Value-Added Recycling of Pre-Consumer Textile Waste: Performance Evaluation of Cotton Blend Knitted T-Shirts

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

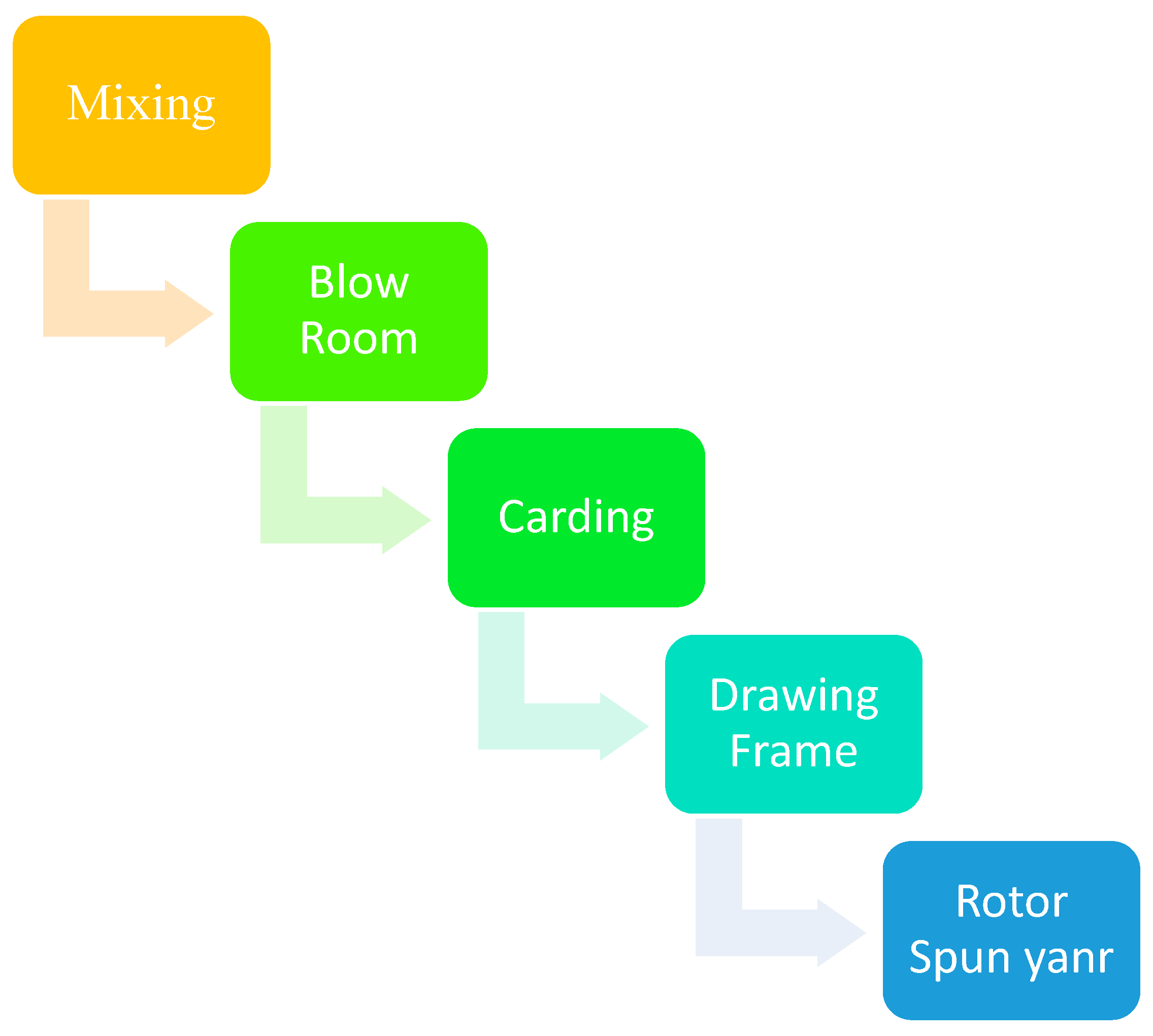

2.2. Methods

2.2.1. Recovery of Fibers from Waste

2.2.2. Ring Spinning of Yarn

2.2.3. Knitting Process

2.2.4. Scouring and Bleaching

2.2.5. Development of T-Shirts

2.3. Characterization

3. Results and Discussion

3.1. Fiber Properties

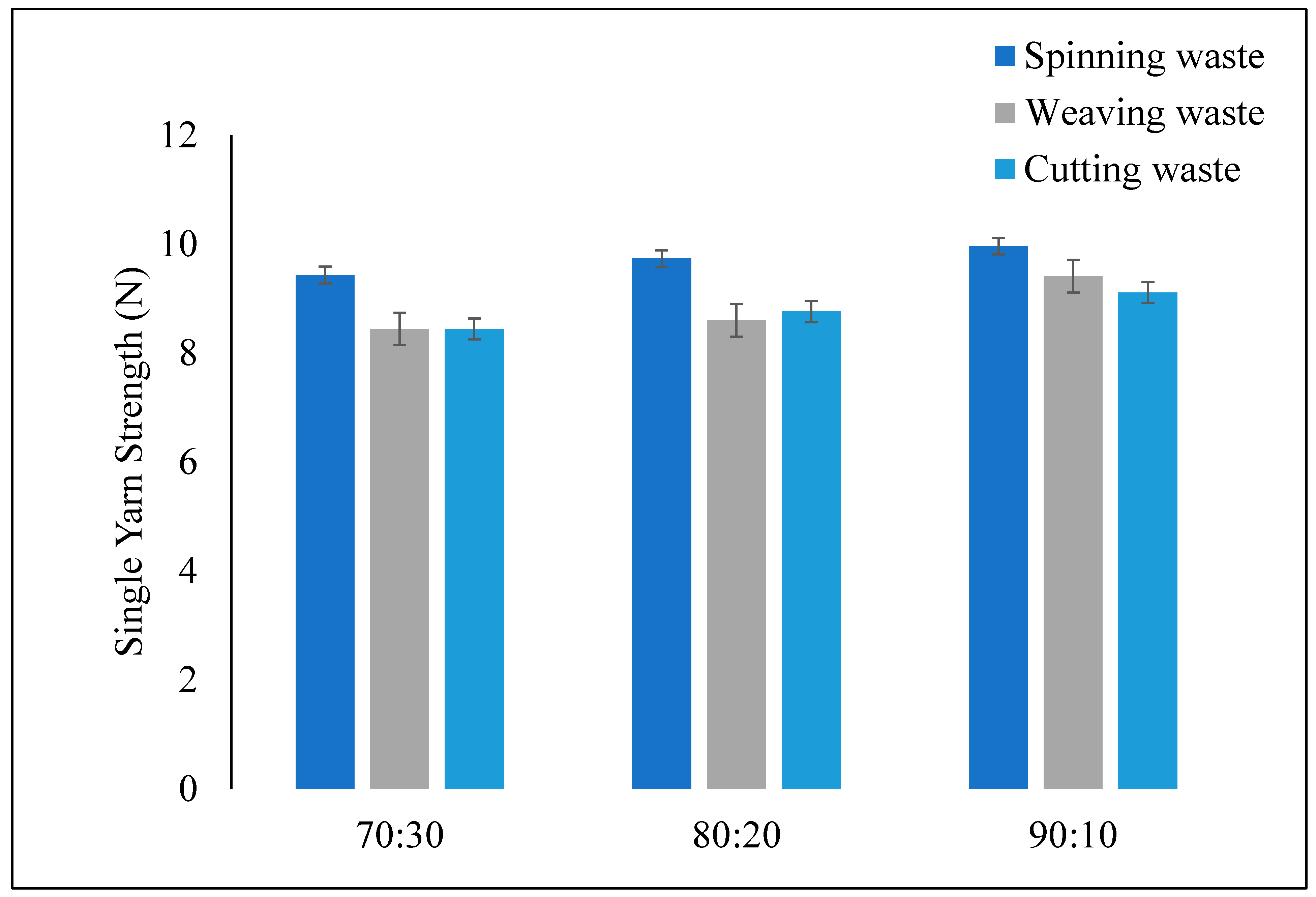

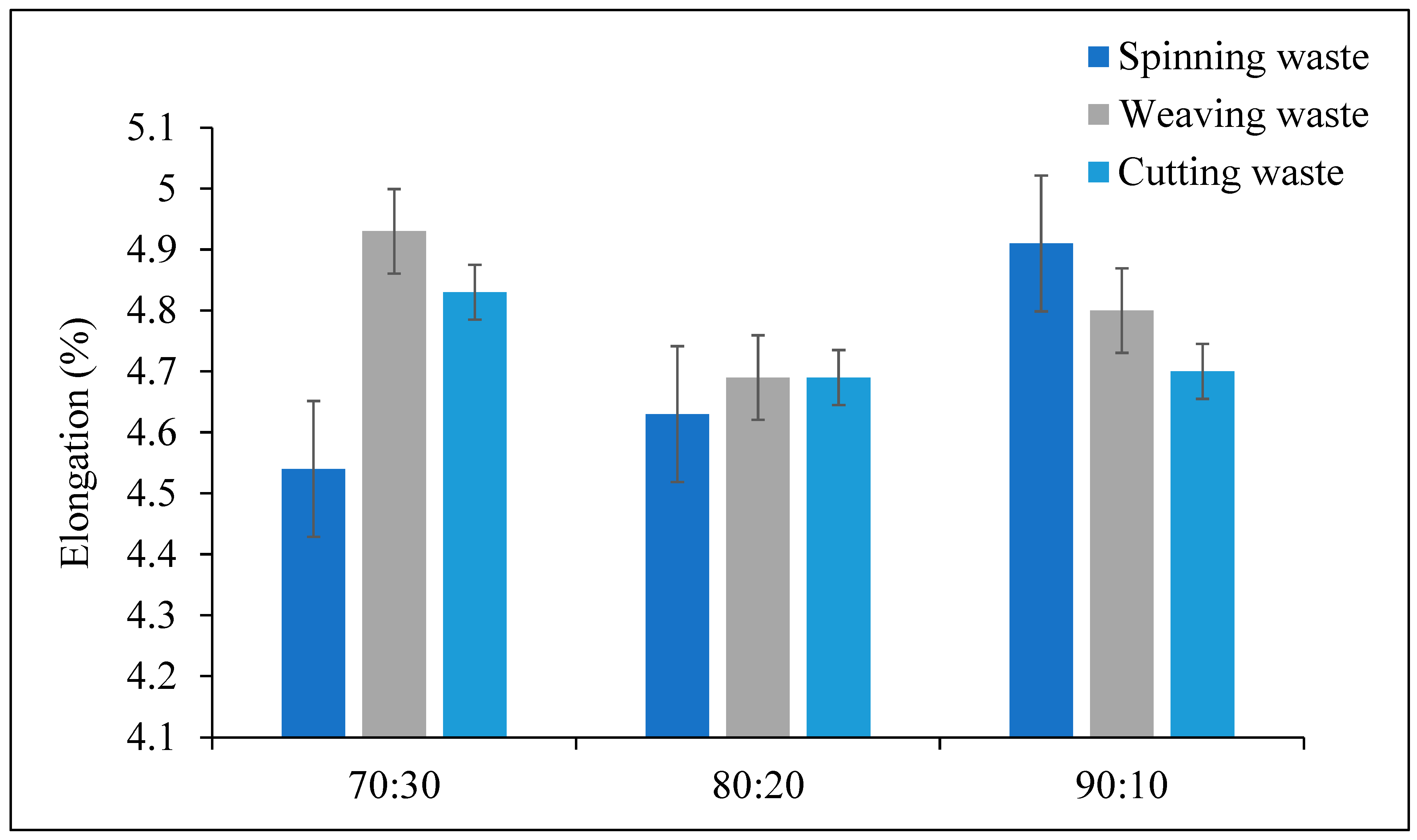

3.2. Yarn Properties

3.2.1. Single Yarn Strength

3.2.2. Yarn Elongation

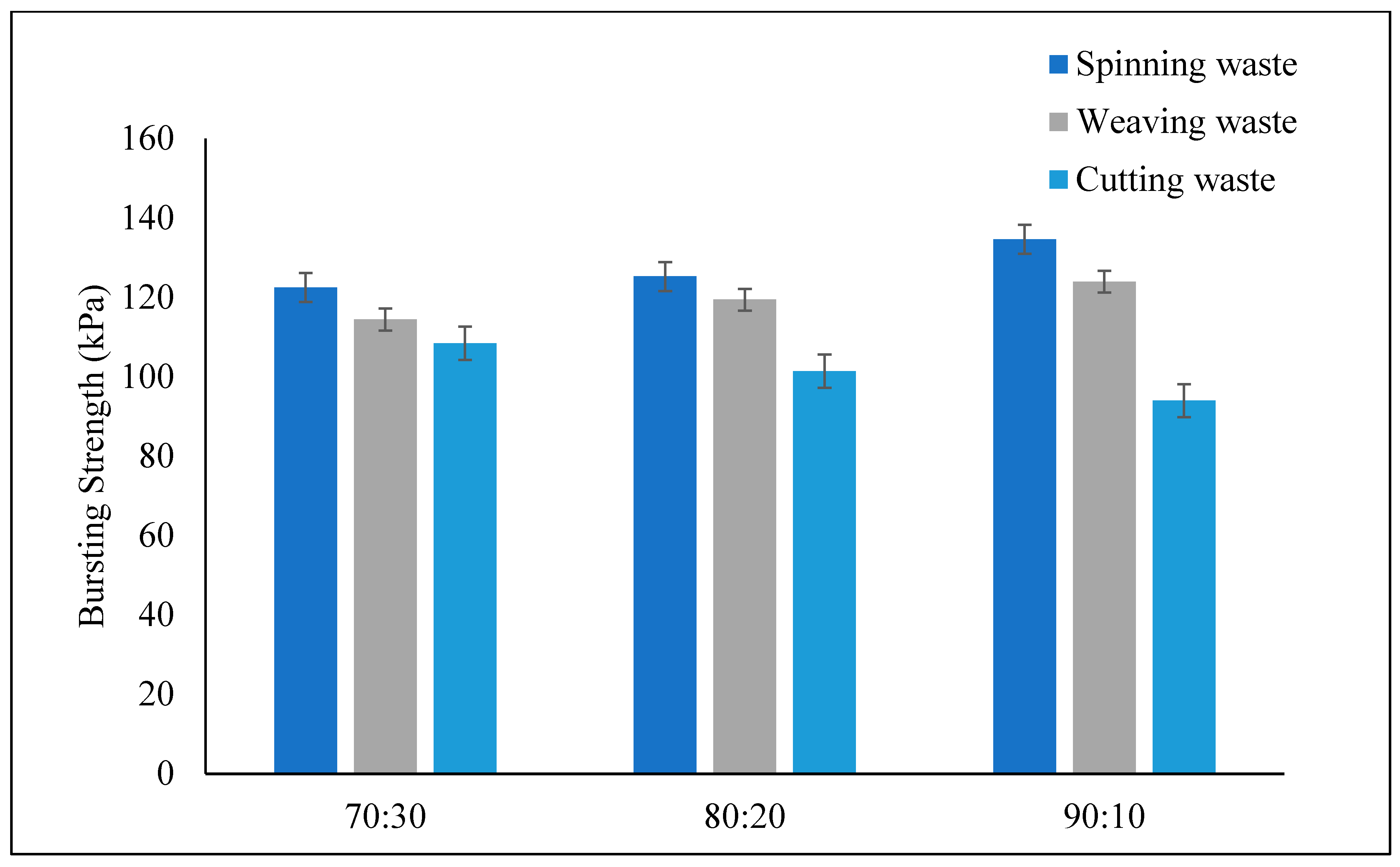

3.3. Fabric Results

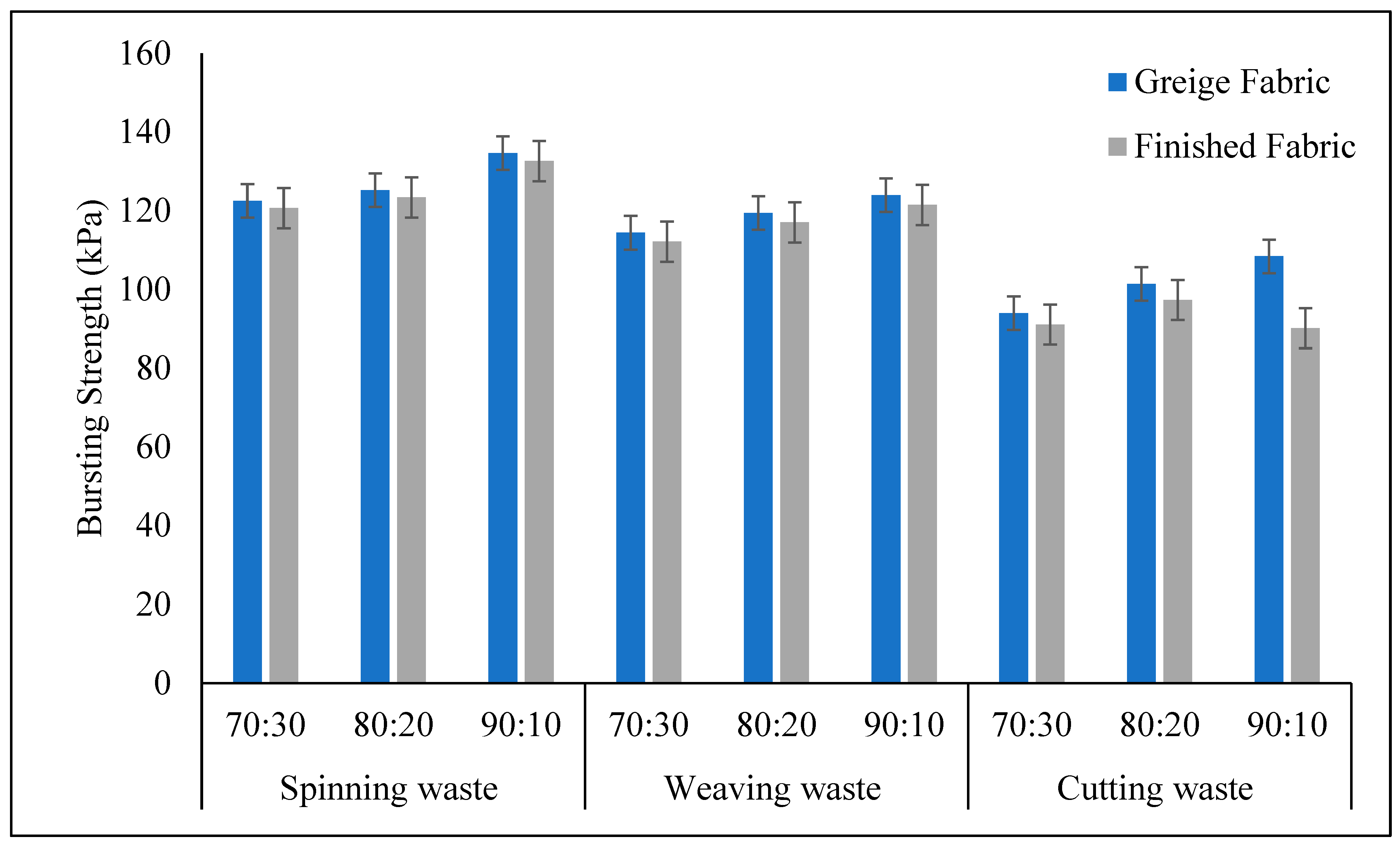

3.3.1. Bursting Strength

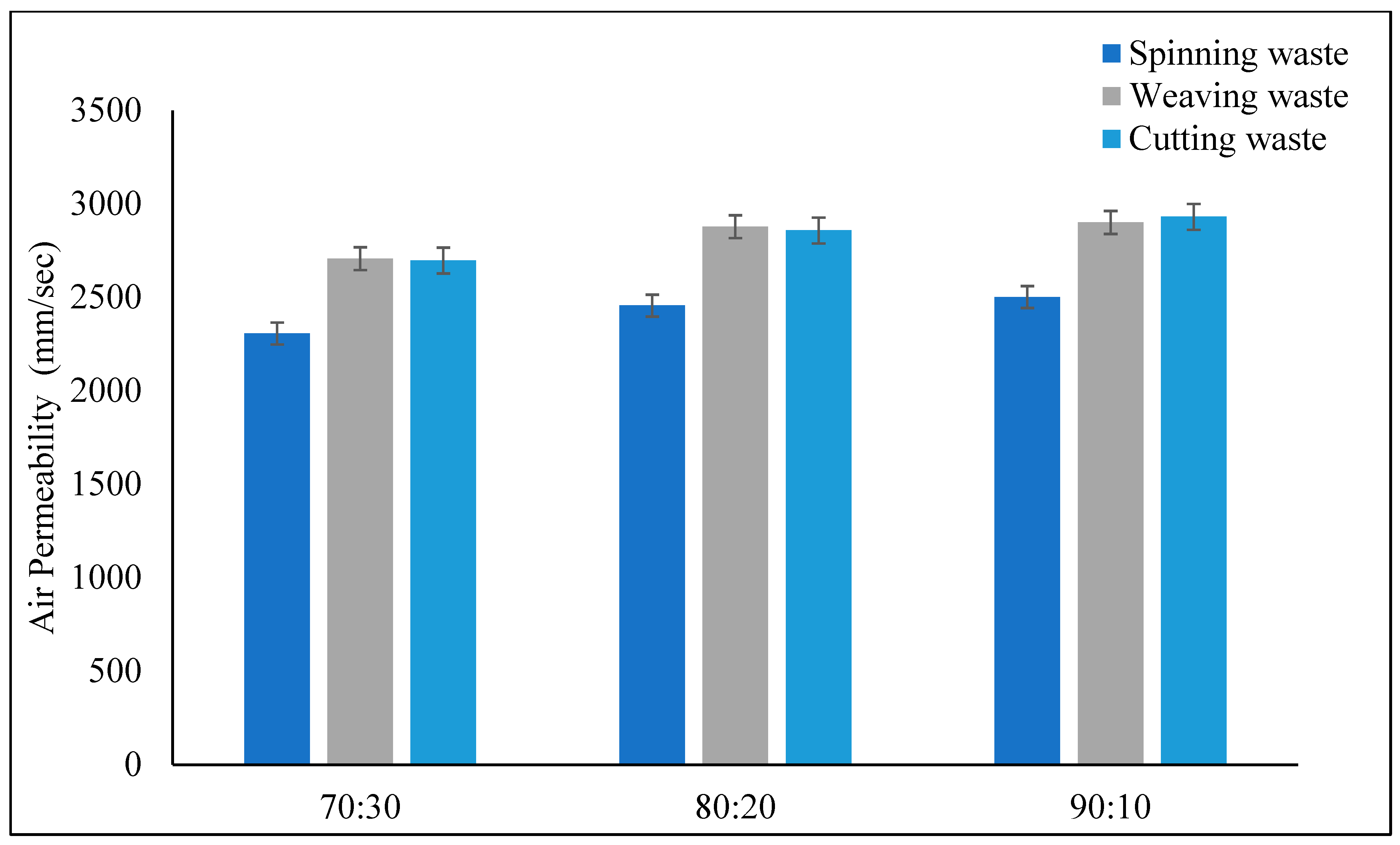

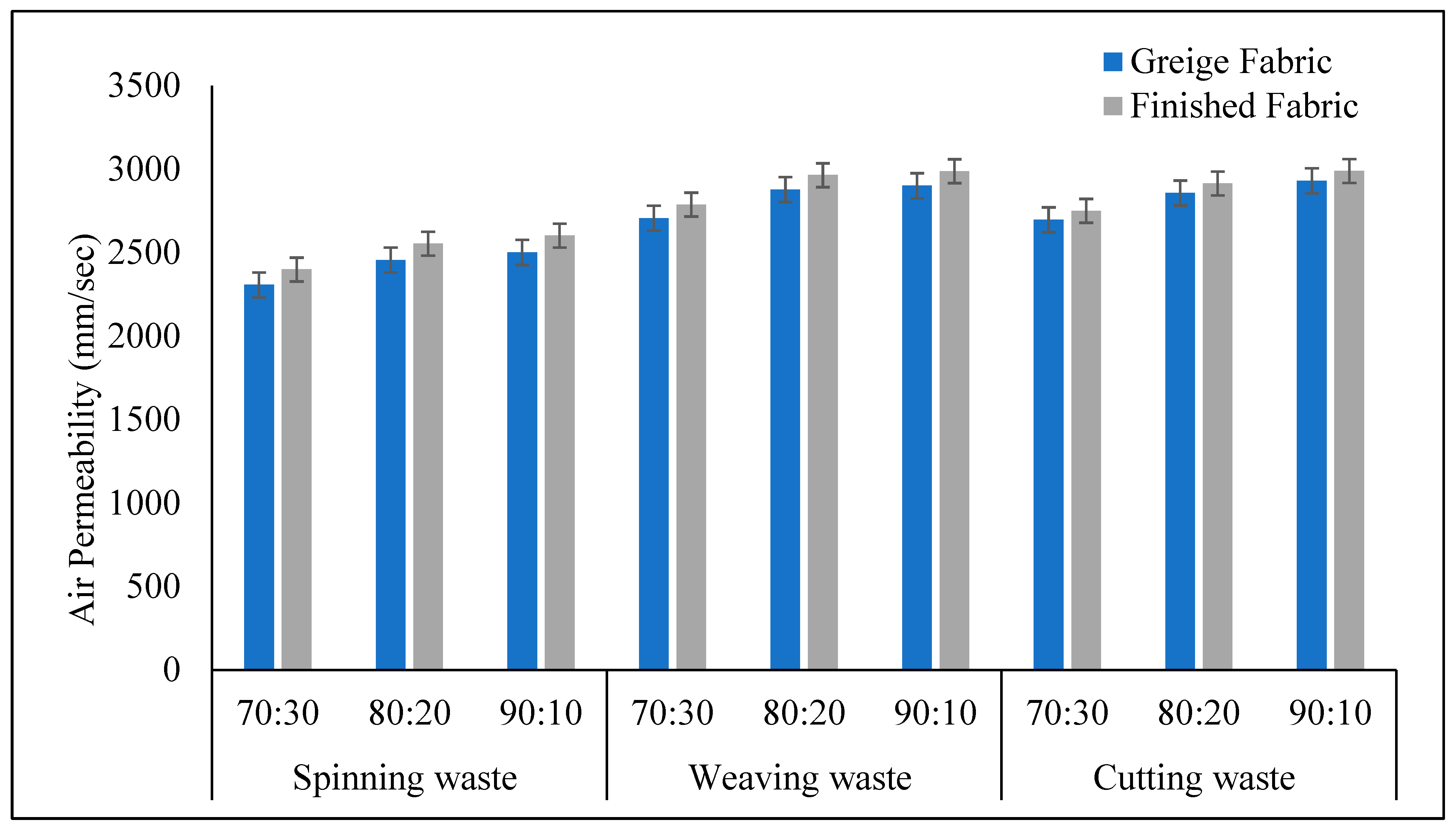

3.3.2. Air Permeability

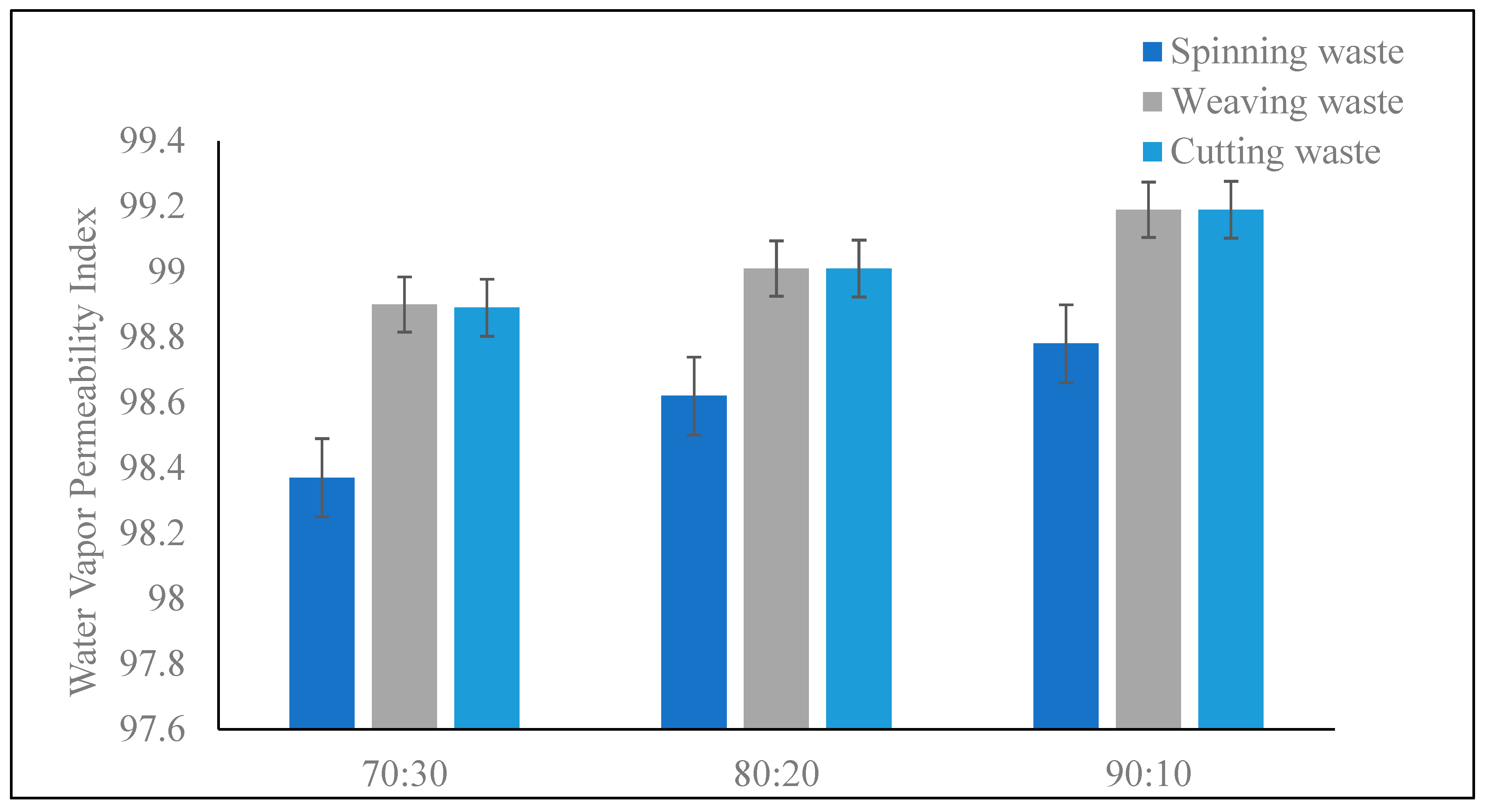

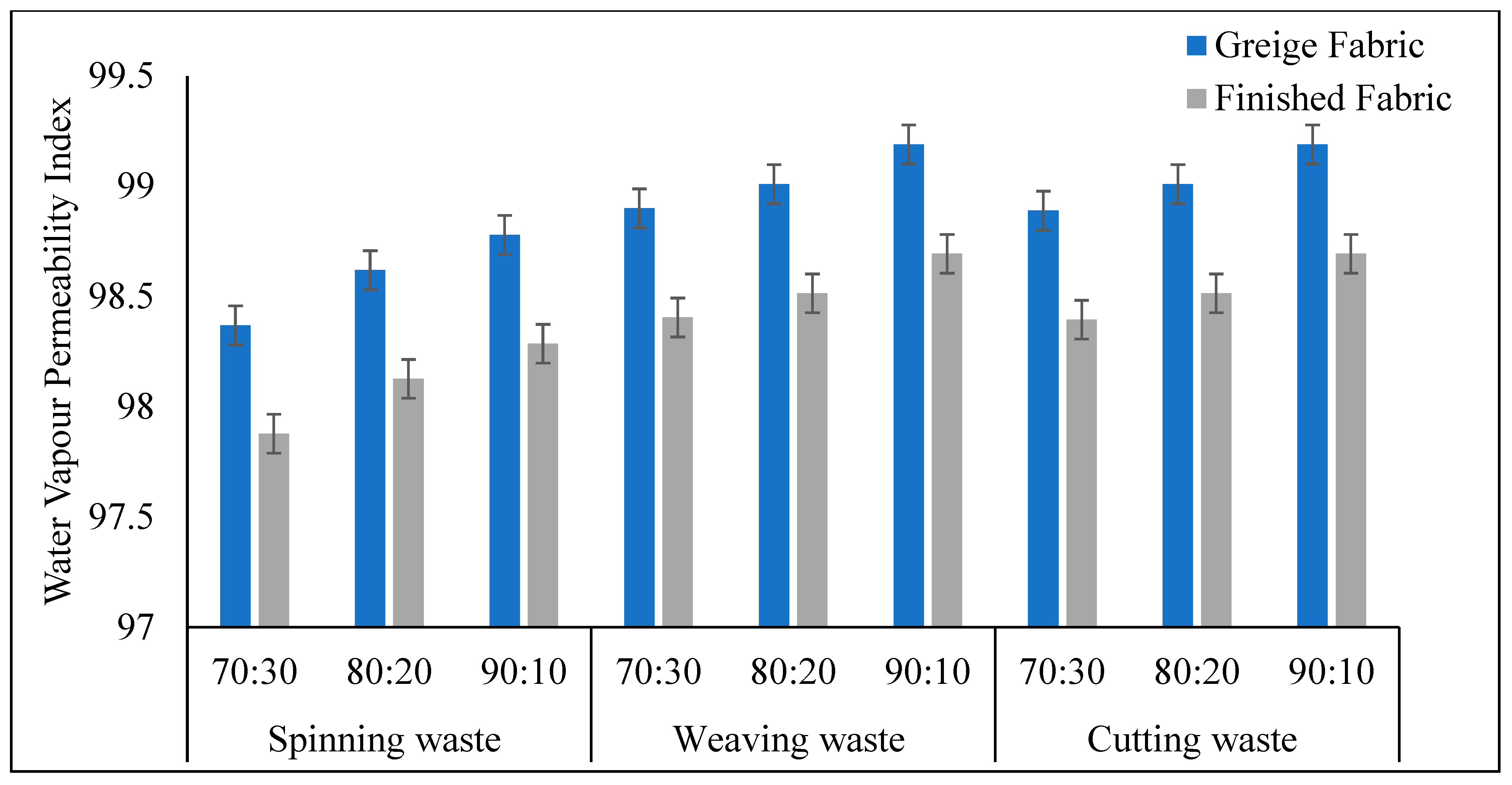

3.3.3. Water Vapor Permeability Index

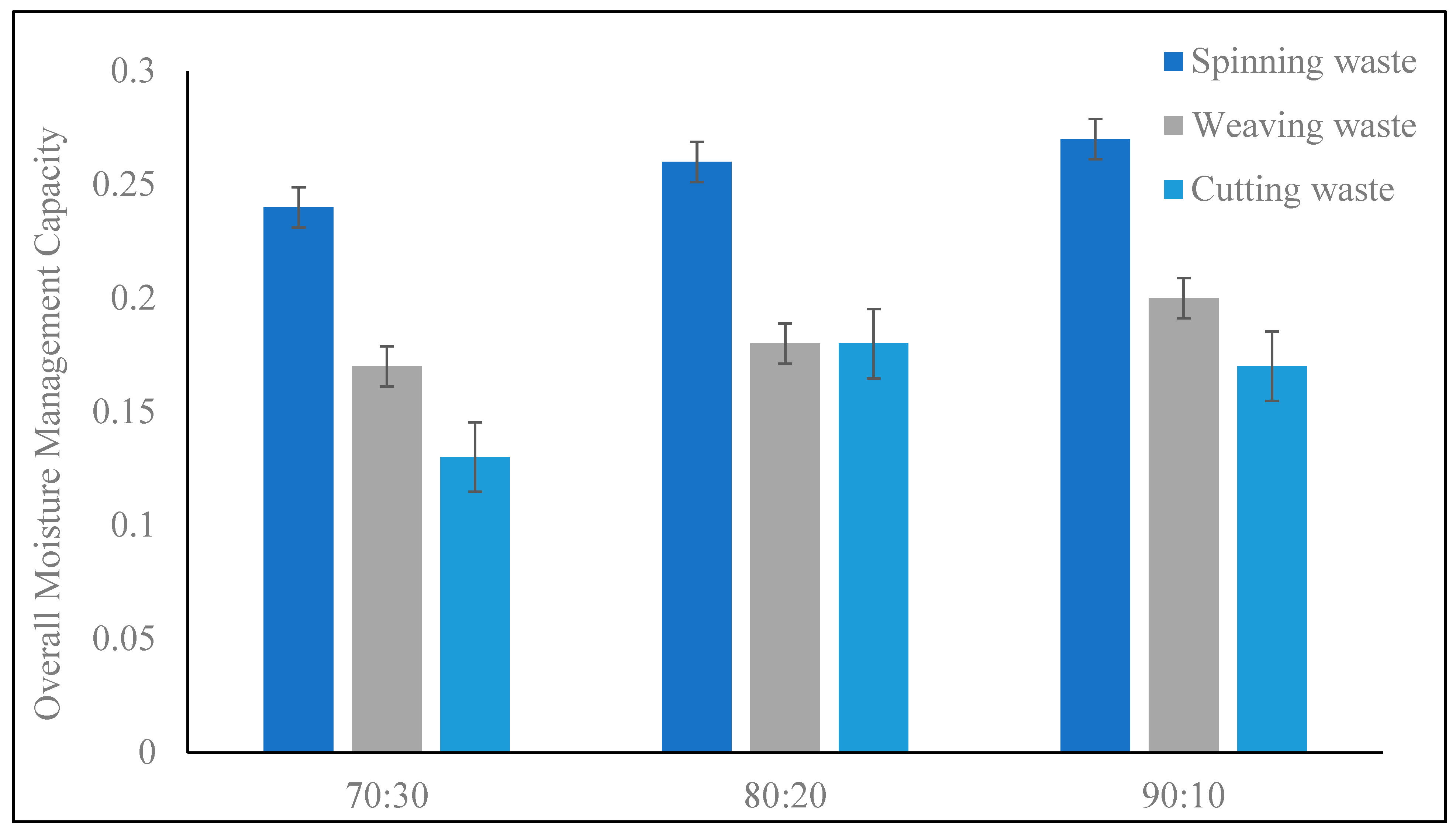

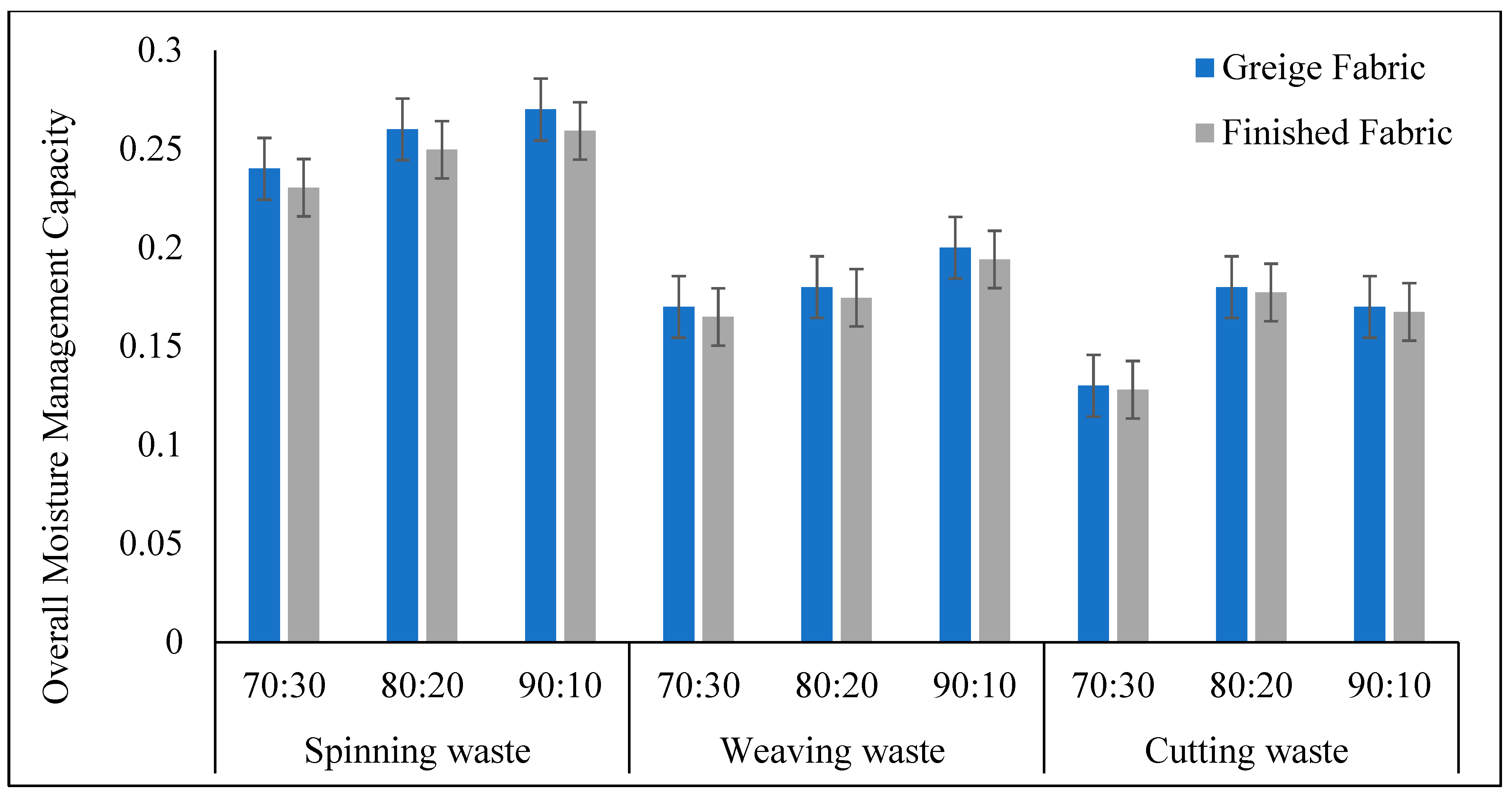

3.3.4. Overall Moisture Management Capacity

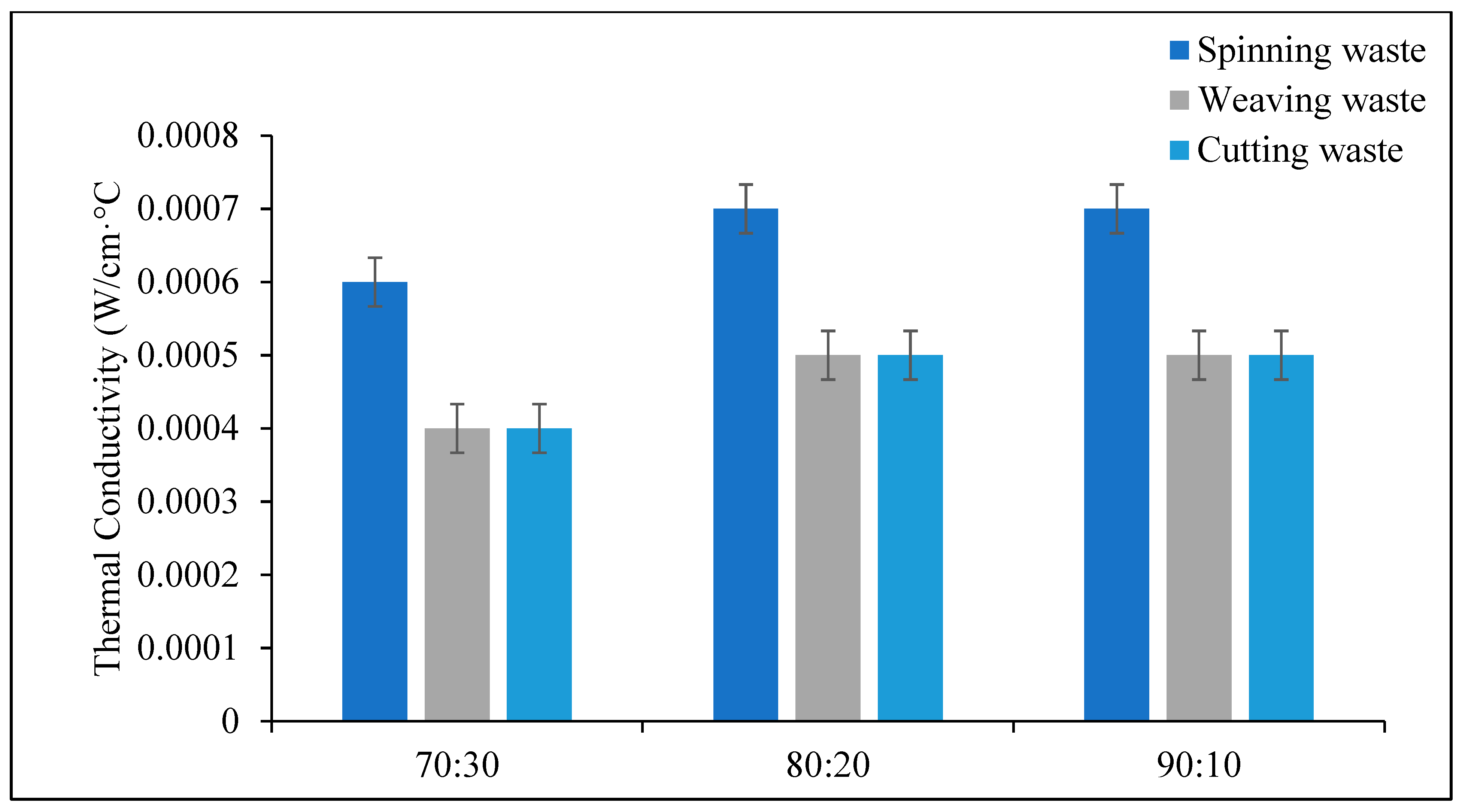

3.3.5. Thermal Conductivity

3.4. Finished Fabric Results

3.4.1. Bursting Strength

3.4.2. Air Permeability

3.4.3. Water Vapor Permeability Index

3.4.4. Overall Moisture Management Capacity

3.4.5. Thermal Conductivity

3.5. Effect of Washing on Comfort Properties

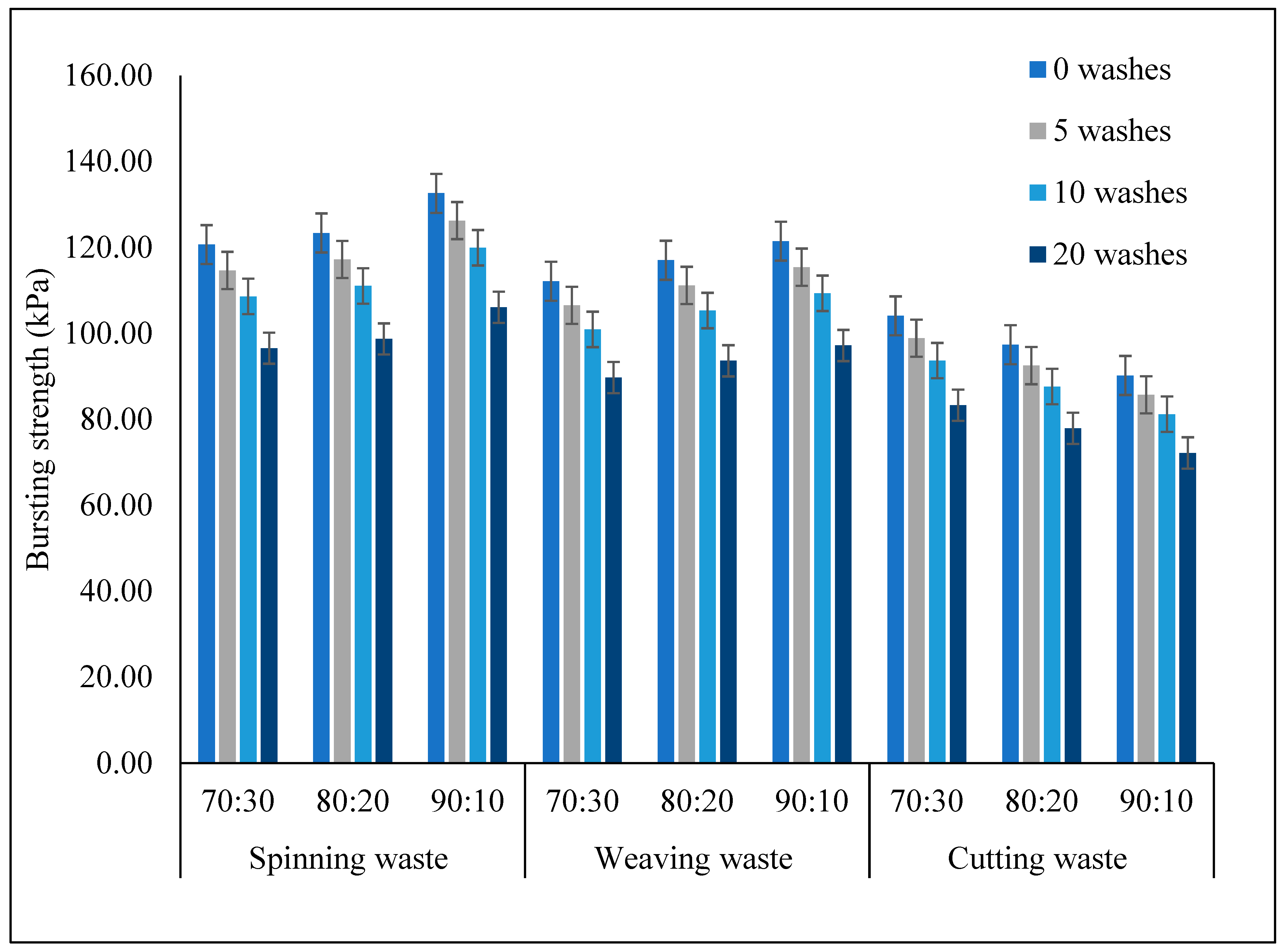

3.5.1. Bursting Strength

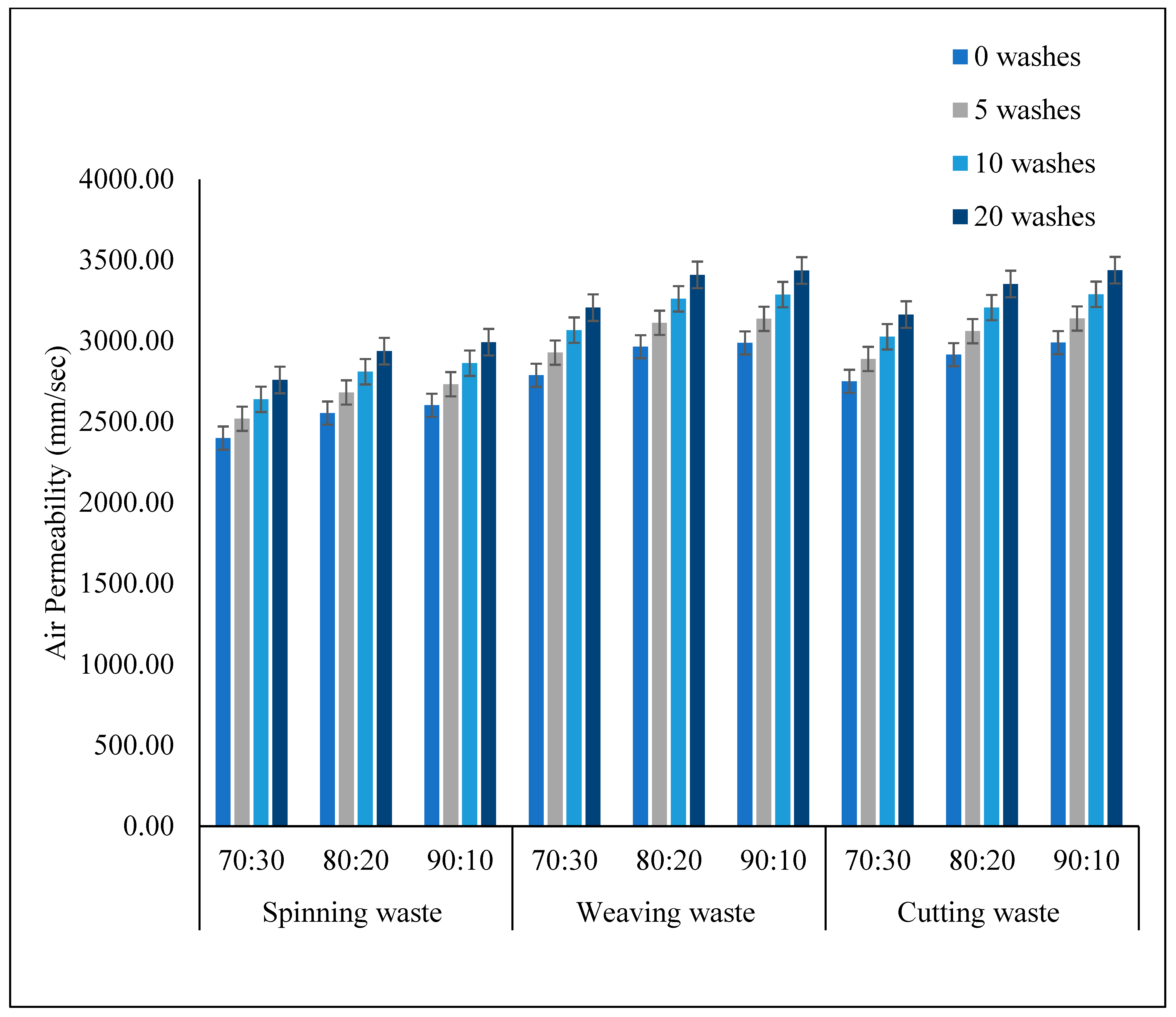

3.5.2. Air Permeability

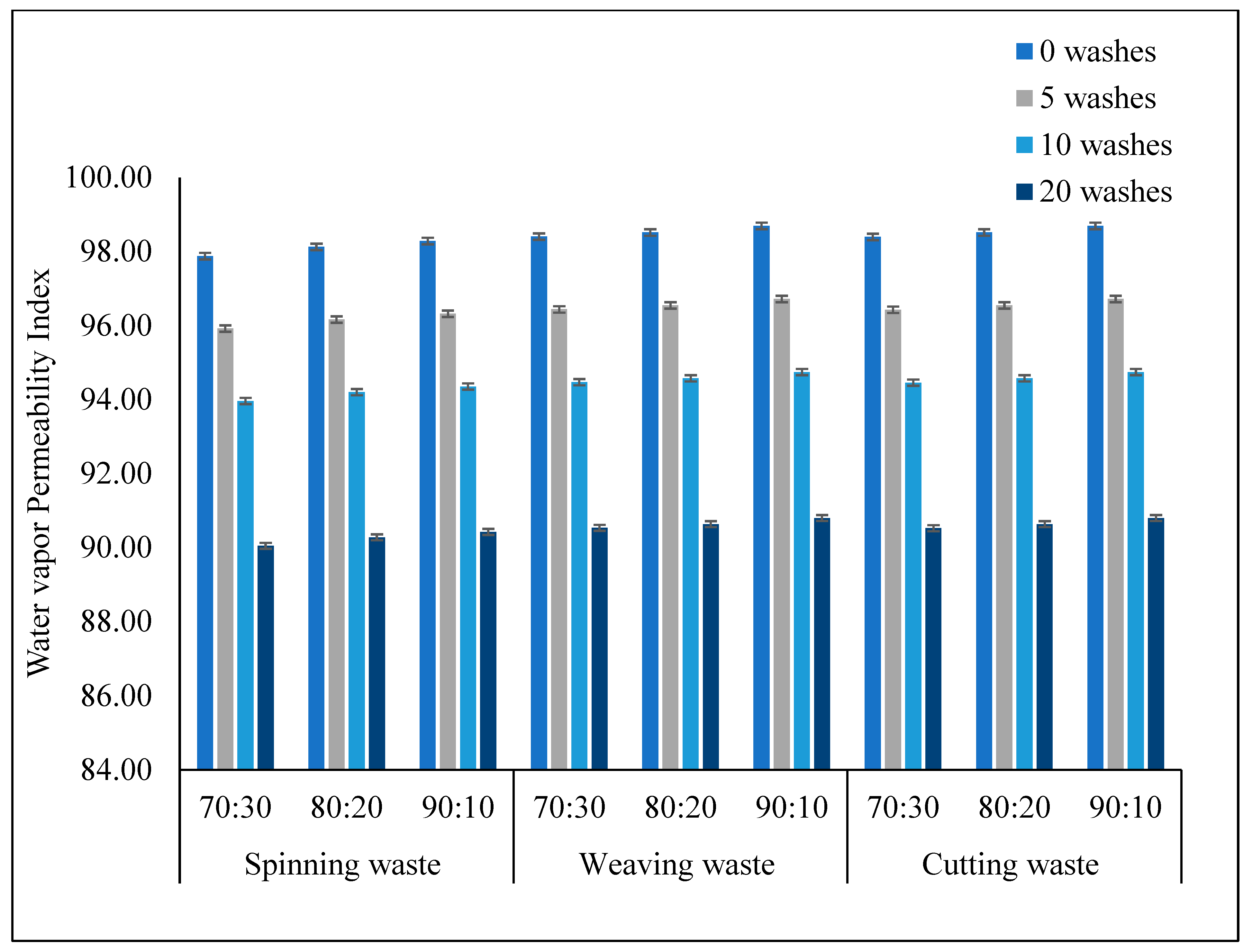

3.5.3. Water Vapour Permeability

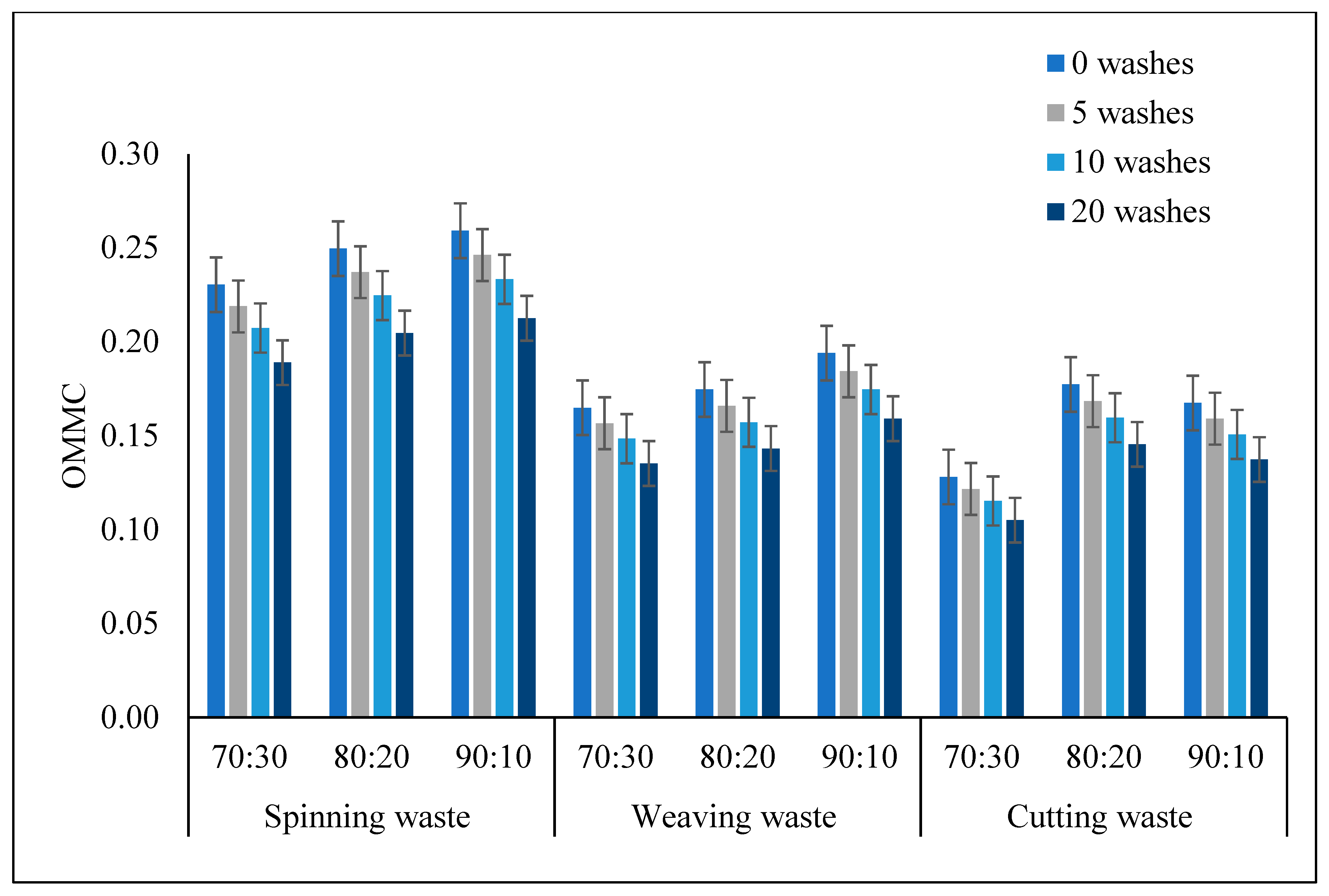

3.5.4. Overall Moisture Management Capacity

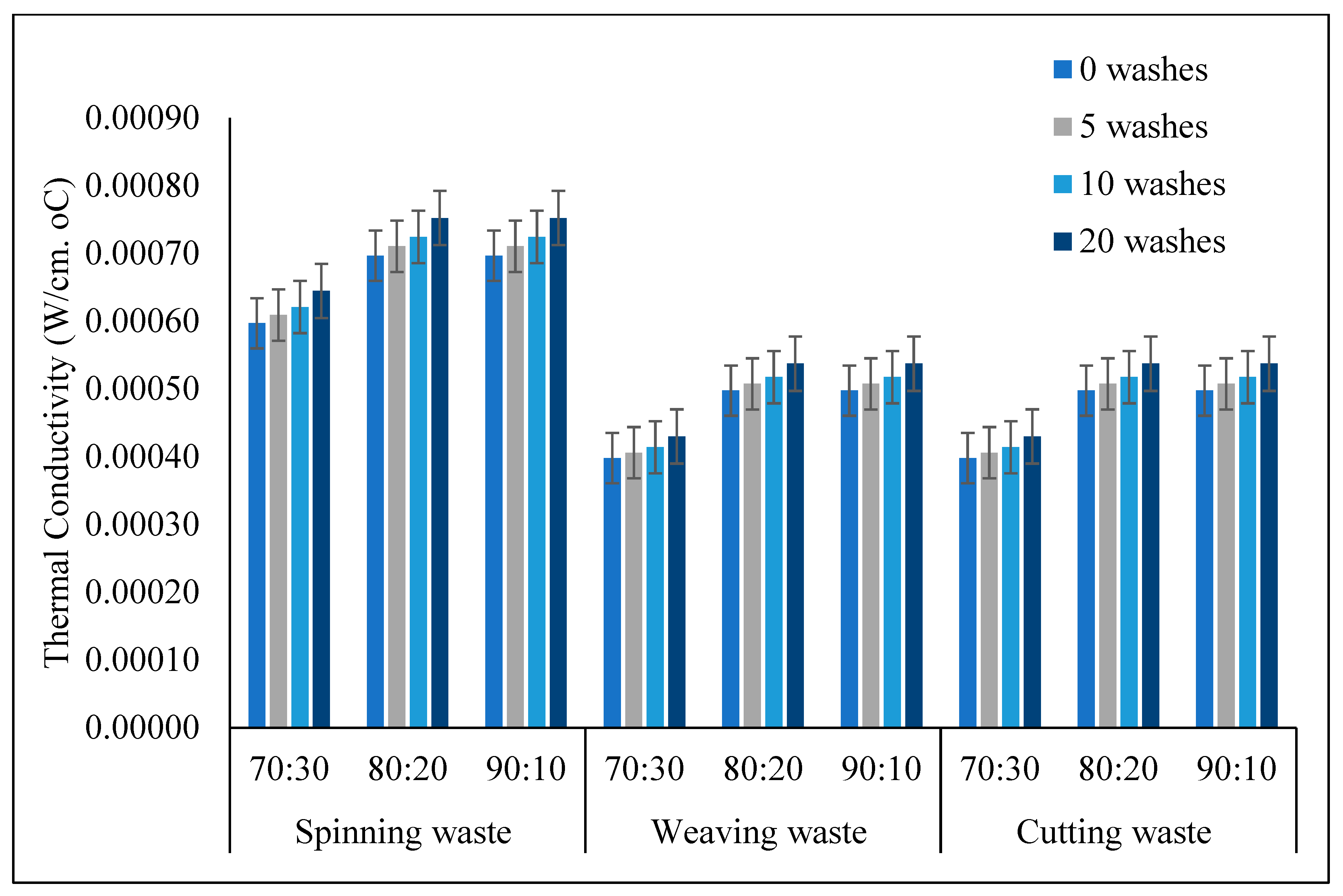

3.5.5. Thermal Conductivity

4. Conclusions

- Waste Segregation and Sorting

- Pre-processing w.r.t. Cleaning and Opening

- Blending Strategy

- Carding and Drawing Process Adjustment

- Chemical Treatments

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Arafat, Y.; Uddin, A.J. Recycled fibers from pre-and post-consumer textile waste as blend constituents in manufacturing 100% cotton yarns in ring spinning: A sustainable and eco-friendly approach. Heliyon 2022, 8, 2405–8440. [Google Scholar] [CrossRef]

- Ma, K.; Wang, L.; Chen, Y. A collaborative cloud service platform for realizing sustainable make-to-order apparel supply chain. Sustainability 2017, 10, 11. [Google Scholar] [CrossRef]

- Shahid, M.A.; Hossain, M.T.; Habib, M.A.; Islam, S.; Sharna, K.; Hossain, I.; Limon, M.G.M. Prospects and challenges of recycling and reusing post-consumer garments: A review. Cleaner Eng. Technol. 2024, 19, 100744. [Google Scholar] [CrossRef]

- Stanescu, M.D. State of the art of post-consumer textile waste upcycling to reach the zero waste milestone. Environ. Sci. Pollut. Res. 2021, 28, 14253–14270. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Chen, Q.; Fu, B.; Zheng, R.; Fan, J. Current situation and construction of recycling system in China for post-consumer textile waste. Sustainability 2022, 14, 16635. [Google Scholar] [CrossRef]

- Koszewska, M. Circular economy-challenges for the textile and clothing industry. Autex Res. J. 2018, 18, 337–347. [Google Scholar] [CrossRef]

- Piribauer, B.; Bartl, A. Textile recycling processes, state of the art and current developments: A mini review. Waste Manag. Res. 2019, 37, 112–119. [Google Scholar] [CrossRef]

- Shahid, I.; Mujtaba, M.A.; Muhammad, M.Z.; Amjad, H.; Amjad, M.; Umm, E.F.; Korakianitis, T.; Kalam, M.A.; Fayaz, H.; Saleel, C.A. Assessing the potential of GHG emissions for the textile sector: A baseline study. Heliyon 2023, 9, 2405–8440. [Google Scholar] [CrossRef]

- Das, A.; Ishtiaque, S.M. End breakage in rotor spinning: Effect of different variables on cotton yarn end breakage. Autex. Res. J. 2004, 4, 52–59. [Google Scholar] [CrossRef]

- Paço, A.; Leal Filho, W.; Ávila, L.V.; Dennis, K. Fostering sustainable consumer behavior regarding clothing: Assessing trends on purchases, recycling and disposal. Text. Res. J. 2021, 91, 373–384. [Google Scholar] [CrossRef]

- Sharma, I.C.; Mukhopadhyay, D.; Agarwal, B.R. Feasibility of single jersey fabric from open-end spun blended yarn. Text. Res. J. 1986, 56, 249–253. [Google Scholar] [CrossRef]

- Teli, M.D.; Khare, A.R.; Chakrabarti, R. Dependence of yarn and fabric strength on the structural parameters. Autex. Res. J. 2008, 8, 63–67. [Google Scholar] [CrossRef]

- Awgichew, D.; Sakthivel, S.; Solomon, E.; Bayu, A.; Legese, R.; Asfaw, D.; Bogale, M.; Aduna, A.; Senthil, K.S. Experimental study and effect on recycled fibers blended with Rotor/OE yarns for the production of handloom fabrics and their properties. Adv. Mater. Sci. Eng. 2021, 1, 1687–8434. [Google Scholar] [CrossRef]

- Duru, P.N.; Babaarslan, O. Determining an optimum opening roller speed for spinning polyester/waste blend rotor yarns. Text. Res. J. 2003, 73, 907–911. [Google Scholar] [CrossRef]

- Mohamed, T.H.; Bechir, A.; Mohamed, B.H.; Faouzi, S. Influence of spinning parameters and recovered fibers from cotton waste on the uniformity and hairiness of rotor spun yarn. J. Eng. Fibers Fabr. 2009, 4, 1558. [Google Scholar] [CrossRef]

- Gabriela, K. Assessment of the effects of the use of preconsumer cotton waste on the quality of rotor yarns. Heliyon 2024, 10, 2405–8440. [Google Scholar] [CrossRef]

- Vidhya, M.; Parveen, B.K.; Vasanth, K.D.; Prakash, C.; Subramaniam, V. Study on single jersey knitted fabrics made from cotton/polyester core spun yarns. part I: Thermal comfort properties. Text. Apparel. 2021, 31, 295–305. [Google Scholar] [CrossRef]

- Vasanth, K.D.; Raja, D. Study of thermal comfort properties on socks made from recycled polyester/virgin cotton and its blends. Fibers Polym. 2021, 22, 841–846. [Google Scholar] [CrossRef]

- Gun, A.D.; Alan, G.; Macit, A.S. Thermal properties of socks made from reclaimed fibre. J. Text. Inst. 2016, 107, 1112–1121. [Google Scholar] [CrossRef]

- Gun, A.D.; Akturk, H.N.; Macit, A.S.; Alan, G. Dimensional and physical properties of socks made from reclaimed fibre. J. Text. Inst. 2014, 105, 1108–1117. [Google Scholar] [CrossRef]

- Habib, A.; Cozeli, N.; Babaarslan, O.; Kanat, H.; Tan, S. Sustainable production of open-end rotor yarn for denim with maximum utilization of recycled cotton sourced from pre-consumer hard waste. Text. Leather. Rev. 2024, 7, 831–853. [Google Scholar] [CrossRef]

- Akhtar, S.; Ahmad, F.; Nawab, Y.; Rasheed, A.; Ahmad, S.; Azam, F. Development of sustainable comfortable socks from recycled leno waste. J. Eng. Fibers Fabr. 2024, 19. [Google Scholar] [CrossRef]

| Serial # | Waste Type | Yarn Count | Composition |

|---|---|---|---|

| 1 | Spinning | 22/1 Ne | 70:30 |

| 2 | 80:20 | ||

| 3 | 90:10 | ||

| 4 | Weaving | 22/1 Ne | 70:30 |

| 5 | 80:20 | ||

| 6 | 90:10 | ||

| 7 | Cutting | 22/1 Ne | 70:30 |

| 8 | 80:20 | ||

| 9 | 90:10 |

| S. No | Property | Spinning Waste | Weaving Waste | Cutting Waste |

|---|---|---|---|---|

| 1 | Mic Value | 4.25 | 4.84 | 4.91 |

| 2 | 50% Span length (mm) | 9.5 | 8.73 | 7.79 |

| 3 | 25%Span length (mm) | 19.22 | 18.11 | 16.66 |

| 4 | Uniformity Ratio | 52.1 | 48.2 | 47.21 |

| 5 | short Fiber % | 18.33 | 21.52 | 23.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramzan, M.B.; Ikram, S.; Qureshi, S.M.; Iqbal, M.W.; Khan, M.Q. Value-Added Recycling of Pre-Consumer Textile Waste: Performance Evaluation of Cotton Blend Knitted T-Shirts. Recycling 2025, 10, 160. https://doi.org/10.3390/recycling10040160

Ramzan MB, Ikram S, Qureshi SM, Iqbal MW, Khan MQ. Value-Added Recycling of Pre-Consumer Textile Waste: Performance Evaluation of Cotton Blend Knitted T-Shirts. Recycling. 2025; 10(4):160. https://doi.org/10.3390/recycling10040160

Chicago/Turabian StyleRamzan, Muhammad Babar, Sajida Ikram, Sheheryar Mohsin Qureshi, Muhammad Waqas Iqbal, and Muhammad Qamar Khan. 2025. "Value-Added Recycling of Pre-Consumer Textile Waste: Performance Evaluation of Cotton Blend Knitted T-Shirts" Recycling 10, no. 4: 160. https://doi.org/10.3390/recycling10040160

APA StyleRamzan, M. B., Ikram, S., Qureshi, S. M., Iqbal, M. W., & Khan, M. Q. (2025). Value-Added Recycling of Pre-Consumer Textile Waste: Performance Evaluation of Cotton Blend Knitted T-Shirts. Recycling, 10(4), 160. https://doi.org/10.3390/recycling10040160