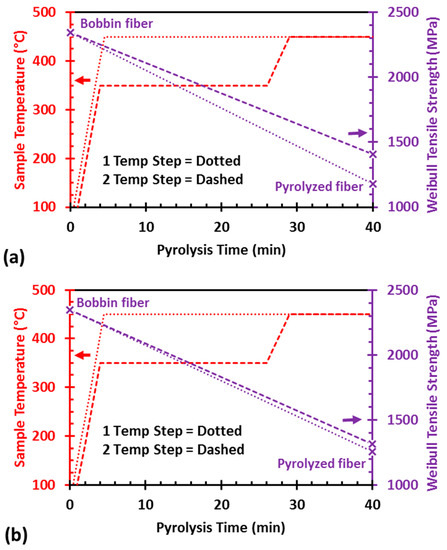

Figure 3.

Measured drops in glass filament Weibull characteristic tensile strength from virgin fiber (represented by the SMC E-glass bobbin sample) to fibers recovered by pyrolysis: (a) wind blade fibers, (b) SMC fibers. Comparison against schematic temperature process curves illustrates correlation between reduced higher temperature exposure and improved recovered filament strength.

Figure 4.

Weibull probability plots of tested filament fracture strengths: (a) wind blade results, (b) SMC results. A leftward shift in sample data indicates a reduction in overall fiber tensile strengths.

Table 1.

Tabulated Weibull characteristic tensile strength results from single filament tension tests.

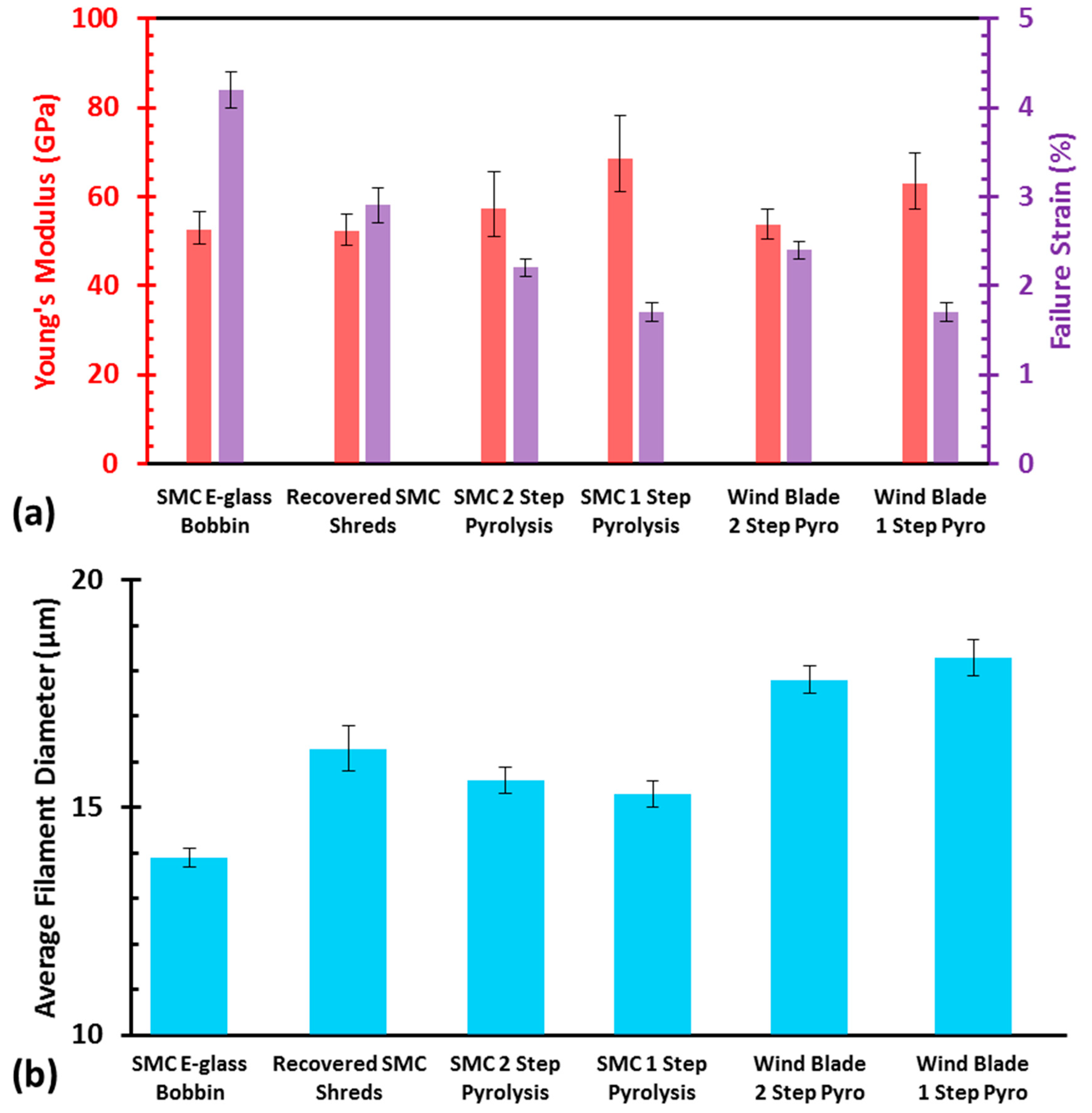

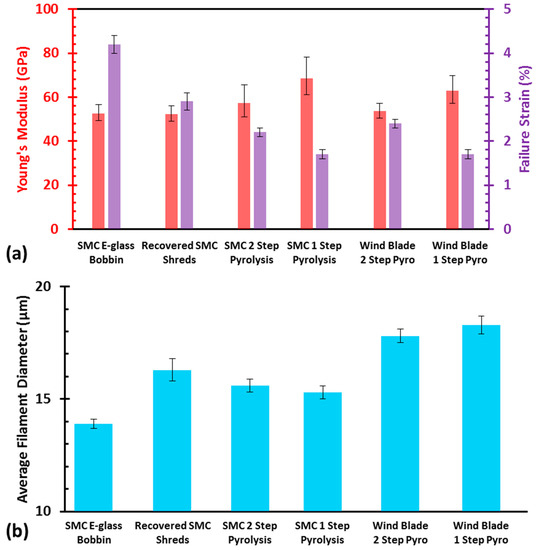

Also of note from the mechanical test results presented in Figure 5a is the effect of pyrolysis processing changes on elastic behavior. Two temperature step pyrolysis yields a relatively minor 2–9% difference increase in Young’s modulus. This increase climbed to 20–30% with the more aggressive single temperature pyrolysis, matching similar Young’s modulus increase observations reported by other authors under much more aggressive pyrolysis conditions [1,15]. The improved residual strength and closer to virgin fiber Young’s modulus of the two temperature step pyrolyzed fibers means such fibers exhibit a noticeably larger strain to failure of 29–43% over their single step equivalents.

Figure 5.

Average individual filament data ± standard error: (a) left/red columns representing Young’s modulus and right/purple columns representing failure strain for each tested condition, (b) average individual filament diameter.

The observed changes in Young’s modulus likely stem from the thermal compaction and densification of E-glass fibers that is known to occur at elevated temperature ranges [16,17]. Examining average filament diameters in Figure 5b, there does not appear to be a significant difference between the fiber diameters from the 1 and 2 step pyrolysis procedures for either sample material; however, comparison of SMC pre-pyrolysis shreds against pyrolyzed fibers does suggest a small contraction in fiber diameter. Interestingly, there also appears to be a clear difference in fiber diameter from the original virgin material and both the pre- and post-pyrolysis fibers. This suggests that further glass fiber structural changes may be occurring earlier in original composite production.

3. Discussion

Perhaps more interesting, though, is the implication of Young’s modulus for the underlying mechanism behind the pyrolyzed E-glass fibers’ reduced strength. According to the well-established Griffith criterion, the failure stress of a glass specimen under tension is governed by the relation:

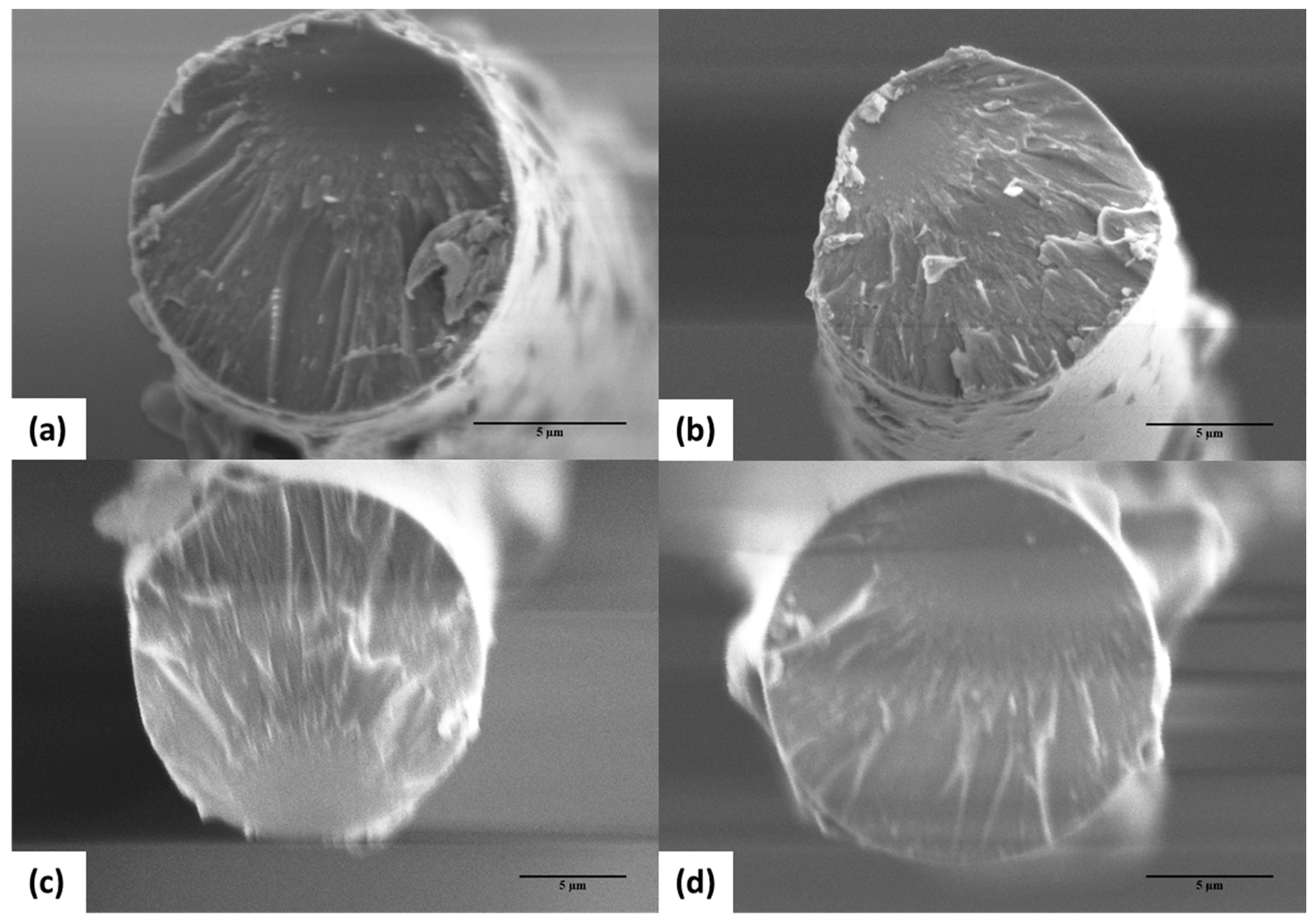

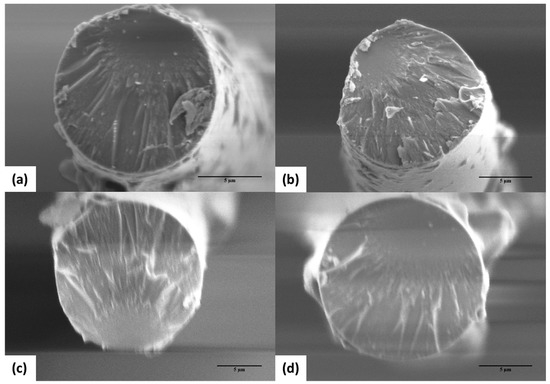

where is the size of an internal, high eccentricity elliptical flaw (modifiable by a constant geometric factor for other flaw shapes and whether the flaw is internal or located at the surface), is Young’s modulus, and is fracture surface energy density [18]. Though the exact flaw shape and size distribution within the surveyed fibers are unknown due to a lack of known method for direct observation, the responsibility of surface flaws for mechanical failure is clear from Figure 6 where the observed fiber fracture surface hackle lines lead back to fracture mirror origins at the specimen surfaces. Examining the SMC material, where the fiber tensile strength right before pyrolysis processing is known, it is observed that the two-step process yields . For Griffith’s criterion to be satisfied, the quantity under the square root must also be reduced to 59% of its pre-pyrolysis value. Figure 5a indicates though that has only changed about 10%, and so the bulk of the fiber strength loss must come from changes in , , or both.

Figure 6.

SEM images of example fracture surfaces observed from recovered pyrolyzed filaments: (a,b) SMC samples; (c,d) wind blade samples. Images captured with a Hitachi S-3400N SEM.

In the extended work of Feih et al., virgin E-glass filaments before and after a 450 °C, 30 min heat treatment were artificially notched via focused ion beam (FIB) and pulled in tension to measure fracture toughness . From their experiments, a relatively stable value of = 0.91 MPa m0.5 was found, close to the bulk value = 0.93 MPa m0.5 measured by Ghosh et al. [19]. These results indicate that any change in , if indeed there is any, must be small and so fracture strength changes will be controlled by . Taking the ratio of Equation (1) for both pre- and post-pyrolysis conditions, assuming no change in and taking the measured changes in into account, indicates an 86% increase in flaw size for the SMC fibers following the two-step pyrolysis versus an 145% increase for the single step. This indicates that, despite the fibers having already been damaged before recycling, even a basic optimization of temperature processing yielded a −41% difference reduction in final fiber flaw size. As such, our results not only appear to support the conclusion of Feih et al. that strength loss from pyrolysis is dominated by temperature driven growth in subcritical surface flaws but that the relationship between temperature and growth rate can be manipulated to reduce fiber damage from pyrolysis. However, it is worth noting that our results also contradict their conclusion that no bulk material property changes occur, as Young’s modulus does appear to have increased more in agreement with the observations of Thomason et al. [10,15]. Furthermore, our study also shows that before pyrolysis was even conducted there had already been an 89% growth in surface flaw size between the pre-pyrolysis shreds and the original virgin fiber. This suggests that glass fiber composite recycling is more complicated than can be captured with simulated experiments on virgin fiber alone and that pre-recycling damage can significantly impact final product quality. While the method of shredding (size reduction) undoubtedly plays some role in the accumulated pre-pyrolysis damage, ongoing preliminary experiments suggest that shredding is only partially responsible and that other elements of the original manufacturing process contribute to this degradation.

4. Materials and Methods

4.1. Surveyed Composite Materials

Composite materials obtained for study were sourced directly from industrial manufacturers. This ensured that the materials characterized would serve as real world representative waste streams that any composite recycling operation would typically encounter. Before any pyrolysis experiments, all test materials were shredded down to approximately 50 mm chips to mimic the same size reduction preprocessing that would be done at a large scale plant. The original E-glass reinforced automotive SMC parts consisted of 49 wt% fiber, 39 wt% unsaturated polyester/vinyl ester blended matrix, and 12 wt% calcium carbonate filler. Exact composition percentages for the wind turbine blade specimens are unknown because the sample came delivered as a pre-shredded mix of large chunks from multiple wind blades; however, their composition can be estimated from that of the original wind blades being processed at the disposal site. As such, the sample roughly consisted of 33% fiber, 33% epoxy matrix, and 33% other blade support materials (primarily PVC foam and balsa wood). Images of the shredded samples before and after pyrolysis are available in the Supplementary Materials.

For comparison with virgin E-glass fiber properties, samples of the virgin E-glass fiber used in the automotive SMC were collected straight from the bobbin. While the pedigree of the E-glass used in the wind turbine blades could not be sourced, the relatively standard behavior of commercial E-glass means that the SMC bobbin material can also serve as a benchmark for the original wind blade fiber properties.

4.2. Thermal Treatment Methodology

To determine appropriate temperature conditions for pyrolysis processing, material samples were probed with a TA Instruments Q500 thermogravimetric analyzer (TGA) under nitrogen. Three specimens from each test material were heated at a rate of 10 °C/min to determine at what temperatures the organic phases of the samples begin breaking down. The results of these tests were used to set conditions for a two temperature step pyrolysis treatment. Before process scale up, the two-step procedure was simulated with the TGA on three specimens from each material to verify complete pyrolysis of the samples’ polymer resins.

The TGA detected polymer breakdown temperatures were then used to set the conditions for pyrolysis of larger sample masses in a tube furnace, continuously purged with flowing nitrogen. To facilitate the two temperature stages of the experimental pyrolysis, the tube furnace was configured with two independently heated zones, which the samples could be moved between during processing. Samples were also processed using a single high temperature step pyrolysis for comparison purposes. Total process time (both temperature ramping and holding) was capped at 40 min for both one and two step processes. Two-step pyrolysis samples were warmed to the desired process low temperature and held isothermal for 22 min. At the completion of the low temperature step, samples were further heated in the high temperature zone and then held isothermal for 11 min. Single step pyrolysis samples were heated to the desired high temperature over approximately 5 min and then held isothermal for 35 min. The samples were then removed from heating and allowed to rapidly cool under nitrogen before removal from the furnace.

4.3. Post-Pyrolysis Products Characterization

To assess the effect of the multi-stage pyrolysis processing, the quality of the reclaimed glass fibers needed to be measured. Individual filaments were extracted from the sample fiber tows by careful hand separation. In the case of the pre-pyrolysis shred samples, during the shredding process the fiber tows became sufficiently detached from the adjacent resin matrix to allow manual separation of individual filaments. Fiber detachment produced during shredding was likely facilitated both by the high fiber and mineral filler content as well as the fact that during original fiber wet out the liquid resin never penetrated into the fiber tow. For mechanical performance characterization, single filaments from each sample material were tested under uniaxial tension using a modified version of ASTM C1557-14 [20]. Individual filament average diameters used for stress calculations were measured via an Olympus BX50 optical microscope after mounting to paper templates for testing. Tests were performed on an MTS Alliance RT/5 load frame with an attached 2N load cell. Filaments were tested using a nominal 12.7 mm gauge length and 0.1 mm/s constant displacement velocity. Young’s modulus measurements were compensated for test system compliance by linear fitting of specimen force normalized filament length change versus cross-sectional area normalized gauge length [20]. Filament tensile strength results were treated with a 2 parameter Weibull analysis, as is typical for brittle materials that can exhibit large scatter in measured results [21]. For the analysis, the filament failure stresses for each tested fiber condition were ranked using the ASTM C1239-13 recommended probability index formula:

where is the estimated probability of failure value corresponding to the th failure stress of total measurements [21]. The ranked failure stress datasets were then fitted to the Weibull cumulative probability distribution function:

where is the cumulative probability of filament failure, is the measured filament tensile strength, is the Weibull modulus (or shape parameter), and is the Weibull characteristic tensile strength (or scale parameter).

5. Conclusions

Two representative materials of common E-glass thermoset composites used in industry were subjected to one and two temperature step pyrolysis treatments for fiber recovery. Analysis of test results for each recycled material yielded the following conclusions:

- Adopting a two temperature stage pyrolysis process can achieve polymeric phase removal and yield recycled glass fibers with improved filament strengths and failure strains.

- Though pyrolysis optimization can improve the quality of recovered fibers, pre-existing damage from manufacturing, in-service use, and size reduction (shredding) may still act as a limiting factor for the quality of reclaimed fibers.

- Experimental observations coupled with basic fracture mechanics theory indicate that the improvement in pyrolyzed fiber strength likely comes from an overall reduction in growth rate of pre-existing surface flaws while at elevated temperature.

Supplementary Materials

The supplementary materials are available online at https://www.mdpi.com/2313-4321/4/2/24/s1.

Author Contributions

Conceptualization, writing—review and editing R.S.G. and S.O.; methodology, validation, formal analysis, investigation, writing—original draft preparation, data curation, visualization R.S.G.; resources, supervision, project administration, funding acquisition S.O.

Funding

The information, data, or work presented herein was funded in part by the Office of Energy Efficiency and Renewable Energy (EERE), U.S. Department of Energy, under Award Number DE-EE0006926. The information, data, or work presented herein was funded in part by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of the authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof. This manuscript has been authored by UT-Battelle, LLC under Contract No. DE-AC05-00OR22725 with the U.S. Department of Energy. The United States Government retains and the publisher, by accepting the article for publication, acknowledges that the United States Government retains a non-exclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this manuscript, or allow others to do so, for United States Government purposes. The Department of Energy will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (http://energy.gov/downloads/doe-public-access-plan).

Acknowledgments

The authors would like to thank the American Composites Manufacturers Association (ACMA) and its members for technical discussions and supplied test materials. In particular, the authors would like to thank David Krug at Continental Structural Plastics for providing the automotive SMC materials and useful feedback.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Thomason, J.; Jenkins, P.; Yang, L. Glass Fibre Strength—A Review with Relation to Composite Recycling. Fibers 2016, 4, 18. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling technologies for thermoset composite materials—current status. Compos. Part A: Appl. Sci. 2005, 37, 1206–1215. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling fibre reinforced polymers. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Yip, H.L.H.; Pickering, S.J.; Rudd, C.D. Characterization of carbon fibres recycled from scrap composites using fluidized bed process. Plast. Rubber Compos. 2002, 31, 278–282. [Google Scholar] [CrossRef]

- Lester, W.; Kingman, S.; Wong, K.H.; Rudd, C.; Pickering, S.; Hilal, N. Microwave heating as a means for carbon fibre recovery from polymer composites: A technical feasibility study. Mater. Res. Bull. 2004, 39, 1549–1556. [Google Scholar] [CrossRef]

- Feih, S.; Boiocchi, E.; Mathys, G.; Mathys, Z.; Gibson, A.G.; Mouritz, A.P. Mechanical properties of thermally-treated and recycled glass fibres. Compos. Part. B 2011, 42, 350–358. [Google Scholar] [CrossRef]

- Cunliffe, A.M.; Jones, N.; Williams, P.T. Pyrolysis of Composites Plastic Waste. Environ. Technol. 2003, 24, 653–663. [Google Scholar] [CrossRef] [PubMed]

- Thomason, J.L.; Kao, C.C.; Ure, J.; Yang, L. The strength of glass fibre reinforcement after exposure to elevated composite processing temperatures. J. Mater. Sci. 2014, 49, 153–162. [Google Scholar] [CrossRef]

- Feih, S.; Manatpon, K.; Mathys, Z.; Gibson, A.G.; Mouritz, A.P. Strength degradation of glass fibers at high temperatures. J. Mater. Sci. 2009, 44, 392–400. [Google Scholar] [CrossRef]

- Feih, S.; Mouritz, A.P.; Case, S.W. Determining the mechanism controlling glass fibre strength loss during thermal recycling of waste composites. Compos. Part. A Appl. Sci. Manuf. 2015, 76, 255–261. [Google Scholar] [CrossRef]

- Cunliffe, A.M.; Williams, P.T. Characterization of products from the recycling of glass fibre reinforced polyester waste by pyrolysis. Fuel 2003, 82, 2223–2230. [Google Scholar] [CrossRef]

- Åkesson, D.; Foltynowicz, Z.; Christéen, J.; Skrifvars, M. Microwave pyrolysis as a method of recycling glass fibre from used blades of wind turbines. J. Reinf. Plast. Compos. 2012, 31, 1136–1142. [Google Scholar] [CrossRef]

- Thomason, J.L.; Nagel, U.; Yang, L.; Sáez, E. Regenerating the strength of thermally recycled glass fibres using hot sodium hydroxide. Compos. Part. A Appl. Sci. Manuf. 2016, 87, 220–227. [Google Scholar] [CrossRef]

- Ginder, R.S.; Ozcan, S. Controlled Pyrolysis: A Case Study of Scalable Glass and Carbon Fiber Composite Recycling Technology. In Proceedings of the CAMX 2018, Dallas, TX, USA, 23–26 September 2018. [Google Scholar]

- Yang, L.; Thomason, J.L. The thermal behavior of glass fibre investigated by thermomechanical analysis. J. Mater. Sci. 2013, 48, 5768–5775. [Google Scholar] [CrossRef]

- Otto, W.H. Compaction effects in glass fibers. J. Am. Ceram. Soc. 1961, 44, 68–72. [Google Scholar] [CrossRef]

- Otto, W.H.; Preston, F.W. Evidence against oriented structure in glass fibres. J. Soc. Glass Technol. 1950, 34, 63–68. [Google Scholar]

- Griffith, A.A. The phenomena of rupture and flow in solids. Phil. Trans. R Soc. Lond. 1921, 221, 163–198. [Google Scholar] [CrossRef]

- Ghosh, S.B.; Jones, F.R.; Hand, R.J. A novel indentation based method to determine the threshold stress intensity factor for subcritical crack growth in glass. Eur. J. Glass Sci Technol. Part A 2010, 51, 156–160. [Google Scholar]

- ASTM C1557-14, Standard Test Method for Tensile Strength and Young’s Modulus of Fibers. Available online: www.astm.org (accessed on 9 August 2018).

- ASTM C1239-13, Standard Practice for Reporting Uniaxial Strength Data and Estimating Weibull Distribution Parameters for Advanced Ceramics. Available online: www.astm.org (accessed on 26 March 2018).

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).