Abstract

The rapid growth in plastic consumption, particularly polyethylene terephthalate (PET), has led to a significant increase in plastic waste, posing a major environmental challenge. Developing an integrated circular economy framework for nanomaterial-enhanced recycled PET (nrPET) can be a promising approach to address this issue and advance sustainable and resilient road construction practices. This comprehensive review examines the current use of rPET in road construction, its existing limitations, and the role of nanomaterials in enhancing the performance of these materials. The review explores the mechanisms by which nanomaterials, such as carbon nanotubes, graphene, nanosilica, and clay nanoplatelets, can improve the properties of rPET, leading to more durable, weather-resistant, and cost-effective road materials. Furthermore, the review analyzes the environmental and sustainability benefits of using nrPET in road construction, focusing on carbon footprint reduction, conservation of natural resources, and alignment with circular economy principles. The potential for job creation, social benefits, and support for circular economy initiatives are also discussed. The review then delves into the challenges associated with the implementation of this framework, including technical barriers, economic and market barriers, regulatory and policy challenges, and environmental and safety considerations. Strategies to address these challenges, such as advancements in nanotechnology, scaling up circular economy models, and fostering collaborative research, are presented. Finally, the article proposes a framework and outlines future directions and research opportunities, emphasizing the exploration of emerging nanomaterials, scaling up circular economy models, and encouraging collaborations between researchers, industry stakeholders, policymakers, and communities.

1. Introduction

The road construction industry faces significant environmental and resource challenges, including substantial waste generation, high carbon emissions, and depletion of natural resources [1,2]. These issues directly impact the achievement of several Sustainable Development Goals (SDGs), such as SDG 12 (Responsible Consumption and Production), SDG 13 (Climate Action), SDG 9 (Industry, Innovation, and Infrastructure), and SDG 11 (Sustainable Cities and Communities) [3,4]. To address these challenges, this article explores the potential of recycled polyethylene terephthalate (PET) and nanomaterials to enhance the sustainability and resilience of road construction materials. Recycled PET (rPET) and nanomaterials can offer innovative solutions to reduce waste, lower carbon emissions, and conserve natural resources, thereby contributing to the realization of the aforementioned SDGs [5,6].

The circular economy framework, which emphasizes the reuse and recycling of materials, is a promising approach to achieve sustainable and resilient road construction. By integrating rPET and nanomaterials into this framework, the article aims to demonstrate how the road construction industry can align its practices with the UN’s 2030 Agenda for Sustainable Development [7,8]. The need for a comprehensive circular economy framework for the use of rpPET in road construction arises from the limitations and challenges associated with the current recycling and reuse of PET materials [9,10]. Specifically, the quality and properties of rPET materials are often degraded compared to virgin PET due to contamination and thermal and mechanical processing during recycling [11,12,13,14,15]. This limits the potential for closed-loop recycling and reuse of PET in high-value applications like road construction [16,17]. In addition, incorporating rPET aggregates or fibers into concrete and asphalt mixes can lead to reduced strength and performance compared to conventional materials [12,13,15]. This poses challenges for using rPET in sustainable road construction practices. In addition, the circular economy principles of “narrowing, slowing, and closing material loops” are not fully realized in current PET recycling and reuse systems [18,19]. There is a need for a more integrated approach to enhance the circularity and sustainability of PET-based road construction materials. On the other hand, the integration of digital technologies like digital twins can further advance the implementation of circular economy principles in the construction industry, but the linkages between design, demolition, and circularity are not well established [20,21]. Due to material deterioration during processing, current PET recycling techniques for road construction have significant limits. Thermal degradation, contamination, and polymer chain scission are the main causes of conventional rPET’s markedly lower mechanical qualities and durability when compared to virgin materials. Despite considerable advancements, the use of PET fibers as reinforcement for concrete is still restricted to single-lifecycle applications in the absence of efficient recovery technologies. Recycling procedures for plastic trash have not yet been successfully incorporated with the construction industry’s increasing use of digital technologies. Most significantly, the core issues of material performance, closed-loop recyclability, and extensive application in infrastructure projects are not all concurrently addressed by current solutions.

Hence, this study presents an integrated system that blends circular economy management with superior material engineering using digital technologies. The main breakthrough is the use of carefully designed nanoparticles to improve and restore the qualities of rPET, allowing for several high-value reuse cycles without performance deterioration. This is an intelligent tracking and optimization system that keeps an eye on material conditions at every stage of the lifecycle, from initial processing to construction, service life, and recovery. Two crucial gaps are uniquely filled by the framework: it creates true closed-loop material flows and maintains performance on par with traditional materials. When it comes to sustainable infrastructure development, this all-encompassing strategy is a major improvement over the existing single-aspect approaches.

Accordingly, to address the above limitations, a comprehensive circular economy framework that integrates the use of nanomaterial-enhanced recycled PET (nrPET) in road construction is needed to improve the quality, performance, and sustainability of these materials [22,23,24,25,26]. This article provides a detailed framework for implementing rpPET circular economy in road construction, highlighting the synergies and trade-offs between the various SDGs.

2. Research Methodology

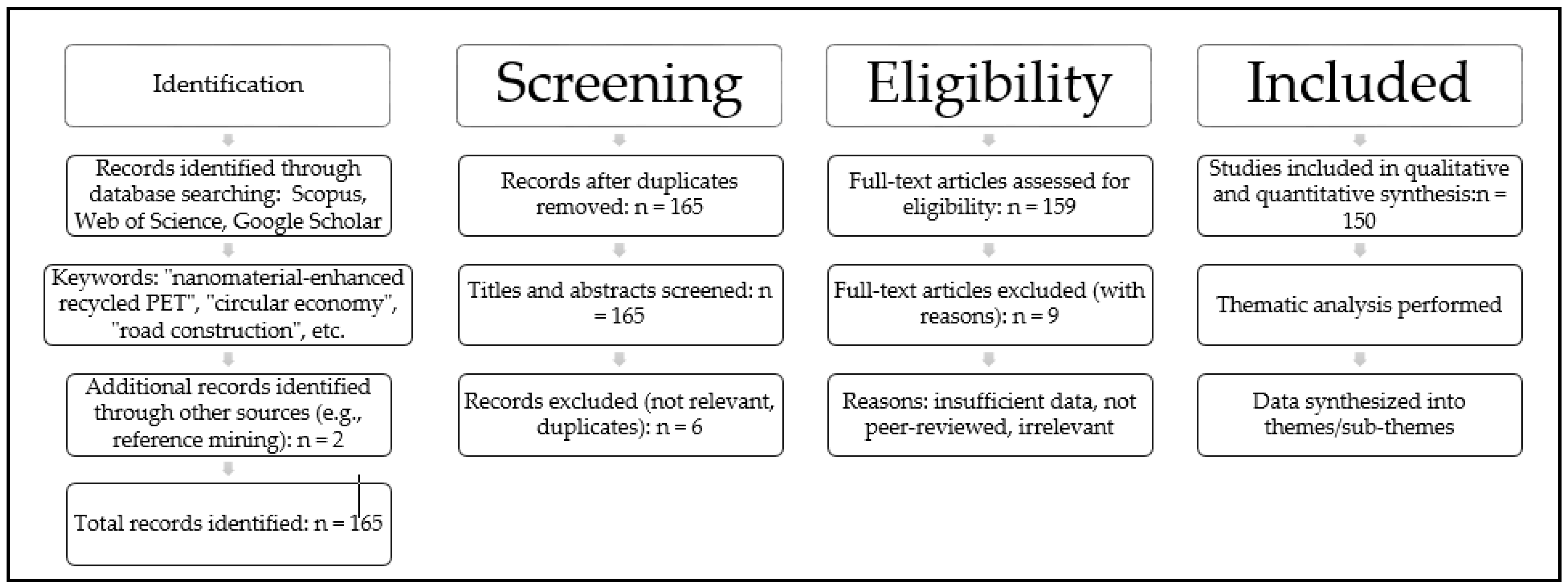

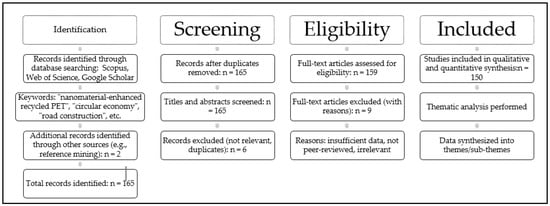

The research methodology for this article employed a systematic literature review approach to comprehensively gather, analyze, and synthesize the existing knowledge on the topic. The review incorporates both qualitative and quantitative analysis methods to gain a deeper understanding of the subject matter. The data collection process involves a thorough search of relevant academic databases, such as Scopus, Web of Science, and Google Scholar, using keywords related to the topic, including “nanomaterial-enhanced recycled PET,” “circular economy,” “road construction,” “sustainability,” and “resilience.” The search results were carefully screened to identify high-quality, peer-reviewed journal articles, conference papers, and other relevant publications that address the key aspects of the framework. Additionally, the reference lists of the selected publications were examined to identify additional relevant sources that may have been missed in the initial search. Figure 1 describes PRISMA for Systematic Literature Review for this article.

Figure 1.

PRISMA for Systematic Literature Review.

Regional differences exist in the use of circular economy frameworks and nanomaterial-enhanced rPET technologies in road construction, with the US, China, and the EU leading the way in both research output and application. These areas gain from sophisticated recycling infrastructure, robust institutional support, and legislative frameworks that encourage the use of sustainable materials. The majority of pertinent research, according to a survey of the literature, comes from Asia, North America, and Western Europe; Africa, South America, and portions of Southeast Asia are still underrepresented. This suggests that in order to guarantee the worldwide relevance and applicability of the suggested framework, there is a need for more extensive international cooperation as well as the inclusion of varied regional case studies.

The data analysis involves a thematic analysis, where the selected references were thoroughly reviewed, and the information was organized into coherent themes and subthemes that align with the structure of the integrated circular economy framework. The extracted data was then synthesized to identify common trends, gaps, and opportunities in the existing literature, which informed the development of the framework. A critical evaluation of the quality, reliability, and relevance of the information presented in the reviewed studies was also conducted to assess the strengths, weaknesses, and potential limitations of the existing research.

Based on the synthesized information, the research team developed the key components. The framework was designed to be comprehensive, coherent, and aligned with the principles of circular economy, sustainability, and resilience in the road construction industry. Relevant case studies, best practices, and expert insights from the reviewed literature were incorporated to strengthen the framework and its practical applicability. To validate and refine the developed framework, the research team engaged with relevant stakeholders, including researchers, industry experts, policymakers, and community representatives. The feedback received was used to address any gaps, inconsistencies, or areas that required further clarification or enhancement, ensuring the framework’s feasibility, effectiveness, and potential for implementation. Finally, the article was organized and presented in a clear and well-structured format, following academic writing conventions and guidelines.

By following this research methodology, the article provides a comprehensive and well-grounded foundation for the development and implementation of this innovative approach in the road construction industry.

3. Results and Discussion

Made from ethylene glycol and terephthalic acid, polyethylene terephthalate (PET) is a thermoplastic polymer with a linear aromatic structure that contributes to its strength, durability, and recyclability. Recycled PET (rPET) is becoming more and more significant in sustainability initiatives because of its significant contribution to the world’s plastic trash. The mechanical, thermal, and environmental qualities of rPET can be further enhanced by adding nanomaterials. This makes it appropriate for high-performance uses like road construction in the context of a circular economy.

3.1. Challenges and Limitations of rPET in Road Construction

rPET can be used as a partial replacement for fine aggregates [10,26] or as fibers in concrete and asphalt mixes [12,15]. Incorporating rPET aggregates or fibers into concrete and asphalt can help reduce the consumption of natural aggregates and improve certain properties of the construction materials [12,15,27].

However, the use of rPET aggregates or fibers in concrete and asphalt can lead to reduced compressive, flexural, and tensile strengths compared to conventional materials. RPET materials may have lower resistance to weathering and environmental degradation, affecting the long-term durability of road construction [13,15]. During the recycling process, PET materials can become contaminated and experience degradation in their physical and chemical properties, limiting their suitability for high-value applications like road construction [11,16,17]. Moreover, current recycling and reuse of PET materials do not fully align with the principles of a circular economy, such as narrowing, slowing, and closing material loops [19].

As an opportunity for improvement, the following issues were suggested by different scholars:

- Enhancing the mechanical and durability properties of rPET materials through the use of nanomaterials or other additives [25].

- Developing integrated circular economy frameworks that can improve the quality, performance, and sustainability of rPET in road construction applications [18].

- Exploring advanced recycling technologies, such as enzymatic or chemical depolymerization, to recover high-purity monomers from PET waste for closed-loop recycling [28,29].

While rPET has been used in road construction, its current limitations in terms of mechanical properties, durability, and alignment with circular economy principles highlight the need for a comprehensive framework to enhance the sustainability and resilience of these materials in road construction practices.

3.1.1. Performance Challenges

Regarding mechanical properties, the incorporation of rPET aggregates or fibers in concrete and asphalt mixes can lead to a decrease in compressive, flexural, and tensile strengths compared to conventional materials. The reduced mechanical performance is attributed to the lower stiffness and strength of rPET compared to natural aggregates, as well as the poor interfacial bonding between the PET and the cementitious matrix [30].

Concerning durability concerns, rPET materials may have lower resistance to weathering, UV radiation, and environmental degradation, which can affect the long-term durability and service life of road infrastructure. The degradation of rPET under harsh environmental conditions, such as temperature fluctuations, moisture, and chemical exposure, can lead to premature failure of the road construction materials [31].

Attempts to improve the mechanical and durability properties of recycled PET-based construction materials through the use of additives, such as fibers or mineral admixtures, have shown mixed results. The effectiveness of these approaches is often limited, and further research is needed to develop more robust and reliable methods for enhancing the performance of rPET in road construction applications [32,33].

The current recycling and reuse of PET materials do not fully align with the principles of a circular economy, such as narrowing, slowing, and closing material loops [19]. The quality degradation and contamination of rPET limit its potential for closed-loop recycling and high-value applications like road construction [11,16,17].

Hence, the key performance challenges associated with the use of rPET in road construction include reduced mechanical properties, durability concerns, limitations in enhancing performance, and challenges in achieving circularity. These limitations highlight the need for a comprehensive framework that can address these issues and advance the sustainable and resilient use of rPET in road construction practices.

3.1.2. Recycling Challenges

During the recycling process, PET materials can become contaminated with other polymers, such as PVC, nylon, and various additives [34,35]. The presence of these contaminants can significantly degrade the quality and properties of the recycled PET, making it less suitable for high-value applications like road construction [11,36]. The simultaneous presence of retained moisture and contaminants during mechanical recycling can also lead to further degradation of the PET material [34].

Moreover, inefficient collection and sorting of PET waste streams can result in the mixing of different types of plastics, leading to contamination and reduced quality of the rPET. Improving the collection and separation of PET waste, especially from post-consumer sources, is crucial to ensure a consistent and high-quality supply of rPET for road construction applications [37].

Concerning Suboptimal Processing Techniques, conventional mechanical recycling methods, such as melting and extrusion, can cause further degradation of the PET material due to the thermal and mechanical stresses involved [11]. Moreover, exploring alternative recycling techniques, such as enzymatic or chemical depolymerization, can help recover high-purity monomers from PET waste and improve the quality of the recycled material [38,39].

There are also barriers to closed-loop recycling. The current recycling and reuse of PET materials do not fully align with the principles of a circular economy, as the quality degradation and contamination limit the potential for closed-loop recycling [11,16,19]. Accordingly, developing integrated circular economy frameworks that can enhance the quality, performance, and sustainability of rPET in road construction applications is crucial to overcome these barriers [18].

Hence, the key challenges and limitations related to the effective recycling of PET for use in road construction include contamination and quality degradation, collection inefficiencies, suboptimal processing techniques, and barriers to closed-loop recycling. Addressing these issues through improved collection, sorting, and advanced recycling technologies, as well as the integration of circular economy principles, is essential to enable the sustainable and resilient use of rPET in road construction practices.

3.2. Nanomaterials and Their Role in Enhancing rPET

The incorporation of nanomaterials into rPET-based composites can improve their mechanical properties, thermal and dimensional stability, barrier performance, and overall suitability for sustainable and resilient road construction applications. Table 1 summarizes a comparison of the nanomaterials—Carbon Nanotubes (CNTs), Nanocellulose, Graphene, Clay Nanoplatelets, Nanosilica, and Metakaolin—in enhancing rPET for road construction applications.

Table 1.

Comparison of the nanomaterials used to enhance rPET for road construction applications.

As shown in Table 1, the following summaries were made:

- The performance of rPET composites for road building applications is greatly improved by the use of several nanomaterials. By encouraging efficient load transfer and matrix reinforcement, all the above nanomaterials help to improve mechanical qualities like tensile, compressive, or flexural strength.

- Nanomaterials that provide tortuous pathways that decrease gas permeability, such as nanocellulose, graphene, clay nanoplatelets, and nanosilica, are very effective at improving barrier qualities.

- All nanoparticles exhibit consistently increased thermal and dimensional stability, which aids in the composites’ capacity to tolerate temperature variations. While CNTs, graphene, nanosilica, and particularly metakaolin—because of its pozzolanic action—significantly increase durability, compatibility and interfacial bonding are also essential, frequently necessitating compatibilizers or surface changes for best results.

- Additionally, the functional and structural properties of rPET composites are further improved by the synergistic effects of combining nanoparticles with additional additives (such as fibers or rejuvenators), which makes them more resilient, long-lasting, and appropriate for demanding infrastructure applications.

3.3. Mechanisms of Enhancement: Summary

The incorporation of nanomaterials into rPET-based composites can improve their mechanical properties, thermal and dimensional stability, barrier performance, and durability through various mechanisms, such as effective load transfer, enhanced interfacial interactions, and the creation of tortuous diffusion paths. The synergistic effects between nanomaterials and other additives can further enhance the overall performance of these materials, making them more suitable for sustainable and resilient road construction applications.

3.3.1. Improved Mechanical Properties

Incorporation of nanomaterials, such as CNTs, graphene, nanosilica, and clay nanoplatelets, can enhance the tensile strength, modulus, and impact resistance of recycled PET-based composites. The high aspect ratio, exceptional mechanical properties, and strong interfacial interactions between the nanomaterials and the PET matrix enable effective load transfer, leading to improved overall mechanical performance [40,44,47,49].

Strategies to improve the compatibility and interfacial bonding between the nanomaterials and the rPET matrix, such as surface modifications or the use of compatibilizers, can further enhance the mechanical properties [41,63,65].

3.3.2. Enhanced Thermal and Dimensional Stability

The incorporation of nanomaterials, such as graphene, nanosilica, and clay nanoplatelets, can improve the thermal and dimensional stability of recycled PET-based materials. The interactions between the nanomaterials and the PET matrix can help mitigate thermal-induced deformation and dimensional changes, contributing to the overall stability and durability of the composite [47,58,61].

3.3.3. Improved Barrier Properties

Nanomaterials, such as clay nanoplatelets, nanosilica, and graphene, can enhance the barrier properties of recycled PET-based materials, reducing the permeability to gases and other substances. The tortuous path created by the well-dispersed nanomaterials within the PET matrix can effectively hinder the diffusion of various permeants, improving the overall barrier performance of the composite [50,54,55].

3.3.4. Increased Durability

The incorporation of nanomaterials, such as metakaolin, can improve the durability of recycled PET-based construction materials, enhancing their resistance to weathering, chemical attack, and alkali-silica reactions. The pozzolanic properties of nanomaterials like metakaolin can contribute to the densification of the PET matrix, reducing permeability and improving the overall durability of the composite [51].

3.3.5. Synergistic Effects

The combination of nanomaterials with other additives, such as fibers or rejuvenators, can result in synergistic effects that further enhance the performance of recycled PET-based construction materials. Exploring the synergistic interactions between nanomaterials and other reinforcing or modifying agents can help develop more robust and versatile recycled PET-based road construction materials [14,70,75].

3.4. Benefits for Road Construction

The benefits of using rpPET for more durable, weather-resistant, cost-effective and sustainable road construction materials can be summarized as follows:

3.4.1. Enhanced Durability and Weather Resistance

Nanomaterials, such as metakaolin, can improve the durability of rPET-based construction materials, enhancing their resistance to weathering, chemical attack, and alkali-silica reactions. The pozzolanic properties of nanomaterials can contribute to the densification of the PET matrix, reducing permeability and improving the overall durability and weather resistance of the composite [51].

Nanomaterials like graphene, nanosilica, and clay nanoplatelets can enhance the thermal and dimensional stability of recycled PET-based materials, helping them withstand extreme weather conditions [47,58,61].

3.4.2. Cost-Effectiveness

The use of rPET as a base material, combined with the enhanced performance provided by nanomaterials, can lead to more cost-effective road construction solutions compared to using virgin materials [67]. The improved durability and weather resistance of rpPET can reduce the need for frequent maintenance and repairs, further contributing to the cost-effectiveness of these materials [77].

3.4.3. Sustainability and Environmental Benefits

The use of rPET as the base material, along with the incorporation of nanomaterials, can contribute to the development of more sustainable and environmentally friendly road construction practices [67]. The reduced consumption of virgin materials and the potential for closed-loop recycling can enhance the circular economy aspects of these rpPET-based road construction materials [19].

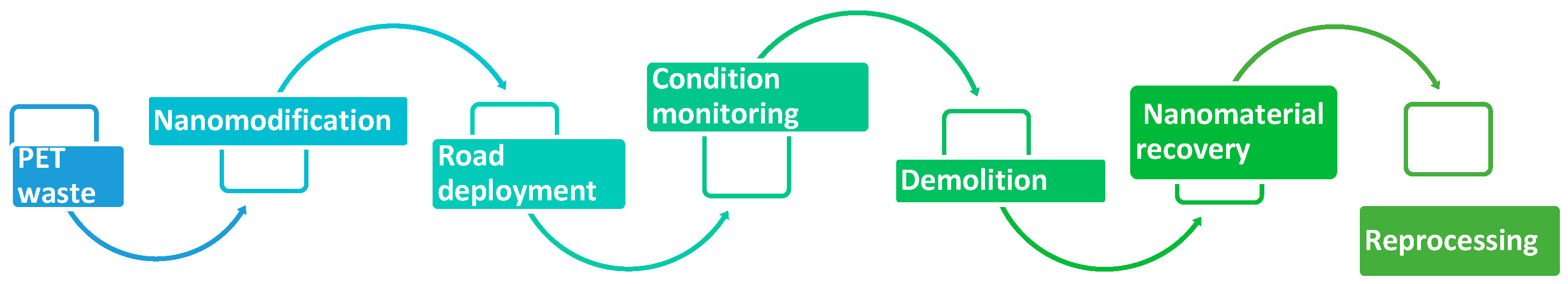

Figure 2 shows a circular economy process that transforms PET waste into high-performance road construction materials through nanomodification and smart recycling.

Figure 2.

A circular flow diagram showing rPET transformation.

As shown in Figure 2, PET flakes from collected waste are enhanced with nanomaterials like carbon nanotubes to create composites with superior strength and durability, which are then used in asphalt or concrete applications. During the road’s lifespan, embedded nanosensors monitor structural health, enabling predictive maintenance. At end-of-life, specialized recycling recovers both rPET and nanomaterials for reprocessing, creating a closed-loop system that supports multiple reuse cycles. The integration of nanotechnology, digital monitoring, and circular principles delivers sustainable infrastructure solutions that reduce environmental impact while improving material performance and cost-efficiency throughout the product lifecycle.

Table 2 shows proposed material interactions that integrate rpPET with circular economy principles in road construction.

Table 2.

Proposed material interactions for circular road construction.

Therefore, the use of rpPET in road construction can lead to more durable, weather-resistant, and cost-effective materials, while also contributing to the sustainability and environmental benefits of the construction industry.

3.5. Circular Economy Framework for rpPET in Road Construction

Principles of Circular Economy

The key principles of a circular economy and how they apply to road construction can be summarized as follows:

- a.

- Reduce

The circular economy principle of “reduce” can be applied to road construction by minimizing the consumption of virgin materials and promoting the use of recycled and secondary materials, such as rpPET. Reducing the use of virgin materials can lead to lower resource extraction, energy consumption, and environmental impacts associated with the production of new construction materials [78].

- b.

- Reuse

The “reuse” principle of the circular economy can be implemented in road construction by extending the lifespan of existing road infrastructure through maintenance, repair, and refurbishment. Reusing and repurposing road construction materials, such as recycled aggregates or nrPET, can contribute to the circularity of the road construction industry [79].

- c.

- Recycle

The “recycle” principle is a core aspect of the circular economy and can be applied to road construction by ensuring the effective recycling and recovery of materials at the end of a road’s life cycle [78]. Developing advanced recycling technologies, such as enzymatic or chemical depolymerization of PET, can help recover high-purity monomers and enable closed-loop recycling [28,29].

Integrating digital technologies, such as digital twins, can enhance the traceability and circularity of materials used in road construction [20,21].

- d.

- Synergistic Interactions

The combination of the “reduce, reuse, recycle” principles with the incorporation of nanomaterials can lead to synergistic effects that further enhance the circularity and sustainability of road construction materials. Exploring the synergistic interactions between different circular economy strategies and rpPET can help develop more robust and versatile road construction solutions [70].

- e.

- Alignment with Sustainable Development Goals

The implementation of circular economy principles in road construction can contribute to the achievement of various Sustainable Development Goals (SDGs), such as SDG 6 (Clean Water and Sanitation), SDG 7 (Affordable and Clean Energy), SDG 8 (Decent Work and Economic Growth), and SDG 12 (Responsible Consumption and Production). Integrating circular economy practices into road construction can help address environmental, economic, and social sustainability challenges, aligning with the broader objectives of sustainable development [80].

Hence, the core principles of a circular economy—reduce, reuse, and recycle—can be effectively applied to the road construction industry through the use of rpPET and the integration of digital technologies. This holistic approach can lead to more sustainable, durable, and cost-effective road construction practices, contributing to the overall circularity and sustainability of the built environment.

3.6. Closed-Loop Recycling in Road Construction

Closed-loop recycling refers to the process of recycling a material in a way that allows it to be reused in the same or similar applications, maintaining the quality and value of the material. This is in contrast to open-loop recycling, where the recycled material is used in different applications with lower-value or degraded properties [81].

Implementing closed-loop recycling in road construction can help retain the quality and performance of materials, such as rpPET, enabling their reuse in high-value applications [82].

Maintaining the quality and properties of recycled materials, such as ABS or PET, can be challenging after multiple recycling cycles, leading to degradation in performance [83,84]. Effective separation and purification of recycled materials are crucial to enable closed-loop recycling and avoid contamination issues [85]. The economic feasibility and environmental benefits of closed-loop recycling need to be carefully evaluated, as the net impact may not always be superior to open-loop recycling [86].

In situ cold recycling of asphalt materials can be considered a form of closed-loop recycling, as it allows the reuse of existing road materials on-site, reducing the need for virgin aggregates [87]. The use of recycled construction and demolition waste, including recycled aggregates, in road construction can also contribute to closed-loop recycling principles [88]. Integrating digital technologies, such as digital twins, can enhance the traceability and circularity of materials used in road construction, facilitating closed-loop recycling [20,21].

The combination of closed-loop recycling with other circular economy strategies, such as reuse and remanufacturing, can lead to synergistic effects that further enhance the sustainability and circularity of road construction practices [89,90,91] Exploring the integration of closed-loop recycling with the use of rpPET can contribute to the development of a comprehensive circular economy framework for road construction [14,70,75].

The implementation of closed-loop recycling principles in road construction, particularly through the use of rpPET, can lead to more durable, weather-resistant, and cost-effective road materials, while also contributing to the overall circularity and sustainability of the built environment.

3.7. Resource Efficiency and Waste Minimization

The incorporation of rpPET in road construction can help reduce the consumption of virgin materials, such as aggregates and bitumen [36,92]. Recycled materials, including construction and demolition waste, can be effectively used as substitutes for virgin aggregates in road construction, contributing to resource efficiency [92,93,94].

Nanomaterials can enhance the mechanical, thermal, and barrier properties of recycled PET-based construction materials, improving their durability and recyclability at the end of the road’s lifecycle [40,47,49].

Advanced recycling technologies, such as enzymatic or chemical depolymerization of PET, can help recover high-purity monomers and enable closed-loop recycling, minimizing waste [28,29]. Moreover, integrating digital technologies, such as digital twins, can enhance the traceability and circularity of materials used in road construction, facilitating the recycling and reuse of materials [20,21].

The use of rpPET and other recycled materials in road construction can lead to reduced greenhouse gas emissions, energy consumption, and environmental impacts compared to the use of virgin materials [94,95,96]. Implementing circular economy principles, such as reduce, reuse, and recycle, can contribute to cost savings and improved economic viability of road construction projects [96,97].

The combination of nanomaterials with other recycled materials, such as construction and demolition waste or fly ash, can result in synergistic effects that further enhance the resource efficiency and waste minimization in road construction [98,99,100]. Exploring the integration of rpPET with other circular economy strategies, such as reuse and remanufacturing, can lead to more comprehensive and effective solutions for sustainable road construction [14,70,75].

Hence, the integration of nanomaterials into recycled PET-based road construction materials can significantly contribute to resource efficiency and waste minimization by reducing the consumption of virgin materials, improving the recyclability and durability of the materials, and providing environmental and economic benefits. This aligns with the principles of a circular economy and can help advance the sustainability of the road construction industry.

3.8. Sustainability in Road Infrastructure

The development of sustainable road infrastructure is a crucial aspect of achieving overall sustainability in the built environment [101,102]. Researchers have emphasized the importance of incorporating sustainability principles, such as energy efficiency, resource conservation, and environmental impact reduction, into road construction and maintenance practices [103,104,105].

Various frameworks and rating systems have been developed to evaluate the sustainability of road infrastructure projects, considering factors like environmental impact, social responsibility, and economic viability [103,105,106]. Life cycle assessment (LCA) has emerged as a widely adopted approach to assess the sustainability of road infrastructure, including the use of recycled and nanomaterial-enhanced materials [103,107].

The integration of resilience and climate change adaptation strategies into road infrastructure design and management is essential for long-term sustainability [107,108]. Addressing the impacts of natural hazards, extreme weather events, and the transition to a low-carbon economy are key considerations in sustainable road infrastructure development [108,109].

The use of recycled and secondary materials, such as nrPET, in road construction can contribute to improved resource efficiency and reduced carbon footprints [92,93,94]. Integrating digital technologies, like building information modeling (BIM), can enhance the traceability and circularity of materials used in road infrastructure, further improving sustainability [110,111].

Addressing the social aspects of sustainability, such as community well-being, accessibility, and stakeholder engagement, is crucial for the long-term acceptance and success of sustainable road infrastructure projects. Incorporating social sustainability considerations into the decision-making process can help ensure that road infrastructure development aligns with the broader goals of sustainable development [112,113,114].

Therefore, the development of sustainable road infrastructure that incorporates rpPET requires a holistic approach that addresses resource efficiency, carbon footprint reduction, resilience, and social sustainability. By integrating these principles, road construction can contribute to the overall sustainability of the built environment and support the transition towards a more circular and low-carbon economy.

3.9. Addressing Challenges in Implementation

The integration of nanomaterials into rPET for road construction faces several barriers. Table 3 shows the key challenges of integrating nanomaterials into rPET for road construction, categorizing them into technical, economic, regulatory, and environmental barriers along with their specific sub-challenges. It provides a concise overview of the obstacles to implementation, from material processing difficulties to policy gaps and safety concerns, while attributing each issue to relevant research studies.

Table 3.

Key challenges of integrating nanomaterials into rPET.

In general, by addressing these technical, economic, regulatory, and environmental challenges, the integration of rpPET in road construction can be advanced, leading to the development of a comprehensive circular economy framework for sustainable and resilient infrastructure.

4. Future Directions and Research Opportunities

Future directions and research opportunities on rpPET in road construction can prioritize the following three key areas: advancements in nanotechnology, scaling circular economy models, and collaborative research. Table 4 discusses prioritized and measurable goals for further research on rpPET in road construction.

Table 4.

Prioritized and measurable goals for further research on rpPET in road construction.

4.1. Advancements in Nanotechnology

- -

- Exploration of emerging nanomaterials, such as novel carbon-based nanomaterials, metal-organic frameworks, or two-dimensional nanomaterials, and their potential to further enhance the performance of rPET in road construction applications [117,118].

- -

- Investigation of new processing techniques and manufacturing methods to improve the scalability and cost-effectiveness of integrating nanomaterials into recycled PET-based construction materials [115,116].

- -

- Research on the long-term durability and weathering resistance of rpPET under extreme environmental conditions, such as temperature fluctuations, UV exposure, and chemical attacks [131]

4.2. Scaling Circular Economy Models

- -

- Developing strategies to scale up the circular economy model for rpPET, moving from pilot projects to full-scale adoption in infrastructure projects [131,132,133]

- -

- Exploring the integration of digital technologies, such as building information modeling (BIM) and digital twins, to enhance the traceability, circularity, and scalability of rpPET in road construction [20,21].

- -

- Investigating the economic feasibility and cost–benefit analysis of adopting the circular economy framework with rpPET in large-scale infrastructure projects, considering both material costs and long-term maintenance savings [131,132,133]

4.3. Collaborative Research

- -

- Encouraging collaborations between researchers, industry stakeholders (e.g., construction companies, material suppliers, recyclers), policymakers, and local communities to foster innovation and overcome barriers to the implementation of rpPET in road construction [134].

- -

- Engaging with regulatory bodies and policymakers to develop clear standards, guidelines, and policies that support the safe and sustainable use of nanomaterials in construction materials, including rpPET [121].

- -

- Promoting interdisciplinary research and knowledge-sharing among experts in materials science, civil engineering, environmental science, and sustainability to address the technical, economic, and environmental challenges associated with the implementation of the integrated circular economy framework [101,135].

As shown in Table 4, the goal of nanotechnology should be to find at least three new nanomaterials that enhance rPET performance by 20%, provide two economical, scalable production techniques, and show a 30% increase in durability in harsh environmental settings. A regional model that increases rPET use by 50% should be piloted, digital technologies like BIM should be integrated into at least two infrastructure projects, and a cost–benefit analysis demonstrating 10–15% lifespan savings should be carried out as part of the circular economy scaling efforts. In addition, collaborative research should form a consortium with at least five stakeholders, organize international seminars and regular publications to facilitate interdisciplinary knowledge-sharing, and collaborate with regulatory agencies to draft standards for the safe use of nanomaterials.

By addressing these future directions and research opportunities, the development of an integrated circular economy framework for rpPET can be advanced, leading to more sustainable, resilient, and cost-effective road construction practices that contribute to the overall sustainability of the built environment.

5. Development of Integrated Circular Economy Framework for rpPET

The rapid growth in plastic consumption, particularly polyethylene terephthalate (PET), has led to a significant increase in plastic waste, posing a major environmental challenge. Developing an integrated circular economy framework for rpPET can be a promising approach to address this issue and advance sustainable and resilient road construction practices.

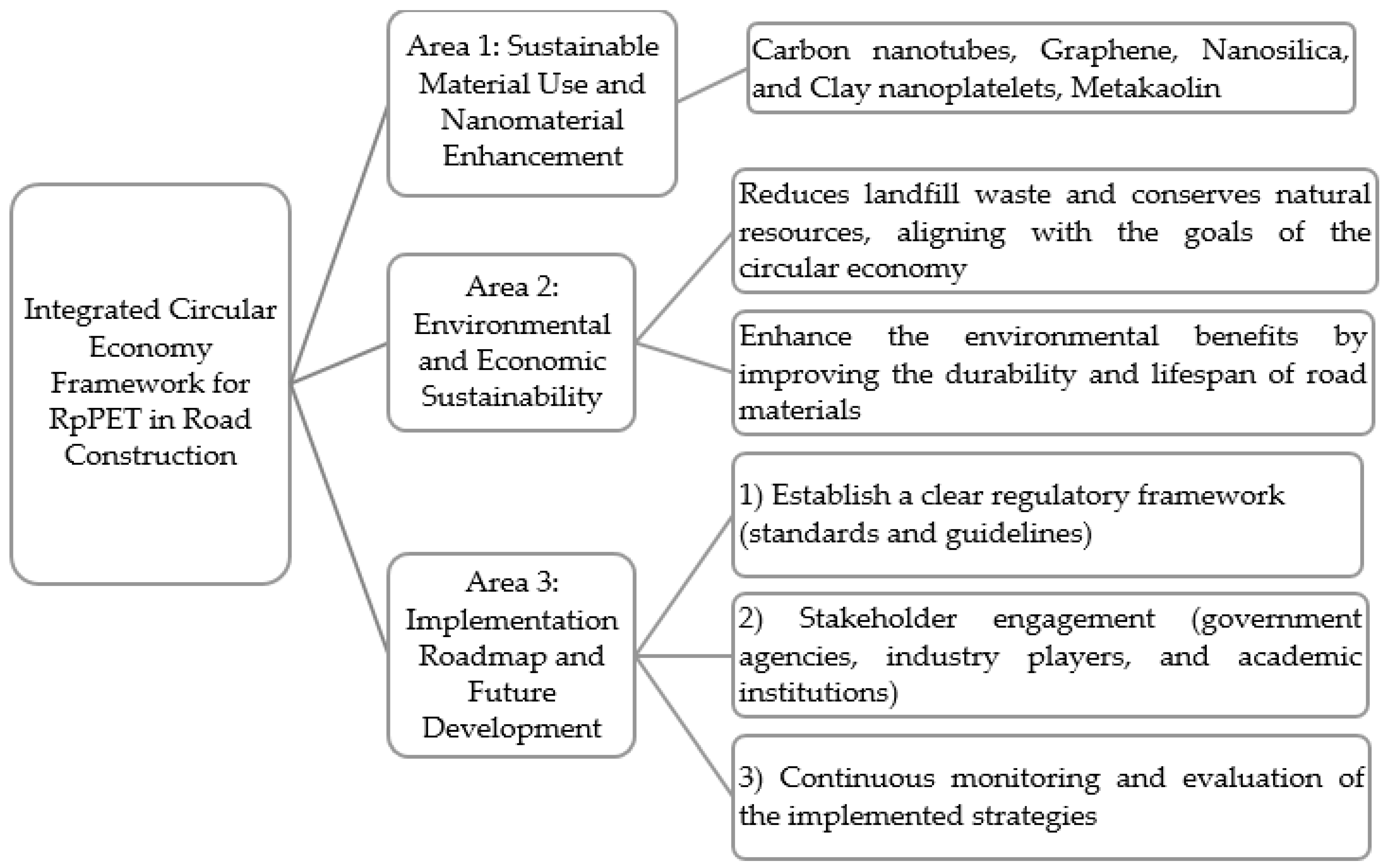

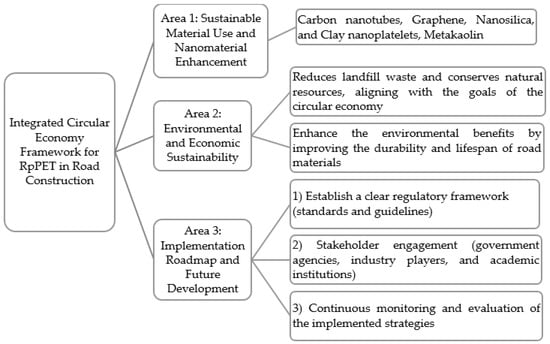

The development of an integrated circular economy framework for rpPET in road construction can be approached through three key areas, as shown in Figure 3. Each area is critical for ensuring that the integration of nanomaterials into rPET not only enhances performance but also aligns with circular economy principles.

Figure 3.

Key areas for development of an integrated circular economy framework for nrPET in road construction.

Sustainable material use in road construction necessitates the incorporation of innovative materials that can enhance the properties of rPET. Nanomaterials, such as carbon nanotubes and nanoclays, have been shown to improve the mechanical properties and durability of polymers, making them suitable for use in construction applications [136]. The integration of these nanomaterials into rPET can lead to a significant reduction in the environmental footprint of road construction by enhancing the material’s performance and longevity, thereby reducing the need for frequent repairs and replacements [137]. Moreover, the adoption of a circular economy approach in material sourcing and usage is essential. This involves not only recycling PET but also ensuring that the materials used in the enhancement process are sourced sustainably. The principles of the circular economy advocate for the reduction, reuse, and recycling of materials, which can be effectively applied to the use of nanomaterials in road construction [138,139]. By closing the material loops and utilizing waste materials as inputs, the overall sustainability of the construction process can be significantly improved [140].

Moreover, the environmental and economic sustainability of using rpPET in road construction is multifaceted. Environmentally, the use of recycled materials reduces landfill waste and conserves natural resources, aligning with the goals of the circular economy [141]. The incorporation of nanomaterials can further enhance the environmental benefits by improving the durability and lifespan of road materials, thus minimizing maintenance needs and associated environmental impacts over time [142]. Economically, the transition to a circular economy framework can lead to cost savings through reduced material costs and waste management expenses [143]. The initial investment in nanomaterial technology may be offset by the long-term savings achieved through enhanced material performance and reduced lifecycle costs [144]. Furthermore, the development of new business models that incorporate circular economy principles can create additional economic opportunities, such as job creation in recycling and materials innovation sectors [145].

Finally, an effective implementation roadmap for integrating rpPET in road construction involves several strategic steps. First, it is crucial to establish a clear regulatory framework that supports the use of recycled materials and nanotechnology in construction [146]. This includes developing standards and guidelines that ensure the safety and efficacy of nanomaterials in construction applications. Second, stakeholder engagement is vital. Collaboration among government agencies, industry players, and academic institutions can facilitate knowledge sharing and innovation [147]. Educational programs and training initiatives can also be developed to enhance understanding of circular economy principles and nanomaterial applications among construction professionals [148]. Lastly, continuous monitoring and evaluation of the implemented strategies are essential to assess their effectiveness and make necessary adjustments. This can be achieved through the establishment of key performance indicators (KPIs) that measure the environmental and economic impacts of using rpPET in road construction [149]. Future research should focus on optimizing the formulations of nanomaterials and exploring new applications within the circular economy framework to further enhance sustainability in the construction sector [150].

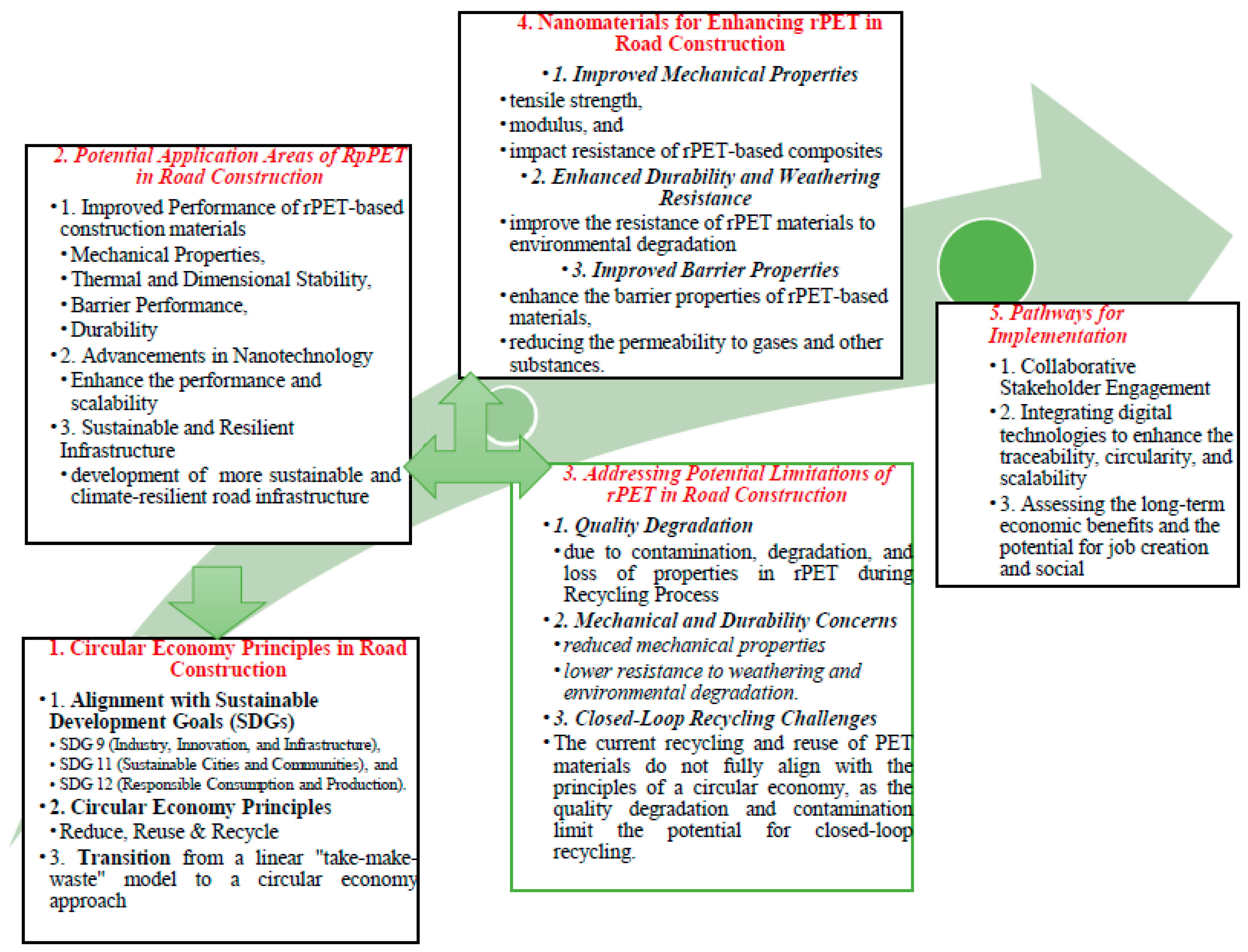

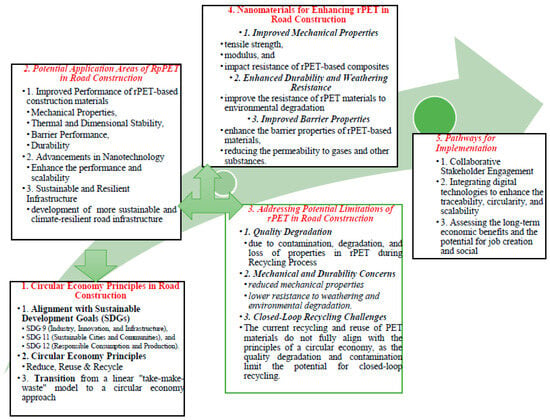

Figure 4 shows the proposed integrated circular economy framework for rpPET. The framework provides a comprehensive and holistic approach to addressing the challenges in the road construction industry and promoting the adoption of more sustainable and resilient infrastructure solutions. By incorporating circular economy principles, leveraging the benefits of nanomaterials, and addressing the limitations of rPET, this framework can contribute to the development of a more sustainable and circular built environment.

Figure 4.

Integrated circular economy framework for nrPET.

As shown in Figure 4, the framework integrates circular economy principles into road construction by enhancing rPET with nanomaterials. It aligns with key SDGs (9, 11, 12) by promoting sustainable infrastructure, responsible consumption, and innovation. The approach shifts from linear “take-make-waste” models to circular systems emphasizing reuse and recycling. Nanomaterials (e.g., carbon nanotubes, nanosilica) address PET’s limitations—improving mechanical strength, durability, and weather resistance while enabling closed-loop recycling. Implementation requires stakeholder collaboration, digital tools (BIM, digital twins) for scalability, and assessments of economic/social impacts. Challenges like quality degradation and contamination are mitigated through nanotechnology, advancing resilient and sustainable roads.

6. Conclusions and Further Research

6.1. Summary of Key Findings

This article highlights the significant potential of this innovative approach in promoting sustainability, resilience, and resource efficiency in the road construction industry. The following key findings were identified:

- The incorporation of nanomaterials, such as carbon nanotubes, graphene, nanosilica, and clay nanoplatelets, can enhance the mechanical properties, thermal and dimensional stability, barrier performance, and durability of rPET-based construction materials.

- Implementing the principles of a circular economy, such as reduce, reuse, and recycle, in road construction through the use of nrPET can lead to reduced consumption of virgin materials, minimized waste, and improved environmental and economic sustainability.

- nrPET-based road construction materials exhibit enhanced resistance to extreme weather events, such as floods, droughts, and heatwaves, contributing to the development of more climate-resilient infrastructure.

- The use of nrPET in road construction can result in long-term cost savings, job creation in the recycling and nanotechnology sectors, and the promotion of sustainable urban development, aligning with the Sustainable Development Goals.

- While there are technical, economic, regulatory, and environmental challenges to overcome, the literature review highlights the importance of collaborative research, advancements in nanotechnology, and strategies to scale up the circular economy model for nrPET in road construction. Through the incorporation of nanotechnology, recycled materials, and circular economy principles, the suggested framework promotes urban sustainability (SDG 11), fosters innovation (SDG 9), and turns waste into value (SDG 12). Indicators such as recycling rates, material efficiency, and CO2 reduction make this alignment quantifiable and show how important it is to fulfill the 2030 Agenda for Sustainable Development.

In conclusion, the development of an integrated circular economy framework for nrPET holds great promise for advancing sustainable and resilient road construction practices, contributing to the overall sustainability of the built environment. Continued research, innovation, and stakeholder collaboration are crucial to realizing the full potential of this approach.

6.2. Further Research

The following key takeaways were identified from this article for Further Research:

- Exploring emerging nanomaterials and new processing techniques can further enhance the performance and scalability of rpPET in road construction. Continued research in this area is crucial to unlock the full potential of these advanced materials.

- Developing strategies to scale up the circular economy model for nrPET, from pilot projects to full-scale adoption, is essential. Integrating digital technologies, such as BIM and digital twins, can enhance the traceability and circularity of these materials, enabling their widespread use in infrastructure projects.

- Fostering collaborations between researchers, industry stakeholders, policymakers, and local communities is key to overcoming the technical, economic, regulatory, and environmental challenges associated with the implementation of rpPET in road construction. Engaging with relevant stakeholders can help build trust and support for this innovative approach.

- Clear regulatory standards and policies that promote the safe and sustainable use of nanomaterials in construction materials, as well as the adoption of circular economy practices, are necessary to incentivize the widespread use of rpPET in road infrastructure development.

By addressing these future directions and research opportunities, the development of an integrated circular economy framework for rpPET can contribute to the achievement of the United Nations Sustainable Development Goals (SDGs), particularly SDG 9 (Industry, Innovation, and Infrastructure), SDG 11 (Sustainable Cities and Communities), and SDG 12 (Responsible Consumption and Production).

Continued investment in research, industry collaboration, and supportive policy frameworks will be crucial to realizing the full potential of this innovative approach and advancing sustainable and resilient road construction practices that benefit both the environment and society.

6.3. Final Call to Action

This article has highlighted the immense potential of this innovative approach in shaping the future of road infrastructure. As this article stands at the crossroads of environmental challenges and the urgent need for sustainable development, it is time for all stakeholders to prioritize innovation, sustainability, and circular economy principles in their decision-making processes. In general, the following key takeaways were taken as a final call to action:

- Researchers, industry leaders, and policymakers must continue to explore emerging nanomaterials and new processing techniques to further enhance the performance and scalability of rpPET in road construction. Fostering a culture of innovation is crucial to unlocking the full potential of these advanced materials.

- Integrating the principles of a circular economy, such as reduce, reuse, and recycle, into road infrastructure development is no longer a choice but a necessity. Stakeholders must prioritize the use of recycled and secondary materials, like nrPET, to reduce the environmental impact and promote resource efficiency in the construction industry.

- Collaborative research and stakeholder engagement are the keys to overcoming the barriers to the implementation of nrPET in road construction. Fostering partnerships between researchers, industry, policymakers, and local communities can drive innovation, build trust, and enable the widespread adoption of this circular economy framework.

- Policymakers must take the lead in developing clear regulatory standards and incentives that support the safe and sustainable use of nanomaterials in construction materials, as well as the adoption of circular economy practices in the road infrastructure sector. These policy frameworks will be crucial in accelerating the transition towards a more sustainable and resilient built environment.

By heeding this call to action, the article can collectively shape a future where rpPET becomes the cornerstone of sustainable and resilient road construction practices, contributing to the achievement of the United Nations Sustainable Development Goals (SDGs) and creating a better world for generations to come.

The time for action is now. Let it embrace the power of innovation, sustainability, and collaboration to build the roads of the future—roads that not only connect our communities but also serve as a testament to our commitment to a more circular, resilient, and environmentally conscious world.

Author Contributions

Conceptualization, methodology, thematic analysis, and writing—original draft preparation, D.A.B.; writing—review and editing, W.A.E. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by University of South Africa and the APC was funded by University of South Africa.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors upon request.

Acknowledgments

The authors thank UNISA (University of South Africa) for administrative and technical support. The authors have reviewed and edited the output and take full responsibility for the content of this publication.

Conflicts of Interest

The authors declare that there are no conflicts of interest.

References

- Fonseca, L.; Domingues, P.; Dima, A. Mapping the sustainable development goals relationships. Sustainability 2020, 12, 3359. [Google Scholar] [CrossRef]

- Sukmana, R.; Rusydiana, A.S. Waqf Model for Climate Change: A Delphi Method Approach. Int. J. Waqf 2023, 3. [Google Scholar] [CrossRef]

- Nilsson, M.; Chisholm, E.; Griggs, D.; Howden-Chapman, P.; McCollum, D.; Messerli, P.; Smith, M. Mapping interactions between the sustainable development goals: Lessons learned and ways forward. Sustain. Sci. 2018, 13, 1489–1503. [Google Scholar] [CrossRef] [PubMed]

- Yacob, P.; Peter, D.; Chin, K. Sustainable business practices in manufacturing SMEs: The mediating effect of dynamic capabilities. Int. Soc. Sci. J. 2021, 72, 73–89. [Google Scholar] [CrossRef]

- Pérez-Peña, M.d.C.; Jiménez-García, M.; Ruiz-Chico, J.; Peña-Sánchez, A.R. Analysis of Research on the SDGs: The Relationship between Climate Change, Poverty and Inequality. Appl. Sci. 2021, 11, 8947. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, X.; Gao, L.; Wang, T.; Qin, Z.; Fang, D.; Gao, Y. Progress towards the sustainable development goals has been slowed by indirect effects of the COVID-19 pandemic. Commun. Earth Environ. 2023, 4, 184. [Google Scholar] [CrossRef]

- Coenen, J.; Glass, L.; Sanderink, L. Two degrees and the SDGs: A network analysis of the interlinkages between transnational climate actions and the sustainable development goals. Sustain. Sci. 2021, 17, 1489–1510. [Google Scholar] [CrossRef]

- Kostetckaia, M.; Hametner, M. How sustainable development goals interlinkages influence European Union countries’ progress towards the 2030 agenda. Sustain. Dev. 2022, 30, 916–926. [Google Scholar] [CrossRef]

- Perera, S.; Arulrajah, A.; Wong, Y.; Horpibulsuk, S. Utilizing rPET blends with demolition wastes as construction materials. Constr. Build. Mater. 2019, 221, 200–209. [Google Scholar] [CrossRef]

- Priya, I.; Akshaya, S.; Neya, S.; Vanitha, S.; Priya, P.; Johnson, J. Experimental investigation on replacement of pet aggregate as fine aggregate and water hyacinth as bio plasticizer in concrete. Int. Rev. Appl. Sci. Eng. 2023, 14, 358–365. [Google Scholar] [CrossRef]

- Atakan, R.; Sezer, S.; Karakas, H. Development of nonwoven automotive carpets made of rPET fibers with improved abrasion resistance. J. Ind. Text. 2018, 49, 835–857. [Google Scholar] [CrossRef]

- Borg, R.; Baldacchino, O.; Ferrara, L. Early age performance and mechanical characteristics of rPET fibre reinforced concrete. Constr. Build. Mater. 2016, 108, 29–47. [Google Scholar] [CrossRef]

- Jaskowska-Lemańska, J.; Kucharska, M.; Matuszak, J.; Nowak, P.; Łukaszczyk, W. Selected properties of self-compacting concrete with rPET aggregate. Materials 2022, 15, 2566. [Google Scholar] [CrossRef] [PubMed]

- Monti, M.; Scrivani, M.; Kociolek, I.; Larsen, Å.; Olafsen, K.; Lambertini, V. Enhanced impact strength of recycled pet/glass fiber composites. Polymers 2021, 13, 1471. [Google Scholar] [CrossRef] [PubMed]

- Shamsudin, M.; Hamid, N.; Fauzi, M. Compressive and flexural strength of concrete containing recycled polyethylene terephthalate (pet). Key Eng. Mater. 2021, 879, 13–21. [Google Scholar] [CrossRef]

- Eriksen, M.; Christiansen, J.; Daugaard, A.; Astrup, T. Closing the loop for PET, PE and PP waste from households: Influence of material properties and product design for plastic recycling. Waste Manag. 2019, 96, 75–85. [Google Scholar] [CrossRef]

- Mohammad Hosseini, H.; Alyousef, R.; Tahir, M. Towards sustainable concrete composites through waste valorisation of plastic food trays as low-cost fibrous materials. Sustainability 2021, 13, 2073. [Google Scholar] [CrossRef]

- Eberhardt, L.; Birkved, M.; Birgisdóttir, H. Building design and construction strategies for a circular economy. Archit. Eng. Des. Manag. 2020, 18, 93–113. [Google Scholar] [CrossRef]

- Pinter, E.; Welle, F.; Mayrhofer, E.; Pechhacker, A.; Motloch, L.; Lahme, V.; Tacker, M. Circularity study on pet bottle-to-bottle recycling. Sustainability 2021, 13, 7370. [Google Scholar] [CrossRef]

- Behún, M.; Behúnová, A. Advanced innovation technology of BIM in a circular economy. Appl. Sci. 2023, 13, 7989. [Google Scholar] [CrossRef]

- Meng, X. Integration of digital twin and circular economy in the construction industry. Sustainability 2023, 15, 13186. [Google Scholar] [CrossRef]

- Agrela, F.; González-Gallardo, F.; Rosales, J.; Tavira, J.; Ayuso, J.; Cabrera, M. Complete real-scale application of recycled aggregates in a port loading platform in Huelva, Spain. Materials 2020, 13, 2651. [Google Scholar] [CrossRef] [PubMed]

- Al-Shihabi, S. A system dynamic model for polyethylene terephthalate supply chain in the United Arab Emirates—Status, projections, and environmental impacts. Sustainability 2023, 15, 13119. [Google Scholar] [CrossRef]

- Barbosa, K.; Santos, E.; Gusmão, A. Geogrid mechanical damage caused by recycled construction and demolition waste (rcdw) under in-field cyclic loading. Soils Rocks 2021, 44, e2021056520. [Google Scholar] [CrossRef]

- Majka, T. Research on the development of a way to modify asphalt mixtures with pet recyclates. Materials 2023, 16, 6258. [Google Scholar] [CrossRef]

- Nadimalla, A.; Masjuki, S.A.B.; Saad, A.B.; Ismail, K.M.; Ali, M.B. Polyethylene terephthalate (PET) bottles waste as fine aggregate in concrete. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 1177–1180. [Google Scholar] [CrossRef]

- Koo, B.; Kim, J.; Kim, S.; Mun, S. Material and structural performance evaluations of hwangtoh admixtures and rPET fiber-added eco-friendly concrete for CO2 emission reduction. Materials 2014, 7, 5959–5981. [Google Scholar] [CrossRef]

- Yang, R.; Xu, G.; Dong, B.; Xuan-hua, G.; Wang, Q. Selective, sequential, and “one-pot” depolymerization strategies for chemical recycling of commercial plastics and mixed plastics. ACS Sustain. Chem. Eng. 2022, 10, 9860–9871. [Google Scholar] [CrossRef]

- Zhu, B.; Ye, Q.; Seo, Y.; Wei, N. Enzymatic degradation of polyethylene terephthalate plastics by Bacterial curli display PETase. Environ. Sci. Technol. Lett. 2022, 9, 650–657. [Google Scholar] [CrossRef]

- Marthong, C. Effects of pet fiber arrangement and dimensions on mechanical properties of concrete. IES J. Part A Civ. Struct. Eng. 2015, 8, 111–120. [Google Scholar] [CrossRef]

- Enfrin, M.; Giustozzi, F. Recent advances in the construction of sustainable asphalt roads with recycled plastic. Polym. Int. 2022, 71, 1376–1383. [Google Scholar] [CrossRef]

- Kumar, K.; Kumar, P. Comparative study on durability of concrete using recycled and natural aggregate. E3s Web Conf. 2023, 405, 03018. [Google Scholar] [CrossRef]

- Spadea, S.; Farina, I.; Carrafiello, A.; Fraternali, F. Recycled nylon fibers as cement mortar reinforcement. Constr. Build. Mater. 2015, 80, 200–209. [Google Scholar] [CrossRef]

- Kang, D.; Auras, R.; Vorst, K.; Singh, J. An exploratory model for predicting post-consumer rPET content in pet sheets. Polym. Test. 2011, 30, 60–68. [Google Scholar] [CrossRef][Green Version]

- Smith, R.; Rao, T.; Riegerix, R. Recycling of plastics in the United States: Plastic material flows and polyethylene terephthalate (pet) recycling processes. ACS Sustain. Chem. Eng. 2022, 10, 2084–2096. [Google Scholar] [CrossRef]

- Kang, D.; Gupta, S.; Ranaivoson, A.; Siekmeier, J.; Roberson, R. Recycled materials as substitutes for virgin aggregates in road construction: I. hydraulic and mechanical characteristics. Soil Sci. Soc. Am. J. 2011, 75, 1265–1275. [Google Scholar] [CrossRef]

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of post-consumer plastic packaging waste in the EU: Recovery rates, material flows, and barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef]

- Liu, B.; Lü, X.; Ju, Z.; Sun, P.; Xin, J.; Yao, X.; Zhang, S. Ultrafast homogeneous glycolysis of waste polyethylene terephthalate via a dissolution-degradation strategy. Ind. Eng. Chem. Res. 2018, 57, 16239–16245. [Google Scholar] [CrossRef]

- Wang, Q.; Geng, Y.; Lü, X.; Zhang, S. First-row transition metal-containing ionic liquids as highly active catalysts for the glycolysis of poly(ethylene terephthalate) (pet). ACS Sustain. Chem. Eng. 2015, 3, 340–348. [Google Scholar] [CrossRef]

- Tsai, J.; Tzeng, S.; Chiu, Y. Characterizing elastic properties of carbon nanotubes/polyimide nanocomposites using multi-scale simulation. Compos. Part B Eng. 2010, 41, 106–115. [Google Scholar] [CrossRef]

- Yang, S. Understanding covalent grafting of nanotubes onto polymer nanocomposites: Molecular dynamics simulation study. Sensors 2021, 21, 2621. [Google Scholar] [CrossRef]

- Omran, A.; Mohammed, A.; Sapuan, S.; Ilyas, R.; Asyraf, M.; Koloor, S.; Petrů, M. Micro- and nanocellulose in polymer composite materials: A review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef]

- Srichola, P. Recycling of nanocellulose from polyester–cotton textile waste for modification of film composites. Polymers 2023, 15, 3324. [Google Scholar] [CrossRef] [PubMed]

- Aoyama, S.; Ismail, I.; Park, Y.; Yoshida, Y.; Macosko, C.; Ougizawa, T. Polyethylene terephthalate/trimellitic anhydride modified graphene nanocomposites. ACS Appl. Nano Mater. 2018, 1, 6301–6311. [Google Scholar] [CrossRef]

- Istrate, O.; Paton, K.; Khan, U.; O’Neill, A.; Bell, A.; Coleman, J. Reinforcement in melt-processed polymer–graphene composites at extremely low graphene loading level. Carbon 2014, 78, 243–249. [Google Scholar] [CrossRef]

- Vickery, W. Plastic composites from repurposed poly(ethylene terephthalate) wasted functionalized graphene oxide through dynamic depolymerization. ACS Appl. Nano Mater. 2024, 7, 3691–3701. [Google Scholar] [CrossRef]

- Hayrapetyan, S.; Kelarakis, A.; Estevez, L.; Qin, L.; Dana, K.; Chung, Y.; Giannelis, E. Non-toxic poly(ethylene terephthalate)/clay nanocomposites with enhanced barrier properties. Polymer 2012, 53, 422–426. [Google Scholar] [CrossRef]

- Shen, Y.; Harkin-Jones, E.; Hornsby, P.; McNally, T.; Abu-Zurayk, R. The effect of temperature and strain rate on the deformation behaviour, structure development and properties of biaxially stretched pet–clay nanocomposites. Compos. Sci. Technol. 2011, 71, 758–764. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Z.; Tang, D.; Kong, M.; Yang, Q.; Huang, Y.; Niu, Y. Effect of nanoparticles on the morphology and properties of pet/pp in situ microfibrillar reinforced composites. Polym. Compos. 2015, 38, 2718–2726. [Google Scholar] [CrossRef]

- Zhu, Z.; Gao, C.; Shen, Y.; Wang, T.; Hu, G. Improving oxygen barrier properties of PET composites via grafting hydroxy-terminated polybutadiene with nanosilica. Polym. Adv. Technol. 2020, 31, 2561–2568. [Google Scholar] [CrossRef]

- Verma, M. Analysis of the properties of recycled aggregates concrete with lime and metakaolin. Mater. Res. Express 2023, 10, 095508. [Google Scholar] [CrossRef]

- Guo, Z.; Feng, Y.; He, S.; Qu, M.; Chen, H.; Liu, H.; Wang, Y. CO2-responsive “smart” single-walled carbon nanotubes. Adv. Mater. 2012, 25, 584–590. [Google Scholar] [CrossRef] [PubMed]

- Klayya, S.; Tawichai, N.; Intatha, U.; Zhang, H.; Bilotti, E.; Soykeabkaew, N. Sustainable nanocomposite coating for moulded pulp with enhanced barrier properties for food packaging applications. Polym. Int. 2022, 72, 323–332. [Google Scholar] [CrossRef]

- Yu, Z.; Ji, Y.; Meredith, J. Multilayer chitin–chitosan–cellulose barrier coatings on poly(ethylene terephthalate). ACS Appl. Polym. Mater. 2022, 4, 7182–7190. [Google Scholar] [CrossRef]

- Paszkiewicz, S.; Kwiatkowska, M.; Rosłaniec, Z.; Szymczyk, A.; Jotko, M.; Lisiecki, S. The influence of different shaped nanofillers (1d, 2d) on barrier and mechanical properties of polymer hybrid nanocomposites based on pet prepared by in situ polymerization. Polym. Compos. 2015, 37, 1949–1959. [Google Scholar] [CrossRef]

- Ghasemi, H.; Carreau, P.; Kamal, M.; Tabatabaei, S. Properties of pet/clay nanocomposite films. Polym. Eng. Sci. 2011, 52, 420–430. [Google Scholar] [CrossRef]

- Li, C.; Tong, L.; Wang, S.; Liu, Q.; Wang, Y.; Li, X.; Li, X. Nitrogen doping induced by intrinsic defects of recycled polyethylene terephthalate-derived carbon nanotubes. SusMat 2023, 3, 431–440. [Google Scholar] [CrossRef]

- Awad, S.; Khalaf, E. Improvement of the chemical, thermal, mechanical and morphological properties of polyethylene terephthalate–graphene particle composites. Bull. Mater. Sci. 2018, 41, 67. [Google Scholar] [CrossRef]

- Xia, T.; Xi, Z.; Yi, X.; Liu, T.; Zhao, L. Melt foamability of poly(ethylene terephthalate)/clay nanocomposites prepared by extrusion blending in the presence of pyromellitic dianhydride. Ind. Eng. Chem. Res. 2015, 54, 6922–6931. [Google Scholar] [CrossRef]

- Mathu, A.; Asif, S.; Chandra, K.; Motru, S.; Patel, D.; Syed, R. Development of composite using rPET reinforced with fiberglass powder, sawdust and gypsum. Mater. Sci. Forum 2021, 1019, 19–24. [Google Scholar] [CrossRef]

- Mebarki, F.; David, É. Dielectric characterization of thermally aged recycled polyethylene terephthalate and polyethylene naphthalate reinforced with inorganic fillers. Polym. Eng. Sci. 2017, 58, 701–712. [Google Scholar] [CrossRef]

- Aoyama, S.; Ismail, I.; Park, Y.; Macosko, C.; Ougizawa, T. Pet/graphene compatibilization for different aspect ratio graphenes via trimellitic anhydride functionalization. ACS Omega 2020, 5, 3228–3239. [Google Scholar] [CrossRef]

- Shim, S.; Kim, Y.; Lee, J.; Jo, W. Facile method to functionalize graphene oxide and its application to poly(ethylene terephthalate)/graphene composite. ACS Appl. Mater. Interfaces 2012, 4, 4184–4191. [Google Scholar] [CrossRef]

- Chen, R.; Ahmad, S.; Gan, S.; Ghani, M.; Salleh, M. Effects of compatibilizer, compounding method, extrusion parameters, and nanofiller loading in clay-reinforced recycled HDPE/PET nanocomposites. J. Appl. Polym. Sci. 2015, 132, 1–9. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A. Development and thermo-mechanical behavior of nanocomposite epoxy adhesives. Polym. Adv. Technol. 2011, 23, 660–668. [Google Scholar] [CrossRef]

- Arias, J.; Thielemans, W. Efficient depolymerization of glass fiber reinforced pet composites. Polymers 2022, 14, 5171. [Google Scholar] [CrossRef]

- Sadeghi, B.; Marfavi, Y.; AliAkbari, R.; Kowsari, E.; Ajdari, F.; Ramakrishna, S. Recent studies on rPET fibers: Production and applications: A review. Mater. Circ. Econ. 2021, 3, 4. [Google Scholar] [CrossRef]

- Patel, V.; Modhera, C.; Chavda, M.; Panseriya, M. Effect of metakaolin on mechanical properties of different grades concretes inclusion of recycled aggregates from C&D waste and ceramic waste. Int. J. Eng. Technol. 2018, 7, 138. [Google Scholar] [CrossRef]

- Leng, Z.; Sreeram, A.; Padhan, R.; Tan, Z. Value-added application of waste pet based additives in bituminous mixtures containing high percentage of reclaimed asphalt pavement (rap). J. Clean. Prod. 2018, 196, 615–625. [Google Scholar] [CrossRef]

- Merkel, D.; Kuang, W.; Malhotra, D.; Petrossian, G.; Zhong, L.; Simmons, K.; Cosimbescu, L. Waste pet chemical processing to terephthalic amides and their effect on asphalt performance. ACS Sustain. Chem. Eng. 2020, 8, 5615–5625. [Google Scholar] [CrossRef]

- Khan, U.; Young, K.; O’Neill, A.; Coleman, J. High strength composite fibres from polyester filled with nanotubes and graphene. J. Mater. Chem. 2012, 22, 12907. [Google Scholar] [CrossRef]

- Toh, C.; Yang, L.; Pramoda, K.; Lau, S.; Lu, X. Poly(ethylene terephthalate)/clay nanocomposites with trisilanolphenyl polyhedral oligomeric silsesquioxane as dispersant: Simultaneously enhanced reinforcing and stabilizing effects. Polym. Int. 2013, 62, 1492–1499. [Google Scholar] [CrossRef]

- Wu, J.; Yen, M.; Kuo, M.; Tsai, Y.; Leu, M. Poly(ethylene terephthalate)/poly(ethylene glycol-co-1,3/1,4-cyclohexanedimethanol terephthalate)/clay nanocomposites: Mechanical properties, optical transparency, and barrier properties. J. Appl. Polym. Sci. 2013, 131, 487–497. [Google Scholar] [CrossRef]

- Duan, R.; Wei, L.; Coates, P.; Kelly, A.; Wang, C.; Chen, B.; Lu, C. Reinforcing mechanically reclaimed polyurethane foam wastes-based elastomer with modified recycled polyester fibers. J. Polym. Sci. 2023, 62, 3183–3194. [Google Scholar] [CrossRef]

- Rusu, M. RPET composites reinforced with stainless steel lattice structures made by AM. Polymers 2023, 15, 4591. [Google Scholar] [CrossRef]

- Xie, J.; Chen, W.; Wang, J.; Fang, C.; Zhang, B.; Liu, F. Coupling effects of recycled aggregate and GGBs/metakaolin on physicochemical properties of geopolymer concrete. Constr. Build. Mater. 2019, 226, 345–359. [Google Scholar] [CrossRef]

- Du, S.; Wu, J.; AlShareedah, O.; Shi, X. Nanotechnology in cement-based materials: A review of durability, modeling, and advanced characterization. Nanomaterials 2019, 9, 1213. [Google Scholar] [CrossRef]

- Mantalovas, K.; Mino, G. Integrating circularity in the sustainability assessment of asphalt mixtures. Sustainability 2020, 12, 594. [Google Scholar] [CrossRef]

- Tsarenkova, I.M.; Zharin, N.S. Organizational, economic and technological aspects of recycling of flow processes in the road construction. Bull. Transp. Ind. Econ. 2021, 72–73, 38–46. [Google Scholar] [CrossRef]

- Schroeder, P.; Anggraeni, K.; Weber, U. The relevance of circular economy practices to the sustainable development goals. J. Ind. Ecol. 2018, 23, 77–95. [Google Scholar] [CrossRef]

- Larraín, M.; Passel, S.; Thomassen, G.; Kresovic, U.; Alderweireldt, N.; Moerman, E.; Billen, P. Economic performance of pyrolysis of mixed plastic waste: Open-loop versus closed-loop recycling. J. Clean. Prod. 2020, 270, 122442. [Google Scholar] [CrossRef]

- Entrop, A.; Hagen, L.; Leeuwen, J. Aligning actors in a road renovation project by a co-design process: The road to circularity? IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012119. [Google Scholar] [CrossRef]

- Fabbro, P.; Gala, A.; Steene, W.; D’hooge, D.; Lucchetta, G.; Cardon, L.; Fiório, R. Influence of machine type and consecutive closed-loop recycling on macroscopic properties for fused filament fabrication of acrylonitrile-butadiene-styrene parts. Rapid Prototyp. J. 2020, 27, 268–277. [Google Scholar] [CrossRef]

- Mohammed, M.; Wilson, D.; Gomez-Kervin, E.; Tang, B.; Wang, J. Investigation of closed-loop manufacturing with acrylonitrile butadiene styrene over multiple generations using additive manufacturing. ACS Sustain. Chem. Eng. 2019, 7, 13955–13969. [Google Scholar] [CrossRef]

- Mwanza, B.; Mbohwa, C. A review of technologies for managing plastic solid wastes. In Sustainable Technologies and Drivers for Managing Plastic Solid Waste in Developing Economies; Springer: Berlin/Heidelberg, Germany, 2021; pp. 25–49. [Google Scholar] [CrossRef]

- Haupt, M.; Vadenbo, C.; Hellweg, S. Do we have the right performance indicators for the circular economy?: Insight into the swiss waste management system. J. Ind. Ecol. 2016, 21, 615–627. [Google Scholar] [CrossRef]

- Tabakovic, A.; McNally, C.; Fallon, E. Specification development for cold in-situ recycling of asphalt. Constr. Build. Mater. 2016, 102, 318–328. [Google Scholar] [CrossRef]

- Shivaprasad, H.; Koppoju, S. Geo technical laboratory evaluation of construction demolition recycled material for road embankments. IOP Conf. Ser. Earth Environ. Sci. 2022, 982, 012064. [Google Scholar] [CrossRef]

- Jiang, H. Research on coordination in the closed-loop supply chain with remanufacturing. Appl. Mech. Mater. 2012, 220–223, 319–322. [Google Scholar] [CrossRef]

- Miao, S.; Chen, D.; Wang, T. System dynamics modelling of remanufacturing and recycling mode based on closed-loop across-chain competition. Discret. Dyn. Nat. Soc. 2017, 2017, 8152365. [Google Scholar] [CrossRef]

- Xie, B.; Guo, T.; Zhao, D.; Jiang, P.; Li, W. A closed-loop supply chain operation problem under different recycling modes and patent licensing strategies. Sustainability 2022, 14, 4471. [Google Scholar] [CrossRef]

- Maghool, F.; Senanayake, M.; Arulrajah, A.; Horpibulsuk, S. Permanent deformation and rutting resistance of demolition waste triple blends in unbound pavement applications. Materials 2021, 14, 798. [Google Scholar] [CrossRef]

- Martínez-García, R.; Rojas, M.; Pozo, J.; Fraile-Fernández, F.; Juan-Valdés, A. Evaluation of mechanical characteristics of cement mortar with fine recycled concrete aggregates (frca). Sustainability 2021, 13, 414. [Google Scholar] [CrossRef]

- Yamasue, E.; Minamino, R.; Tanikawa, H.; Daigo, I.; Okumura, H.; Ishihara, K.; Brunner, P. Quality evaluation of steel, aluminum, and road material recycled from end-of-life urban buildings in Japan in terms of total material requirement. J. Ind. Ecol. 2013, 17, 555–565. [Google Scholar] [CrossRef]

- Hasan, A.; Hasan, U.; Whyte, A.; Jassmi, H. Lifecycle analysis of recycled asphalt pavements: Case study scenario analyses of an urban highway section. CivilEng 2022, 3, 242–262. [Google Scholar] [CrossRef]

- Hasan, U.; Whyte, A.; Jassmi, H. Critical review and methodological issues in integrated life-cycle analysis on road networks. J. Clean. Prod. 2019, 206, 541–558. [Google Scholar] [CrossRef]

- Dharmadhikari, N.; Lee, E.; Kayabas, P. The lifecycle benefit–cost analysis for a rural bridge construction to support energy transportation. Infrastructures 2016, 1, 2. [Google Scholar] [CrossRef]

- Hoy, M.; Horpibulsuk, S.; Arulrajah, A. Strength development of recycled asphalt pavement—Fly ash geopolymer as a road construction material. Constr. Build. Mater. 2016, 117, 209–219. [Google Scholar] [CrossRef]

- Udomchai, A.; Hoy, M.; Suddeepong, A.; Phuangsombat, A.; Horpibulsuk, S.; Arulrajah, A.; Thành, N. Generalized interface shear strength equation for recycled materials reinforced with geogrids. Sustainability 2021, 13, 9446. [Google Scholar] [CrossRef]

- Zhi, X. Experimental study on the mechanical properties and permeability of cement-stabilized permeable recycle aggregate materials. Sustainability 2023, 15, 14063. [Google Scholar] [CrossRef]

- Kissi, E.; Babon-Ayeng, P.; Aigbavboa, C.; Duah, D.; Smith, E.; Tannor, R. Examining green road construction components: The case of Ghana. Built Environ. Proj. Asset Manag. 2023, 13, 682–699. [Google Scholar] [CrossRef]

- Wanume, P. The mediating role of transition management in the relationship of strategic planning systems and sustainable urban road infrastructure development among town councils in Uganda. Am. J. Ind. Bus. Manag. 2023, 13, 1153–1174. [Google Scholar] [CrossRef]

- Arshad, H.; Thaheem, M.; Bakhtawar, B.; Shrestha, A. Evaluation of road infrastructure projects: A life cycle sustainability-based decision-making approach. Sustainability 2021, 13, 3743. [Google Scholar] [CrossRef]

- Handayani, F.; Setyawan, A.; Pramesti, F.; Wibowo, M. Strategy toward sustainable local road network infrastructure. Matec Web Conf. 2017, 138, 07007. [Google Scholar] [CrossRef]

- Steyn, W.; Visser, A. Evaluation of sustainability of low-volume roads treated with nontraditional stabilizers. Transp. Res. Rec. J. Transp. Res. Board 2011, 2204, 186–193. [Google Scholar] [CrossRef]

- Nyanduku, F.K.; Kyalo, J. An investigation of project management practices on sustainability of selected road projects in Kiambu County, Kenya. Strat. J. Bus. Chang. Manag. 2023, 10, 762–777. [Google Scholar] [CrossRef]

- Vieira, J.; Martins, J.; Almeida, N.; Patrício, H.; Morgado, J. Towards resilient and sustainable rail and road networks: A systematic literature review on digital twins. Sustainability 2022, 14, 7060. [Google Scholar] [CrossRef]

- Dimnet, E. 3 key notions for road transport sustainability: Resilience, climate action and energy transition. Rom. J. Transp. Infrastruct. 2022, 11, 1–20. [Google Scholar] [CrossRef]

- Chamorro, A.; Echaveguren, T.; Allen, E.; Contreras, M.; Dagá, J.; Solminihac, H.; Lara, L. Sustainable risk management of rural road networks exposed to natural hazards: Application to volcanic lahars in Chile. Sustainability 2020, 12, 6774. [Google Scholar] [CrossRef]

- Maibaum, J.; Block, M.; König, M. Resource indicator-oriented building information modeling for the management of infrastructure. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 062034. [Google Scholar] [CrossRef]

- Patel, K.; Ruparathna, R. Life cycle sustainability assessment of road infrastructure: A building information modeling-(BIM) based approach. Int. J. Constr. Manag. 2021, 23, 1837–1846. [Google Scholar] [CrossRef]