Sustainable Fire-Resistant Materials: Recycled Polyethylene Composites with Non-Halogenated Intumescent Flame Retardants for Construction Applications

Abstract

1. Introduction

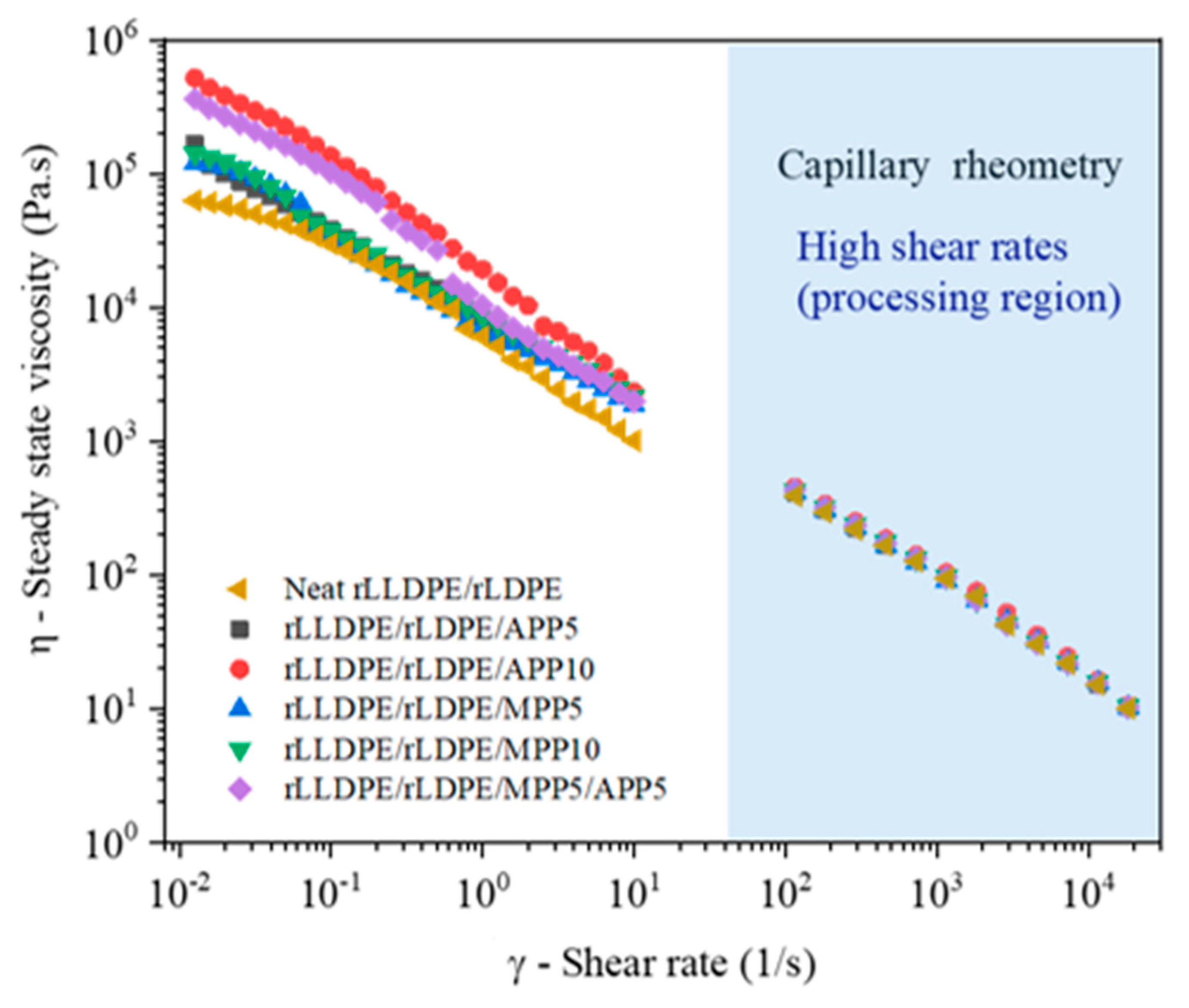

2. Results and Discussion

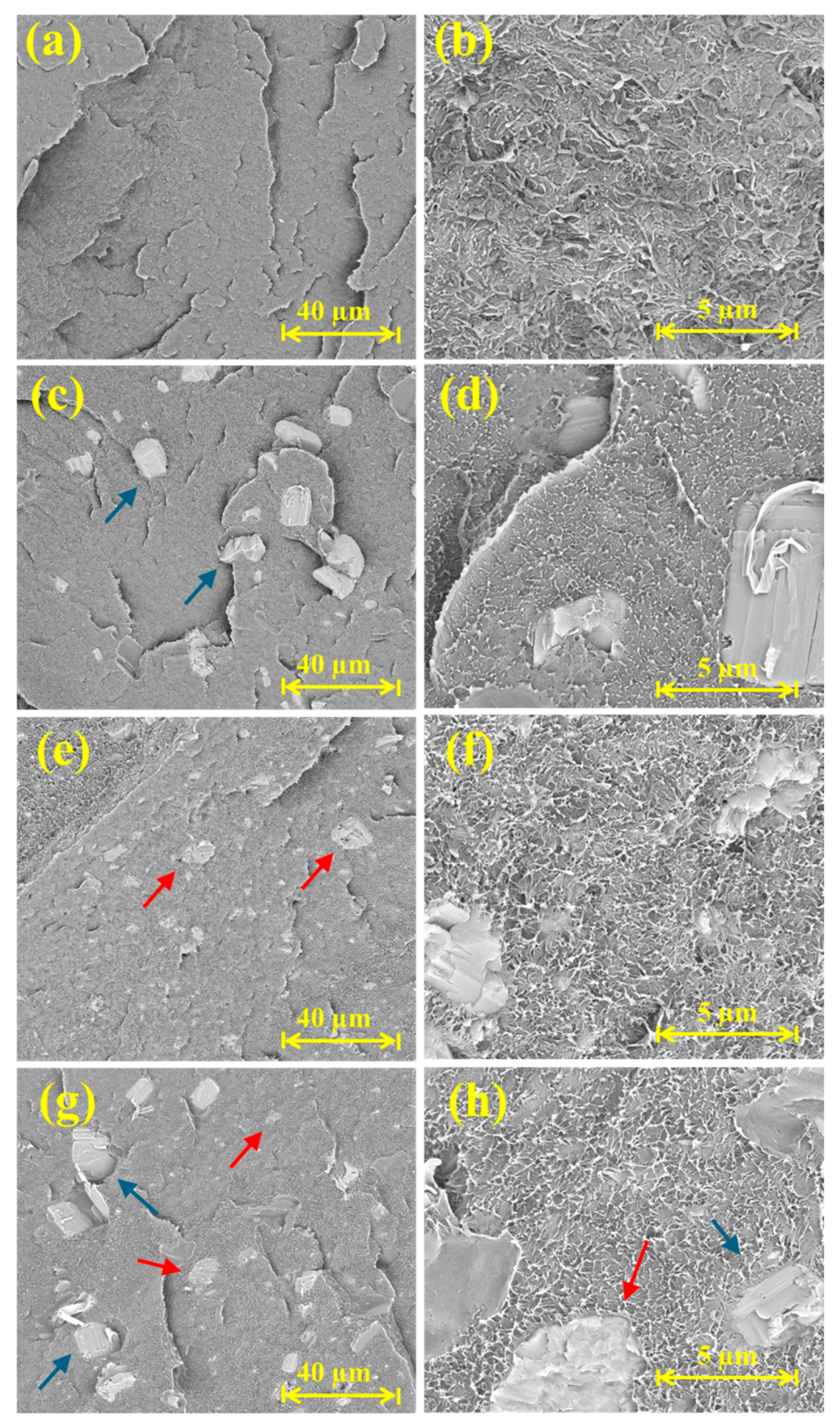

2.1. Morphology of rLLDPE/rLDPE-Based FR Composites

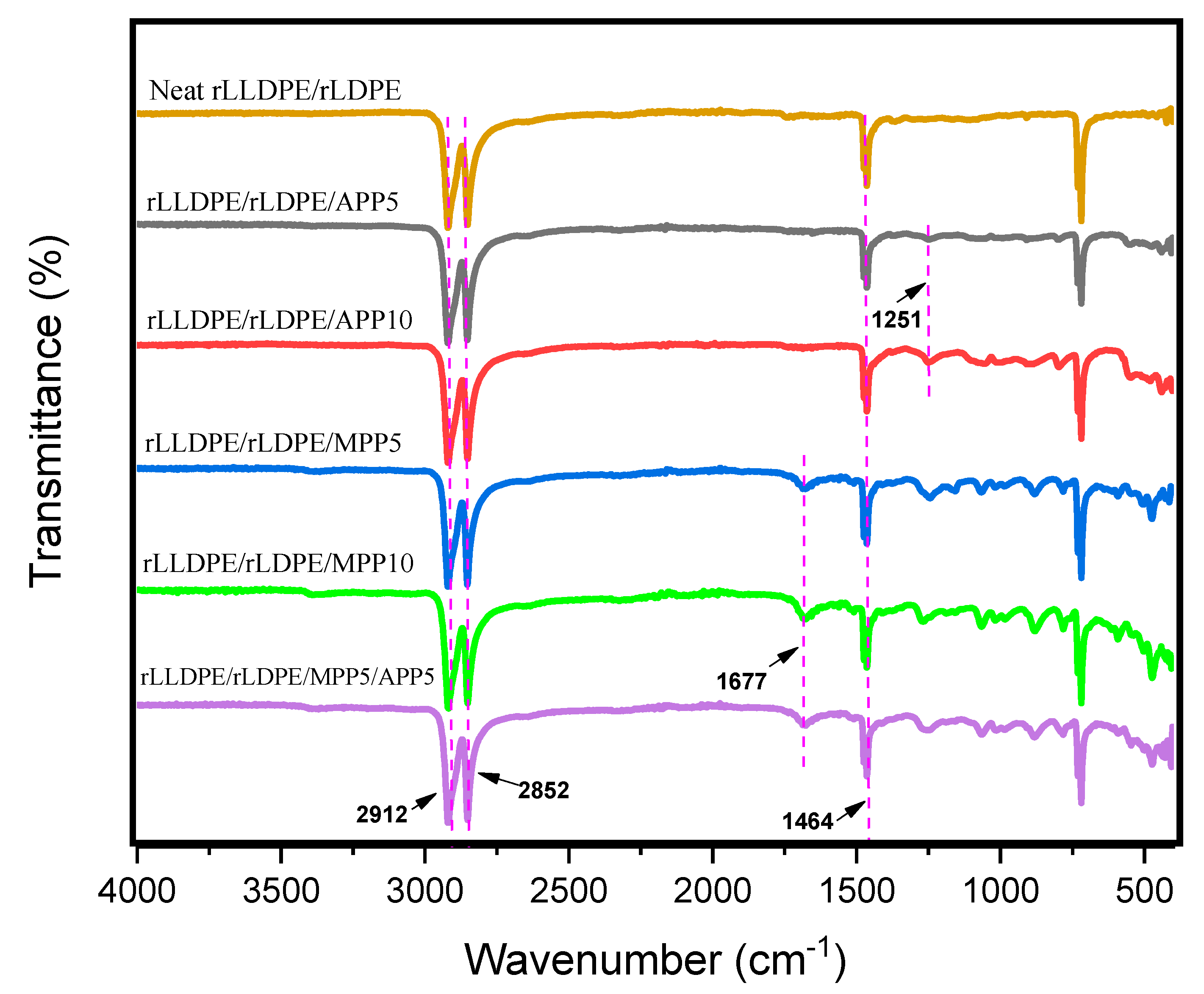

2.2. FTIR Analysis

2.3. TGA of rLLDPE/rLDPE Composites

2.4. Flammability Study of rLLDPE/rLDPE Composites

2.5. Evaluation of the Mechanical Properties

3. Materials and Methods

3.1. Materials

3.2. Preparation of r-LLDPE/r-LDPE Containing Intumescent Flame Retardants

3.3. Characterization Methods

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tiago, G.A.; Mariquito, A.; Martins-Dias, S.; Marques, A.C. The problem of polyethylene waste–recent attempts for its mitigation. Sci. Total Environ. 2023, 892, 164629. [Google Scholar] [CrossRef] [PubMed]

- Hashemnejad, M. Composition analysis of post-consumer recycled blends of linear low- and low-density polyethylene using a solution-based technique. J. Appl. Polym. Sci. 2023, 140, e54099. [Google Scholar] [CrossRef]

- Balema, V.P.; Hlova, I.Z.; Carnahan, S.L.; Seyedi, M.; Dolotko, O.; Rossini, A.J.; Luzinov, I. Depolymerization of polystyrene under ambient conditions. New J. Chem. 2021, 45, 2935–2938. [Google Scholar] [CrossRef]

- Wang, N.M.; Strong, G.; DaSilva, V.; Gao, L.; Huacuja, R.; Konstantinov, I.A.; Rosen, M.S.; Nett, A.J.; Ewart, S.; Geyer, R.; et al. Chemical Recycling of Polyethylene by Tandem Catalytic Conversion to Propylene. J. Am. Chem. Soc. 2022, 144, 18526–18531. [Google Scholar] [CrossRef] [PubMed]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A Review. Macromol. Rapid Commun. 2020, 42, e2000415. [Google Scholar] [CrossRef]

- Najafi, S.K. Use of recycled plastics in wood plastic composites—A review. Waste Manag. 2013, 33, 1898–1905. [Google Scholar] [CrossRef]

- Feng, C.; Liang, M.; Jiang, J.; Huang, J.; Liu, H. Flame retardancy and thermal degradation behavior of efficient intumescent flame retardant LDPE composite containing 4A zeotile. J. Anal. Appl. Pyrolysis 2016, 118, 9–19. [Google Scholar] [CrossRef]

- Liu, M.; Brandsma, S.H.; Schreder, E. From e-waste to living space: Flame retardants contaminating household items add to concern about plastic recycling. Chemosphere 2024, 365, 143319. [Google Scholar] [CrossRef]

- Pearce, E. Flame-Retardant Polymeric Materials; Springer Science & Business Media: New York, NY, USA, 2012; Available online: https://books.google.com.my/books?id=jPIHCAAAQBAJ&printsec (accessed on 25 September 2024).

- Lu, S.-Y.; Hamerton, I. Recent developments in the chemistry of halogen-free flame retardant polymers. Prog. Polym. Sci. 2002, 27, 1661–1712. [Google Scholar] [CrossRef]

- Levchik, S.; Levchik, G.; Balabanovich, A.; Camino, G.; Costa, L. Mechanistic study of combustion performance and thermal decomposition behaviour of nylon 6 with added halogen-free fire retardants. Polym. Degrad. Stab. 1996, 54, 217–222. [Google Scholar] [CrossRef]

- Lim, K.-S.; Bee, S.-T.; Sin, L.T.; Tee, T.-T.; Ratnam, C.T.; Hui, D.; Rahmat, A.R. A review of application of ammonium polyphosphate as intumescent flame retardant in thermoplastic composites. Compos. Part B Eng. 2016, 84, 155–174. [Google Scholar] [CrossRef]

- Adisa, A.; Asante, J.K.O.; Ojijo, V.O.; Mapossa, A.B.; Mhike, W. Polyaniline as a dual flame retardant and electrostatic dissipative additive in polyethylene nanocomposites. J. Vinyl Addit. Technol. 2024, 1–17. [Google Scholar] [CrossRef]

- Laoutid, F.; Bonnaud, L.; Alexandre, M.; Lopez-Cuesta, J.-M.; Dubois, P. New prospects in flame retardant polymer materials: From fundamentals to nanocomposites. Mater. Sci. Eng. R Rep. 2009, 63, 100–125. [Google Scholar] [CrossRef]

- Mapossa, A.B.; dos Anjos, E.G.R.; Sundararaj, U. Boosting Flame Retardancy of Polypropylene/Calcium Carbonate Composites with Inorganic Flame Retardants. Materials 2024, 17, 4553. [Google Scholar] [CrossRef]

- Mapossa, A.B.; Mehdipour, N.M.; Sundararaj, U. Thermal, mechanical, flammability properties, and morphologies of polypropylene/calcium carbonate-based on carbon nanomaterials and layered silicates composites: A future perspective of new sheet material for flooring application. J. Vinyl Addit. Technol. 2024, 31, 146–181. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.M. Mechanical properties of linear low-density polyethylene fire-retarded with melamine polyphosphate. J. Appl. Polym. Sci. 2018, 135, 46770. [Google Scholar] [CrossRef]

- Ghomi, E.R.; Khosravi, F.; Mossayebi, Z.; Ardahaei, A.S.; Dehaghi, F.M.; Khorasani, M.; Neisiany, R.E.; Das, O.; Marani, A.; Mensah, R.A.; et al. The Flame Retardancy of Polyethylene Composites: From Fundamental Concepts to Nanocomposites. Molecules 2020, 25, 5157. [Google Scholar] [CrossRef]

- Mathot, V.B.F. Temperature dependence of some thermodynamic functions for amorphous and semi-crystalline polymers. Polymer 1984, 25, 579–599. [Google Scholar] [CrossRef]

- Shao, Z.-B.; Deng, C.; Tan, Y.; Yu, L.; Chen, M.-J.; Chen, L.; Wang, Y.-Z. Ammonium polyphosphate chemically-modified with ethanolamine as an efficient intumescent flame retardant for polypropylene. J. Mater. Chem. A 2014, 2, 13955–13965. [Google Scholar] [CrossRef]

- Zhou, T.; Chen, W.; Duan, W.; Liu, Y.; Wang, Q. In situ synthesized and dispersed melamine polyphosphate flame retardant epoxy resin composites. J. Appl. Polym. Sci. 2019, 136, 47194. [Google Scholar] [CrossRef]

- Chen, W.; Wang, L.; Liu, G. Synthesis of ammonium polyphosphate with crystalline form V (APP-V) from melamine polyphosphate (MPP). Polym. Degrad. Stab. 2012, 97, 2567–2570. [Google Scholar] [CrossRef]

- Barczewski, M.; Lewandowski, K.; Schmidt, M.; Szostak, M. Melt fracture and rheology of linear low density polyethylene–calcium carbonate composites. Polym. Eng. Sci. 2016, 57, 998–1004. [Google Scholar] [CrossRef]

- Rueda, M.M.; Auscher, M.-C.; Fulchiron, R.; Périé, T.; Martin, G.; Sonntag, P.; Cassagnau, P. Rheology and applications of highly filled polymers: A review of current understanding. Prog. Polym. Sci. 2017, 66, 22–53. [Google Scholar] [CrossRef]

- da Costa, H.M.; Ramos, V.D.; Rocha, M.C. Rheological properties of polypropylene during multiple extrusion. Polym. Test. 2004, 24, 86–93. [Google Scholar] [CrossRef]

- Sangroniz, L.; Santamaría, A.; Müller, A. Rheology of polymer blend nanocomposites. In Rheology of Polymer Blends and Nanocomposites: Theory, Modelling and Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 123–160. [Google Scholar] [CrossRef]

- Pérez, R.; Rojo, E.; Fernández, M.; Leal, V.; Lafuente, P.; Santamaría, A. Basic and applied rheology of m-LLDPE/LDPE blends: Miscibility and processing features. Polymer 2005, 46, 8045–8053. [Google Scholar] [CrossRef]

- Delgadillo-Velázquez, O.; Hatzikiriakos, S.G.; Sentmanat, M. Thermorheological properties of LLDPE/LDPE blends. Rheol. acta 2007, 47, 19–31. [Google Scholar] [CrossRef]

- Czarnecka-Komorowska, D.; Wiszumirska, K.; Garbacz, T. Films LDPE/LLDPE made from post–consumer plastics: Processing, structure, mechanical properties. Adv. Sci. Technol. Res. J. 2018, 12, 134–142. [Google Scholar] [CrossRef]

- Ishida, H. Infrared and Raman Spectroscopics. Sen’i Gakkaishi 1993, 49, P121–P124. [Google Scholar] [CrossRef]

- Jiang, Z.; Liu, G. Microencapsulation of ammonium polyphosphate with melamine-formaldehyde-tris(2-hydroxyethyl)isocyanurate resin and its flame retardancy in polypropylene. RSC Adv. 2015, 5, 88445–88455. [Google Scholar] [CrossRef]

- Ma’ali, R.; Surkhi, O.; Sawalha, S.; Jibreeni, S.; Fanoun, S.; Al-Khatib, A. Effects of Flame Retardants Additives on the Properties of Low-Density Polyethylene. Int. J. Eng. Technol. Sci. (IJETS) 2018, 5, 57–65. [Google Scholar] [CrossRef]

- Xu, Z.-Z.; Huang, J.-Q.; Chen, M.-J.; Tan, Y.; Wang, Y.-Z. Flame retardant mechanism of an efficient flame-retardant polymeric synergist with ammonium polyphosphate for polypropylene. Polym. Degrad. Stab. 2013, 98, 2011–2020. [Google Scholar] [CrossRef]

- Schinazi, G.; Price, E.J.; Schiraldi, D.A. Chapter 3—Fire testing methods of bio-based flame-retardant polymeric materials. In Bio-Based Flame-Retardant Technology for Polymeric Materials; Elsevier Inc.: Amsterdam, The Netherlands, 2022; pp. 61–95. ISBN 9780323907712. [Google Scholar] [CrossRef]

- Xu, C.; Jian, W.; Xing, C.; Zhou, H.; Zhao, Y.; Pan, H.; Xiong, X. Flame retardancy and mechanical properties of thermal plastic composite panels made from Tetra Pak waste and high-density polyethylene. Polym. Compos. 2014, 37, 1797–1804. [Google Scholar] [CrossRef]

- Horrocks, A.R.; Tune, M.; Cegielka, L. The Burning Behaviour of Textiles and its Assessment by Oxygen-index Methods. Text. Prog. 1988, 18, 1–186. [Google Scholar] [CrossRef]

- Amariei, G.; Henriksen, M.L.; Klarskov, P.; Hinge, M. In-line quantitative estimation of ammonium polyphosphate flame retardant in polyolefins via industrial hyperspectral imaging system and machine learning. Waste Manag. 2023, 170, 1–7. [Google Scholar] [CrossRef]

- Liu, J.-C.; Xu, M.-J.; Lai, T.; Li, B. Effect of Surface-Modified Ammonium Polyphosphate with KH550 and Silicon Resin on the Flame Retardancy, Water Resistance, Mechanical and Thermal Properties of Intumescent Flame Retardant Polypropylene. Ind. Eng. Chem. Res. 2015, 54, 9733–9741. [Google Scholar] [CrossRef]

- ASTM D3835-16; Standard Test Method for Determination of Properties of Polymeric Materials by Means of a Capillary Rheometer. ASTM: West Conshohocken, PA, USA, 2024.

- ASTM D2863-19; Standard Test Method for Measuring the Minimum Oxygen Concentration to Support Candle-Like Combustion of Plastics (Oxygen Index). ASTM: West Conshohocken, PA, USA, 2023.

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

- ISO 180:2023; Plastics—Determination of Izod impact strength. ISO Central Secretariat: Geneva, Switzerland, 2023.

| Samples | Fit Intercept | Fit Slope | Consistency Index (m) 104 (Pa·sn) | Pseudoplasticity Index (n) | R2 |

|---|---|---|---|---|---|

| Neat rLLDPE/rLDPE | 4.13 ± 0.05 | −0.72 ± 0.02 | 13.6 ± 0.7 | 0.28 ± 0.02 | 0.994 |

| rLLDPE/rLDPE/APP5 | 4.13 ± 0.05 | −0.72 ± 0.01 | 13.6 ± 0.6 | 0.28 ± 0.01 | 0.996 |

| rLLDPE/rLDPE/APP10 | 4.21 ± 0.06 | −0.73 ± 0.02 | 16.4 ± 0.9 | 0.27 ± 0.02 | 0.994 |

| rLLDPE/rLDPE/MPP5 | 4.15 ± 0.03 | −0.72 ± 0.01 | 14.1 ± 0.5 | 0.28 ± 0.01 | 0.998 |

| rLLDPE/rLDPE/MPP10 | 4.20 ± 0.04 | −0.74 ± 0.01 | 15.7 ± 0.6 | 0.26 ± 0.01 | 0.997 |

| rLLDPE/rLDPE/MPP5/APP5 | 4.20 ± 0.04 | −0.74 ± 0.01 | 15.8 ± 0.6 | 0.26 ± 0.01 | 0.997 |

| Samples | Tm (°C) | ΔHm (J/g) | Xc (%) | Tc (°C) | ΔHc (J/g) | Tm (°C) | ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|---|---|---|---|

| Neat rLLDPE/rLDPE | 135.83 ± 0.05 | 184.2 ± 0.2 | 63 | 117.24 ± 0.04 | 188.0 ± 0.2 | 136.14 ± 0.03 | 186.7 ± 0.3 | 64 |

| rLLDPE/rLDPE/APP5 | 135.73 ± 0.58 | 179.4 ± 0.2 | 64 | 116.82 ± 0.07 | 195.2 ± 0.2 | 136.57 ± 0.09 | 186.8 ± 0.2 | 67 |

| rLLDPE/rLDPE/APP10 | 135.26 ± 0.15 | 175.4 ± 0.2 | 67 | 117.06 ± 0.02 | 177.3 ± 0.2 | 134.85 ± 0.01 | 167.3 ± 0.2 | 63 |

| rLLDPE/rLDPE/MPP5 | 133.39 ± 0.33 | 169.2 ± 0.2 | 61 | 118.55 ± 0.08 | 186.3 ± 0.2 | 134.81 ± 0.15 | 180.5 ± 0.2 | 65 |

| rLLDPE/rLDPE/MPP10 | 135.29 ± 0.21 | 182.3 ± 0.2 | 69 | 118.41 ± 0.13 | 182.5 ± 0.2 | 135.62 ± 0.11 | 177.7 ± 0.2 | 67 |

| rLLDPE/rLDPE/MPP5/APP5 | 136.27 ± 0.18 | 157.3 ± 0.2 | 60 | 117.30 ± 0.28 | 153.4 ± 0.2 | 136.04 ± 0.04 | 154.7 ± 0.3 | 59 |

| Samples | Tonset (°C) | Tmax (°C) | Char Residue at 900 °C (%) | LOI (%) |

|---|---|---|---|---|

| Neat rLLDPE/rLDPE | 451.06 ± 0.32 | 505.35 ± 0.11 | 0.75 ± 0.02 | 18.5 ± 0.5 |

| rLLDPE/rLDPE/APP5 | 457.20 ± 0.21 | 449.18 ± 0.32 | 1.08 ± 0.01 | 19.3 ± 0.3 |

| rLLDPE/rLDPE/APP10 | 456.44 ± 0.14 | 500.42 ± 0.21 | 2.99 ± 0.01 | 21.2 ± 0.7 |

| rLLDPE/rLDPE/MPP5 | 453.23 ± 0.42 | 503.46 ± 0.14 | 1.20 ± 0.03 | 19.4 ± 0.2 |

| rLLDPE/rLDPE/MPP10 | 458.59 ± 0.17 | 502.11 ± 0.02 | 2.05 ± 0.02 | 20.3 ± 0.6 |

| rLLDPE/rLDPE/MPP5/APP5 | 459.73 ± 0.13 | 506.49 ± 0.16 | 3.00 ± 0.05 | 22.4 ± 0.4 |

| Samples | Elastic Modulus (MPa) | Tensile Strength (MPa) | Strain at Break (%) | Notched Izod Impact Strength (kJ/m2) |

|---|---|---|---|---|

| Neat rLLDPE/rLDPE | 451.9 ± 2.2 | 29.1 ± 0.3 | 60.6 ± 2.0 | 28.7 ± 0.9 |

| rLLDPE/rLDPE/APP5 | 461.4 ± 1.6 | 26.9 ± 1.6 | 54.2 ± 1.7 | 7.8 ± 0.4 |

| rLLDPE/rLDPE/APP10 | 478.4 ± 1.4 | 26.2 ± 1.2 | 59.8 ± 2.0 | 7.6 ± 0.7 |

| rLLDPE/rLDPE/MPP5 | 520.4 ± 1.9 | 28.5 ± 0.8 | 39.1 ± 1.5 | 7.2 ± 0.7 |

| rLLDPE/rLDPE/MPP10 | 515.2 ± 1.7 | 28.0 ± 0.5 | 28.9 ± 2.0 | 5.3 ± 0.4 |

| rLLDPE/rLDPE/MPP5/APP5 | 503.1 ± 1.9 | 26.7 ± 1.0 | 31.0 ± 1.6 | 6.6 ± 0.9 |

| Samples | rLLDPE/rLDPE (wt.%) | APP (wt.%) | MPP (wt.%) |

|---|---|---|---|

| Neat rLLDPE/rLDPE | 100 | 0 | 0 |

| rLLDPE/rLDPE/APP5 | 95 | 5 | - |

| rLLDPE/rLDPE/APP10 | 90 | 10 | - |

| rLLDPE/rLDPE/MPP5 | 95 | - | 5 |

| rLLDPE/rLDPE/MPP10 | 90 | - | 10 |

| rLLDPE/rLDPE/MPP5/APP5 | 90 | 5 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akindele, O.E.; dos Anjos, E.G.R.; Mapossa, A.B.; Sundararaj, U. Sustainable Fire-Resistant Materials: Recycled Polyethylene Composites with Non-Halogenated Intumescent Flame Retardants for Construction Applications. Recycling 2025, 10, 45. https://doi.org/10.3390/recycling10020045

Akindele OE, dos Anjos EGR, Mapossa AB, Sundararaj U. Sustainable Fire-Resistant Materials: Recycled Polyethylene Composites with Non-Halogenated Intumescent Flame Retardants for Construction Applications. Recycling. 2025; 10(2):45. https://doi.org/10.3390/recycling10020045

Chicago/Turabian StyleAkindele, Oluwatobi Elijah, Erick Gabriel Ribeiro dos Anjos, Antonio Benjamim Mapossa, and Uttandaraman Sundararaj. 2025. "Sustainable Fire-Resistant Materials: Recycled Polyethylene Composites with Non-Halogenated Intumescent Flame Retardants for Construction Applications" Recycling 10, no. 2: 45. https://doi.org/10.3390/recycling10020045

APA StyleAkindele, O. E., dos Anjos, E. G. R., Mapossa, A. B., & Sundararaj, U. (2025). Sustainable Fire-Resistant Materials: Recycled Polyethylene Composites with Non-Halogenated Intumescent Flame Retardants for Construction Applications. Recycling, 10(2), 45. https://doi.org/10.3390/recycling10020045