Abstract

Food waste (FW) presents a critical issue, representing an environmental liability and a largely untapped resource. Its heterogeneity and low valorization rate among main-stream alternative treatments challenge its integration into economically and environmentally sustainable bioprocesses. We explore biorefineries as a solution that can address the complexity of urban food waste through biological strategies capable of converting food waste into valuable products. Exploring the current landscape of FW biorefineries, this study focused on the interplay between feedstock heterogeneity, pretreatment strategies, microbial dynamics, and integration potential. We propose a framework distinguishing between robust fermentations that can use minimally treated FW and tailored fermentations, which require refined media pretreatment and/or supplementation to yield higher-value compounds. Drawing on recent techno-economic and life cycle assessments, this article evaluates process viability and environmental impacts across multiple scales, reinforcing the need for robust analysis to support decision-making. Real-world initiatives and policy frameworks are analyzed to contextualize technological advances within regulatory and infrastructural realities. By linking practical constraints to biochemical and operational strategies, this work outlines how food waste biorefineries can contribute meaningfully to circular economy goals. Instead of treating FW as an intractable problem, it is seen as a versatile feedstock that demands integration, investment, and adaptive process design.

1. Introduction

Waste generated in the process for food consumption, from field to table, is a global problem of severe environmental and economic consequences. Supply-chain food loss generated in the stages from agricultural to arrival at retail outlets represents 13% of the food globally produced [1,2]. The impact goes beyond just the disposal logistics factor. All resources used in the discarded volume, like energy, used land, water, fertilizers, are also wasted. Then, there is food waste (FW) from consumption. According to the United Nations Environment Programme [3], FW generated in retail, food service and households amounted to 1.05 billion tons/year in 2022, meaning that 19% of food that reaches the consumption stage is then wasted. Estimates are that 8 to 10% of greenhouse gases can be associated with this waste. In Brazil, the FW average generation in households has reached 94 kg/capita/year in recent years [3].

Due to the proportion of this issue, the target 12.3 of the United Nations’ 17 Sustainable Development Goals (SDGs), established in 2015, recommends halving food loss in the supply chain and FW at the consumer level by 2030. However, the latest UNEP report in 2024 indicated that FW is still increasing as the years pass or, at least, the numbers are showing relative stability, as more research sheds light on the real proportion of this issue. Considering that there are unavoidable losses, completely eliminating food waste appears to be an unrealistic goal, and recovering value from it is a necessary step [4].

One way to address this problem is through the developing lens of a circular bioeconomy. Besides generation reduction, this system sees waste as an opportunity to recycle, reuse and repurpose [5]. Waste then becomes re-valued raw material. Food waste biorefineries fall into this category, being a sustainable subject for FW management. Biorefineries integrate bioprocesses in a zero-waste-oriented manner, reframing and upgrading waste into value-added products. The main benefits of bioprocesses are their reduction in energy consumption and dependence on fossil fuels, in an inherently sustainable approach.

There are diverse bioprocesses that can be used in a biorefinery context, such as aerobic decomposition, anaerobic digestion, biodiesel production, fermentation, and microbial electrolysis [6]. For FW management, anaerobic digestion and composting have been the most studied and implemented bioprocesses. Their negative aspects are such things as prolonged execution times and products with low economic value, so there is a need for economically attractive integrated biorefinery models [7,8]. Since FW management is in itself a pressing issue, adding economic value to proposed solutions constitutes a great incentive. This raises the question: which bioprocesses can add value and be better explored using heterogeneous urban food waste as feedstock? Can a food waste biorefinery be technologically, environmentally and also economically sustainable?

Since the concept is still in development, it is necessary to understand what alternatives are available to improve results, such as multifeedstock use, bioprospecting or genetic engineering of microorganisms, and achievement of valuable products as outcomes. Therefore, this review explores the current panorama of food waste biorefineries, with emphasis on the influence of substrate composition and process conditions. Additionally, it addresses both the constraints of scale-up bioprocesses and the economic feasibility of urban food waste biorefineries.

2. Food Waste: What It Is and What Is Done About It

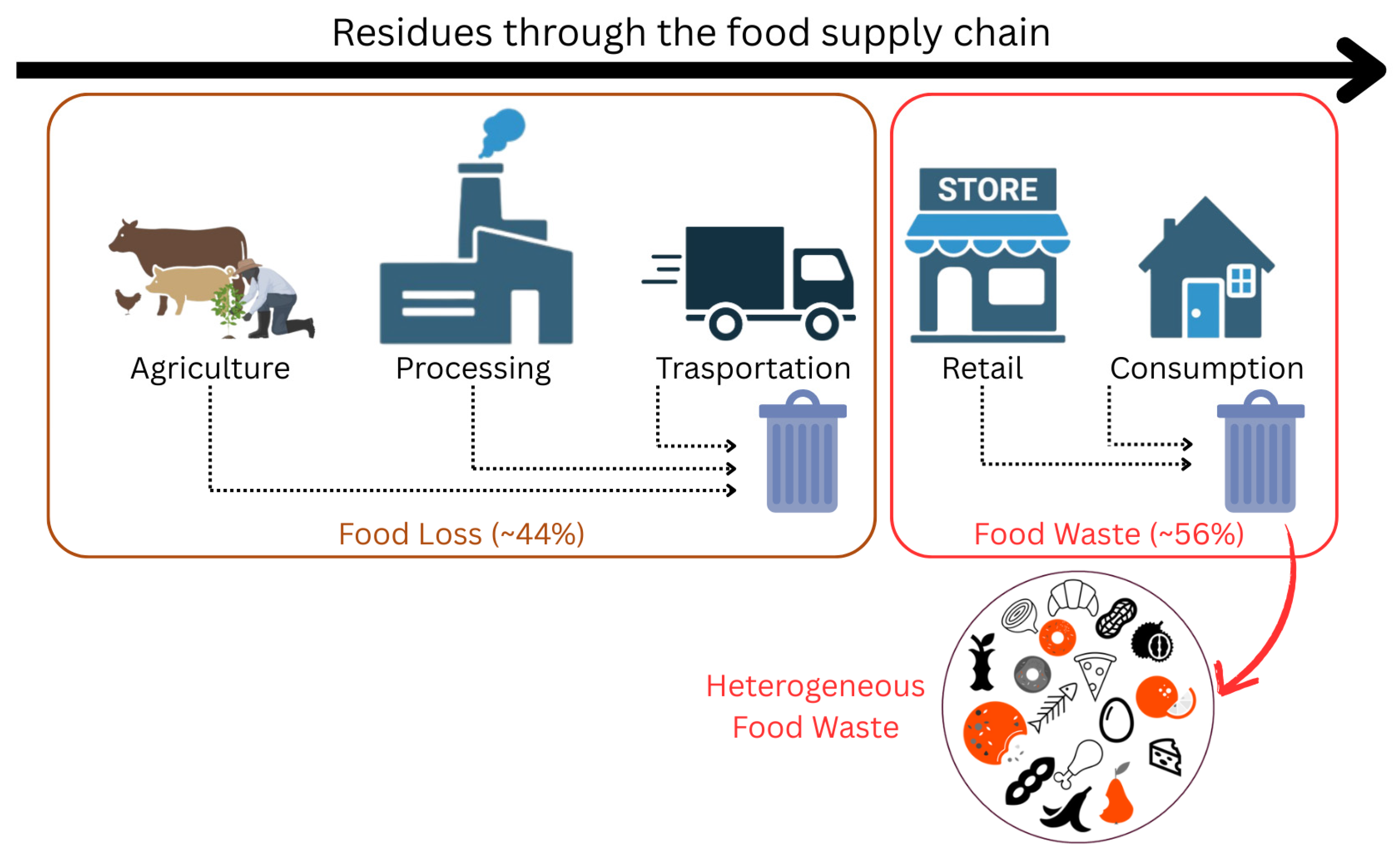

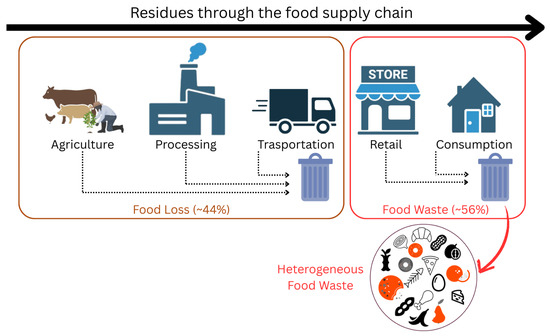

Organic waste is generated across the food supply chain and is intrinsically diverse. Looking on a large scale, the supply chain from start to finish has different types of losses involved. Ref. [3] defines “food loss” as the residue generated from agriculture to transportation and “food waste,” as the residue which is left from retail to end-of-line consumption (Figure 1). Each of these losses is complex in terms of composition and treatment [9,10,11]. However, particular attention should be paid to the consumption-stage food waste. It stands out both because it has a uniquely complex heterogeneous composition and represents more than 50% of the total waste [3]. This is the waste generated in households and food services, from diverse people with diverse tastes and diets.

Figure 1.

The flow of food residue generation.

This kind of FW generated in the consumption stages is generally collected and treated together with Municipal Solid Waste (MSW). There are a lot of challenges in the treatment and management of MSW, including its organic fraction. Suggested waste management hierarchies are used by different institutions such as the European Union and agencies in the United States to define what kind of solutions should be prioritized by order: non-generation, reduction, reuse, recycling, recovery, and environmentally appropriate final disposal of waste. It is important to highlight that the option of environmentally appropriate final disposal applies only to solid waste that, after all treatment and recovery possibilities have been exhausted, presents no other possibility than disposal in a sanitary landfill [12].

Even so, despite prioritizing non-generation and reduction in FW, some losses are inevitable with today’s technology and society culture [8]. For example, materials like fruit peels and bones of meat will not be totally consumed as food, but they have potential for reuse or recycling before the leftovers go for traditional disposal. Despite this potential, the initial challenge falls at the waste collection stage. If the disposal of waste is not conducted separately, segregation of organic waste from inorganic waste can be difficult in the next stages [13]. The next challenge is the already mentioned characteristic heterogeneity of FW, which is an issue that needs to be addressed, since variability of feedstock can heavily impact bioprocesses. For instance, ref. [14] found that the high variability in the biochemical components of food waste can be seen when compared geographically and by food source, projecting that the impact of this variability on production of biofuel can be at a level of 80% to almost 100% in efficiency reduction in the worst scenarios.

Characterization of the average composition of the FW is crucial to understand its variability and, consequently, to explore its full potential [15]. Seasonality and sociodemographic patterns are factors that can impact the volume and composition of food waste, with the majority of waste consistently being composed of major food groups such as bakery, dairy, cereals, vegetables and fruits, and animal protein [16]. This is what makes FW a rich source of important biochemical components such as carbohydrates, lipids, proteins, and vitamins. In Table 1, it is possible to see the large difference in the composition of FW obtained in different studies.

Table 1.

Variation in the biochemical composition of Heterogeneous Food Waste from different sources.

Ref. [18] acknowledges that the variability of FW composition used as feedstock in bioprocesses like anaerobic digestion can lead to unstable results. However, this problem is mitigated by the correct waste characterization and by the establishment of processes with well-defined parameters that can be controlled. In this way, the necessary corrections for effective results can be easily made. Afterwards, ref. [19] proposed that different kinds of FW with known compositions can be blended on the basis of similarity or complementarity to produce substrates that suit specific bioprocesses, such as in bioethanol production.

Regardless of the approach used to prepare the matrix, effective FW treatment does not have a one-size-fits-all solution. Instead, FW should be considered as a dynamic, location-specific resource: a pantry of ingredients that changes with time, geography, and culture. This way, treatments that go beyond disposal and unlock FW real value can be increasingly targeted, as opposed to the traditional go-to disposal methods. The challenges in MSW management have made it easier for governments and waste management companies to justify generic solutions, so food waste often has no planned treatment besides the options that historically have been used for waste: sanitary landfills, incineration, and in the worst case scenario, open dumps [11].

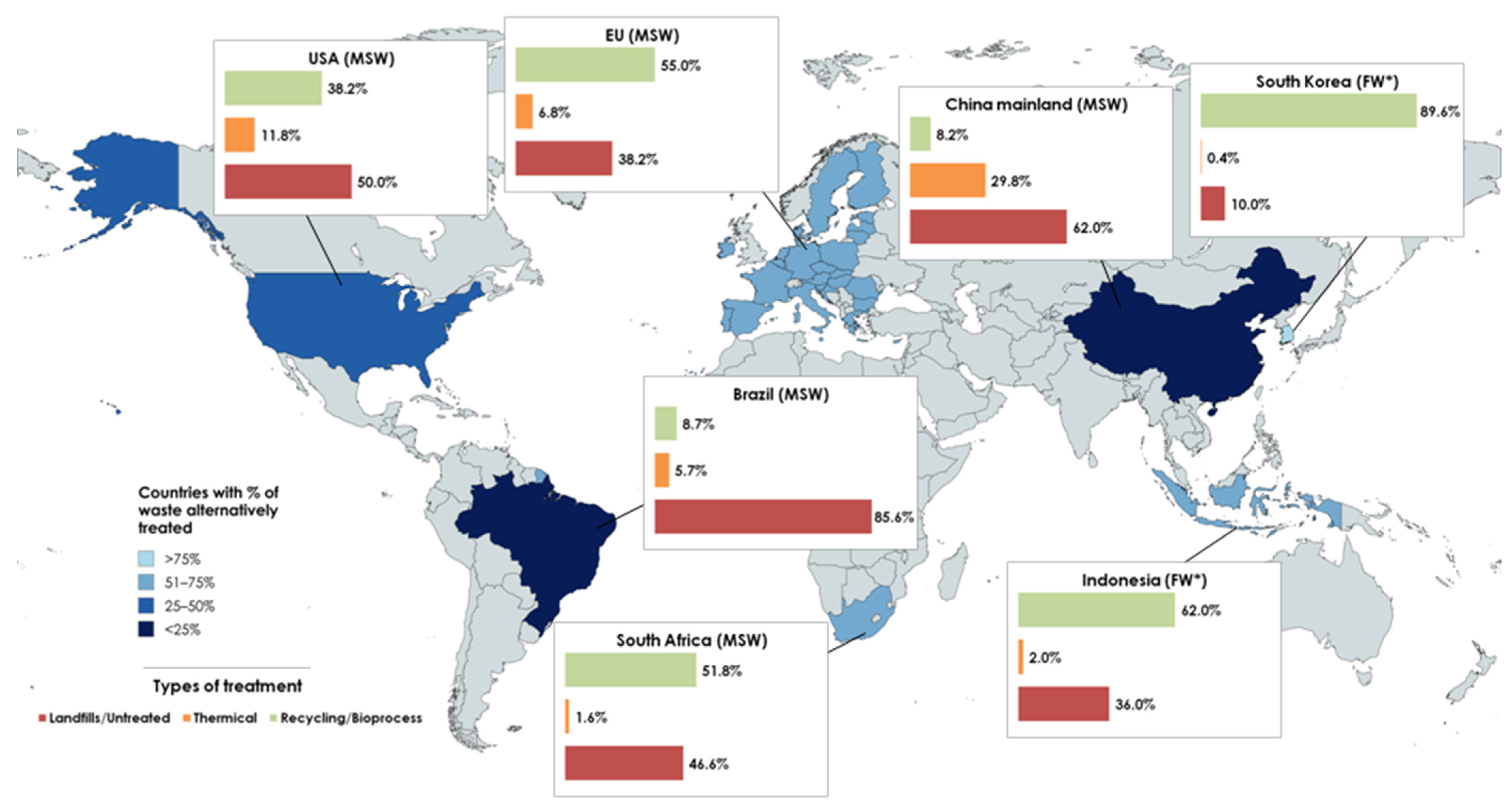

Even when the organic fraction of MSW (OFMSW) is segregated at source, it often ends up not being correctly treated anyway due to logistical, infrastructural, and cultural limitations [20]. Traditional treatments are known to be environmentally damaging options. In landfills, the high moisture and degradable organic content of FW accelerate greenhouse gas emission, with each ton releasing over 2.7 tons of CO2-equivalent. Globally, this practice contributes more than 120 million metric tons of CO2 annually and is responsible for nearly 20% of methane emissions and notable amounts of nitrous oxide, gases 25 and 300× more potent than CO2 respectively, in terms of greenhouse warming potential [8]. Beyond greenhouse gas emissions, FW disposal also entails considerable water and land use burdens. Incineration, although effective in reducing waste mass, produces combustion gases that carry toxic compounds, including persistent organic pollutants and heavy metals, which can contribute to air contamination and pose risks to ecosystems and human health [8]. Landfilling and incineration should currently be the last chosen option for waste management, yet they remain common, despite being discouraged by modern waste hierarchies (Figure 2).

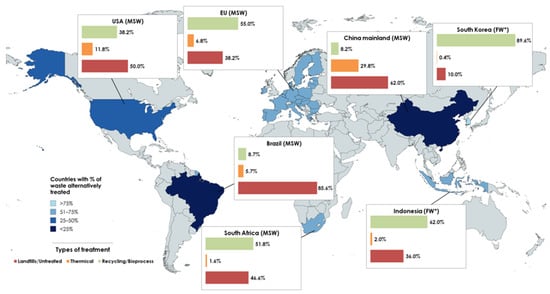

Figure 2.

Municipal Solid Waste (MSW) management across multiple countries. Data from refs. [21,22,23,24,25,26,27,28,29]. * Food Waste (FW) management was used when information was found.

Waste management practices vary widely across countries: Developing nations typically produce less waste per capita, but a high share of this waste is organic, which is ideal for valorization [13]. However, limited infrastructure and informal handling systems hamper effective management. In contrast, developed countries tend to generate more waste per capita. But they benefit from established collection services, advanced treatment technologies, and policy frameworks that support recycling and source separation [13]. Still, they have room for improvement.

Around the world, landfilling remains expressively the most popular form for FW disposal, but there have been attempts at increasing composting and anaerobic digestion participation. Some examples of the world’s contrasting scenario are discussed next. Brazil treats only 9% of MSW via composting, recycling, or combustion, while 34% of the waste could be recycled, and 45% is organic and could be re-valued [21]. In stark contrast, South Korea has introduced a series of substantial initiatives and nowadays recycles 95% of its food waste [22]. Indonesia, which identified FW as a serious problem due to space limitations, is in the middle ground, working towards effective and sustainable solutions, with 62% of its food waste being treated by bioprocesses [23]. China has implemented waste reduction policies [24], but still sends 60% of MSW to landfills [25], and the United States continues to landfill roughly half of its municipal waste despite advanced infrastructure [26]. South Africa, with recent advances in recent years to increase recycling, also shows a more balanced distribution, but still about 46% of its municipal waste is landfilled [27].

Public policies of the European Union (EU) prioritize preventing waste and encouraging the re-use of products whenever possible. When these options are not feasible, they favor modern waste management practices [28]. And although they have strong policies such as the 2008 Waste Framework Directive and the European Green Deal, the reality is an amalgam of mixed results among the countries. Recycling rates (including composting and other bioprocesses) differ significantly across countries. In 2022, while some countries reported recycling at least 50% of their municipal waste, other countries had rates below 20%. So, while the EU aims to reduce the overall amount of municipal waste sent to landfill to 10% or less, the current figure remains at 30% [29].

The above-mentioned international experiences show that progress depends on coherent public policies, infrastructure investment, and community engagement. The 2024 Yale Environmental Performance Index (EPI) reinforces that the global landscape of waste management remains uneven. The Solid Waste score, which is included as an issue category in the EPI, ranks countries based on MSW generation per capita, controlled waste treatment, and material recovery efficiency [30]. Although countries like Singapore, Japan, and Sweden stand out for high performance in recycling and energy recovery, many others fall behind either due to policy gaps, infrastructure limitations, or both.

The need for a global effort to invest in sustainable alternatives for waste management is pressing. Integrated processes rise as cost-effective and attractive options, which include integrated bioprocesses, such as those in biorefineries. There are challenges to be addressed so that food waste can be a reliable feedstock source, such as the bioavailability of the biochemical compounds that make up FW, but even so, this residue becomes an excellent low-cost candidate for biomass.

3. How Can Bioprocesses Contribute to Food Waste Management?

Biorefineries using residues or biomass with no food chain competition as feedstock have been idealized, designed, and discussed for years. Some pilot plants and bigger facilities have been implemented, with a limited range of products and productivity, primarily for energy production [31,32]. This can be attributed in part to the Technological Readiness Level (TRL). The TRL is a scale to measure the maturity of a technology as it progresses through the research, development, validation, and commercialization stages, going from concept (TRL 1: scientific principle observed, basic research) to real-world use (TRL 9: system proven in mission conditions, fully operational system). In the case of bioprocesses, they can range from fermentations that are still in the laboratory validation and prototyping stages, to those like windrow composting, which are ready for large-scale production and have been tried and tested to such an extent that variables are known and controllable.

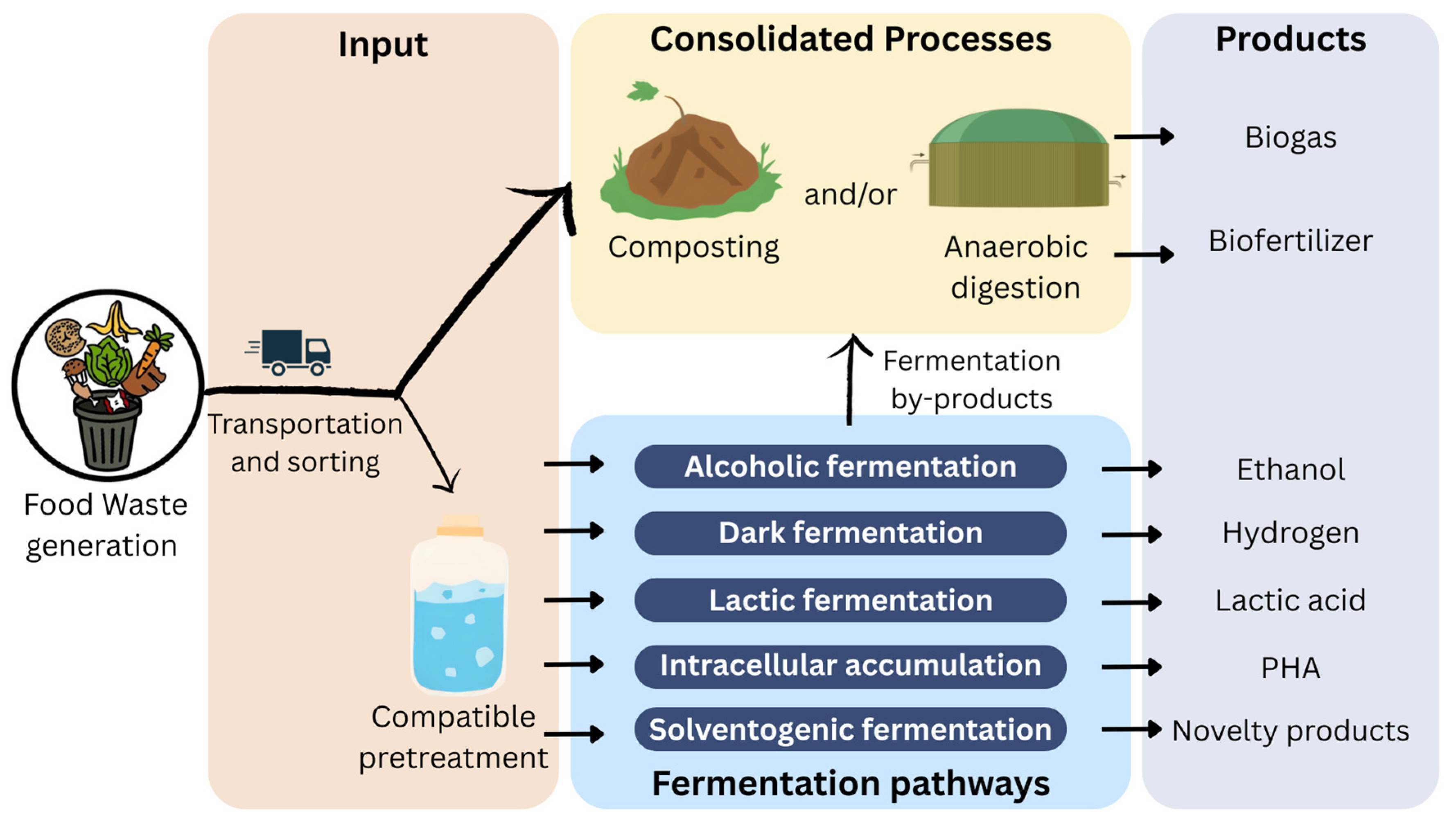

Regarding specifically FW biorefineries, the possible processes that apply also have varying TRL. Nowadays, composting to produce fertilizer and biodigestion to produce biogas from food waste are consolidated processes with high TRL and adaptability from small to large scale, and as important, they are well established as alternatives for food waste treatment. However, they have a long operating time and products with low economic value [8,33,34]. Thus, an option for FW biorefineries is to add value by integrating those established methods with the production of higher-value chemicals, thereby achieving better economic results through an integrated approach. It is important to say that biodigestion is a process that has untapped potential for other products besides biogas, such as biomaterials, biochemicals, and biofuels, but those flows of production are still being further studied [34]. Fermentation is a possibility that can reduce processing time to generate products that have greater economic value, particularly high-value platform molecules.

- Food Waste as Feedstock for Biofuels and Biochemicals

Food waste fermentation has been explored as a promising route to obtain valuable bioproducts such as organic acids, alcohols, hydrogen, and biopolymers. Since FW is rich in nutrients embedded in complex macromolecules, a pretreatment step such as hydrolysis is generally required to increase nutrient bioavailability [35]. Hydrolysis can be performed using thermal, chemical, enzymatic, or a combination of these methods [36,37].

Thermal hydrolysis can enhance processes like anaerobic digestion, exemplified by the Billund Biorefinery, which increased biogas production by 50% via high-pressure thermal pretreatment [38,39]. Chemical methods use acids, bases, or solvents [40]. However, enzymatic hydrolysis is more selective, converting polysaccharides (starch and cellulose) into sugars using enzymes such as amylases and cellulases. Moreover, proteases can also be used to release peptides and amino acids [35,41]. Combining thermo-chemical and enzymatic steps is also a viable strategy. Trade-offs exist: the harsher conditions of thermo-chemical approaches may degrade target molecules or create inhibitors, in addition to generating chemical residue, while the use of enzymes may increase costs unless there are alternative solutions like production in situ [36,40,42,43].

In the hydrolysis stage, value-added compounds such as amino acids, fatty acids, sugars, carotenoids, and phenolic acids may be recovered as products [44,45]. However, to maximize the revenue of the biorefinery, hydrolysates are often directed to fermentation processes capable of producing more complex and valuable products. The composition of the hydrolysate becomes critical at this stage. Some high-value bioproducts require microorganisms with complex nutritional needs, such as production of specialty alcohols. For example, there is 1,3-propanediol and butanol, which can depend on media with specific amino acids, vitamins, or cofactors not always bioavailable in untreated FW [46,47]. For these cases, the hydrolysis step must be tailored or supplemented to ensure sufficient availability of required nutrients. In contrast, native strains such as Clostridium spp. and Lactobacillus spp., as well as more robust strains such as Saccharomyces cerevisiae, can thrive in nutrient-variable, less-treated environments [48,49,50].

Fermentation itself is a highly versatile process, supported by a wide array of microorganisms capable of converting biomass into target compounds, but additional challenges in FW fermentation include variable yields, low titers that hinder downstream separation, and high operational costs [37]. Downstream processing, in particular, is frequently the most limiting and expensive phase. Even when fermentation is successful, purifying the target compound from complex media may account for a substantial portion of total costs [43]. Thus, it is crucial to choose fermentation pathways that yield products with sufficient value to justify separation.

Co-substrate supplementation is a strategy used to improve fermentation performance and diversify product profiles. Among the options for FW fermentation, crude glycerol has gained attention as a cost-effective and reduced carbon source that enhances microbial redox balance. In Lactobacillus spp., glycerol supplementation can lead not only to increased lactic acid yields but also to the formation of higher-value compounds, depending on the strain and fermentation conditions [46]. This expands the role of food-waste-associated bacteria from acidifiers to producers of higher-value chemicals, broadening their potential in bioprocessing.

The biotechnological valorization of FW can yield a wide range of biofuels and biochemicals, many of which have growing market relevance and environmental value. The search for higher value products, satisfactory cost–benefit, and increasingly greener processes is continuous [51]. The design of fermentation systems for food waste valorization must consider not only the choice of microorganism, but also the compatibility between the pretreatment method and the type of product desired. While robust strains can generate simpler compounds from minimally treated substrates, more complex or high-value products often require tailored hydrolysates and controlled conditions. In the following sections, we explore how the nature of target bioproducts affects the level of pretreatment required and the overall biorefinery strategy of existing literature (Table 2) and extrapolate possibilities of novelty pathways.

Table 2.

Different products obtained from Food Waste (FW) fermentation.

3.1. Resilient Fermentations: Bioproducts from Simplified Streams

As stated, certain fermentation processes can be carried out using a more straightforward pretreatment of food waste. Those processes, such as ethanol, hydrogen, and lactic acid production, rely on robust or mixed microbial cultures that do not need supplementation when compared to other nutritionally demanding cultures. These routes should offer more accessible and cost-effective options for decentralized or early-stage biorefinery systems.

Ethanol is the most widely used biofuel in the world. The International Energy Agency [63] estimated that ethanol production reached 187 billion liters in 2024 and is expected to reach 280 billion liters in 2030. Ethanol production is achieved mainly with robust yeasts such as S. cerevisiae, which biosynthesize fermentable sugars into ethanol via the glycolytic pathway. This bioprocess is highly tolerant to variability of fermentation conditions (temperature, pH, and osmotic pressure) and also related to nutrient availability present in diverse substrates such as sugarcane juice, molasses, corn, and food waste [50,64]. In this scenario, a noteworthy parameter is the C/N (carbon-to-nitrogen) ratio, as it influences both yeast growth and ethanol yield. Higher C/N ratios are often optimal, ensuring sufficient nitrogen for biomass formation while avoiding overproliferation that can divert metabolic flux away from ethanol synthesis. Too little nitrogen hinders yeast growth and reduces ethanol production, but excess nitrogen can inhibit ethanol production not by direct toxicity, but by stimulating excessive biomass formation and repressing fermentative metabolism [65,66].

Sugar availability remains the central focus in ethanol fermentation design, as it directly drives productivity. The main producers of this biofuel are Brazil and the USA, which use carbohydrate-rich sugarcane and corn, respectively, as the main biomass in their processes. Despite the high productivity, using these biomasses has negative aspects, such as a possible competition over land use for food and energy. In addition, using food crops, such as corn, generates concerns about rising prices, which can lead to food insecurity [67]. The use of waste, such as FW, is an alternative to the production of biofuels.

The main carbohydrate in FW is starch, which becomes the focus of hydrolysis before fermentation. This polysaccharide is formed by two biopolymers: amylose and amylopectin, both with glucose as the forming monomer [68] Despite being practically an amorphous solid, some fractions of amylopectin may present a certain degree of crystallinity, which can hinder hydrolysis [69]. In Table 2, we show different studies that carried out the production of ethanol from food waste, using different routes. It was possible to observe a yield of 0.43 g of ethanol. g/dry FW, with hydrolysis and fermentation in separate processes [56]. The use of SSF (simultaneous saccharification and fermentation) processes has also been studied for the production of ethanol from FW. Ethanol removal by vacuum pressure evaporation was used, increasing the yield from 0.33 to 0.36 g/g [57].

Chemical hydrolysis can also be used. As an amorphous solid, starch is more susceptible to chemical attack than cellulose, for example. The yields, however, are still lower than those from the enzymatic process. A yield of 0.20 g/g with fermentation with S. cerevisiae after acid hydrolysis with H2SO4 (1.5% v/v), 15% solids (w/v), 127 °C for 1 h was reported by [50]. Although yeasts, such as S. cerevisiae, are the most common fermentative microorganisms, the literature deals with fermentations with bacteria. A one-pot CRUDE (Conversion on Raw and Untreated Disposal into Ethanol) process was used for FW fermentation, without prior hydrolysis, using thermophilic bacteria (Thermoanaerobacter mathranii A3). After 13 days of fermentation, with 5% solids, 65 °C, and pH 6.8, a yield of 0.17 g/g was obtained [58]. Enzymatic hydrolysis has high efficiency and greater selectivity, but it is the costliest step in the ethanol production phase [70]. To reduce costs, some authors propose the use of genetically modified fungi and yeasts for the on-site production of enzymes, with subsequent fermentation by the same microorganism, a process called Consolidated Bioprocessing [71].

Meanwhile, hydrogen fermentation via dark fermentation routes may combine with simpler pretreatment protocols. Food waste’s high content of degradable organic matter makes it ideal for hydrogenogenic microbial consortia, which tend to include native strains such as Clostridium spp. The use of hydrogen as a clean and carbon-neutral energy carrier is gaining renewed attention, particularly in the context of global decarbonization efforts. Its combustion produces only water, without emitting CO2, making it a compelling alternative to fossil-based fuels. Currently, mainstream production methods include steam methane reforming, water electrolysis, and hydrocarbon reforming. However, these approaches are either energy-intensive or heavily reliant on fossil inputs, limiting their sustainability [72]. In contrast, dark fermentation from biomass stands out as a biologically feasible and environmentally friendly option for hydrogen production [73]. Unlike conventional anaerobic digestion, which prioritizes methane production and often suppresses hydrogen-producing pathways, dark fermentation specifically targets the microbial conversion of biomass into hydrogen via hydrogenogenic bacteria [74].

Despite the use of mixed microbial communities and their compatibility with organic-rich substrates, dark fermentation faces critical metabolic bottlenecks that can limit yield. The actual yield often falls short of the theoretical maximum (4 mol H2/mol glucose), due to competing microbial pathways that divert carbon and electrons toward other products like acetate and butyrate [75]. Moreover, hydrogen-consuming microbes such as methanogens can significantly reduce net yields unless selectively inhibited. Strategies to overcome these limitations include substrate conditioning, inoculum pretreatment, and use of genetically enriched consortia [76]. Also, emerging process intensification techniques, such as membrane-integrated reactors, continuously remove H2 and VFAs, stabilize acids, and reduce cell washout.

Key factors influencing hydrogen yields produced from food waste include the inoculum source, substrate-to-inoculum ratio, and pretreatment strategy, as can be seen in Table 2. Ref. [59] proposed a bioaugmentation strategy based on a lactate-driven hydrogen-producing pathway. Using a microbial consortium composed of Clostridium and Lactobacillus strains, they achieved a yield of 76.7 mL H2/gVS from non-sterile food waste. In this setup, Clostridium butyricum was the primary contributor to hydrogen production, and the natural presence of Enterobacter species was associated with lower yields. To avoid reliance on pure cultures, other strategies are being developed to selectively enrich hydrogenogenic bacteria from mixed inocula such as anaerobic digestion sludge. One such approach demonstrated that using waste frying oil as a selective stressor inhibited methanogens and enhanced hydrogen production, reaching 71.34 mL H2/gVS, indicating its potential as a cost-effective possibility [60].

The main barriers to broader application include high capital costs, intensive energy demands and costly chemical inputs. To be viable, the energy gains from hydrogen production must outweigh pretreatment energy losses. For this, two-stage anaerobic reactor systems (with the second stage favoring methanogenesis), can help improve overall energy recovery and process balance. Ref. [74] demonstrated through an environmental impact study that this kind of process significantly reduces Global Warming Potential compared to established methods like conventional anaerobic digestion and incineration. The use of electricity and sulfuric acid, however, remained critical contributors to environmental burdens, emphasizing the need for process optimization. Coupling dark fermentation with other waste valorization strategies, such as photofermentation or integration into existing anaerobic digestion facilities, could increase total hydrogen and energy yields, contribute to better effluent quality, reduce environmental impacts, and improve economic viability through a multi-stage treatment approach. All of this aligns with circular biorefinery goals.

Another opportunity to explore is the native acidogenic bacteria found in FW, such as Lactobacillus spp. The lactic acid (LA) market reached 1.7 million tons globally in 2023 and is expected to grow at 10% annually, driven by its versatility. It is emerging as an alternative sustainable practice, since it is the precursor of polylactic acid, a biodegradable polymer [77]. Most LA production is attributed to fermentation rather than chemical synthesis. This fermentation is usually performed with species of Lactic Acid Bacteria (LAB). LAB are a metabolically diverse group known for their adaptability across environments [78] that produce LA as a result of the glycolytic pathway.

To simplify the process, large-scale LA production commonly uses first-generation biomass like food-grade sugars due to their purity and ease of processing. On the other hand, the use of a different biomass like FW is more sustainable and has the potential to reduce cost [79,80]. In the context of mixed FW feedstock, associated with different strains of bacteria that include engineered microorganisms, LA was obtained in different studies with titers of 28–157 g/L and yield of 0.1–0.46 g/g on a laboratory scale [52,53,54,55]. Those ranges are influenced by waste variability, strain metabolism and process parameters such as pretreatment and process flow, as can be seen in Table 2.

It should be noted that downstream recovery of LA is a critical bottleneck, often representing up to 50% of total production costs [8]. There are options to improve profit, such as using lactic acid for intermediate to higher-value products such as bioplastic. In these cases, while LA production is compatible with food waste-based fermentations, especially when using robust strains, certain high-purity applications may require more precise control of nutrient levels and substrate composition. Here, the line between resilient and tailored fermentations begins to blur. These more demanding setups, including those aimed at polymer-grade LA or use in biomedical materials, are addressed in Section 3.2, where essential specific media formulations and tightly regulated fermentation conditions are discussed.

Still, techno-economic assessments suggest that food waste–based production solely from lactic acid can be financially viable. Scalability simulation of a process from raw material to purification using filtration and solvent extraction shows that a biorefinery of FW with LA as product has a payback period of only five years and annual net profits of approximately US$20 million [53]. The production of LA from FW is a promising route within biorefineries due to its wide market applicability and alignment with sustainability goals. The development of robust microbial consortia, improved pretreatment strategies, and cost-effective purification techniques will be key to its broader implementation at an industrial scale.

These examples illustrate the viability of producing key bioproducts from food waste under conditions of moderate or minimal pretreatment. Their compatibility with robust microbial systems and scalable designs makes them strong candidates for integration into sustainable and flexible biorefinery models.

3.2. Tailored Fermentations: Unlocking Complex Products

While robust or mixed microbial strains can convert minimally treated food waste into simpler bioproducts, more complex and high-value compounds often require a tailored fermentation approach. These processes typically rely on microorganisms with specific metabolic requirements that only thrive under controlled nutritional and environmental conditions. In such cases, hydrolysates focused on sugar bioavailability may be insufficient; instead, a more refined pretreatment or the addition of supplements such as nitrogen sources, amino acids, vitamins, or reduced carbon sources becomes essential.

Bioplastics are a key example of this category. By definition, they are polymers manufactured from biomass, either by direct extraction or by biomass fermentation [81]. Among them, biopolymers such as polyhydroxyalkanoate (PHA) can be produced by microorganisms. PHAs are intracellular carbon storage polymers synthesized by various bacteria like Pseudomonas spp. when exposed to certain types of stress. Excess carbon coupled with nutrient limitation (like nitrogen or phosphorus) redirects cellular carbon flux from biomass formation into polymer storage [82]. These dynamics underscore the need for tailored feed compositions (carbon source level and C/N or C/P ratio) to maximize PHA yields.

PHA production from FW has attracted growing interest, as can be seen in Table 2, due to its biodegradability, renewable origin, and mechanical properties comparable to petroleum-based plastics. Since food waste contains carbohydrates, lipids, proteins, and micronutrients, it presents itself as a viable substrate for PHA-producing fermentations [83]. However, its inherent variability often necessitates process adaptation or co-feeding strategies.

For instance, ref. [33] produced PHA on a pilot scale (100 L) using fresh OFMSW and mixed microbial cultures, achieving 33.2 g PHA/kg of OFMSW. With PHA market values ranging from $2600 to $5800 per ton, this process demonstrated clear economic potential. Ref. [62] proposed an integrated approach of PHA production in an OFMSW biorefinery that also produces biogas via anaerobic digestion. The use of mixed microbial cultures instead of sterile conditions was asserted to enable an upgrade of an existing conventional single-stage anaerobic digestion process to include PHA production which would have a payback time of less than two years if the PHA were sold at the minimum value of 0.90 €/kg.

Ref. [61] structured and operated for 6 months an urban biorefinery technology chain on a pilot scale with a TRL 5 using multifeedstock (OFMSW and biological sludge from wastewater treatment) to produce biogas and PHA from mixed microbial culture. They obtained a yield of 76 g PHA/kg of volatile solids, and the biorefinery showed a higher revenue than only with biogas production, given the appropriate restrictions of the study. Besides that, they also conducted a social acceptance survey to understand the acceptability of materials coming from heterogeneous organic waste, since not much is known about consumer acceptance of bio-based products. They found that the development of quality standards is a prerequisite to increase the confidence of market operators, social acceptance and to fill regulatory gaps based on adequate standards, especially when it came to products made of plastic that had more direct contact with people or food.

The valorization of FW into bioplastics aligns with circular economy principles. And also, it addresses growing concerns over plastic pollution. However, successful implementation at scale will depend on further optimization of production chains, development of quality standards, and consumer education to ensure acceptance of waste-derived materials.

Beyond polymers, there are novel examples of tailored fermentation of FW that have not yet been extensively explored. These involve the production of platform chemicals such as specialty alcohols, like 1,3-propanediol (1,3-PDO) and butanol, or different organic acids such as succinic and propionic acid [46,47,84]. Among those, 1,3-PDO production stands out as a match for the heterogeneous characteristics of kitchen food waste, and we will delve deeper into the tailored necessities of this fermentation.

Bioproduction for commercialization of 1,3-PDO has been carried out mainly using corn glucose, with a genetically modified strain of Escherichia coli. However, there are bacteria that naturally produce 1,3-PDO from glycerol supplementation, such as Klebsiella spp., Clostridium spp. and Lactobacillus spp. [85]. Lentilactobacillus diolivorans is a strain that has shown promising yields when fermenting agro-industrial residues and food waste. Their metabolism is highly demanding, requiring a carbon source, glycerol supplementation and elevated levels of available nitrogen and cofactors such as vitamin B12 [46,86,87]. Food waste, being naturally rich in proteins and micronutrients, offers a promising base substrate, but careful process design of pretreatment is needed to optimize the use of the nutrients available and avoid expensive supplementation.

As with other complex bioproducts, 1,3-PDO production from FW faces challenges in scalability, especially in terms of downstream recovery and purification, which impact overall process economics. But expanding to multi-product biorefineries that include compounds like 1,3-PDO could unlock greater economic resilience if pretreatment, media optimization, and recovery bottlenecks could be addressed.

In addition to the production of entirely new compounds, tailored fermentation strategies can also enhance the quality and market relevance of more conventional bioproducts. For instance, while lactic acid can be produced in robust systems, the generation of high-purity or polymer-grade lactic acid especially for applications in food packaging or medical materials often requires refined substrates, tight pH control, and supplementation with nutrients or cofactors to meet microbial demands [8,55,88].

In sum, tailored fermentation strategies enable the transformation of food waste into high-value compounds. While these processes demand greater control over media composition and microbial physiology, often involving engineered or selectively enriched strains, they offer a powerful route to diversify biorefinery outputs and improve economic feasibility when integrated with simpler, more robust pathways.

4. Then, Are Integrated Food Waste Biorefineries Viable?

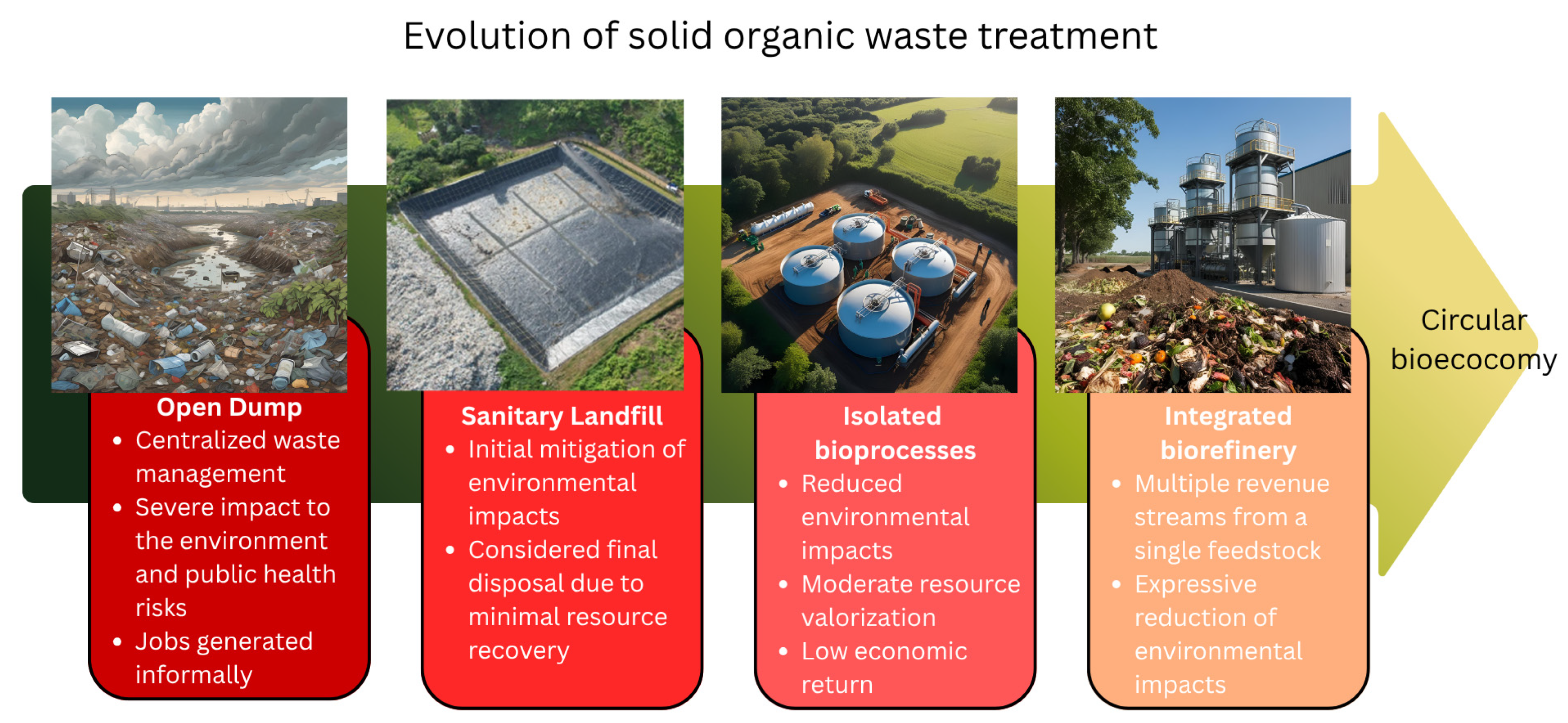

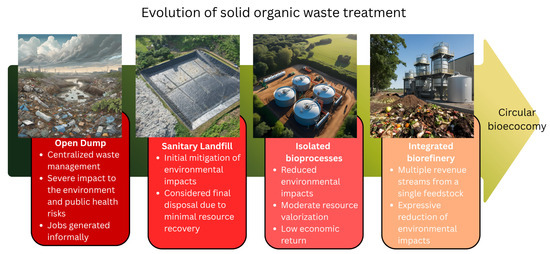

Many studies have shown the benefits and products of bioprocesses using food waste in an isolated way. Increasingly, the need to really integrate them in a holistic approach is being addressed [35,84]. This comes from the need to reach zero waste targets, working towards a truly circular bioeconomy where every part of waste reenters the value chain. This approach seeks to offer higher technical-economic appeal to the sustainable use of residues as raw material, proposing an alternative to a fossil fuel-based economy. The environmental benefits of a greener economy also come into play, in reducing greenhouse gas emissions, conserving natural resources, and mitigating pollution (Figure 3).

Figure 3.

Benefits of greener treatments for the Organic Fraction of Municipal Solid Waste.

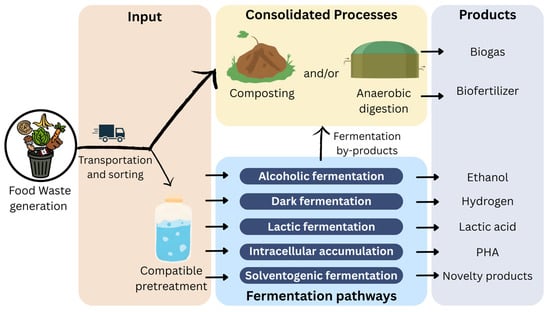

However, ref. [84] suggests that the lack of studies that report the numbers of techno-economic viability and environmental impact of bioprocesses with low TRL is a challenge towards this integrated approach. Further studies that will allow higher technological maturity for these processes are very necessary, as well as studies that show economic feasibility on a large scale. The majority of studies focus mainly on anaerobic digestion as an immediate alternative to FW management, due to its high TRL and feasibility at small and large scale. However, as shown in this review, other processes like well-designed fermentations have a high probability of return due to production of value-added composts, and should be integrated in FW biorefineries proposals (Figure 4).

Figure 4.

Proposal for integrated urban food waste biorefineries.

For example, in the study carried out by [7], a food waste biorefinery pilot plant was designed and studied. Using an integrated approach, they developed as the main sustainable options for FW treatment the production of biodiesel, biogas and organic compost, which already showed significant annual savings compared to disposal in a landfill. Nonetheless, the developers reported that the possibility of including the production of value-added chemicals in the integrated approach could increase the plant revenue.

The URBIOFIN biorefinery in Spain was an example of a multi-output system treating OFMSW. The URBIOFIN project (2017–2022), funded under the EU Horizon 2020 program, aimed to demonstrate the techno-economic and environmental viability of converting waste into valuable bioproducts through an integrated urban biorefinery [89]. While the model helped clarify what is technically feasible in lab, both on a pilot and semi-industrial scale, to achieve competitive bioethanol, PHA, bioethylene, and solid and liquid fertilizer prices, the process also exposed existing gaps. Achieving results on a full industrial scale is still a challenge, and advancement in the field will only come alongside strong legislation and a shift in the global market towards searching for a greener production.

To encourage decision-making and public policies, it is necessary to evaluate the gains of these alternative treatments. Methodologies like Techno-Economic Assessment (TEA) and Life Cycle Assessment (LCA) help test the viability of proposed models.

4.1. Techno-Economic Assessment

TEA is a structured methodology used to evaluate the technical performance and economic viability of processes, technologies, and full-scale production systems. In biorefinery contexts, TEA plays a role in identifying whether a process can be scaled beyond the lab or pilot stage while maintaining financial sustainability. In the context of food waste valorization, a TEA must account not only for capital and operating costs, but also for variables like feedstock variability, preprocessing needs, process integration, and downstream product recovery [53,62,90]. The boundaries of the cited TEA studies, in a general approach, follow the process flow. Starting at raw food waste arrival in the biorefinery plant and going until product recovery in the downstream flow. The studies also include pretreatment, bioprocess units as applicable, the utilities used in the plant, and revenue generated from the sales of products and food waste treatment service fee. Then, it is possible to assert the profitability of the designed plant, as well as the payback time.

But there are not a lot of economic analysis studies conducted on FW biorefineries with a more complex setup, since further development of TRL is necessary [91]. When talking about single processes or simpler multi-processes, anaerobic digestion appears strongly in the spotlight. Other single processes have a sparse literature that address techno-economic assessments with direct use of urban food waste. Ethanol production appears as an option with promising studies that show competitive costs [92]. When comparing the existing data, it appears that some factors that influence economic success are the market value of the product, scale of the biorefinery, and methods chosen. That is to say, the biorefinery products must be chosen carefully, and higher-value products can tip the scales towards profit [91].

Given this, optimal energy use can be better achieved with an integrated approach rather than a single process, and producing chemicals can be 10 times more profitable than using FW only for electricity or biofuel generation. Integrating production of higher-value products to existing sites tends to increase economic profitability, such as adding lactic acid or PHA production to an existing biodigestion plant [62] or integrating it with biofuel production [90]. Moreover, the most promising biorefinery approach can be to utilize diverse feedstocks, including agro-industrial waste and sewage, while generating multiple products [6].

Additionally, given that some processes will only have payback once a minimum volume is produced monthly, the waste required must be generated in sufficient quantities close to the biorefinery, considering the expense of transporting feedstock. Economies of scale significantly influence profitability of biorefineries, as larger centralized plants tend to yield better financial metrics. But then, they also increase logistical challenges [93].

4.2. Life Cycle Assessment

LCA has gained prominence as a tool capable of providing a quantitative analysis of potential environmental impacts. According to [94], the strength of LCA is that it enables a broad, consistent and transparent view of process flows in waste management systems. The four main objectives of LCA studies aimed at evaluating biorefineries from food waste are (a) Compare performance between technologies to achieve a specific product, (b) Compare technologies for the use of a specific waste, (c) Evaluate a technological pathway and its respective critical points, and (d) Assess the impacts on the manufacturing of the main product, with waste treatment included in the analysis boundaries [95].

The functional unit and boundaries of the system analyzed in the LCA depend on the type of study conducted. Studies in category ‘a’, for example, use the quantity produced of the specific product under analysis as the functional unit. In this case, the boundaries are usually limited to the valorization process and employ the ‘zero-burden assumption’, i.e., the environmental impact of producing the material that originated the waste is not considered. In category ‘b’ studies, on the other hand, credits for the substitution of primary materials avoided by waste processing are generally included [95]. According to [96], 65% of biorefinery studies that used residual feedstock employed the cradle-to-gate approach, i.e., the scope includes everything from waste generation to the production of the biorefinery’s final products. Among the impact categories assessed in LCA studies of biorefineries, the most common is global warming potential (GWP), which is present in 97% of the studies [96].

Most of the published works regarding food residue focus mainly on homogeneous residues, originating from agricultural and industrial processes. Among those that use OFMSW, which includes FW, there is a tendency for more positive results for the production of chemical products to the detriment of energy generation [97]. In the study by [98], regarding the climate change category, the generation of biomethane combined with the production of microbial protein obtained superior results to cogeneration from biogas. Another interesting scenario was the production of biomethane linked to the production of lactic acid.

A similar conclusion was reached by [99]: the scenario evaluated with biodiesel and biomethane production was the one with the best environmental performance, 84% higher than the reference scenario, with only electricity production from biogas generated in an anaerobic digester. The production of ethanol from FW did not prove to be advantageous, mainly due to the saccharification and distillation processes. Table 3 presents some studies that compare technologies for food waste processing.

Table 3.

Results from Life Cycle Assessment studies on alternative treatments to Food Waste.

Since energy and material consumption directly affect processes, they can limit the environmental benefits obtained by replacing fossil-based chemicals with bioproducts [101]. For example, when using acetone in the pre-treatment of FW, ref. [102] were unable to offset the environmental impact related to the production of this input with the use of the ethanol generated. Therefore, it is essential that future studies seek to increase efficiency when using chemicals and enzymes in biorefineries and aim to make these plants energy independent, generating electricity on site and using residual heat.

Finally, segregation and optimization of waste collection and transportation before arrival at the biorefinery must be emphasized. The energy consumed to carry out manual or mechanical separation of waste can compromise the environmental sustainability of the system, which highlights the importance of correct separation at the generating source. Furthermore, emissions related to fossil fuels consumed in transport vehicles can also have a significant impact, especially in developing countries, where trucks and road infrastructure are precarious, so alternatives that decentralize waste treatment should be considered.

5. Conclusions and Future Directions

Taken together, the challenges and opportunities outlined in this review point toward a common thread: Food waste represents one of the most abundant and underutilized organic resources globally. It can be used as feedstock for the production of diverse materials, but attention must be given to emerging bioprocesses that, while still at low TRLs, show strong potential for high-value integration. Organic acids, hydrogen, alcohols, and biopolymers each offer unique technical pathways and market opportunities, and there are still novel pathways in food waste fermentation to be explored.

These processes must mature enough to allow more robust evaluation of their economic and environmental impacts. Challenges such as substrate heterogeneity, process optimization, downstream recovery, and microbial performance still limit large-scale implementation. Their success depends on efforts to simplify and minimize chemical inputs, reduce costs, and ensure compatibility with real-world feedstocks, which can be optimized in integrated approaches. As waste streams vary by region and season, multifeedstock strategies may become essential to designing flexible and resilient systems.

Also, for food waste biorefineries to function effectively, feedstock logistics must be clearly defined. Collection, transport, and separation require not only infrastructure but also coordination across municipal systems, particularly when dealing with heterogeneous and decentralized waste streams. A robust MSW management plan becomes the backbone of any scalable biorefinery. The success of such systems depends on effective public policies, infrastructure investments, and social engagement. Countries with well-defined regulations and citizen participation like South Korea and EU members have demonstrated significant progress, while developing nations face systemic barriers that require targeted support.

Ultimately, food waste is not just a burden to manage; it is a material full of untapped value. To unlock this value, the field must move beyond isolated optimizations and toward integrated solutions. Needed, besides innovation in the lab is alignment across policy, logistics, and investment. Food waste is waiting for the right lens to bring it to focus and resources to sharpen the view.

Author Contributions

Conceptualization, S.B.d.S. and R.B.d.S.; methodology, S.B.d.S. and R.B.d.S.; investigation, S.B.d.S.; resources, A.A.A., R.B.d.S. and E.D.D.; data curation, S.B.d.S. and R.B.d.S.; writing—original draft preparation, S.B.d.S., Í.B.S.d.A. and M.H.d.S.; writing—review and editing, A.A.A., R.B.d.S. and R.K.S.; visualization, S.B.d.S.; supervision, R.B.d.S., E.D.D. and M.A.d.M.J.; project administration, R.B.d.S., E.D.D. and M.A.d.M.J.; funding acquisition, R.B.d.S. and E.D.D. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—CAPES, process number 88887.963615/2024-00, by the Human Resources Training Program of the Brazilian National Agency for Petroleum, Natural Gas and Biofuels—PRH-ANP, via PRH 48.1/UFPE (ANP/FINEP process number 48610.201019/2019-38 and FAPESP process number 2024/10544-2), and by the Conselho Nacional de Desenvolvimento Científico—CNPq, process number 440444/2022-5.

Data Availability Statement

No new data were created or analyzed in this study.

Acknowledgments

The authors express their gratitude to the institutions that support the research teams, Federal University of Pernambuco (UFPE) and University of Pernambuco (UPE), as well as to the Graduate Support Program (PROAP) for the Graduate Program in Energy and Nuclear Technologies of UFPE. The English text of this paper has been revised by Sidney Pratt, Canadian, MAT (Johns Hopkins University), RSAdip—TESL (Cambridge University). During the preparation of this manuscript, the authors used ChatGPT 5 for the purposes of improved language and readability. The authors have reviewed and edited the output and take full responsibility for the content of this publication.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| 1,3-PDO | 1,3-Propanediol |

| CRUDE | Conversion on Raw and Untreated Disposal into Ethanol |

| EPI | Environmental Performance Index |

| EU | European Union |

| FW | Food Waste |

| GWP | Global Warming Potential |

| IEA | International Energy Agency |

| LA | Lactic Acid |

| LAB | Lactic Acid Bacteria |

| LCA | Life Cycle Assessment |

| MSW | Municipal Solid Waste |

| OFMSW | Organic Fraction of Municipal Solid Waste |

| PHA | Polyhydroxyalkanoate |

| SDGs | Sustainable Development Goals |

| SSF | Simultaneous Saccharification and Fermentation |

| TEA | Techno-Economic Assessment |

| TRL | Technological Readiness Level |

| UNEP | United Nations Environment Programme |

References

- Food and Agriculture Organization of the United Nations—SDG Indicators Data Portal. Available online: https://www.fao.org/sustainable-development-goals-data-portal/data/indicators/1231-global-food-losses/en (accessed on 26 April 2024).

- Organisation for Economic Co-operation and Development (OECD). Beyond food loss and waste reduction targets: Translating reduction ambitions into policy outcomes. In OECD Food, Agriculture and Fisheries Papers; OECD: Paris, France, 2025; Volume 214. [Google Scholar] [CrossRef]

- United Nations Environment Programme—Food Waste Index Report 2024. Available online: https://www.unep.org/resources/publication/food-waste-index-report-2024 (accessed on 5 May 2024).

- Rolewicz-Kalińska, A.; Lelicińska-Serafin, K.; Manczarski, P. Selection Path for Energy-Efficient Food Waste Management in Urban Areas: Scenario Analysis and Insights from Poland. Energies 2025, 18, 385. [Google Scholar] [CrossRef]

- Mir-Cerdà, A.; Nuñez, O.; Granados, M.; Sentellas, S.; Saurina, J. An overview of the extraction and characterization of bioactive phenolic compounds from agri-food waste within the framework of circular bioeconomy. Trends Anal. Chem. 2023, 161, 116994. [Google Scholar] [CrossRef]

- Roy, P.; Mohanty, A.K.; Dick, P.; Misra, M. A Review on the Challenges and Choices for Food Waste Valorization: Environmental and Economic Impacts. ACS Environ. 2023, 3, 58–75. [Google Scholar] [CrossRef]

- Sousa, M.H.; Silva, A.S.F.; Correia, R.C.; Leite, N.P.; Bueno, C.E.G.; Pinheiro, R.L.S.; Santana, J.S.; Silva, J.L.; Sales, A.T.; Souza, C.C.; et al. Valorizing municipal organic waste to produce biodiesel, biogas, organic fertilizer, and value-added chemicals: An integrated biorefinery approach. Biomass. Convers. Biorefin. 2022, 12, 827–841. [Google Scholar] [CrossRef]

- Bilal, M.; Niu, D.; Wang, Z. Biotechnological Strategies and Perspectives for Food Waste Treatment: The Role of Lactic Acid and Microbial Biomass. Waste Biomass Valorization 2025, 16, 547–569. [Google Scholar] [CrossRef]

- del Mar Contreras, M.; Romero-García, J.M.; López-Linares, J.C.; Romero, I.; Castro, E. Residues from grapevine and wine production as feedstock for a biorefinery. Food Bioprod. Process. 2022, 134, 56–79. [Google Scholar] [CrossRef]

- Arya, P.S.; Yagnik, S.M.; Rajput, K.N.; Panchal, R.R.; Raval, V.H. Valorization of agro-food wastes: Ease of concomitant-enzymes production with application in food and biofuel industries. Bioresour. Technol. 2022, 361, 127738. [Google Scholar] [CrossRef] [PubMed]

- Antonisamy, A.J.; Marimuthu, S.; Malayandi, S.; Rajendran, K.; Lin, Y.-C.; Andaluri, G.; Lee, S.L.; Ponnusamy, V.K. Sustainable approaches on industrial food wastes to value-added products—A review on extraction methods, characterizations, and its biomedical applications. Environ. Res. 2023, 217, 114758. [Google Scholar] [CrossRef]

- Environmental Protection Agency—Sustainable Materials Management: Non-Hazardous Materials and Waste Management Hierarchy. Available online: https://www.epa.gov/smm/sustainable-materials-management-non-hazardous-materials-and-waste-management-hierarchy (accessed on 6 March 2025).

- Zhang, X.; Liu, C.; Xen, Y.; Zheng, G.; Chen, Y. Source separation, transportation, pretreatment, and valorization of municipal solid waste: A critical review. Environ. Dev. Sustain. 2022, 24, 11471–11513. [Google Scholar] [CrossRef]

- de Abreu, I.B.S.; Sousa, M.H.; Silva, A.P.; Padilha, C.E.A.; Sales, A.T.; Silva, A.S.A.; Dutra, E.D.; Menezes, R.S.C. Global variability of food waste chemical composition and its consequences on the production of biofuels and chemical compounds. J. Mater. Cycles Waste Manag. 2023, 25, 1309–1324. [Google Scholar] [CrossRef]

- Eičaitė, O.; Baležentis, T. Disentangling the sources and scale of food waste in households: A diary-based analysis in Lithuania. Sustain. Prod. Consum. 2024, 46, 195–207. [Google Scholar] [CrossRef]

- Grant, F.; Di Veroli, J.N.; Rossi, L. Characterization of household food waste in Italy: Three year comparative assessment and evaluation of seasonality effects. Waste Manag. 2023, 164, 171–180. [Google Scholar] [CrossRef]

- Alzate, C.A.C.; Ortiz-Sanchez, M.; Solarte-Toro, J.C. Design strategy of food residues biorefineries based on multifeedstocks analysis for increasing sustainability of value chains. Biochem. Eng. J. 2023, 194, 108857. [Google Scholar] [CrossRef]

- Slopiecka, K.; Liberti, F.; Massoli, S.; Bartocci, P.; Fantozzi, F. Chemical and physical characterization of food waste to improve its use in anaerobic digestion plants. Energy Nexus 2022, 5, 100049. [Google Scholar] [CrossRef]

- Bender, L.E.; Colvero, G.L.; Monteiro, E.L.; Rempel, A.; Colla, L.M. Utilization of food waste for bioethanol production in a circular bioeconomy approach. Biomass Convers. Biorefin. 2024, 15, 8525–8541. [Google Scholar] [CrossRef]

- Cordova-Buiza, F.; Paucar-Caceres, A.; Quispe-Prieto, S.C.; Rivera-Garré, A.P.; Huerta-Tantalean, L.N.; Valle-Paucar, J.E.; León-Panduro, C.V.P.; Burrowes-Cromwell, T. Strengthening Collaborative Food Waste Prevention in Peru: Towards Responsible Consumption and Production. Sustainability 2022, 14, 1050. [Google Scholar] [CrossRef]

- Associação Brasileira de Resíduos e Meio Ambiente—Panorama dos Resíduos Sólidos no Brasil 2024. Available online: https://www.abrema.org.br/panorama/ (accessed on 5 March 2025).

- Lee, E.; Shurson, G.; Oh, S.-H.; Jang, J.-C. The Management of Food Waste Recycling for a Sustainable Future: A Case Study on South Korea. Sustainability 2024, 16, 854. [Google Scholar] [CrossRef]

- Farahdiba, A.U.; Warmadewanthi, I.D.A.A.; Fransiscus, Y.; Rosyidah, E.; Hermana, J.; Yuniarto, A. The present and proposed sustainable food waste treatment technology in Indonesia: A review. Environ. Technol. Innov. 2023, 32, 103256. [Google Scholar] [CrossRef]

- SWITCH-Asia—Reducing Food Waste in China: Experiences from Six Cities. Available online: https://www.switch-asia.eu/news/reducing-food-waste-in-china-experiences-from-six-cities/ (accessed on 25 June 2025).

- Kurniawan, T.A.; Liang, X.; O’Callaghan, E.; Goh, H.; Othman, M.H.D.; Avtar, R.; Kusworo, T.D. Transformation of Solid Waste Management in China: Moving towards Sustainability through Digitalization-Based Circular Economy. Sustainability 2022, 14, 2374. [Google Scholar] [CrossRef]

- Environmental Protection Agency—Advancing Sustainable Materials Management: 2018 Fact Sheet. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/advancing-sustainable-materials-management (accessed on 29 June 2024).

- Department of Forestry, Fishery & the Environment—State of Waste Management: Analysis of 2022 General Waste Quantities. Available online: https://soer.environment.gov.za/soer/CMSWebSite/Content.aspx?menuId=18893,17982,0,Analysisof2022generalwastequantities (accessed on 9 September 2025).

- European Parliament—Sustainable Waste Management: What the EU Is Doing. Available online: https://www.europarl.europa.eu/topics/en/article/20180328STO00751/sustainable-waste-management-what-the-eu-is-doing (accessed on 7 June 2025).

- Eurostat—Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics#Waste_treatment (accessed on 16 July 2025).

- Block, S.; Emerson, J.W.; Esty, D.C.; de Sherbinin, A.; Wendling, Z.A. 2024 Environmental Performance Index; Yale Center for Environmental Law & Policy: New Haven, CT, USA, 2024; Available online: https://www.epi.yale.edu (accessed on 24 March 2025).

- Annevelink, B.; Chavez, L.G.; van Ree, R.; Gursel, I.V. Global Biorefinery Status Report 2022; International Energy Agency Bioenergy (IEA Bioenergy): Paris, France, 2022. [Google Scholar]

- Solarte-Toro, J.C.; Alzate, C.A.C. Sustainability of Biorefineries: Challenges and Perspectives. Energies 2023, 16, 3786. [Google Scholar] [CrossRef]

- Colombo, B.; Favini, F.; Scaglia, B.; Sciarria, T.P.; D’Imporzano, G.; Pognani, M.; Alekseeva, A.; Eisele, G.; Cosentino, C.; Adani, F. Enhanced polyhydroxyalkanoate (PHA) production from the organic fraction of municipal solid waste by using mixed microbial culture. Biotechnol. Biofuels 2017, 10, 201. [Google Scholar] [CrossRef]

- Bühlmann, C.H.; Mickan, B.S.; Tait, S.; Batstone, D.J.; Bahri, P.A. Waste to Wealth: The power of food-waste anaerobic digestion integrated with lactic acid fermentation. Front. Chem. Eng. 2023, 5, 1285002. [Google Scholar] [CrossRef]

- Patel, A.; Hrůzová, K.; Rova, U.; Christakopoulos, P.; Matsakas, L. Sustainable biorefinery concept for biofuel production through holistic valorization of food waste. Bioresour. Technol. 2019, 294, 122247. [Google Scholar] [CrossRef] [PubMed]

- Vavouraki, A.I.; Volioti, V.; Kornaros, M.E. Optimization of thermo-chemical pretreatment and enzymatic hydrolysis of kitchen wastes. Waste Manag. 2014, 34, 167–173. [Google Scholar] [CrossRef] [PubMed]

- Ortiz-Sanchez, M.; Inocencio-García, P.; Alzate-Ramírez, A.F.; Alzate, C.A.C. Potential and Restrictions of Food-Waste Valorization through Fermentation Processes. Fermentation 2023, 9, 274. [Google Scholar] [CrossRef]

- Saragih, F.N.A.; Priadi, C.R.; Adityosulindro, S.; Abdillah, A.; Islami, B.B. The effectiveness of anaerobic digestion process by thermal pre-treatment on food waste as a substrate. IOP Conf. Ser. Earth Environ. Sci. 2019, 251, 012014. [Google Scholar] [CrossRef]

- Billund Biorefinery—The Termal Hydrolysis: The Energetic Heart. Available online: https://www.billundbiorefinery.com/our-refinery/the-termal-hydrolysis/ (accessed on 11 October 2024).

- Raj, T.; Chandrasekhar, K.; Morya, R.; Pandey, A.K.; Jung, J.; Kumar, D.; Singhania, R.R.; Kim, S. Critical challenges and technological breakthroughs in food waste hydrolysis and detoxification for fuels and chemicals production. Bioresour. Technol. 2022, 360, 127512. [Google Scholar] [CrossRef]

- Szucs, M.; Angulo, M.; Costa, C.; Márquez, M.C. Meat Waste Valorization through Protein Hydrolysis using Different Types of Proteases. Recent Prog. Mater. 2021, 3, 1–19. [Google Scholar] [CrossRef]

- Zabed, H.; Sahu, J.N.; Suely, A.; Boyce, A.N.; Faruq, G. Bioethanol production from renewable sources: Current perspectives and technological progress. Renew. Sustain. Energy Rev. 2017, 71, 475–501. [Google Scholar] [CrossRef]

- Wang, Q.; Li, H.; Feng, K.; Liu, J. Oriented Fermentation of Food Waste towards High-Value Products: A Review. Energies 2020, 13, 5638. [Google Scholar] [CrossRef]

- Dahiya, S.; Kumar, A.N.; Sravan, J.S.; Chatterjee, S.; Sarkar, O.; Mohan, S.V. Food waste biorefinery: Sustainable strategy for circular bioeconomy. Bioresour. Technol. 2018, 248, 2–12. [Google Scholar] [CrossRef]

- Pal, P.; Singh, A.K.; Srivastava, R.K.; Rathore, S.S.; Sahoo, U.K.; Subudhi, S.; Sarangi, P.K.; Prus, P. Circular Bioeconomy in Action: Transforming Food Wastes into Renewable Food Resources. Foods 2024, 13, 3007. [Google Scholar] [CrossRef]

- Alencar, B.R.A.; Silva, S.P.; Silva, T.C.; Valle, D.S.G.M.; Souza, R.B.; Dutra, E.D.; Morais, M.A., Jr.; Menezes, R.S.C. Integrated production of ethanol and 1,3-propanediol from food waste enzymatic hydrolysates in a biorefinery approach. Bioresour. Technol. Rep. 2024, 27, 101934. [Google Scholar] [CrossRef]

- Zhang, C.; Ling, Z.; Huo, S. Anaerobic fermentation of pretreated food waste for butanol production by co-cultures assisted with in-situ extraction. Bioresour. Technol. Rep. 2021, 16, 100852. [Google Scholar] [CrossRef]

- Kim, D.; Kim, S.; Shin, H. Hydrogen fermentation of food waste without inoculum addition. Enzyme Microb. Technol. 2009, 45, 181–187. [Google Scholar] [CrossRef]

- Tang, J.; Wang, X.C.; Hu, Y.; Zhang, Y.; Li, Y. Effect of pH on lactic acid production from acidogenic fermentation of food waste with different types of inocula. Bioresour. Technol. 2017, 224, 544–552. [Google Scholar] [CrossRef]

- de Abreu, I.B.S.; Silva, R.K.; Siqueira, J.G.W.; Silva, P.K.N.; Sonego, J.L.S.; de Souza, R.B.; Antonino, A.C.D.; Menezes, R.S.C.; Dutra, E.D. Brazilian Food Waste as a Substrate for Bioethanol Production. Foods 2024, 13, 4032. [Google Scholar] [CrossRef]

- Bhatia, L.; Jha, H.; Sarkar, T.; Sarangi, P.K. Food Waste Utilization for Reducing Carbon Footprints towards Sustainable and Cleaner Environment: A Review. Int. J. Environ. Res. Public Health 2023, 20, 2318. [Google Scholar] [CrossRef]

- Kwan, T.H.; Hu, Y.; Lin, C.S.K. Valorisation of food waste via fungal hydrolysis and lactic acid fermentation with Lactobacillus casei Shirota. Bioresour. Technol. 2016, 217, 129–136. [Google Scholar] [CrossRef]

- Kwan, T.H.; Hu, Y.; Lin, C.S.K. Techno-economic analysis of a food waste valorisation process for lactic acid, lactide and poly(lactic acid) production. J. Clean. Prod. 2018, 181, 72–87. [Google Scholar] [CrossRef]

- Thygesen, A.; Tsapekos, P.; Alvarado-Morales, M.; Angelidaki, I. Valorization of municipal organic waste into purified lactic acid. Bioresour. Technol. 2021, 342, 125933. [Google Scholar] [CrossRef] [PubMed]

- Song, L.; Cai, C.; Chen, Z.; Lin, C.; Lv, Y.; Ye, X.; Liu, Y.; Dai, X.; Liu, M. Lactic acid production from food waste: Advances in microbial fermentation and separation technologies. Bioresour. Technol. 2024, 414, 131635. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, J.C.; Pak, D. Feasibility of producing ethanol from food waste. Waste Manag. 2011, 31, 2121–2125. [Google Scholar] [CrossRef]

- Huang, H.; Qureshi, N.; Chen, M.H.; Liu, W.; Singh, V. Ethanol production from food waste at high solids content with vacuum recovery technology. J. Agric. Food Chem. 2015, 63, 2760–2766. [Google Scholar] [CrossRef] [PubMed]

- Dhiman, S.S.; David, A.; Shrestha, N.; Johnson, G.R.; Benjamin, K.M.; Gadhamshetty, V.; Sani, R.K. Simultaneous hydrolysis and fermentation of unprocessed food waste into ethanol using thermophilic anaerobic bacteria. Bioresour. Technol. 2017, 244, 733–740. [Google Scholar] [CrossRef]

- Díez, M.P.; Villanueva-Galindo, E.; Moreno-Andrade, I.; Díaz, E.; de la Rubia, M.A.; Mohedano, A.F.; Perez-Rangel, M. Enhanced hydrogen production from food waste via bioaugmentation with Clostridium and Lactobacillus. Biomass Convers. Bioref. 2025, 1–13. [Google Scholar] [CrossRef]

- Rafieenia, R.; Pivato, A.; Lavagnolo, M.C. Optimization of hydrogen production from food waste using anaerobic mixed cultures pretreated with waste frying oil. Renew. Energy 2019, 139, 1077–1085. [Google Scholar] [CrossRef]

- Moretto, G.; Russo, I.; Bolzonella, D.; Pavan, P.; Majone, M.; Valentino, F. An urban biorefinery for food waste and biological sludge conversion into polyhydroxyalkanoates and biogas. Water Res. 2020, 170, 115371. [Google Scholar] [CrossRef] [PubMed]

- Kannah, R.Y.; Merrylin, J.; Devi, T.P.; Kavitha, S.; Sivashanmugam, P.; Kumar, G.; Banu, J.R. Food waste valorization: Biofuels and value added product recovery. Bioresour. Technol. Rep. 2020, 11, 100524. [Google Scholar] [CrossRef]

- International Energy Agency—Renewable Energy Progress Tracker. Available online: https://www.iea.org/data-and-statistics/data-tools/renewable-energy-progress-tracker (accessed on 9 February 2024).

- de Souza, R.B.; de Menezes, J.A.S.; de Souza, R.d.F.R.; Dutra, E.D.; de Morais, M.A., Jr. Mineral Composition of the Sugarcane Juice and Its Influence on the Ethanol Fermentation. Appl. Biochem. Biotechnol. 2015, 175, 209–222. [Google Scholar] [CrossRef]

- Martínez-Moreno, R.; Morales, P.; Gonzalez, R.; Mas, A.; Beltran, G. Biomass production and alcoholic fermentation performance of Saccharomyces cerevisiae as a function of nitrogen source. FEMS Yeast Res. 2012, 12, 477–485. [Google Scholar] [CrossRef]

- Sheikh, R.A.; Al-Bar, O.A.; Soliman, Y.M.A. Biochemical studies on the production of biofuel (bioethanol) from potato peels wastes by Saccharomyces cerevisiae: Effects of fermentation periods and nitrogen source concentration. Biotechnol. Biotechnol. Equip. 2016, 30, 497–505. [Google Scholar] [CrossRef]

- Hao, N.; Pedroni, P.; Colson, G.; Wetzstein, M. The linkage between the U.S. ethanol market and developing countries’ maize prices: A panel SVAR analysis. Agric. Econ. 2017, 48, 629–638. [Google Scholar] [CrossRef]

- Pazur, J.H.; Ando, T. The action of an amyloglucosidase of Aspergillus niger on starch and malto-oligosaccharides. J. Biol. Chem. 1959, 234, 1966–1970. [Google Scholar] [CrossRef]

- Rodriguez-Garcia, M.E.; Hernandez-Landaverde, M.A.; Delgado, J.M.; Ramirez-Gutierrez, C.F.; Ramirez-Cardona, M.; Millan-Malo, B.M.; Londoño-Restrepo, S.M. Crystalline structures of the main components of starch. Curr. Opin. Food Sci. 2021, 37, 107–111. [Google Scholar] [CrossRef]

- Karmee, S.K. Liquid biofuels from food waste: Current trends, prospect and limitation. Renew. Sustain. Energy Rev. 2016, 53, 945–953. [Google Scholar] [CrossRef]

- van Dyk, J.; Görgens, J.F.; van Rensburg, E. Enhanced ethanol production from paper sludge waste under high-solids conditions with industrial and cellulase-producing strains of Saccharomyces cerevisiae. Bioresour. Technol. 2024, 394, 130163. [Google Scholar] [CrossRef] [PubMed]

- Dahiya, S.; Chatterjee, S.; Sarkar, O.; Mohan, V. Renewable hydrogen production by dark-fermentation: Current status, challenges and perspectives. Bioresour. Technol. 2021, 321, 124354. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Liu, H.; Liu, W.; Guo, J.; Xian, M. Debottlenecking the biological hydrogen production pathway of dark fermentation: Insight into the impact of strain improvement. Microb. Cell Fact. 2022, 21, 166. [Google Scholar] [CrossRef] [PubMed]

- Becerra-Quiroz, A.-P.; Rodríguez-Morón, S.-A.; Acevedo-Pabón, P.-A.; Rodrigo-Ilarri, J.; Rodrigo-Clavero, M.-E. Evaluation of the Dark Fermentation Process as an Alternative for the Energy Valorization of the Organic Fraction of Municipal Solid Waste (OFMSW) for Bogotá, Colombia. Appl. Sci. 2024, 14, 3437. [Google Scholar] [CrossRef]

- Yu, L.; Cheng, W.; Wang, Q. The enhancement on biohydrogen production by the driving forces from extracellular iron oxide respiration. Bioresour. Technol. 2022, 361, 127679. [Google Scholar] [CrossRef]

- Albuquerque, M.M.; Sartor, G.d.B.; Martinez-Burgos, W.J.; Scapini, T.; Edwiges, T.; Soccol, C.R.; Medeiros, A.B.P. Biohydrogen Produced via Dark Fermentation: A Review. Methane 2024, 3, 500–532. [Google Scholar] [CrossRef]

- Chemanalyst—Decode the Future of Lactic Acid: Lactic Acid Market Analysis. Available online: https://www.chemanalyst.com/industry-report/lactic-acid-market-3078#:~:text=Testimonials%20Disruption%20Tracker-,Description,extensive%20utility%20across%20diverse%20industries (accessed on 6 March 2025).

- Mozzi, F. Lactic Acid Bacteria. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 501–508. [Google Scholar]

- Ojo, A.O.; de Smidt, O. Lactic Acid: A Comprehensive Review of Production to Purification. Processes 2023, 11, 688. [Google Scholar] [CrossRef]

- Haris, N.I.N.; Salleh, S.F.; Nolasco-Hipolito, C.; Husaini, A.A.S.A.; Wondi, M.H.; Harun, N.H.; Raof, N.A. A review on lactic acid production via microbial fermentation from biowaste: Insights on scaling up to industrial process. Biofuel. Bioprod. Biorefin. 2024, 19, 437–452. [Google Scholar] [CrossRef]

- Sharma, P.; Gaur, V.K.; Sirohi, R.; Varjani, S.; Kim, S.H.; Wong, J.W.C. Sustainable processing of food waste for production of bio-based products for circular bioeconomy. Bioresour. Technol. 2021, 325, 124684. [Google Scholar] [CrossRef]

- Kourmentza, C.; Plácido, J.; Venetsaneas, N.; Burniol-Figols, A.; Varrone, C.; Gavala, H.N.; Reis, M.A.M. Recent Advances and Challenges towards Sustainable Polyhydroxyalkanoate (PHA) Production. Bioengineering 2017, 4, 55. [Google Scholar] [CrossRef]

- Valentino, F.; Gottardo, M.; Micolucci, F.; Pavan, P.; Bolzonella, D.; Rossetti, S.; Majone, M. Organic Fraction of Municipal Solid Waste Recovery by Conversion into Added-Value Polyhydroxyalkanoates and Biogas. ACS Sustain. Chem. Eng. 2018, 6, 16375–16385. [Google Scholar] [CrossRef]

- Fraia, S.D.; Sharmila, V.G.; Banu, J.R.; Massarotti, N. A comprehensive review on upcycling of food waste into value added products towards a circular economy: Holistic approaches and life cycle assessments. Trends Food Sci. Technol. 2024, 143, 104288. [Google Scholar] [CrossRef]

- Tey, K.Y.; Tan, J.P.; Yeap, S.K.; He, N.; Bukhari, N.A.; Hui, Y.W.; Luthfi, A.A.I.; Manaf, S.F.A. Current analysis on 1,3-propanediol production from glycerol via pure wild strain fermentation. J. Environ. Chem. Eng. 2023, 11, 110998. [Google Scholar] [CrossRef]

- de Santana, J.S.; Silva, J.L.; Dutra, E.D.; Menezes, R.S.C.; Souza, R.B.; Pinheiro, I.O. Production of 1,3-propanediol by Lactobacillus diolivorans from agro-industrial residues and cactus cladode acid hydrolyzate. Appl. Biochem. Biotechnol. 2021, 193, 1585–1601. [Google Scholar] [CrossRef] [PubMed]

- Russmayer, H.; Egermeier, M.; Marx, H.; Leitner, V.; Sauer, M. Entirely oil palm-based production of 1,3-propanediol with Lentilactobacillusdiolivorans. Environ. Technol. Innov. 2023, 29, 103024. [Google Scholar] [CrossRef]

- Ma, K.; Cui, Y.; Zhao, K.; Yang, Y.; Wang, W.; Hu, G.; He, M. d-Lactic acid production from agricultural residues by membrane integrated continuous fermentation coupled with B vitamin supplementation. Biotechnol. Biofuels 2022, 15, 24. [Google Scholar] [CrossRef] [PubMed]

- European Commission—Demonstration of an Integrated Innovative Biorefinery for the Transformation of Municipal Solid Waste (MSW) into New BioBased Products (URBIOFIN). Available online: https://cordis.europa.eu/article/id/442883-transforming-urban-waste-into-new-bioproducts (accessed on 29 May 2025).

- Rajendran, N.; Han, J. Techno-economic analysis of food waste valorization for integrated production of polyhydroxyalkanoates and biofuels. Bioresour. Technol. 2022, 348, 126796. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Kabir, M.; Mehjabin, A.; Oishi, F.T.Z.; Ahmed, S.; Mannan, S.; Mofijur, M.; Almomani, F.; Badruddin, I.A.; Kamangar, S. Waste biorefinery to produce renewable energy: Bioconversion process and circular bioeconomy. Energy Rep. 2023, 10, 3073–3091. [Google Scholar] [CrossRef]

- Muhammad, N.I.S.; Rosentrater, K.A. Techno-Economic Evaluation of Food Waste Fermentation for Value-Added Products. Energies 2020, 13, 436. [Google Scholar] [CrossRef]

- Cristóbal, J.; Caldeira, C.; Corrado, S.; Sala, S. Techno-economic and profitability analysis of food waste biorefineries at European level. Bioresour. Technol. 2018, 259, 244–252. [Google Scholar] [CrossRef] [PubMed]

- Christensen, T.H.; Damgaard, A.; Levis, J.; Zhao, Y.; Björklund, A.; Arena, U.; Barlaz, M.A.; Starostina, V.; Boldrin, A.; Astrup, T.F.; et al. Application of LCA modelling in integrated waste management. Waste Manag. 2020, 118, 313–322. [Google Scholar] [CrossRef]