1. Introduction

Over the years, waste collection, sorting and recycling have been consolidated, and today they are essential for guaranteeing high levels of secondary raw material recovery. This sector has primary importance in the urban waste management system and represents a foundation for the ecological transition, leading to benefits in environmental, economic and social domains [

1]. In Europe, each person produced 530 kg of waste in 2021, and about 49% of all municipal solid waste (MSW) in the EU was either recycled or composted [

2]. Nowadays, the recycling of the organic part of MSW is identified as one of the key elements for transforming the economy toward the circular economy model, converting biowastes, residues and discards into useful products. The main processes for treating organic waste are anaerobic digestion and composting [

3].

With the Circular Economy Package in 2018, new targets for municipal waste management were adopted: recycling of 65% of MSW by 2035, a maximum of 10% disposal in landfills and the mandatory separated collection of biowaste by 2023 [

4].

Among all municipal waste, biowaste represents on average 50% of the total mass of MSW produced globally [

5]. Biowaste is defined by the Waste Framework Directive (1998/2008/EC) of the European Parliament as “biodegradable garden and park waste, food and kitchen waste from households, restaurants, caterers and retail premises and comparable waste from food processing plants” [

6]. It can be mainly divided into two types: waste food from kitchens and canteens (60% of the total biowaste generated) and waste from gardens and parks [

3]. In Italy, for 2021, biowaste represented 39% of the total MSW, of which 73.8% is food waste and 26.2% is park and garden waste [

7]. As the organic fraction is so relevant to the produced waste, the future of food waste becomes a key issue.

Anaerobic digestion is widely utilized to produce and capture methane biogas from organic materials [

8]. Instead, composting is a biological and aerobic degradation process, which means that it occurs in the presence of oxygen. During this process, naturally occurring microorganisms break down organic residues, converting them into a nutrient-rich product known as compost [

9]. The composting process has been demonstrated to be an efficient and sustainable technology for recycling the organic fraction of waste [

10,

11]. There are two configurations of composting: in-vessel composting, which is performed in closed containers, and windrow composting, which is performed in the open air. The product obtained from the composting process can be used as fertilizer or soil improver [

9].

Tognetti et al. [

12] affirmed that the different process techniques directly impact the product quality and degradation processes. Parameters such as porosity, moisture, interstitial oxygen, temperature, C/N ratio, nutrients, pH and biological activity, significantly contribute to optimizing process efficiency [

13]. Furthermore, Cerda et al. [

14] demonstrated the feasibility of improving compost quality by grinding and sieving, highlighting the role of mechanical processes in enhancing impurities removal. The quality of compost is influenced by various factors; thus, mechanical processes play a crucial role in enhancing compost quality. Understanding the environmental impacts and implementing process control measures and mechanical treatment methods are essential for improving compost quality and ensuring its successful application.

According to previous studies, proper sorting methods have proven to reduce the quantity of plastic contained in waste, thus enhancing its recycling [

15]. Thus, a pre-treatment phase and a refining process are fundamental for obtaining the final product. Typically, mechanical processing technologies include unpacking, metals removal, irregular substance removal, size reduction and screening [

9]. Girón-Rojas et al. [

16] demonstrated that the evaluation of the biowaste composting process is crucial for the development of industrial support tools, emphasizing the importance of understanding and monitoring the process to enhance compost quality.

Therefore, the SICOMPOSTA project had the main goal of increasing the compost quality of the plant under study. It was funded by the Regional Operational Program of the Piedmont Region—Italy (Call: PRISM-E, cod. I1b12_Bando_progetti_ricerca_2018). The SICOMPOSTA project started in January 2021 and ended in December 2022.

The research aims (i) to investigate the efficiency of the pre-treatment, performed in the Gestione Ambientale Integrata dell’Astigiano (GAIA S.p.A) waste management plant, to recover the maximum quantity of final product, and (ii) to improve its quality, by means of a prototype machine.

2. Materials and Methods

The design and the construction of a prototype machine based on the necessities for improvement were performed after an initial characterization of the overflow product obtained by the composting plant, which is object of this study. To evaluate the design and the efficiency of the prototype machine, tests were performed in different conditions: at the lab scale and in the operational environment.

2.1. Municipal Waste Composting Plant

The GAIA composting plant belongs to the municipality of San Damiano d’Asti in the Asti Province, located in the Piedmont region in the north of Italy. It has recovered 24 thousand tonnes/year of biodegradable waste from 115 local municipalities since 2003 for a total of approximately 210,000 inhabitants [

17].

From waste sorting, two types of flows arrive to be treated: (i) the humid fraction, composed of food waste; (ii) the green fraction, consisting of mowing and pruning waste. The plant has a capacity to treat 70,000 tonnes/year of food waste and 20,000 tonnes/year of mowing/pruning waste.

In the arrival area, the biowaste is weighed and sent to a mechanical treatment. First, the plastic bags containing the biowaste are opened and then the material is shredded, screened, and subjected to an iron removal process to eliminate metals. After that, part of the food waste and part of the green fraction waste enter in the digester, i.e., a closed cylindrical reactor in which the waste, without the supply of oxygen, is degraded and continuously mixed. Over an interval of 20 days, anaerobic microorganisms transform the incoming material into a uniform mixture known as digestate, a product of significant interest for downstream use in the processing line.

Once produced, digestate is mixed with the green waste fraction and subsequently introduced into biocells where the aerobic composting phase begins. Inside these biocells, the perfect aerobic conditions are generally maintained for the continuation of the process by injecting air from below and thus modifying the humidity and temperature of the pile. After approximately 40 days, the organic mixture is ready to move on to the refining phase. Throughout the process, unpleasant odorous fumes are generated, which are sucked up and conducted via pipes to the washing and biofiltration system to avoid possible negative impacts on the environment.

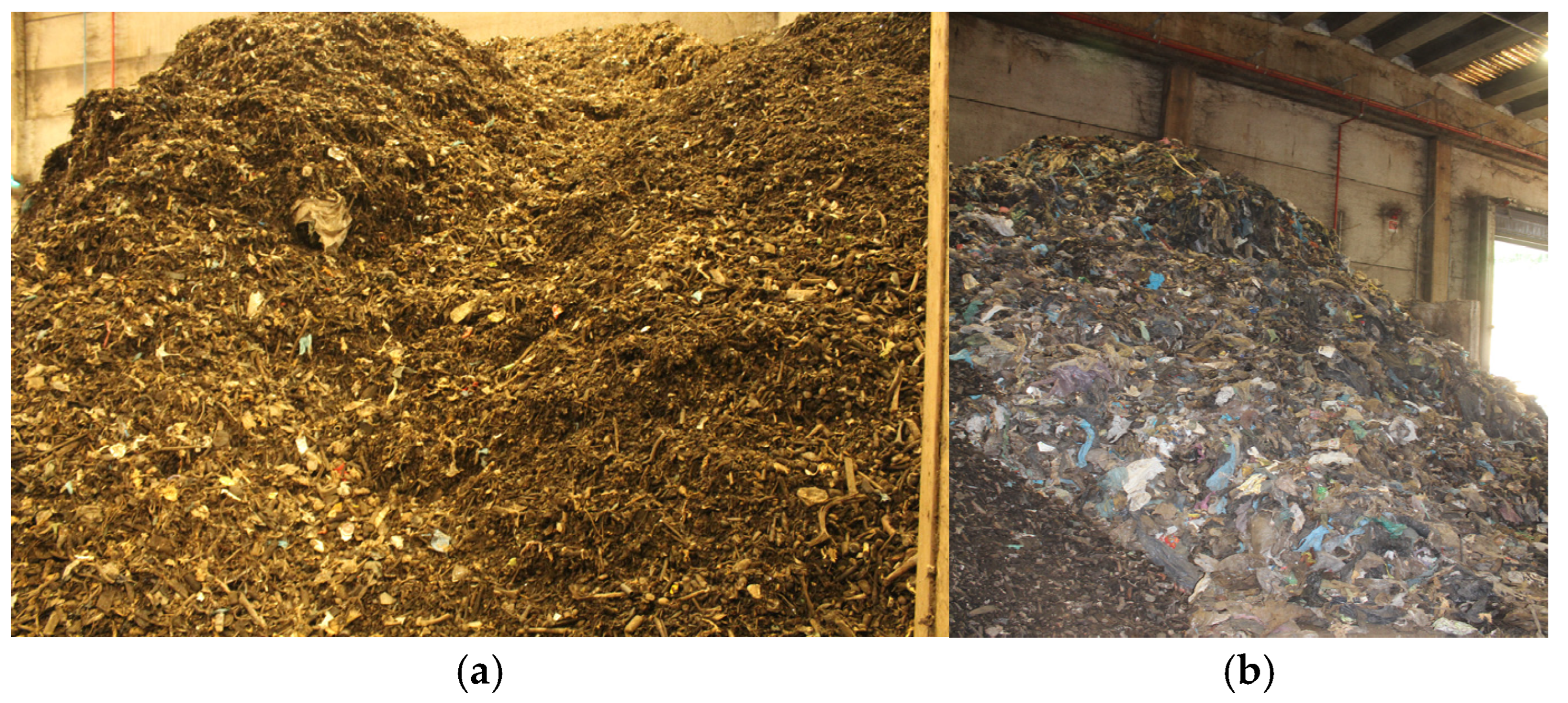

The GAIA ‘s compost refining plant is made up of two screening systems. The first is a trommel with a screen of 12 mm (

Figure 1a), in which the fine organic fraction (<12 mm) fall to the ground due to gravity, and it is recovered as compost. In the second, the oversized material is passed, through the conveyor belt, to a disc screen separator (

Figure 1b), a machine that due to the opening (50 mm) between the discs, allows the coarse material (>50 mm), generally large plastic bags, to be separated and subsequently sent for disposal in a landfill.

2.2. Product 50–12 Mm Characterization Method

The product with a size range between 12 mm and 50 mm, passing through the disc screen in the compost refining, (

Figure 2a) is used as the inoculum, being rich in useful microorganisms for starting the biodegradation. It still contains a significant amount of plastic film (

Figure 2b) and because of the recirculation as the inoculum, it continues to remain in the process.

To reduce the quantity of plastic recirculating, the following actions were carried out: granulometric and material characterization of the product 50–12 mm; development of engineering solutions for a conveyor belt prototype; validation of the prototype; an evaluation of performances in the operational environment.

Two samples of product 50–12 mm from the disc screen separator were taken, one of approximately 11 kg in April and another of 23 kg in July. The first step was to obtain the particle size distribution and to evaluate the composition of each class size analyzed. To perform it, a laboratory sieving machine was used, set to 10 min, during which sieves of different sizes were set up (25, 19, 12, 9, 6 and 2 mm).

The product characterization analysis of each class size was performed through macroscopic recognition and manual separation of the material retained through the sieve class by class, to evaluate the composition of the entire sample both in terms of weight and in terms of percentage of impurities. In some cases, granulometric classes consisting of abundant quantities, in terms of volume, were quartered with the “Coning and Quartering” technique: reaching a volume suitable for carrying out subsequent analyzes. Coning and quartering is a well-established technique for sample reduction. This process involved piling the bulk material into a conical shape, resembling an inverted funnel. The material was then levelled to ensure uniformity and divided into four equal sections. Two diagonally opposite quadrants were selected for further processing, while the remaining two were preserved as reserve material. This method was aimed at reducing sampling bias and ensuring homogeneity. However, its reliance on manual handling introduced potential inconsistencies, making its reproducibility dependent on the operator’s precision.

2.3. Conveyor Belt Design and Tests

The results of the first phase of characterization were the base of the second phase, which focused on designing a machine to increase the production and quality of the compost. During the design process, particular attention was also given to the aspect of energy consumption, trying to obtain the maximum technical/qualitative result of the final product through the minimum possible energy spending. The goal was to present a new generation machine to the market that meets all requirements for environmental responsibility.

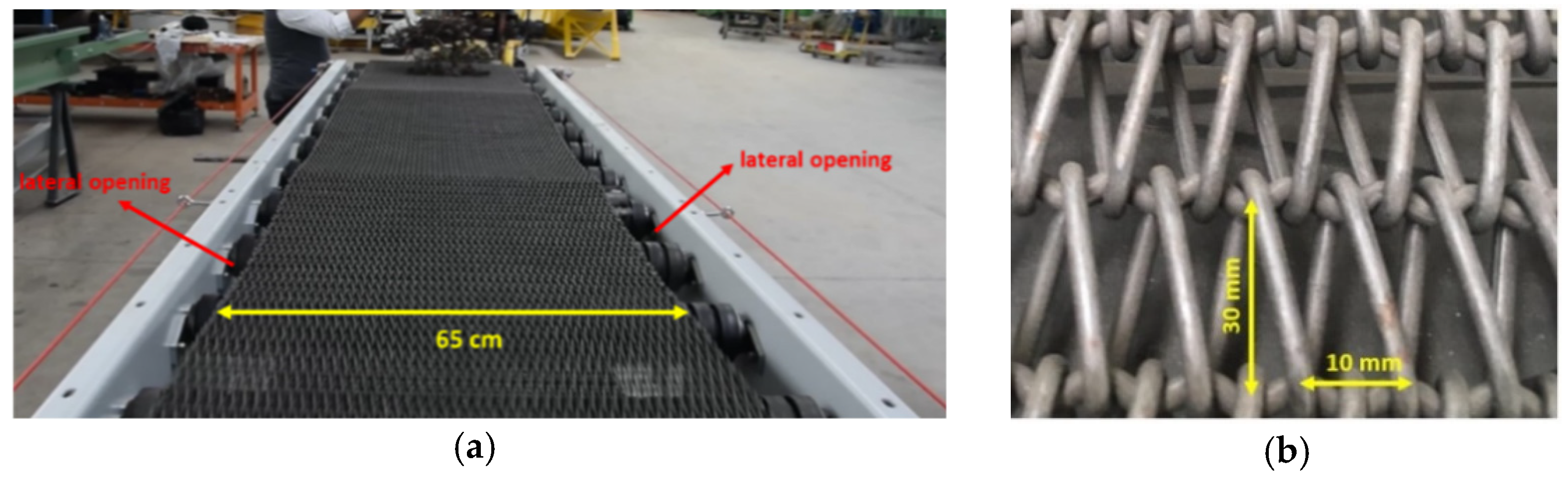

A conveyor belt prototype was built, in which beater rollers were applied to recreate the vibration motion capable of making the loaded material jump over the belt. The fine material falls through the metal mesh and the coarser material is retained. The prototype had dimensions of 5 × 0.65 m (

Figure 3a) with a 1 × 3 cm rectangular mesh (

Figure 3b).

To evaluate the efficiency of the conveyor belt prototype, a preliminary test was performed, using a speed of 70 Hz and passing the material over the belt three times to simulate a 15 m belt length. The conveyor belt loading capacity is 1 t/h.

After the preliminary test on the conveyor belt, the necessity to improve the machine was clear. After, further tests were carried out to evaluate the modified version with lateral protections to prevent material from falling off during the jumps. Also, a vacuum cleaner (to simulate an aeraulic separator) was placed at the end of the conveyor for the removal of the light plastic/paper fraction.

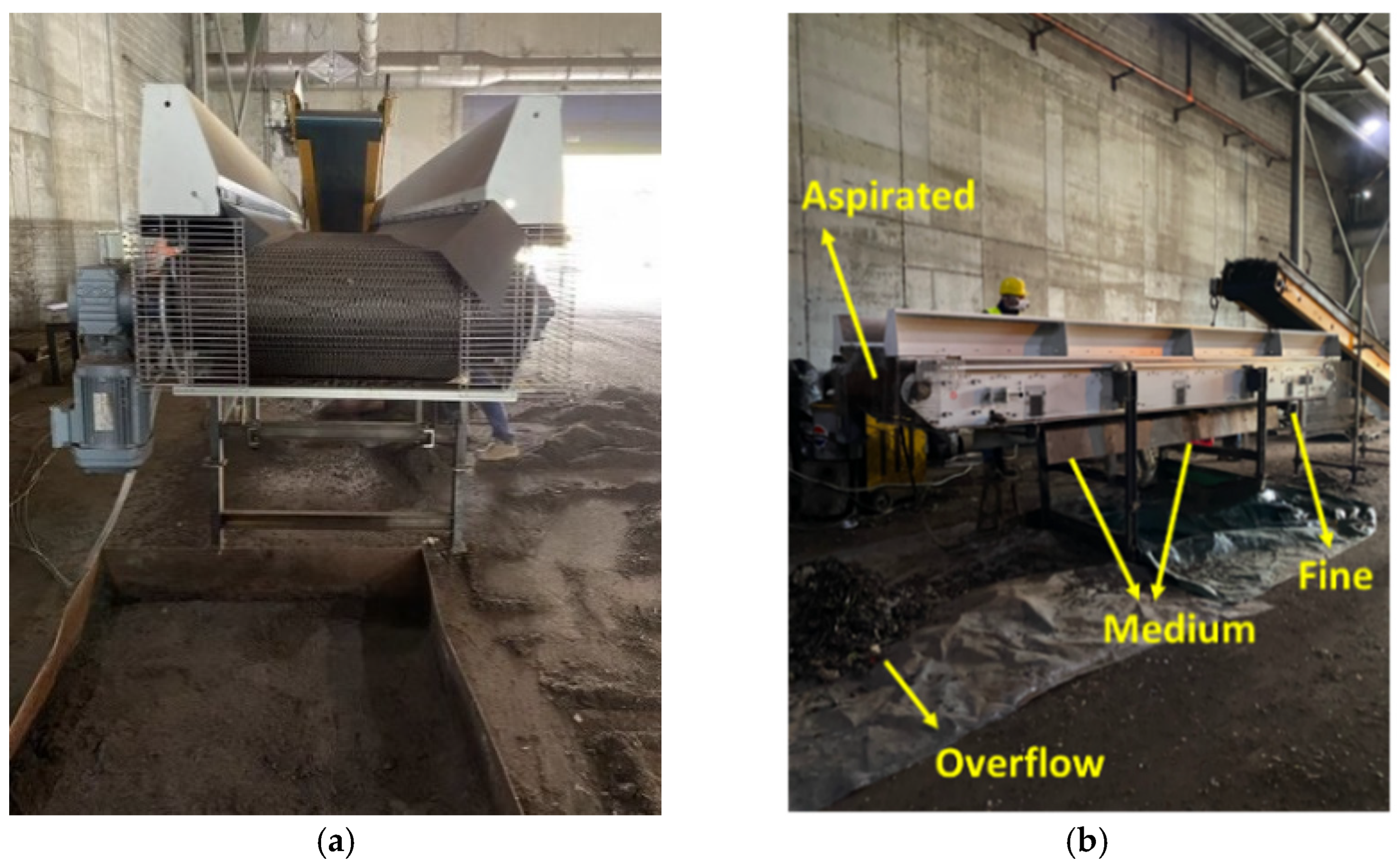

In

Figure 4, it is possible to see the final conveyor belt with the products obtained (

Figure 4a,b).

To assess the conveyor belt’s performance in the operational environment, a sample of the disc screen product 50–12 mm weighing approximately 180 kg was loaded onto the feeder belt.

The input parameters for the operation of the conveyor belt are roller rotation speed 0–1.4 m/s; mesh speed 0–1 m/s; brush speed 0–1.6 m/s; feeder belt speed 0–0.08 m/s. To verify the efficiency and determine the suitable parameters for the conveyor belt in the refining line, four possible solutions were tested in situ:

Test 1: Rollers (0.7 m/s), Mesh (0.5 m/s), Brush (0.4 m/s), Feeder (0.04 m/s);

Test 2: Rollers (0.98 m/s), Mesh (0.7 m/s), Brush (0.4 m/s), Feeder (0.056 m/s);

Test 3: Rollers (0.98 m/s), Mesh (0.5 m/s), Brush (0.4 m/s, Feeder (0.056 m/s);

Test 4: Rollers (0.7 m/s), Mesh (0.7 m/s), Brush (0.4 m/s), Feeder (0.056 m/s).

Following these four tests, a validation test was performed using the parameters that yielded the best results (paragraph 3.4).

3. Results and Discussion

3.1. Product 50–12 mm Characterization

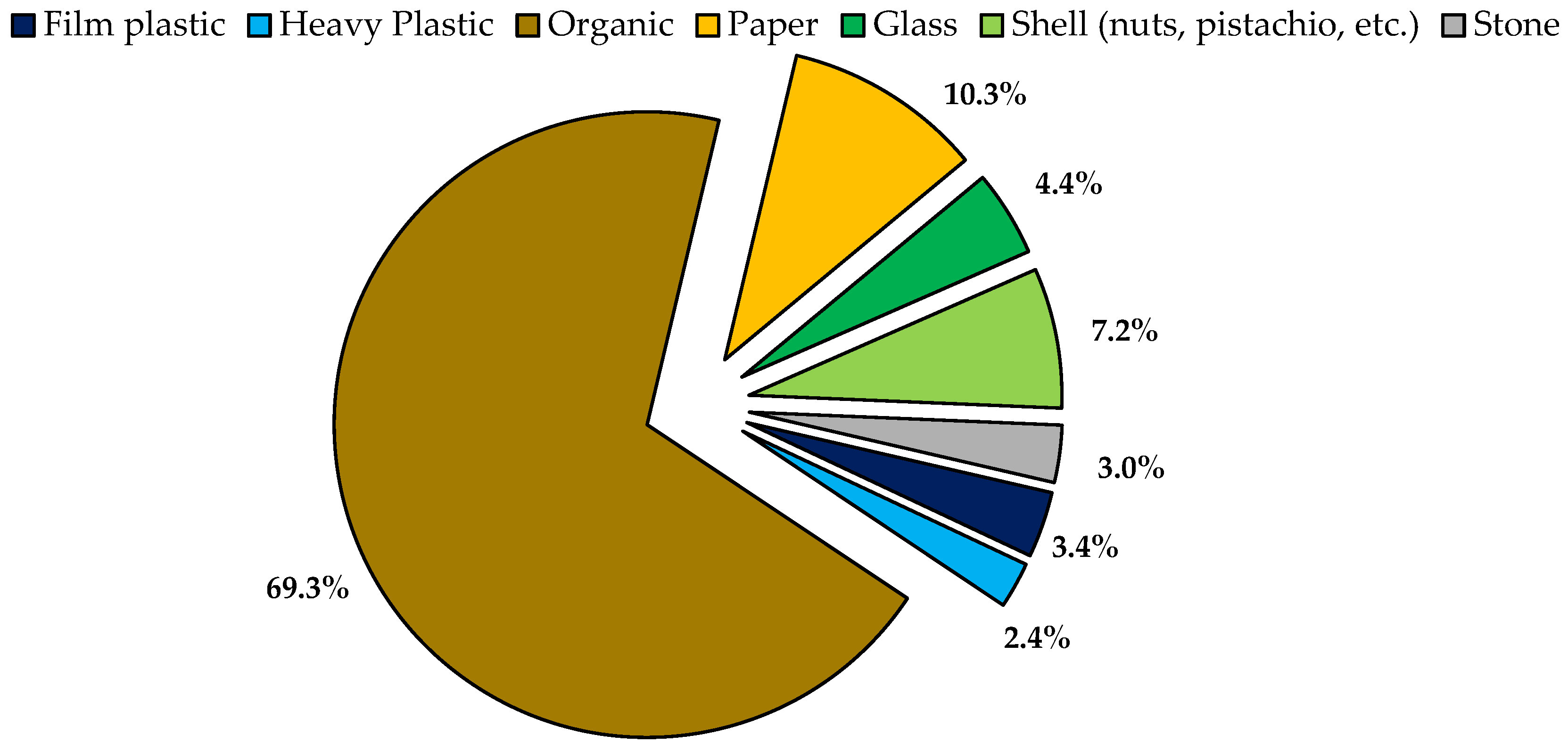

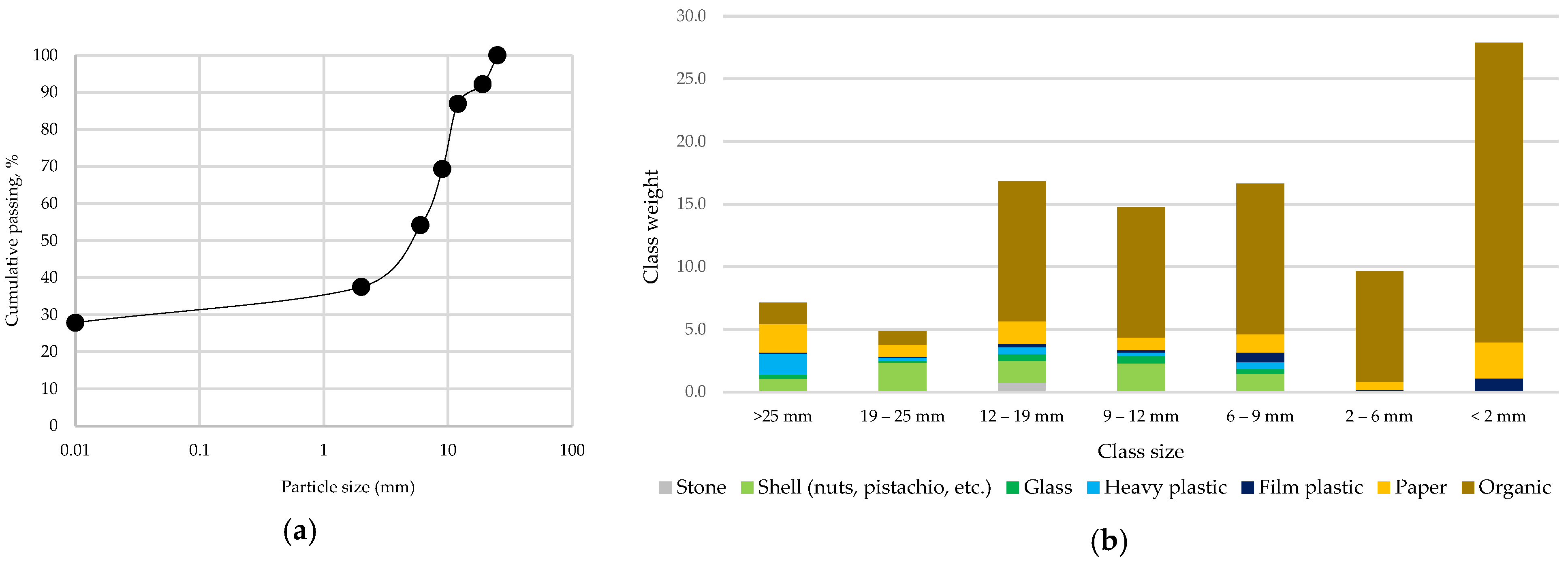

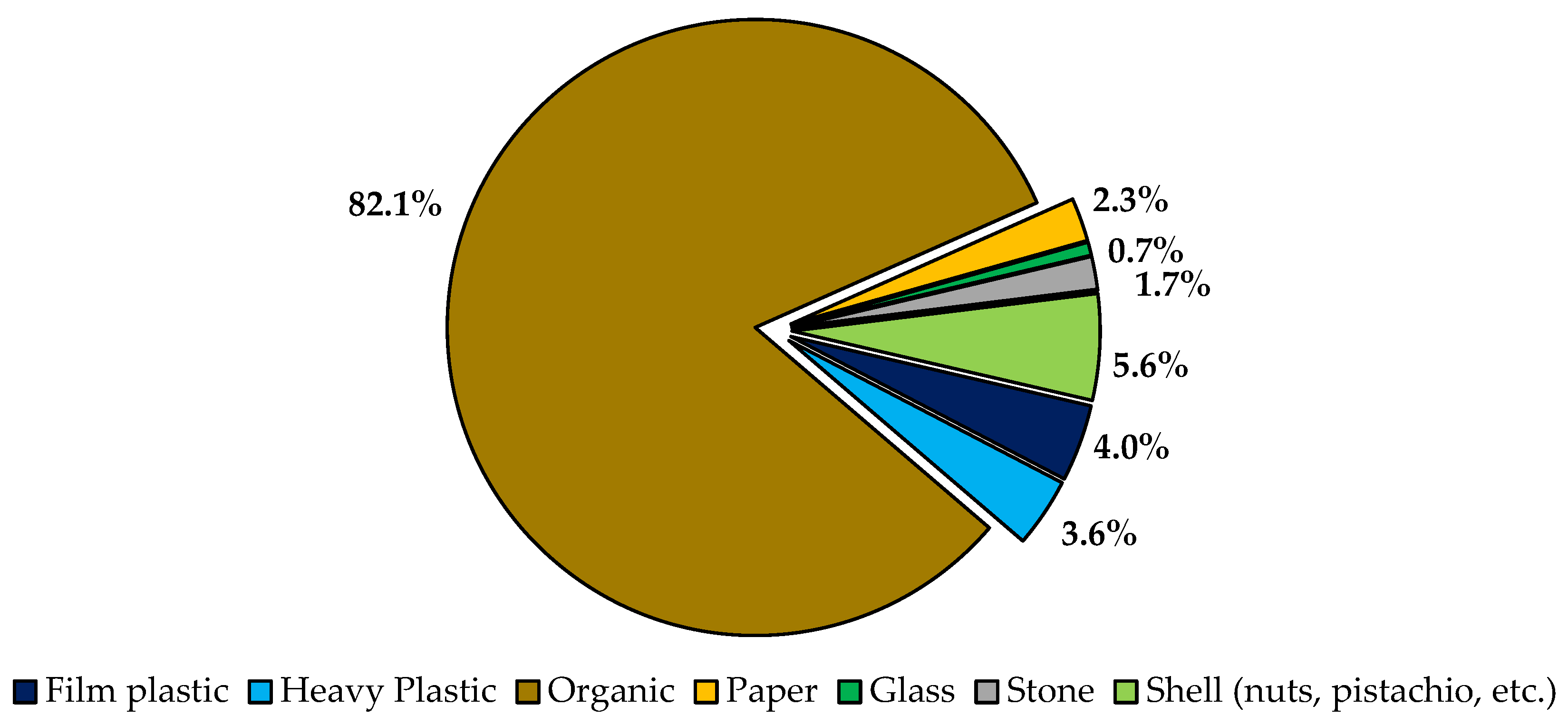

As indicated in the Materials and Methods section, two samples of product 50–12 mm were analyzed. The average composition of the samples is shown in

Figure 5, it is possible to see the presence of unwanted materials, mainly film plastic (3%), heavy plastic (2%), paper (10%) and glass (4%).

The graphic representation of the granulometric curve obtained is shown in

Figure 6a, highlighting that approximately 75% of the entire sample has a dimension of 12 mm or less. In particular, (

Figure 6b), the granulometric classes between 12 and 9 mm, 9–6, 6–2 and <2 mm contain a large quantity of organic substance, indicating a low efficiency in the refining line and a significant loss of clean product. These analyses also demonstrated the considerable presence of fine material below 12 mm and organic substances being lost in the refining line without being recovered.

3.2. Preliminary Test on Conveyor Belt Prototype

Following the characterization of GAIA’s 50–12 mm product, the concept was to develop a conveyor belt, to recover fine compost from this product and effectively remove plastic, thereby increasing the quality of the inoculum.

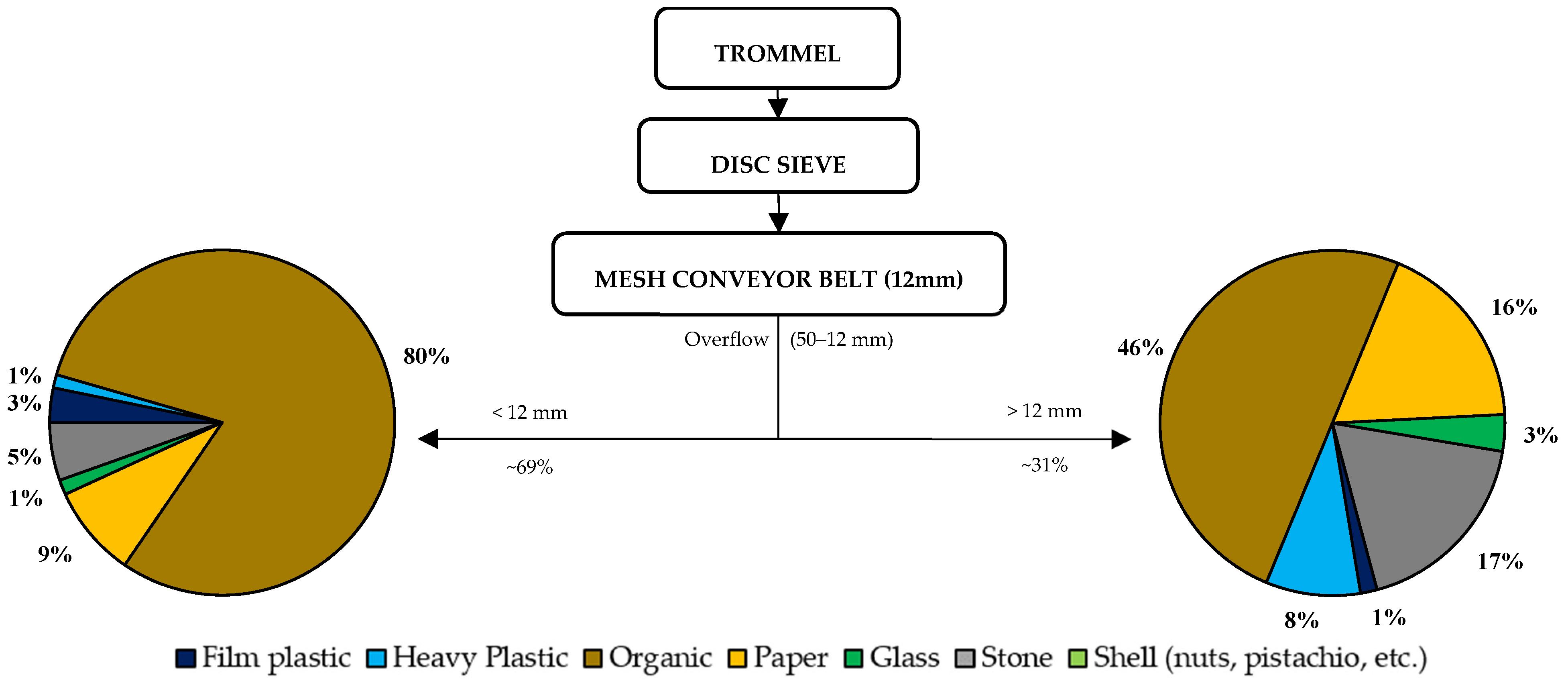

Figure 7 and

Figure 8 show the results obtained using this first prototype machine.

Figure 9 presents a photo of the compost after treatment. The use of the mesh belt enabled us to recover a high amount of organic matter smaller than 12 mm, while also resulting in a very low quantity of unwanted materials. In fact, excellent results can be seen in reference to the presence of plastic films.

Indeed, in this first phase of design and improvement, the machine has proven to be quite effective in terms of recovering fine material under 12 mm.

However, it still has non-negligible percentages of plastic (light in weight but high in volume), glass and paper. Therefore, a new system solution was proposed.

3.3. Evaluation of the Proposed Final Conveyor Belt

The efficiency of the proposed final system was evaluated through four tests. Each test utilized different working parameters for the conveyor belt prototype, as described in the Materials and Methods section. Three different products were obtained from each test: fine compost < 12 mm with near 80% < 2 mm, medium compost < 12 mm with slightly more of 40% < 2 mm, the overflow used as inoculum with more than 50% > 12 mm and a waste constituted by the plastic aspirated (0.1% in wt).

For each test, an approximately 13 kg sample of each product was collected for the compositional analysis reported in

Table 1. The use of the mesh conveyor effectively recovered a large portion of the fraction finer than 12 mm and minimized the quantity of undesirable materials. Notably, excellent results were observed regarding the reduction in plastic films, although issues concerning the presence of paper and glass remain unresolved.

The results demonstrated that the parameters of Test 2, using this conveyor belt prototype, are considered suitable for further testing, as this test yielded the highest quantity of organic substances in the fine and medium product, at 70.6% (

Table 1).

3.4. Validation Test

A validation test was then performed on 184 kg of 50–12 mm overflow, applying the parameters from test 2: rotation speed of the rollers 0.98 m/s, speed of the feeding belt 0.056 m/s, speed of the mesh 0.7 m/s and speed of the brush 0.4 m/s (as indicated in

Section 2.3). An industrial vacuum cleaner was placed at the end of the conveyor belt for the aspiration of light elements.

Figure 10 shows the composition analysis of the feed input test. It can be seen the plastic weight percentage is very similar to the 50–12 mm sample characterization (

Figure 5), at around 3–4%.

Table 2 shows the weight values obtained from the validation test.

The fine and the medium products are considered recovered material. Thus, it can be confirmed that around 11% (in weight) of the initial sample could be suitable for use as a soil improver since it was clean and low in impurities (

Figure 11). In particular, for the parts finer than 12 mm and for the fine and medium products, the organic part reaches a purity of 92%.

We also notice that the aspirated product consisted of organic material dust and light materials (plastics and paper), which highly affect the quality of inoculum, (

Figure 11).

A comparison of the overflow sample before and after the test is shown in

Table 3, and the percentages of the materials with dimensions >12 mm and <12 mm are shown.

The use of the conveyor belt enabled the recovery of over 70% of the parts that are finer than 12 mm.

Through the changes desired for improving in the refining line, it should be possible to solve the problems on which the SICOMPOSTA project is focused, consequently allowing the GAIA company to obtain, downstream of their post-treatment, a pure compost that is in accordance with the parameters reported in the current decree on fertilizers (Italian Legislative Decree 75/2010) [

18].

The final configuration (see results in

Figure 10 and

Figure 11) of the conveyor belt, with lateral protection, yielded the best results by preventing the loss of fine organic material that could be recovered for compost. In addition, performing tests with different speed parameters helped to determine the suitable rollers, mesh, brush and feeder velocity (respectively, 0.98 m/s, 0.7 m/s, 0.4 m/s and 0.056 m/s). Under these conditions, the highest yield of fine and medium product was obtained.

Finally, the results from the operational environment demonstrated the efficiency of the conveyor prototype and highlighted the importance of the aspiration process, which is crucial for removing light materials such as paper and plastic film present in the bio-waste.

The prototype machine has proven to be effective with regard to the recovery of fine material under 12 mm, with a percentage of 32.9% remaining in the overflow (reduction of almost 40% before the test, see

Table 3). Lengthening the belt by 2–3 m could solve this problem and improve separation efficiency, representing a potential future step for this application.

4. Conclusions

The study of the compost refining line of a waste plant in Piedmont, Italy, provides useful suggestions for designing innovative equipment.

The characterization of the overflow product revealed a significant quantity of fine organic material being lost and recirculated within the plant, without being recovered as compost. Moreover, the composition analysis made possible to improve the efficiency of the plant’s processing line.

Analyses of an initial 17 kg sample of the overflow product, used as an inoculum of aerobic bacteria for the first phase of the composting process, demonstrated the presence of unwanted materials, mainly film plastic (3%), heavy plastic (2%), paper (10%) and glass (4%). Furthermore, a considerable percentage of organic material with a diameter of less than 12 mm (approximately 75%) was found, suitable for use as a soil improver, as it is clean and low in impurities.

The study successfully developed and tested a mesh conveyor belt prototype. This prototype uses beating rollers to agitate the material on the belt, allowing clean compost with a diameter of less than 12 mm to fall through the mesh, thereby separating it from coarse, impure material.

The greater length of the belt will ensure that the light fraction can arrange itself in a single-granular veil due to the jolts, in order to be sucked up more efficiently at the end of the perforated belt, thus increasing the percentage of plastic eliminated from the residue. The results were satisfactory, with a recovery of more than 50% of fine, pure compost and a 75% reduction in plastic impurities.