Recycled Concrete Aggregate in Self-Consolidating Concrete: A Systematic Review and Meta-Analysis of Mechanical Properties, RCA Pre-Treatment and Durability Behaviour

Abstract

1. Introduction

1.1. Problem Statement

1.2. Research Significance

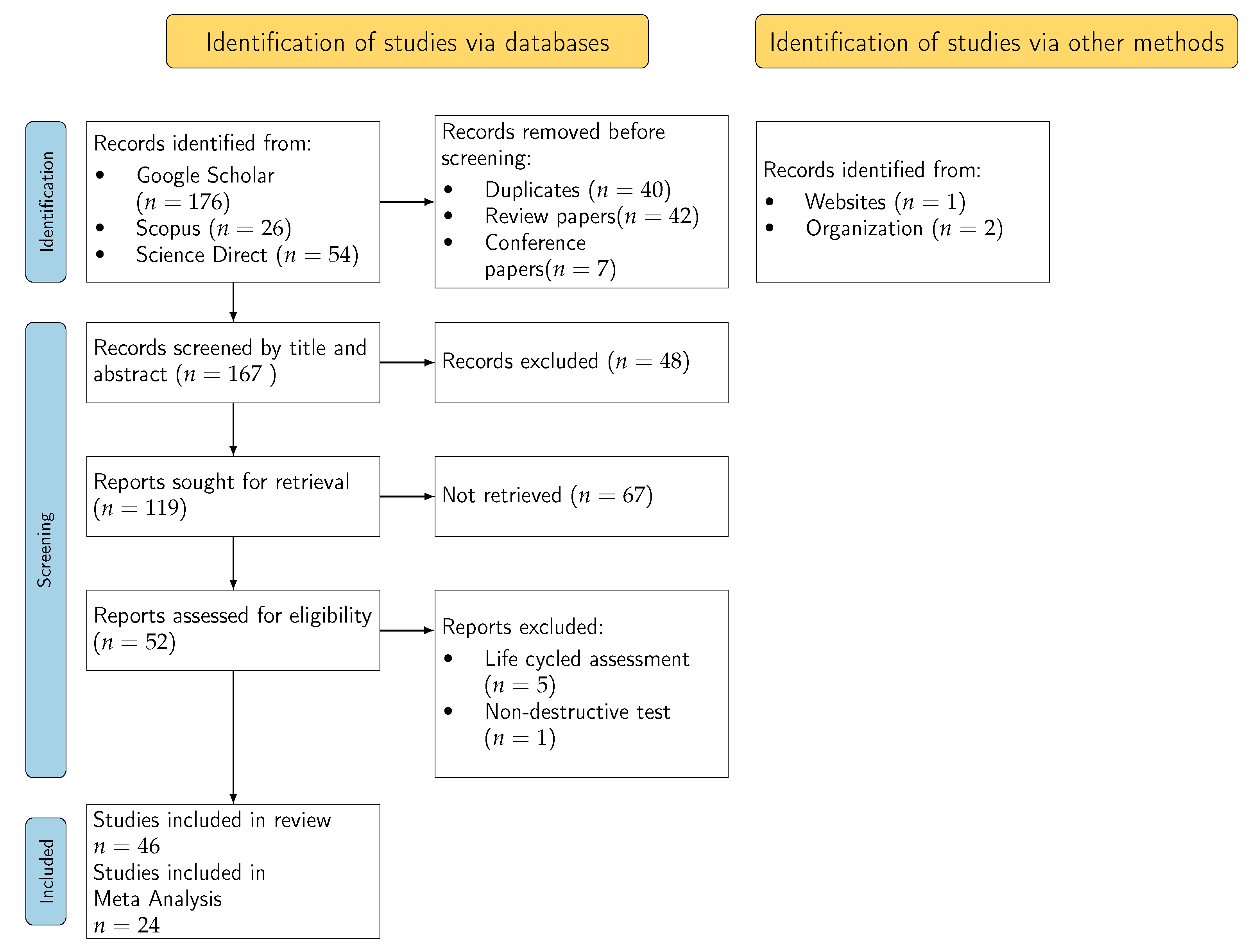

2. Methodology

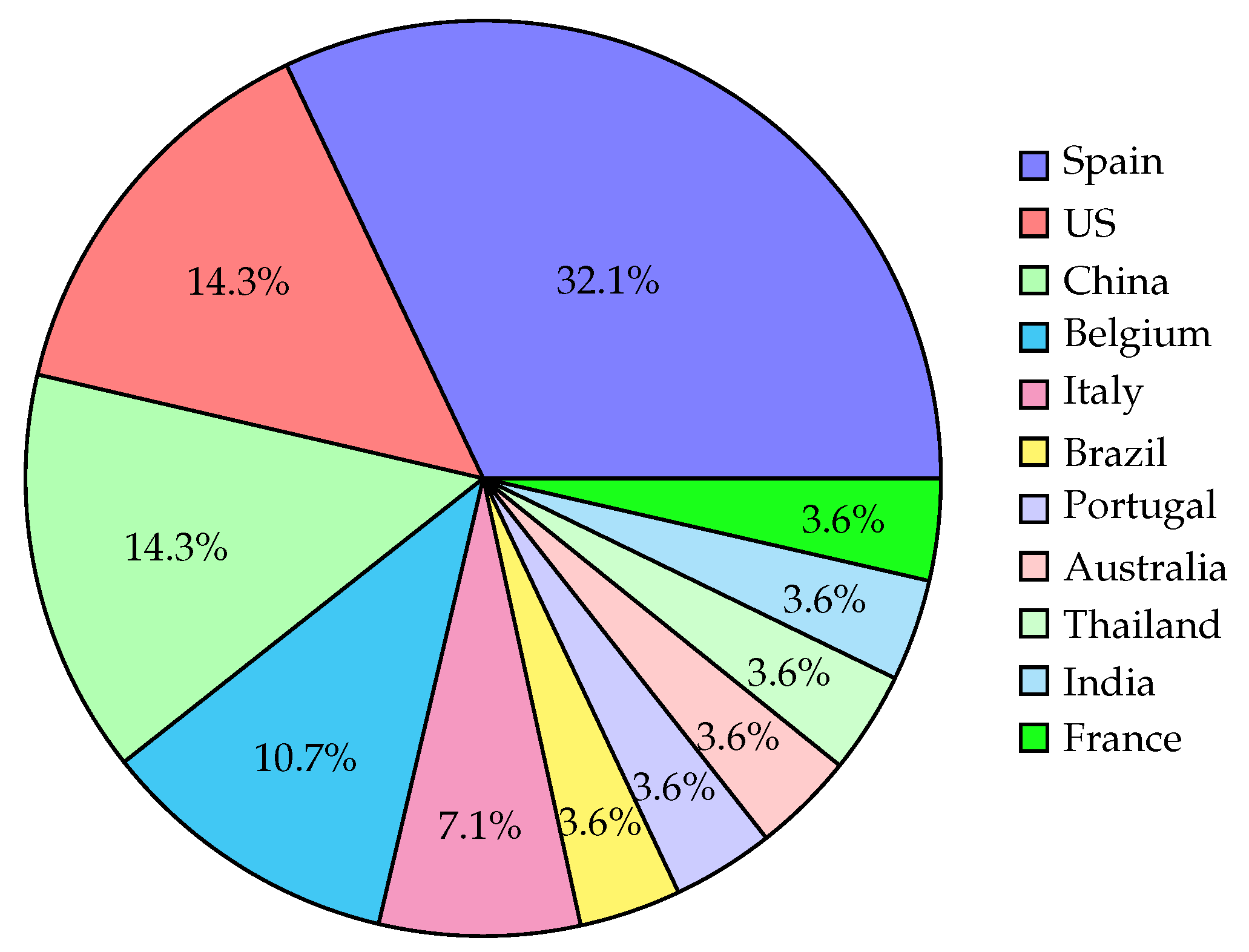

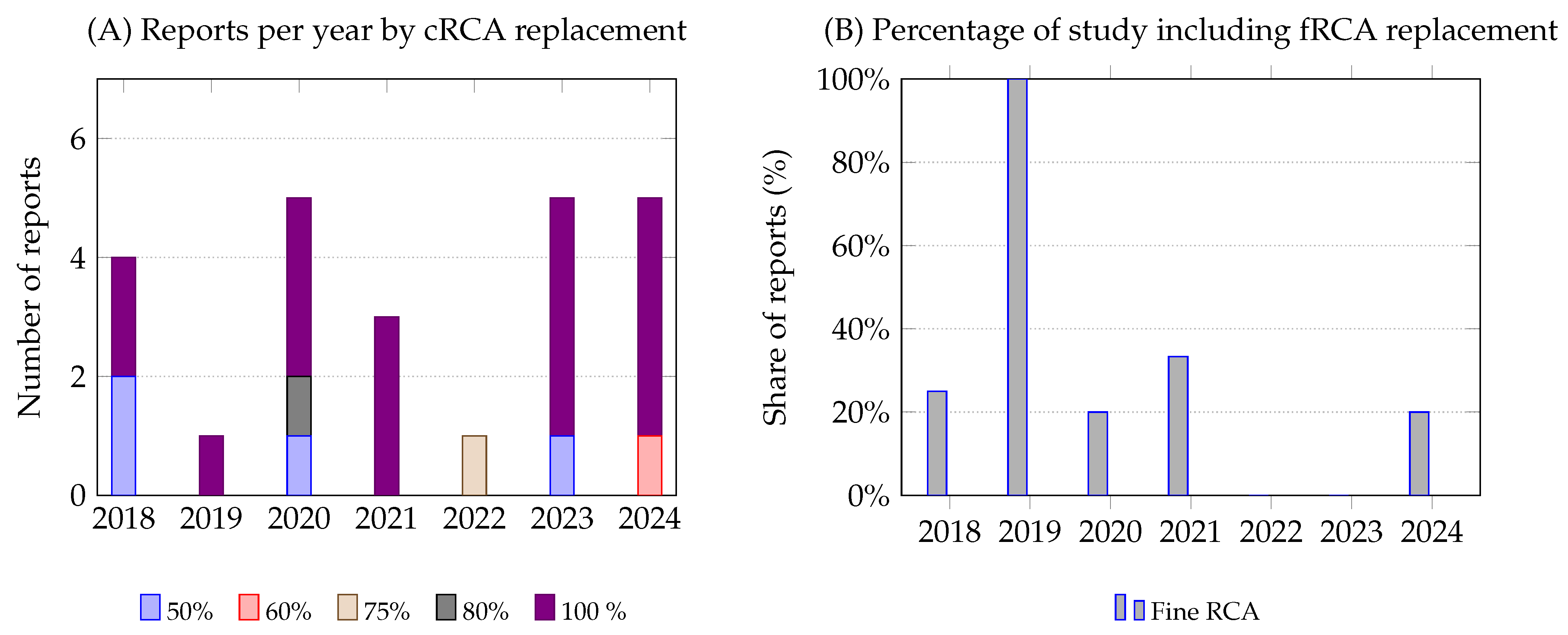

3. Qualitative Analysis

4. RCA Sources and Pre-Treatment

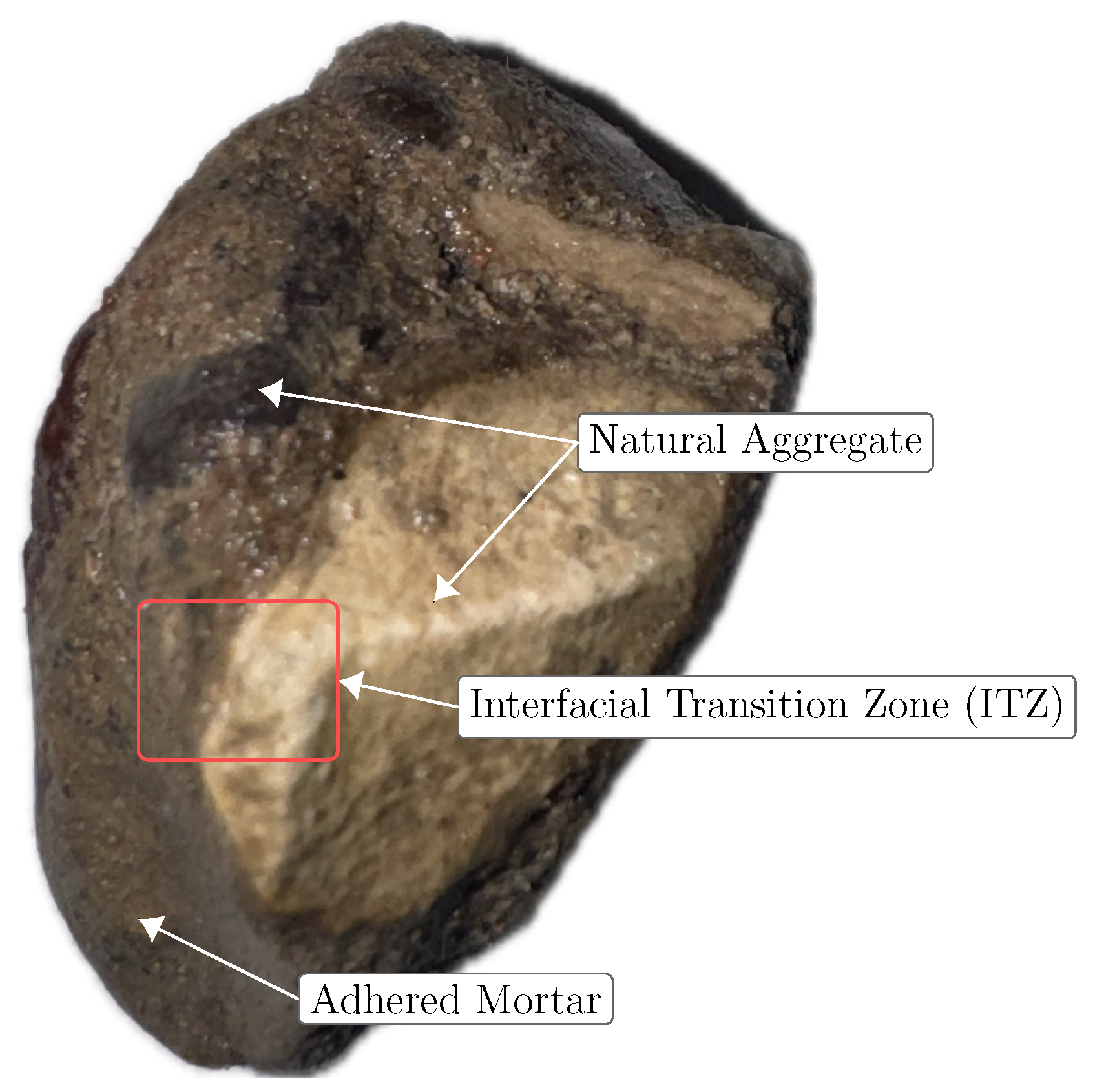

- RCA Pre-Treatment: These treatments consist in partially removing the adhered mortar attached to the aggregate. As a subcategory can be found the Mechanical Treatment Method (MTM) and the Chemical Treatment Method (CTM).Mechanical removal via ball milling or grinding effectively removes the weak old cement paste and reduces water absorption but can induce microcracks in the stone [12,39,40]. Thermal routes such as heating–grinding, known as “heating and rubbing”, can detach the cement paste after applying heat followed by mechanical grinding of the RCA. This treatment can improve the quality of the aggregate and give them similar properties to the natural stone [41]. Similarly to the heating method, the microwave heating method creates a differential expansion between the stone and the mortar, inducing thermal stresses that break the paste–aggregate bond [38]. Finally, the ultrasonic cleaning method consists of washing the RCA in an ultrasonic bath to remove the crumbs from the surface of the aggregate, increasing the strength by 7% [42].Chemical treatments can also be used to remove the adhered mortar in RCA. This method includes pre-soaking the RCA in acidic solutions. Three acids have been studied, hydrochloric acid (HCL), sulphuric (H2SO4), and phosphoric acid (H3PO4). The result has shown a reduction in water absorption and improvements in the concrete mechanical properties [43]. Another approach is the impregnation of the RCA using a slurry of pozzolanic materials, such as silica fume. This impregnation of the aggregate has the potential to enhance the quality of the adhered mortar by filling up the pores with the pozzolanic solution. This solution would then react with the calcium hydroxide in the cement paste of the RCA and the CO2 in the atmosphere, creating CaCO3, thus strengthening the RCA. Studies have shown that using silica fume in this way can increase compressive strength by up to 30% at 7 days and 15% at 28 days [42].

- RCA Surface Quality Improvement: In addition to the RCA pre-treatment to improve the recycled concrete behaviour, some methodologies have been developed to improve the performance of the RCA itself. Accelerated carbonation of the RCA has proven to reduce the water absorption, reduce its permeability, and improve durability [44]. The freeze–thaw method on recycled aggregates consists of inducing cracks in the adhered mortar of RCA. Ice formation within the pores causes the water in the cracks to expand, which facilitates the separation between the mortar and the aggregate [45,46]. Another variant of this method exists, and it includes high-temperature drying after the freeze–thaw cycle. This additional step induces thermal shrinkage differentiation, accelerating the mortar separation without damaging the natural stone [47].

5. Meta-Analysis Results

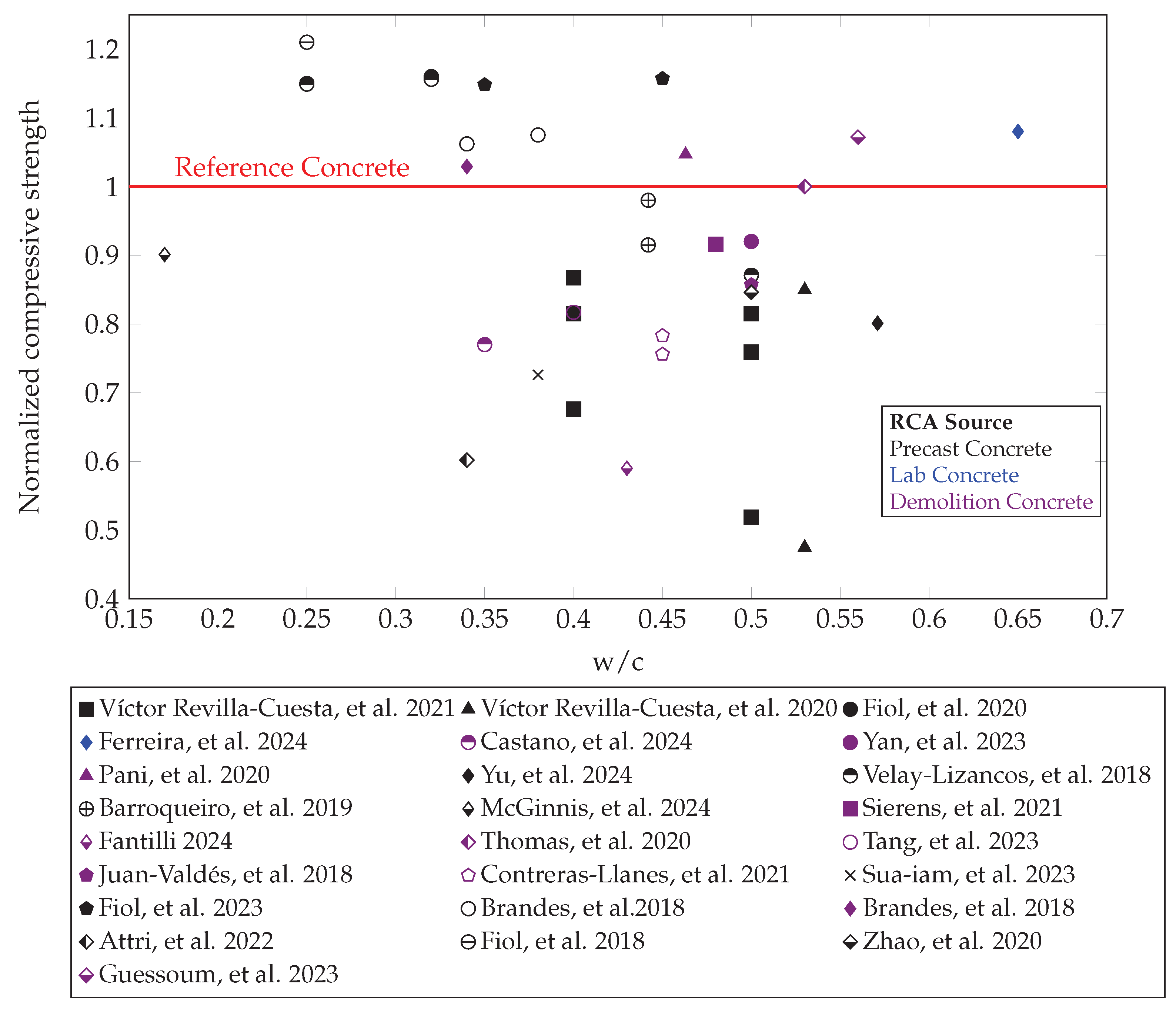

5.1. RCA-SCC Compressive Strength

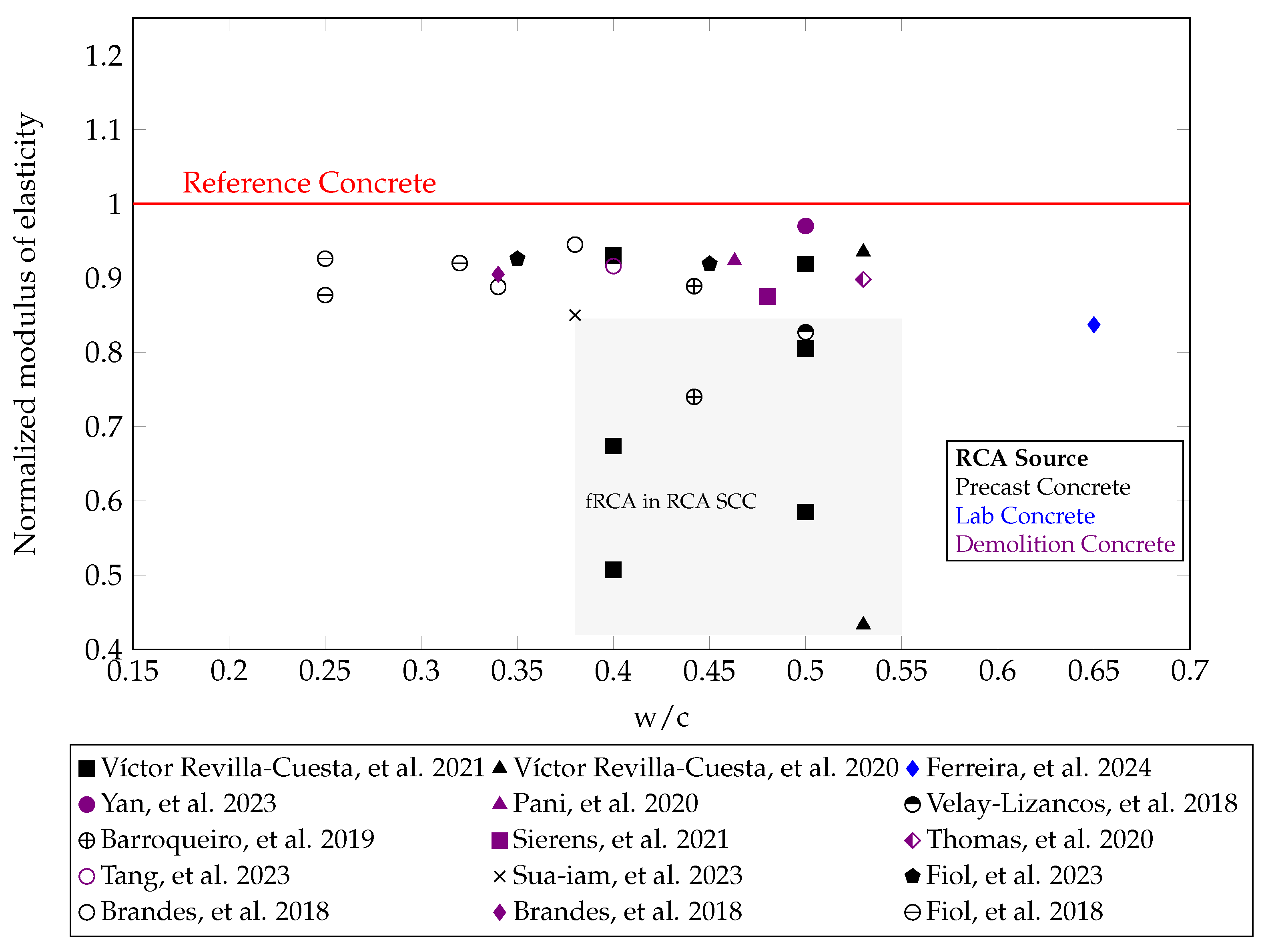

5.2. RCA-SCC Modulus of Elasticity

5.3. RCA-SCC Durability

6. Discussion

6.1. RCA-SCC for Structural Use

6.2. RCA SCC for Non-Structural Use

6.3. Real Case Applications

7. Conclusions

7.1. Workability and Mix Design

7.2. Shrinkage, Creep and Prestress Losses

7.3. Structural Applications

8. Future Research

Supplementary Materials

Funding

Acknowledgments

Conflicts of Interest

References

- Andrew, R.M. Global CO2 Emissions from Cement Production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Cement Is a Big Problem for the Environment. Here’s How to Make It More Sustainable. 2024. Available online: https://www.weforum.org/stories/2024/09/cement-production-sustainable-concrete-co2-emissions/ (accessed on 13 August 2025).

- Javadpour, M.; McCoy, S.; Sleep, S. Assessment of Technology Pathways for Net-Zero Concrete Production. In Proceedings of the 17th Greenhouse Gas Control Technologies Conference (GHGT-17), Calgary, AB, Canada, 20–24 October 2024. [Google Scholar] [CrossRef]

- U.S. Geological Survey. Mineral Commodity Summaries; U.S. Geological Survey: Reston, VA, USA, 2024. [Google Scholar]

- The European Cement Association. Activity Report 2023; Technical Report; The European Cement Association: Brussels, Belgium, 2023. [Google Scholar]

- Gu, D.; Andreev, K.; Dupre, M.E. Major Trends in Population Growth Around the World. China CDC Wkly. 2021, 3, 604–613. [Google Scholar] [CrossRef]

- EuroStat. Waste Generation, Excluding Major Mineral Waste. 2022. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics (accessed on 13 August 2025).

- Wilke, S. Abfallaufkommen. 2013. Available online: https://www.umweltbundesamt.de/daten/ressourcen-abfall/abfallaufkommen (accessed on 8 October 2025).

- US Environmental Protection Agency. Construction and Demolition Debris: Material-Specific Data. 2017. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/construction-and-demolition-debris-material (accessed on 13 August 2025).

- Emmanuel, S. Estimation and Projection of Construction and Demolition Waste Generation in Beijing Using Empirical Construction Data. In Proceedings of the 2023 Beijing International Environmental Technology Conference, Beijing, China, 21–23 October 2023. [Google Scholar]

- European Comission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; Technical Report; European Comission: Brussel, Belgium, 2025. [Google Scholar]

- Savva, P.; Ioannou, S.; Oikonomopoulou, K.; Nicolaides, D.; Petrou, M.F. A Mechanical Treatment Method for Recycled Aggregates and Its Effect on Recycled Aggregate-Based Concrete. Materials 2021, 14, 2186. [Google Scholar] [CrossRef]

- Kuoribo, E.; Shokry, H.; Mahmoud, H. Attaining Material Circularity in Recycled Construction Waste to Produce Sustainable Concrete Blocks for Residential Building Applications. J. Build. Eng. 2024, 96, 110503. [Google Scholar] [CrossRef]

- Velay-Lizancos, M.; Martinez-Lage, I.; Azenha, M.; Granja, J.; Vazquez-Burgo, P. Concrete with Fine and Coarse Recycled Aggregates: E-modulus Evolution, Compressive Strength and Non-Destructive Testing at Early Ages. Constr. Build. Mater. 2018, 193, 323–331. [Google Scholar] [CrossRef]

- Hatungimana, D.; Yazıcı, Ş.; Mardani-Aghabaglou, A. Effect of recycled concrete aggregate quality on properties of concrete. J. Green Build. 2020, 15, 57–69. [Google Scholar] [CrossRef]

- Hassan, S.S. Effects of Recycled Concrete Aggregate on Some Mechanical Properties of High Strength Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2018, 433, 012033. [Google Scholar] [CrossRef]

- Sadik, M.N.; Akter, T.; Proma, P.D.; Prodhan, M.A.R.; Momotaj, M. Impact of Recycled Coarse Aggregates on the Mechanical Properties and Durability of Concrete. Eur. J. Theor. Appl. Sci. 2024, 2, 738–759. [Google Scholar] [CrossRef] [PubMed]

- Gebremariam, H.G.; Taye, S.; Tarekegn, A.G.; Woldesenbet, A. Revolutionizing sustainable construction through recycled concrete aggregate production: A systemic review of codes, standards and guidelines. J. Civ. Eng. Sci. Technol. 2025, 16, 102–118. [Google Scholar] [CrossRef]

- Gherman, I.E.; Lakatos, E.S.; Clinci, S.D.; Lungu, F.; Constandoiu, V.V.; Cioca, L.I.; Rada, E.C. Circularity Outlines in the Construction and Demolition Waste Management: A Literature Review. Recycling 2023, 8, 69. [Google Scholar] [CrossRef]

- Guessoum, M.; Boukhelf, F.; Khadraoui, F. Full Characterization of Self-Compacting Concrete Containing Recycled Aggregates and Limestone. Materials 2023, 16, 5842. [Google Scholar] [CrossRef] [PubMed]

- Castano, J.E.; Abdel-Mohti, A. Assessing the Impact of Recycled Concrete Aggregates on the Fresh and Hardened Properties of Self-Consolidating Concrete for Structural Precast Applications. Infrastructures 2024, 9, 177. [Google Scholar] [CrossRef]

- Tang, W.; Khavarian, M.; Yousefi, A.; Landenberger, B.; Cui, H. Influence of Mechanical Screened Recycled Coarse Aggregates on Properties of Self-Compacting Concrete. Materials 2023, 16, 1483. [Google Scholar] [CrossRef]

- Morales Rapallo, A.C.; Zum Brock, J.; Doostdar, M.; Kuchta, K. Utilization of recycled aggregates in concrete: Case study. Detritus 2024, volume 26, 69–73. [Google Scholar] [CrossRef]

- Martínez-García, R.; Jagadesh, P.; Fraile-Fernández, F.; Morán-del Pozo, J.; Juan-Valdés, A. Influence of Design Parameters on Fresh Properties of Self-Compacting Concrete with Recycled Aggregate—A Review. Materials 2020, 13, 5749. [Google Scholar] [CrossRef] [PubMed]

- Peiris, D.; Gunasekara, C.; Law, D.W.; Patrisia, Y.; Tam, V.W.Y.; Setunge, S. Impact of Treatment Methods on Recycled Concrete Aggregate Performance: A Comprehensive Review. Environ. Sci. Pollut. Res. 2025, 32, 14405–14438. [Google Scholar] [CrossRef]

- Tošić, N.; Torrenti, J.M.; Sedran, T.; Ignjatović, I. Toward a Codified Design of Recycled Aggregate Concrete Structures: Background for the New Model Code 2020 and Eurocode 2. Struct. Concr. 2021, 22, 2916–2938. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Skaf, M.; Santamaría, A.; Ortega-López, V.; Manso, J.M. Assessment of Longitudinal and Transversal Plastic Behavior of Recycled Aggregate Self-Compacting Concrete: A Two-Way Study. Constr. Build. Mater. 2021, 292, 123426. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Ortega-López, V.; Skaf, M.; Manso, J.M. Effect of Fine Recycled Concrete Aggregate on the Mechanical Behavior of Self-Compacting Concrete. Constr. Build. Mater. 2020, 263, 120671. [Google Scholar] [CrossRef]

- Fiol, F.; Thomas, C.; Muñoz, C.; Ortega-López, V.; Manso, J. The Influence of Recycled Aggregates from Precast Elements on the Mechanical Properties of Structural Self-Compacting Concrete. Constr. Build. Mater. 2018, 182, 309–323. [Google Scholar] [CrossRef]

- Fiol, F.; Thomas, C.; Manso, J.M.; López, I. Influence of Recycled Precast Concrete Aggregate on Durability of Concrete’s Physical Processes. Appl. Sci. 2020, 10, 7348. [Google Scholar] [CrossRef]

- Fiol, F.; Revilla-Cuesta, V.; Thomas, C.; Manso, J.M. Self-Compacting Concrete Containing Coarse Recycled Precast-Concrete Aggregate and Its Durability in Marine-Environment-Related Tests. Constr. Build. Mater. 2023, 377, 131084. [Google Scholar] [CrossRef]

- Juan-Valdés, A.; García-González, J.; Rodríguez-Robles, D.; Guerra-Romero, M.I.; López Gayarre, F.; De Belie, N.; Morán-del Pozo, J.M. Paving with Precast Concrete Made with Recycled Mixed Ceramic Aggregates: A Viable Technical Option for the Valorization of Construction and Demolition Wastes (CDW). Materials 2018, 12, 24. [Google Scholar] [CrossRef]

- Velay-Lizancos, M.; Vazquez-Burgo, P.; Restrepo, D.; Martinez-Lage, I. Effect of Fine and Coarse Recycled Concrete Aggregate on the Mechanical Behavior of Precast Reinforced Beams: Comparison of FE Simulations, Theoretical, and Experimental Results on Real Scale Beams. Constr. Build. Mater. 2018, 191, 1109–1119. [Google Scholar] [CrossRef]

- Barroqueiro, T.; Da Silva, P.R.D.; De Brito, J.D. Fresh-State and Mechanical Properties of High-Performance Self-Compacting Concrete with Recycled Aggregates from the Precast Industry. Materials 2019, 12, 3565. [Google Scholar] [CrossRef]

- Guyatt, G.; Oxman, A.D.; Akl, E.A.; Kunz, R.; Vist, G.; Brozek, J.; Norris, S.; Falck-Ytter, Y.; Glasziou, P.; deBeer, H. GRADE Guidelines: 1. Introduction—GRADE Evidence Profiles and Summary of Findings Tables. J. Clin. Epidemiol. 2011, 64, 383–394. [Google Scholar] [CrossRef] [PubMed]

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of Recycled Concrete Aggregate and Their Influence in New Concrete Production. Resour. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.; Zhang, M.; Tam, C.; Foo, T. Microwave-Assisted Beneficiation of Recycled Concrete Aggregates. Constr. Build. Mater. 2011, 25, 3469–3479. [Google Scholar] [CrossRef]

- Al-Bayati, H.K.A.; Das, P.K.; Tighe, S.L.; Baaj, H. Evaluation of Various Treatment Methods for Enhancing the Physical and Morphological Properties of Coarse Recycled Concrete Aggregate. Constr. Build. Mater. 2016, 112, 284–298. [Google Scholar] [CrossRef]

- Dilbas, H.; Çakır, Ö.; Atiş, C. Experimental Investigation on Properties of Recycled Aggregate Concrete with Optimized Ball Milling Method. Constr. Build. Mater. 2019, 212, 716–726. [Google Scholar] [CrossRef]

- Pawluczuk, E.; Kalinowska-Wichrowska, K.; Bołtryk, M.; Jiménez, J.; Fernández, J. The Influence of Heat and Mechanical Treatment of Concrete Rubble on the Properties of Recycled Aggregate Concrete. Materials 2019, 12, 367. [Google Scholar] [CrossRef]

- Katz, A. Treatments for the Improvement of Recycled Aggregate. J. Mater. Civ. Eng. 2004, 16, 597–603. [Google Scholar] [CrossRef]

- Tam, V.W.; Tam, C.; Le, K. Removal of Cement Mortar Remains from Recycled Aggregate Using Pre-Soaking Approaches. Resour. Conserv. Recycl. 2007, 50, 82–101. [Google Scholar] [CrossRef]

- Xuan, D.; Zhan, B.; Poon, C.S. Durability of Recycled Aggregate Concrete Prepared with Carbonated Recycled Concrete Aggregates. Cem. Concr. Compos. 2017, 84, 214–221. [Google Scholar] [CrossRef]

- Guo, J.; Sun, W.; Xu, Y.; Lin, W.; Jing, W. Damage Mechanism and Modeling of Concrete in Freeze–Thaw Cycles: A Review. Buildings 2022, 12, 1317. [Google Scholar] [CrossRef]

- Wu, Q.; Gong, F.; Zhi, D.; Zhao, Y. Removing Attached Mortar from Recycled Aggregate by the Combined Freeze–Thaw Cycles and High-temperature Drying. Struct. Concr. 2022, 23, 3126–3139. [Google Scholar] [CrossRef]

- Gong, F.; Wang, Z.; Ning, Y.; Yang, L.; Zeng, Q. Investigation on the Impact of Thermo-Drying towards Freeze-Thaw Cycle Processing for Recycled Coarse Aggregate. Constr. Build. Mater. 2023, 392, 131914. [Google Scholar] [CrossRef]

- Ferreira, M.D.P.; Santos, K.D.D.; Pereira Filho, M.J.M.; Cordeiro, L.D.N.P. Effect of Recycled Concrete Aggregates on the Concrete Breakout Resistance of Headed Bars Embedded in Slender Structural Elements. Buildings 2024, 14, 2102. [Google Scholar] [CrossRef]

- Yan, P.; Wu, J.; Lin, D. Axial Compression Behavior of Composite Sandwich Panel with Mixed Recycled Coarse Aggregate Concrete. KSCE J. Civ. Eng. 2023, 27, 5294–5306. [Google Scholar] [CrossRef]

- Pani, L.; Rombi, J.; Francesconi, L.; Mereu, A. Circular economy model of recycled aggregates for the construction sector of Sardinia Island. Environ. Eng. Manag. J. 2020, 19, 1847–1855. [Google Scholar] [CrossRef]

- Yu, Y.; Pacheco-Torgal, F.; Zhao, X.Y.; Wang, X.L. Cleaner Production of the Precast Concrete Industry: Comparative Life Cycle Analysis of Concrete Using Recycled Aggregates from Crushed Precast Rejects. Eur. J. Environ. Civ. Eng. 2024, 28, 1014–1038. [Google Scholar] [CrossRef]

- McGinnis, M.J.; Gangone, M.V.; Nogales, A.; Gomez-Santana, L.M.; Weldon, B.; Reihl, A.; Tošić, N.; Kurama, Y. Experimental and Numerical Investigation of the Bending, Shear, and Punching Shear Behavior of Recycled Aggregate Concrete Precast/Prestressed Hollow Core Slabs. Struct. Concr. 2024, 25, 4340–4364. [Google Scholar] [CrossRef]

- Sierens, Z.; Vandevyvere, B.; Xiaoguang, C.; Jiabin, L. Green Concrete with High Quality Recycled Concrete Aggregate for Precast Elements: Mechanical Properties at Early Ages. Indian Concr. J. 2021, 95, 7–19. [Google Scholar]

- Fantilli, A.P. Green Public Procurement Applied to Partially Precast Reinforced Concete Slabs. Eng. Struct. 2024, 301, 117338. [Google Scholar] [CrossRef]

- Thomas, C.; Cimentada, A.I.; Cantero, B.; Sáez Del Bosque, I.F.; Polanco, J.A. Industrial Low-Clinker Precast Elements Using Recycled Aggregates. Appl. Sci. 2020, 10, 6655. [Google Scholar] [CrossRef]

- Contreras-Llanes, M.; Romero, M.; Gázquez, M.J.; Bolívar, J.P. Recycled Aggregates from Construction and Demolition Waste in the Manufacture of Urban Pavements. Materials 2021, 14, 6605. [Google Scholar] [CrossRef]

- Sua-iam, G.; Makul, N. Recycling Prestressed Concrete Pile Waste to Produce Green Self-Compacting Concrete. J. Mater. Res. Technol. 2023, 24, 4587–4600. [Google Scholar] [CrossRef]

- Brandes, M.R.; Kurama, Y.C. Service-Load Behavior of Precast/Prestressed Concrete Beams with Recycled Concrete Aggregates. ACI Struct. J. 2018, 115, 861–873. [Google Scholar] [CrossRef]

- Attri, G.K.; Gupta, R.C.; Shrivastava, S. Sustainable Precast Concrete Blocks Incorporating Recycled Concrete Aggregate, Stone Crusher, and Silica Dust. J. Clean. Prod. 2022, 362, 132354. [Google Scholar] [CrossRef]

- Zhao, Z.; Courard, L.; Groslambert, S.; Jehin, T.; Léonard, A.; Xiao, J. Use of Recycled Concrete Aggregates from Precast Block for the Production of New Building Blocks: An Industrial Scale Study. Resour. Conserv. Recycl. 2020, 157, 104786. [Google Scholar] [CrossRef]

- Gao, S.; Guo, J.; Zhu, Y.; Jin, Z. Study on the Influence of the Properties of Interfacial Transition Zones on the Performance of Recycled Aggregate Concrete. Constr. Build. Mater. 2023, 408, 133592. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Skaf, M.; Santamaría, A.; Romera, J.M.; Ortega-López, V. Elastic Stiffness Estimation of Aggregate–ITZ System of Concrete through Matrix Porosity and Volumetric Considerations: Explanation and Exemplification. Arch. Civ. Mech. Eng. 2022, 22, 59. [Google Scholar] [CrossRef]

- Zhao, X.; Zhan, M.; Chen, Z.; Zhang, J.; Li, Q.; Song, W. Prediction of Elastic Modulus of Leached Fly Ash Concrete Based on Non-Uniform ITZ Model. Materials 2025, 18, 3779. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Ba, M.; Yi, B.; Liu, J. Experimental and Numerical Investigation on the Effect of Cracks on Chloride Diffusion and Steel Corrosion in Concrete. J. Build. Eng. 2024, 86, 108521. [Google Scholar] [CrossRef]

- Das Deutsche Institut für Bautechnik. Allgemeine Bauaufsichtliche Zulassung/Allgemeine Bauartgenehmigung. Available online: https://www.dibt.de/de/ (accessed on 9 September 2025).

- Breit, W.; Burgmann, S. Concrete with Recycled Aggregates - Update of the Application Rules in Germany and Outlook. ce/papers 2023, 6, 956–963. [Google Scholar] [CrossRef]

- The “Büscher Wall”–Building Sustainably with Concrete Containing Recycled Constituents-Concrete Plant Precast Technology. Available online: https://www.bft-international.com/en/artikel/the-buescher-wall-building-sustainably-with-concrete-containing-recycled-constituents-3897796.html (accessed on 9 September 2025).

- Recycled Concrete. Available online: https://www.muensterland.com/en/economy/business-location/innovations/innovation-stories/recycling-beton/ (accessed on 9 September 2025).

| RCA Pre-Treatment | Advantages | Disadvantages |

|---|---|---|

| Mechanical removal (ball-milling or grinding) [12,39,40] | Removes adhered mortar and lowers water absorption | Can induce micro-cracks; energy-intensive; useful for coarse RCA with high attached mortar. |

| Thermal–mechanical (heating and grinding) [41] | Detaches old cement paste; yields aggregates closer to natural stone | Requires heating equipment; possible thermal damage; suited for demolition-derived RCA when heat and grinding equipment are available. |

| Microwave heating [38] | Breaks the paste–aggregate bond via thermal stress | Needs specialised microwave reactors currently limited to laboratory or high-value applications. |

| Ultrasonic cleaning [42] | Cleans aggregate surface and can raise strength by | Only removes superficial mortar; equipment is expensive; best for small batches of high-quality RCA. |

| Acid soaking (chemical treatment) [43] | Reduces water absorption and improves mechanical properties | Handling and disposing of acids poses safety and environmental risks; may roughen aggregate; suitable in controlled lab settings or where regulations allow acid use. |

| Silica-fume slurry impregnation [42] | Fills pores and forms CaCO3, boosting strength up to 30% at 7 days and 15% at 28 days | Adds processing steps and cost; effectiveness depends on penetration and curing; suited for high-performance SCC requiring enhanced strength and durability. |

| Accelerated carbonation [44] | Lowers water absorption and permeability and improves durability; also stores CO2 | Requires CO2 supply and controlled conditions; treatment time can be longer; appropriate for sustainable, high-replacement SCC with carbonation facilities. |

| Freeze–thaw cracking (and freeze–thaw + high-temperature drying) [45,46,47] | Facilitates mortar separation without chemicals; high-temperature variant accelerates detachment | Time-consuming; may damage natural stone; needs freeze–thaw and drying equipment; mainly for research or low-cost non-chemical treatments. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morales Rapallo, A.C.; Kuchta, K. Recycled Concrete Aggregate in Self-Consolidating Concrete: A Systematic Review and Meta-Analysis of Mechanical Properties, RCA Pre-Treatment and Durability Behaviour. Recycling 2025, 10, 214. https://doi.org/10.3390/recycling10060214

Morales Rapallo AC, Kuchta K. Recycled Concrete Aggregate in Self-Consolidating Concrete: A Systematic Review and Meta-Analysis of Mechanical Properties, RCA Pre-Treatment and Durability Behaviour. Recycling. 2025; 10(6):214. https://doi.org/10.3390/recycling10060214

Chicago/Turabian StyleMorales Rapallo, Ariana C., and Kerstin Kuchta. 2025. "Recycled Concrete Aggregate in Self-Consolidating Concrete: A Systematic Review and Meta-Analysis of Mechanical Properties, RCA Pre-Treatment and Durability Behaviour" Recycling 10, no. 6: 214. https://doi.org/10.3390/recycling10060214

APA StyleMorales Rapallo, A. C., & Kuchta, K. (2025). Recycled Concrete Aggregate in Self-Consolidating Concrete: A Systematic Review and Meta-Analysis of Mechanical Properties, RCA Pre-Treatment and Durability Behaviour. Recycling, 10(6), 214. https://doi.org/10.3390/recycling10060214