Abstract

Advancements in material science have allowed us to exploit the potential of new era for aircraft production. High-performance composites and alloys have allowed us to improve the performance and durability of aircraft, but they have become more and more precious with time. These materials can provide significant advantages in use but are costly, energy-intensive to produce, and their recovery and reuse has become a critical step to be addressed. Accordingly, a new approach in which end-of-life aircrafts represent unconventional mines rather than a disposal challenge is becoming increasingly relevant, providing access to high-value strategic raw materials and aligning with circular economy principles including European Green Deal and the United Nations Sustainable Development Goals. The complexity of dismantling and processing hybrid structures composed of metal alloys, ceramics, and advanced composites requires multiple approaches able to integrate chemical, mechanical, and thermal recovery routes. Accordingly, this review critically discusses the state of the art of the routes of end-of-life aircraft treatments, evaluating the connections between technology and regulation, and positions material recycling and reuse as central pillars for advancing sustainability in aerospace. Furthermore, this review provides a comprehensive reference for addressing the technical, economic, and policy challenges of waste management in aviation, contributing to broader goals of resource circularity and environmental preservation set forth by international sustainability agendas.

1. Introduction

In recent years, global manufacturing sectors have faced increasing pressure to address environmental and climate issues. Relevant EU initiatives aimed at promoting sustainability include the European Green Deal and the Circular Economy Action Plan [1]. The Green Deal outlines a series of proposals with the goal to overcome the challenges of climate change and environmental degradation. Key targets include reducing net greenhouse gas emissions by at least 55% by 2030 and achieving net zero emissions by 2050. These proposals span multiple sectors, such as: climate change, energy, industry, transport, and research and innovation. Specifically, for the transport sector, the Green Deal aims to reduce its greenhouse gas emissions by 90% [2,3,4]. The aerospace industry is responsible for approximately 2% of the total CO2 emissions on the planet [5]. Therefore, in recent years, the aeronautical sector has been showing considerable interest in the topics of sustainability and circular economy [6,7].

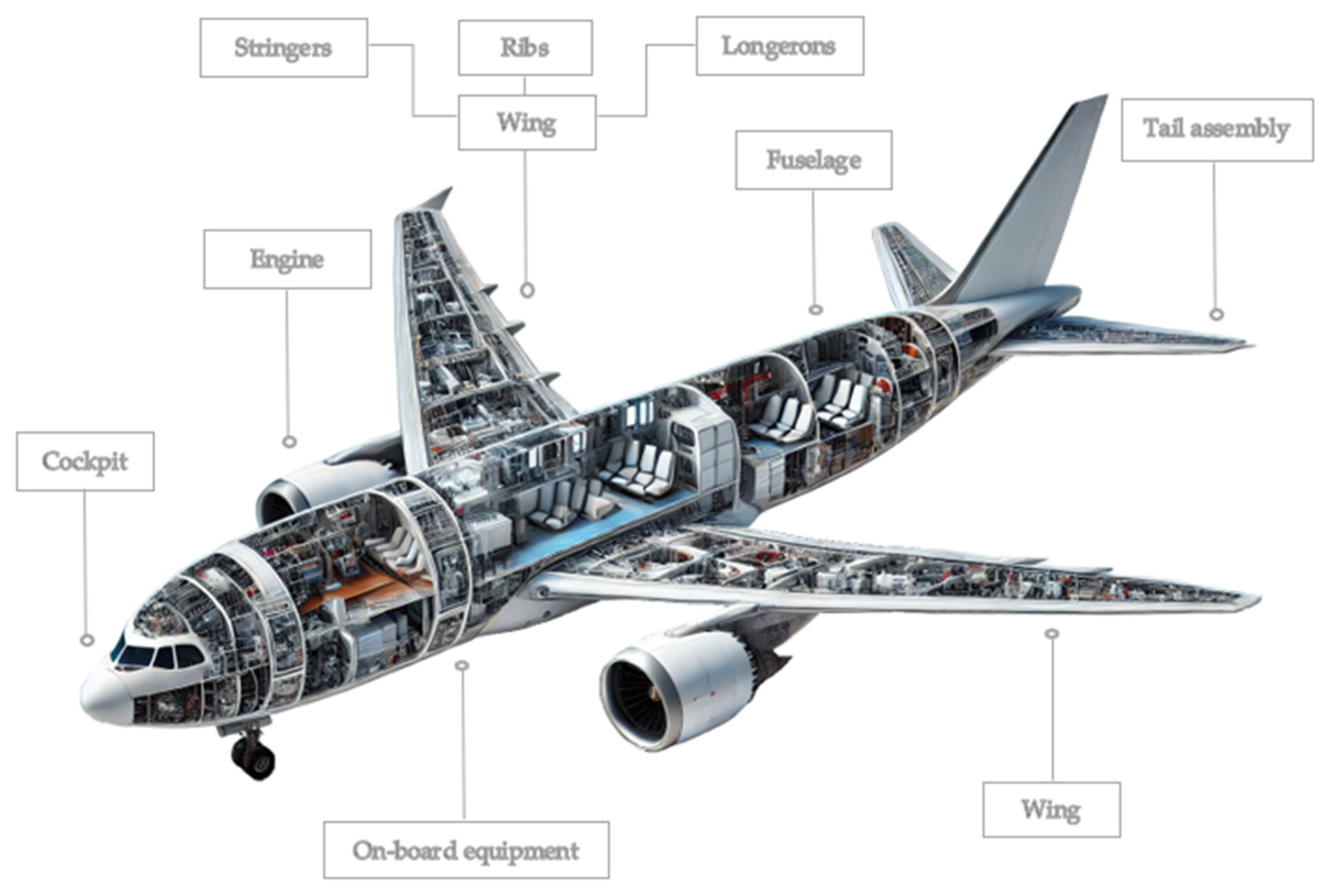

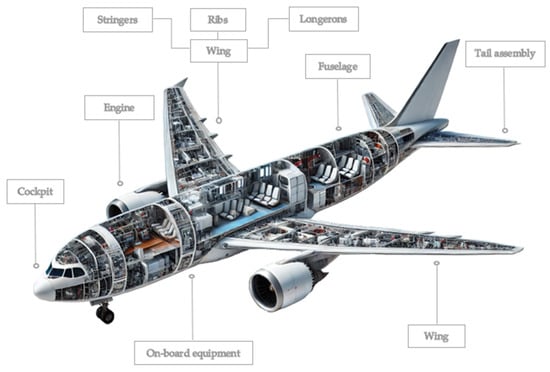

Considering the number of commercial aircraft exceeds 28,000 units and is set to exceed 35,000 units in the next decade, the aviation sector has a considerable challenge to face. In the last five years, the number of aircraft annually retired from service is over 600 units [8]; consequently, the volume of material from end-of-life (EOL) airplanes that would become waste, contributing to global pollution if not properly recycled and recovered, has to be properly managed [9,10] as summarized in Figure 1.

Figure 1.

Main components of aircrafts.

With the development of efficient recycling and recovery technologies, the aircraft sector is able to reduce its environmental impact, both in terms of the lower demand for virgin raw material and the drastic reduction, or elimination, of aircrafts sent for landfill disposal [6,11,12]. A noteworthy first step in this direction is represented by the Process for Advanced Management of End-of-Life of Aircraft (PAMELA) project, funded by the European Union and led by Airbus in 2005 [13]. The main objective was to demonstrate that up to 85% of an aircraft’s weight could be recycled, reused, or recovered, while establishing new standards for sustainable dismantling and recycling processes. The project provided significant benefits, including 90% energy saving in aluminum casting, the reuse of materials for aerospace applications, a 66% reduction in landfill waste, and enhanced safety and sustainability in resource management. Additionally, PAMELA ensured the safety and reliability of aerospace components while substantially reducing the environmental impact of end-of-life aircraft. Another project funded by the European Union is the Aircraft Metal Recycling (AiMeRe) CleanSky project [14]. Its primary objectives included enhancing the reutilization of high-grade alloys for industrial applications, ensuring the profitability of recycling practices, improving adherence to environmental regulations, and identifying new recycling pathways and opportunities. The project’s scientific contributions provided a comprehensive overview of the current state of the aircraft recycling industry, detailing existing practices, legislative aspects, and aircraft composition in terms of valuable metals and hazardous waste. Additionally, it introduced economically and environmentally optimized methods for dismantling, cutting, sorting, and processing materials, alongside exploring new applications for recycled metal alloys in both aerospace and other industries. The technical achievements included cartographic analyses of aircraft materials and waste, evaluations of enhanced recycling methods, studies on gold-containing components, and lifecycle assessments for aircraft metals recycling. The project also emphasized recommendations for design-for-environment practices and established dissemination activities to promote sustainable recycling approaches within the aerospace sector and beyond. The last noteworthy project is SUSTAINair [15], funded by the H2020 program, which integrates circular economy principles into all stages of an aircraft’s lifecycle, from design to end-of-life. SUSTAINair aims to achieve several key outcomes: reducing weight and improving fuel efficiency through a multi-material design philosophy involving advanced metal alloys and composites; enhancing aerodynamic performance and safety by implementing onboard structural health-monitoring sensors for real-time damage diagnostics; introducing flexible wings with morphing capabilities; and minimizing waste during manufacturing and end-of-life processes through innovative recycling and upcycling methods for both metallic and composite materials. This includes developing solutions for carbon- and glass-fiber thermosets, as well as high-performance thermoplastic composites. Some projects have been launched to increase the recyclability of carbon waste. Indeed, Airbus has an ongoing project involving the recycling of carbon waste for bicycle production [16]. Boeing recycles composite materials from production waste to reuse them in cars and consumer goods [17].

Other projects focused on the alternative reutilization of end-of-life aircraft components into high-value products beyond the aerospace sector. A notable example is the “Eco-design of products” project, a collaboration between Bombardier, the University of Montreal, and the Consortium for Research and Innovation in Aerospace in Québec [18]. This initiative integrates end-of-life aircraft parts into conceptual designs using a lifecycle approach, focusing on the complexity of repurposing, environmental benefits, and public communication of sustainability impacts. The project demonstrated that alternative reuse often results in lower environmental impacts compared to recycling, with examples like bicycles, leather jackets, and wall clocks made from aircraft materials. When reusing aircraft components, the priority is to preserve their original form and function to maintain maximum value, as seen in cockpits repurposed as simulators and floor panels used for staging. If preserving form and function is not possible, the focus shifts to maintaining the material properties through upcycling.

The shared efforts of a large number of companies in such a complex and challenging field have led to progress in understanding and knowledge of the problem. A first example of innovation in this direction is the integration of disassembly planning during aircraft design [19].

In this review, we will discuss the three main material families that find application in aircraft construction: composites, metals, and polymers [20,21]. Moreover, we will focus on the state of the art of recycling and recovery techniques and their application to different materials. Furthermore, some considerations will be made about the advantages of one method rather than another, based on economic considerations, circularity, and when, instead, landfill disposal is the best choice.

2. Insight on Aircraft Materials and Their Components

The aviation sector relies on specialized materials to meet strict safety, durability, and performance standards, particularly given the industry’s focus on lightweight, fuel-efficient aircraft. In recent years, the emergence of electric and hybrid aircrafts has driven the need for innovative materials that support efficient energy use and comply with stringent European regulations on critical raw materials (CRMs). The scarcity of certain metals and minerals essential for manufacturing advanced aircraft components, especially those classified as CRMs by the European Union, poses unique challenges [22]. The European Union has identified materials crucial to its technological and economic sectors, and its 2023 Critical Raw Materials Act now lists 34 elements [23]. This regulation impacts the aviation industry, as many of these materials are essential for producing lightweight, high-strength parts.

The European Union’s Critical Raw Materials list covers essential metals and minerals that are either scarce or whose supply chains are vulnerable [24]. These include cobalt, tungsten, rare-earth elements (such as neodymium, dysprosium, and praseodymium), and magnesium, all of which are used in the production of aircraft components. Due to limited sources and high import dependency, the EU has prioritized recycling, alternative sourcing, and minimizing waste. For example, cobalt, which is 100% imported into the EU, is integral to lithium-ion battery production, a core component in electric aircraft. The scarcity of cobalt presents a significant obstacle in the aerospace sector, where reliance on advanced battery technology is growing [25].

In addition to cobalt, neodymium, and praseodymium are crucial for manufacturing high-strength magnets used in electric motors and control systems [26]. Electric and hybrid aerotaxis, in particular, are dependent on high-efficiency motors and require neodymium–iron–boron (NdFeB) magnets, which deliver superior magnetic power with minimal weight [27]. According to EU directives, alternative sources and recycling processes are being investigated to limit dependency on imports from regions like China, which controls over 80% of the global rare-earth supply [28].

Tungsten is another critical element, often used for high-temperature applications due to its exceptional melting point and density. Tungsten is essential in aerospace components such as turbine blades, which must withstand high stress and heat. Tungsten carbide, which comprises approximately 2–3% of an aerotaxi’s critical components, is used for parts that undergo intense mechanical stress, contributing to overall efficiency in propulsion and durability.

The EU’s Critical Raw Materials Act promotes sustainable mining and processing of these materials, prioritizing local sources and exploring recycling options to secure their supply [29]. These efforts are crucial in light of the increased demand for lightweight, fuel-efficient aircraft. Approximately 40% of aircraft manufacturing materials are on the EU’s CRM list, a considerable share highlighting the urgency for alternative sourcing or substitution strategies.

Beyond metals and rare-earth elements, polymers play a substantial role in aircraft manufacturing. While traditional plastics are often inadequate due to insufficient strength or heat resistance, advanced composites, and high-performance polymers have become integral to the aerospace industry. Carbon-fiber-reinforced plastics (CFRP) and glass-fiber-reinforced plastics (GFRP) account for a significant portion of these materials due to their high strength-to-weight ratios [30]. CFRPs are widely used in structural components like fuselage sections, wing structures, and control surfaces, representing roughly 50–70% of the primary structure in modern aircrafts. The fraction of plastics in total aircraft weight has grown as manufacturers focus on achieving lighter aircraft with increased fuel efficiency. Compared to metallic counterparts, CFRPs can reduce structural weight by up to 40%, directly contributing to energy savings and, in turn, reducing operational costs and emissions [31].

Thermosetting resins, such as epoxy, are common binding agents in these composites, providing strength and durability under high-stress conditions. In aerotaxis, where weight and efficiency are dominant, these polymers are essential for achieving competitive fuel efficiency and payload capacity. Epoxy resins are responsible for approximately 30–40% of the total composite fraction, depending on the aircraft model and the extent to which CFRP is used [32].

Additionally, polyether ether ketone (PEEK) and polyimides are used in high-temperature areas like engine components, while polyamide-imide (PAI) provides excellent wear resistance and strength for interior components such as seating frames [33]. In aircraft applications, these plastics also contribute to noise reduction and passenger comfort, as they absorb vibrations better than metal. With the growing demand for these materials, recycling and alternative sourcing remain important considerations for sustainable manufacturing, particularly under EU regulations.

Metals and alloys are essential for aircraft construction, particularly for components that require high strength, durability, and resistance to environmental stress. The aerospace industry extensively uses aluminum, titanium, and nickel alloys due to their mechanical properties and relative lightness compared to steel.

Aluminum–lithium (Al-Li) alloys are a popular choice for aircraft due to their low density and high stiffness. Aluminum components represent approximately 40–50% of a traditional aircraft’s structural weight, though in newer aircraft this share may be lower due to increased CFRP usage [34]. The inclusion of lithium enhances the material’s resistance to fatigue and corrosion, providing a weight savings of approximately 7% over standard aluminum alloys. This makes it ideal for fuselage and wing components where strength-to-weight ratios are critical.

Titanium alloys (primarily Ti-6Al-4V) are commonly used in aircraft due to their high strength, low density, and resistance to corrosion and heat. Titanium is found in 10–15% of structural components, particularly in areas requiring high resistance to fatigue, such as landing gear, wing spars, and engine mounts [35]. Titanium’s high melting point allows it to maintain integrity under extreme heat and stress, a crucial property in areas exposed to high thermal loads.

Nickel-based superalloys, such as Inconel, are primarily used in turbine engines and areas exposed to high temperatures, where their resistance to oxidation and creep deformation is essential. Nickel alloys account for approximately 5–7% of an aircraft’s total structural weight [36]. These materials are indispensable for maintaining performance in high-stress environments, such as engine turbine blades.

The use of alloys in aircraft is guided by both performance and sustainability. For instance, replacing traditional steel components with high-strength aluminum or titanium alloys reduces weight and enhances fuel efficiency. However, many of these metals, such as titanium and nickel, are on the EU’s CRM list, necessitating careful management and recycling practices to ensure long-term availability [25].

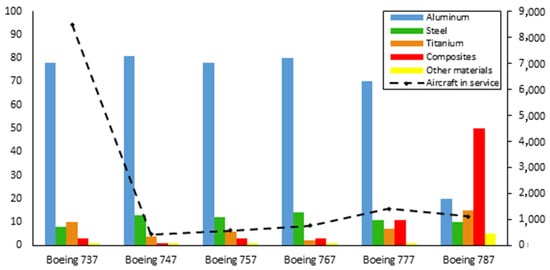

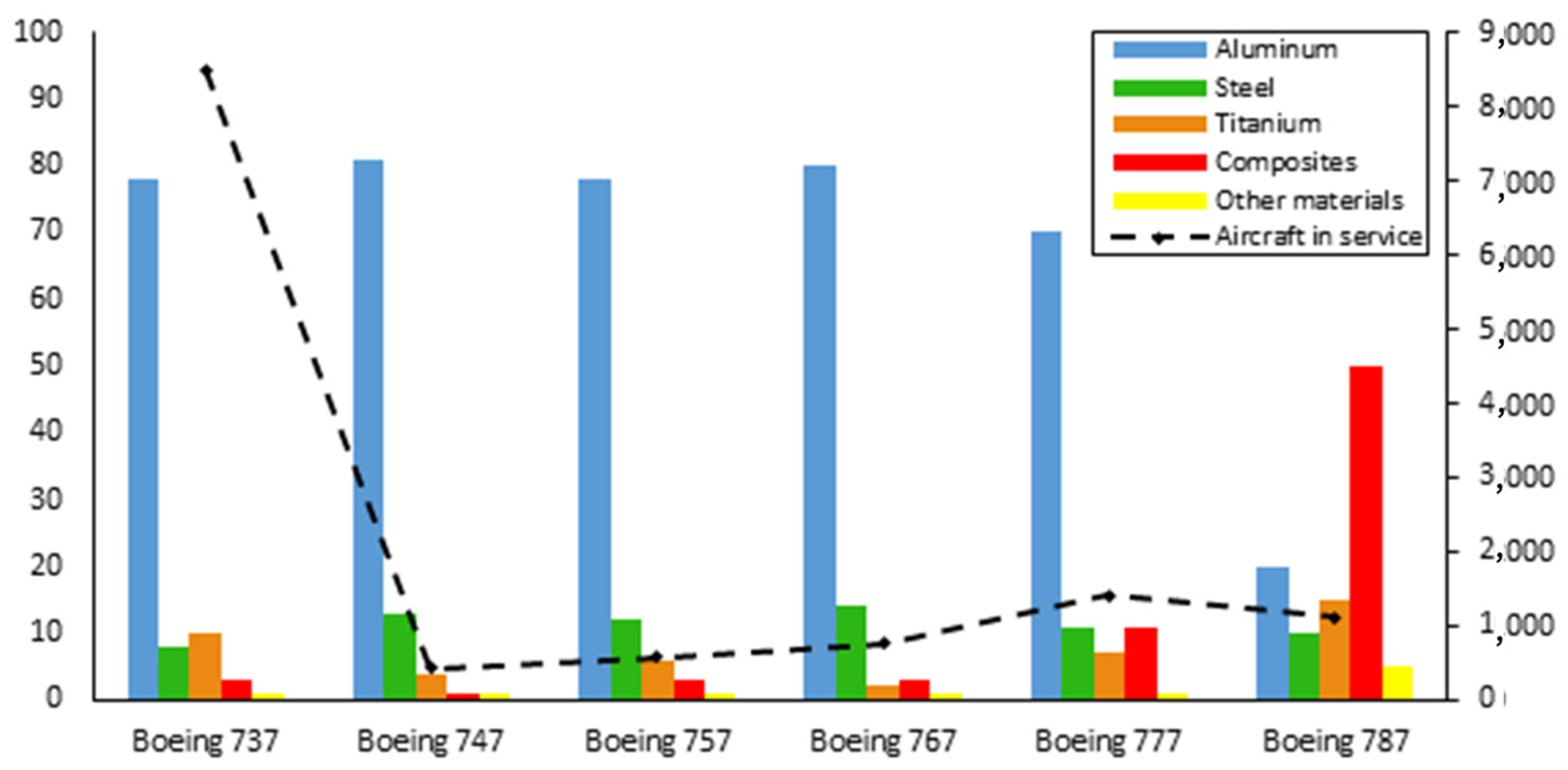

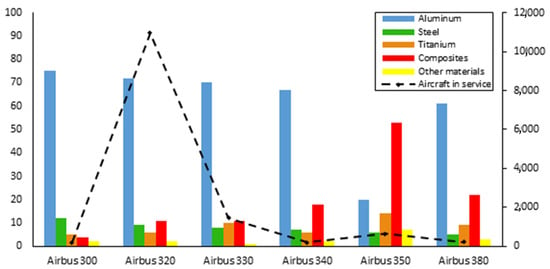

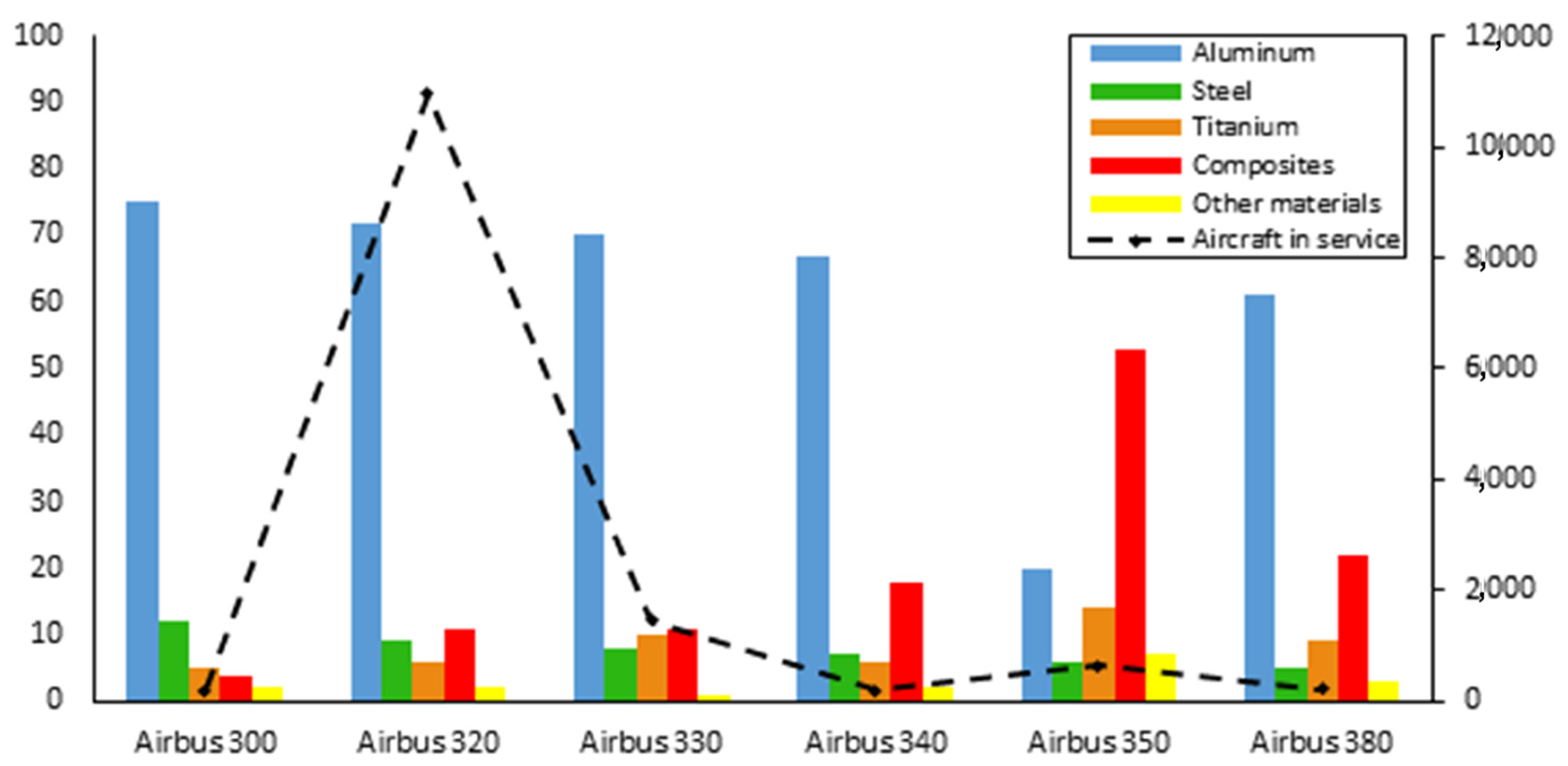

With the rise in sustainable urban mobility solutions, aircrafts are becoming a central focus of innovation in aerospace. These vehicles aim to be highly efficient, eco-friendly, and lightweight, using advanced materials to meet strict weight and safety criteria [37]. Over time, there has been a significant shift in the percentages of materials used in aircraft manufacturing, driven by the goal of reducing weight and improving fuel efficiency. This evolution is evident in the comparison of materials used in various Airbus and Boeing aircraft models, spanning older to more recent designs, as shown in Figure 2 and Figure 3.

For example, earlier models such as the Boeing 747 and Airbus A320 relied heavily on aluminum, making up 70–80% of their structural weight. In contrast, newer aircraft like the Boeing 787 and Airbus A350 feature a much higher percentage of carbon-fiber composites, which account for 50–53% of their structure, significantly reducing weight while maintaining strength [38,39].

Titanium and advanced alloys have also increased in use, particularly in areas where resistance to high temperatures and corrosion is critical. The trend towards lightweight composite materials reflects the industry’s commitment to lowering fuel consumption, reducing emissions, and aligning with global sustainability goals.

Figure 2.

Material composition of the most important Boeing aircraft with the actual number of aircraft in service (2025) [40,41].

Figure 2.

Material composition of the most important Boeing aircraft with the actual number of aircraft in service (2025) [40,41].

Figure 3.

Material composition of the most important Airbus aircraft with the actual number of aircraft in service (2025) [42,43].

Figure 3.

Material composition of the most important Airbus aircraft with the actual number of aircraft in service (2025) [42,43].

3. Strategy for Disposal and Recovery of End-of-Life Aircrafts

3.1. Disassembling and Wastestreams

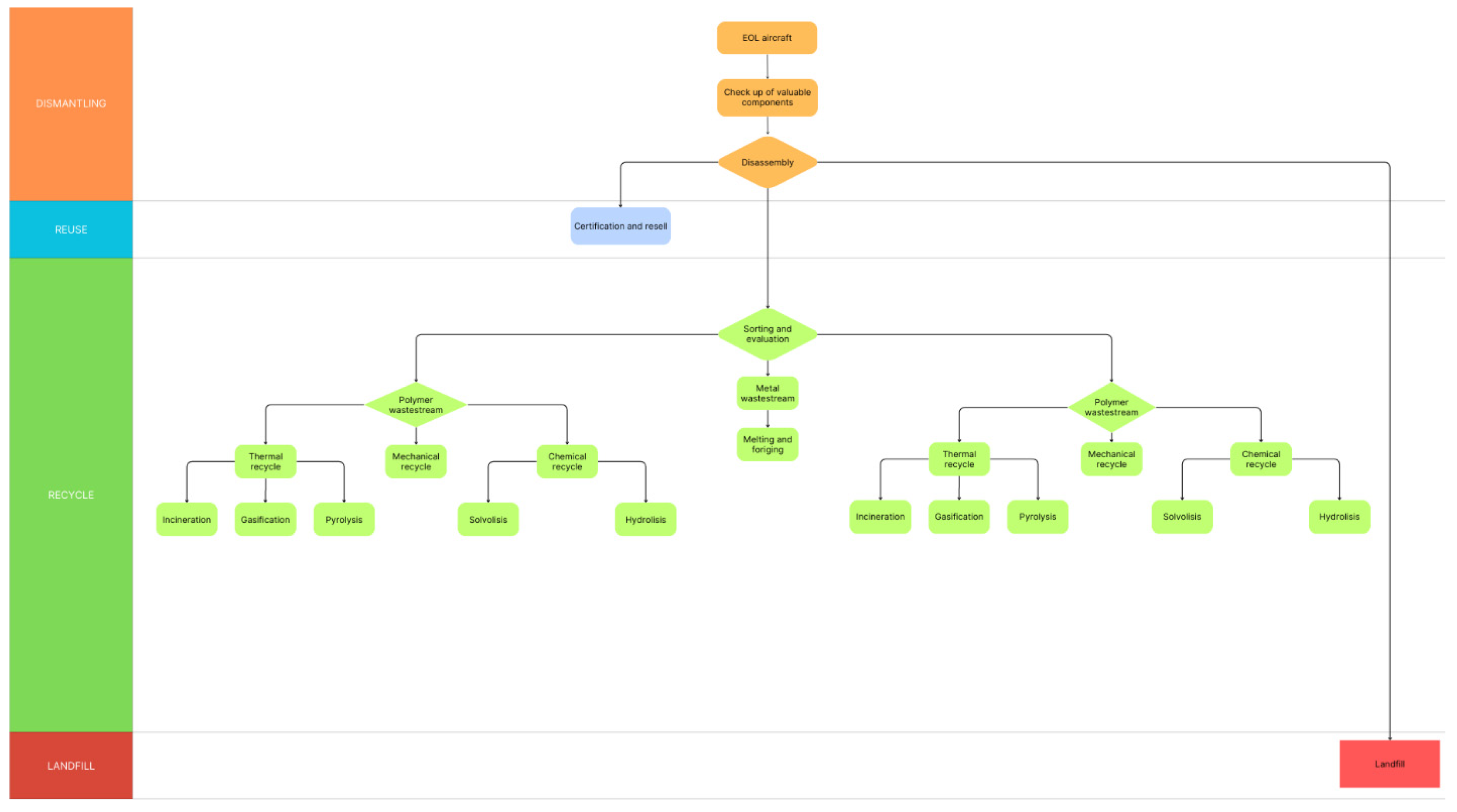

As reported in Figure 4, Aircraft dismantling constitutes the entry of aircraft parts and materials to the waste business, meaning that they cannot re-enter the aerospace business and fall under the general regulations covering waste treatment. The aircraft-dismantling industry emerged at the beginning of this century and involves various organizations, such as the official civil aviation agency, companies specialized in aircraft dismantling, aircraft manufacturers, maintenance, and waste-recycling companies [44]. Organizations like the International Civil Aviation Organization (ICAO), civil aviation authorities, and environmental protection agencies create rules and guidelines to ensure that dismantling and recycling are carried out safely and in an environmentally friendly manner. Associations like the International Air Transport Association (IATA) and Aircraft Fleet Recycling Association (AFRA) work on creating manuals and procedures for aircraft dismantling and help standardize the industry. In addition, professional dismantling companies, such as AELS (Aircraft End-of-Life Solutions) in the Netherlands, not only handle aircraft dismantling but also focus on reusing materials from decommissioned aircraft.

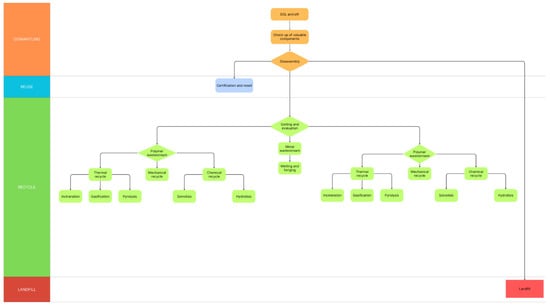

Figure 4.

Scheme for disposal and recovery of EoL aircraft.

After excluding the possibility of passenger aircraft being converted to cargo aircraft, the procedure of dismantling involves the removal of components and materials for purposes such as reuse, recycling, recovery, or disposal [45]. The process gives economic value to the retired aircraft while promoting its environmental sustainability. In a typical aircraft-dismantling scenario (Figure 5), the process begins with the transportation of the aircraft to a certified facility, where a general inspection is carried out to assess the condition of its components.

Figure 5.

Airbus’s 3-D process for aircraft dismantling.

If the owner wishes to resell certain high-value parts, such as engines or avionics, these components undergo rigorous testing and certification before proceeding to the next stages. Certified components are either returned to the aviation market or sent for necessary repairs and overhauls by authorized units [46].

Once the certification process is completed, all fluids are removed from the aircraft, ensuring compliance with environmental safety standards. Subsequently, high-value components, such as engines and avionics, are carefully extracted for resale. These parts, which can account for 40–50% of the aircraft’s total weight, play a significant role in the second-hand aviation materials market, offering a cost-effective alternative to new components [47]. The next step involves the removal of internal components, including seats, overhead bins, panels, and carpets, many of which are made of polymers [48,49]. These materials are classified based on polymer type and contamination level, such as mixed plastics, to determine their appropriate recycling path. The final stage involves processing the external structure. The fuselage, wings, and tail are segmented into manageable sections, and metal components are sorted based on their base metal matrix. Recyclable metals are directed toward recycling processes, while non-recyclable materials are prepared for disposal. The engine, accounting for over 60% of the aircraft’s value, often receives special attention due to its high recyclability and resale potential [50]. A significant challenge in the dismantling process of EOL aircraft arises from the presence of various hazardous materials. For example, older military aircraft may contain asbestos, while fire extinguishers often contain bromotrifluoromethane [51]. Additionally, commercial aircraft frequently feature smoke detectors and emergency exit signs that contain radioactive elements. Hexavalent chromium is another concern, commonly found in aircraft paint primers. Proper handling and disposal of these hazardous materials add to the overall costs of dismantling. The presence of hexavalent chromium in aluminum scrap further complicates its reuse, particularly in industries like packaging [52]. While techniques exist to remove paint primers containing this substance, their economic feasibility and environmental impact require further investigation to determine their viability.

Through this structured process, a retired aircraft can yield up to 50,000 components, with approximately 20,000 parts being suitable for reuse in the aviation market after proper testing and certification [44]. Components not fit for aviation reuse may find applications in non-aerospace sectors, maximizing the value extracted from retired aircraft while minimizing waste. Logistical challenges further complicate aircraft recycling. To make this a scalable industry, it would be advantageous to concentrate recycling activities in global hubs where sufficient numbers of EOL aircraft can be processed. Alternatively, mobile dismantling units could address this issue by servicing remote locations, such as desert storage areas where EOL aircraft are often left to corrode. However, the recovered metals must still be transported to recycling facilities, making centralized dismantling and recycling locations more efficient. Aircraft could ideally perform a final flight to such facilities, streamlining the process.

Different strategies were carried out by the biggest aircraft producers. In 2006, the AFRA was established in order to look for a standard approach for aircraft disassembly [53]. Boeing, as a founding member, played a pivotal role in its development and growth. The organization aimed to create standardized practices for aircraft disassembly, develop efficient technologies for material recovery, and reduce the environmental impact of aircraft disposal. Thanks to the contributions of all participants taking part to the project, AFRA created a guide, known as Best Management Practices, as an approach to managing EOL aircraft [54]. The guide aims to create a standard for uniformity and safety in dismantling process, while maximizing the recovery of valuable parts that can re-enter the market. Moreover, it provides information for efficient recycling of materials such as metals and composites. After advancements in knowledge and technology, the guidelines has undergone revision and updates; nowadays, the association counts a large number of members all over the world, with advanced facilities able to recover a significative amount of retired aircraft. An example of a fruitful collaboration is the agreement established in 2008 between Boeing and Alenia Aeronautica for the development of the first Italian center for the recovery of carbon-fiber composites (following the design of the Boeing 787 Dreamliner, in which the primary structure is made of this material) [55].

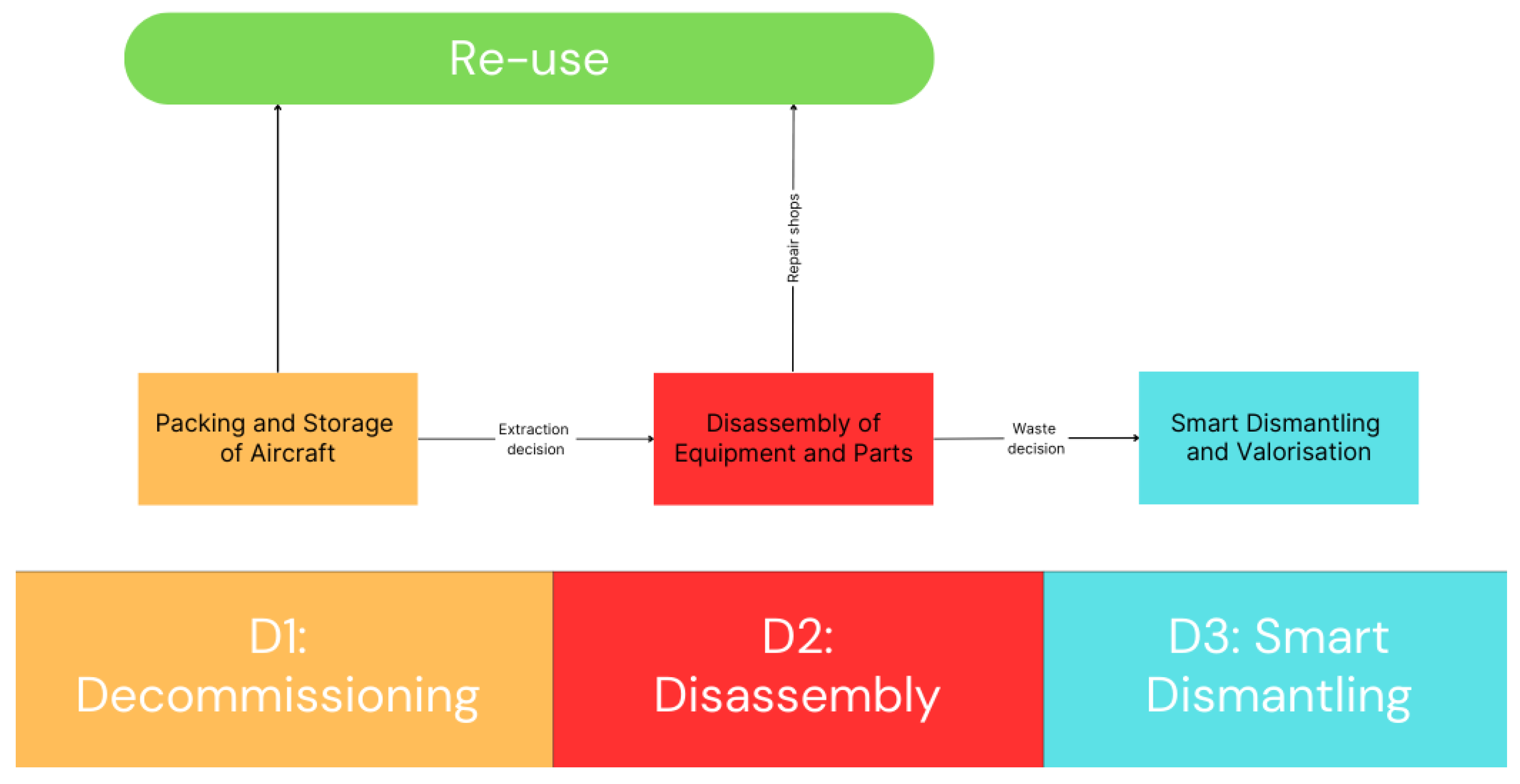

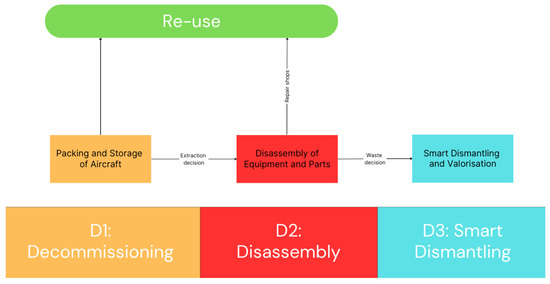

Due to the large number of aircraft close to their end of their life, in 2005 Airbus launched the PAMELA project, aiming to create a systematic and sustainable approach for aircraft dismantling and recycling [13]. The company selected a EOL Airbus A300 as a full-scale demonstration and developed a structured three-step process to manage its dismantling [56].

The first stage, known as Decommissioning, involves removing the aircraft from service and decontaminating it to ensure safety for subsequent steps [57]. This includes removing all operating fluids (e.g., fuel residues, technical fluids, wastewater) and hazardous substances, such as depleted uranium or explosive devices from army aircrafts, in accordance with existing regulations. Additional preparatory steps include the inspection, cleaning, and decontamination of components such as electronic devices, passenger equipment, and auxiliary systems. These initial processes also involve creating a detailed inventory of parts to be reused, enabling traceability throughout the aircraft’s end-of-life phase [46]. The second stage, named Disassembly, focuses on systematically removing high-value components, such as engines, avionics, landing gears, and auxiliary power units. These components are selected based on market demand for spare parts and undergo inspection, repair, or certification to return them to service [58]. A detailed disassembly plan is created, which includes grouping components into families, determining disassembly sequences, and optimizing shop floor operations to enhance efficiency [59]. The final stage, Dismantling, involves recovering structural materials by grouping them according to type (e.g., aluminum alloys, stainless steel, composites) to optimize recycling. Advanced tools, such as plasma torches, hydraulic scissors, and water jets, are used to cut the aircraft into manageable sections. After initial sorting, materials are sent through dedicated recovery channels for further processing [60]. This stage ensures that up to 80% of the materials can be recycled, while the remaining non-recyclable waste is disposed of following standard procedures [61]. The PAMELA project achieved notable milestones: the project demonstrated an effective recovery rate of 85% of an aircraft, established a replicable model for the management of EOL aircraft, and reduced landfill disposal and greenhouse gas emissions (by recycling aluminum and other materials). Moreover, the project led to a new vision in designing aircraft, emphasizing the importance of a lifecycle approach for better recyclability in modern aircraft. Since the project was successfully concluded, Airbus decided to valorize it by founding in 2007, together with other partners, Tarmac Aerosave, a company specialized in the efficient recovery of EOL aircraft [62]. The company has developed its technology over the years, assuming a leading role in maintenance, the resale of high-added-value components and almost total recovery of EOL aircraft (up to 92% by weight). In 2024, Airbus, in collaboration with Tarmac Aerosave and the city of Chengdu, inaugurated the Airbus Lifecycle Services Centre, a multi-service facility aimed to offer solutions for the management of EOL aircraft, exploiting Tarmac Aerosave’s expertise in the field [63].

3.1.1. Polymer Wastestreams

Aircraft tires are highly engineered products designed to endure extreme stresses, including heavy loads, rapid acceleration, and temperatures generated during takeoff and landing. They are essential for the safe operation of aircraft, yet their limited lifespan contributes significantly to waste. Civil aviation tires typically last between 250 and 300 landings, while military aircraft tires often last only 20 to 50 landings [64]. With airlines like Southwest Airlines replacing nearly 40,000 tires annually, the disposal of end-of-life tires (ELTs) is a pressing issue. Larger aircraft exacerbate the challenge: a Boeing 777 uses 14 tires, an A380 requires 22, and the AN225 cargo aircraft has 32 tires [65].

The short service life of aircraft tires is partially offset by retreading, which allows tires to be reused up to seven times before they become non-viable. However, even with retreading, significant quantities of ELTs are generated, creating an opportunity to improve recycling and waste management practices [66]. Sustainable solutions are especially important given the materials used in tire production. Aircraft tires are predominantly made of rubber, including natural rubber (NR), Styrene–Butadiene Rubber (SBR), Polybutadiene Rubber (BR), and Isobutylene–Isoprene Rubber (IR), along with textiles and metals such as steel cords for reinforcement [67]. Additives such as sulfur compounds and other hazardous chemicals, including heavy metals and polycyclic aromatic hydrocarbons (PAHs), are also present in varying amounts depending on the manufacturer.

Two primary types of tires are used in aviation: bias-ply and radial. Bias-ply tires, known for their durability and retreadability, are commonly employed due to their robust construction. Radial tires, while lighter and offering reduced rolling resistance, provide higher performance with increased landing capacity [68]. Both types undergo rigorous testing to ensure they meet operational requirements, including tread designs tailored for traction under diverse runway conditions.

The environmental impact of aircraft tires stems from their short service life, complex composition, and hazardous materials. As air travel expands, driven by the rise in low-cost carriers and the demand for new aircraft, the number of ELTs requiring proper disposal will increase [69]. This underscores the necessity of advancing recycling technologies to recover valuable materials and minimize the environmental footprint of the aviation industry.

Scrap tire (ST) recycling can be broadly categorized into three main approaches: reuse, material recovery, and energy recovery. Reuse involves directly extending the tire’s lifecycle, with retreading being a key method in this category. Material recovery transforms STs into new products or materials, employing technologies like shredding and grinding to produce rubber granulates or powders. Finally, energy recovery involves using STs as a fuel source, particularly in industries such as cement manufacturing, where tires are incinerated to generate energy.

Among these methods, retreading is a standout for its environmental and economic benefits. Retreading involves replacing the worn tread of a tire with a new one, allowing it to be reused multiple times while conserving resources and reducing waste. This process is particularly significant for truck and aircraft tires, which can undergo retreading up to three and twelve times, respectively. The process can be classified by the renewed surface: integral (tread and sidewall), semi-integral (tread and part of the sidewall), or tread-only [70]. Retreading can also be divided by adhesion system: hot retreading involves vulcanization at high temperatures (150–160 °C) [71], while cold retreading uses lower temperatures (98–125 °C) in autoclaves [72].

Retreading reduces raw material consumption by 30–50% and generates tires with comparable performance to new ones, making it a cost-effective and sustainable alternative. However, the process is contingent on the condition of the tire’s casing, which must be intact and undamaged. Despite some limitations, such as the restricted number of possible retreads, this method significantly contributes to reducing the environmental impact of tire waste, particularly in regions with strong retread markets like Scandinavia, Germany, and Finland [73].

Aircraft interiors, including seats, overhead bins, and cabin linings, represent a significant source of polymer waste in the aviation sector [74]. These components are engineered to be lightweight, durable, and compliant with stringent safety and fire-resistance standards, making them highly specialized but challenging to recycle. The materials used in interiors range from thermoplastics and thermosetting polymers to polymer foams and fiber-reinforced composites, chosen for their balance between performance, weight, and cost [75].

Aircraft seats are among the most frequently replaced components within the cabin. They are constructed using a combination of lightweight metals for structural frames, polyurethane foams for cushioning, and synthetic materials like polyester or nylon for upholstery. In premium classes, advanced materials such as memory foam may also be incorporated to enhance passenger comfort. Thermoplastics such as polycarbonate, polyetherimide, and polyphenylene sulfide are used for seatbacks, tray tables, and armrests. A narrow-body aircraft seat typically weighs between 15 and 25 kg, while wide-body and premium-class seats can weigh significantly more. For instance, a fully equipped business-class seat may exceed 100 kg. On a Boeing 777, which has 396 seats, the combined weight can exceed 7500 kg.

Seats are typically replaced or refurbished every five to ten years, depending on usage, regulatory changes, or updates to airline branding. This results in substantial waste generation, with thousands of tonnes of materials discarded annually. Airlines with large fleets, such as Delta or Emirates, periodically refurbish or replace all their seating systems, contributing significantly to this wastestream.

Recycling seats is a complex process due to their multi-material construction. While metal frames are relatively straightforward to recycle, polymer foams and fabrics present challenges. Polyurethane foams, for example, are difficult to recycle mechanically and often end up in landfills. Additionally, adhesives and coatings used in seat assembly can hinder the separation and recovery of individual materials. For fiber-reinforced composites used in premium seating, recycling is even more difficult due to the nature of thermosetting polymers, which are not easily remoldable.

Recent advancements offer some solutions. Chemical recycling methods are being developed to break down polymers like polyurethane into reusable monomers, while mechanical recycling can transform thermoplastics into pellets for use in lower-grade applications [76]. In recent years, airlines have increasingly focused on reusing and repurposing interior components, particularly textiles and foams. Upholstery materials and fabrics removed from aircraft are often cleaned, repaired, and reused on other planes to extend their service life [77]. When direct reuse is not viable, these materials are sometimes upcycled into furniture, insulation panels, or decorative items for home and office applications, contributing to the growing trend of repurposing in aviation recycling. Non-metal parts such as textiles, insulation, mixed plastics, and rubber are typically processed at certified recycling centers, where they undergo separation and treatment to recover usable materials or convert them into new products. Despite these efforts, the recycling of seats remains a significant environmental challenge, highlighting the need for more sustainable materials and design practices.

In addition to seats, other cabin components such as overhead bins, interior linings, and flooring contribute substantially to polymer waste. These components are designed for high durability and compliance with fire safety standards and are typically made from materials such as glass-fiber-reinforced polymers, thermoplastics like polyetheretherketone and polyphenylene sulfide, and flame-retardant polycarbonates. Flooring and carpets, which are predominantly composed of nylon or polyester with fire-resistant treatments, also contribute to this wastestream. The interior panels of a narrow-body aircraft can weigh around 1200 kg, while those in wide-body aircraft, such as the Airbus A380, may exceed 3000 kg. These components are replaced less frequently than seats, with a typical lifespan of 10 to 20 years, but their eventual disposal represents a significant environmental challenge.

The recycling of cabin linings and bins is hindered by their composite nature and the presence of flame retardants. However, thermoplastics used in these components are more easily recycled than thermosetting polymers. Remanufacturing programs, where airlines and manufacturers refurbish interior panels instead of replacing them entirely, are also emerging as an effective waste-reduction strategy. Additionally, research into bio-based and biodegradable polymers holds promise for future sustainability.

Aircraft interiors constitute a substantial wastestream, with significant environmental implications due to the volume of materials used and their extended replacement cycles. As the aviation industry continues to grow, with approximately 40,000 new aircraft expected to enter service by 2040, polymer waste from cabin interiors will increase unless proactive measures are adopted. Transitioning to recyclable materials, investing in advanced recycling technologies, and adopting circular design principles will be essential to mitigate the environmental impact of this waste.

Cables and wiring represent another substantial source of polymer waste in decommissioned aircraft. While the focus of recycling efforts often lies on the conductive metals within cables, such as copper, silver, and aluminum, the polymeric insulating layers also pose significant challenges. These insulators are typically made from thermoplastics or elastomers such as polyvinyl chloride (PVC), polyethylene (PE), or polytetrafluoroethylene (PTFE), chosen for their heat resistance, durability, and lightweight properties.

Modern aircraft can contain significant quantities of wiring. For example, a Boeing 777 has about 100 miles of cables, adding substantial weight and complexity to the aircraft [78]. Once removed, the metal and plastic components of cables are separated during recycling. Larger-scale wires are shredded and granulated, with separators used to distinguish metal particles from the polymeric insulation [79]. The recovered polymers are then melted and reprocessed into new materials for use in less critical applications.

Possible solutions involve a multi-pronged approach. Design-for-recycling strategies, such as modular construction and selective use of thermoplastics, can facilitate easier recovery. Advances in solvent-based chemical recycling show promise in selectively depolymerizing PEEK into reusable monomers while minimizing degradation. Hybrid recycling processes that combine mechanical and chemical routes may further enhance efficiency. Moreover, developing secondary markets for recycled PEEK—such as in automotive, electronics, or consumer goods—can improve economic viability, even if aerospace reuse is limited. Additionally, PEEK is often used matrix for together with carbon and glass fibers requiring environmental impacting procedures [80,81]. Furthermore, the aerospace industry certification standards make it difficult to reintroduce recycled PEEK into high-value applications, as even small changes in material properties can compromise safety compliance. As reported by McLauchlin et al. [82], in order to preserve the PEEK properties, a multistep rout should be followed and virgin PEEK should be added, even if only in small amounts.

For very thin cables, however, recycling becomes more complex due to the difficulty in separating the insulating polymers from the metals. In such cases, thermal processing may be used to burn off the plastic layers, though this method raises environmental concerns regarded the presence of toxic flame-retardant agents [83] including halogenated and heavy-metal-containing compounds [84]. The heat generated during burning can be captured and reused within the industry, enhancing energy efficiency and reducing waste.

3.1.2. Composite Wastestreams

In the aerospace field, composite materials are widely used due to their exceptional mechanical properties and lightweight characteristics [85]. These materials can be classified into three main categories based on their matrix type: metal-matrix composites (MMCs), ceramic-matrix composites (CMCs), and polymer-matrix composites (PMCs) [86]. Each category offers specific advantages, making them suitable for various aerospace applications, from structural components to thermal protection systems [87]. The properties and manufacturing costs of metal-matrix composites change significantly depending on material composition, processing techniques, and product quality [88]. The aerospace sector, for instance, demands materials with attributes like high weldability and a high specific modulus, such as extruded alumina-reinforced aluminum. MMCs have become integral to aerospace applications due to their superior strength, stiffness, and fatigue resistance, which enhance overall aircraft performance.

In aerospace, MMCs are employed in critical components like engine parts, brake systems, and drive shafts [89]. A notable example is the substitution of aluminum access doors on the F-16 aircraft with MMCs reinforced by SiC particles, which significantly improved fatigue life [90]. Titanium-based MMCs reinforced with SiC monofilaments have also been used in military applications, such as the F119 engine nozzle actuator control device on the F-16 [91]. These composites replaced heavier materials like Inconel 718 in actuator rods and stainless steel in piston rods, offering weight reduction alongside enhanced specific stiffness and fatigue resistance. Additionally, MMCs serve as alternatives to carbon/epoxy composites, which are prone to foreign object damage [92]. In addition to MMCs, the development of fiber–metal laminates (FMLs) represents a major advancement in aerospace materials [93]. FMLs, which combine metal and polymer composite laminates, create a synergistic effect, yielding superior mechanical properties compared to aluminum alloys or polymer composites alone [94]. These materials, such as GLARE (glass-reinforced aluminum) and ARALL (aramid-reinforced aluminum laminates), offer improved damage tolerance and weight reduction [95,96]. FMLs are widely used in wing structures, fuselage components, and ballistic protection. For instance, ARALL was developed for the lower wing-skin panels of the Fokker 27 aircraft and the Boeing C-17 cargo door, while GLARE is used in the cargo floor impact-resistant sections of the Boeing 777 [97,98]. The Airbus A380 extensively employs FMLs in its structure, underscoring their importance as a structural material [99]. Numerous aeronautical companies, including Aerospatiale, NASA, Bombardier, and EMBRAER, explored FML composites to replace traditional aluminum components due to their enhanced properties [100]. The continual evolution of MMCs and FMLs reflects the aerospace industry’s drive to innovate and optimize materials that balance weight reduction, mechanical performance, and cost-effectiveness [101]. These advancements not only improve the durability and efficiency of aircraft but also redefine the possibilities for future aeronautical engineering.

CMCs are advanced materials that stand out for their exceptional performance at high temperatures, exceeding that of traditional superalloys [102]. Unlike monolithic ceramics, they exhibit higher fracture toughness, making them more suitable for applications requiring structural integrity [103]. In addition to these mechanical benefits, CMCs significantly reduce the overall weight of components, making them ideal for both structural and non-structural parts in aircraft engines [104]. Their ability to operate at higher temperatures and eliminate the need for cooling air through innovations such as thermal barrier coatings and air-cooled sheets allows for considerable performance improvements in aeroengines [97].

One major application of CMCs is in turbine blades, which require materials capable of withstanding extremely high temperatures [105]. C/C (carbon–carbon) composites are particularly suitable due to their ability to maintain strength at 1050 °C while being lightweight. These characteristics allow aircraft to achieve speeds of up to Mach 10, compared to titanium-based composites that are limited to Mach 3.8. C/C composites achieve a specific tensile strength of 160 MPa/g·cm3 at 2000 °C, far surpassing traditional ceramics [106]. Furthermore, SiC-coated carbon-fiber composites in a carbon matrix are widely adopted in aerospace for their superior performance [107]. In recent years, projects like HIPOC (High-Performance Oxide Composite) have been initiated to develop oxide-based CMCs for hot-section applications in aircraft turbines [108]. Another critical application is in braking systems. The extreme temperatures generated during braking can reach up to 3000 °C. C/C composites, when used in aircraft braking systems, offer significant weight reductions compared to traditional materials like high-strength steel or sintered metals [109]. For example, the weight of commercial aircraft braking systems can be reduced from 1100 kg to 700 kg. These materials not only improve performance and resistance but also enhance process reliability and reduce manufacturing costs [110]. CMCs also play a crucial role in the development of lightweight blisks, which combine blades and rotating disks into a single component [111]. The reduced weight of these components helps decrease axle and bearing chamber loads, resulting in broader system benefits [112]. Blisks made from three-dimensional woven fabrics, such as Tyrannoe Si-Ti-C-O composites, are densified through techniques like chemical vapor infiltration (CVI) and polymer impregnation and pyrolysis (PIP). These materials can achieve tensile strengths of up to 500 MPa at room temperature, making them well-suited for high-performance applications [113]. Exhaust nozzles are another area where CMCs excel. Companies like Boeing and GE Aviation are developing Ox/Ox (oxide–oxide) CMCs to replace titanium in subsonic jet engines [114]. These composites improve durability while avoiding the weight increase associated with higher-performance metal alloys. Notably, GE Aviation has incorporated Ox/Ox CMCs in the divergent exhaust seals of F414 engines, demonstrating their suitability for both commercial and supersonic aircraft [115]. Finally, turbine nozzle blades, which have complex geometries, benefit from advancements in CMC materials. For example, slip/hip mold casting of SiC whiskers with Si3N4 powder has been explored for shaping these components [116]. GE Aviation tested the world’s first rotating turbine blade made from a SiC matrix CMC for the low-pressure turbine of the F414 engine [117]. Such developments aim to double the use of CMCs in aero-engines, particularly by leveraging their high-temperature resistance and weight-saving advantages, which eliminate the need for cooling air.

Composite materials, particularly carbon fiber-reinforced polymers (CFRPs), have revolutionized the aerospace industry due to their exceptional mechanical properties and lightweight nature [118]. Weight is an important consideration when it comes to the design of aircraft because weight savings means saving on fuel consumption. Composite materials are lightweight and provide high strength, and so it results in a better strength-to-weight ratio compared to metallic alloys [119]. Various polymers, such as PLA, PP, and epoxy resins, have been used as matrix materials to develop composites for aerospace applications. For non-critical components like shroud panels, fans, duct fairings, spacers, and seals, fiberglass/epoxy composites have been employed. However, CFRPs dominate the practical applications in aircraft component design. CFRPs are widely used in aircraft due to their lightweight properties and ability to endure demanding conditions. For instance, the use of polymer-matrix composites in a four-seater aircraft resulted in a weight reduction of nearly 25% compared to its metal alloy counterpart [120]. Furthermore, efforts to reduce aircraft weight have led to the integration of components into single composite parts, such as the main landing gear integrated with the fuselage in the landing gear bay. This design, primarily composed of CFRP with minimal use of titanium, was manufactured using a one-shot curing process [121]. This approach not only reduces the overall weight but also cuts recurrent assembly costs by up to 80% [122,123].

The application of advanced composites has also revolutionized commercial aviation. The Boeing 787 stands as a milestone in composite material usage, with 80% of its structure by volume comprising composites [124,125]. This includes a material composition of 50% composites, 20% aluminum, 15% titanium, 10% steel, and 5% other by weight. The carbon fiber-reinforced plastic and other composites used in its airframe enable a 20% weight reduction compared to traditional aluminum designs [126]. This lightweight construction significantly enhances fuel efficiency and performance. Boeing engineers adopted a design approach that prioritized selecting optimal materials for specific structural needs, resulting in a composite-dominated fuselage and main structure [127].

Nanocomposites are advanced materials with significant potential for aerospace applications, thanks to their unique properties that enhance safety, efficiency, and aircraft maintenance [128]. Key applications include electromagnetic interference (EMI) shielding, anti-corrosion and anti-icing coatings, and structural health monitoring (SHM). Electromagnetic interference protection is essential to ensure the proper functioning of aircraft electronic systems [129]. Polymer-based nanocomposites, combined with magnetic metallic nanoparticles, provide a lightweight and corrosion-resistant alternative to traditional metals [130,131]. For instance, PVDF/Fe3O4 composites and hybrid materials like CNTs/rGO/epoxy achieve shielding effectiveness (SSE) values of up to 93.8 dB, effectively protecting electronic devices [131]. These materials integrate electrical conductivity and magnetic behavior, creating Faraday cage-like protection without adding significant weight. Corrosion protection is critical to maintaining aircraft structural integrity. Polymer-matrix nanocomposites reinforced with inorganic nanoparticles offer durable and lightweight coatings. Examples include CoFe2O4/PANI composites and graphene oxide-enhanced epoxy systems, which exhibit excellent anticorrosive properties [132]. Additionally, anti-icing nanocomposites, such as Fe3O4- or CNT/SiO2-based materials, delay ice formation and reduce adhesion, making them highly suitable for extreme polar aviation environments [133]. SHM is vital to ensure aircraft safety by detecting structural damage or failures promptly [134,135]. Piezoelectric nanocomposites, such as PZT/PDMS-based materials, are used in sensors to monitor structural integrity in real time, even at high temperatures. These materials exhibit superior piezoelectric performance, making them ideal for aerospace applications in extreme environments [136].

However, the increased adoption of composites introduces substantial challenges, particularly in managing their end-of-life phase. Unlike metals, which are efficiently recyclable through established processes, CFRPs are difficult to recycle due to their thermoset polymer matrices [137]. These matrices consist of cross-linked molecular structures that cannot be remelted or reshaped, rendering traditional recycling methods ineffective [77]. As a result, composite waste often ends up in landfills or is incinerated, practices that are increasingly unsustainable both economically and environmentally [138,139].

The end-of-life phase of an aircraft typically occurs after 25 to 30 years of service [77]. While components like engines, avionics, and landing gear are salvaged, re-certified, and resold, the airframe, which contains a significant amount of composite materials, poses a major disposal challenge [77]. Landfilling composite waste is becoming less viable due to increasing costs, diminishing landfill space, and stricter environmental regulations [140]. Additionally, some composites are classified as hazardous waste, requiring expensive treatments before disposal [138]. Incineration, another common disposal method, reduces waste volume but destroys valuable carbon fibers and generates harmful emissions [141]. For an industry striving to reduce its environmental footprint, these methods are no longer sustainable. The need for alternative solutions is pressing, especially as the global aerospace fleet is projected to double by 2040, further amplifying the volume of composite waste.

Recycling composite materials presents an opportunity to mitigate EoL challenges while aligning with global sustainability goals [127]. The production of virgin carbon fibers is energy-intensive and costly, making the recovery of these fibers from waste an attractive solution. Recycling can help address the growing demand for carbon fibers, which are projected to face shortages in the near future, while also reducing environmental impacts and fostering a circular economy [142,143,144]. Composite recycling methods can be categorized into three main approaches: thermal, chemical, and mechanical.

Recognizing the urgency of the issue, leading aerospace manufacturers Airbus and Boeing have spearheaded initiatives to develop sustainable EoL solutions for composites.

Airbus has been at the forefront of composite recycling through projects like PAMELA (Process for Advanced Management of End-of-Life Aircraft) and its evolution, LIFE-PAMELA, supported by the European Commission [56]. These initiatives demonstrated that up to 85–90% of an aircraft’s materials could be reused, recycled, or recovered. Metals like aluminum and titanium were relatively easy to process, but the projects also explored advanced methods for composite recovery, laying the groundwork for future advancements. Airbus’s participation in the Clean Sky 2 program underscores its commitment to sustainable aviation. This public–private partnership focuses on developing greener technologies, including the integration of sustainable materials and improving the recyclability of composites in future aircraft designs. Airbus has set an ambitious target to recycle 95% of materials from retired aircraft by 2025, with particular emphasis on recovering high-value carbon fibers. The 2022 report of Airbus stated that they are able to recover more than 90% of an aircraft’s weight at end-of-life through a selective dismantling process [145].

Boeing’s efforts in composite recycling are equally significant. Through its leadership in the Aircraft Fleet Recycling Association, Boeing has helped establish global standards for EoL aircraft recycling [146]. AFRA’s Best Management Practices (BMP) provide guidelines for dismantling and recovering materials from retired aircraft, emphasizing economic and environmental viability [59]. The ecoDemonstrator program is another cornerstone of Boeing’s sustainability strategy. This initiative has recycled over 90% of materials from test aircraft, leveraging advanced recycling techniques [147]. Boeing’s collaboration with ELG Carbon Fibre, a leader in carbon-fiber recycling, has resulted in the recovery of fibers through pyrolysis, which are then repurposed for use in non-structural aerospace components and other industries. Boeing is also exploring the integration of recycled fibers into manufacturing processes, creating lighter and more cost-effective components. These efforts align with Boeing’s broader commitment to achieving net-zero carbon emissions and reducing resource consumption.

Beyond individual manufacturers, collaborative efforts play a crucial role in advancing composite recycling technologies. The Re-Carbon Project, funded by the European Union, focuses on developing scalable chemical and thermal recycling methods to recover high-quality carbon fibers and reintegrate them into new composites, creating a closed-loop manufacturing cycle. The UK’s HiPerDiF (High-Performance Discontinuous Fibre) project explores using recycled fibers to produce high-performance materials, demonstrating that, with proper processing, recycled fibers can match or even exceed virgin fiber performance in some applications. The Composite Recycling Technology Center (CRTC) in Washington State is a notable example of innovation in recycling. This nonprofit organization collaborates with manufacturers to repurpose scrap carbon fiber into consumer products, reducing waste and promoting circular economy principles.

The future of composite materials in aerospace hinges on developing efficient and scalable recycling solutions. Airbus and Boeing’s leadership, combined with collaborative research efforts, exemplify the industry’s commitment to addressing EoL challenges. Advanced recycling technologies, such as enhanced solvolysis and low-temperature pyrolysis, offer promising avenues for improving recovery rates and fiber quality.

Emerging trends, including the use of bio-based resins and thermoplastics, aim to simplify recycling processes by enabling re-melting and reshaping. Additionally, investments in artificial intelligence and machine learning could optimize recycling workflows, improving material sorting and processing efficiency.

As composite usage continues to grow, the aerospace industry must integrate sustainability principles into all stages of the lifecycle. By fostering innovation and collaboration, manufacturers can transform EoL challenges into opportunities, ensuring the long-term viability of composite materials while meeting environmental and economic goals.

3.1.3. Metal Wastestreams

Metal materials have been fundamental in shaping modern aircraft manufacturing, evolving alongside advancements in the aerospace industry. From the wooden airframes of early aviation in 1903 to the widespread adoption of aluminum alloys in 1927, metals have played a pivotal role due to their strength-to-weight ratios, damage tolerance, and high-temperature performance [148]. Despite the increasing use of composite materials, metals remain indispensable. This discussion investigates into the primary metal materials used in aircraft manufacturing, such as aluminum, magnesium, and titanium alloys, while also addressing recycling and sustainability practices.

Aluminum alloys have served as the cornerstone of aerospace materials for over 80 years, prominently featured in airframes, fuselages, and structural components [149,150]. Their low cost, manufacturability, and lightweight properties make them ideal for aircraft structures. Aluminum alloys are broadly categorized into cast and wrought types, with wrought alloys accounting for 80% of applications due to their superior strength and lightweight characteristics [79]. Among the aluminum alloys, the 2000 series, such as the Al-Cu-based 2024 alloy, is renowned for its damage tolerance and fatigue resistance. Enhanced versions, like the 2224-T39 alloy, exhibit higher tensile strength through refined microstructural features [44]. Meanwhile, the 7000 series, including the Al-Zn-based 7075 alloy, stands out for its exceptional strength, although advances such as the 7085 alloy have improved its fracture toughness and corrosion resistance. Al-Li alloys, like the 2199, further enhance stiffness and reduce weight, making them suitable for fuselage and wing skins, although challenges like anisotropy persist [79].

Magnesium alloys, celebrated as the lightest structural metals, offer significant weight reduction, which increases payload capacity. Despite this advantage, their mechanical properties and corrosion resistance pose challenges. To address these, alloying with elements such as aluminum, zinc, and rare-earth metals has proven effective [151]. Mg-Al alloys achieve solid-solution strengthening, while Mg-Zn alloys exhibit improved strength and ductility. Alloys with rare-earth additions, like the Mg97Zn1Y2 alloy, reach impressive yield strengths through advanced techniques such as powder metallurgy [152].

Titanium alloys have seen increasing use in aerospace applications, growing from 1% to 19% of an aircraft’s operating empty weight in modern designs. Known for their high specific strength, corrosion resistance, and high-temperature performance, these alloys are categorized into alpha, beta, and alpha–beta types [148]. Alpha alloys excel at high temperatures, beta alloys offer superior formability and strength, and alpha–beta alloys provide a balance of these properties, making them widely applicable in both structural and engine components [153]. Notable examples include Ti-6Al-4V, used in compressor parts and structural elements, and Ti-10V-2Fe-3Al, employed in arrestor hook structures due to its high tensile strength.

Other metal alloys, such as stainless steel, nickel-based, and cobalt-based variants, are essential for high-temperature and high-pressure environments, particularly in engine blocks. These materials ensure durability and reliability under extreme conditions, contributing to the efficiency and performance of modern aircraft [154].

Recycling and sustainability efforts have become integral to the aerospace industry. For instance, aluminum, which constitutes 80% of a civil aircraft’s weight, is extensively recycled. Programs like Bombardier’s aircraft dismantling initiative recover over 1500 reusable parts per aircraft, integrating reclaimed materials back into production [155]. Innovations in recycling processes have preserved the mechanical properties of aluminum and titanium alloys, fostering circular manufacturing practices. Ongoing advancements in aerospace materials research aim to enhance alloy compositions and processing techniques. By optimizing elements such as zinc, magnesium, and copper, engineers improve mechanical properties while reducing costs and environmental impact. The integration of advanced alloys with composite materials further reflects the industry’s commitment to balancing performance with sustainability.

The correct management of metal components is fundamental for effective recycling and for the consequent reduction in environmental impact, given the large amount of energy required for the production of raw materials through primary processes. In addition, modern aircraft contain a significant amount of electronic material which is subject to strict regulations that complicate its recovery. At their end-of-life, these materials are known as waste electrical and electronic equipment (WEEE).

The majority of aircraft wiring consists of conductive metals such as copper, silver, and aluminum, which come in various sizes and shapes and are coated with plastic insulation. In recent years, fiber optic cables have also been incorporated into aircraft design. Among these materials, copper remains the primary choice for electrical wiring in aviation. For example, the Boeing 787 Dreamliner contains approximately 60 miles of wiring, while the Boeing 777 has around 100 miles of cables [78].

When aircraft wiring is dismantled, recycling becomes more manageable. Larger wires are typically shredded and granulated into smaller pieces to facilitate separation of metals from plastic insulation. Methods such as gravity, electrical, and optical separation are commonly employed for this purpose. One example is the use of an eddy-current separator, which processes granulated copper wires to separate the metal from the plastic. Afterward, both materials can be repurposed for use in new aircraft through melting and reprocessing. However, recycling very thin copper wires is more challenging. In such cases, burning the plastic insulation may be the primary method for recovering the metal. The heat generated during the burning process can also be harnessed as an energy source within the industry. Depending on the wire size, complexity, and recycling methods employed, recovery rates for wires and cables can range from 50% to 90% or higher [83].

The proper management of WEEE is a complex topic. In European Union, the management of this waste is regulated by Directive 2012/19/EU [156]. The regulation attributes to the producer the responsibility for the EOL of the product, thus encouraging the development of a product that can be more easily disassembled. The directive also encourages the recovery of valuable metals. The wastestream of WEEE begins with the disposal in a collection center. Then, hazardous materials are separated from other components. The waste is ready to be mechanically processed. After shredding, other separation techniques are performed to isolate plastics (by density), ferrous and non-ferrous metals [157].

3.2. Recycling Technologies

Recovery technologies represent a large field filled with very different approaches to face the wastestream management. As shown in Table 1, each recycling route show intrinsically advantages and disadvantages related to the materials processability, energy consumption and environmental impact. Actually, there is not a common framework to select one technology upon the others other than a balanced economical analysis based on regulatory framework and marketplace. Nevertheless, some general guidelines and good practices are arising across the companies.

Table 1.

Comparative evaluation of recycling technologies.

3.2.1. Thermal Processes

Thermal recycling involves the heat-induced decomposition of polymeric matrix wastestreams with the recovery of reusable raw materials [158] and combustibles both gaseous and liquid [159]. The common methods for thermal recycling include pyrolysis, gasification, and incineration [160].

Incineration is a process that consists of completely burning waste materials and maintaining low levels of emissions, dramatically reducing the waste volume producing inert residues and heat [161]. Its use in the treatment and management of waste dates back to the 19th century and is still practiced today. Incineration is carried out at high temperatures, generally between 750 °C and 1200 °C, in an oxygen-enriched atmosphere in order to guarantee the total combustion of the waste [162], as this means that polluted flue gases can be formed and cleaned before being released into the atmosphere. The solid residue produced is an powder material classified into bottom and fly ash. Bottom ashes are solid combustion residues while fly ash is generally recovered from flue gas cleaning. Both types of ash can either be landfilled or reused, depending on their composition and processing [163]. Different kind of furnaces suitable for specific kinds of waste were developed for incineration, including rotary kilns [164], fluidized bed incinerators [165], and moving grate furnaces [166]. Rotary kilns incinerators are versatile systems mainly used for the treatment of hazardous materials composed by cylindrical furnaces that can rotate to give uniform mixing of waste [167]. Fluidized bed incinerators are cylindrical furnaces inside which there is a bed of inert material [168] and heated air to separate fillers from resin particles for polymer-based carbon-fiber composites. In this case, the process starts by heating the air to 450–500 °C, which volatilizes the organic resin while enabling the sand to transport the non-organic materials, such as fibers and fillers, for further collection [169]. The clean fibers are separated from the gas stream using a cyclone, and the gas is then reheated to around 1000 °C in a secondary combustion chamber to fully combust any residual organic material [158]. This reheating step also allows for energy recovery in the form of heat from the polymers. The fluidized bed process offers efficient heat transfer and mixing, as well as precise temperature control, making it applicable across various industries [170]. Initially, it was used to recover glass fibers, but its scope has expanded to include carbon fibers, which have a higher economic value. Recovered carbon and glass fibers can be reused in applications such as molding compounds and veil-type products [171]. Research on the process has focused on understanding and improving the quality of recovered fibers, as reported by Yip et al. [158]. Authors reported that the key factors influencing the process are the bed temperature and fluidizing velocity, allowing for the recovery of short and randomly oriented carbon fibers. Pickering et al. [172] applied the fluidized bed process to recover fibers from various composite materials, including chopped E-glass fiber sheets and automobile body panels made from E-glass/polyester. Interestingly, the temperature of the fluidized bed was found to inversely affect fiber strength, with higher temperatures leading to reduced fiber strength. Additionally, veils fabricated using a mixture of recovered and virgin fibers exhibited reduced strength as the proportion of recovered fibers increased, highlighting the influence of fiber length, strength, and content on the final product’s performance. Kennerley et al. [173] designed a test rig to recover glass fibers from polyester-based sheet-molding compounds. Their study confirmed that the temperature of the fluidized bed had a greater impact on fiber strength than fluidizing velocity, with higher temperatures weakening the fibers. Recovered glass fibers, often contaminated with fillers, required washing and treatment to improve their compatibility with the matrix [174]. These treated fibers were used to manufacture polyester dough-molding compounds, with tests revealing that while flexural and tensile strength decreased as the proportion of recovered fibers increased, stiffness remained unaffected. This outcome suggests that recovered fibers can be incorporated into composite materials without significant loss in mechanical properties, particularly at concentrations up to 50%. Moving grate furnaces are the most common system for incineration of municipal solid waste for many reasons. This technology does not require any preprocessing of waste showing a good flexibility and it can work continuously ensuring efficient treatment for different waste compositions. It involves placing the feedstock onto a moving grate, where it falls through different zones and is exposed to oxygen and burnt [87,175]. In fact, plastic waste materials are burned primarily to recover energy instead to recovery raw materials. The heat released during the combustion of organic components can be captured and transformed into other forms of energy such as electricity [118]. Nevertheless, several factors reduced the efficiency of energy recovery from composites including the high filler loading as in the case sheet-molding compounds (SMC). SMC is composed only of 35 wt.% resin, which is the only degradable organic material [176]. Additionally, some fillers act as a proper flame retardant reducing the overall energy efficiency of incineration [177] generating solid residues that are difficult to use [178].

Gasification is a thermal process used to convert organic materials into syngas, a mixture primarily composed of carbon monoxide and hydrogen. Industrially, gasification is typically run using autothermal using a sub-stoichiometric amount of oxygen in the atmosphere at temperatures ranging from 800 to 1200 °C [179]. Gasification can be used to recycle components composed of carbon-based composite materials, such as PCM [180]; this method is particularly relevant for aerospace applications, where components such as carbon-fiber-reinforced polymers (CFRPs) are extensively used [181,182]. However, gasification still faces relevant challenges such as the loss of metal from PCM components with a significant treat for the air quality [180]. Nonetheless, gasification provides an environmentally alternative to traditional incineration methods according to European environmental regulations under the Green Deal plan [183].

Alternatively to oxidizing processes, pyrolysis is performed in the absence of oxygen, inhibiting the production of combustion-related products in a temperature range up to 800 °C [184]. The process leads to the generation of three fractions, gases, liquids, and solid char, with yields varying accordingly to both feedstocks and process parameters used [185,186]. As a result, the pyrolytic process is able to create added value compared to incineration, even if it is highly energy intense [187]. The highest processing temperature and heating rate and residence time are the more relevant parameters and they can be used to tune the fraction ratio [188]. Oils can be used directly as drop-in fuel for energy purposes, or further refined to produce higher-value-added fuels [189]. The gas fraction generally contains hydrogen, small hydrocarbons, and traces of both carbon monoxide and dioxide based on the feedstock used [185,186], while solids can be used for several applications [190,191,192,193,194,195]. When the feedstock is composed of plastic wastes, polymers undergo a depolymerization process that leads to the formation of monomers or short-chain hydrocarbons [189,196]. Thermal pyrolysis is suitable for the treatment of a large number of wastes, including contaminated and mixed materials (e.g., mixed plastics). It offers an effective solution for processing EOL aircraft materials, such as common polyolefins and polyesters, without the need for cleaning of separation of materials. Moreover, pyrolysis has demonstrated potential application for recovery of polymer composite materials, such as CFRP and GFRP. A wide number of studies explored the feasibility of this method for the recovery of good-quality carbon fibers [197,198,199]. Many studies demonstrated properties suitable for other kinds of applications. In addition to the recovery of hydrocarbons and gases, this process allows for the recovery of carbon fibers with high mechanical properties, slightly lower than the virgin product. Furthermore, the use of appropriate process parameters guarantees the achievement of good surface properties of the fiber, allowing its reuse in field such as automotive. Given the potential of the process, which guarantees the recovery of high-added-value materials, many companies have started projects for the development of pilot plants, aiming to a large-scale development [200,201,202,203].

Alternatively to thermal pyrolysis, microwave-assisted pyrolysis have been explored even if it struggles to reach large-scale development due to intrinsic issues related to temperature control [204,205,206,207]. Nevertheless, the processing of composites represent an interesting application for such techniques considering that is not necessary the addition of any additives for boosting the microwave-induced heating [208,209,210,211,212,213,214]. As mentioned by Lester et al. [215], the processing of carbon-fiber composites can be easily processed with high-quality fibers that can be recovered a limited number of times. Alternatively, microwave techniques can be combined with solvent media for the recycling of complex materials such as poly(carbonate) glasses for the production of high-value monomers [216,217].

3.2.2. Melting and Forging

After the aircraft is scrapped, the recovered metals are mechanically treated (shredding) in order to reduce their size for better handling. When an aircraft reaches the end of its life, the recovery and recycling of materials begins with a mechanical shredding process to reduce the size of recovered metals for easier handling. After shredding, various sorting technologies, such as density separation with air streams, eddy-current separation, and magnetic separation, are employed to segregate the materials, which are then sold to recyclers [218,219]. In some cases, flotation techniques are also utilized for additional sorting. This process is exemplified by Bartin’s dismantling and shredding facilities in Châteauroux and Bourges, although other companies may adopt slightly different approaches that generally follow a similar framework [18].

The primary metals recovered from end-of-life aircraft include aluminum, alloy steel, titanium, and tungsten, with aluminum being the predominant material, especially in the fuselage and wings. Tungsten is often found in counterweights, and copper wires can also be separated. Certain dismantlers recover smaller quantities of rare and precious metals, such as those in electrical connectors, although these are often neglected due to their limited presence. Most of the recovered metals, like aluminum, are of mixed quality. The mixed quality of recovered aluminum, which often contains different alloys, limits its reuse in more demanding applications. However, since the primary production of aluminum is an energy-intensive process, the demand for it to be recycled is huge [220]. For example, EOL aircraft aluminum may contain a combination of different alloys, primarily from the 7000 and 2000 series, along with traces of other metals like steel and titanium from rivets. Additionally, composites, plastics, and textiles are frequently mixed in, especially if the aircraft’s interior is not fully removed before scrapping [218]. While manual dismantling could improve material quality, it significantly increases costs, particularly in regions with high labor expenses. Thus, a trade-off exists between the costs of manual dismantling and the quality of recovered materials. To address this, advancements in automated dismantling techniques, such as small drilling robots to recover specific types of aluminum, steel, and titanium rivets, could offer a more cost-effective solution.

Recycling avionics and electronics from EOL aircraft poses additional challenges. These components can be shredded in waste electrical and electronic equipment shredders to recover rare earths and precious metals, but the quality of the recovered fragments is often suboptimal. Moreover, the recycling of emerging aluminum alloys, such as aluminum–lithium (Al-Li), aluminum–scandium (Al-Sc), and aluminum–magnesium–lithium (Al-Mg-Li), presents unresolved issues. For instance, the presence of lithium in aluminum scrap creates explosion risks during remelting, making it undesirable in recycling processes [218].