The Feasibility of Using Marble Cutting Waste in a Sustainable Building Clay Industry

Abstract

1. Introduction

2. Experimental Procedures

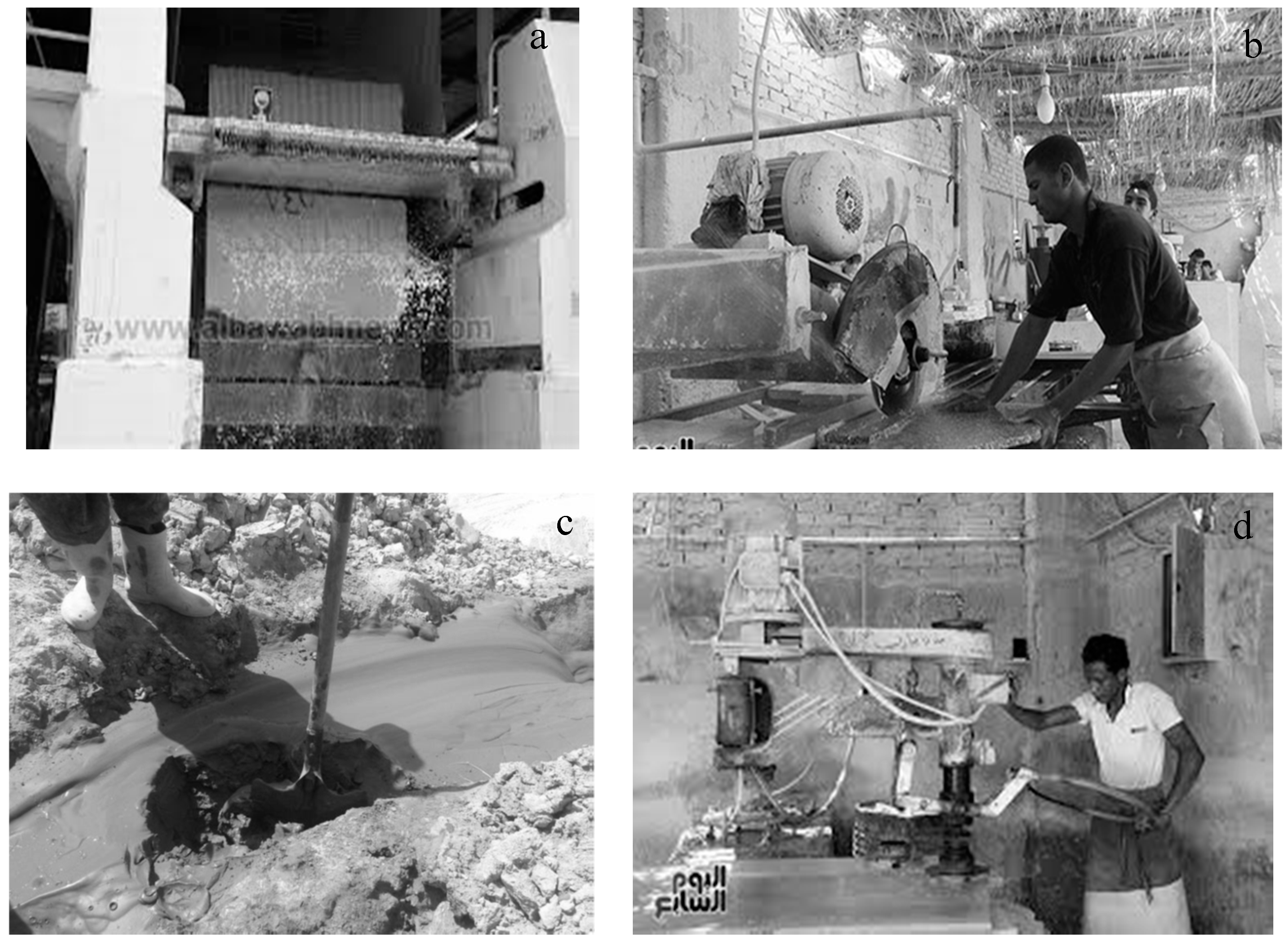

2.1. Materials

2.2. Methods

2.3. Mix Composition and Specimen Preparation

2.4. Testing Procedures

3. Results and Discussion

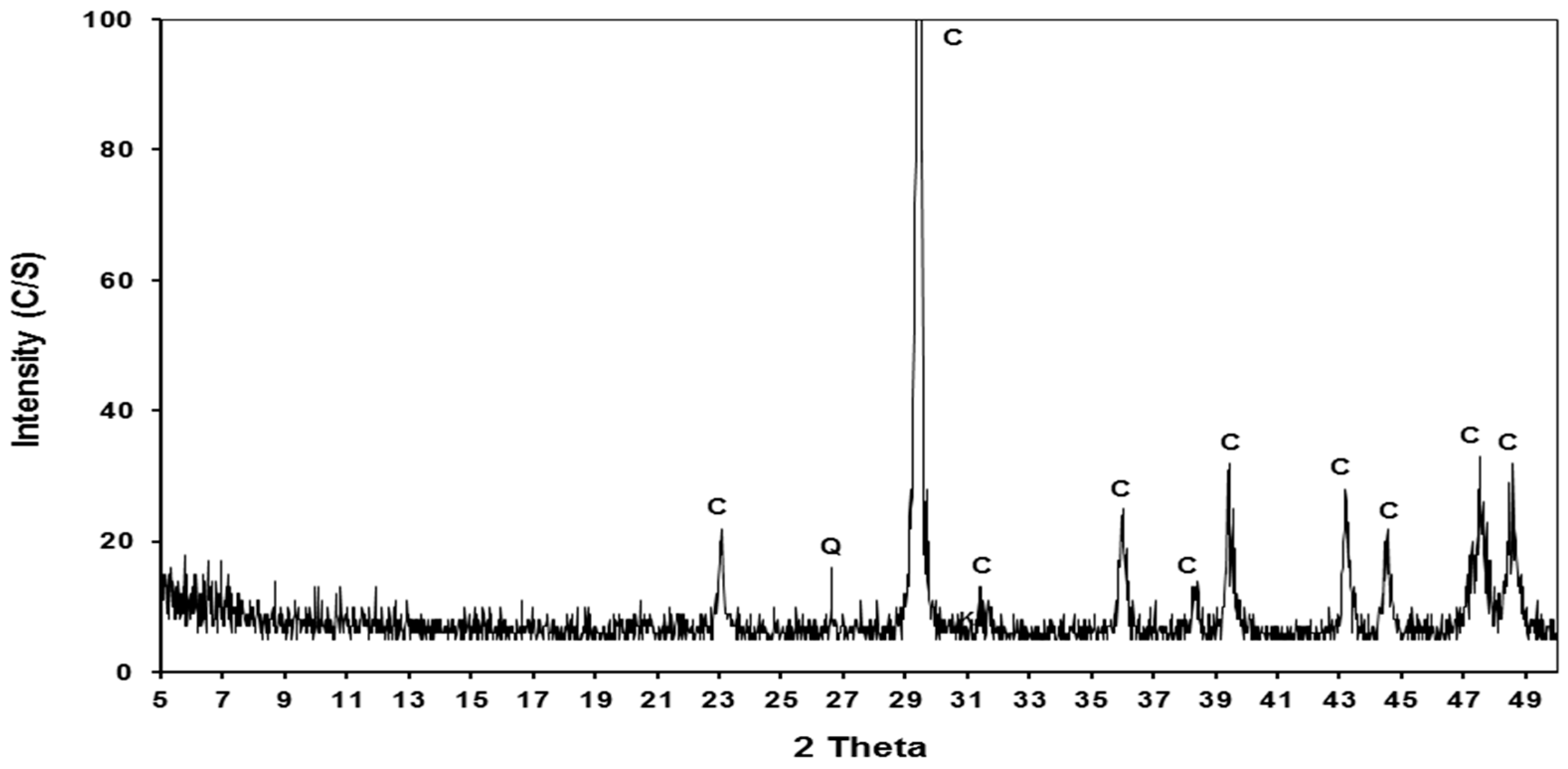

3.1. Characteristics of the Raw Materials

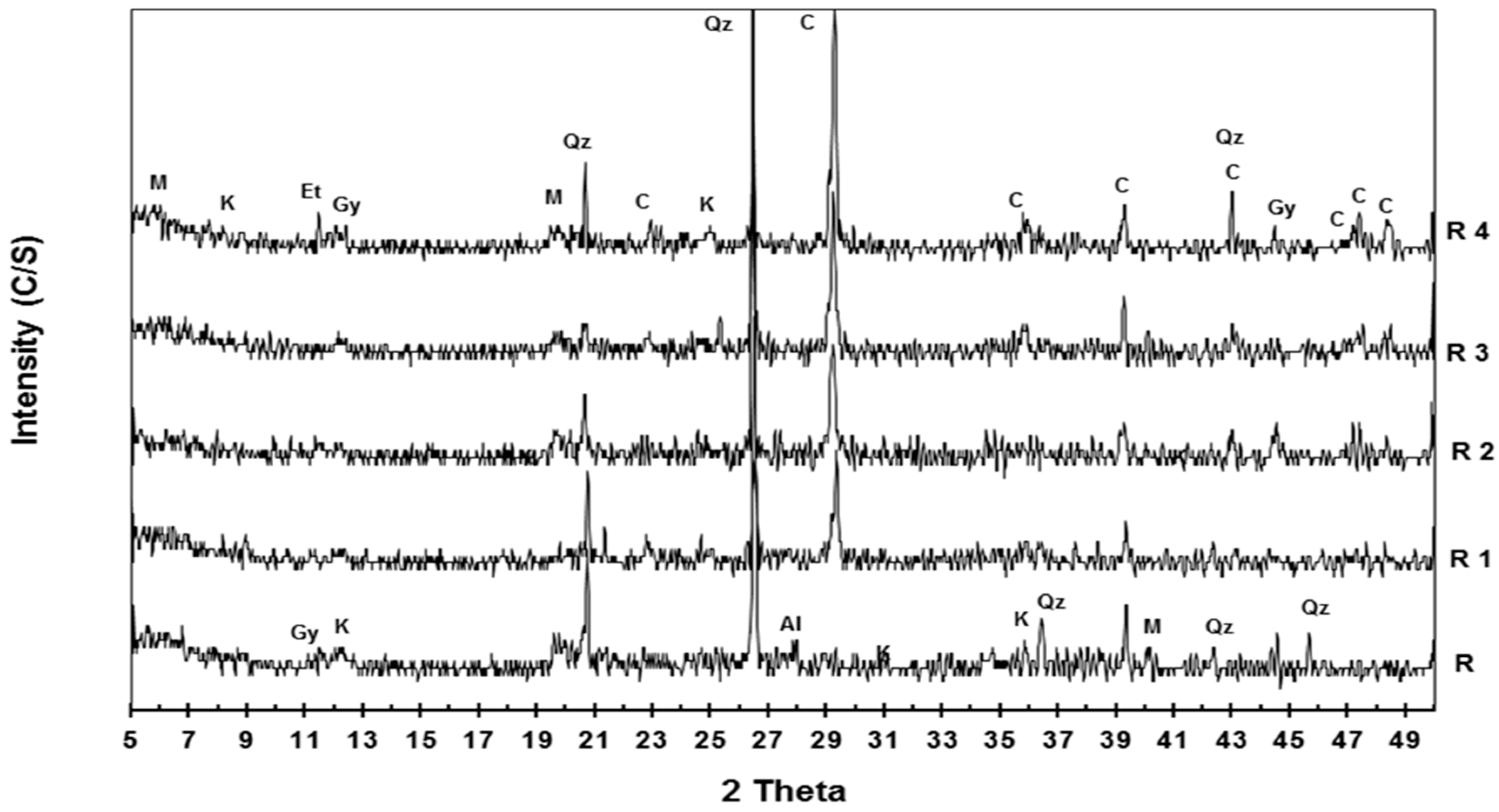

3.2. Mineralogy of the Cured Specimens of Different Mixes

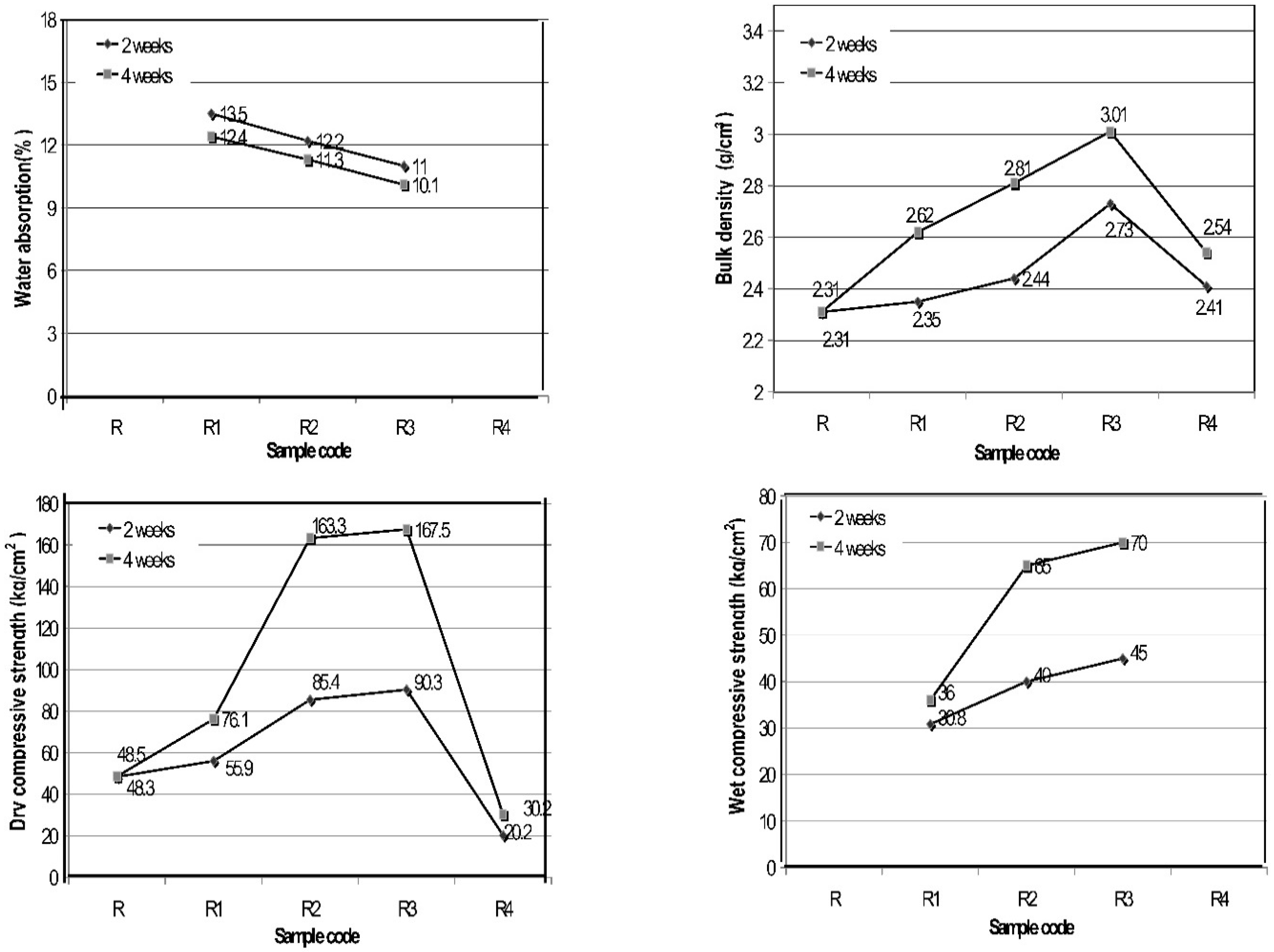

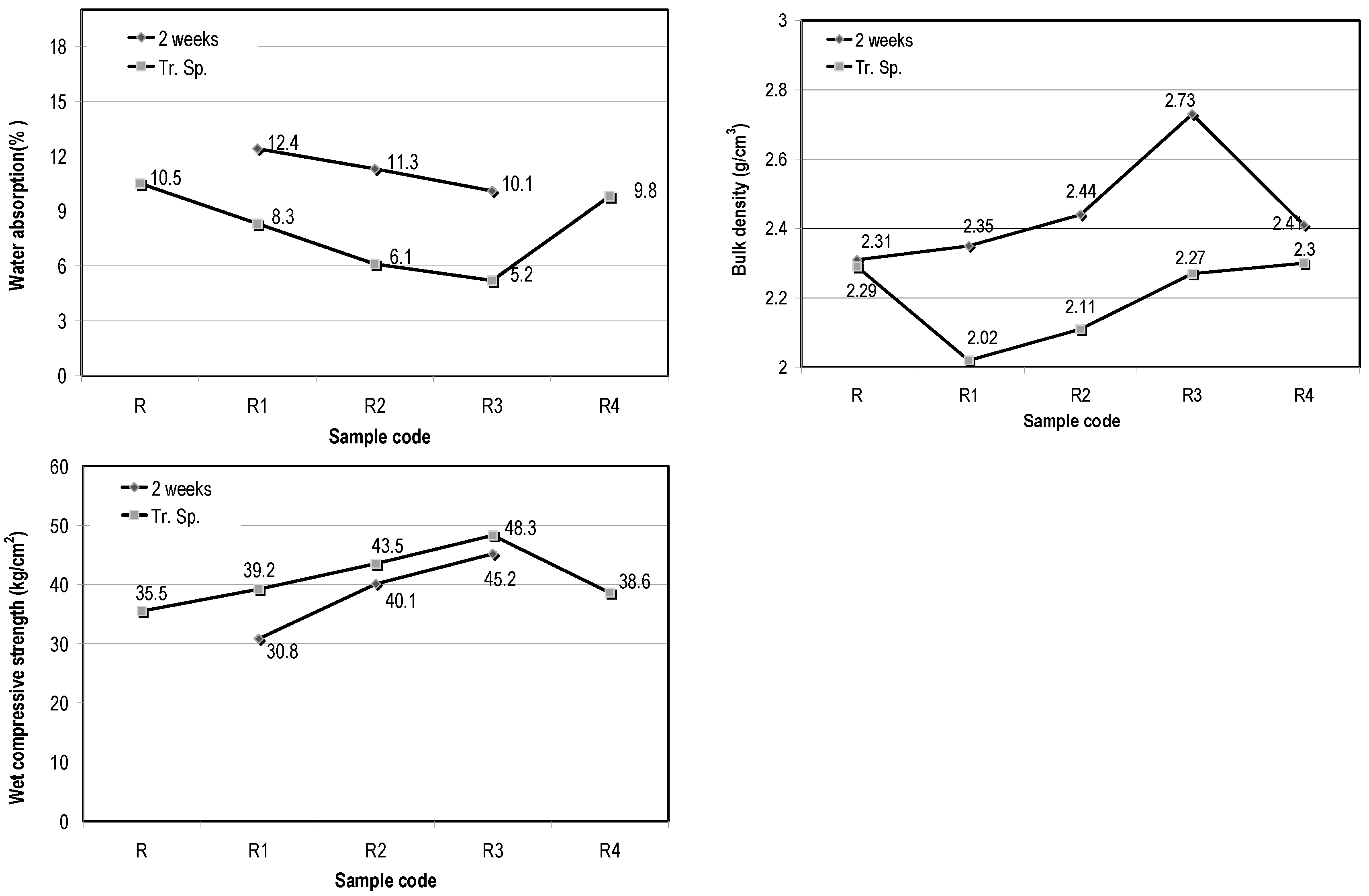

3.3. Physico-Mechanical Properties of the Cured Specimens

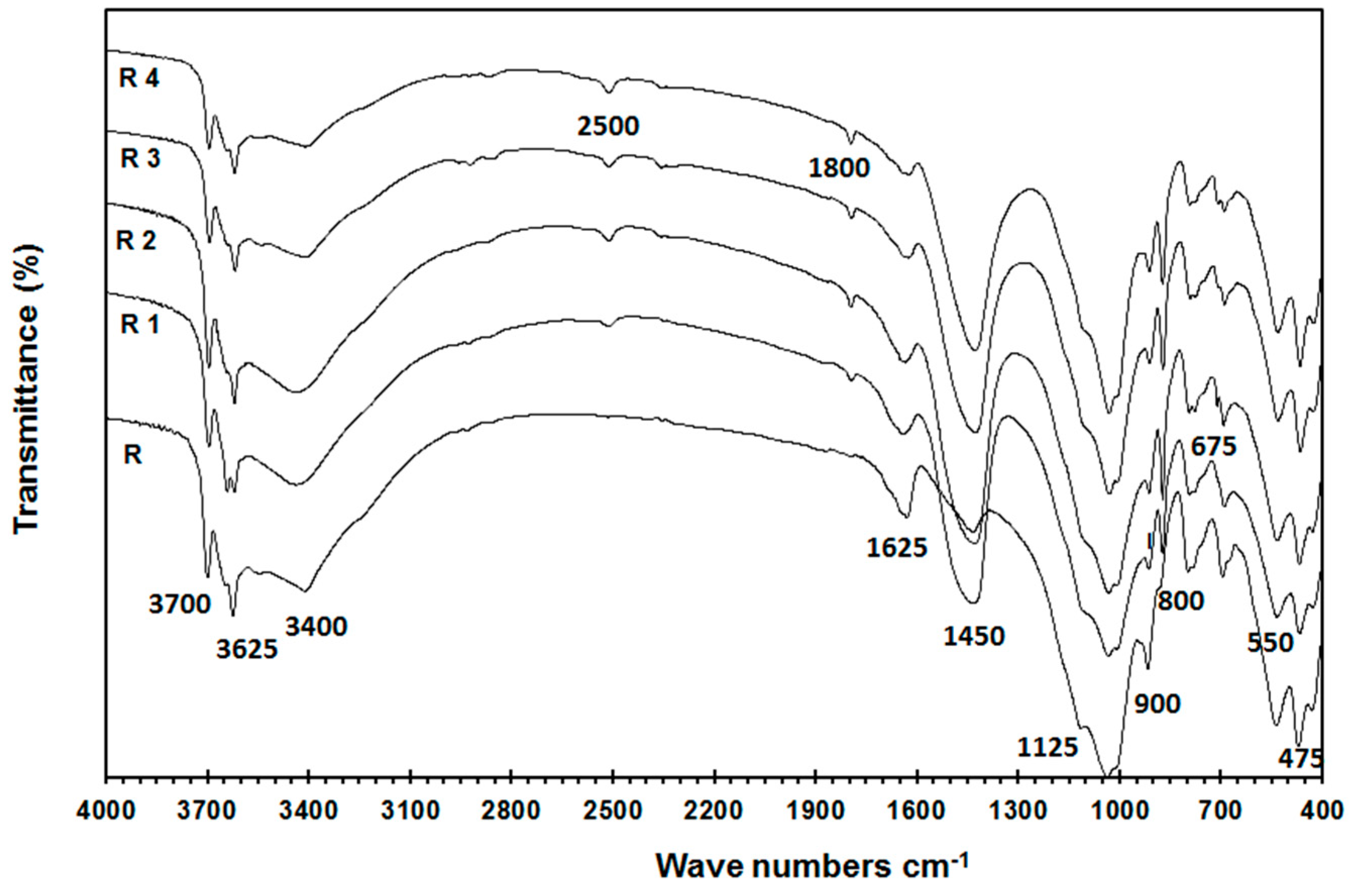

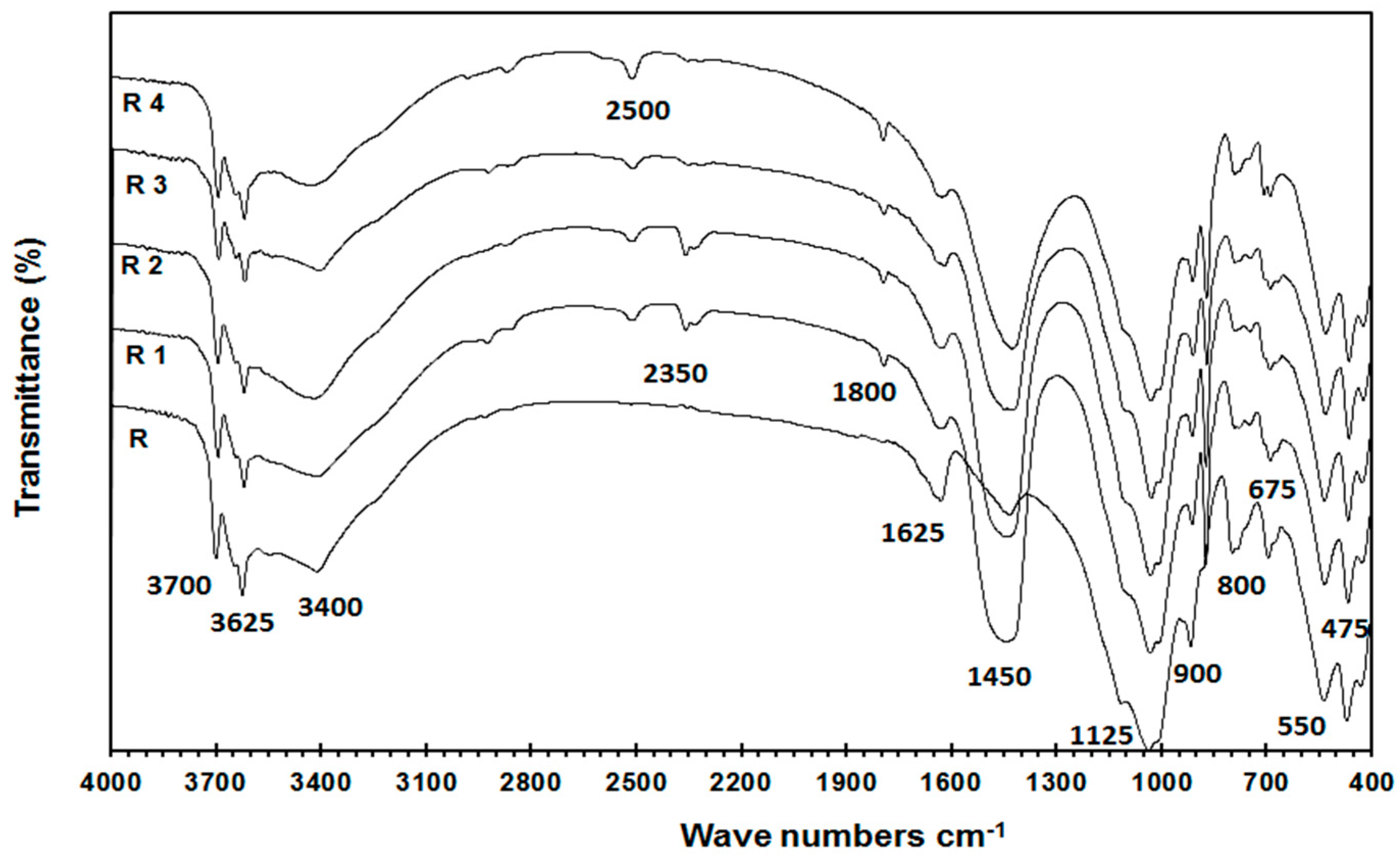

3.4. Results of the FTIR Analysis of the Cured Specimens of Different Mixes

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References and Notes

- Reddy, B.; Jagadish, K. Embodied energy of common and alternative building materials and technology. Energy Build. 2003, 35, 129–137. [Google Scholar] [CrossRef]

- Zhang, L. Production of bricks from waste materials—A review. Constr. Build. Mater. 2013, 47, 643–655. [Google Scholar] [CrossRef]

- Turkmen, I.; Ekinci, E.; Kantarc, F.; Sarc, T. The mechanical and physical properties of unfired earth bricks stabilized with gypsum and Elazig Ferrochrome slag. Int. J. Sus. Built Environ. 2017, 6, 565–573. [Google Scholar] [CrossRef]

- Siddiqua, S.; Barreto, P. Chemical stabilization of rammed earth using calcium carbide residue and fly ash. Constr. Build. Mater. 2018, 169, 364–371. [Google Scholar] [CrossRef]

- Sekhar, D.; Nayak, S. Utilization of granulated blast furnace slag and cement in the manufacture of compressed stabilized earth blocks. Constr. Build. Mater. 2018, 166, 531–536. [Google Scholar] [CrossRef]

- Sore, S.; Messan, A.; Prud’homme, E.; Escadeillas, G.; Tsobnang, F. Stabilization of compressed earth blocks (CEBs) by geopolymer binder based on local materials from Burkina Faso. Constr. Build. Mater. 2018, 165, 333–345. [Google Scholar] [CrossRef]

- Rahman, M.; Rehman, S.; Al-Amoudi, O. Literature review on cement kiln dust usage in soil and waste stabilization and experimental investigation. IJRRAS 2011, 1, 77–87. [Google Scholar]

- Zaliha, S.; Kamarudin, H.; Al Bakri, A.; Binhussain, M.; Salwa, M. Review on soil stabilization techniques. Aust. J. Basic Appl. Sci. 2013, 7, 258–265. [Google Scholar]

- Galan-Marin, C.; Rivera-Gomez, C.; Petric, J. Clay-based composite stabilized with natural polymer and fiber. Constr. Build. Mater. 2010, 24, 1462–1468. [Google Scholar] [CrossRef]

- Espuelas, S.; Omer, J.; Marcelino, S.; Echeverria, A.; Seco, A. Magnesium oxide as alternative binder for unfired clay bricks manufacturing. Appl. Clay Sci. 2017, 146, 23–26. [Google Scholar] [CrossRef]

- Oti, J.; Kinuthia, J. Designed non-fired clay mixes for sustainable and low carbon use. Appl. Clay Sci. 2012, 59, 131–139. [Google Scholar]

- Jawad, I.; Taha, M.; Majeed, Z.; Khan, T. Soil stabilization using lime: Advantages and proposing a potential alternative. Res. J. Appl. Sci. Eng. Technol. 2014, 8, 510–520. [Google Scholar]

- Yesilay, S.; Munevver, C.; Ergun, H. Usage of marble wastes in traditional artistic stoneware clay body. Ceram. Int. 2017, 43, 8912–8921. [Google Scholar] [CrossRef]

- Aliabdo, A.; Abd Elmoaty, A.; Auda, E. Re-use of waste marble dust in the production of cement and concrete. Constr. Build. Mater. 2014, 50, 28–41. [Google Scholar] [CrossRef]

- Ghorbani, S.; Taji, I.; Tavakkolizade, M.; Davodi, A.; Brito, J. Improving corrosion resistance of steel rebars in concrete with marble and granite waste dust as partial cement replacement. Constr. Build. Mater. 2018, 185, 110–119. [Google Scholar] [CrossRef]

- Bilgin, N.; Yeprem, H.; Arslan, S.; Bilgin, A.; Günay, A.; Marşoglu, A. Use of waste marble powder in brick industry. Constr. Build. Mater. 2018, 29, 449–457. [Google Scholar] [CrossRef]

- Mashaly, A.; Shalaby, B.; El-Hefnawi, M. Characterization of the marble sludge of the Shaq El Thoban industrial zone, Egypt and its compatibility for various recycling applications. Aust. J. Basic Appl. Sci. 2012, 6, 153–161. [Google Scholar]

- Zami, M.; Lee, A. Stabilized or unstabilized earth construction for contemporary urban housing. In Proceedings of the 5th International Conference on Responsive Manufacturing—Green Manufacturing, Ningbo, China, 11–13 January 2010. [Google Scholar]

- El-Sayed, H.; Farag, A.; Kandeel, A.; Younes, A.; Yousef, M. Characteristics of the marble processing powder waste at Shaq El Thoban industrial zone, Egypt and its suitability for cement manufacture. HBRC J. 2016, 14, 171–179. [Google Scholar] [CrossRef]

- Said, R. The Geology of Egypt, 3rd ed.; Elsevier Publ. Co.: Amesterdam, The Netherlands, 1962. [Google Scholar]

- ASTM DStandard Test Methods for Loss on Ignition (LOI) of Solid Combustion Residues; Standard Annual Book of ASTM Standards; ASTM: West Conshohocken, PA, USA, 2008.

- ASTM D Standard Test Method for pH of Soils; Standard Annual Book of ASTM Standards; ASTM: West Conshohocken, PA, USA, 2013.

- Oti, J.; Kinuthia, J.; Bai, J. Engineering properties of unfired clay masonry bricks. Eng. Geol. 2009, 107, 130–139. [Google Scholar] [CrossRef]

- Millogo, Y.; Hajjaji, M.; Ouedraogo, R. Microstructure and physical properties of lime-clayey adobe bricks. Constr. Build. Mater. 2008, 22, 2386–22392. [Google Scholar] [CrossRef]

- Bahar, R.; Benazzoug, M.; Kenai, S. Performance of compacted cement-stabilised soil. Cem. Concr. Compos. 2004, 26, 811–820. [Google Scholar] [CrossRef]

- Egyptian Code for the Building by the Soil (ECBS). The Building by the Stabilized and Compressed Earth Blocks; 2016; HBRC, Volume 1, pp. 1–144.

- Egyptian Standard Specification (ESS). Quick and Hydrated Lime. Definitions, Requirements and Conformity Criteria; Egyptian Quality and Specification Association, Egypt, 2008.

- El-Mahllawy, M. Effect of activation of granulated blast-furnace slag on the properties of unfired eco-friendly clay bricks. In Proceedings of the 1st International Conference on Innovative Building Materials, Cairo, Egypt, 28–30 December 2014. [Google Scholar]

- El-Mahllawy, M.; Kandeel, A. Engineering and mineralogical characteristics of stabilized unfired montmorillonitic clay bricks. HBRC J. 2014, 10, 82–91. [Google Scholar] [CrossRef]

- Nair, S.; Little, D. Mechanisms of distress associated with sulfate-induced heaving in lime-treated soils. Transp. Res. Record J. Trans. Res. Board 2011, 2212, 82–90. [Google Scholar] [CrossRef]

- Abd Elaty, M.; Ghazy, M. Performance of Portland cement mixes containing silica fume and mixed with lime-water. HBRC J. 2014, 10, 247–257. [Google Scholar] [CrossRef]

- Choller, M.; Horgnies, M. Analyses of the surface of concrete by Raman and FT-IR spectroscopies comparative study of hardened samples after demoulding and after organic post-treatment. Surf. Interface Anal. 2010, 43, 714–725. [Google Scholar] [CrossRef]

- Djomgoue, P.; Njopwouo, D. FT-IR spectroscopy applied for surface clays characterization. J. Surf. Eng. Mat. Adv. Technol. 2013, 3, 275–282. [Google Scholar] [CrossRef]

- Madejova, J. FTIR techniques in clay minerals studies. Vib. Spectrosc. 2003, 31, 1–10. [Google Scholar] [CrossRef]

- Yu, P.; Kirkpatrick, R.; Poe, B.; McMillan, P.; Cong, X. Structure of calcium silicate hydrate (C-S-H): Near-, mild-, and far-infrared spectroscopy. J. Am. Ceram. Soc. 1999, 82, 742–748. [Google Scholar] [CrossRef]

| Mix Code | Mix Ingredient, % | pH | ||||

|---|---|---|---|---|---|---|

| Clay | Sand | HL | MCW | OPC | ||

| R | 75 | 25 | 0 | 0 | 0 | 6.7 |

| R 1 | 50 | 25 | 20 | 0 | 5 | 12.8 |

| R 2 | 50 | 25 | 10 | 10 | 5 | 12.5 |

| R 3 | 50 | 25 | 5 | 15 | 5 | 12.4 |

| R 4 | 50 | 25 | 0 | 20 | 5 | 11.5 |

| Oxide Content % | Hydrated Lime (HL) | Ordinary Portland Cement (OPC) | Clay | Sand | Marble Cutting Waste (MCW) |

|---|---|---|---|---|---|

| SiO2 | 1.69 | 20.59 | 49.95 | 93.88 | 0.52 |

| Al2O3 | 1.11 | 4.02 | 22.51 | 3.86 | 0.12 |

| Fe2O3 | 0.24 | 3.31 | 6.87 | 0.68 | 0.18 |

| CaO | 70.52 | 62.71 | 1.64 | 0.65 | 56.35 |

| MgO | 0.75 | 1.95 | 1.22 | 0.37 | 0.35 |

| Na2O | 0.01 | 0.47 | 3.11 | 0.21 | 0.05 |

| K2O | 0.05 | 0.18 | 0.92 | 0.09 | 0.04 |

| SO3 | 0.14 | 2.95 | 3.12 | 0.02 | 0.01 |

| L.O.I | 25.69 | 3.81 | 10.28 | 0.23 | 42.38 |

| pH | 12.82 | 13.52 | 6.72 | 7.11 | 8.13 |

| Cl− | Nil | Nil | 0.86 | Nil | 0.01 |

| Specimens of the Mix | Status of the Specimens Cured for | ||

|---|---|---|---|

| 2 Weeks | 4 Weeks | ||

| Before | After | ||

| R | C | PF | C |

| R1 | PF | ND | PF |

| R2 | ND | ND | ND |

| R3 | ND | ND | ND |

| R4 | C | ND | C |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Mahllawy, M.S.; Kandeel, A.M.; Abdel Latif, M.L.; El Nagar, A.M. The Feasibility of Using Marble Cutting Waste in a Sustainable Building Clay Industry. Recycling 2018, 3, 39. https://doi.org/10.3390/recycling3030039

El-Mahllawy MS, Kandeel AM, Abdel Latif ML, El Nagar AM. The Feasibility of Using Marble Cutting Waste in a Sustainable Building Clay Industry. Recycling. 2018; 3(3):39. https://doi.org/10.3390/recycling3030039

Chicago/Turabian StyleEl-Mahllawy, Medhat S., Ayman M. Kandeel, Mahmoud L. Abdel Latif, and Abdeen M. El Nagar. 2018. "The Feasibility of Using Marble Cutting Waste in a Sustainable Building Clay Industry" Recycling 3, no. 3: 39. https://doi.org/10.3390/recycling3030039

APA StyleEl-Mahllawy, M. S., Kandeel, A. M., Abdel Latif, M. L., & El Nagar, A. M. (2018). The Feasibility of Using Marble Cutting Waste in a Sustainable Building Clay Industry. Recycling, 3(3), 39. https://doi.org/10.3390/recycling3030039