Abstract

Sheep manure and beet waste (the uneatable leaf part of the beet) are promising feedstock for biogas production due to their abundance and organic richness. However, their high lignocellulosic content reduces anaerobic digestibility and controls methane yield. This study investigates the effect of various pretreatment strategies, namely physical, thermal, and combined physical–thermal methods, on the Biochemical Methane Potential (BMP) of sheep manure and beet waste. Batch anaerobic digestion experiments were conducted under mesophilic conditions, with BMP values recorded for each treatment. The highest BMP for sheep manure, 125 Nml CH4/g VS, was achieved using combined physical and thermal pretreatment. This approach enhanced methane production by 16%, 25%, and 60% compared to physical pretreatment (PP) alone, thermal pretreatment (TP) alone, and no pretreatment, respectively, while the one BMP for beet waste is 80 Nml CH4/g VS and obtained with thermal pretreatment. To predict BMP outcomes, three machine learning approaches are applied, namely Linear Regression (LM), Random Forest Regression (RFR), and Gradient Boosting Machine (GBM), using digestion time (N days), total solids (Ts), volatile solids (Vs), pretreatment type, and biomass type. The variance analysis confirmed that the interaction between pretreatment and biomass type significantly improved model performance. While diagnostic checks revealed non-linear patterns limiting the linear model, ensemble methods achieved stronger results. The RFR model explained 79.5% of the variance with a Root Mean Square Error (RMSE) of about 15.7, whereas the GBM model achieved the lowest RMSE of 5.05. GBM captures complex non-linear interactions. In addition, variable importance analyses identified digestion time, solid content, and pretreatment as the most influential factors for methane yield, with the combined chemical and physical pretreatment producing the highest biogas outputs. These findings underscore the potential of advanced machine learning models, particularly GBM (Gradient Boosting Machine), for optimizing anaerobic digestion strategies and maximizing biogas recovery from sheep manure and beet waste.

1. Introduction

Biogas technology is a renewable process for turning organic waste into energy. It is becoming more popular worldwide as part of the shift to sustainable energy systems. Rich in methane, biogas provides a sustainable and feasible fuel substitute that also addresses greenhouse gas emissions, enhances rural sanitation, and advances the ideas of the circular economy [1]. Numerous nations have already put in place extensive biogas projects, the authors point out, particularly in areas with promising agricultural potential and growing infrastructure.

The global push toward sustainable energy solutions have intensified interest in biogas technology, a renewable pathway to convert organic waste into methane-rich fuel. As of 2024, biogas systems contribute over 132 GW of installed capacity worldwide, with countries like Germany, China, and Brazil leading large-scale implementation [2]. Biogas is increasingly recognized not only for its climate mitigation potential but also for rural electrification, waste management, and the promotion of circular economy practices.

In Morocco, the demand for sustainable energy is growing, driven by rural development priorities, energy independence goals, and intensified agricultural activity. The Generation Green 2020–2030 strategy and the National Biomass Energy Roadmap (2021) aim to unlock Morocco’s massive biomass potential. Each year, the country produces approximately 60 million tons of organic waste, of which 92% originates from agriculture. This resource could yield over 25 TWh/year in energy, yet only ~2% is currently utilized [3]. Despite these initiatives, Morocco’s small-scale biogas sector remains underdeveloped. Most household digesters are unheated, manually operated, and operate under suboptimal thermal and feeding conditions. The lack of tailored data on local biomass limits effective digester design and feedstock optimization. Moreover, overloading remains a frequent problem, often caused by farmers’ unawareness of the BMP of their feedstocks, leading to methane surpluses that surpass household demand and release unutilized greenhouse gases [4]. In a broad range of contexts, several studies [5,6,7] have established strong correlations between biomass composition and methane yield, but such investigations are limited in the North African context, where climatic, agricultural, and livestock practices differ significantly from Europe or Asia. Consequently, the extrapolation of BMP values from foreign studies often results in misleading performance predictions for Moroccan digesters.

It is worth noting that a growing number of literature reviews on machine learning (ML) applications in biogas prediction demonstrate that models such as XGBoost (Extreme Gradient Boosting) and ensemble techniques can accurately predict methane yield based on feedstock and operating conditions such as reaction time, temperature, total solids, volatile solids, and pH [8]. In addition, several recent studies achieved high prediction accuracy when predicting cumulative methane yield from lignocellulosic waste using physicochemical properties and digestion parameters [9]. These findings underscore the potential of ML approaches to model complex non-linear interactions and process variability, making them particularly well-suited to improving BMP prediction under North African conditions.

In this context, our study aims to address the lack of region-specific data on BMP in North Africa by evaluating sheep manure and beet waste. Physical, thermal, and combined pretreatments were applied to assess their influence on methane production. To enhance predictive accuracy, advanced machine learning models were employed, and key predictors were used to capture complex non-linear interactions affecting methane output. The ultimate goal is to develop a scalable, cost-effective biogas production framework tailored to rural Moroccan conditions.

While the machine learning models employed in this study are well-established in the field of data science, their application to predict the Biochemical Methane Potential of co-digestion systems involving sheep manure and beet waste is novel. This work represents, to the best of our knowledge, the first attempt to develop predictive models for biogas production from these specific feedstocks in the Meknes–Fès region of Morocco. In fact, the key novelty of the statistical analysis in this paper lies not in the algorithms themselves, but in the generation of a unique, localized dataset and the subsequent models that can accurately forecast methane yield. Therefore, this work provides a valuable tool for optimizing biogas plant efficiency and feasibility assessments specific to the agricultural waste streams and climatic conditions of the Meknes–Fès region.

2. Results and Discussion

2.1. Compositions of the Substrate Samples

The substrates studied, sheep feces and beet waste, exhibit markedly different physicochemical properties, which are likely to influence anaerobic digestion performance. As shown in Table 1, sheep feces have a balanced moisture content and a high volatile solid (VS) concentration (≈50.37%), indicating a substantial proportion of organic (biodegradable) material available for methane production. Because VS represents the fraction of material that microbes can consume under anaerobic conditions, this suggests that sheep feces are a promising feedstock for biogas generation. The moderate moisture content further helps it support microbial activity without necessitating large volumes of water for dilution. In comparison, the VS value for sheep feces in our study (50.37%) differs slightly from that reported by T.T. Cu [10], which was ~58%.

Table 1.

Chemical composition of the studied biomass.

Conversely, beet waste shows very high dry matter (DM ≈ 92.07%) but low volatile solids (≈7.17%), meaning that most of its mass is likely composed of nondegradable or slowly degradable components (e.g., lignocellulosic fibers, minerals). Without pretreatment, such substrates usually contribute little to biogas yield. Lignocellulosic agricultural residues like beet waste often require physical, chemical, or combined pretreatment to break down structural barriers and increase digestibility.

The inoculum, by contrast, has a low absolute VS content, but a relatively moderate VS/DM ratio (~74.5%). Its VS (≈5.25%) are close to values reported by T.T.T. Cu [10] (~5.8%). In this case, the main role of the inoculum is not to serve as a primary feedstock, but rather to ‘seed’ the microbial community to provide active microbes that accelerate degradation of the sheep feces or pretreated beet waste.

2.2. Biochemical Methane Production Potential

2.2.1. Sheep Manure

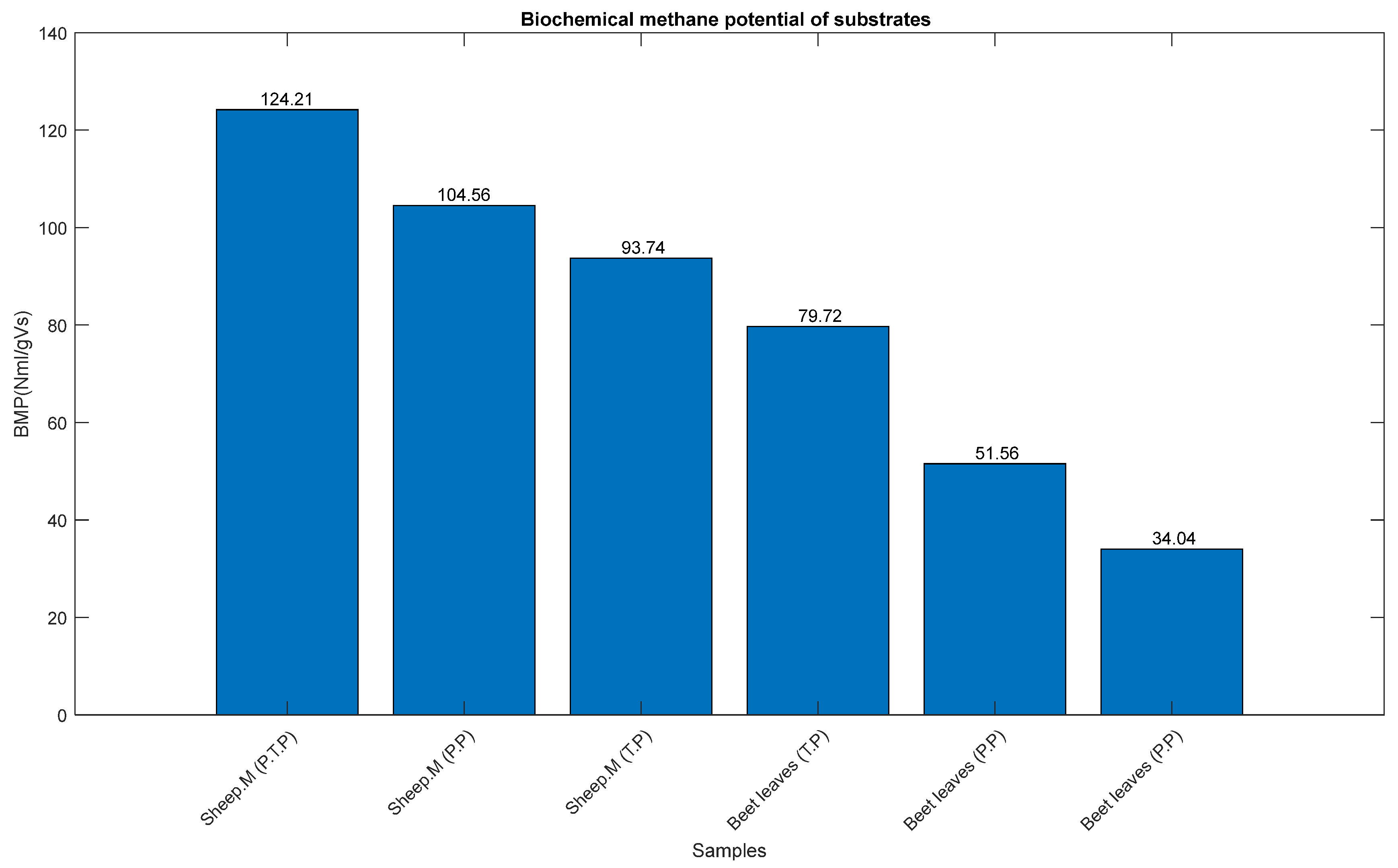

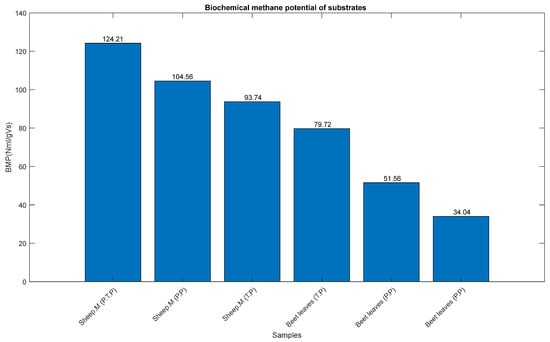

The Biochemical Methane Potential (BMP) tests were carried out on several substrates using different pretreatment methods, with the goal of evaluating cumulative methane yield (in NmL CH4 per g VS). The results shown in Figure 1 clearly highlight animal waste, especially when subjected to combined physical and thermal pretreatment, as superior to other pretreatments and biomass types. This enhanced performance is attributable to the high content of readily biodegradable organic compounds (e.g., proteins and lipids) in animal waste.

Figure 1.

Summary of methane production potential from the BMP (Biochemical Methane Potential) test of substrates. PTP: physical and thermal pretreatment, TP: thermal pretreatment, and PP: physical pretreatment.

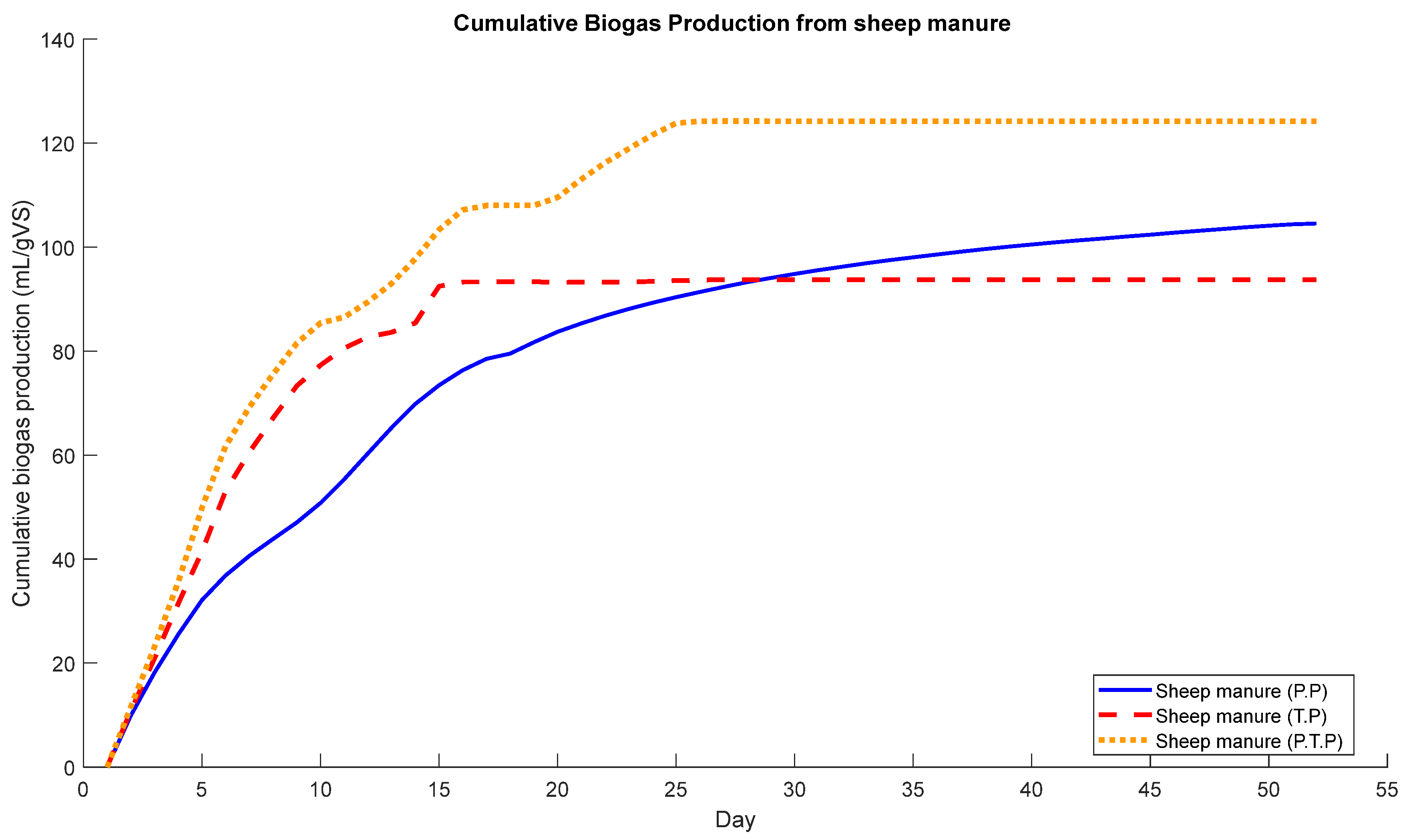

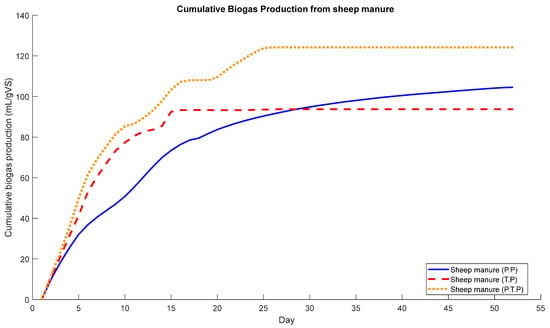

In Figure 2, the combined physical + thermal pretreatment achieves the highest methane yield (≈124 NmL/g VS), which is about 18% higher than physical pretreatment alone, and ~32% higher than thermal alone. The cumulative yield curves further demonstrate that combined pretreatment both increases total yield and accelerates methane release. Regarding kinetics and hydraulic retention time (HRT), the faster methane generation (green curve) suggests that reactors can be operated with shorter HRTs, improving overall productivity.

Figure 2.

BMP test of sheep manure with different pretreatments: PTP, TP, and PP.

This observation is supported by study [11] in which thermal hydrolysis pretreatment increased methane yield by over 1.4 and allowed the system to operate at much shorter HRTs while maintaining performance [11].

It is worth noting that animal manures, because of their lignocellulosic fiber content, often suffer low volatile solids (VS) conversion: without pretreatment, only ~50% of VS may be degraded. Pretreatments, especially those combining thermal and chemical or physical methods, can enhance methane yields significantly; for example, some studies report improvements in yield by over 100% [12].

Therefore, the best strategy appears to be combined physical and thermal pretreatment, which delivers the highest BMP, accelerates gas production, and allows for reduced HRTs and better reactor utilization. Physical or thermal pretreatment used alone is beneficial but less effective: physical methods show moderate gains, while thermal alone tends to increase yield more slowly. The overall benefit is consistent with findings in the literature showing up to ~1.4× increases in methane yield through effective pretreatment [11].

2.2.2. Beet Waste

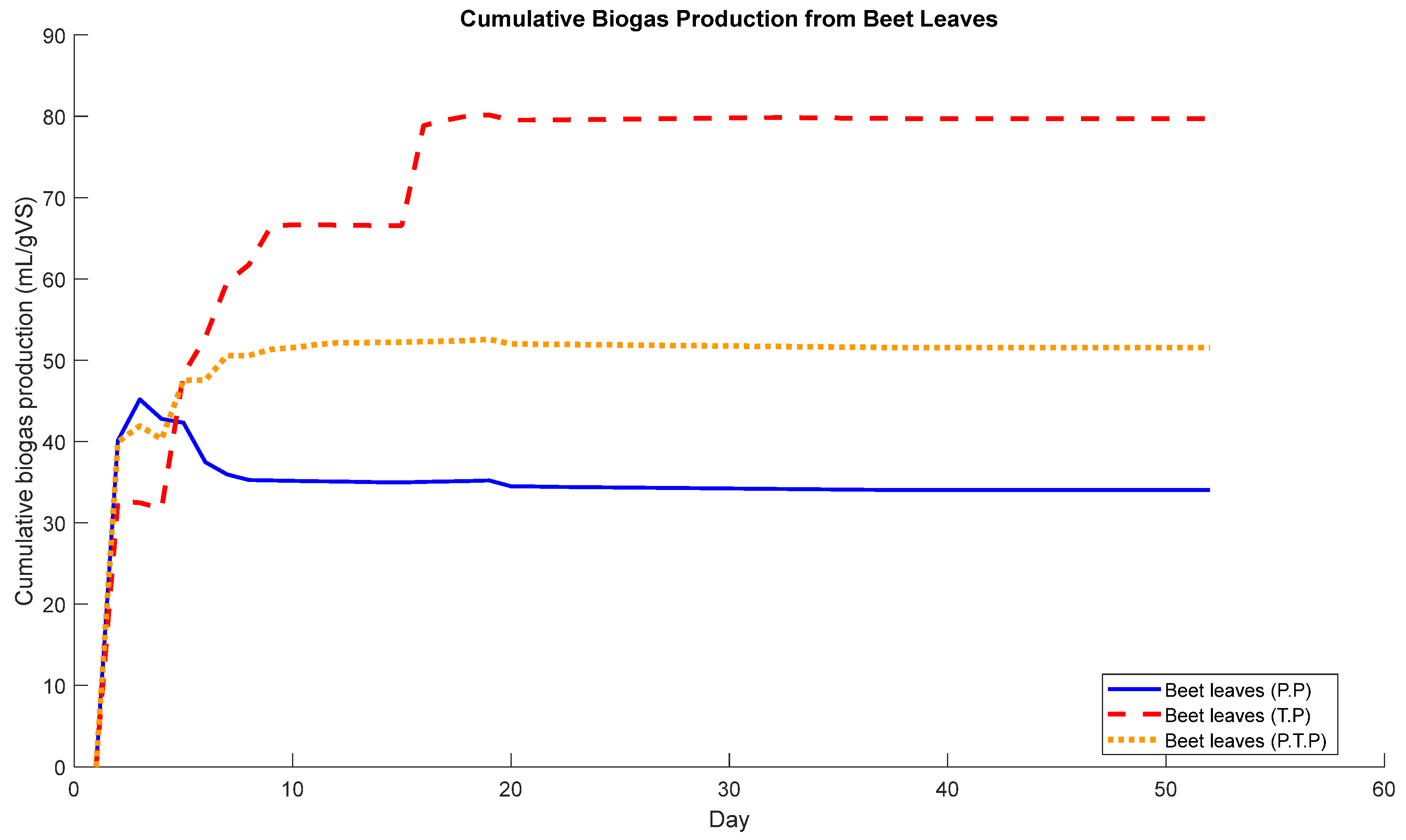

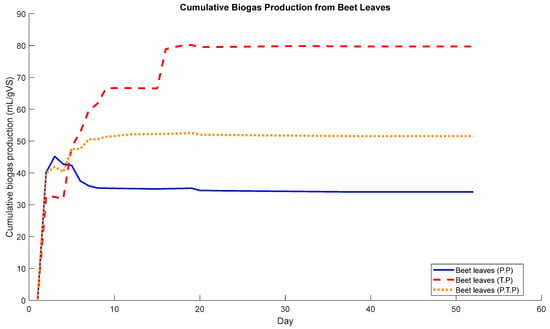

Cumulative methane yields over time in Figure 3 show a rapid increase, plateauing at 79–80 NmL/g VS around day 15–20 for thermal treatment; however, a slower rise, leveling at 51 NmL/g VS by day 10 and even slower, flattening at 34 NmL/g VS by day 5–7, is shown for successively combined physical and thermal pretreatment and the physical one alone.

Figure 3.

BMP (Biochemical Methane Potential) test of beet waste with different pretreatment: PTP, TP, and PP.

The thermal treatment dominates BMP by achieving the highest methane yield (~80 NmL/g VS) and fastest kinetics. Thermal pretreatment reduces lignin and enhances hydrolysis, aligning with studies on agricultural residues that report 30–50% yield improvements above 120 °C [13].

Physical treatment alone is less effective with a yield of ~34 NmL/g VS; physical disruption alone yields less than 50% of the thermal treatment’s performance. This result is explained by the literature, that mechanical size reduction (to ≤2 mm) enhances gas yields by only 16–23%, consistent with our results [14].

Surprisingly, combining physical + thermal treatments (51.6 NmL/g VS) performs worse than the thermal treatment alone. This could be due to energy misallocation: the literature suggests that multi-step pretreatment improves yields only if steps are well optimized (like grinding + enzymatic + thermal) [15]. Added mechanical pretreatment here may have limited incremental benefit or may have caused inhibitor formation during thermal treatment.

TP is most effective for beet waste, delivering ~80 NmL/g VS methane and rapid digestion. PP alone offers limited benefits. Combining PTP, in this case, underperformed, likely due to ineffective integration; other studies show that multi-step pretreatment can improve yields if properly coordinated.

The BMP test conducted on different substrates with various pretreatment methods aimed to evaluate their cumulative methane yield (in NmL/VS). The results show a clear superiority of animal waste, particularly when subjected to combined PTP. This performance is attributed to the high content of easily biodegradable organic matter, such as lipids and proteins, in animal waste.

2.3. Modeling Biogas Yield Results

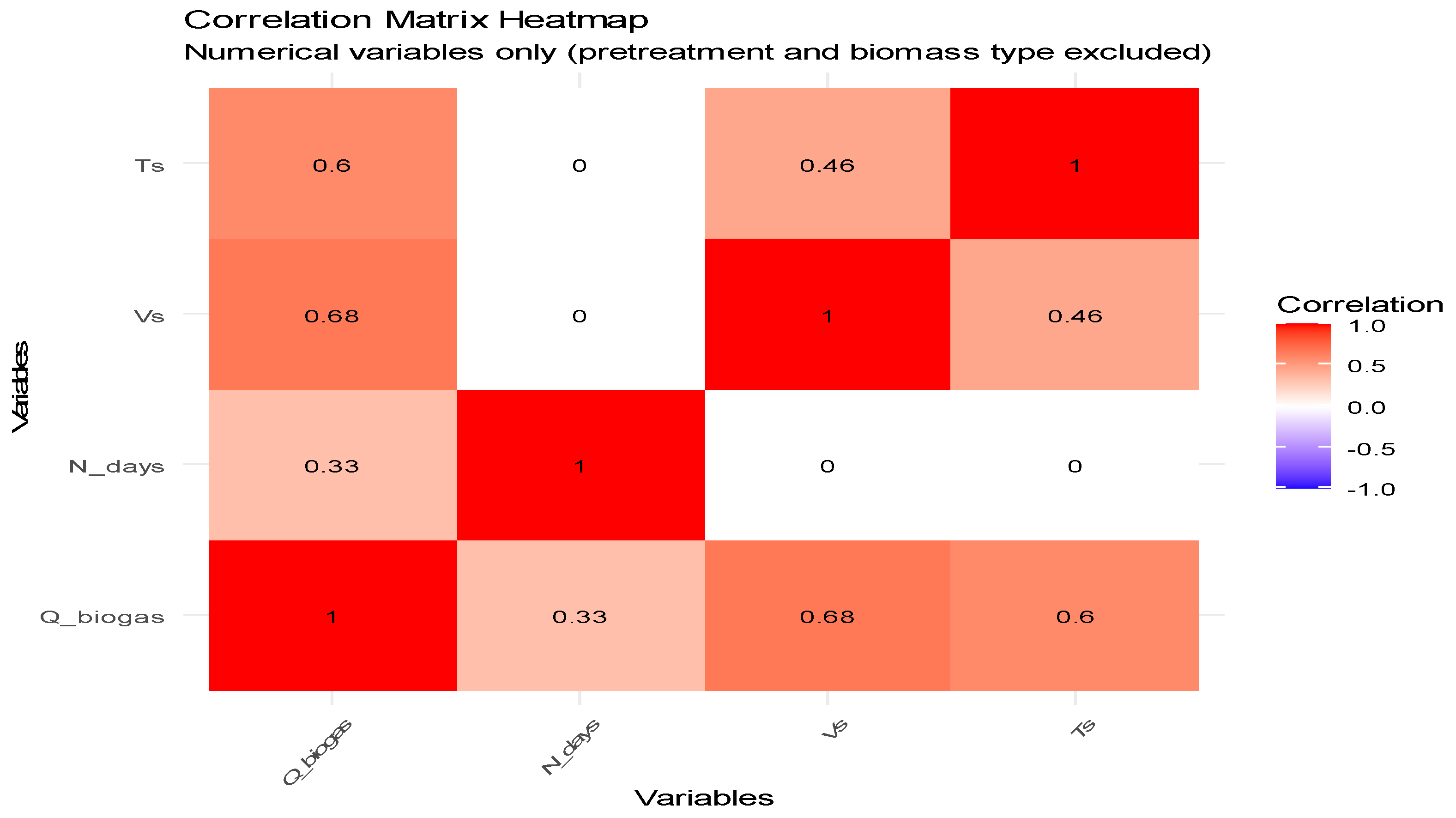

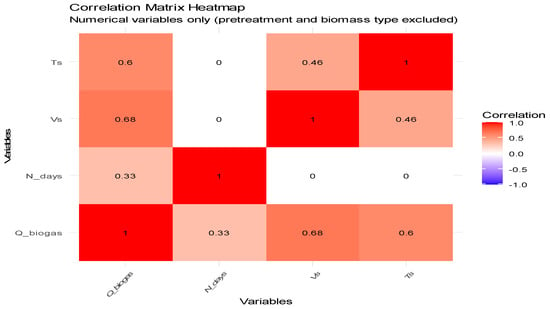

Exploratory Data Analysis (EDA) indicated that VS had the strongest correlation with methane yield with a value of correlation coefficient equal to 66%, underscoring its predictive importance (Figure 4).

Figure 4.

Correlation matrix.

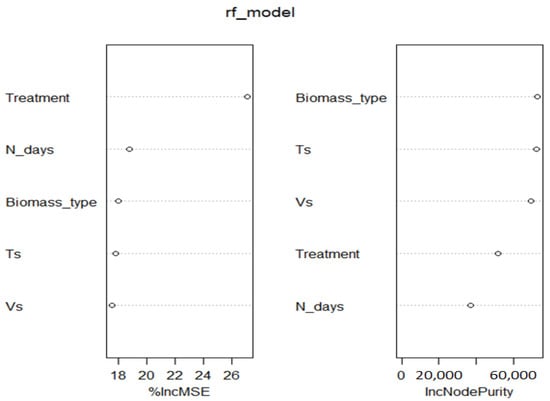

Boxplots (Figure 5) revealed significant yield variations across treatment types, suggesting that pretreatment strategies substantially influence AD efficiency. These observations are consistent with Carrere et al. (2010) [16], who highlighted the role of substrate characteristics and pretreatment methods in enhancing biodegradability and methane potential.

Figure 5.

Boxplot variable importance—rf.

Thermal pretreatment was found to improve BMP consistency and yield, showing strong correlations between VS solubilization and methane output, consistent with findings by others [16,17]. Time series analysis revealed rapid methane generation within the first 10 days for pretreated samples. To quantify these effects, multiple regression models were developed (Table 2). A baseline model without interaction terms showed that digestion time significantly increased biogas yield by 0.77 units per day and physical pretreatment reduced yield by 20.34 units, while the combined pretreatment showed no significant main effect. In addition, biomass types 2 and 3 yielded considerably less biogas than cow manure, by 37.22 and 60.64 units, respectively. This model explained 73.95% of the variance with an adjusted R2 equal to 73%, closely aligning with Rosi et al. (2024) [18], who reported similar predictive contributions of digestion time and feedstock type.

Table 2.

Multiple regression with and without interaction.

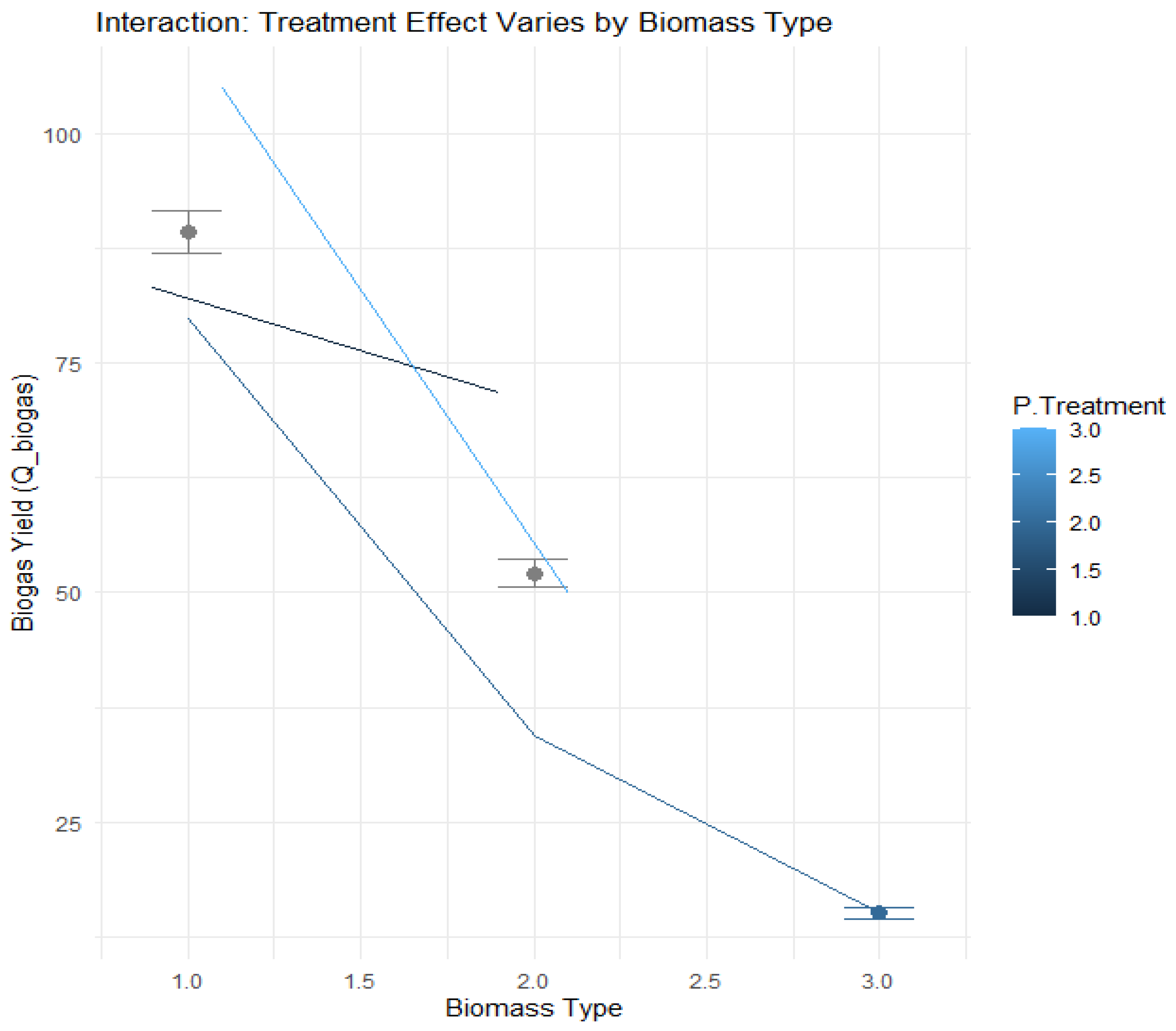

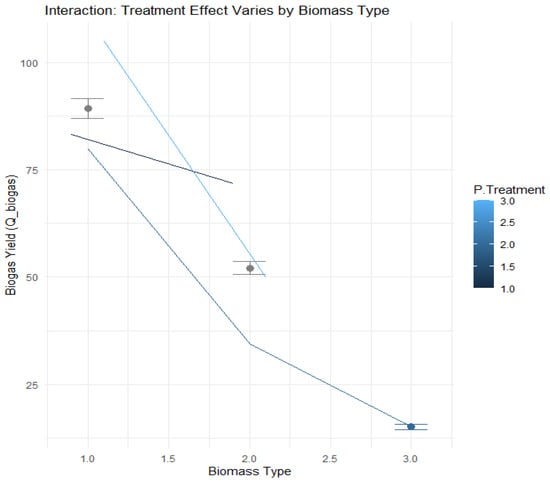

In addition, an extended model with interaction terms between treatment and biomass type provided a significantly better fit with an adjusted R2 equal to 79%, capturing combined effects overlooked in the baseline model (Figure 6). ANOVA confirmed this improvement, reducing residual error from 113,859 to 86,619. However, diagnostic checks revealed key assumption violations in terms of non-linearity and heteroscedasticity, non-normal residuals, and influential observations.

Figure 6.

Interaction between treatment and biomass type.

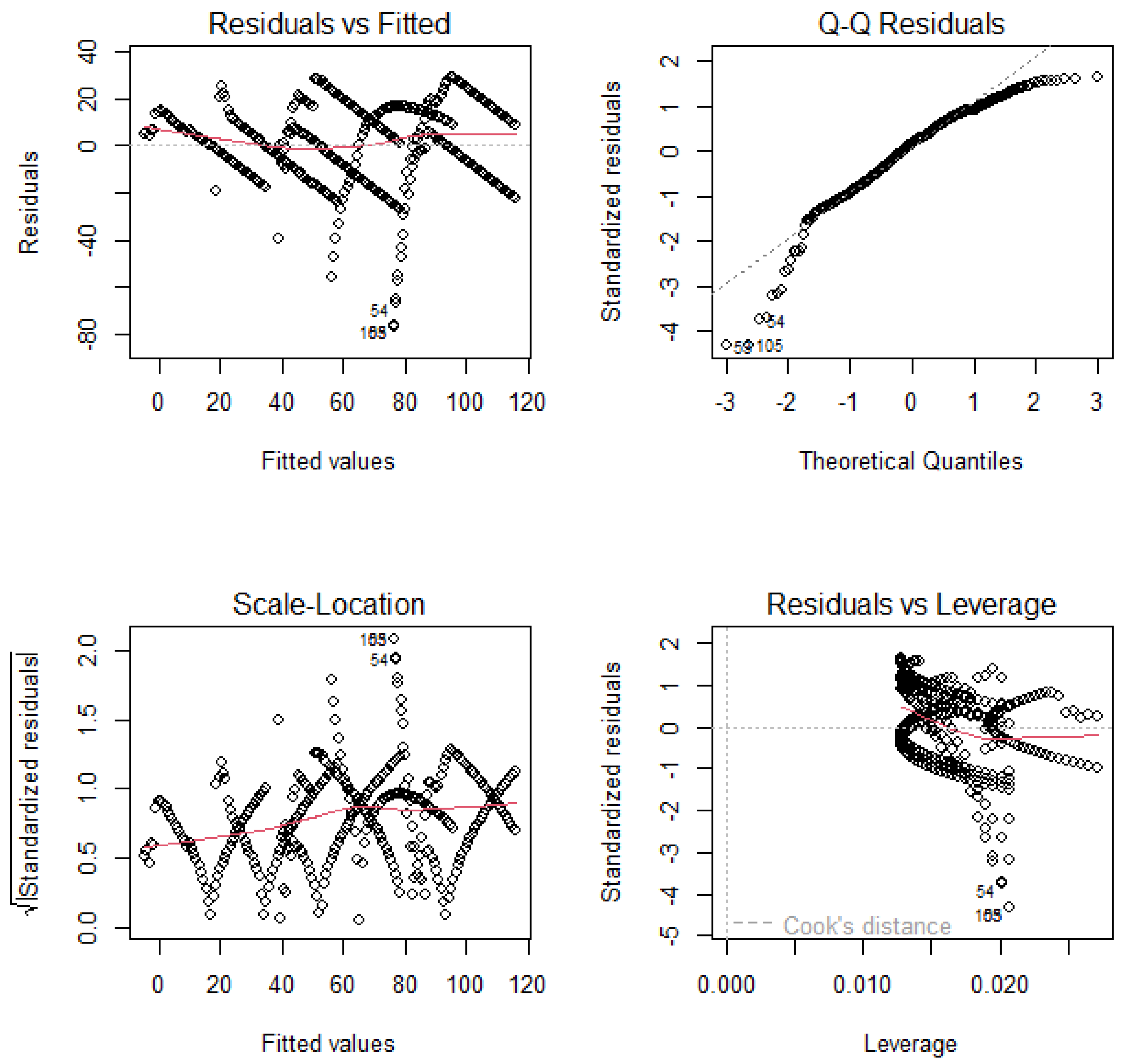

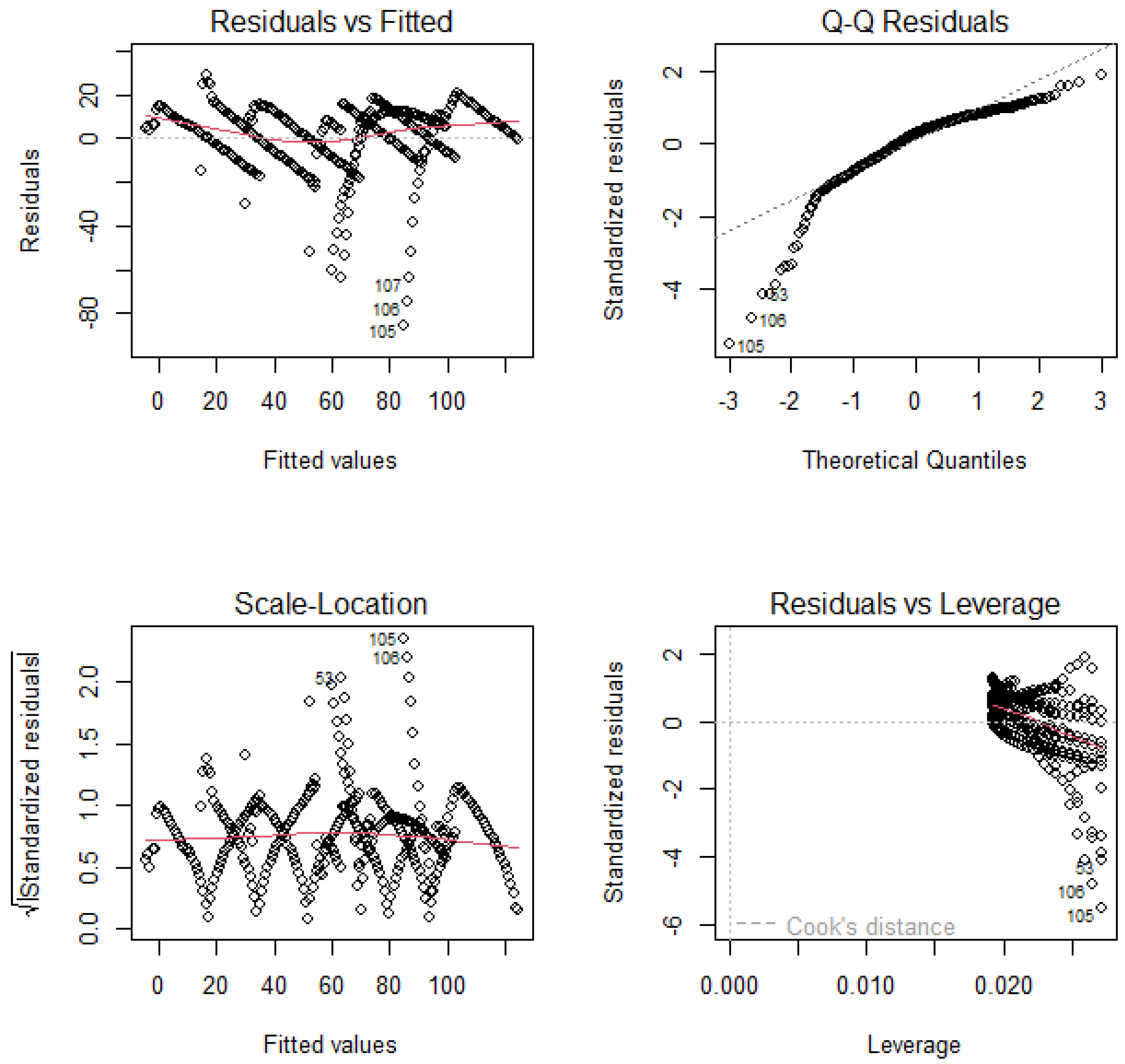

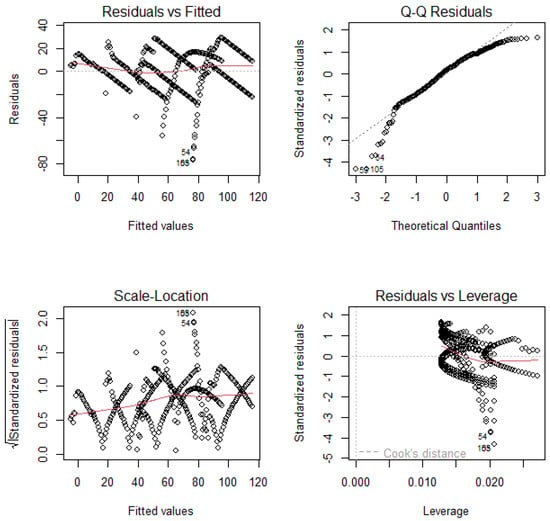

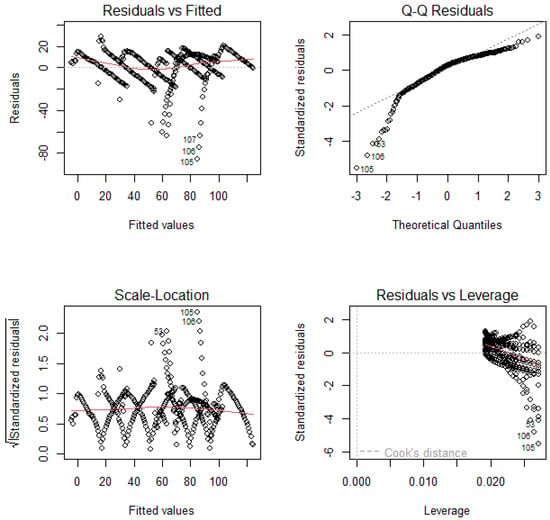

A detailed examination of the regression diagnostics for both Model 1 and Model 2 (Figure 7 and Figure 8) confirmed these violations. The residuals vs. fitted plot showed a distinct non-random, funnel-shaped pattern, indicating heteroscedasticity and suggesting a systematic error in the model’s predictions across the range of fitted values. The normal Q–Q plot revealed significant deviations of the standardized residuals from the theoretical diagonal line, confirming the non-normality of the error distribution. Furthermore, the scale–location plot reinforced the evidence of heteroscedasticity by showing a clear trend in the spread of residuals. Finally, the residuals vs. leverage plot identified several data points with high leverage, indicating influential observations that disproportionately affected the model’s parameters. The collective failure of these diagnostic tests to meet the core assumptions of linear regression unequivocally justifies the employment of more flexible ensemble machine learning methods, which are robust to such violations.

Figure 7.

Diagnostic regression Model 1.

Figure 8.

Diagnostic Regression Model 2.

These results align with Peng et al. (2020) and Obileke et al. (2023) [8,17], who reported that ensemble methods, particularly GBM, outperform linear models in capturing complex, non-linear biogas production dynamics. The good performance of GBM reflects its capacity to provide actionable recommendations such as the optimal conditions of digestion times of approximately 15 days, the superiority of combined pretreatment that produced higher methane yields than physical or chemical methods alone, and the preference of biomass type 1.

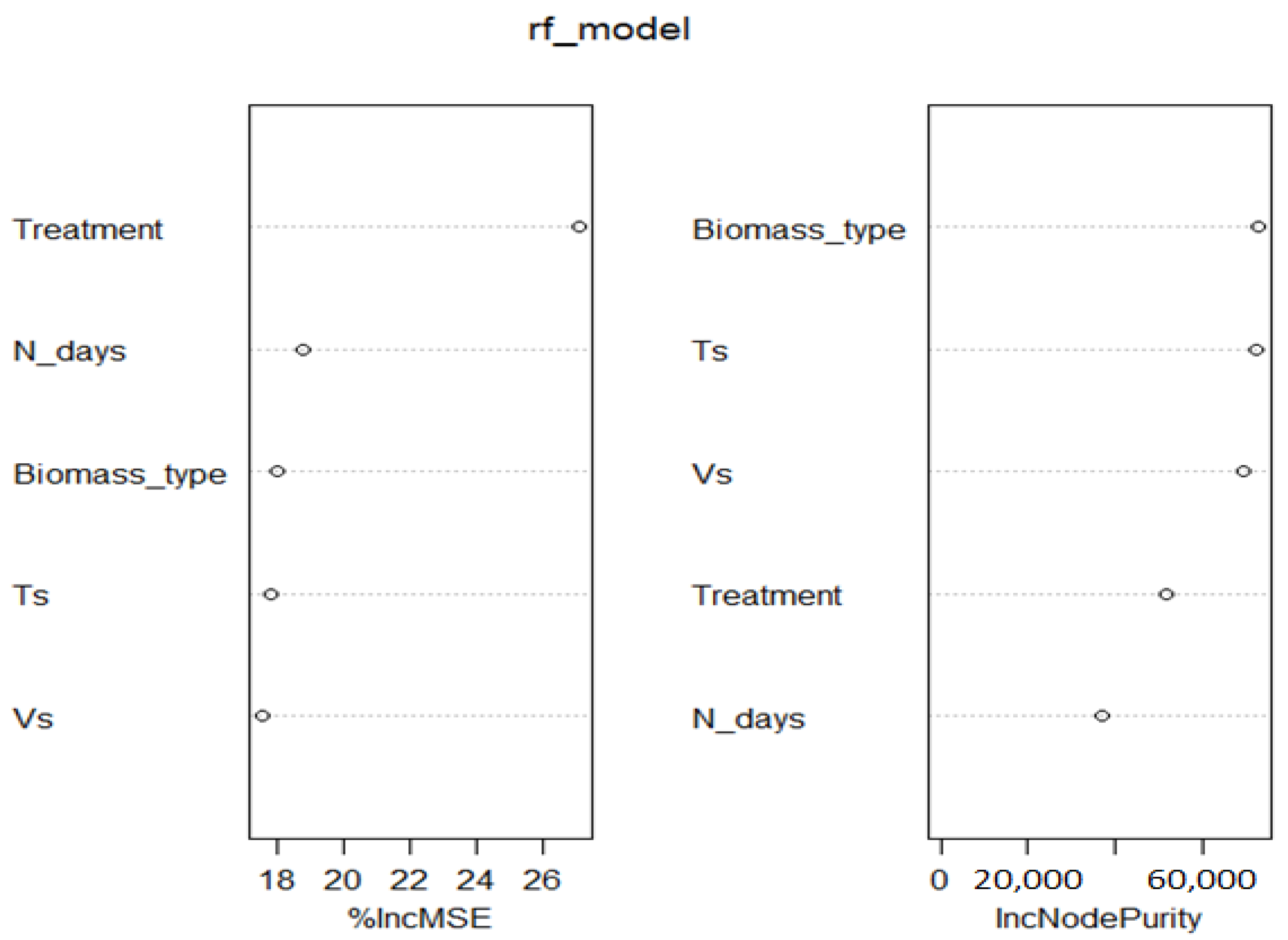

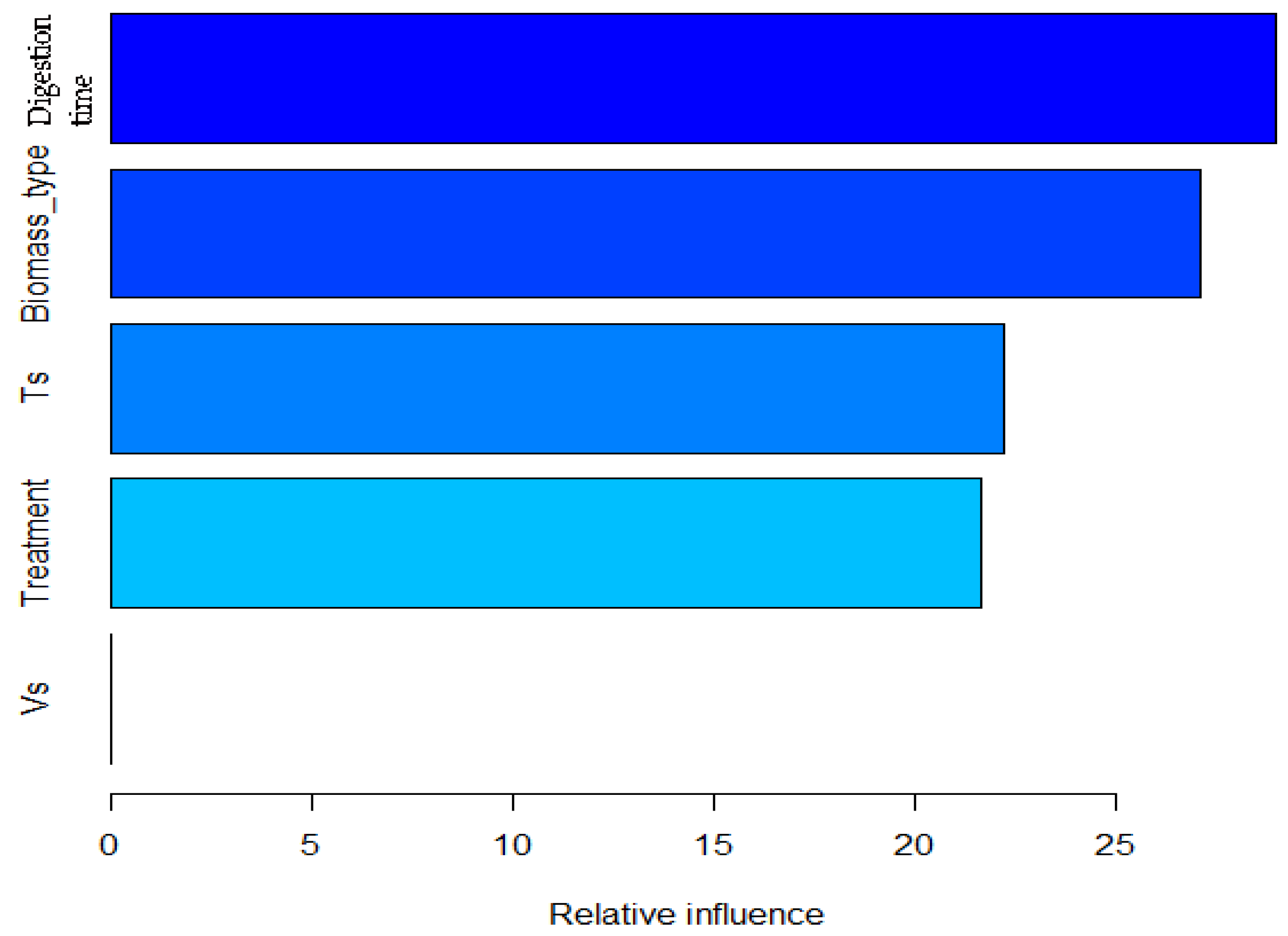

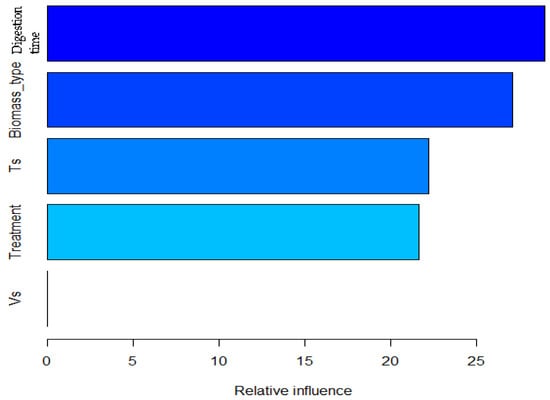

To address these limitations, ensemble ML methods were applied. The first model is Random Forest Regression and explained 79.49% of variance with RMSE = 15.7, confirming its ability to generalize well (Figure 8). Analysis of importance analysis showed treatment as the most influential predictor, followed by digestion time, Ts, and biomass type. The second model, GBM, further improved performance, achieving the lowest RMSE and ranking digestion time, Ts, biomass type, and treatment as the most critical predictors (Figure 9). The results reflect GBM’s capacity to prioritize non-linear and interaction effects. This mirrors the work of Deval et al. (2024) [19], who also showed that ensemble methods like GBM outperform simpler models in forecasting biogas production from complex feedstocks. Table 3 compares the three approaches, showing GBM’s clear superiority over RFR, LM.

Figure 9.

Relative influence—GBM.

Table 3.

Comparison of the performance of models used.

3. Materials and Methods

3.1. Sample Collection

This study focused on two primary feedstocks: sheep manure and beet waste. These substrates were selected for their availability, nutrient diversity, and relevance to agricultural waste valorization in anaerobic digestion (AD) systems. Sheep manure was collected fresh from a local livestock farm located in the Meknès region, Morocco. The manure was gathered immediately after excretion to prevent pre-digestion or drying. The samples were stored in sealed containers at 4 °C and processed within 24 h to preserve microbial and chemical stability.

Beet waste, considered as lignocellulosic biomass, was sourced from post-harvest agricultural residues of local beet waste production fields. Only green, intact leaves without signs of decay were selected. The collected leaves were washed to remove soil or debris, then chopped to approximately 2–3 cm segments to standardize size for pretreatment procedures. Inoculum from a stabilized anaerobic digester treating different biomass waste was used in this study.

3.2. Substrate Characterization

The collected biomass samples were analyzed for dry matter (DM) and VS. The DM was determined after a 24 h drying period at 105 °C. The VS were measured as the difference between DM and ash content following the incineration of DM at 550 °C for three hours.

3.3. Pretreatment Methods

Three pretreatment methods were applied to each substrate. PP was based on mechanical size reduction using a grinder to enhance surface area and substrate accessibility. Manure and leaves were reduced to particles < 1 cm. In TP, samples were subjected to heat treatment at 80 °C for 1 h in a thermostatic water bath. This step aims to break down lignocellulosic structures (especially in beet waste) and improve the solubility of organic matter. However, in the combined physical and thermal pretreatment (PTP), the feedstocks first undergo grinding, followed by the same thermal treatment described above. This approach synergizes mechanical disintegration with thermal hydrolysis. All samples were subsequently used in batch BMP assays to assess their methane yield under identical anaerobic conditions.

3.4. Biochemical Methane Potential Assay

Fresh sheep manure and beet waste were tested in an automatic methane potential testing system (AMPTS III) (BPC Instruments AB, Lund, Sweden), using batch reactors with a volume of 2 L. After adding a known amount of substrate and an active anaerobic inoculum, the bottles were sealed tightly with butyl rubber stoppers and flushed with nitrogen gas for 30 s into the loaded vials to create anaerobic conditions before starting the digestion. This provides useful information for the understanding of waste degradation dynamics. All bottles were incubated at a constant mesophilic temperature (37 °C). The reacting mixtures in digesters were agitated the entire time at 20 rev/min throughout the 40-day incubation period.

3.5. Exploratory Data Analysis and Predictive Modeling Workflow

Initial data preparation in Excel included outlier removal and methane yield normalization, followed by Exploratory Data Analysis (EDA) using descriptive statistics, box plots, histograms, correlation matrices, and statistical significance tests (t-test, ANOVA, and Chi-square).

The dataset was partitioned for training/testing, and models were evaluated using k-fold cross-validation and learning curves to assess performance and overfitting. Multiple regression models, linear, Bayesian, Support Vector Regression (SVR), random forest, and XGBoost, were implemented, with GBM. The data preprocessing, visualization, and implementation of algorithms are done using R version 4.4.2.

4. Conclusions

This study has demonstrated that sheep manure and beet waste from the Meknès–Fès region in Morocco hold promising potential as feedstocks for anaerobic digestion, especially when the biomass is treated appropriately and modeled with advanced prediction techniques. Among the pretreatment approaches tested, combined physical and thermal treatment yielded the highest methane potential for sheep manure, improving output by up to 60% relative to untreated biomass, and outperforming physical or thermal pretreatment alone. For beet waste, thermal pretreatment emerged as the most effective strategy, with combined pretreatment offering no further benefit under the conditions tested.

On the modeling side, machine learning approaches significantly outperformed linear regression in predicting biochemical methane potential (BMP). In particular, a Gradient Boosting Machine (GBM) model achieved the lowest RMSE, capturing non-linear interactions among digestion time, solid content, biomass type, and pretreatment. Variable importance analyses further highlighted digestion time, pretreatment method, and solid parameters as the key drivers of methane yield. The main contributions of this work are therefore twofold: empirical evidence from local Moroccan biomass showing how pretreatment strategies can enhance biogas recovery, which is relevant for designing small- to mid-scale digesters in similar agroclimatic zones and the demonstration of the value of ensemble machine learning methods (especially GBM) in accurately predicting BMP and guiding operational decisions.

Author Contributions

Conceptualization, A.E.A., M.R. and H.B.; Methodology, H.B., M.R. and A.A.; Software, A.A. and H.B.; Validation, A.E.A. and R.L.; Formal analysis, M.R., H.B. and A.E.A.; Investigation, M.R., H.B. and A.E.A.; Resources, F.R.; Data curation, M.R., H.B. and A.A.; Writing—original draft, H.B. and M.R.; Writing—review & editing, H.B., M.R., A.A., A.E.A. and R.L.; Supervision, A.E.A. and R.L.; Project administration, A.E.A. and R.L.; Funding acquisition, W.Z., A.E.A. and F.R. All authors have read and agreed to the published version of the manuscript.

Funding

This project is funded by the German Academic Exchange Service (DAAD) project number 57647326. The funded project is entitled: Accelerating Moroccan Biomass Education and Research (AMBER) and will run over a period of three years (2023–2025).

Data Availability Statement

The data supporting the findings of this study are available at the Bioenergies Laboratory, Al Akhawayn University in Ifrane (AUI). Data can be accessed upon reasonable requests to the corresponding author.

Acknowledgments

This research work was funded by the DAAD within a collaboration between Ingolstadt university (ITH) Germany, Al Akhawayn university in Ifrane (AUI) Morocco, and Ecole National D’Agriculture (ENA) Meknes Morocco. Our thanks go to Zoorner, the leader of this AMBER project. Portions of this manuscript were prepared and refined with the assistance of AI-based language editing tools (ChatGPT 4) to improve clarity and readability.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Abbreviation

| BMP | Biochemical Methane Potential |

| LM | Regression |

| RFR | Random Forest Regression |

| GBM | Gradient Boosting Machine |

| Ts | Total Solids |

| Vs | Volatile Solids |

| PP | Physical Pretreatment |

| TP | Thermal Pretreatment |

| PTP | Physical and Thermal Pretreatment |

| AMPTS III | Automatic Methane Potential Testing System |

| EDA | Exploratory Data Analysis |

| SVR | Support Vector Regression |

| XGBoost | Extreme Gradient Boosting |

| HRT | Hydraulic Retention Time |

References

- Surendra, K.C.; Takara, D.; Hashimoto, A.G.; Khanal, S.K. Biogas as a sustainable energy source for developing countries: Opportunities and challenges. Renew. Sustain. Energy Rev. 2014, 31, 846–859. [Google Scholar] [CrossRef]

- Dina Bacovsky Chair IEA, Andrea Rossi Secretary, Bioenergy. Available online: https://www.ieabioenergy.com/wp-content/uploads/2024/06/Annual-Report-2023.pdf (accessed on 10 October 2025).

- Tayibi, S.; Monlau, F.; Marias, F.; Cazaudehore, G.; Fayoud, N.-E.; Oukarroum, A.; Barakat, A. Coupling anaerobic digestion and pyrolysis processes for maximizing energy recovery and soil preservation according to the circular economy concept. J. Environ. Manag. 2021, 279, 111632. [Google Scholar] [CrossRef] [PubMed]

- Koch, K.; Helmreich, B.; Drewes, J.E. Co-digestion of food waste in municipal wastewater treatment plants: Effect of different mixtures on methane yield and hydrolysis rate constant. Appl. Energy 2015, 137, 250–255. [Google Scholar] [CrossRef]

- Gunaseelan, V.N. Anaerobic digestion of biomass for methane production: A review. Biomass Bioenergy 1997, 13, 83–114. [Google Scholar] [CrossRef]

- Amon, T.; Amon, B.; Kryvoruchko, V.; Zollitsch, W.; Mayer, K.; Gruber, L. Biogas production from maize and dairy cattle manure: Influence of biomass composition on methane yield. Agric. Ecosyst. Environ. 2007, 118, 173–182. [Google Scholar] [CrossRef]

- Zhang, H.; Han, L.; Dong, H. An insight to pretreatment, enzyme adsorption and enzymatic hydrolysis of lignocellulosic biomass: Experimental and modeling studies. Renew. Sustain. Energy Rev. 2021, 140, 110758. [Google Scholar] [CrossRef]

- Peng, S.; Guo, L.; Li, Y.; Huang, H.; Peng, J.; Liu, X. Biogas production prediction based on feature selection and ensemble learning. Appl. Sci. 2024, 14, 901. [Google Scholar] [CrossRef]

- Song, C.; Cai, F.; Yang, S.; Wang, L.; Liu, G.; Chen, C. Machine learning-based prediction of methane production from lignocellulosic wastes. Bioresour. Technol. 2024, 393, 129953. [Google Scholar] [CrossRef] [PubMed]

- Cu, T.T.T.; Nguyen, T.X.; Triolo, J.M.; Pedersen, L.; Le, V.D.; Le, P.D.; Sommer, S.G. Biogas Production from Vietnamese Animal Manure, Plant Residues and Organic Waste: Influence of Biomass Composition on Methane Yield. Asian-Australas. J. Anim. Sci. 2014, 28, 280–289. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Lee, C.; Kim, J.; Kim, J.Y. Feasibility of thermal hydrolysis pretreatment to reduce hydraulic retention time of anaerobic digestion of cattle manure. Bioresour. Technol. 2023, 384, 129308. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.U.; Ahring, B.K. Pretreatment of digested manure fibers at high temperature (185 °C) with lime added enhances methane production. Biocatal. Agric. Biotechnol. 2022, 44, 102460. [Google Scholar] [CrossRef]

- Nyang’aU, J.O.; El Mahdi, J.; Møller, H.B.; Sørensen, P. Unlocking higher methane yields and digestate nitrogen availability in soil through thermal treatment of feedstocks in a two-step anaerobic digestion. Chem. Biol. Technol. Agric. 2024, 11, 186. [Google Scholar] [CrossRef]

- Peguero, D.A.; Gold, M.; Velasquez, L.; Niu, M.; Zurbrügg, C.; Mathys, A. Physical pretreatment of three biowastes to improve black soldier fly larvae bioconversion efficiency. Waste Manag. 2024, 178, 280–291. [Google Scholar] [CrossRef] [PubMed]

- Ziemiński, K.; Kowalska-Wentel, M. Effect of Different Sugar Beet Waste Pulp Pretreatments on Biogas Production Efficiency. Appl. Biochem. Biotechnol. 2016, 181, 1211–1227. [Google Scholar] [CrossRef] [PubMed]

- Carrere, H.; Dumas, C.; Battimelli, A.; Batstone, D.J.; Delgenès, J.P.; Steyer, J.P.; Ferrer, I. Pretreatment methods to improve sludge anaerobic degradability: A review. J. Hazard. Mater. 2010, 183, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Obileke, K.C.; Tangwe, S.; Makaka, G.; Mukumba, P. Comparison of prediction of biogas yield in a batch-mode underground fixed-dome digester with cow dung. Biomass Convers. Biorefinery 2023, 14, 26427–26442. [Google Scholar] [CrossRef]

- Rosi, L.; Cenni, M.; Ciuffi, B.; Casini, D.; Rizzo, A.M.; Chiaramonti, D. Enhancing biogas production in anaerobic digestion by the addition of oxidized and non-oxidized biochars. Biomass Convers. Biorefinery 2022, 14, 5457–5468. [Google Scholar] [CrossRef]

- Deval, S.; Mamta, T.; Kundeshwar, P.; Dikshit, A.K. Machine learning based prediction of biogas generation from municipal solid waste: A data-driven approach. Renew. Energy. 2024, 213, 118–127. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).