Indicators Targeting the Retrieval of Polymers in EEE and Their Re-Integration into New Equipment

Abstract

1. Introduction

2. Results

2.1. Contents of the Section

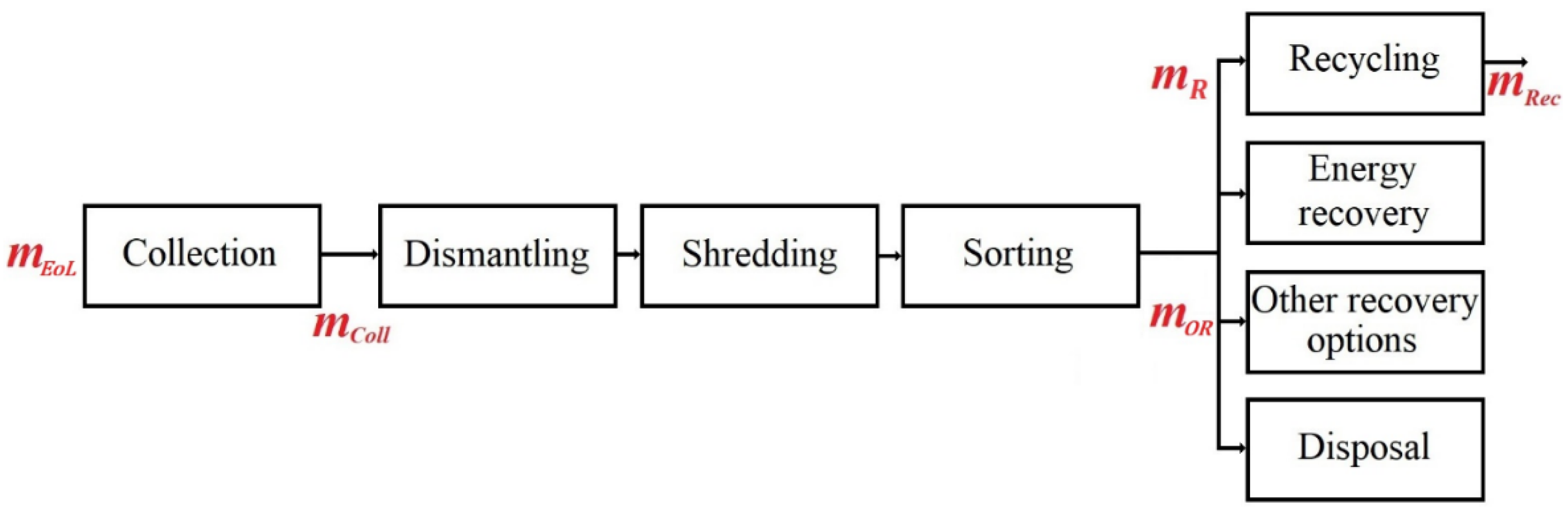

2.2. Construction of the Retrievability Index

2.2.1. Disassembly Indicator

2.2.2. Indicator of Material Separability

2.2.3. Treatment Facility Availability Indicator

- If the disassembly and regeneration facilities are the same, we just calculate the average of the two values.

- If the disassembly and regeneration facilities are different, it means that additional transportation steps will be necessary. This must be reflected in the value of the indicator. Hence, instead of calculating the average value, we are going to multiply the two sub-indicators.

2.2.4. Material Recyclability Indicator

2.2.5. The Retrievability Index

2.3. Construction of the Reintegrability Index

2.3.1. Indicator of Material Availability

2.3.2. Material Purity Indicator

2.3.3. Environmental Impact Indicator

2.3.4. Material Traceability Indicator

2.3.5. The Reintegrability Index

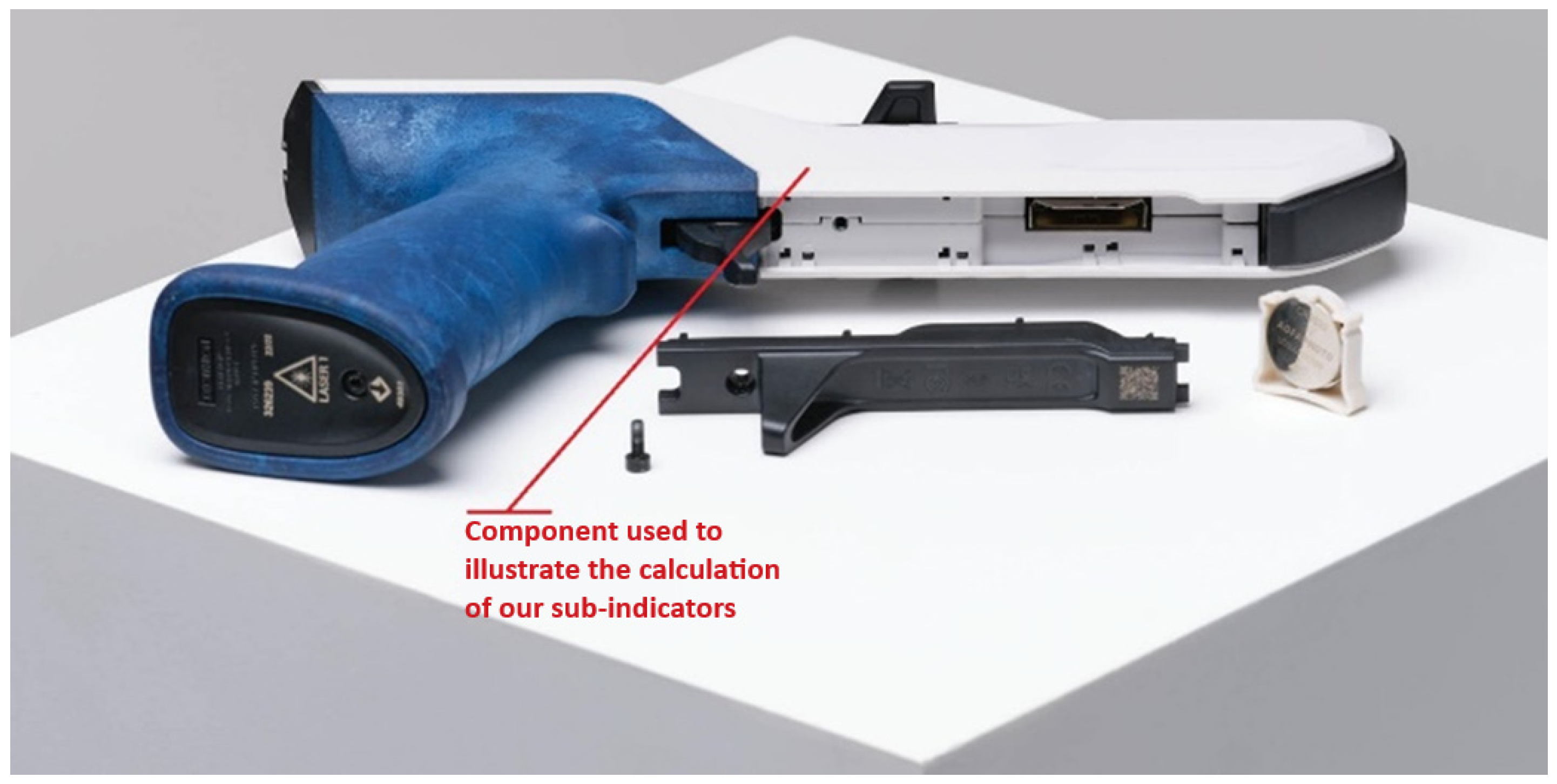

2.4. Presentation of the Studied Equipment

2.5. Calculation of the Retrievability Index Sub-Indicators

- Dismantlability

- −

- Concentration of FE

- − Connection accessibility

- − Number of types of FE

- − Type of FE

- Material separability

- −

- Material compatibility

- − Material hazardousness

- − Material contamination

- Treatment availability

- −

- Availability of dismantling facilities

- − Availability of recycling facilities

- Material recyclability

- −

- Theoretical recycling rate

- − Collection rate

- − Diversity of materials

2.6. Calculation of the Reintegrability Index Sub-Indicators

- Material availability

- −

- Volume of the deposit

- − Volume of production

- Purity rate

- −

- Proportion of the main material

- − Proportion of contaminants

- − Filtration level

- Environmental impact

- −

- Proportion of recycled material

- − Carbon savings

- − Material criticality

- Traceability

- −

- Category of origin of the waste

- − Geographical origin of the waste

- − Regulation compliance

2.7. Retrievability Index

2.8. Reintegrability Index

2.9. Conclusions of the Case Study

3. Discussion

4. Methods

4.1. Indicators for the Ecodesign of WEEE, Centred on the Use of Recycled Polymers

4.1.1. Selection of Eco-Design Indicators

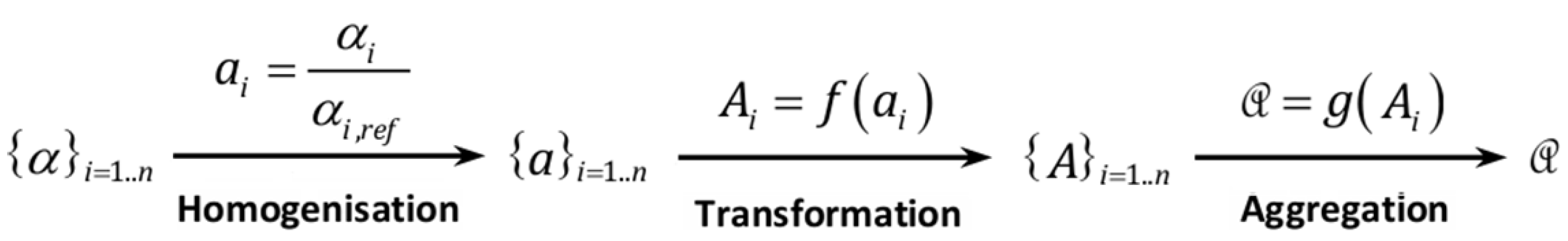

4.1.2. Calculation and Construction of the Indicators

- An indicator is a tool for the evaluation of a physical measure.

- An index is a function which takes the indicators as arguments. It expresses a synthesis of information of different natures.

- A sub-indicator is, in our case, an entity based directly on a measurable value. In other words, there is a causal relationship between the sub-indicator and the physical measure. The indicator itself is the synthesis of several sub-indicators.

4.1.3. Homogeneity and Normalisation Principles

- equals 100% since the batch taken for reference is totally pure;

- equals 95% since it is the value that has been measured.

- Principle 1: By calculating all the indicators using a reference quantity , they become homogeneous and can be compared and used for aggregation even if the measured values were not of the same physical quantity.

- Principle 2: by setting all indicators to a common value , they have indeed been normalised. This principle is used to make all indicators vary within the same interval, thus making them easier to compare.

- Principle 3: if these two principles are respected for all mathematical entities (indices, indicators, and sub-indicators), we ensure that they will all be part of the same ensemble, hence avoiding any mathematical errors.

4.1.4. Transformation and Aggregation

- Principle 4: Invariance by permutation of indicators.

- Principle 5: Monotony of the transformation function.

- Principle 6, the “efficiency” principle: The aggregated entity must highlight the efforts made on the worst argument. This is to encourage the users of this method to try and improve the worst indicators instead of trying to compensate them by increasing the value of already good ones.

4.1.5. Construction of the Mathematical Entities for Our Study

- Arithmetic average value: A , n > 0;

- Multiplication of indicators:

- Complements to 1:

- Hybrid forms , n > 0.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CO2 | Carbon dioxide |

| EoL | End of life |

| FEs | Fastening elements |

| RPM | Recycled plastic material |

| WEEE | Waste electrical and electronic equipment |

Appendix A

Numerical Calculation of Disassembly Indicators

| Measured Physical Value | Corresponding Value | Magnetic bond | Nut and bolt | Circlip | Clip | Nail | Nylon cord | Interlock | Glue | Pin | Rivet | |

| tD: time for disassembly (s) | from 0 to 13 s | 1 | 1 | 0.66 | 1 | 1 | 0.33 | 1 | 1 | 0.66 | 0.66 | 0 |

| from 13.1 to 16 s | 0.66 | |||||||||||

| from 16.1 to 40 s | 0.33 | |||||||||||

| >40 s | 0 | |||||||||||

| Nt: number of tools necessary | 0 | 1 | 1 | 0.66 | 0.66 | 1 | 0.66 | 0.66 | 1 | 0.33 | 0.66 | 0 |

| 1 | 0.66 | |||||||||||

| 2 | 0.33 | |||||||||||

| > 3 | 0 | |||||||||||

| SD: Necessary strength (N) | from 0 to 12 N | 1 | 0.33 | 1 | 1 | 0.66 | 0 | 0.33 | 1 | 0 | 1 | 0 |

| from 12.1 to 25 N | 0.66 | |||||||||||

| 25.1 to 47 N | 0.33 | |||||||||||

| >47 N | 0 | |||||||||||

| Da: Destructivity | Non-destructive, no residue | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0.66 | 1 | 0.33 |

| Non-destructive, with residue | 0.66 | |||||||||||

| Destructive, no residue | 0.33 | |||||||||||

| Destructive, with residue | 0 | |||||||||||

| Sum | 3.33 | 3.33 | 3.66 | 3.66 | 2 | 3 | 4 | 1.66 | 3.33 | 0.33 | ||

| Average value | 0.83 | 0.83 | 0.92 | 0.92 | 0.5 | 0.75 | 1 | 0.42 | 0.83 | 0.08 | ||

| Normalised value: | 0.85 | 0.85 | 0.95 | 0.95 | 0.55 | 0.8 | 1 | 0.45 | 0.85 | 0.1 | ||

Appendix B

Numerical Calculation of Several Sub-Indicators

| Component | Sub-Indicator of Type of FE | Sub-Indicator of Number of Types of FE | Sub-Indicator of Connection Availability | Sub-Indicator of FE Concentration |

|---|---|---|---|---|

| Forward weight | 0.85 | 0.50 | 0.50 | 0.70 |

| Backwards weight | 0.85 | 0.50 | 0.50 | 0.70 |

| Right half of the barrel | 0.95 | 1.00 | 1.00 | 0.80 |

| Left half of the barrel | 0.95 | 1.00 | 1.00 | 0.80 |

| Battery hood | 0.95 | 1.00 | 0.50 | 0.80 |

| Outer casing | 0.85 | 0.50 | 1.00 | 0.80 |

| Handle hood | 0.85 | 1.00 | 1.00 | 0.80 |

| Internal lever | 0.85 | 1.00 | 0.50 | 0.70 |

| Reload lever | 0.85 | 1.00 | 0.50 | 0.70 |

| Trigger | 0.85 | 1.00 | 0.50 | 0.80 |

| Vertical camera | 0.85 | 1.00 | 1.00 | 0.80 |

| Handle—first half | 0.85 | 0.50 | 1.00 | 0.70 |

| Handle—second half | 0.85 | 0.50 | 1.00 | 0.70 |

| Battery | 0.85 | 1.00 | 0.50 | 0.80 |

| Battery support | 0.45 | 1.00 | 0.50 | 0.80 |

| Active electronic component | 0.85 | 1.00 | 0.50 | 0.80 |

| Electro-mechanical component | 0.85 | 1.00 | 0.50 | 0.80 |

| Printed circuit board | 0.85 | 1.00 | 0.50 | 0.80 |

| Passive electronic component | 0.85 | 1.00 | 0.50 | 0.80 |

| LASER module | 0.85 | 1.00 | 0.50 | 0.80 |

| Printed circuit board frame | 0.45 | 1.00 | 0.50 | 0.80 |

| Component | Sub-Indicator of Material Compatibility | Sub-Indicator of Material Hazardousness | Sub-Indicator of Material Contamination |

|---|---|---|---|

| Forward weight | 1.00 | 1.00 | 1.00 |

| Backwards weight | 1.00 | 1.00 | 1.00 |

| Right half of the barrel | 0.50 | 1.00 | 1.00 |

| Left half of the barrel | 0.50 | 1.00 | 1.00 |

| Battery hood | 0.50 | 1.00 | 1.00 |

| Outer casing | 0.50 | 1.00 | 1.00 |

| Handle hood | 0.50 | 1.00 | 1.00 |

| Internal lever | 0.50 | 1.00 | 1.00 |

| Reload lever | 0.50 | 1.00 | 1.00 |

| Trigger | 0.50 | 1.00 | 1.00 |

| Vertical camera | 0.50 | 1.00 | 1.00 |

| Handle—first half | 1.00 | 1.00 | 1.00 |

| Handle—second half | 1.00 | 1.00 | 1.00 |

| Battery | 0.75 | 1.00 | 1.00 |

| Battery support | 0.00 | 1.00 | 1.00 |

| Active electronic component | 0.75 | 1.00 | 1.00 |

| Electro-mechanical component | 0.75 | 1.00 | 1.00 |

| Printed circuit board | 0.75 | 1.00 | 1.00 |

| Passive electronic component | 0.75 | 1.00 | 1.00 |

| LASER module | 0.75 | 1.00 | 1.00 |

| Printed circuit board frame | 0.00 | 1.00 | 1.00 |

| Component | Sub-Indicator of Dismantling Availability | Sub-Indicator of Recycling Availability |

|---|---|---|

| Forward weight | 0.75 | 0.75 |

| Backwards weight | 0.75 | 0.75 |

| Right half of the barrel | 0.75 | 0.75 |

| Left half of the barrel | 0.75 | 0.75 |

| Battery hood | 0.75 | 0.75 |

| Outer casing | 0.75 | 0.75 |

| Handle hood | 0.75 | 0.75 |

| Internal lever | 0.75 | 0.75 |

| Reload lever | 0.75 | 0.75 |

| Trigger | 0.75 | 0.75 |

| Vertical camera | 0.75 | 0.75 |

| Handle—first half | 0.75 | 0.75 |

| Handle—second half | 0.00 | 0.00 |

| Battery | 0.75 | 0.75 |

| Battery support | 0.75 | 0.75 |

| Active electronic component | 0.75 | 0.75 |

| Electro-mechanical component | 0.75 | 0.75 |

| Printed circuit board | 0.75 | 0.75 |

| Passive electronic component | 0.75 | 0.75 |

| LASER module | 0.75 | 0.75 |

| Printed circuit board frame | 0.75 | 0.75 |

| Component | Sub-Indicator of Material Diversity | Sub-Indicator of Collection Rate | Sub-Indicator of Theoretical Recycling Rate |

|---|---|---|---|

| Forward weight | 0.42 | 0.48 | 0.95 |

| Backwards weight | 0.42 | 0.48 | 0.95 |

| Right half of the barrel | 0.14 | 0.48 | 0.90 |

| Left half of the barrel | 0.14 | 0.48 | 0.90 |

| Battery hood | 0.14 | 0.48 | 0.00 |

| Outer casing | 0.14 | 0.48 | 0.90 |

| Handle hood | 0.14 | 0.48 | 0.00 |

| Internal lever | 0.14 | 0.48 | 0.90 |

| Reload lever | 0.14 | 0.48 | 0.90 |

| Trigger | 0.14 | 0.48 | 0.00 |

| Vertical camera | 0.14 | 0.48 | 0.00 |

| Handle—first half | 0.13 | 0.48 | 0.90 |

| Handle—second half | 0.09 | 0.48 | 0.00 |

| Battery | 0.00 | 0.48 | 0.75 |

| Battery support | 0.07 | 0.48 | 0.50 |

| Active electronic component | 0.00 | 0.48 | 0.50 |

| Electro-mechanical component | 0.00 | 0.48 | 0.50 |

| Printed circuit board | 0.00 | 0.48 | 0.50 |

| Passive electronic component | 0.00 | 0.48 | 0.50 |

| LASER module | 0.00 | 0.48 | 0.50 |

| Printed circuit board frame | 0.07 | 0.48 | 0.50 |

| Component | Sub-Indicator of Production Volume | Sub-Indicator of Deposit Volume |

|---|---|---|

| Forward weight | 1.00 | 1.00 |

| Backwards weight | 1.00 | 1.00 |

| Right half of the barrel | 1.00 | 1.00 |

| Left half of the barrel | 1.00 | 1.00 |

| Battery hood | 1.00 | 1.00 |

| Outer casing | 1.00 | 1.00 |

| Handle hood | 1.00 | 1.00 |

| Internal lever | 1.00 | 1.00 |

| Reload lever | 1.00 | 1.00 |

| Trigger | 1.00 | 1.00 |

| Vertical camera | 1.00 | 1.00 |

| Handle—first half | 1.00 | 1.00 |

| Handle—second half | 0.00 | 0.00 |

| Battery | 0.00 | 0.50 |

| Battery support | 0.00 | 0.00 |

| Active electronic component | 0.00 | 0.50 |

| Electro-mechanical component | 0.00 | 0.50 |

| Printed circuit board | 0.50 | 0.50 |

| Passive electronic component | 0.00 | 0.50 |

| LASER module | 0.00 | 0.50 |

| Printed circuit board frame | 0.00 | 0.00 |

| Component | Sub-Indicator of Proportion of Main Material | Sub-Indicator of Proportion of Contaminants | Sub-Indicator of Filtration Before Granulation |

|---|---|---|---|

| Forward weight | 1.00 | 1.00 | 1.00 |

| Backwards weight | 1.00 | 1.00 | 1.00 |

| Right half of the barrel | 0.95 | 0.90 | 0.75 |

| Left half of the barrel | 0.95 | 0.90 | 0.75 |

| Battery hood | 0.95 | 0.90 | 0.75 |

| Outer casing | 0.95 | 0.90 | 0.75 |

| Handle hood | 0.95 | 0.90 | 0.75 |

| Internal lever | 0.95 | 0.90 | 0.75 |

| Reload lever | 0.95 | 0.90 | 0.75 |

| Trigger | 0.95 | 0.90 | 0.75 |

| Vertical camera | 0.95 | 0.90 | 0.75 |

| Handle—first half | 0.95 | 0.94 | 0.75 |

| Handle—second half | 1.00 | 1.00 | 1.00 |

| Battery | 1.00 | 1.00 | 1.00 |

| Battery support | 1.00 | 1.00 | 1.00 |

| Active electronic component | 1.00 | 1.00 | 1.00 |

| Electro-mechanical component | 1.00 | 1.00 | 1.00 |

| Printed circuit board | 1.00 | 1.00 | 1.00 |

| Passive electronic component | 1.00 | 1.00 | 1.00 |

| LASER module | 1.00 | 1.00 | 1.00 |

| Printed circuit board frame | 1.00 | 1.00 | 1.00 |

| Component | Sub-Indicator of Carbon Savings | Sub-Indicator of Material Criticality | Sub-Indicator of Proportion of Recycled Content |

|---|---|---|---|

| Forward weight | 0.00 | 0.59 | 0.00 |

| Backwards weight | 0.00 | 0.59 | 0.00 |

| Right half of the barrel | 0.50 | 0.17 | 1.00 |

| Left half of the barrel | 0.50 | 0.17 | 1.00 |

| Battery hood | 0.50 | 0.17 | 1.00 |

| Outer casing | 0.50 | 0.17 | 1.00 |

| Handle hood | 0.50 | 0.17 | 1.00 |

| Internal lever | 0.50 | 0.17 | 1.00 |

| Reload lever | 0.50 | 0.17 | 1.00 |

| Trigger | 0.50 | 0.17 | 1.00 |

| Vertical camera | 0.50 | 0.17 | 1.00 |

| Handle—first half | 0.50 | 0.17 | 1.00 |

| Handle—second half | 0.00 | 1.00 | 0.00 |

| Battery | 0.00 | 0.31 | 0.00 |

| Battery support | 0.50 | 0.17 | 0.00 |

| Active electronic component | 0.00 | 0.10 | 0.00 |

| Electro-mechanical component | 0.00 | 0.10 | 0.00 |

| Printed circuit board | 0.00 | 0.10 | 0.00 |

| Passive electronic component | 0.00 | 0.10 | 0.00 |

| LASER module | 0.00 | 0.10 | 0.00 |

| Printed circuit board frame | 0.50 | 0.17 | 0.00 |

| Component | Sub-Indicator of Regulation Compliance | Sub-Indicator of Geographical Origin | Sub-Indicator of Waste Category of Origin |

|---|---|---|---|

| Forward weight | 1.00 | 0.00 | 0.00 |

| Backwards weight | 1.00 | 0.00 | 0.00 |

| Right half of the barrel | 1.00 | 1.00 | 1.00 |

| Left half of the barrel | 1.00 | 1.00 | 1.00 |

| Battery hood | 1.00 | 1.00 | 1.00 |

| Outer casing | 1.00 | 1.00 | 1.00 |

| Handle hood | 1.00 | 1.00 | 1.00 |

| Internal lever | 1.00 | 1.00 | 1.00 |

| Reload lever | 1.00 | 1.00 | 1.00 |

| Trigger | 1.00 | 1.00 | 1.00 |

| Vertical camera | 1.00 | 1.00 | 1.00 |

| Handle—first half | 1.00 | 1.00 | 1.00 |

| Handle—second half | 1.00 | 0.00 | 0.00 |

| Battery | 1.00 | 0.00 | 0.00 |

| Battery support | 1.00 | 0.00 | 0.50 |

| Active electronic component | 1.00 | 0.00 | 0.00 |

| Electro-mechanical component | 1.00 | 0.00 | 0.00 |

| Printed circuit board | 1.00 | 0.00 | 0.00 |

| Passive electronic component | 1.00 | 0.00 | 0.00 |

| LASER module | 1.00 | 0.00 | 0.00 |

| Printed circuit board frame | 1.00 | 0.00 | 0.50 |

References

- Directive (UE) 2018/851 Du Parlement Européen et Du Conseil Du 30 Mai 2018 Modifiant La Directive 2008/98/CE Relative Aux Déchets (Texte Présentant de l’intérêt Pour l’EEE). Available online: https://eur-lex.europa.eu/eli/dir/2018/851/oj?locale=fr (accessed on 5 January 2021).

- Buekens, A.; Yang, J. Recycling of WEEE Plastics: A Review. J. Mater. Cycles Waste Manag. 2014, 16, 415–434. [Google Scholar] [CrossRef]

- Martinez Leal, J.; Charbuillet, C.; Pompidou, S.; Perry, N. Recycling Chains: A Proposal for an Exhaustive Definition. In Proceedings of the 10th International Conference on Society & Materials, SAM10, Rome, Italy, 9–10 May 2016. [Google Scholar]

- Nève, N. Proposition d’un Outil D’écoconception des Équipements Électriques et Électroniques Alimenté par des Indicateurs centrés sur L’intégration de Matières Plastiques Recyclées Issues de DEEE dans le cadre d’une Économie Circulaire. Ph.D. Thesis, ENSAM, Paris, France, 2024. [Google Scholar]

- EU Parliament Directive 2012/19/UE du Parlement Européen et du Conseil DU 4 Juillet 2012 Relative Aux Déchets D’équipements Électriques et Électroniques (DEEE). Available online: https://eur-lex.europa.eu/legal-content/FR/ALL/?uri=CELEX%3A32012L0019 (accessed on 3 June 2021).

- Martinez-Leal, J. Développement D’outils D’aide à la Décision en Conception Pilotés par L’analyse Multicritère de la Valorisabilité du Produit et L’outillage des Lignes Directrices D’écoconception Pour la fin de vie. Text; ENSAM: Bordeaux, France, 2019. [Google Scholar]

- Fangeat, E.; Deprouw, A.; Jover, M.; Borie, M.; Tonsart, O. ADEME—Rapport Annuel du Registre des Déchets D’équipements Électriques et Électroniques; ADEME: Montrouge, France, 2020; p. 102. [Google Scholar]

- Horta, R.; Grimaud, G.; Martinez-Leal, J.; Perry, N.; Laratte, B.; Pompidou, S.; Alix, T.; Charbuillet, C. Influence of Scope Definition in Recycling Rate Calculation for European E-Waste Extended Producer Responsibility. Waste Manag. 2019, 84, 256–268. [Google Scholar] [CrossRef] [PubMed]

- Plastics Europe Plastics-the Facts 2020. 2020. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2020/ (accessed on 6 September 2023).

- Kaliyavaradhan, S.K.; Prem, P.R.; Ambily, P.S.; Mo, K.H. Effective Utilization of E-Waste Plastics and Glasses in Construction Products—A Review and Future Research Directions. Resour. Conserv. Recycl. 2022, 176, 105936. [Google Scholar] [CrossRef]

- IEC/TR 62635:2012; Guidelines for End-of-Life Information Provided by Manufacturers and Recyclers and for Recyclability Rate Calculation of Electrical and Electronic Equipment. AFNOR: La Plaine Saint-Denis, France, 2012. Available online: https://www.boutique.afnor.org/norme/iec-tr-626352012/-/article/805943/xs124796 (accessed on 24 June 2021).

- CEN/CLC/TC EN 45555:2019; General Methods for Assessing the Recyclability and Recoverability of Energy-Related Products. 2019; p. 25. Available online: https://standards.iteh.ai/catalog/standards/cen/a6432062-6e44-4011-9720-fcbc99e61feb/en-45555-2019?srsltid=AfmBOoq9fWTO-P0FZdZ8cG3Xyp_6tDrV27WNvOm5_qpcPLL-p0xhp6D6 (accessed on 5 September 2023).

- De Aguiar, J.; De Oliveira, L.; Oliveira Da Silva, J.; Bond, D.; Kovacs Scalice, R.; Becker, D. A Design Tool to Diagnose Product Recyclability during Product Design Phase. J. Clean. Prod. 2017, 141, 219–229. [Google Scholar] [CrossRef]

- Dostatni, E.; Diakun, J.; Grajewski, D.; Wichniarek, R.; Karwasz, A. Multi-Agent System to Support Decision-Making Process in Design for Recycling. Soft Comput. 2016, 20, 4347–4361. [Google Scholar] [CrossRef]

- Mathieux, F.; Lescuyer, L.; Moenne-Loccoz, G.; Brissaud, D. Proposition of New Recoverability Indicators as Support for the Product Design Process: The Electr(on)Ic Sector Experience; G-SCOP, University of Grenoble: Grenoble, France, 2008; p. 6. [Google Scholar]

- Peeters, J.R.; Vanegas, P.; Tange, L.; Van Houwelingen, J.; Duflou, J.R. Closed Loop Recycling of Plastics Containing Flame Retardants. Resour. Conserv. Recycl. 2014, 84, 35–43. [Google Scholar] [CrossRef]

- Grimaud, G. Conception des Scénarios de Recyclage Pilotée par L’évaluation des Performances des Proceeds; Text; ENSAM: Bordeaux, France, 2019. [Google Scholar]

- Alassali, A.; Barouta, D.; Tirion, H.; Moldt, Y.; Kuchta, K. Towards a High Quality Recycling of Plastics from Waste Electrical and Electronic Equipment through Separation of Contaminated Fractions. J. Hazard. Mater. 2020, 8, 121741. [Google Scholar] [CrossRef] [PubMed]

- Caro, D.; Albizzati, P.F.; Cristobal, G.J.; Saputra, L.I.; Garcia-Gutierrez, P.; Juchtmans, R.; Garbarino, E.; Blengini, G.; Manfredi, S.; De, M.S.; et al. Towards a Better Definition and Calculation of Recycling. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC131531 (accessed on 14 November 2023).

- Stenvall, E.; Tostar, S.; Boldizar, A.; Foreman, M.R.S.; Möller, K. An Analysis of the Composition and Metal Contamination of Plastics from Waste Electrical and Electronic Equipment (WEEE). Waste Manag. 2013, 33, 915–922. [Google Scholar] [CrossRef] [PubMed]

- Ioannidou, D.; Heeren, N.; Sonnemann, G.; Habert, G. The Future in and of Criticality Assessments. J. Ind. Ecol. 2019, 23, 751–766. [Google Scholar] [CrossRef]

- Schrijvers, D.; Hool, A.; Blengini, G.A.; Chen, W.-Q.; Dewulf, J.; Eggert, R.; van Ellen, L.; Gauss, R.; Goddin, J.; Habib, K.; et al. A Review of Methods and Data to Determine Raw Material Criticality. Resour. Conserv. Recycl. 2020, 155, 104617. [Google Scholar] [CrossRef]

- CEN EN 15343:2008; Plastics—Recycled Plastics—Plastics Recycling Traceability and Assessment of Conformity and Recycled Content. 2008. Available online: https://standards.iteh.ai/catalog/standards/cen/a1a8ffaf-bf7d-4b1c-ba13-f8b368625569/en-15343-2007 (accessed on 29 November 2022).

- Comission Européenne Règlement (UE) 2019/1021 du Parlement Européen et du Conseil DU 20 Juin 2019 Concernant Les Polluants Organiques Persistants. 2019, p. 33. Available online: https://eur-lex.europa.eu/legal-content/FR/TXT/PDF/?uri=CELEX:32019R1021 (accessed on 5 May 2023).

- EU Parliament Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 Concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH). 2006, p. 552. Available online: https://eur-lex.europa.eu/eli/reg/2006/1907/oj/eng (accessed on 14 April 2022).

- Parlement Européen. Directive 2011/65/UE du Parlement Européen et du Conseil du 8 Juin 2011 Relative à la Limitation de L’utilisation de Certaines Substances Dangereuses dans les Équipements Électriques et Électroniques Texte Présentant de L’intérêt Pour l’EEE. 2011. Volume 174. Available online: https://eur-lex.europa.eu/legal-content/fr/ALL/?uri=CELEX:32011L0065 (accessed on 24 April 2022).

- Deprouw, A.; Borie, M.; Rouquette, L.; Moriceau, S. Equipements Électriques et Électroniques: Données 2021; Rapport Annuel; ADEME: Montrouge, France, 2022; p. 112. [Google Scholar]

- Nève, N.; Mackré-Delannoy, X.; Fayolle, B.; Gervais, M.; Pompidou, S.; Charbuillet, C.; Sollogoub, C.; Perry, N. A Review of Methods and Data on the Recycling of Plastics from the European Waste Stream of Electric and Electronic Equipment. Recycling 2025, 10, 148. [Google Scholar] [CrossRef]

- Turner, A. Black Plastics: Linear and Circular Economies, Hazardous Additives and Marine Pollution. Environ. Int. 2018, 117, 308–318. [Google Scholar] [CrossRef] [PubMed]

- Product Reparability Scoring System: Specific Application to Smartphones and Slate Tablets; Publications Office of the European Union: Luxembourg, 2022; ISBN 978-92-76-52268-3.

- Maurin, M. Pour une Construction Formelle D’indice Global Agrégé en Pollution de l’air (Projet PIE. L’environnement et son Évaluation). 2009. Available online: https://www.researchgate.net/publication/238735605_Pour_une_construction_formelle_d’indice_global_agrege_en_pollution_de_l’air (accessed on 15 November 2023).

- Gan, X.; Fernandez, I.C.; Guo, J.; Wilson, M.; Zhao, Y.; Zhou, B.; Wu, J. When to Use What: Methods for Weighting and Aggregating Sustainability Indicators. Ecol. Indic. 2017, 81, 491–502. [Google Scholar] [CrossRef]

| Indicator | WEEE (Computer and Telecom) | Plastic Fraction Found in This Equipment |

|---|---|---|

| Collection rate of the equipment | 53% | |

| Proportion of plastics in the stream | 31% | 78% |

| Efficiency of the recycling process | 87% | 53% |

| Recycling rate of collected equipment | 85.2% | 55% |

| EoL recycling rate of the equipment | 41.6% | 11% |

| Number of Types of FE | Value of the Sub-Indicator |

|---|---|

| 1 | 1 |

| 2 | 0.5 |

| >2 | 0 |

| Number of Types of FE | Value of the Sub-Indicator |

|---|---|

| Totally accessible | 1 |

| Partially accessible | 0.5 |

| Not accessible | 0 |

| Material Compatibility | Value of the Sub-Indicator |

|---|---|

| Totally compatible/mono-material | 1 |

| Partially compatible, separable | 0.75 |

| Partially compatible, non-separable | 0.5 |

| Non-compatible, separable | 0.25 |

| Non-compatible, non-separable | 0 |

| Material Hazardousness | Value of the Sub-Indicator |

|---|---|

| Non-reactive, non-hazardous | 1 |

| Reactive, non-hazardous | 0.5 |

| Hazardous | 0 |

| Material Contamination | Value of the Sub-Indicator |

|---|---|

| Non-contaminated, non-contaminant | 1 |

| Contaminated or contaminant | 0 |

| Disassembly Facility Availability | Value of the Sub-Indicator |

|---|---|

| Locally available | 1 |

| Nationally available | 0.75 |

| Internationally available (same continent) | 0.5 |

| Internationally available (different continent) | 0.25 |

| Unknown/non-existent | 0 |

| Material Regeneration Facility Availability | Value of the Sub-Indicator |

|---|---|

| Locally available | 1 |

| Nationally available | 0.75 |

| Internationally available (same continent) | 0.5 |

| Internationally available (different continent) | 0.25 |

| Unknown/non-existent | 0 |

| Retrievability Index | ||

|---|---|---|

| Indicators | Sub-Indicators | |

| Dismantlability | Concentration in FE | |

| Number of FE types | ||

| Type of FE | Time for disassembly | |

| Number of necessary tools | ||

| Force necessary for disassembly | ||

| Destructivity of disassembly | ||

| Accessibility of the connection | ||

| Separability of materials | Compatibility of materials | |

| Materials hazardousness | ||

| Contamination | ||

| Availability of treatment | Availability of dismantling facilities | |

| Availability of regeneration facilities | ||

| Recyclability | Theoretical recycling rate | |

| Diversity of materials | ||

| Collection rate | ||

| Volume of Material in the Waste Deposit | Value of the Sub-Indicator |

|---|---|

| Known for this type of material | 1 |

| Known for the waste category | 0.5 |

| Unknown | 0 |

| Volume of Production | Value of the Sub-Indicator |

|---|---|

| Known and sufficient | 1 |

| Known | 0.5 |

| Unknown | 0 |

| Proportion of Main Material | Value of the Sub-Indicator |

|---|---|

| 100–97.5% | 1–0.975 |

| 97.5–90% | 0.5 |

| <90% | 0 |

| Contaminant Rate | Value of the Sub-Indicator |

|---|---|

| <5% | 0.9–1 |

| 5–10% | 0.5 |

| >10% | 0 |

| Filtration Level | Value of the Sub-Indicator |

|---|---|

| 50–100 μm | 1 |

| 100–200 μm | 0.75 |

| 200–300 μm | 0.5 |

| >300 μm | 0.25 |

| Unknown | 0 |

| Proportion of Recycled Material | Value of the Sub-Indicator |

|---|---|

| 0–100% | 0–1 |

| Carbon Savings | Value of the Sub-Indicator |

|---|---|

| Calculated: calculation method known | 1 |

| Calculated | 0.5 |

| Not calculated | 0 |

| Category of Origin | Value of the Sub-Indicator |

|---|---|

| Same category | 1 |

| Different category | 0.5 |

| Unknown | 0 |

| Geographical Origin of the Waste | Value of the Sub-Indicator |

|---|---|

| EU only | 1 |

| Blend EU + non-EU | 0.5 |

| Non-EU/Unknown | 0 |

| Regulation Compliance | Value of the Sub-Indicator |

|---|---|

| Yes for Reach, RoHS, POP | 1 |

| No for at least one/Unknown | 0 |

| Reintegrability Index | ||

|---|---|---|

| Sub-Indicators | ||

| Availability of materials | Volume of material in the deposit | |

| Volume of production | ||

| Material purity rate | Main material rate | |

| Contaminant rate | Polymeric contaminants | |

| Particle contaminants | ||

| Additives and fillers | ||

| Filtration level | ||

| Environmental impact | Proportion of recycled material | |

| Carbon savings | ||

| Material criticality | ||

| Traceability | Category of origin of the waste | |

| Geographical origin of the waste | ||

| Regulation compliance | Reach | |

| RoHS | ||

| POP | ||

| Indices | Retrievability Index | Reintegrability Index | ||||||

|---|---|---|---|---|---|---|---|---|

| Indicators |

Dismantlability | Separability |

Treatment availability |

Recyclability |

Material availability |

Material purity |

Environmental impact |

Material traceability |

| Value of the indicators | 0.786 | 0.619 | 0.714 | 0.16 | 0.655 | 0.89 | 0.31 | 0.5 |

| Value of the indices | 0.504 | 0.52 | ||||||

| Retrievability Rate | Reintegrability Rate | ||||

|---|---|---|---|---|---|

| Indicators | Sub-indicators | Sub-indicators | Indicators | ||

| Dismantling | FE concentration | Volume of the deposit | Material availability | ||

| Number of FE types | Volume of production | ||||

| Type of FE | Disassembly time | Proportion of main material | Material purity | ||

| Necessary tools | Polymer contaminants | Proportion of contaminants | |||

| Necessary force | Particle contaminants | ||||

| Destructivity | Additives, fillers | ||||

| Accessibility of the FE | Filtration level before extrusion | ||||

| Material separability | Material compatibility | Proportion of recycled material | Environmental impact | ||

| Material hazard | Carbon savings | ||||

| Material contamination | Raw material criticality | ||||

| Existence of treatment facilities | Existence of dismantling facilities | Waste stream of origin for recycled materials | Traceability of the materials | ||

| Existence of recycling facilities | Geographic origin of the materials | ||||

| Recyclability | Potential recycling rate | Reach compliance | EU regulation compliance | ||

| Material diversity | RoHS compliance | ||||

| Collection rate for the EoL category of the product | POP compliance | ||||

| Transformation Function | Efficiency Principle Respected? | Separation of Average and Dispersion Variables? | Remarks |

|---|---|---|---|

| No (compensatory) | Partial | Simple to use | |

| No, reversed | Partial | Simple to use | |

| Yes | Partial | Niche use | |

| Yes | Yes | Can be complex, but respects all principles | |

| No | Partial | Weighting is not a real transformation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nève, N.; Pompidou, S.; Charbuillet, C.; Perry, N. Indicators Targeting the Retrieval of Polymers in EEE and Their Re-Integration into New Equipment. Recycling 2025, 10, 212. https://doi.org/10.3390/recycling10060212

Nève N, Pompidou S, Charbuillet C, Perry N. Indicators Targeting the Retrieval of Polymers in EEE and Their Re-Integration into New Equipment. Recycling. 2025; 10(6):212. https://doi.org/10.3390/recycling10060212

Chicago/Turabian StyleNève, Nicolas, Stéphane Pompidou, Carole Charbuillet, and Nicolas Perry. 2025. "Indicators Targeting the Retrieval of Polymers in EEE and Their Re-Integration into New Equipment" Recycling 10, no. 6: 212. https://doi.org/10.3390/recycling10060212

APA StyleNève, N., Pompidou, S., Charbuillet, C., & Perry, N. (2025). Indicators Targeting the Retrieval of Polymers in EEE and Their Re-Integration into New Equipment. Recycling, 10(6), 212. https://doi.org/10.3390/recycling10060212