Abstract

The objective of the study is to develop a methodology for strength characterization by vibrational analysis of a batch of wood from building demolitions with a view to its reuse. This approach is part of an experimental deconstruction/reconstruction project located in the Vosges “département” of France and led by the social housing landlord, VOSGELIS. The main constraint related to this intention of reuse is the obtention of the strength class of the elements, which is not recorded in the standards. The comparative study of different non-destructive technologies has shown that the values of the longitudinal dynamic modulus of elasticity obtained by the vibrational method are closer on average (15%) to the actual value obtained by the bending tests than those obtained by the ultrasonic method (35%). A portable measuring bench suitable for the deconstruction site was also developed during the study for the utilization of the vibrational method. The values of the dynamic modules of elasticity obtained on this bench are close, on average, to the values of the modulus of elasticity obtained by bending tests executed on a test slab (13%). This study made it possible to extend the use of the NF EN 14081-2+A1 standard to woods from building demolitions. However, this standard needs to be adapted for the classification of that typology of wood, with a reference batch constituted of 15 to 20 samples.

1. Introduction

In the contemporary context, the Earth is grappling with increasingly pressing ecological problems. Among these issues are the climate crisis, biodiversity loss and deforestation. These threats are no longer simply distant geopolitical challenges but are materializing into realities whose effects are being felt both globally and locally. The effects of these phenomena can be observed in two ways: firstly, on the quality of life of populations, and secondly, on the stability of ecosystems. Climate change, which manifests itself in extreme weather events, rising temperatures, droughts and floods, is caused by the excessive use of natural resources and the implementation of unsustainable economic practices through the so-called linear economy. The ongoing deterioration of the environment has led to improvements in environmental quality, which has become one of the main objectives of modern society [1,2]. These intense environmental changes highlight the need to explore the principles of the circular economy as an alternative model of production and consumption, which reduces environmental burdens and maximizes the reuse of resources [3,4,5,6]. However, the effectiveness of this model’s implementation depends largely on the normative and regulatory constraints associated with it. In this context, the reuse of timber plays a key role, as it is one of the most effective strategies for mitigating negative environmental impacts.

Wood, a key material in this transition towards more sustainable construction, is nevertheless vulnerable to the effects of climate change, which are constantly evolving [7]. In the current context of climate change, characterized by an increase in the frequency and intensity of droughts, certain wood species are subject to worrying decline. This situation is exacerbated by an increased water risk, which is a major concern for forest sustainability and environmental security [8]. This analysis shows that wood, which is already present in buildings and acts as a carbon sink, appears to be of definite interest in terms of long-term conservation. This representation is part of the concept of ‘Cascading wood’ [9]. Structural timber is particularly important in this system, as it can be reused in various ways after its initial use. This property is essential for promoting carbon sequestration over a prolonged period. In this context, reuse is emerging as a relevant strategy for ensuring the conservation of forest resources and maintaining carbon storage continuity. However, in practice, a significant portion of this wood resource is considered to fall into the waste category. It should be noted that international research on this topic is scarce. However, many countries have conducted specific studies on the subject [10]. Within the European Union, which has 28 member states, wood waste from construction and demolition sites accounted for 50.2 million tons in 2020 alone [11]. Despite the abundance of this resource, its recovery remains insufficient, with the focus being on recycling to produce panels or energy recovery. In addition, it has been observed that, in certain circumstances, it is sent to landfill sites for certain categories of wood, particularly treated wood.

In the context of France, the building and public works sector produces a significant share of the waste produced, contributing significantly to environmental problems. Figures indicate that the construction sector alone generates approximately 46 million tons of construction and demolition waste each year, representing approximately 17% of all waste produced in the country [12]. At the same time, the sector is responsible for about 18% of total CO2 emissions in 2022 in France [13]. This considerable carbon footprint highlights the need to change building practices to reduce the environmental impact of the sector. Faced with these environmental challenges, the reuse and repurpose of building materials are promising solutions that are constantly improving. Wood material plays a key role in this transition to more sustainable construction since it ensures the continuity of the carbon storage it contains. Initiatives to promote the reuse of wood are gaining popularity, both in new buildings and in renovation [14,15,16]. However, despite these positive advances, the reuse of wood in France faces heavy normative and regulatory constraints that can hinder its large-scale use.

The primary constraint associated with reclaimed wood pertains to the characterization phase, particularly the strength characterization. Prior to the integration of wood into a construction project, it is imperative to ascertain its designated strength class. This strength class can be obtained using two standard methods: a visual method [17] or a machine method [18]. However, it should be noted that the validity of these two standards is restricted to new woods. Considering this, various scientific studies are underway to adapt existing standards to reused woods. The visual method garners a particular interest due to its simplicity in implementation. Research in this area has identified the need for adapting existing standard parameters, such as cracks and knots. Alternatively, studies may seek to establish novel parameters [19,20]. Nevertheless, this method, which is based on visual criteria, tends to greatly under-classify woods, even in the context of new woods. The machine method, conversely, has received comparatively less attention in research. Studies conducted on non-destructive technologies essential for machine grading of reclaimed wood do not prioritize the strength grading.

Dynamic modulus of elasticity of a wood sample can be determined non-destructively by sound waves. Indeed, by considering wood as a material with orthotropic symmetry [21], the rigidity matrix linked to it contains nine independent elastic coefficients. In addition, the opposite of a stiffness matrix is a compliance matrix [22], which then results in a relationship between the engineering constants and the terms of the stiffness matrix. According to the hypothesis taken at the outset, if sound waves are applied along the orthotropic axes at different angles to a sample of wood prepared accordingly, the velocities obtained after the measurements will allow the calculation of these different parameters, as has already been demonstrated on numerous occasions [23,24,25,26,27,28]. However, a simplification can be achieved for the calculation of dynamic modulus of elasticity, according to (1).

El = vl2 × ρ

El: dynamic modulus of elasticity [Pa].

vl: speed of sound waves in the longitudinal direction [m/s].

ρ: density of the species considered taken at 20 °C and 65% RH [kg/m3].

The Sylvatest® Duo, a product from Concept Bois Technology based in Saint-Sulpice, Switzerland, represents an exemplary of the technology employing this method [29,30]. The device consists of two probes connected to a microcomputer for entering the data required for the measurement.

The natural frequency of a wood sample can be used to determine its dynamic modulus of elasticity in a non-destructive way [24,31,32,33,34]. The dynamic modulus of elasticity was determined according to (2) [33].

El = (4π2 × ρ × S × L4 × fi2)/(I × Xi)

El: dynamic modulus of elasticity [Pa].

ρ: density of the sample in question [kg/m3].

S: mean cross-section of the sample in question [m2].

L: sample length [m].

fi: frequency relative to the ith mode resulting from transverse vibrations [Hz].

I = (b h3)/12: quadratic moment for a beam with rectangular section with b, the beam width, and h, the beam thickness [m4].

Xi = ((2 I + 1) π/2)4: scalar relative to the mode studied with the number of the mode studied.

In the field of materials science, particularly the study of wood, it is imperative to consider the impact of moisture content on the material’s mechanical properties. This is because moisture content significantly affects the material’s mechanical properties [35,36,37,38]. In the context of materials analysis, the age of wood is a factor to be considered, as it can have a significant influence on its mechanical characteristics [21,39,40,41].

This article, therefore, presents the strength characterization by longitudinal vibrational analysis of a batch of wood recovered from building demolitions with a view to its reuse. The aim of this study is to demonstrate the effectiveness of the vibrational method in evaluating the stiffness of reused timber. This method uses the wood’s natural vibrations to determine the stiffness required to obtain its strength class. The results show that the vibrational analysis method is promising for assessing the quality of reused timber. It allows a quick and accurate estimation, without damaging the material. This could facilitate the reuse of timber in construction, thereby reducing its environmental impact. However, further research is needed to refine the method and to establish evaluation standards. This work offers new perspectives for the reuse of timber, promoting more sustainable construction.

2. Materials and Methods

2.1. Material

The wood elements that were examined in this study come from two deconstruction sites.

The first samples are joists that come from a deconstruction site located in the town of Remiremont in the Vosges “département” of France. This deconstruction project covers four former social housing buildings dating from the 1930s that the owner, Vosgelis, a Vosges social housing landlord, wishes to deconstruct. The sampling, therefore, focused on three buildings and on different floors of the buildings, which ultimately allowed the extraction of 15 samples. Each joist was given a code. This code corresponds to the building, the floor—the C designating the attic—and the order of removal—the order of removal being from the outer wall to the inner wall—of the sample taken. The wood species was determined for each sample by macroscopy and microscopy. This made it possible to conclude that all the samples consisted of fir wood, Abies Alba Mill. Based on the age of the buildings, we can estimate that the timber was implemented about 90 years ago. The useful length, the useful section and the density for each sample are shown in (Table 1).

Table 1.

Characteristics of the two batches of timber.

The second samples consist of a set of joists and rafters from a deconstruction site located in the city of Épinal in the Vosges “département” of France. Indeed, this deconstruction project concerned the deconstruction of an industrial hall dating from the early 1900s which was the seat of an old Vosges spinning mill. The joists come from different spans of this old building while the rafters come from the framework of the hall. There is a total of 20 samples broken down into 10 joists and 10 rafters. These samples were provided by the Ecole Nationale Supérieure d’Architecture de Nancy, which was commissioned on this project to monitor the deconstruction. For each joist and rafter, a number was assigned, ranging from 1 to 10. The wood species was determined for each sample by macroscopy and microscopy. This made it possible to deduce that all the samples consisted of fir wood, Abies Alba Mill. Based on the age of the buildings, it is estimated that the timber was implemented about 120 years ago. The useful length, the useful section and the density for each sample are shown in (Table 1).

2.2. Overview of Tests Performed

The various tests carried out during this study correspond to the measurement of dynamic modulus of elasticity by using the Sylvatest® (longitudinal), the measurement of dynamic modulus of elasticity (longitudinal) by using a natural frequency on a conventional test bench and portable test bench, the measurement of modulus of elasticity in bending and the measurement of bending strength according to the performance of bending tests in accordance with the NF EN 408+A1 standard [42].

2.3. Estimation of Basic Physical Properties

2.3.1. Estimation of Moisture Content

Each sample was conditioned before testing at an atmosphere of 20 °C and 65% relative humidity, aiming for a moisture content of 12%. The method developed in the NF EN 13183-1 standard [43] made it possible to characterize the destructive tests carried out on the test slab. At the end of the characterization of the various destructive tests, a portion of each sample was dried at a constant temperature of 103 °C. The moisture content was then calculated according to (3).

u = ((mbh − mbs)/mbs) 100

u: Moisture content [%].

mbh: wet weight [g].

mbs: dry weight [g].

The method developed in the NF EN 13183-2 standard [44] made it possible to characterize the non-destructive tests. A moisture meter with tip—Testo 606-1 model—was used to obtain the moisture content. The resistance moisture meter uses electrodes that are inserted into the sample. On average, the room temperature and relative humidity of the laboratory were 20 °C and 65%, respectively.

2.3.2. Estimation of Density

The density of a material is defined according to the ratio of its weight to its volume, in accordance with (4).

ρ = m/V

ρ: density [kg/m3].

m: weight [kg].

V: volume determined by using useful length and useful cross-section for each sample [m3].

However, in the context of wood, which is a hygroscopic material, density is always applied to a given moisture content of the wood. Therefore, normal density obtained in a normal climate, −20 °C and 65% relative humidity, is calculated for a given wood moisture content, according to the NF EN 384+A2 standard [45], according to (5).

ρ = ρu (1 – 0.005 (u − uref))

ρ: density [kg/m3].

u: moisture content at the time of the test (8% ≤ u ≤ 18%).

uref: reference moisture content, usually uref = 12%.

2.3.3. Useful Length

The length of each sample was measured according to the guidelines outlined in NF EN 1309-1 [46], using a tape measure. The useful length was determined by measuring the largest possible rectangular parallelepiped that could be contained in the sample, excluding areas with critical damage and section defects. For example, if a sample is 350 cm long but 10 cm at both ends of the sample have section defects related to their implementation, the useful length of the sample is 330 cm.

2.3.4. Useful Cross-Section

In accordance with NF EN 336 [47], the thickness and width of the samples were measured to determine the size of the cross-sections. For the thickness measurement, at least three clean and defect-free areas were selected, and the measurements were taken perpendicular to the face. The measurements were taken at least 15 cm from each end and the smallest of the measurements was retained. For the width measurement, at least three clean and defect-free areas were selected, and the measurements were taken perpendicular to the longitudinal axis of the sample. As for the thickness measurement, the measurements were taken at least 15 cm from each end and the smallest of the measurements were retained.

2.3.5. Biological Defect

Past biological defects were identified visually. The moisture content of the samples was measured to ensure that it had not risen above 20% during the selective removal phase. It is generally accepted that humidity levels above 20% can encourage biological decomposition.

2.3.6. Metallic Contamination

Metal contamination of wood includes fasteners such as nails and screws that were inserted into the wood during its installation or its service life. For both sample sources, the metal elements had been removed by the companies in charge of the construction by mutual agreement. A metal detector was still used to check whether the parts contained metal residues not visible to the naked eye. During this check, no metal elements were detected.

2.3.7. Non-Metallic Contamination

For the joists from Remiremont, non-metallic contamination by plaster, resulting from the implementation of the wooden lath on the lower part of the floor complex, was recorded. The contamination was easily removed by rubbing the samples concerned and therefore could not have had an impact on the other measurements.

2.4. Estimation of Mechanical Properties

2.4.1. Estimation of Dynamic Modulus of Elasticity Using Ultrasound Device

The tests carried out on the samples required the use of the Sylvatest® Duo. The two probes were placed at the two ends of each sample, for a longitudinal measurement, perpendicular to two opposite sides, thereby implementing the direct measurement method. The ends were drilled (Figure 1) in the center of the section of each sample using a tool supplied with the Sylvatest® Duo.

Figure 1.

Photos of the holes at the end of the parts for the installation of the Sylvatest®.

Using this protocol, the probes placed in these machining operations are guaranteed to have good contact with the material for optimal sound transmission. After having entered the species, the length and the moisture content of the sample in the device, after carrying out the test, it determines a reference ultrasound speed for a reference humidity taken at 12%, an ultrasound speed without considering the humidity of the sample and a dynamic modulus of elasticity value. For the experiment, the tests were carried out at a temperature of 20 °C and a relative humidity of around 10%. To study the variation due to the average density taken as a reference for each sample of a given species, the dynamic modulus of elasticity was recalculated according to Equation (5) using the actual density of each sample and the ultrasound velocity without considering the humidity of the sample. Indeed, the Sylvatest® Duo does not allow a decimal input of humidity, so it was necessary to use (6) for the calculation of the corrected and reference ultrasound velocities taken at 12%.

v12% = vreading + 33 (ω − 12)

v12%: reference sound wave velocity taken at 12% [m/s].

vreading: sound wave velocity recorded on the device [m/s].

ω: moisture content of the sample [%].

2.4.2. Estimation of Dynamic Modulus of Elasticity Using Natural Frequency

In our case, the natural frequency was measured using two B12/500 accelerometers from the HBM brand. These sensors were then placed, respectively, at half and three quarters of the length of the sample to quantify different frequency modes, including the first. The samples were tested on two different supports, a first support fixed onto a test slab (Figure 2) and a second moving support (Figure 3) designed especially for the occasion by the Viry Fayat company.

Figure 2.

Photo of the bracket mounted on a test slab.

Figure 3.

Photo of the portable support designed by the Viry Fayat company.

The vibration was induced manually using a wooden carpenter’s mallet. In our case, only the first mode was studied and calculated based on the natural frequency obtained by the equipment. For the experiment, the tests were carried out at a temperature of 20 °C and a relative humidity of around 50%.

2.4.3. Determination of Modulus of Elasticity by Bending Test

Modulus of elasticity can be determined according to a four-point bending test following the requirements described by the NF EN 408+A1 standard [42]. The samples were tested in their entirety, since this measurement was coupled with the measurement of the bending strength, on a test slab using a hydraulic cylinder from the Thema Concept brand and several LVDT displacement sensors from the Solartron brand. The measurements were taken in a climate identical to the previous ones, i.e., at a temperature of 20 °C and a relative humidity of 50%. According to standard NF EN 408+A1, the shear modulus G used when calculating the modulus of elasticity is set at 650 MPa for softwoods.

2.5. Determination of the Strength Class of the Batch of Wood

The strength class process of the batch of wood was only carried out for the wood provided by Vosgelis, with the aim of being able to reuse the overall wood batch in the landlord’s construction project. The classification was carried out according to the indicator property (IP) method described in the NF EN 14081-2+A1 standard [18]. Nevertheless, this method has been adapted to the deconstruction of timber, which means that the number of samples has been significantly reduced compared to what is recommended in the standard. Reuse requires work on a micro-batch since we want to preserve the available resources as much as possible. The reference batch for the classification of the overall batch on site has therefore been reduced from 700 samples, as recommended in the standard, to only 14 samples.

The classification of the reference batch made it possible to determine a threshold value of the indicator property, which is here represented by the dynamic modulus of elasticity obtained using the natural frequency method, which will allow the overall classification of the batch of wood present on site. This threshold value corresponds to the threshold value that wood must reach to be of the desired strength class; in our case, strength class C18. For the classification of the reference batch, the NF EN 384+A2 standard was used to determine the different characteristic values of the mechanical properties considered but also to adjust these different properties with respect to certain parameters such as the humidity or the dimension of the section considered [45]. So, during the deconstruction phase of the Vosgelis project, each joist was specifically removed and tested. The on-site tests resulted in the determination of the dynamic modulus of elasticity for each joist, as well as the strength class of the global batch. This was achieved by means of the natural frequency method.

In order to ensure that the classification that has just been carried out was indeed valid, the method of the overall cost matrix described in NF EN 14081-2+A1 standard was verified [18]. This methodology determines the overall cost matrix presented in (Table 2). It is the number below the diagonal that interests us since it corresponds to the elements that would have been upgraded in our case, samples that should not be in class C18 but rather in lower classes such as C16 or C14. This number must be less than the value of 0.4, as defined in the standard, for the classification to be valid, which is the case here. It should be noted that we are not interested in the number above the diagonal that corresponds to the elements that would be downgraded, namely samples that should not be in class C18 but in higher classes such as C22 or C24. In this instance, downgrading is not a relevant consideration, since the objective is to target a single strength class. However, this could be a pertinent issue if the intention was to target multiple strength classes or to optimize the wood working rate.

Table 2.

Overall cost matrix resulting from the classification of the reference batch of joists from Remiremont according to the NF EN 14081-2+A1 standard.

3. Results and Discussion

The relative density of each sample is shown in (Table 3). In this study, it was established that these densities are in the same order of magnitude as the average density of fir, which is 450 kg/m3.

Table 3.

Density of the two batches of timber.

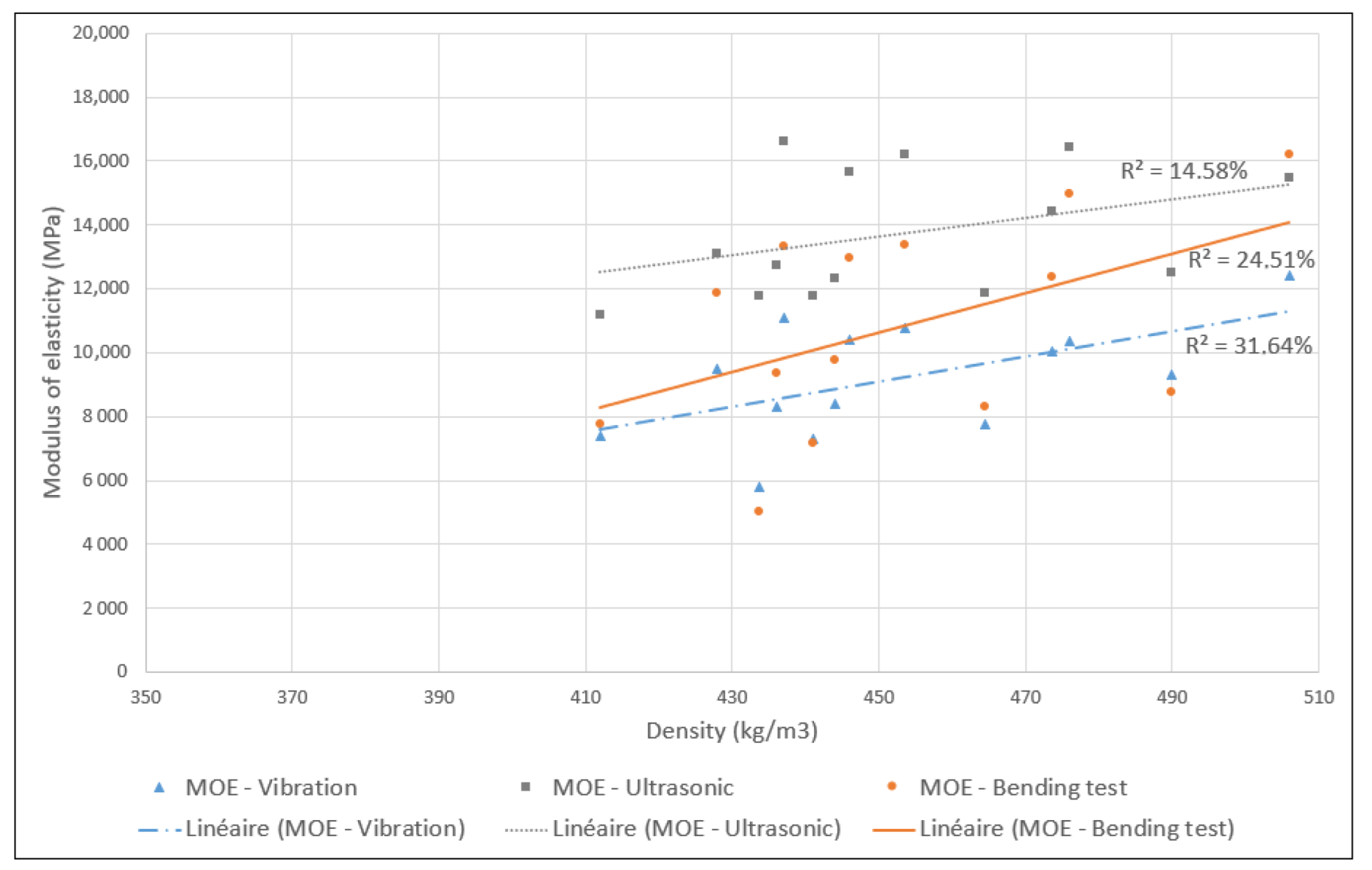

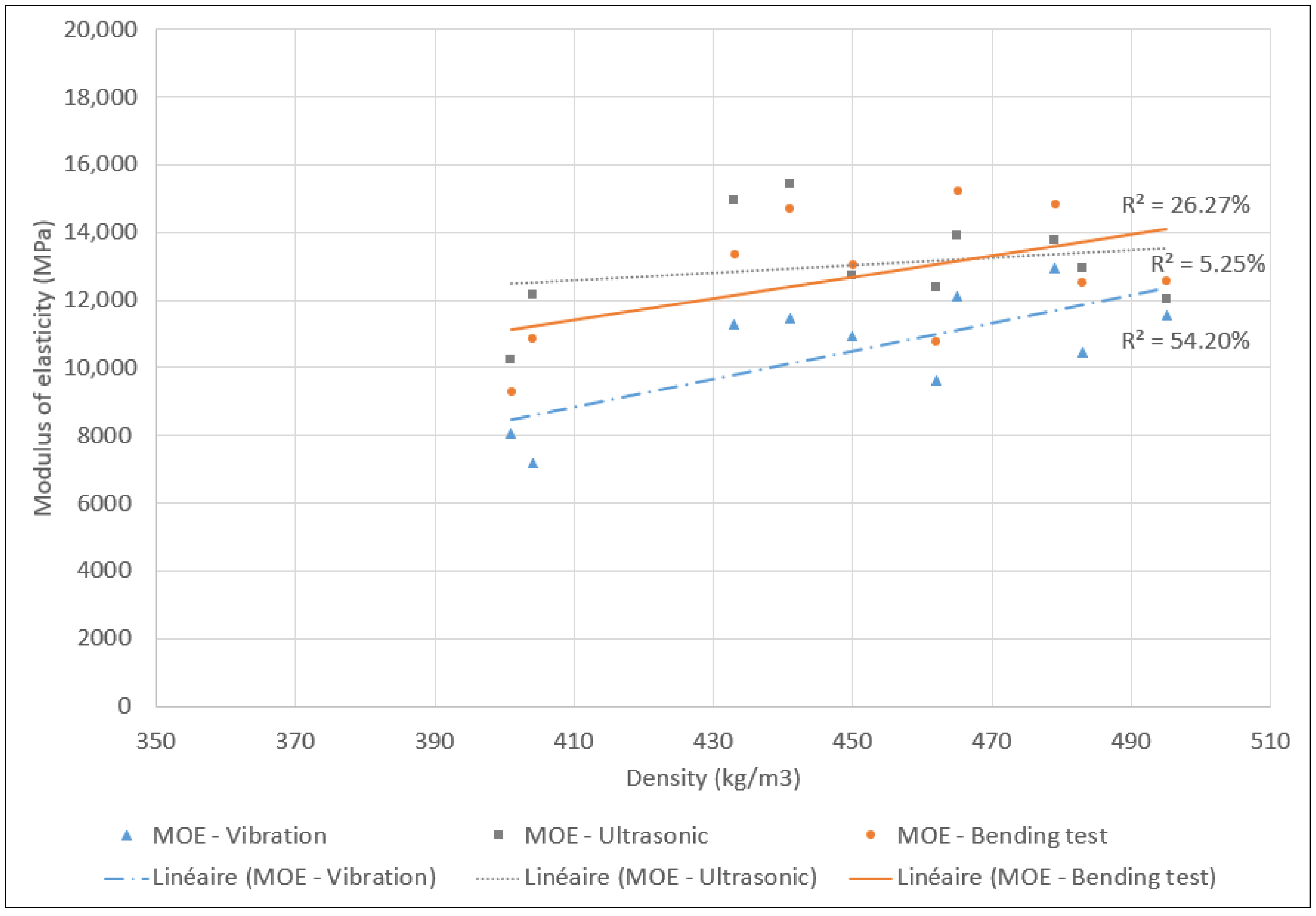

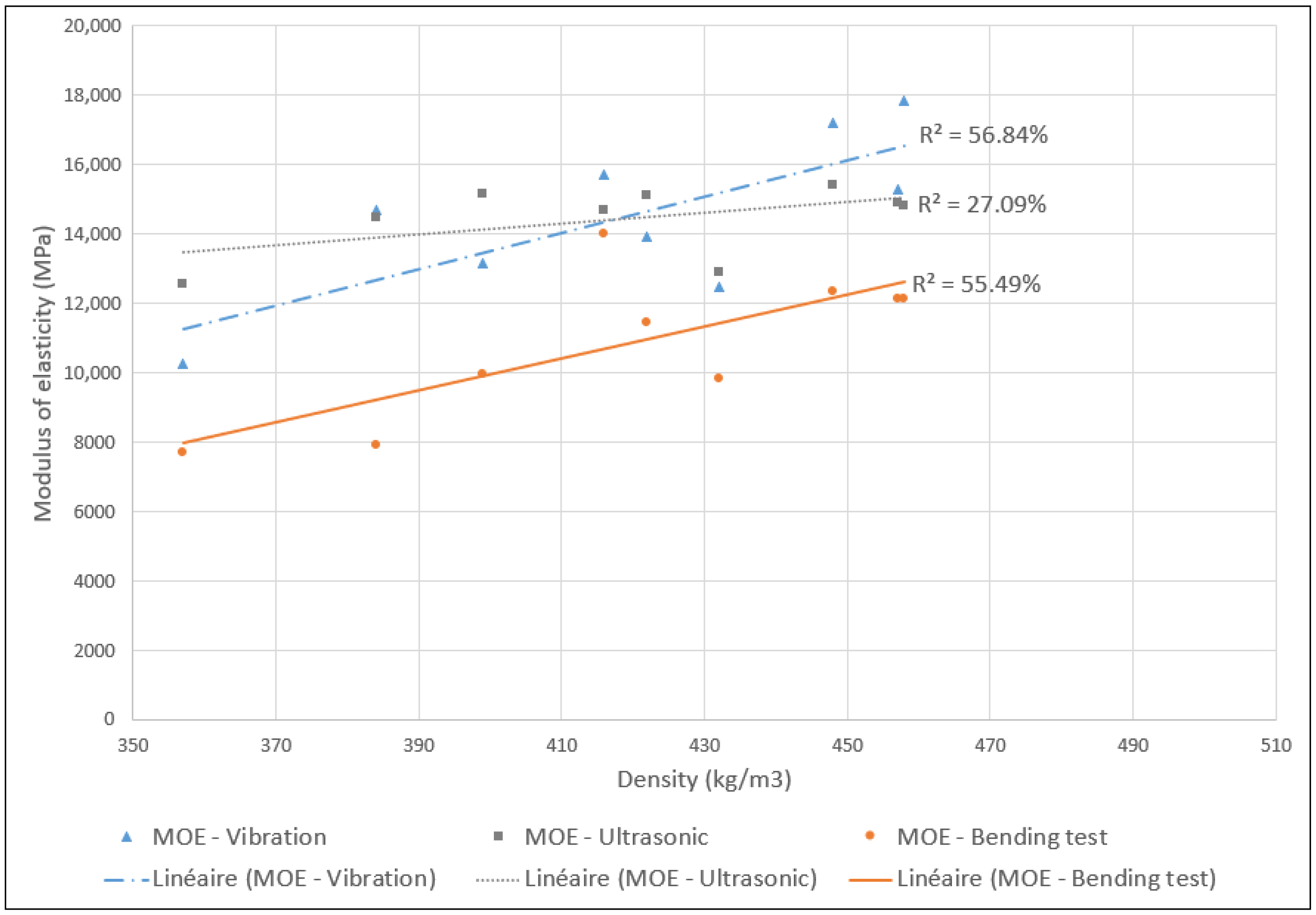

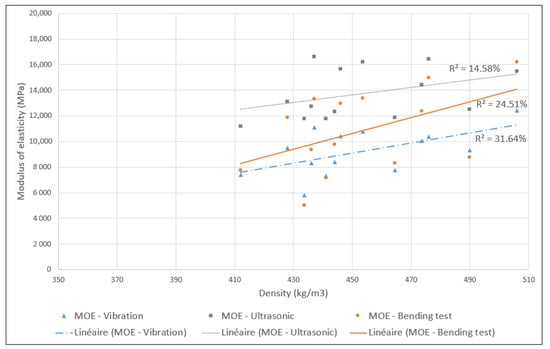

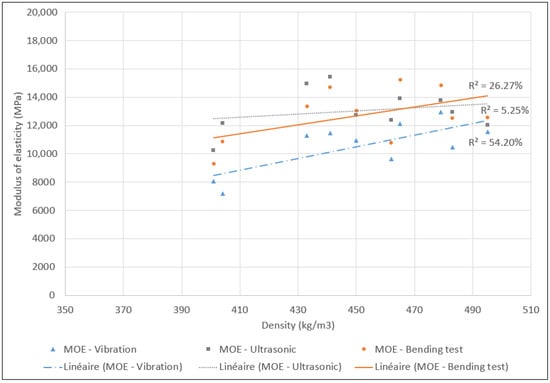

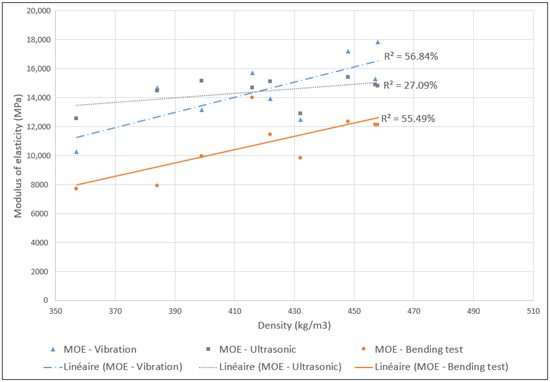

The results of the different moduli of elasticity obtained were initially related to density, the only factor common to all the methods. The values of the dynamic modulus of elasticity, obtained by the different technologies, for the samples from Remiremont are presented in (Figure 4) while those from Epinal are presented in (Figure 5 and Figure 6). In both cases they are plotted according to density. It can be noted that the same logic is observed in the three figures, i.e., that the vibrational method is the one that is best correlated with density, followed by the bending method and then the ultrasonic method.

Figure 4.

The following graph illustrates the correlation between the moduli of elasticity of the various methods and the density of the joists from Remiremont.

Figure 5.

The following graph illustrates the correlation between the moduli of elasticity of the various methods and the density of the joists from Epinal.

Figure 6.

The following graph illustrates the correlation between the moduli of elasticity of the various methods and the density of the rafters from Epinal.

In addition, the objective of this study is to compare the dynamic modulus of elasticity values obtained by non-destructive technologies with the reference values calculated by bending test. These different comparisons are presented in (Table 4).

Table 4.

Values of the moduli of elasticity of the different methods and the differences existing between the moduli of elasticity from non-destructive methods compared to the moduli of elasticity from destructive methods.

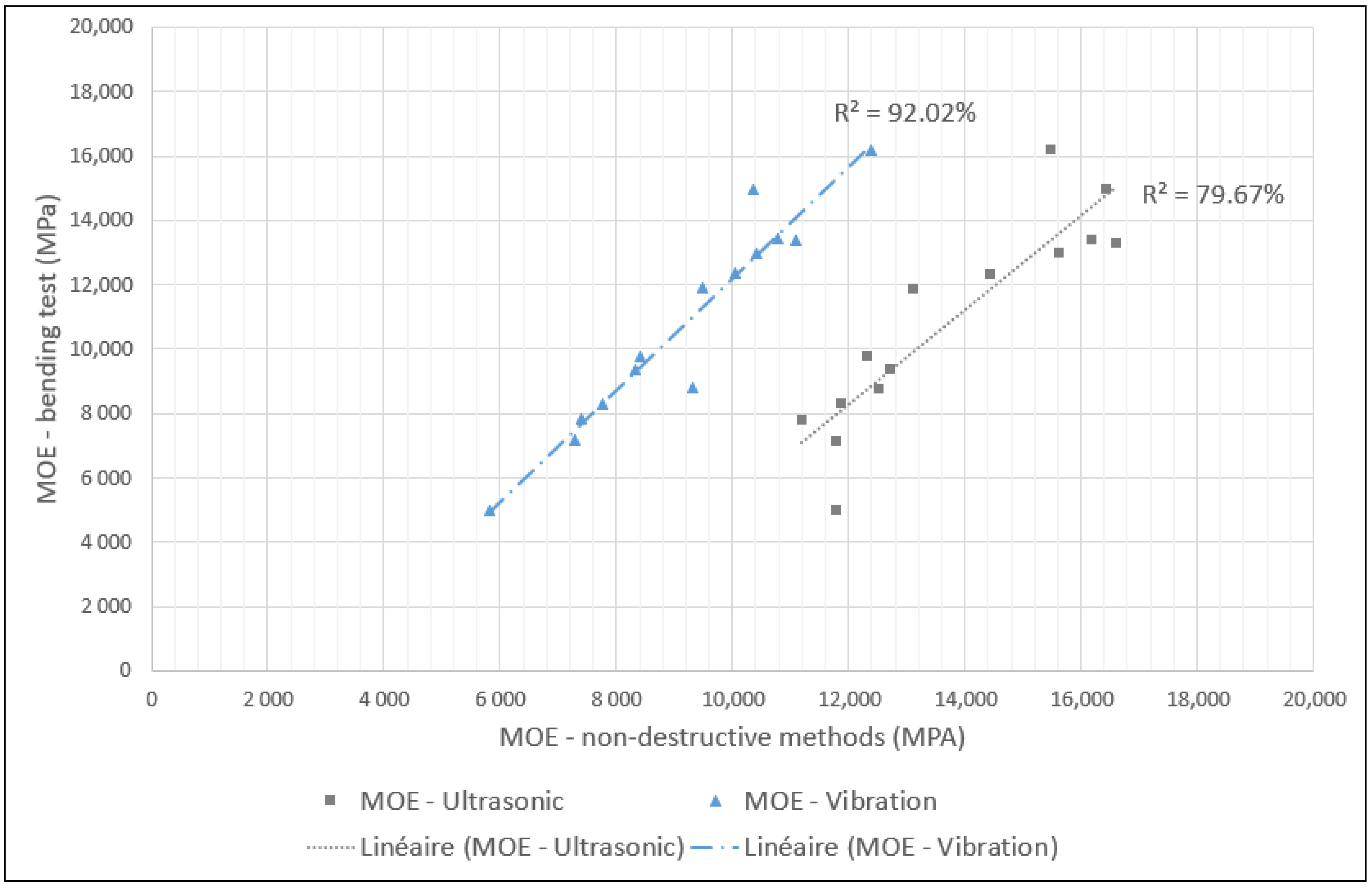

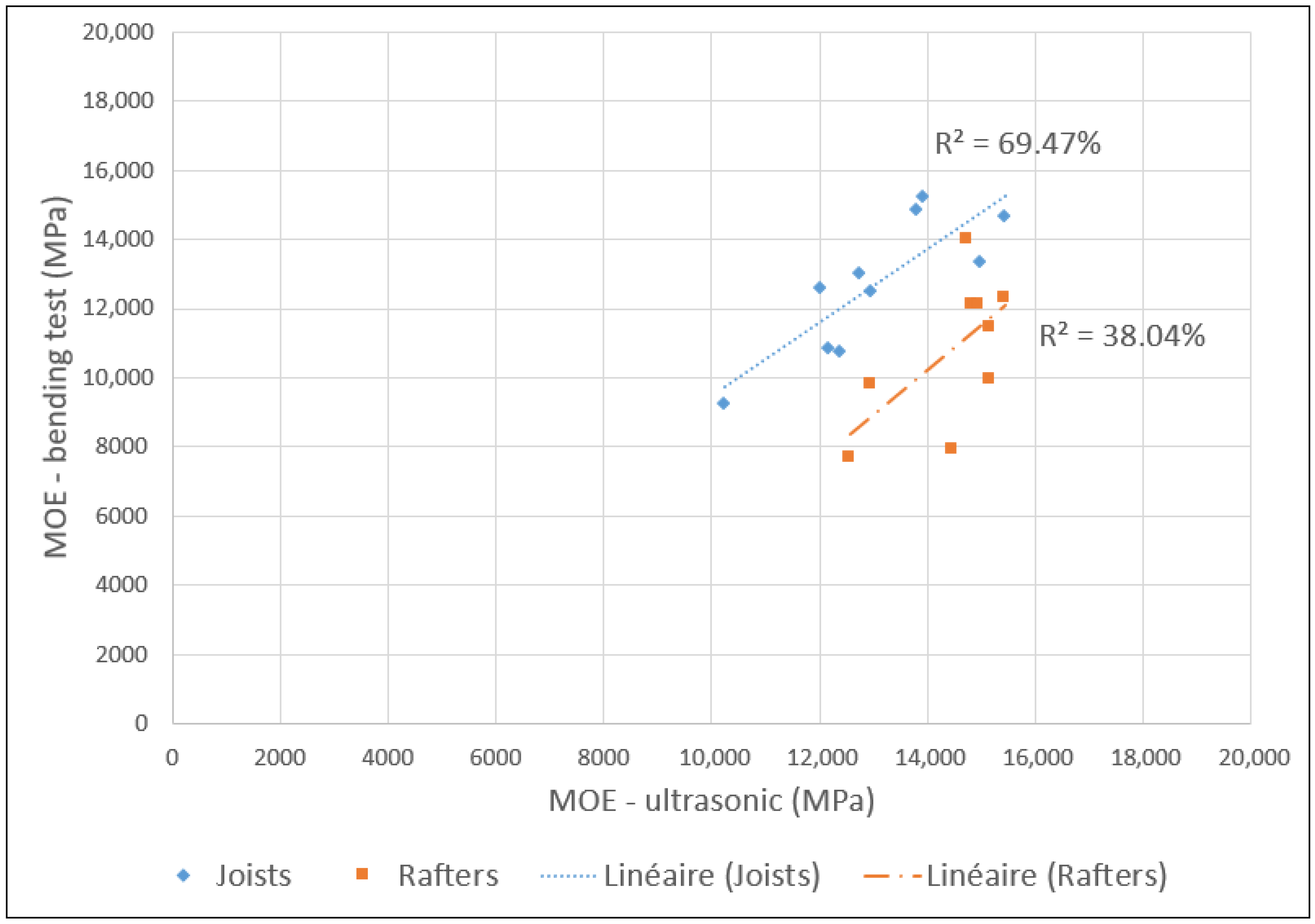

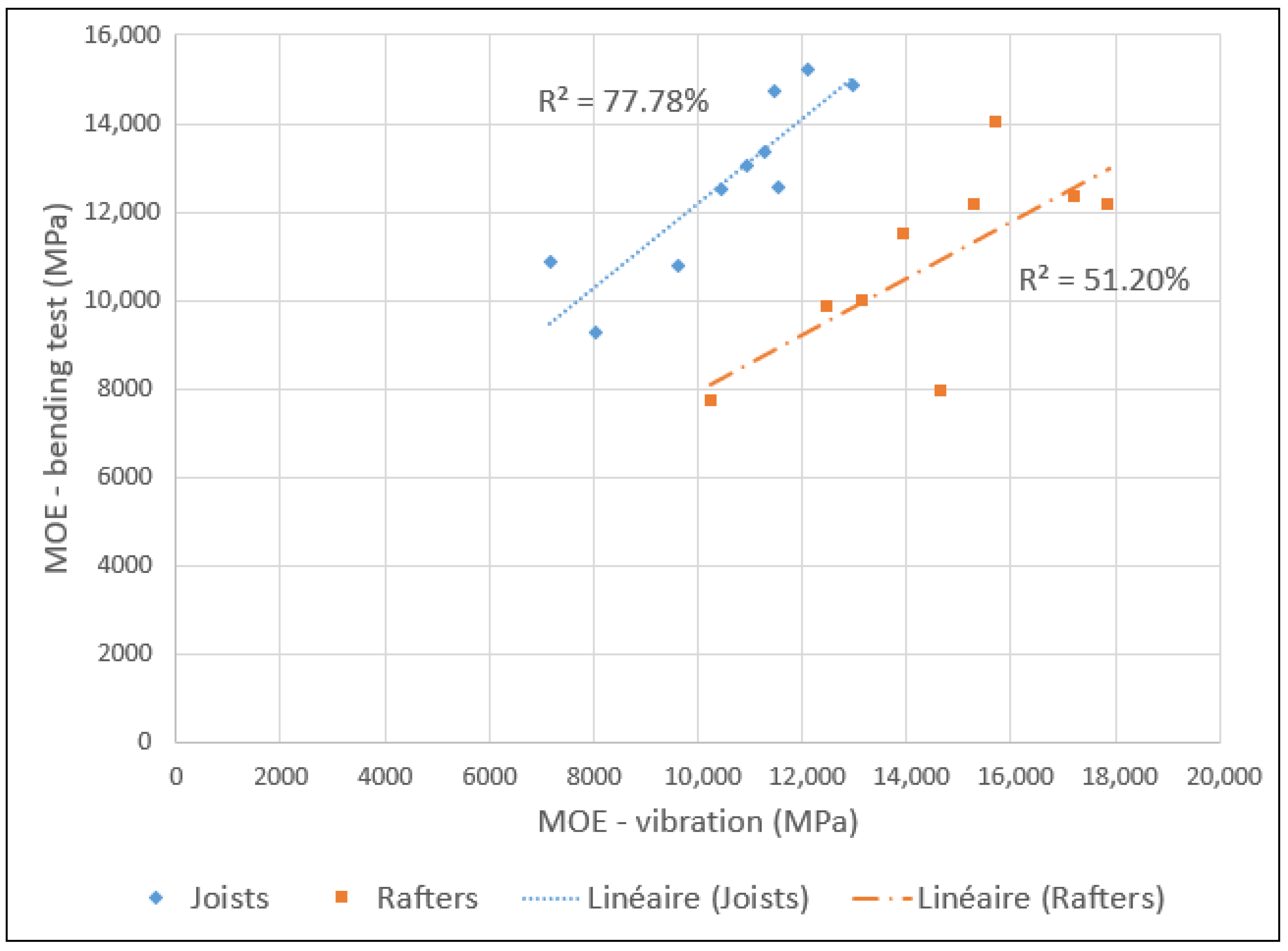

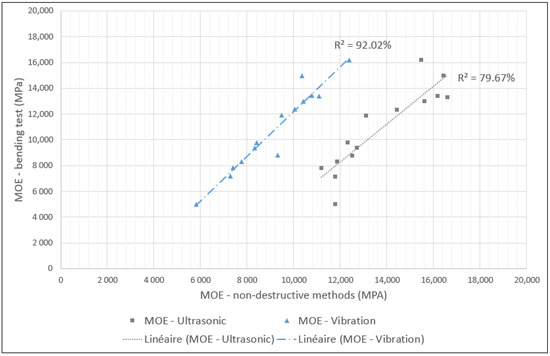

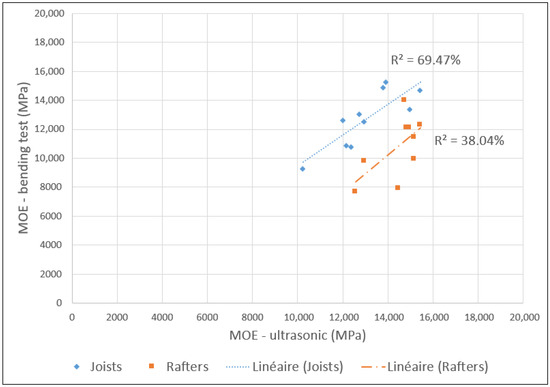

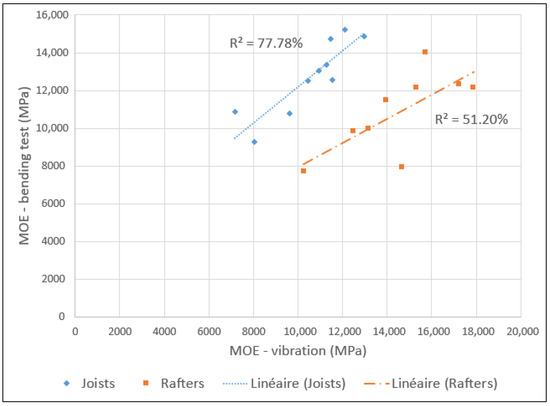

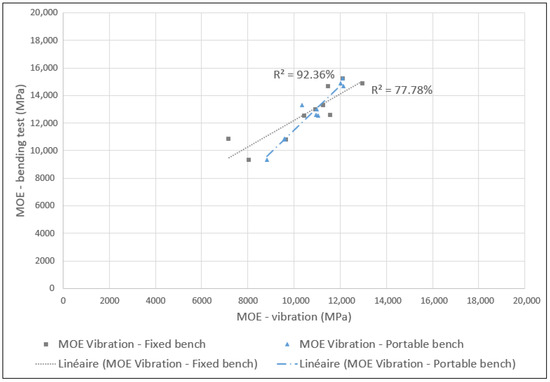

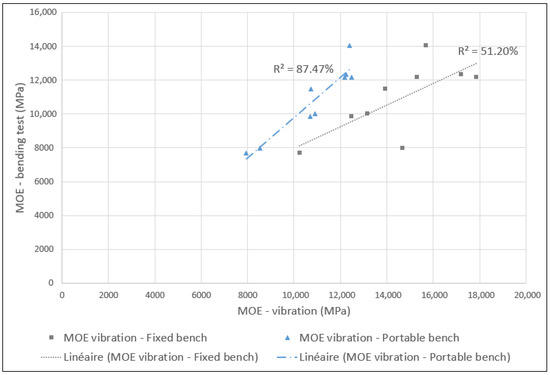

Of the 33 samples studied, 21 samples have a dynamic modulus of elasticity value obtained by vibrational technology lower than the modulus of elasticity value obtained by bending test. In the case of the rafters, the values obtained by vibrational technology are higher than those obtained by bending test, which is explained by the fact that these samples were not suitable for the implementation of this technology. Two reasons can explain these results. Firstly, the length of the samples and, secondly, their general condition. It was found that most of the rafters were not long enough to be correctly positioned on the fixed bench, which is 4 m long. It was observed that the rafters exhibited a certain resistance to vibration, which could lead to values higher than the reference values. In addition, all the rafters have significant cracks several centimeters deep and present over a good part of the lengths. The presence of these defects could cause a disturbance in the vibrational measurement. It may also be observed that 28 samples have a dynamic modulus of elasticity value obtained by ultrasound technology higher than the modulus of elasticity value obtained by bending test. This shows that ultrasound technology tends to overestimate the modulus of elasticity. Finally, 27 samples have a dynamic modulus of elasticity value obtained by vibrational technology that is lower than the dynamic modulus of elasticity value obtained by ultrasonic technology. Looking at the differences, we note that ultrasonic technology, on the joists from Remiremont, gives on average dynamic modulus of elasticity results that are 35% higher than bending test values. On the other hand, vibrational technology gives on average dynamic modulus of elasticity results that are 12% lower than values from bending tests. In this case, vibrational technology gives results closer to and lower than values from bending tests, which suggests that the use of this methodology is more suitable on these woods than the ultrasonic method. A lower value guarantees that the wood will be sufficiently resistant for its structural reuse, with the use of safety factors considered during the design phase. On average, on the joists from Epinal, ultrasonic technology produces dynamic moduli of elasticity results that are 3% higher than values from bending tests, while vibrational technology gives dynamic moduli of elasticity results that are 17% lower than values from bending tests. In this case, ultrasound technology gives results closer to but always higher than values from bending tests, which suggests that the use of vibrational methodology is more suitable on these woods than the ultrasound method. Although the vibrational method gives more distant results than the ultrasonic method, the fact that it gives lower values than the values from bending tests, unlike the ultrasonic method, shows greater confidence in the approach. However, the defect highlighted will then lead to an under-exploitation of the wood’s properties, which is not necessarily problematic in the context of reuse, which is the initial objective of the emergence of the sector. In the context of the rafters from Epinal, ultrasonic technology and vibrational technology give on average relatively similar results in terms of the dynamic modulus of elasticity: 37% higher than values from bending tests for the ultrasonic technology and 36% higher than values from bending tests for the vibrational technology. In this case, both technologies give results that are much higher than values from bending tests and do not seem suitable for the characterization of this type of element. In our case study on Remiremont timber, vibrational technology was chosen because it gives on average dynamic modulus of elasticity values lower than values from bending tests. These lower values offer a significant additional safety margin in the context of structural reuse. This statement can be confirmed by (Figure 7, Figure 8 and Figure 9) which correlate the values from the two non-destructive technologies and the values from bending tests for the different batches of wood.

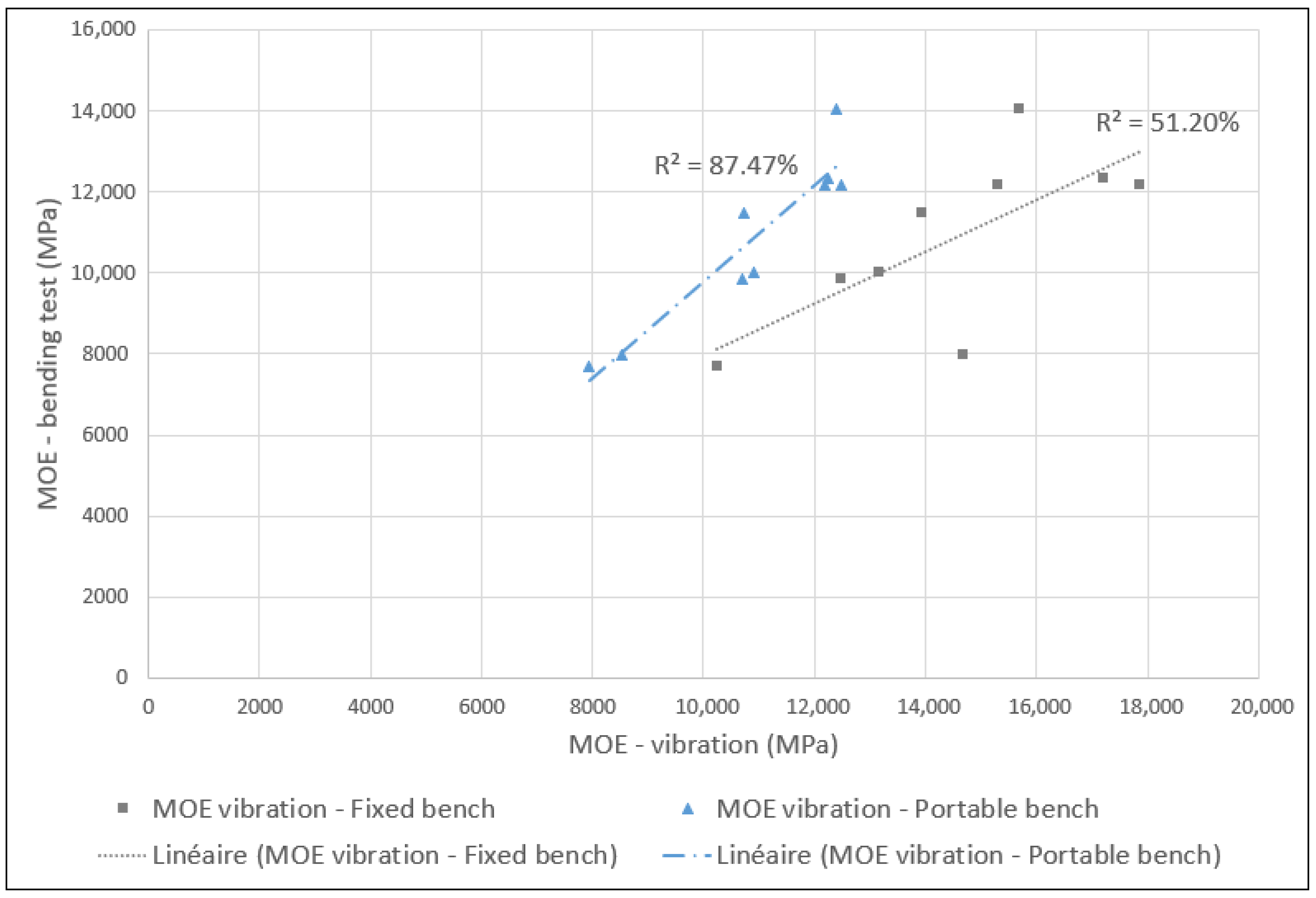

Figure 7.

Correlation graph between non-destructive moduli of elasticity and moduli of elasticity from bending tests for joists from Remiremont.

Figure 8.

Correlation graph between the moduli of elasticity obtained by the ultrasonic method and the moduli of elasticity from bending tests for the joists and rafters from Epinal.

Figure 9.

Correlation graph between the moduli of elasticity obtained by the vibrational method with fixed bench and moduli of elasticity from bending tests for joists and rafters from Epinal.

It is noted from (Figure 7, Figure 8 and Figure 9) that the coefficients for vibrational technology are greater, i.e., there is a better correlation between vibrational and bending tests than between ultrasonic and bending tests. It is again interesting to see that the correlation coefficients obtained on the batch of rafters are lower compared to the other two batches of joists. This again suggests that the technologies are not suitable for this type of element. This inadequacy probably comes from the general state of the elements but also from the implementation of the experimental set-up required by vibrational technology.

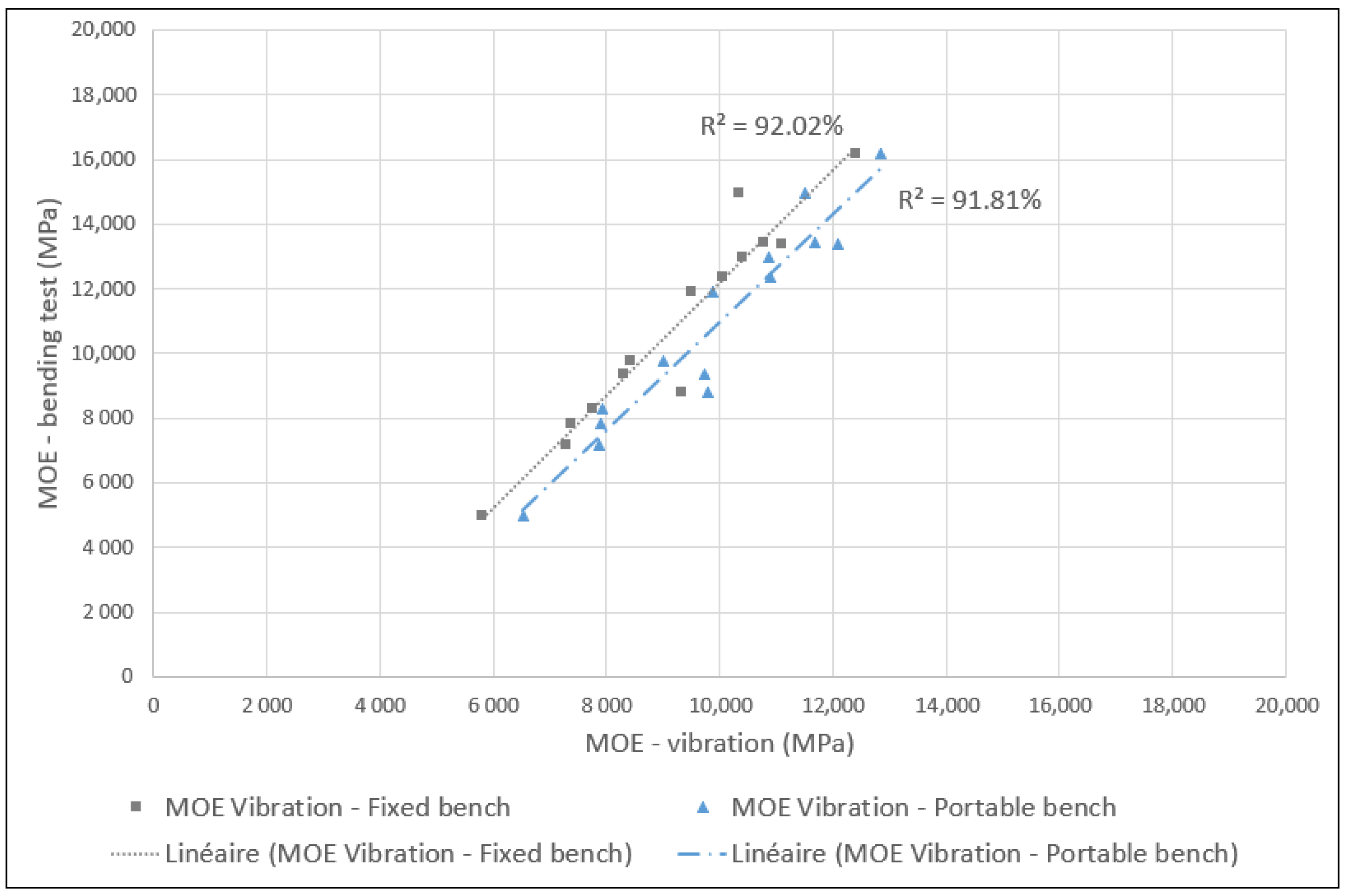

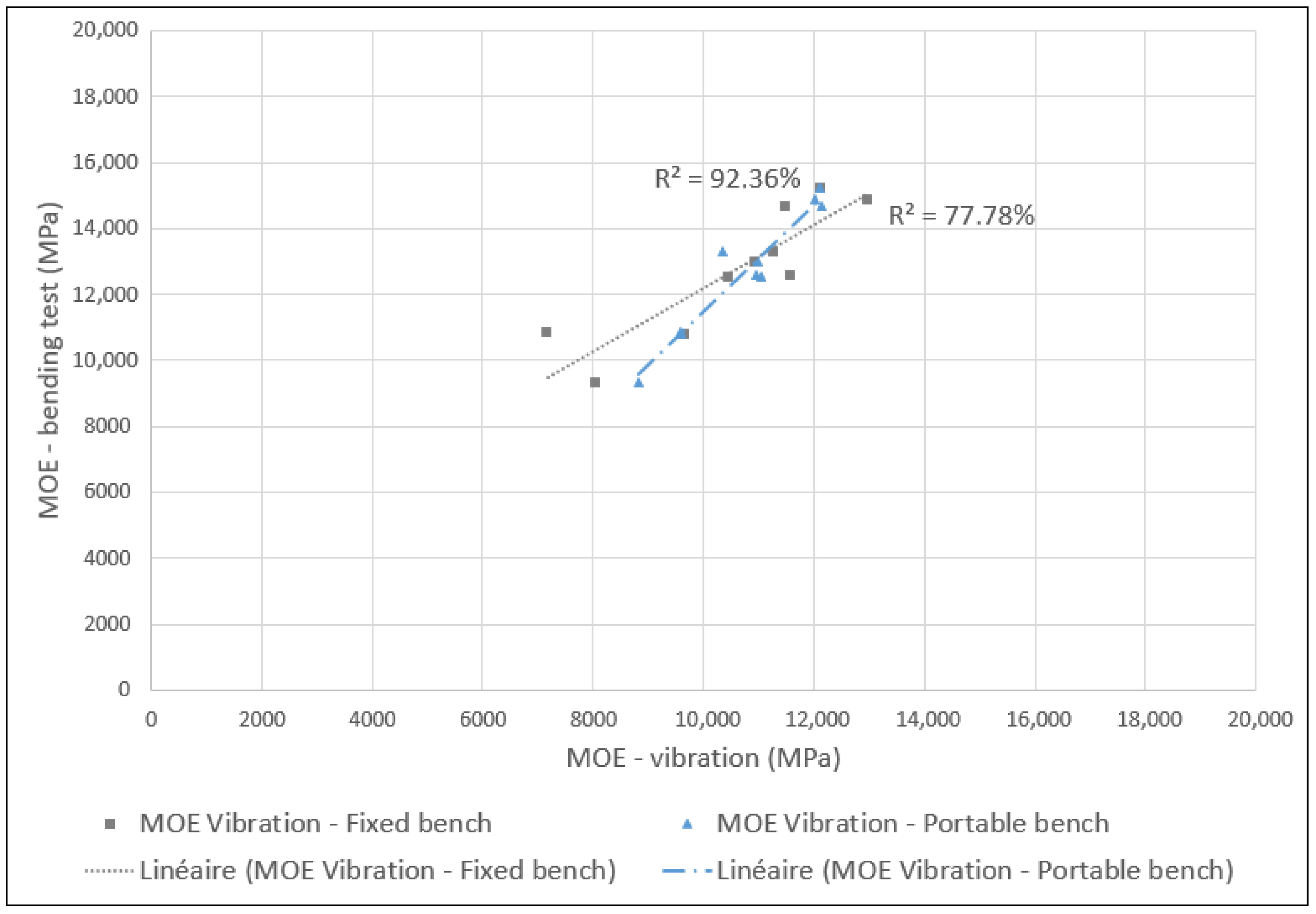

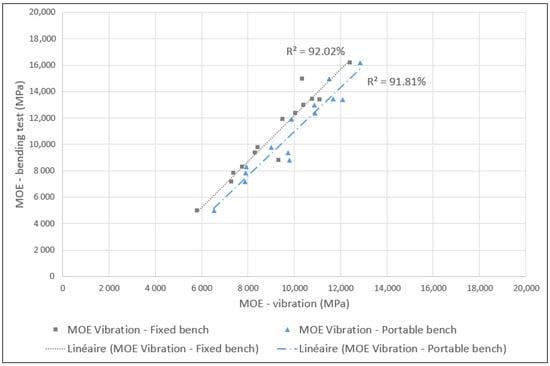

Another part of the study looked at the comparison between the results obtained using a “conventional” test bench, i.e., fixed on a test slab, and the results obtained using a portable bench. These results were compared to the results from bending tests. They are present in (Table 5). In the case of joists from Remiremont, the vibrational tests carried out on the conventional test bench gave, on average, dynamic modulus of elasticity results that are 12% lower than values from bending tests. On the other hand, vibrational tests conducted on the portable bench test produced, on average, dynamic modulus of elasticity results that are 5% lower than values from bending tests. In this case, the portable test bench gives results closer to and lower than values from bending tests, which suggests that the use of this test set-up is suitable for these woods. The conventional test bench would nevertheless provide a higher safety margin insofar as the values obtained on it are lower than and further removed from values from bending tests. In the case of joists from Epinal, the vibrational tests carried out on the conventional test bench gave, on average, dynamic modulus of elasticity results that are 17% lower than values from bending tests. On the other hand, vibrational tests conducted on the portable bench test produce, on average, dynamic modulus of elasticity results that are 15% lower than values from bending tests. In this case also, the portable test bench gives results closer to and lower than the values from bending tests, which suggests that the use of this test set-up is suitable for use for these woods on construction sites. This test bench can therefore be used directly on a deconstruction site to measure wood. In the case of rafters from Epinal, the vibrational tests carried out on the conventional test bench give, on average, dynamic modulus of elasticity results that are 36% higher than values from bending tests. On the other hand, vibrational tests conducted on the portable bench test produce, on average, dynamic modulus of elasticity results that are 1% higher than values from bending tests. In this case, the portable test bench gives results closer to but higher than values from bending tests. The results tend to show the relevance of the use of this test set-up since the hypothesis concerning its defect in the context of the fixed bench is not found for the portable bench. The portable bench can be adapted to any sample length. Therefore, vibration technology again seems more suitable for this type of element than ultrasonic technology in light of these new results.

Table 5.

Values of the moduli of elasticity obtained by vibrational methods and bending tests and their differences.

This statement can be confirmed by (Figure 10, Figure 11 and Figure 12) which correlates the two vibrational operating modes and bending tests for the different batches of wood.

Figure 10.

Correlation graph between the moduli of elasticity obtained by the vibrational method on the two types of benches and the moduli of elasticity from bending tests for the joists from Remiremont.

Figure 11.

Correlation graph between the moduli of elasticity obtained by the vibrational method on the two types of benches and the moduli of elasticity from bending tests for the joists from Epinal.

Figure 12.

Correlation graph between the moduli of elasticity obtained by the vibrational method on the two types of benches and the moduli of elasticity from bending tests for the rafters from Epinal.

It is noted from (Figure 10, Figure 11 and Figure 12) that the correlation coefficients of the portable bench are higher or identical to the correlation coefficients of the fixed bench for each batch of wood, i.e., there is a better correlation between vibration technology on the portable bench and the bending tests than compared to vibration technology on the fixed bench.

The last part of the study focused on the classification of the batch of joists from Remiremont. The classification was carried out according to the indicator property method described in the NF EN 14081-2+A1 standard [16]. The statistical study, therefore, focused on a reference batch that was adapted to the constraints of reuse. To preserve as much of the wood resource available on the site as possible but also for economic reasons, the batch considered included only 14 samples. The strength class of the reference batch must make it possible to estimate a threshold value which then allows for the estimate of the strength class of the batch of wood left on-site. The indicator property is in our case materialized by the dynamic modulus of elasticity obtained by the vibrational method using the portable bench. The classification of the reference batch showed that of the 14 samples, 11 of them were in reference strength class C18, while the other 3 samples were in a lower strength class. It is, nevertheless, interesting to note that the 3 samples that do not comply with class C18 still have a bending strength value greater than 18 MPa, which is the required value for wood in strength class C18. This statement shows that the strength classification of wood is obtained on a statistical basis and can lead to a downgrading of certain samples. The methodology of the indicator property made it possible to determine a threshold value in the dynamic modulus of elasticity, obtained using the vibrational method, equal to 7914 MPa. The strength classification of the wood remaining on the deconstruction site, therefore, consists of the measurement of the dynamic modulus of elasticity, obtained using the vibrational method with the portable bench. Each wood needs to comply with the value of 7914 MPa to be considered class C18. Should the threshold not be compliant, the wood will be of a lower strength class and will not be directed to on-site reuse.

4. Conclusions

- The study that was conducted as part of this deconstruction project showed that vibrational technology was more suitable than ultrasonic technology for the estimation of the dynamic modulus of elasticity since it gives results on average 12% lower, for the Remiremont woods that represent the heart of the study, than the real values obtained by bending tests.

- This technology can also be used directly on the site with the use of a portable test bench whose results are very satisfactory.

- Finally, the classification of the reference batch of Remiremont wood showed that the NF EN 14081-2+A1 standard applied to new wood can also be used for determining the strength class of woods from building demolitions, if it is adapted to reused constraints. Adaptation mainly involves studying parameters specific to wood from deconstruction that are not known, such as previous stresses, invisible damage or local damage.

Author Contributions

Conceptualization, L.B. and O.L.; methodology, L.B. and O.L.; software, O.L.; validation, L.B., C.S. and P.-J.M.; formal analysis, O.L.; investigation, O.L.; resources, O.L. and L.B.; data curation, O.L.; writing—original draft preparation, O.L.; writing—review and editing, O.L., C.S. and P.-J.M.; visualization, L.B., C.S. and P.-J.M.; supervision, C.S. and P.-J.M.; project administration, C.S. and P.-J.M.; funding acquisition, C.S. and P.-J.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by French Association Nationale de la Recherche et de la Technologie, grant number 2022/0101.

Data Availability Statement

The original contributions presented in this study are included in the article. Further information can be obtained from the corresponding author.

Acknowledgments

A special thanks to the social housing landlord VOSGELIS which provided the samples from Remiremont as well as to the Ecole Nationale Supérieure d ‘Architecture de Nancy for providing the samples from Epinal. A thank you also to CRITT BOIS for the help provided on the test slab for the destructive tests.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Piluso, N. Is corporate social responsibility effective in improving environmental quality? Literature review. Environ. Econ. 2024, 15, 1–11. [Google Scholar] [CrossRef]

- Razzaq, A.; Sharif, A.; Afshan, S.; Li, C.J. Do climate technologies and recycling asymmetrically mitigate consumption-based carbon emissions in the United States? New insights from Quantile ARDL. Technol. Forecast. Soc. Change 2023, 186, 122138. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Goyal, S.; Esposito, M.; Kapoor, A. Circular economy business models in developing economies: Lessons from India on reduce, recycle, and reuse paradigms. Thunderbird Int. Bus. Rev. 2018, 60, 729–740. [Google Scholar] [CrossRef]

- Sanguino, R.; Barroso, A.; Fernández-Rodríguez, S.; Sanchez-Hernandez, M. Current trends in economy, sustainable development, and energy: A circular economy view. Environ. Sci. Pollut. Res. 2020, 27, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Kamyshnikov, I.N.; Smirnova, T.S.; Tikhonov, A.I. Sustainable development: Waste Recycling and Circular Economy. In Sustainable Development: Society, Ecology, Economy; Semenov, A.V., Sokolov, I.A., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Parmesan, C.; Morecroft, M.D.; Trisurat, Y.; Adrian, R.; Anshari, G.Z.; Arneth, A.; Gao, Q.; Gonzalez, P.; Harris, R.; Price, J.; et al. Terrestrial and Freshwater Ecosystems and Their Services. In Climate Change 2022: Impacts, Adaptation and Vulnerability. Contribution of Working Group II to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Pörtner, H.-O., Roberts, D.C., Tignor, M., Poloczanska, E.S., Mintenbeck, K., Alegría, A., Craig, M., Langsdorf, S., Löschke, S., Möller, V., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2022; pp. 197–377. [Google Scholar] [CrossRef]

- Bouvet, A.; Berthelot, A.; Chaumet, M. Influence D’Accidents Climatiques Majeurs (Sécheresse, Canicule) Sur la Croissance Peupliers Douglas; Institut Technologique FCBA: Forêt, Cellulose, Bois—Construction Ameublement: Paris, France, 2020. [Google Scholar]

- Sakaguchi, D. Potential for Cascading Wood from Building; School of Chemical Technology, Aalto University: Espoo, Finland, 2014. [Google Scholar]

- Jahan, I.; Zhang, G.; Bhuiyan, M.; Navaratnam, S. Circular Economy of Construction and Demolition Wood Waste—A Theoretical Framework Approach. Sustainability 2022, 14, 10478. [Google Scholar] [CrossRef]

- Borzęcki, K.; Pudełko, R.; Kozak, M.; Borzęcka, M.; Faber, A. Spatial Distribution of Wood Waste in Europe. Sylwan 2018, 162, 563–571. [Google Scholar] [CrossRef]

- Agence de L’environnement et de la Maîtrise de L’énergie. Déchets Chiffres-Clés: L’essentiel Édition 2023. (ADEME Reference n°011983); Agence de L’environnement et de la Maîtrise de L’énergie: Angers, France, 2023. [Google Scholar]

- Ministère de la Transition Energétique. Panorama Français Des Gaz à Effet de Serre—Emissions Des GES en France en (2022); Ministère de la Transition Energétique: Paris, France, 2023.

- Journal Official. Loi n°2018-1021 Portant Sur L’évolution du Logement, de L’aménagement et du Numérique; Journal Official: Paris, France, 2018. [Google Scholar]

- Journal Officiel. Loi n°2020-105 Relative à la Lutte Contre le Gaspillage et à L’économie Circulaire; Journal Officiel: Paris, France, 2021. [Google Scholar]

- Journal Officiel. Décret n°2021-821 Relatif au Diagnostic Portant Sur la Gestion Des Produits, Equipements, Matériaux et Déchets Issus de la Démolition ou de la Rénovation Significative de Bâtiments; Journal officiel: Paris, France, 2021. [Google Scholar]

- NF B52-001-1; Rules For the Use of Wood in Construction—Visual Classification for Use in Structures of Sawn Softwood and Hardwood—Part 1: Solid Wood. Association Française de Normalisation: La Plaine Saint-Denis, France, 2018.

- NF EN 14081-2+A1; Timber Structures—Strength Graded Structural Timber with Rectangular Cross Section—Part 2: Machine Grading; Additional Requirements for Type Testing. Association Française de Normalisation: La Plaine Saint-Denis, France, 2022.

- Sandberg, K.; Sandin, Y.; Harte, A.; Shotton, E.; Hughes, M.; Ridley-Ellis, D.; Turk, G.; Íñiguez-González, G.; Risse, M.; Cristescu, C. Summary Report InFutUReWood–Innovative Design for the Future–Use and Reuse of Wood (Building) Components; RISE Research Institutes of Sweden: Gothenburg, Sweden, 2022. [Google Scholar] [CrossRef]

- Nasiri, B.; Roy, S.; Hughes, M. Determining the quantity and quality of wood recovered from building demolitions to enable effective allocation. Eur. J. Wood Wood Prod. 2025, 83, 1–13. [Google Scholar] [CrossRef]

- Bodig, J.; Jayne, B.A. Mechanics of Wood and Wood Composites; Krieger Publishing Company: Malabar, FL, USA, 1993. [Google Scholar]

- Bucur, V. Theory of and Experimental Methods for the Acoustic Characterization of Wood. In Acoustics of Wood; Springer: Berlin/Heidelberg, Heidelberg, 2006. [Google Scholar] [CrossRef]

- Attar-Hassan, G. The effect of ageing on the mechanical properties of Eastern white pine. Bull. Assoc. Preserv. Technol. 1976, 8, 64–73. [Google Scholar] [CrossRef]

- Noguchi, T.; Obataya, E.; Ando, K. Effects of ageing on the vibrational properties of akamatsu (Pinus densiflora) wood. In Wood Culture and Science; Japan Wood Research Society: Kyoto, Japan, 2011. [Google Scholar] [CrossRef]

- Nier, J. Experimental Strength Investigations on Old Construction Timber and Derived Findings for Load-Bearing Capacity Assessment; Technische Hochschule Leipzig: Leipzig, Germany, 1994. [Google Scholar]

- Baron, T. Investigations on Undamaged and Fungal-Damaged Softwood Components Using Selected Test Methods. Ph.D. Thesis, Bauhaus-University Weimar, Weimar, Germany, 2009. Available online: https://nbn-resolving.org/urn:nbn:de:bsz:14-qucosa-25069 (accessed on 27 August 2025).

- Wang, S.Y.; Chen, J.H.; Tsai, M.J.; Lin, C.J.; Yang, T.H. Grading of softwood lumber using non-destructive techniques. J. Mater. Process. Technol. 2008, 208, 149–158. [Google Scholar] [CrossRef]

- Faggiano, B.; Grippa, M.R.; Marzo, A.; Mazzolani, F.M. Experimental study for non-destructive mechanical evaluation of ancient chestnut timber. J. Civ. Struct. Health Monit. 2011, 1, 103–112. [Google Scholar] [CrossRef]

- Sandoz, J.-L. Grading and Reliability of Construction Timber, Validation of the Ultrasound Method. Ph.D. Thesis, Laboratoire de construction en bois, École Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, 1990. [Google Scholar]

- Sandoz, J.-L.; Benoit, Y. Timber Grading Machine Using Multivariate Parameters Based on Ultrasonic and Density Measurement; European Cooperation in Science and Technology: Brussels, Belgium, 2007; p. 53. [Google Scholar]

- Görlacher, R. A new method for determining the modulus of elasticity of timber. Holz Als Roh-Und Werkst. 1984, 42, 219–222. [Google Scholar] [CrossRef]

- Brancheriau, L.; Baillères, H. Natural vibration analysis of clear wooden beams: A theoretical review. Wood Sci. Technol. 2002, 36, 347–365. [Google Scholar] [CrossRef]

- Faydi, Y. Classement Pour la Résistance Mécanique du Chêne Par Méthodes Vibratoires et Par Mesure Des Orientations Des Fibres. Ph.D. Thesis, Ecole Nationale Supérieure D’arts et Métiers-ENSAM, Paris, France, 2017. [Google Scholar]

- Sonderegger, W.; Mandallaz, D.; Niemz, P. An investigation of the influence of selected factors on the properties of spruce wood. Wood Sci. Technol. 2008, 42, 281–298. [Google Scholar] [CrossRef]

- Niemz, P. Physics of Wood and Wood Materials; DRW Publishing: Leinfelden-Echterdingen, Germany, 1993; p. 243. [Google Scholar]

- Sandoz, J.L. Moisture content and temperature effect on ultrasound timber grading. Wood. Sci. Technol. 1993, 27, 373–380. [Google Scholar] [CrossRef]

- Unterwieser, H.; Schickhofer, G. Influence of moisture content of wood on sound velocity and dynamic MOE of natural frequency-and ultrasonic runtime measurement. Eur. J. Wood Wood Prod. 2010, 69, 171–181. [Google Scholar] [CrossRef]

- Nocetti, M.; Brunetti, M.; Bacher, M. Effect of moisture content on the flexural properties and dynamic modulus of elasticity of dimension chestnut timber. Eur. J. Wood Wood Prod. 2015, 73, 51–60. [Google Scholar] [CrossRef]

- Fridley, K.J.; Mitchell, J.B.; Hunt, M.O.; Senft, J.F. Effect of 85 years of service on mechanical properties of timber roof members. Part 1: Experimental observations. For. Prod. J. 1996, 46, 72–78. [Google Scholar]

- Deppe, H.-J.; Rühl, H. Evaluation of historical construction timber 1. Density and compression strength: Apparent density and compressive strength. Holz Als Roh-Und Werkst. 1993, 51, 379–383. [Google Scholar] [CrossRef]

- Kollmann, F.; Schmidt, E. Structural disruption and loss of strength of permanently stressed softwood. Holz Als Roh-Und Werkst. 1962, 20, 333–338. [Google Scholar] [CrossRef]

- NF EN 408+A1; Timber Structures—Structural Timber and Glued Laminated Timber—Determination of Some Physical and Mechanical Properties. Association Française de Normalisation: La Plaine Saint-Denis, France, 2012.

- NF EN 13183-1; Moisture Content of a Piece of Sawn Timber–Part 1: Determination by Oven Dry Method. Association Française de Normalisation: La Plaine Saint-Denis, France, 2002.

- NF EN 13183-2; Moisture Content of a Piece of Sawn Timber–Part 2: Estimation by Electrical Resistance Method. Association Française de Normalisation: La Plaine Saint-Denis, France, 2002.

- NF EN 384+A2; Structural Timber—Determination of Characteristic Values of Mechanical Properties and Density. Association Française de Normalisation: La Plaine Saint-Denis, France, 2022.

- NF EN 1309-1; Round and Sawn Timber—Method of Measurement of Dimensions. Part 1: Sawn Timber. Association Française de Normalisation: La Plaine Saint-Denis, France, 1997.

- NF EN 336; Structural Timber—Sizes, Permitted Deviations. Association Française de Normalisation: La Plaine Saint-Denis, France, 2013.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).