Strength Characterization by Vibrational Analysis of Building Demolition Wood to Assess Reuse Potential

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Overview of Tests Performed

2.3. Estimation of Basic Physical Properties

2.3.1. Estimation of Moisture Content

2.3.2. Estimation of Density

2.3.3. Useful Length

2.3.4. Useful Cross-Section

2.3.5. Biological Defect

2.3.6. Metallic Contamination

2.3.7. Non-Metallic Contamination

2.4. Estimation of Mechanical Properties

2.4.1. Estimation of Dynamic Modulus of Elasticity Using Ultrasound Device

2.4.2. Estimation of Dynamic Modulus of Elasticity Using Natural Frequency

2.4.3. Determination of Modulus of Elasticity by Bending Test

2.5. Determination of the Strength Class of the Batch of Wood

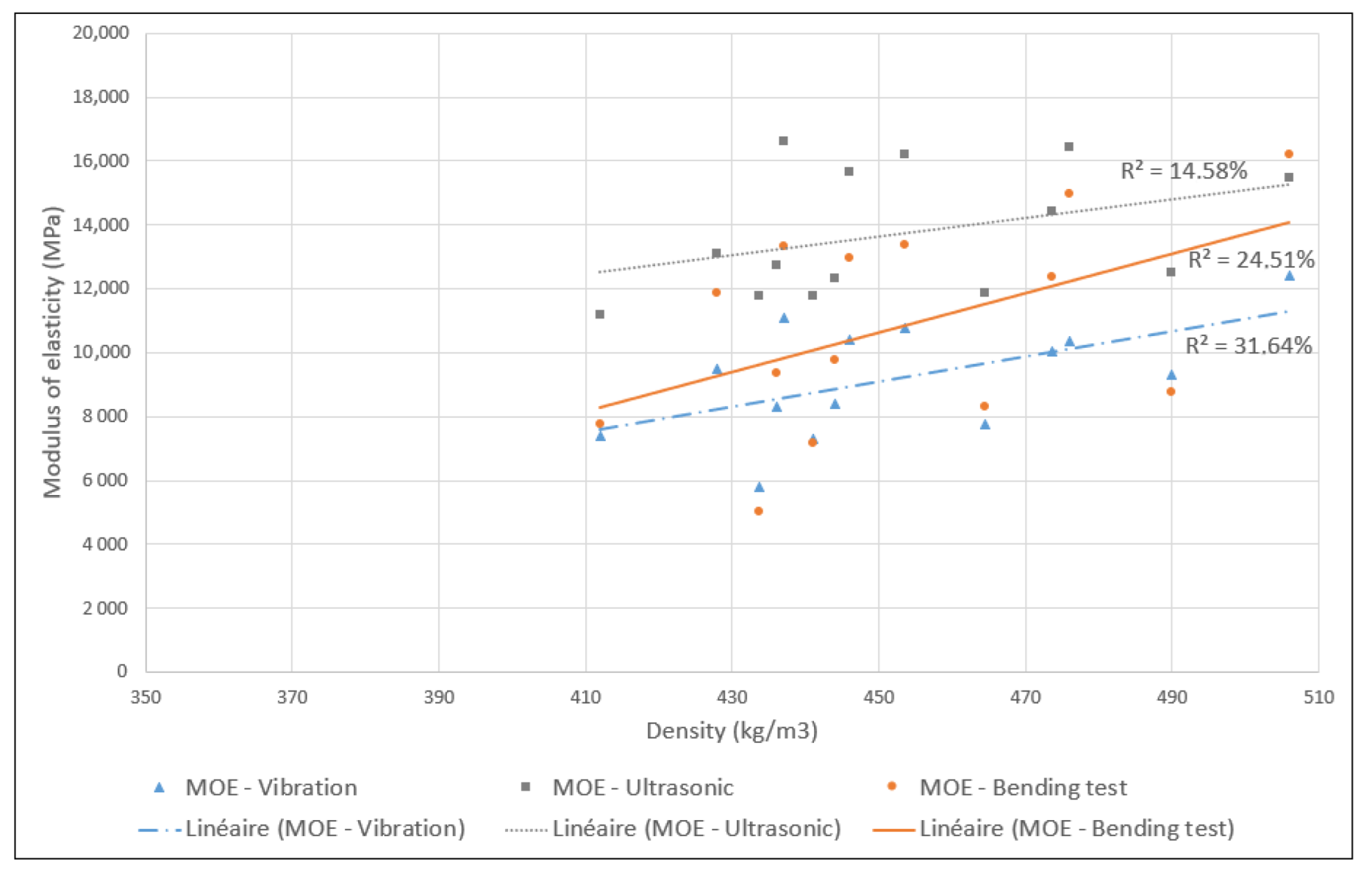

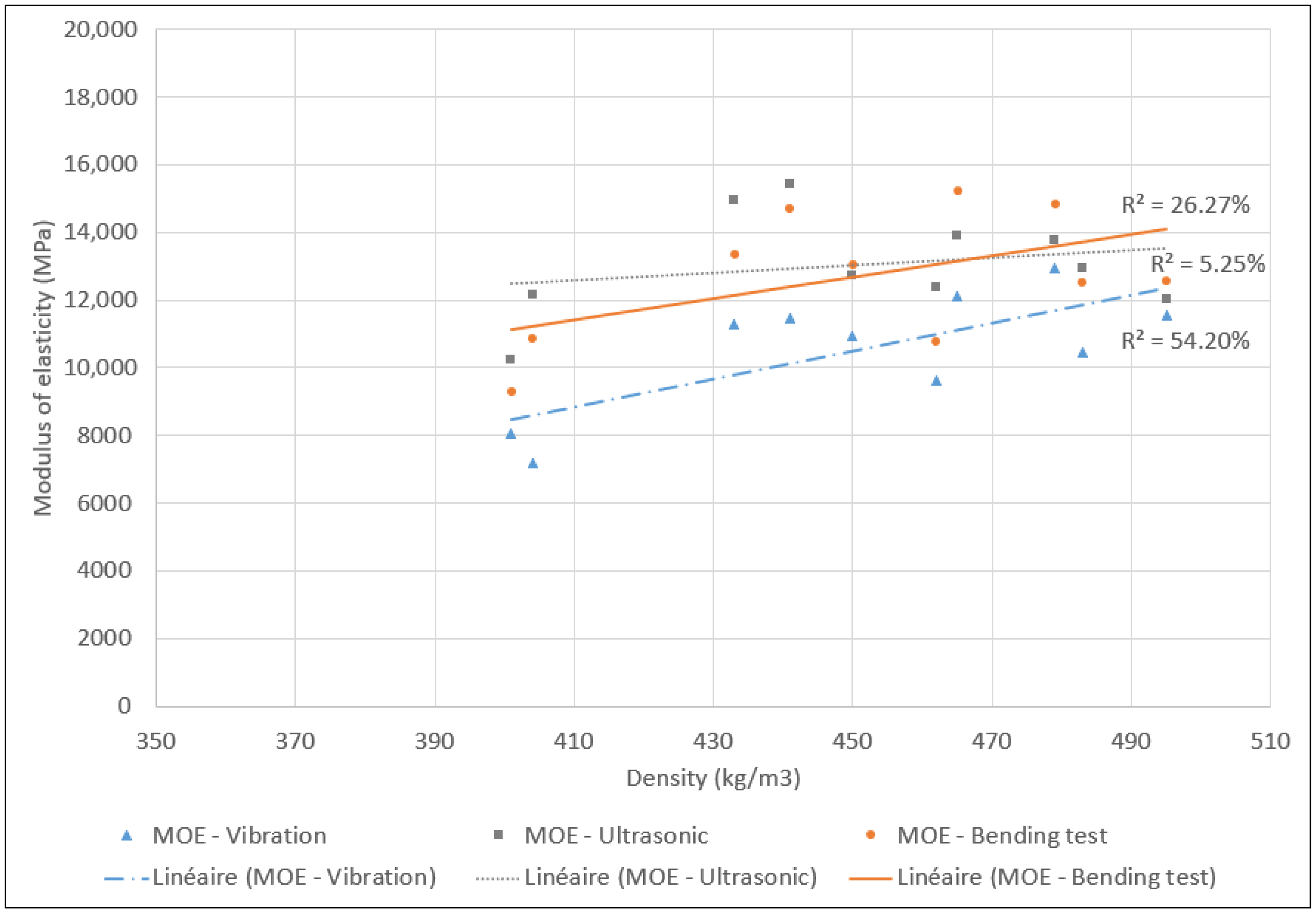

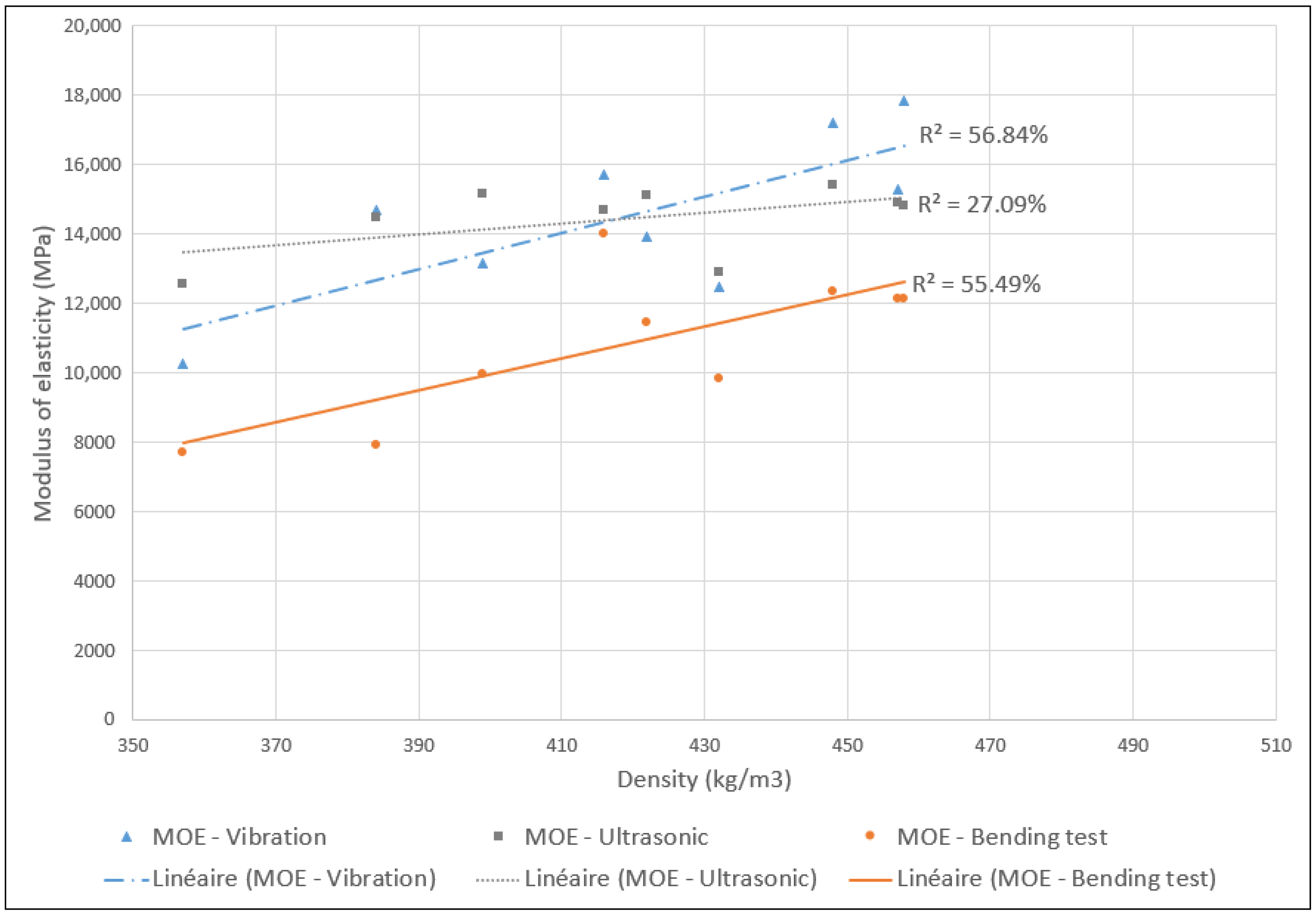

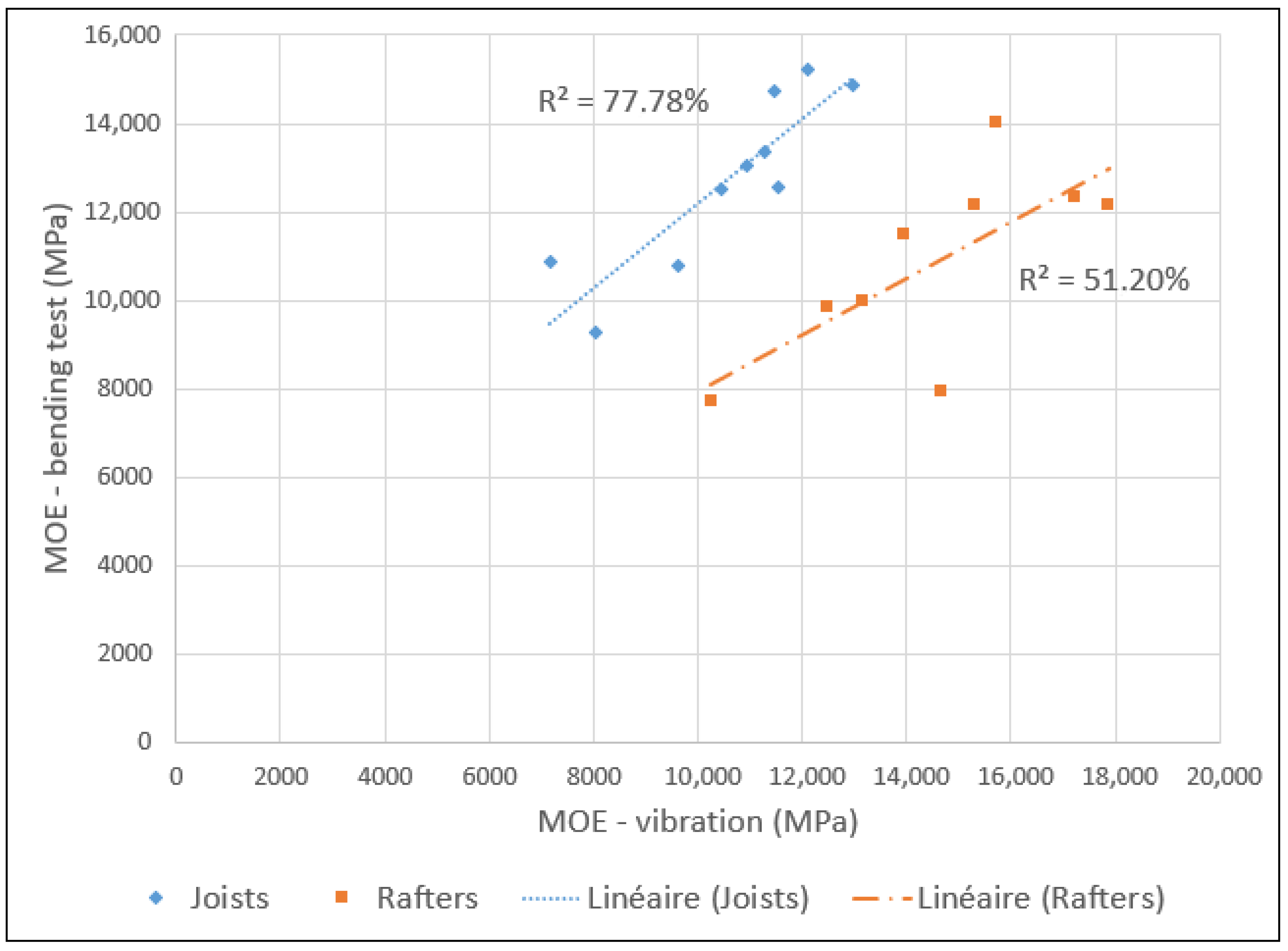

3. Results and Discussion

4. Conclusions

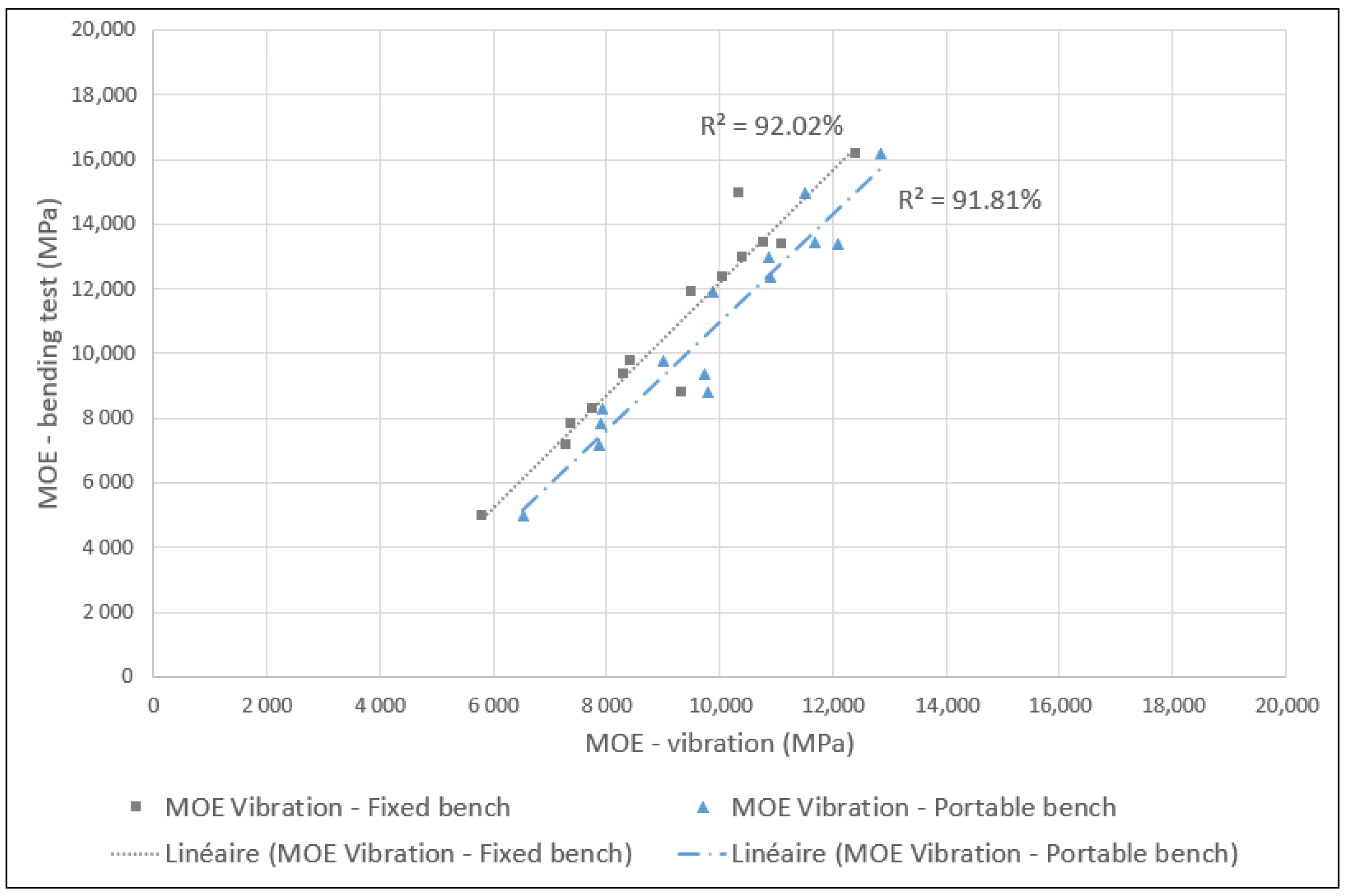

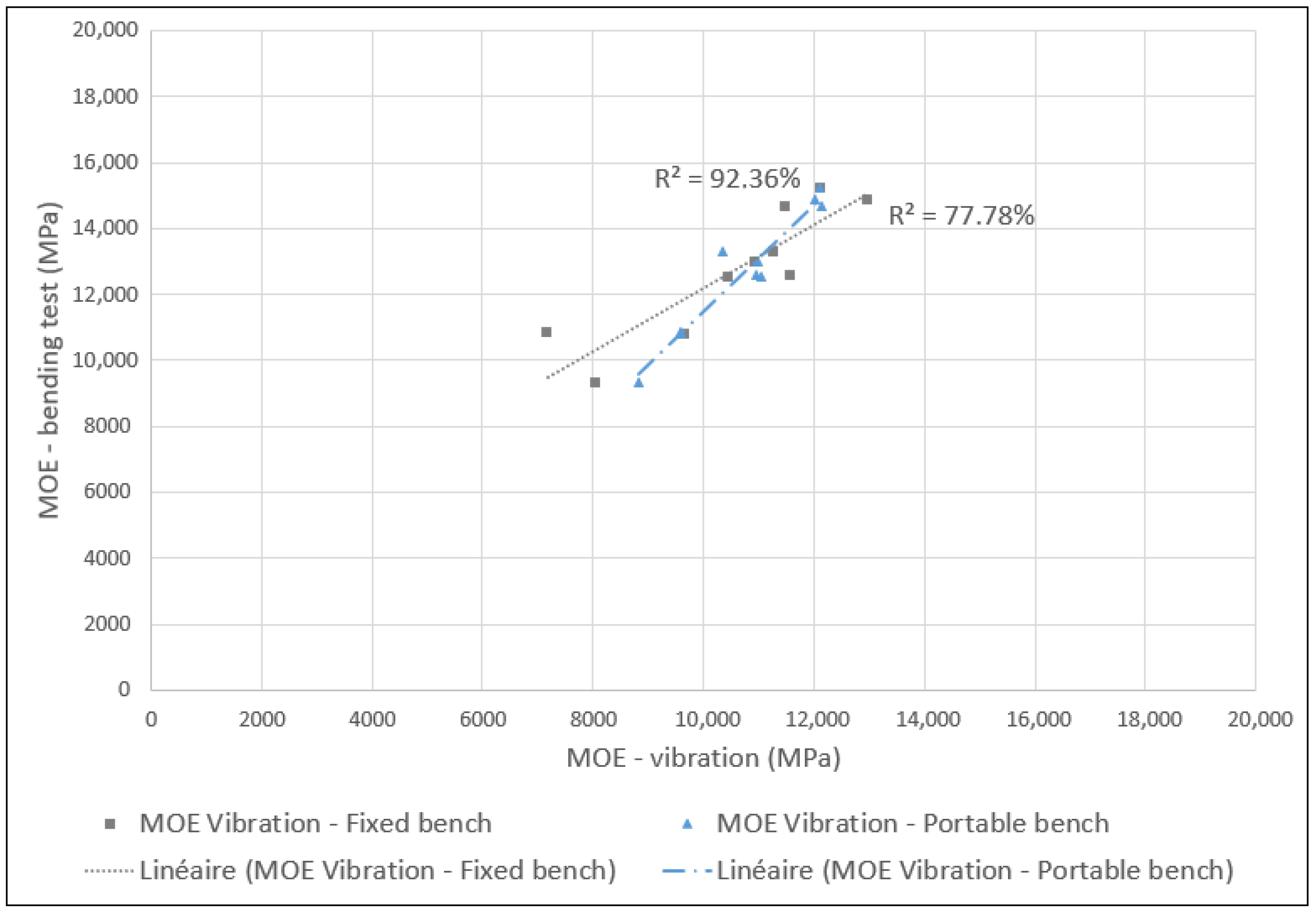

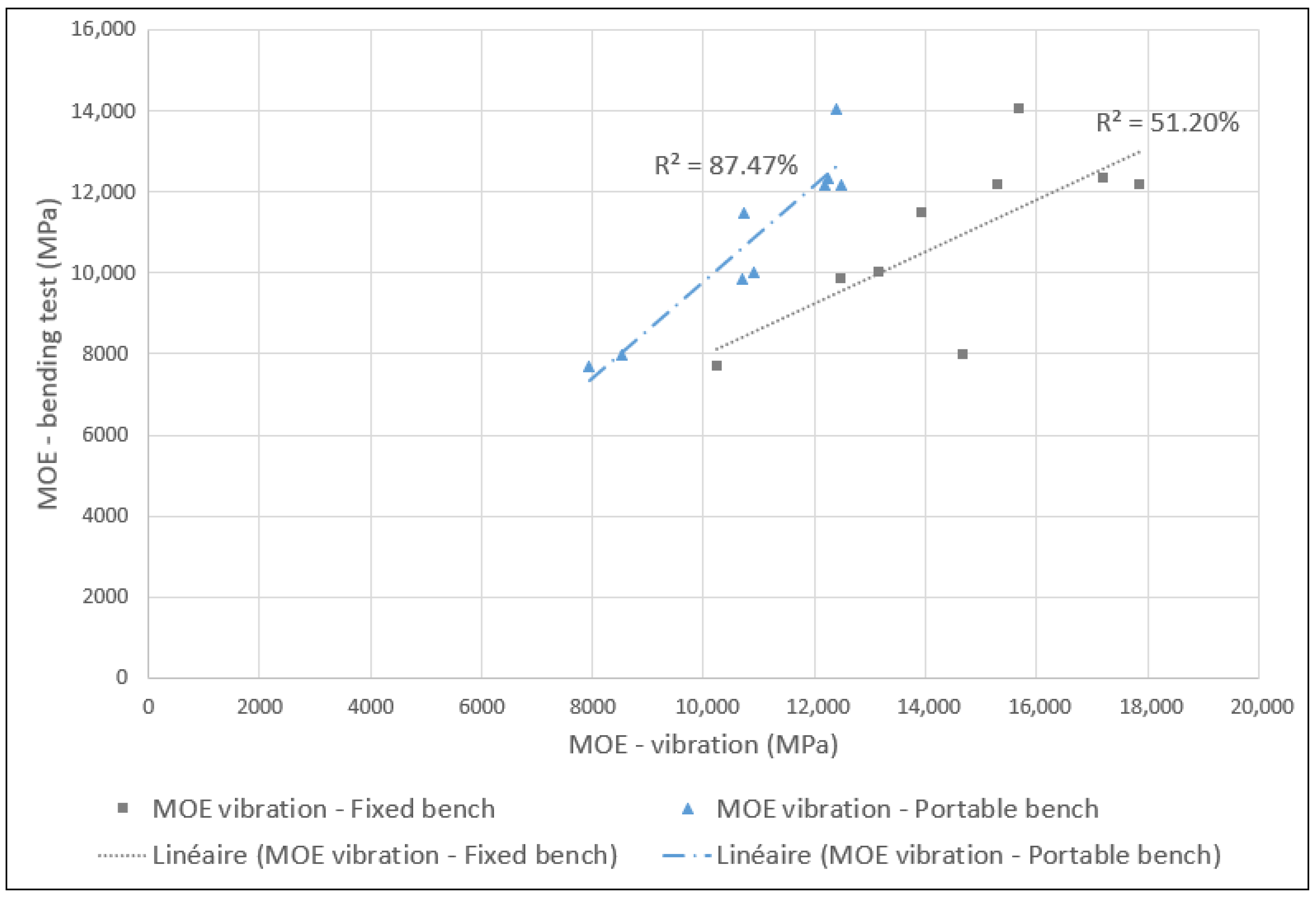

- The study that was conducted as part of this deconstruction project showed that vibrational technology was more suitable than ultrasonic technology for the estimation of the dynamic modulus of elasticity since it gives results on average 12% lower, for the Remiremont woods that represent the heart of the study, than the real values obtained by bending tests.

- This technology can also be used directly on the site with the use of a portable test bench whose results are very satisfactory.

- Finally, the classification of the reference batch of Remiremont wood showed that the NF EN 14081-2+A1 standard applied to new wood can also be used for determining the strength class of woods from building demolitions, if it is adapted to reused constraints. Adaptation mainly involves studying parameters specific to wood from deconstruction that are not known, such as previous stresses, invisible damage or local damage.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Piluso, N. Is corporate social responsibility effective in improving environmental quality? Literature review. Environ. Econ. 2024, 15, 1–11. [Google Scholar] [CrossRef]

- Razzaq, A.; Sharif, A.; Afshan, S.; Li, C.J. Do climate technologies and recycling asymmetrically mitigate consumption-based carbon emissions in the United States? New insights from Quantile ARDL. Technol. Forecast. Soc. Change 2023, 186, 122138. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Goyal, S.; Esposito, M.; Kapoor, A. Circular economy business models in developing economies: Lessons from India on reduce, recycle, and reuse paradigms. Thunderbird Int. Bus. Rev. 2018, 60, 729–740. [Google Scholar] [CrossRef]

- Sanguino, R.; Barroso, A.; Fernández-Rodríguez, S.; Sanchez-Hernandez, M. Current trends in economy, sustainable development, and energy: A circular economy view. Environ. Sci. Pollut. Res. 2020, 27, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Kamyshnikov, I.N.; Smirnova, T.S.; Tikhonov, A.I. Sustainable development: Waste Recycling and Circular Economy. In Sustainable Development: Society, Ecology, Economy; Semenov, A.V., Sokolov, I.A., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Parmesan, C.; Morecroft, M.D.; Trisurat, Y.; Adrian, R.; Anshari, G.Z.; Arneth, A.; Gao, Q.; Gonzalez, P.; Harris, R.; Price, J.; et al. Terrestrial and Freshwater Ecosystems and Their Services. In Climate Change 2022: Impacts, Adaptation and Vulnerability. Contribution of Working Group II to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Pörtner, H.-O., Roberts, D.C., Tignor, M., Poloczanska, E.S., Mintenbeck, K., Alegría, A., Craig, M., Langsdorf, S., Löschke, S., Möller, V., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2022; pp. 197–377. [Google Scholar] [CrossRef]

- Bouvet, A.; Berthelot, A.; Chaumet, M. Influence D’Accidents Climatiques Majeurs (Sécheresse, Canicule) Sur la Croissance Peupliers Douglas; Institut Technologique FCBA: Forêt, Cellulose, Bois—Construction Ameublement: Paris, France, 2020. [Google Scholar]

- Sakaguchi, D. Potential for Cascading Wood from Building; School of Chemical Technology, Aalto University: Espoo, Finland, 2014. [Google Scholar]

- Jahan, I.; Zhang, G.; Bhuiyan, M.; Navaratnam, S. Circular Economy of Construction and Demolition Wood Waste—A Theoretical Framework Approach. Sustainability 2022, 14, 10478. [Google Scholar] [CrossRef]

- Borzęcki, K.; Pudełko, R.; Kozak, M.; Borzęcka, M.; Faber, A. Spatial Distribution of Wood Waste in Europe. Sylwan 2018, 162, 563–571. [Google Scholar] [CrossRef]

- Agence de L’environnement et de la Maîtrise de L’énergie. Déchets Chiffres-Clés: L’essentiel Édition 2023. (ADEME Reference n°011983); Agence de L’environnement et de la Maîtrise de L’énergie: Angers, France, 2023. [Google Scholar]

- Ministère de la Transition Energétique. Panorama Français Des Gaz à Effet de Serre—Emissions Des GES en France en (2022); Ministère de la Transition Energétique: Paris, France, 2023.

- Journal Official. Loi n°2018-1021 Portant Sur L’évolution du Logement, de L’aménagement et du Numérique; Journal Official: Paris, France, 2018. [Google Scholar]

- Journal Officiel. Loi n°2020-105 Relative à la Lutte Contre le Gaspillage et à L’économie Circulaire; Journal Officiel: Paris, France, 2021. [Google Scholar]

- Journal Officiel. Décret n°2021-821 Relatif au Diagnostic Portant Sur la Gestion Des Produits, Equipements, Matériaux et Déchets Issus de la Démolition ou de la Rénovation Significative de Bâtiments; Journal officiel: Paris, France, 2021. [Google Scholar]

- NF B52-001-1; Rules For the Use of Wood in Construction—Visual Classification for Use in Structures of Sawn Softwood and Hardwood—Part 1: Solid Wood. Association Française de Normalisation: La Plaine Saint-Denis, France, 2018.

- NF EN 14081-2+A1; Timber Structures—Strength Graded Structural Timber with Rectangular Cross Section—Part 2: Machine Grading; Additional Requirements for Type Testing. Association Française de Normalisation: La Plaine Saint-Denis, France, 2022.

- Sandberg, K.; Sandin, Y.; Harte, A.; Shotton, E.; Hughes, M.; Ridley-Ellis, D.; Turk, G.; Íñiguez-González, G.; Risse, M.; Cristescu, C. Summary Report InFutUReWood–Innovative Design for the Future–Use and Reuse of Wood (Building) Components; RISE Research Institutes of Sweden: Gothenburg, Sweden, 2022. [Google Scholar] [CrossRef]

- Nasiri, B.; Roy, S.; Hughes, M. Determining the quantity and quality of wood recovered from building demolitions to enable effective allocation. Eur. J. Wood Wood Prod. 2025, 83, 1–13. [Google Scholar] [CrossRef]

- Bodig, J.; Jayne, B.A. Mechanics of Wood and Wood Composites; Krieger Publishing Company: Malabar, FL, USA, 1993. [Google Scholar]

- Bucur, V. Theory of and Experimental Methods for the Acoustic Characterization of Wood. In Acoustics of Wood; Springer: Berlin/Heidelberg, Heidelberg, 2006. [Google Scholar] [CrossRef]

- Attar-Hassan, G. The effect of ageing on the mechanical properties of Eastern white pine. Bull. Assoc. Preserv. Technol. 1976, 8, 64–73. [Google Scholar] [CrossRef]

- Noguchi, T.; Obataya, E.; Ando, K. Effects of ageing on the vibrational properties of akamatsu (Pinus densiflora) wood. In Wood Culture and Science; Japan Wood Research Society: Kyoto, Japan, 2011. [Google Scholar] [CrossRef]

- Nier, J. Experimental Strength Investigations on Old Construction Timber and Derived Findings for Load-Bearing Capacity Assessment; Technische Hochschule Leipzig: Leipzig, Germany, 1994. [Google Scholar]

- Baron, T. Investigations on Undamaged and Fungal-Damaged Softwood Components Using Selected Test Methods. Ph.D. Thesis, Bauhaus-University Weimar, Weimar, Germany, 2009. Available online: https://nbn-resolving.org/urn:nbn:de:bsz:14-qucosa-25069 (accessed on 27 August 2025).

- Wang, S.Y.; Chen, J.H.; Tsai, M.J.; Lin, C.J.; Yang, T.H. Grading of softwood lumber using non-destructive techniques. J. Mater. Process. Technol. 2008, 208, 149–158. [Google Scholar] [CrossRef]

- Faggiano, B.; Grippa, M.R.; Marzo, A.; Mazzolani, F.M. Experimental study for non-destructive mechanical evaluation of ancient chestnut timber. J. Civ. Struct. Health Monit. 2011, 1, 103–112. [Google Scholar] [CrossRef]

- Sandoz, J.-L. Grading and Reliability of Construction Timber, Validation of the Ultrasound Method. Ph.D. Thesis, Laboratoire de construction en bois, École Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, 1990. [Google Scholar]

- Sandoz, J.-L.; Benoit, Y. Timber Grading Machine Using Multivariate Parameters Based on Ultrasonic and Density Measurement; European Cooperation in Science and Technology: Brussels, Belgium, 2007; p. 53. [Google Scholar]

- Görlacher, R. A new method for determining the modulus of elasticity of timber. Holz Als Roh-Und Werkst. 1984, 42, 219–222. [Google Scholar] [CrossRef]

- Brancheriau, L.; Baillères, H. Natural vibration analysis of clear wooden beams: A theoretical review. Wood Sci. Technol. 2002, 36, 347–365. [Google Scholar] [CrossRef]

- Faydi, Y. Classement Pour la Résistance Mécanique du Chêne Par Méthodes Vibratoires et Par Mesure Des Orientations Des Fibres. Ph.D. Thesis, Ecole Nationale Supérieure D’arts et Métiers-ENSAM, Paris, France, 2017. [Google Scholar]

- Sonderegger, W.; Mandallaz, D.; Niemz, P. An investigation of the influence of selected factors on the properties of spruce wood. Wood Sci. Technol. 2008, 42, 281–298. [Google Scholar] [CrossRef]

- Niemz, P. Physics of Wood and Wood Materials; DRW Publishing: Leinfelden-Echterdingen, Germany, 1993; p. 243. [Google Scholar]

- Sandoz, J.L. Moisture content and temperature effect on ultrasound timber grading. Wood. Sci. Technol. 1993, 27, 373–380. [Google Scholar] [CrossRef]

- Unterwieser, H.; Schickhofer, G. Influence of moisture content of wood on sound velocity and dynamic MOE of natural frequency-and ultrasonic runtime measurement. Eur. J. Wood Wood Prod. 2010, 69, 171–181. [Google Scholar] [CrossRef]

- Nocetti, M.; Brunetti, M.; Bacher, M. Effect of moisture content on the flexural properties and dynamic modulus of elasticity of dimension chestnut timber. Eur. J. Wood Wood Prod. 2015, 73, 51–60. [Google Scholar] [CrossRef]

- Fridley, K.J.; Mitchell, J.B.; Hunt, M.O.; Senft, J.F. Effect of 85 years of service on mechanical properties of timber roof members. Part 1: Experimental observations. For. Prod. J. 1996, 46, 72–78. [Google Scholar]

- Deppe, H.-J.; Rühl, H. Evaluation of historical construction timber 1. Density and compression strength: Apparent density and compressive strength. Holz Als Roh-Und Werkst. 1993, 51, 379–383. [Google Scholar] [CrossRef]

- Kollmann, F.; Schmidt, E. Structural disruption and loss of strength of permanently stressed softwood. Holz Als Roh-Und Werkst. 1962, 20, 333–338. [Google Scholar] [CrossRef]

- NF EN 408+A1; Timber Structures—Structural Timber and Glued Laminated Timber—Determination of Some Physical and Mechanical Properties. Association Française de Normalisation: La Plaine Saint-Denis, France, 2012.

- NF EN 13183-1; Moisture Content of a Piece of Sawn Timber–Part 1: Determination by Oven Dry Method. Association Française de Normalisation: La Plaine Saint-Denis, France, 2002.

- NF EN 13183-2; Moisture Content of a Piece of Sawn Timber–Part 2: Estimation by Electrical Resistance Method. Association Française de Normalisation: La Plaine Saint-Denis, France, 2002.

- NF EN 384+A2; Structural Timber—Determination of Characteristic Values of Mechanical Properties and Density. Association Française de Normalisation: La Plaine Saint-Denis, France, 2022.

- NF EN 1309-1; Round and Sawn Timber—Method of Measurement of Dimensions. Part 1: Sawn Timber. Association Française de Normalisation: La Plaine Saint-Denis, France, 1997.

- NF EN 336; Structural Timber—Sizes, Permitted Deviations. Association Française de Normalisation: La Plaine Saint-Denis, France, 2013.

| Origin-Typology | Sample No. | Useful Length [mm] | Useful Section [mm2] |

|---|---|---|---|

| Remiremont—joist | 121 | 3180 | 14,965 |

| 122 | 3200 | 18,915 | |

| 123 | 3355 | 14,784 | |

| 1C1 | 3075 | 15,600 | |

| 1C2 | 3230 | 19,500 | |

| 1C3 | 3215 | 15,169 | |

| 211 | 3190 | 15,015 | |

| 212 | 3140 | 18,050 | |

| 213 | 3100 | 14,100 | |

| 2C1 | 3230 | 14,625 | |

| 2C2 | 3280 | 18,525 | |

| 2C3 | 3190 | 15,400 | |

| 311 | 3155 | 14,784 | |

| 312 | 3515 | 18,525 | |

| 313 | 3705 | 15,920 | |

| Epinal—joist | 1 | 5070 | 33,800 |

| 2 | 5070 | 35,775 | |

| 3 | 5070 | 33,150 | |

| 4 | 5070 | 35,100 | |

| 5 | 5070 | 33,150 | |

| 6 | 5070 | 33,800 | |

| 7 | 5070 | 35,100 | |

| 8 | 5070 | 35,775 | |

| 9 | 5070 | 34,425 | |

| 10 | 5070 | 33,800 | |

| Epinal—rafter | 1 | 3930 | 15,000 |

| 2 | 4000 | 15,000 | |

| 3 | 3840 | 15,000 | |

| 4 | 4060 | 15,000 | |

| 5 | 3940 | 15,000 | |

| 6 | 3950 | 15,000 | |

| 7 | 4000 | 15,000 | |

| 8 | 3980 | 15,000 | |

| 9 | 4000 | 15,000 | |

| 10 | 3980 | 15,000 |

| Optimal Class | Assigned Class | |

| C18 | Rejection | |

| C18 | 0 | X |

| Rejection | 0.08 | 0 |

| Origin-Typology | Sample No. | Density [kg/m3] |

|---|---|---|

| Remiremont-joist | 121 | 436.0 |

| 122 | 446.1 | |

| 123 | 489.9 | |

| 1C1 | 444.0 | |

| 1C2 | 412.0 | |

| 1C3 | 433.7 | |

| 211 | 464.5 | |

| 212 | 441.1 | |

| 213 | 473.6 | |

| 2C1 | 437.1 | |

| 2C2 | 427.9 | |

| 2C3 | 436.8 | |

| 311 | 476.0 | |

| 312 | 506.0 | |

| 313 | 453.5 | |

| Epinal-joist | 1 | 440.6 |

| 2 | 403.6 | |

| 3 | 479.0 | |

| 4 | 432.7 | |

| 5 | 482.5 | |

| 6 | 462.2 | |

| 7 | 464.7 | |

| 8 | 401.4 | |

| 9 | 449.8 | |

| 10 | 494.8 | |

| Epinal-rafter | 1 | 415.6 |

| 2 | 431.7 | |

| 3 | 465.3 | |

| 4 | 458.1 | |

| 5 | 399.3 | |

| 6 | 421.9 | |

| 7 | 456.7 | |

| 8 | 383.6 | |

| 9 | 448.3 | |

| 10 | 356.8 |

| Origin- Typology | Sample No. | Modulus of Elasticity-Vibration (MPa) | Modulus of Elasticity-Ultrasonic (MPa) | Modulus of Elasticity Bending Test (MPa) | Difference Between MOE-Bending Test and Vibrational MOE (%) | Difference Between MOE-Bending Test and Ultrasonic MOE (%) |

|---|---|---|---|---|---|---|

| Remiremont-joist | 121 | 8317 | 12,719 | 9376 | 11.3 | −35.6 |

| 122 | 10,409 | 15,629 | 12,947 | 19.6 | −20.7 | |

| 123 | 9314 | 12,519 | 8783 | −6.1 | −42.5 | |

| 1C1 | 8415 | 12,308 | 9778 | 13.9 | −25.9 | |

| 1C2 | 7387 | 11,186 | 7770 | 4.9 | −44.0 | |

| 1C3 | 5807 | 11,786 | 5001 | −16.1 | −135.7 | |

| 211 | 7754 | 11,872 | 8286 | 6.4 | −43.3 | |

| 212 | 7284 | 11,790 | 7168 | −1.6 | −64.5 | |

| 213 | 10,057 | 14,432 | 12,344 | 18.5 | −16.9 | |

| 2C1 | 11,101 | 16,611 | 13,310 | 16.6 | −24.8 | |

| 2C2 | 2019 | 9961 | - | - | - | |

| 2C3 | 9495 | 13,098 | 11,882 | 20.1 | −10.2 | |

| 311 | 10,350 | 16,431 | 14,983 | 30.9 | −9.7 | |

| 312 | 12,398 | 15,463 | 16,189 | 23.4 | 4.5 | |

| 313 | 10,788 | 16,183 | 13,380 | 19.4 | −20.9 | |

| Epinal-joist | 1 | 11,471 | 15,430 | 14,714 | 22.0 | −4.9 |

| 2 | 7173 | 12,150 | 10,868 | 34.0 | −11.8 | |

| 3 | 12,952 | 13,779 | 14,853 | 12.8 | 7.2 | |

| 4 | 11,262 | 14,968 | 13,353 | 15.7 | −12.1 | |

| 5 | 10,456 | 12,926 | 12,532 | 16.6 | −3.1 | |

| 6 | 9620 | 12,357 | 10,770 | 10.7 | −14.7 | |

| 7 | 12,095 | 13,903 | 15,229 | 20.6 | 8.7 | |

| 8 | 8038 | 10,229 | 9291 | 13.5 | −10.1 | |

| 9 | 10,921 | 12,717 | 13,031 | 16.2 | 2.4 | |

| 10 | 11,555 | 12,019 | 12,580 | 8.1 | 4.5 | |

| Epinal-rafter | 1 | 15,706 | 14,711 | 14,026 | −12.0 | −4.9 |

| 2 | 12,469 | 12,928 | 9836 | −26.8 | −31.4 | |

| 3 | - | 9838 | 9360 | - | −5.1 | |

| 4 | 17,864 | 14,819 | 12,138 | −47.2 | −22.1 | |

| 5 | 13,156 | 15,148 | 9987 | −31.7 | −51.7 | |

| 6 | 13,950 | 15,125 | 11,476 | −21.6 | −31.8 | |

| 7 | 15,298 | 14,923 | 12,143 | −26.0 | −22.9 | |

| 8 | 14,682 | 14,462 | 7925 | −85.3 | −82.5 | |

| 9 | 17,215 | 15,429 | 12,333 | −39.6 | −25.1 | |

| 10 | 10,253 | 12,555 | 7707 | −33.0 | −62.9 |

| Origin- Typology | Sample No. | Modulus of Elasticity-Classic Bench (MPa) | Modulus of Elasticity-Portable Bench (MPa) | Modulus of Elasticity-Bending Test (MPa) | Difference Between MOE-Bending Test and Vibrational MOE-Classic Bench (%) | Difference Between MOE-Bending Test and Vibrational MOE-Portable Bench (%) |

|---|---|---|---|---|---|---|

| Remiremont-joist | 121 | 8317 | 9736 | 9376 | 11.3 | −3.8 |

| 122 | 10,409 | 10,860 | 12,947 | 19.6 | 16.1 | |

| 123 | 9314 | 9791 | 8783 | −6.1 | −11.5 | |

| 1C1 | 8415 | 8999 | 9778 | 13.9 | 8.0 | |

| 1C2 | 7387 | 7911 | 7770 | 4.9 | −1.8 | |

| 1C3 | 5807 | 6528 | 5001 | −16.1 | −30.5 | |

| 211 | 7754 | 7937 | 8286 | 6.4 | 4.2 | |

| 212 | 7284 | 7873 | 7168 | −1.6 | −9.8 | |

| 213 | 10,057 | 10,889 | 12,344 | 18.5 | 11.8 | |

| 2C1 | 11,101 | 12,087 | 13,310 | 16.6 | 9.2 | |

| 2C2 | 2019 | - | - | - | - | |

| 2C3 | 9495 | 9877 | 11,882 | 20.1 | 16.9 | |

| 311 | 10,350 | 11,499 | 14,983 | 30.9 | 23.3 | |

| 312 | 12,398 | 12,836 | 16,189 | 23.4 | 20.7 | |

| 313 | 10,788 | 11,685 | 13,380 | 19.4 | 12.7 | |

| Epinal-joist | 1 | 11,471 | 12,125 | 14,714 | 22.0 | 17.6 |

| 2 | 7173 | 9590 | 10,868 | 34.0 | 11.8 | |

| 3 | 12,952 | 12,040 | 14,853 | 12.8 | 18.9 | |

| 4 | 11,262 | 10,332 | 13,353 | 15.7 | 22.6 | |

| 5 | 10,456 | 11,025 | 12,532 | 16.6 | 12.0 | |

| 6 | 9620 | 9612 | 10,770 | 10.7 | 10.8 | |

| 7 | 12,095 | 12,097 | 15,229 | 20.6 | 20.6 | |

| 8 | 8038 | 8810 | 9291 | 13.5 | 5.2 | |

| 9 | 10,921 | 11,004 | 13,031 | 16.2 | 15.6 | |

| 10 | 11,555 | 10,968 | 12,580 | 8.1 | 12.8 | |

| Epinal-rafter | 1 | 15,706 | 12,394 | 14,026 | −12.0 | 11.6 |

| 2 | 12,469 | 10,689 | 9836 | −26.8 | −8.7 | |

| 3 | - | 8799 | 9360 | - | 6.0 | |

| 4 | 17,864 | 12,189 | 12,138 | −47.2 | −0.4 | |

| 5 | 13,156 | 10,902 | 9987 | −31.7 | −9.2 | |

| 6 | 13,950 | 10,730 | 11,476 | −21.6 | 6.5 | |

| 7 | 15,298 | 12,480 | 12,143 | −26.0 | −2.8 | |

| 8 | 14,682 | 8532 | 7925 | −85.3 | −7.7 | |

| 9 | 17,215 | 12,244 | 12,333 | −39.6 | 0.7 | |

| 10 | 10,253 | 7948 | 7707 | −33.0 | −3.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lemaitre, O.; Bléron, L.; Simon, C.; Méausoone, P.-J. Strength Characterization by Vibrational Analysis of Building Demolition Wood to Assess Reuse Potential. Recycling 2025, 10, 204. https://doi.org/10.3390/recycling10060204

Lemaitre O, Bléron L, Simon C, Méausoone P-J. Strength Characterization by Vibrational Analysis of Building Demolition Wood to Assess Reuse Potential. Recycling. 2025; 10(6):204. https://doi.org/10.3390/recycling10060204

Chicago/Turabian StyleLemaitre, Odran, Laurent Bléron, Caroline Simon, and Pierre-Jean Méausoone. 2025. "Strength Characterization by Vibrational Analysis of Building Demolition Wood to Assess Reuse Potential" Recycling 10, no. 6: 204. https://doi.org/10.3390/recycling10060204

APA StyleLemaitre, O., Bléron, L., Simon, C., & Méausoone, P.-J. (2025). Strength Characterization by Vibrational Analysis of Building Demolition Wood to Assess Reuse Potential. Recycling, 10(6), 204. https://doi.org/10.3390/recycling10060204