Abstract

Essential energy needs are not always met in poor and rural areas of developing counties; therefore, natural energy sources are necessary to mitigate this problem. Rural areas inhabitants utilize methane as a replacement for cooking gas to reduce their gas bill. Methane gas can be produced from a biogas digester; however, operating a large digester in a densely populated village in Jordan can be challenging due to inefficient village waste management systems. On the other hand, using a small-scale portable biogas digester to generate biogas could overcome these problems. In this work, three biogas digester feedstocks for a small portable biogas digester from natural sources available in Jordanian villages such as human and animal waste were designed and evaluated. The three feedstocks are food waste, human waste, and a mixture of human and food waste. The parameters tested were the digester size and the biogas production. The results showed that the best digester for portable application was that which digested a mixture of human and food waste; for a five-member family, this type of digester provided 115% of the family’s cooking gas requirements with a digester volume of 0.54 m3. This design, while applicable for a typical rural Jordanian family, can also be utilized globally.

1. Introduction

In 2015, the United Nations Development Programme (UNDP) identified 17 Sustainable Development Goals (SDGs) to be reached by 2030. Goal number seven of the UNDP SDGs states the need for affordable, clean, and sustainable energy access for all. One in seven people worldwide does not have access to electricity; most of these people are in rural areas, in addition to three billion people using unhealthy fuels for cooking [1]. Biogas digesters can be used in those rural areas to meet the energy demands and satisfy the UNDP goals with an emphasis on clean and sustainable energy under responsible consumption and production.

Waste management is one of the major challenges that face society, especially in developing countries. In several countries, waste management and reduction climbed to the top of their priorities’ list because of their negative environmental effects, representing a very important share of the common responsibilities and efforts in the endeavor to reduce the pollution and greenhouse gas emissions that cause global climate change. The old way of disposing wastes is unacceptable today; because of its undesirable effects, even using landfills for controlled waste disposal is not considered an optimal practice, as environmental standards call for the utilization of waste management through the recovery process, recycling nutrients, and using organic matter to produce biogas.

The anaerobic digestion (AD) of the organic materials that come from animal manure and human waste as digestible organic matter produces biogas as a renewable energy and offers a fertilizer for agriculture uses. Behind that, anaerobic digestion reduces the amount of non-useful materials and increases the utilization factor of the energy conversion process.

Biogas is a by-product of the anaerobic decomposition process of organic matter. It is a combustible gas consisting primarily of methane, carbon dioxide, and small amounts of other gases that are produced when the waste is fermented in the absence of the oxygen. The solid material that remains in the digester after the fermentation, which is rich in macro and micronutrients, can be used as an organic fertilizer.

The documentation process of the production and collection of biogas started for the first time in the United Kingdom in 1895 [2]. Since then, the process was applied and developed for wastewater treatment. The energy crisis of the early 1970s prompted interest in renewable energy and raised awareness about energy alternatives such as biogas from AD. The interest in biogas from AD received more traction with the confirmation of the depletion of fossil fuels along with the need for finding sustainable and environmentally friendly methods of recycling and treating human, animal, and organic waste.

There are over 35 million biogas installations worldwide, with production widely spread in Europe and North America; however, these installations are plant-based, while India and China focus on household biogas production [3]. Those biogas production methods are not applicable for rural areas, so studies in Africa [4,5], Asia [6], and South America [7,8] attempted to adjust biogas production from digesters to meet family needs in rural areas.

Biogas digesters use the anaerobic fermentation of organic matter in the absence of oxygen to produce biogas [9]. The AD is applied globally as a wastewater treatment method for methane production with livestock manures [10]. Several factors can affect the anaerobic digestion process; different feedstock will degrade at different rates and produce different amounts of methane. Different wastes with wastewaters can be mixed together and treated in the co-digestion schemes; the mixing process of different substrates improves the methane production and reduces the life cycle costs.

A biogas digester is an airtight enclosed container that aims to enhance the anaerobic digestion process of biodegradable waste such as animal manure and domestic wastes [11]. Biogas digesters can be classified into three categories: (i) passive systems, where recovered biogas is added to an existing waste treatment facility and there is little control of the anaerobic digestion process; (ii) low rate systems, where the wastes flows through the digester and only leaves when the designed hydraulic retention time (HRT) ends; and (iii) high rate systems, where the methane-forming bacteria is trapped in the digester to enhance the biogas production efficiency.

Jordan is one of the developing countries that is facing waste and pollution problems; at the same time, keeping up with scientific innovations can curtail waste and enhance renewable energy production in an era of constantly increasing fuel prices. As a response to that, the authors have proposed a sustainable design for cities that could utilize biogas to provide sustainable energy [12].

The most recent average growth rate of the Jordanian population stands at about 3.5% due to voluntary and involuntary migration. The influx of refugees and displaced persons has resulted in fast and uncontrolled urbanization; this is another reason for new sources of energy such as biogas.

Biogas production from wastewater in Jordan is very limited; it requires a large-scale biogas production system with high safety standards in addition to high operation and maintenance costs. These constraints motivated the authors to study microscale portable biogas digesters for small Jordanian communities, focusing on biogas production for a single family with the intention of evaluating the effect of this small-scale system on the family’s energy consumption.

Investigations into biomass resources in Jordan for biogas production found that Jordan produces more than 5.83 mega tons (MT) of waste and residue annually, 42% of which is available sources for biogas production and energy generation [13]. The annual biogas and power potentials are 313.14 million cubic meters (MCMs) and 847.39 GWh, respectively. Biogas could replace 23.64% of Jordan’s energy consumption in the year 2012 in the form of natural gas.

Work on the fabrication of a portable digester considering the economic and ergonomic factors with maximum efficiency in methane production in all weather conditions concluded that this digester helped the society in two ways: the first was to reduce waste, and the second was to provide valuable energy [14]. A study of the design of a digester with a fixed dome, unlike the ones used for cow dung, judged all the parameters in the experiment and their effects on the process of the anaerobic digestion of paddy straw [15].

A review of the biogas digester types installed in rural South Africa to help stakeholders in the selection of the most appropriate digester type that was well-suited to their environmental conditions concluded that the in situ cast concrete digester was the most suitable design for installation in rural South Africa [4]. A simulation of the operation of an anaerobic digestion located on a farm and primarily fed by cattle slurry, manure, and ensiled maize to control the methane production discovered that a controlled addition of external substrates was possible to maintain the methane production at the desired level [16].

A novel and universal methodology for the design of low-cost tubular digesters [17] was presented with a recommendation for designing the digester using a trench cross-sectional area. The design also proposed an optimization of the trench dimensions with respect to the angle of the walls and the relationship between the length of the biogas bell and the top width of the trench. A study on the effect of using pasteurized food waste in mixture with cattle manure as a feedstock found that no large-scale inhibition phenomena were observed on the thermophilic anaerobic digestion systems when the hydraulic retention time was sustained to at least 21 days without jeopardizing the process [18].

A design of a floating dome-type portable biogas plant to help farmers in the remote area of Pakistan treat their residue biomass was presented [19], and after testing the portable design, it was found that it was beneficial due to its long life, light weight, and capacity to sufficiently produce biogas.

Another study compared the energy production, wastewater treatment efficiency, and financial cost of communal anaerobic digesters (ADs) used for domestic wastewater treatment with septic tanks (STs), which is the alternative conventional wastewater treatment in Zambia [20]. Data from 15 anaerobic digesters were collected and used in this study; it was found that anaerobic digesters wastewater treatment efficiencies ranging from 61% to 83%, and households with digesters used 29% less energy. Further, the economic effect of installing a biodigester in Arusha, Tanzania can reduce the money, time, cost of fuel procurement, and the fuel wood use [21]. Firewood and kerosene consumption with the digester were 93% (5376 kg) and 98% (48 L) less per year, respectively, compared to households without digesters. Households with digesters spent an average of $249 less per year on energy. No significant differences in agricultural productivity or synthetic fertilizer between households with and without digesters were found.

One study investigated the effect that co-digesting sewage sludge with a small amount of food and farm waste had on increasing the biogas production. This study mixed sewage sludge (SS) with sheep manure (SM), crude glycerol (CG), cheese whey (CW), grape residues (GR), and food waste (FW) in small ratios of 5–10% (v/v). The results determined that there was a significant increase in biogas production—148%—through using a mixture with 5% FW, while 5% FW and 5% CG increased production by nearly 220%. The worst improvement was from the mixture that contained 5% SM, which only increased biogas production by 14% [22].

Based on the literature review, it was found that portable digesters in Jordanian villages have not yet not been investigated. This work covers the utilization of portable digesters to benefit villagers and enhance waste management by treating domestic waste and exploiting alternative sources of energy. Even though the design parameters were Jordan-focused, the concept can be used globally with minor modifications, and the portability factor makes it attractive for rural inhabitant in different parts of the world.

2. Methodology

In 2015, the Jordanian population was 9,531,712 which amounted to 1,977,534 families with an average family size of 4.82 individuals; the average number of family members in the rural areas was higher than the city average [23].

The calculation of the gas production rate per kilograms of a particular process within the body of a digester varies from one biomass material to another. Here, the mathematical calculations for four different types of cylindrical dome digesters are based on the feedstock daily production rate for each case. The calculations took the following into consideration: inlet cylindrical tank, digester volume, dome (gas volume), and outlet chamber agitator.

The process of gas production depends on the type of material that produces biogas and the number of vital elements in it; each material has a specific fermentation period and a specific proportion of gas production according to the normative conditions. Table 1 contains the biogas yield of different available feedstocks on which the design of the biogas digester depends.

Table 1.

Feedstock biogas production [22].

The following equations (1–16, shown in Table 2), and assumptions were all obtained from reference [15] with minor modifications to fit the design of this study.

Table 2.

List of equations and symbol definitions used to calculate the biogas digester’s size.

The assumptions were:

- The total mass is the mass of the solid waste plus the mass of the water; 20 L of water are required for 10 kg of dry waste.

- In the biogas digester, the ratio of the diameter (D) to the height (H) was set at D:2H.

- Cooking was assumed to take place twice a day. 50% of the gas produced in a day was available for one cooking span.

- The slurry displacement height (h) in the inlet and outlet tanks depended upon the following factors: the maximum pressure attained by the gas was equal to the pressure of the water (slurry) column above the lowest slurry level in the inlet/outlet tanks; the pressure was selected to be 0.85 m water gauge as a safe limit.

- Equations (8)–(10) were valid for both the inlet and outlet if both were rectangular, but since only the outlet was rectangular, the equation was modified to Equation (11).

- If the diameters of the inlet pipe were not available in the range of ±15 to 20 cm, the inlet and outlet tanks were not the same dimensions. The inlet diameter was slightly higher because it was also used as the storage tank.

- Vd was fixed at 0.4 G, which was the remaining gas space volume.

The equations in Table 2 were solved using the Engineering Equation Solver (EES) tool to obtain the design of four domestic biogas digesters. The design of the biogas digesters was based on the feedstock. The domestic feedstocks were human waste, food waste, and a mixture of human and food waste. Another design was based on domestic animal waste only. Two parameters were studied: the digester’s size and methane gas production. The first scenario was a human waste biogas digester, from Table 1; the biogas production of human waste was 0.023 m−3 kg−1, and the production rate was taken at 0.6 kg per day. The second scenario was executed using food waste as the feedstock; the equation that calculates the domestic waste as a function of family size [24] was:

where Y is human waste production and N is the number of family members. Less than half (40%) of the domestic waste was organic; one kilogram of food waste yields 0.2 m3 of biogas [24]. The third scenario was executed by using both human and food waste as the feedstock. The fourth scenario utilized a domestic animal manure biogas digester.

Y = 70.767N + 277.2

The results presented in this work were based on the input data obtained from the Jordanian Department of Statistics [23]; these inputs were used in the equations discussed in Table 2. Similarly, the inputs can be adjusted to fit the parameters of different areas, making the proposed portable biogas digester suitable for use in different areas across the globe.

The validation of results presented in Table 3 was done by comparing the results obtained by reference [15] and those obtained in this study. Although the calculations in this study were done using approximation, the maximum error in the results shown in Table 3 was 1.55%; this approximation marginally affected the H and D calculations. Based on that and on equations 18 and 19, the results of this study were validated.

VS = 3.8 G

d = (H/3.8) × 0.4

Table 3.

Validation of results.

3. Results and Discussion

The result of the digester’s design was based on two parameters: the digester’s size and the methane production rate. The digester’s size was important to determine its ability to be used in portable application, while the methane gas production was important to determine how efficient the digester was to cover the family’s cooking gas requirement. The major component of waste was human waste, but since every family has its food residuals, and since those residuals have a percentage of the biogas production, the food residuals were added to the waste to study the improvement in the biogas production.

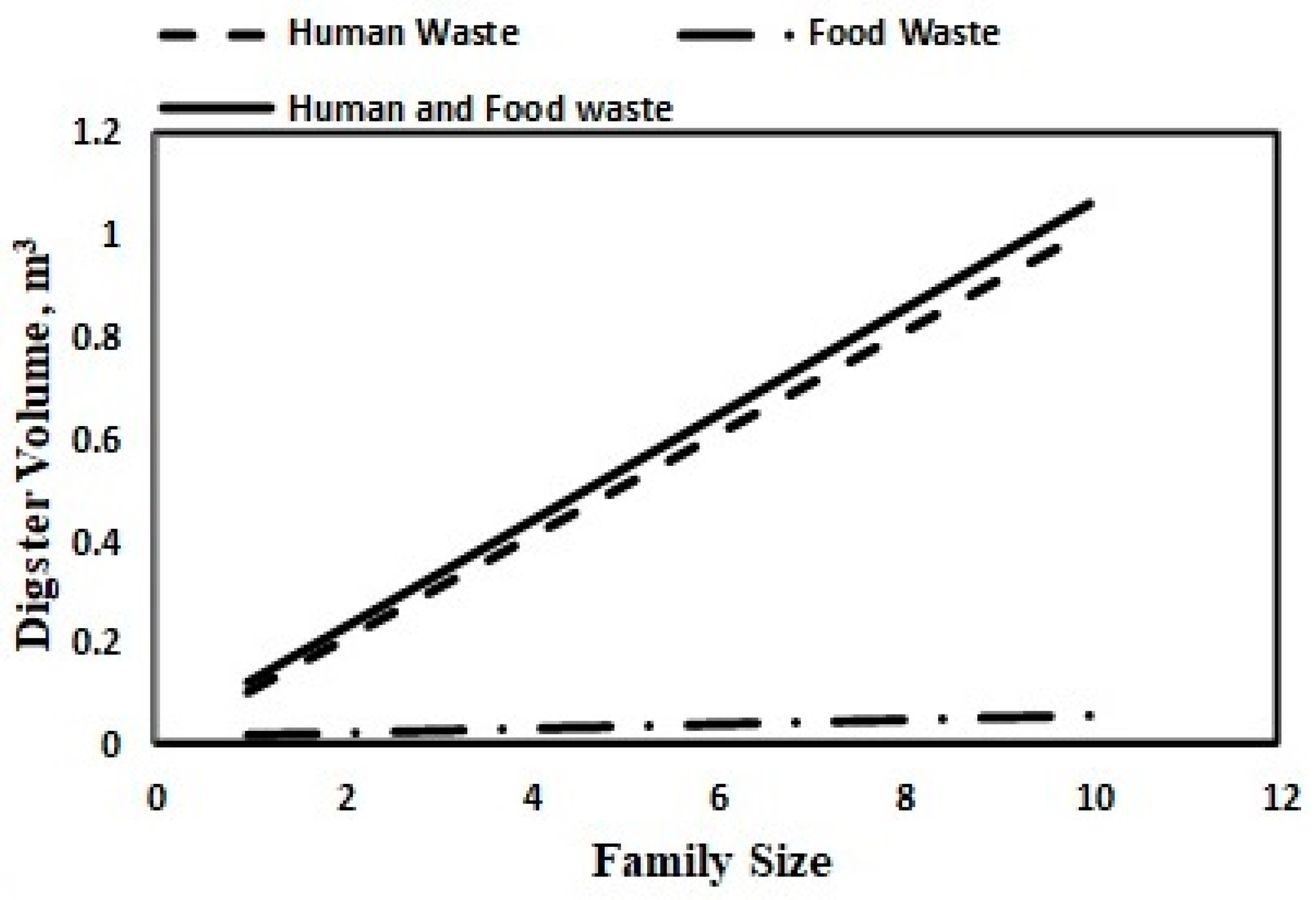

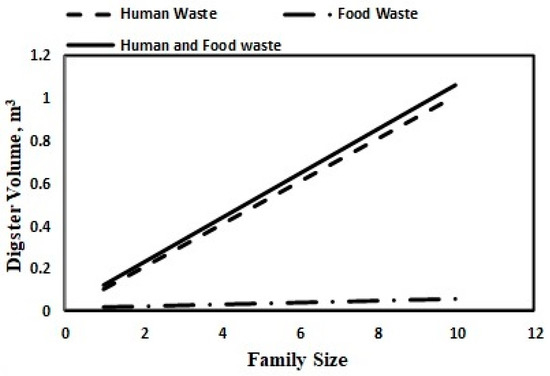

The results of the domestic waste digesters’ diameters are presented in Figure 1; the digester that uses human and food waste has the biggest size, and it is very close to the digester that is used for human waste only. As the family size increases, the difference between the two digesters becomes more significant. Figure 1 also shows that the size of the food waste digester was by far the smallest.

Figure 1.

Digester volume.

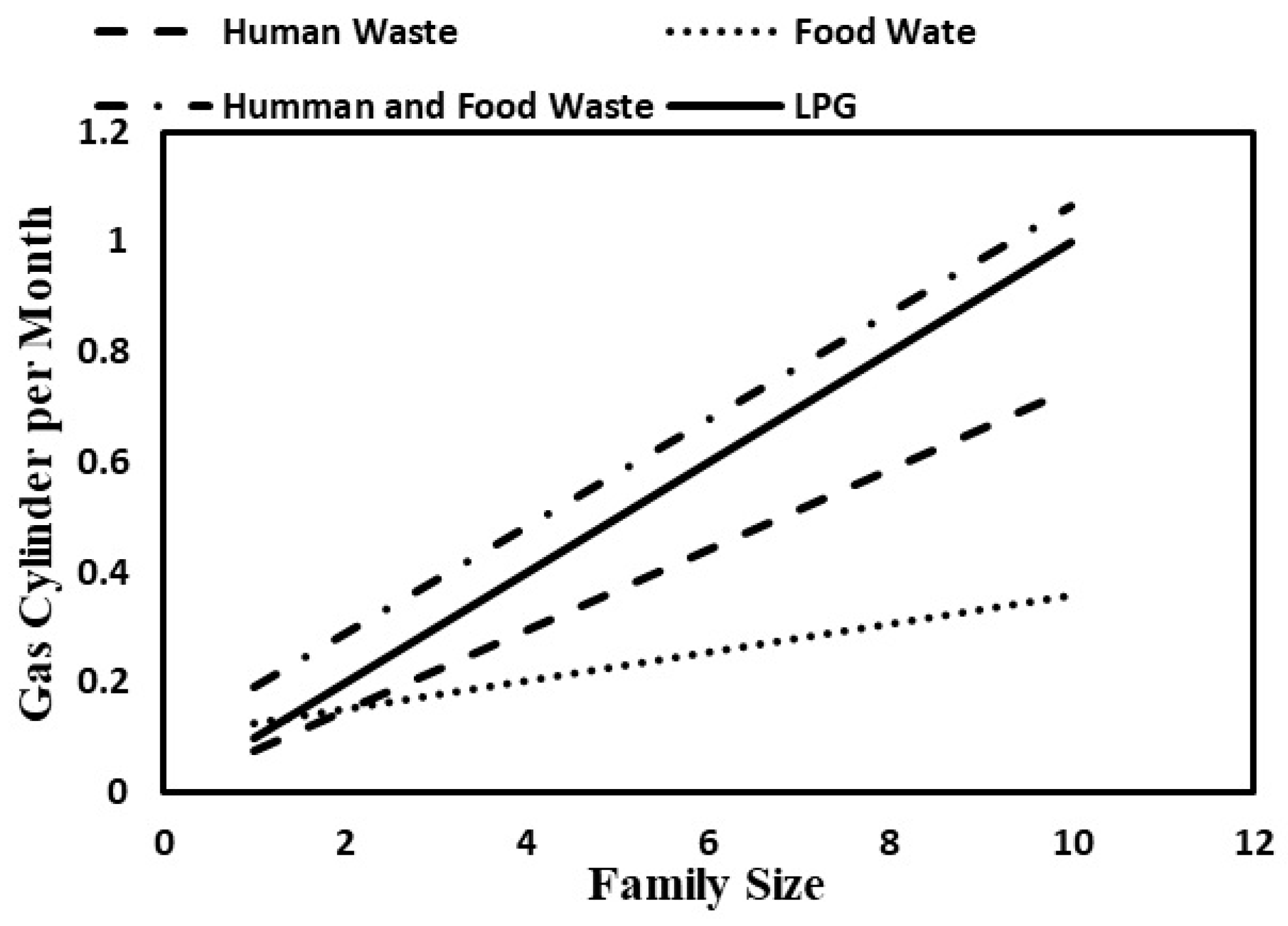

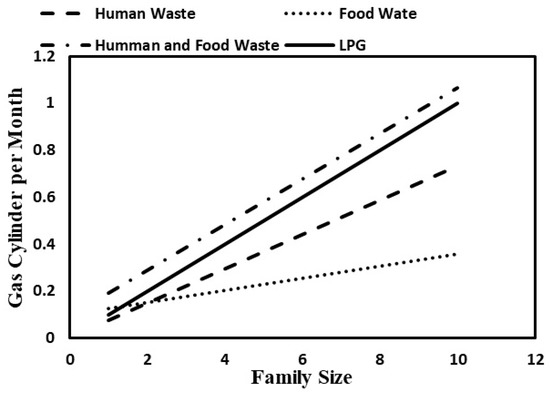

The results of methane gas generation from digesters are presented in Figure 2. It was found that using a mixture of human and food waste feedstock provided 115% of the cooking gas demand for a five-member family; meanwhile, human waste alone and food waste feedstock alone provided 68% and 46%, respectively. For one individual person’s digester, food residues alone can provide the whole liquefied petroleum gas (LPG) cooking gas requirement, while a human waste digester does not cover it. As the family size increases, the food residues digester becomes less efficient, and its ability to cover the LPG cooking gas requirement decreases. Figure 2 shows that for a 10-member family, the biogas digester covers only 35% of the family’s LPG cooking gas. The LPG gas line and the food–human waste digester line will eventually intersect, meaning that an increase in the family size will prevent the digester from covering the family’s demand of LPG cooking gas.

Figure 2.

Number of produced gas cylinders per month.

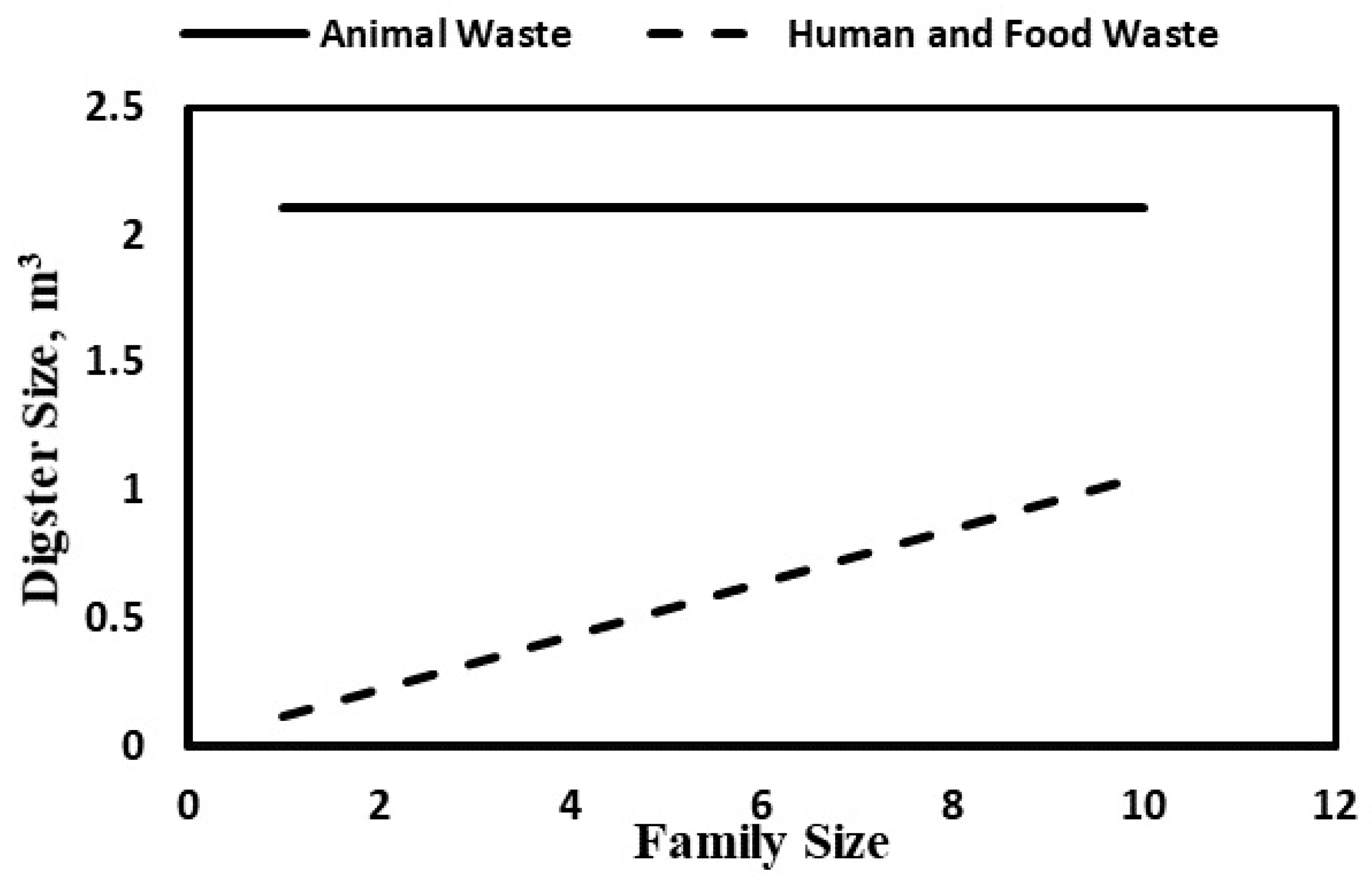

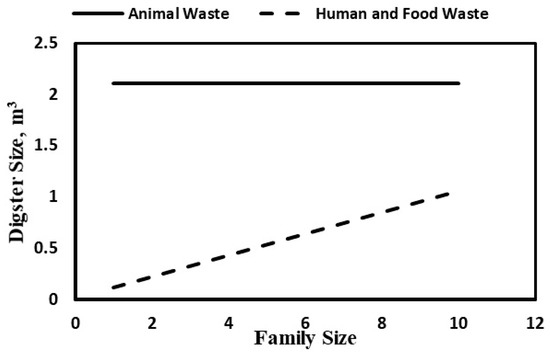

The fourth design utilized domestic animal solid manure feedstock, which was taken as a constant regardless of family size. In this case, the farm was assumed to own one cow, two sheep, and seven chickens. For instance, the amount of the manure has been estimated as 10 kg/day for a cow, 2 kg/day for a sheep, and 0.08–0.1 kg/day for a chicken [25]. Table 1 shows that cow dung generates 0.03 m3 kg−1, sheep manure generates 0.03 m3 kg−1, and chicken waste generates 0.001 m3 kg−1. The digester’s size of domestic animal manure feedstock compared to human and food waste is presented in Figure 3. For a five-member family, the size of the digester’s diameter is eight times bigger than that of the human–food waste digester. More space is required to install a digester of this size, rendering it unsuitable for a portable digester application; so, it has to be fixed, similar to a dome digester.

Figure 3.

Digester size.

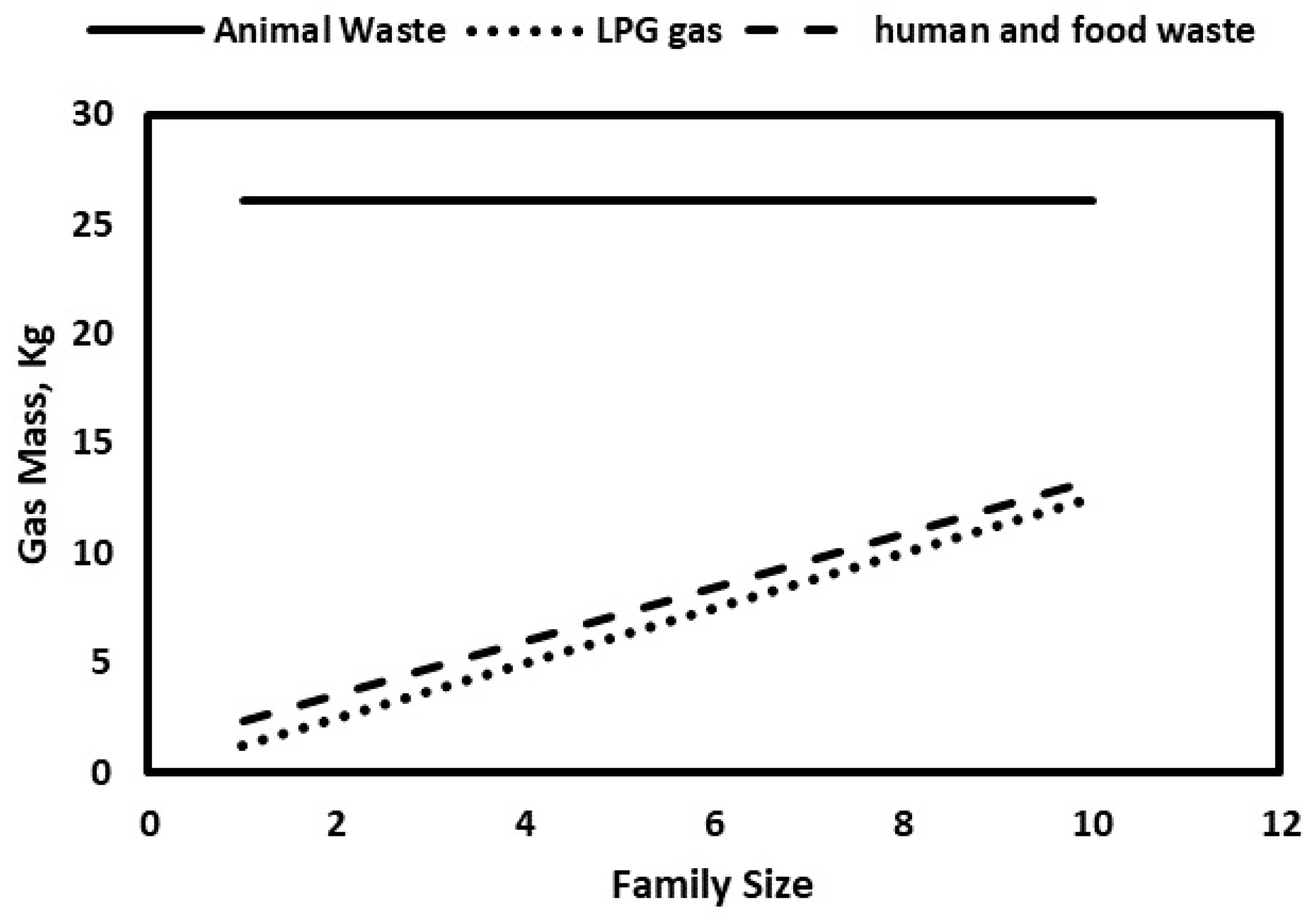

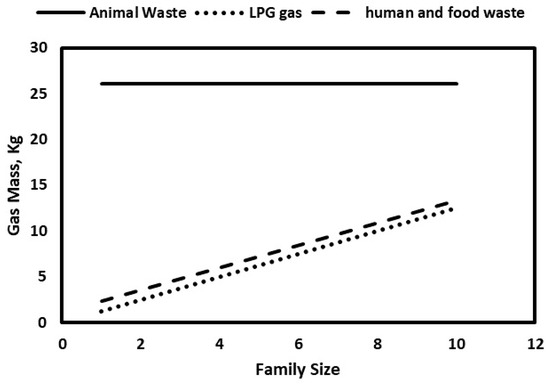

Figure 4 contains the amount of biogas production of the domestic animals compared to human and food waste and the LPG cooking gas requirement. For a five-member family, the domestic animal manure digester provided four times the family’s cooking gas requirement, and the excess can be used for space heating, while the human–food waste digester covered 115% of the family’s cooking gas requirement.

Figure 4.

Digester gas productivity.

The detailed result of a five-member family biodigester system that uses a mixture of human and food waste feedstock is presented in Table 4.

Table 4.

Results of human and food waste feedstock digesters.

The summary of the results of the four cases of the digester design and the gas production capability is presented in Table 5. The average number of individuals in the family was considered to be five, according to the Jordanian Department of Statistics [23]. The gas cylinder is compared to the Jordanian LPG cooking gas cylinder that, according to the Jordanian petroleum refinery company, contains 12.5 kg of LPG gas.

Table 5.

Summary of results.

Table 5 shows that the human waste covers 68% of the monthly cooking gas demand and is enhanced by food residuals to reach 115% of the monthly gas demand. On the other hand, the domestic animal wastes for biogas production can cover the gas demand four times over, but the problem was that the digester size has increased significantly.

4. Conclusions

The digester size and biogas productivity are the parameters controlling the design of a portable digester. Firstly, investment in a portable digester can solve the waste management of rural populations and reduce a family’s gas bill. Secondly, it has been noticed that a farm animal manure digester has the highest biogas productivity, and it covers four times the gas demand of one five-member family; however, with a volume of 2.1 m3, it is oversized for portable applications. Thirdly, organic fertilizers can be made from the slurry generated after the biogas production process. A human waste digester and a food waste digester both met the portable size requirement with digester sizes of 0.5 m3 and 0.09 m3, respectively. Both have a low biogas productivity that covers 68% and 46%, respectively, of the family’s cooking gas requirement. Finally, the best design was one that was able to digest a mixture of human and food waste, this digester met the portable size requirement, with a digester size of 0.54 m3, and supplied 115% of a family’s cooking gas requirement. Different geographical locations, rural area climates, and rural family sizes will require minor adjustments in this design, yet it will also provide the required energy to meet the demand of a rural family anywhere in the world.

Author Contributions

Conceptualization, A.A.; Investigation, K.A.A., A.S.N. and M.A.A.-S.; Writing, review & editing, M.K.K. All the authors have worked as a team on this study.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- United Nations Development Programme. The Sustainable Development Goals Report 2018; United Nations: New York, NY, USA, 2018. [Google Scholar]

- Metcalf, E.; Eddy, H. Wastewater Engineering: Treatment and Reuse; McGraw-Hill: New York, NY, USA, 2003; ISBN 9780874216561. [Google Scholar]

- Kemausuor, F.; Adaramola, M.; Morken, J.; Kemausuor, F.; Adaramola, M.S.; Morken, J. A Review of Commercial Biogas Systems and Lessons for Africa. Energies 2018, 11, 2984. [Google Scholar] [CrossRef]

- Mutungwazi, A.; Mukumba, P.; Makaka, G. Biogas digester types installed in South Africa: A review. Renew. Sustain. Energy Rev. 2018, 81, 172–180. [Google Scholar] [CrossRef]

- Kabyanga, M.; Balana, B.B.; Mugisha, J.; Walekhwa, P.N.; Smith, J.; Glenk, K. Economic potential of flexible balloon biogas digester among smallholder farmers: A case study from Uganda. Renew. Energy 2018, 120, 392–400. [Google Scholar] [CrossRef]

- Khan, E.U.; Martin, A.R. Review of biogas digester technology in rural Bangladesh. Renew. Sustain. Energy Rev. 2016, 62, 247–259. [Google Scholar] [CrossRef]

- Garfí, M.; Castro, L.; Montero, N.; Escalante, H.; Ferrer, I. Evaluating environmental benefits of low-cost biogas digesters in small-scale farms in Colombia: A life cycle assessment. Bioresour. Technol. 2019, 274, 541–548. [Google Scholar] [CrossRef] [PubMed]

- Ferrer-Martí, L.; Ferrer, I.; Sánchez, E.; Garfí, M. A multi-criteria decision support tool for the assessment of household biogas digester programmes in rural areas. A case study in Peru. Renew. Sustain. Energy Rev. 2018, 95, 74–83. [Google Scholar] [CrossRef]

- Walekhwa, P.N.; Mugisha, J.; Drake, L. Biogas energy from family-sized digesters in Uganda: Critical factors and policy implications. Energy Policy 2009, 37, 2754–2762. [Google Scholar] [CrossRef]

- Global Methane Initiative—Agriculture Subcommittee. A Global Perspective of Anaerobic Digestion Policies and Incentives; Global Methane Initiative: Washington, DC, USA, 2014. [Google Scholar]

- Spuhler, D. Anaerobic Digestion (Small-Scale). Available online: https://webcache.googleusercontent.com/search?q=cache:E4OhS5P2mi8J:https://sswm.info/sites/default/files/ppts/SPUHLER%25202010%2520Anaerobic%2520Digester%2520Smallscale_2.ppt+&cd=1&hl=en&ct=clnk&gl=hk (accessed on 16 May 2014).

- Alkhalidi, A.; Qoaider, L.; Khashman, A.; Al-Alami, A.R.; Jiryes, S. Energy and water as indicators for sustainable city site selection and design in Jordan using smart grid. Sustain. Cities Soc. 2018, 37, 125–132. [Google Scholar] [CrossRef]

- Al-Hamamre, Z.; Saidan, M.; Hararah, M.; Rawajfeh, K.; Alkhasawneh, H.E.; Al-Shannag, M. Wastes and biomass materials as sustainable-renewable energy resources for Jordan. Renew. Sustain. Energy Rev. 2017, 67, 295–314. [Google Scholar] [CrossRef]

- Jyothilakshmi, R.; Prakash, S.V. Design, Fabrication and Experimentation of a Small Scale Anaerobic Biodigester for Domestic Biodegradable Solid Waste with Energy Recovery and Sizing Calculations. Procedia Environ. Sci. 2016, 35, 749–755. [Google Scholar] [CrossRef]

- Kaur, H.; Sohpal, V.K.; Kumar, S. Designing of small scale fixed dome biogas digester for paddy straw. Int. J. Renew. Energy Res. 2017, 7, 422–431. [Google Scholar] [CrossRef]

- Adouani, N.; Pons, M.N.; Assaad, A.; Hreiz, R.; Ravard, B.; Pacaud, S. Control of a farm anaerobic digester for agricultural wastes. IFAC-PapersOnLine 2017, 50, 3923–3928. [Google Scholar] [CrossRef]

- Martí-Herrero, J.; Cipriano, J. Design methodology for low cost tubular digesters. Bioresour. Technol. 2012, 108, 21–27. [Google Scholar] [CrossRef] [PubMed]

- Zarkadas, I.S.; Sofikiti, A.S.; Voudrias, E.A.; Pilidis, G.A. Thermophilic anaerobic digestion of pasteurised food wastes and dairy cattle manure in batch and large volume laboratory digesters: Focussing on mixing ratios. Renew. Energy 2015, 80, 432–440. [Google Scholar] [CrossRef]

- Mushtaq, K.; Zaidi, A.A.; Askari, S.J. Design and performance analysis of floating dome type portable biogas plant for domestic use in Pakistan. Sustain. Energy Technol. Assessments 2016, 14, 21–25. [Google Scholar] [CrossRef]

- Laramee, J.; Tilmans, S.; Davis, J. Costs and benefits of biogas recovery from communal anaerobic digesters treating domestic wastewater: Evidence from peri-urban Zambia. J. Environ. Manag. 2018, 210, 23–35. [Google Scholar] [CrossRef] [PubMed]

- Laramee, J.; Davis, J. Economic and environmental impacts of domestic bio-digesters: Evidence from Arusha, Tanzania. Energy Sustain. Dev. 2013, 17, 296–304. [Google Scholar] [CrossRef]

- Maragkaki, A.E.; Fountoulakis, M.; Kyriakou, A.; Lasaridi, K.; Manios, T. Boosting biogas production from sewage sludge by adding small amount of agro-industrial by-products and food waste residues. Waste Manag. 2018, 71, 605–611. [Google Scholar] [CrossRef] [PubMed]

- Jordanian Department of Statistics. General Population and Housing Census 2015—Main Results; Jordanian Department of Statistics: Amman, Jordan, 2015.

- Deublein, D.; Steinhauser, A. Biogas from Waste and Renewable Resources: An Introduction, 2nd ed.; WILEY-VCH: Deggendorf, Germany, 2010; ISBN 9783527327980. [Google Scholar]

- Abdeshahian, P.; Lim, J.S.; Ho, W.S.; Hashim, H.; Lee, C.T. Potential of biogas production from farm animal waste in Malaysia. Renew. Sustain. Energy Rev. 2016, 60, 714–723. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).