Towards a Circular Solution for Healthcare Plastic Waste: Understanding the Legal, Operational, and Technological Landscape

Abstract

1. Introduction

2. Research Methodology

2.1. Research Approach

2.2. Primary Data Collection

2.3. Data Analysis

3. Themes Relevant to Healthcare Plastic Waste Management

3.1. Regulation for Managing Healthcare Waste in Sweden

3.2. Operational Routines for Handling Healthcare Waste

3.3. Technological Solutions for Management of HCPW

3.3.1. Technologies for Disinfection of Healthcare Waste

3.3.2. Technologies for Recycling for Healthcare Plastic Waste

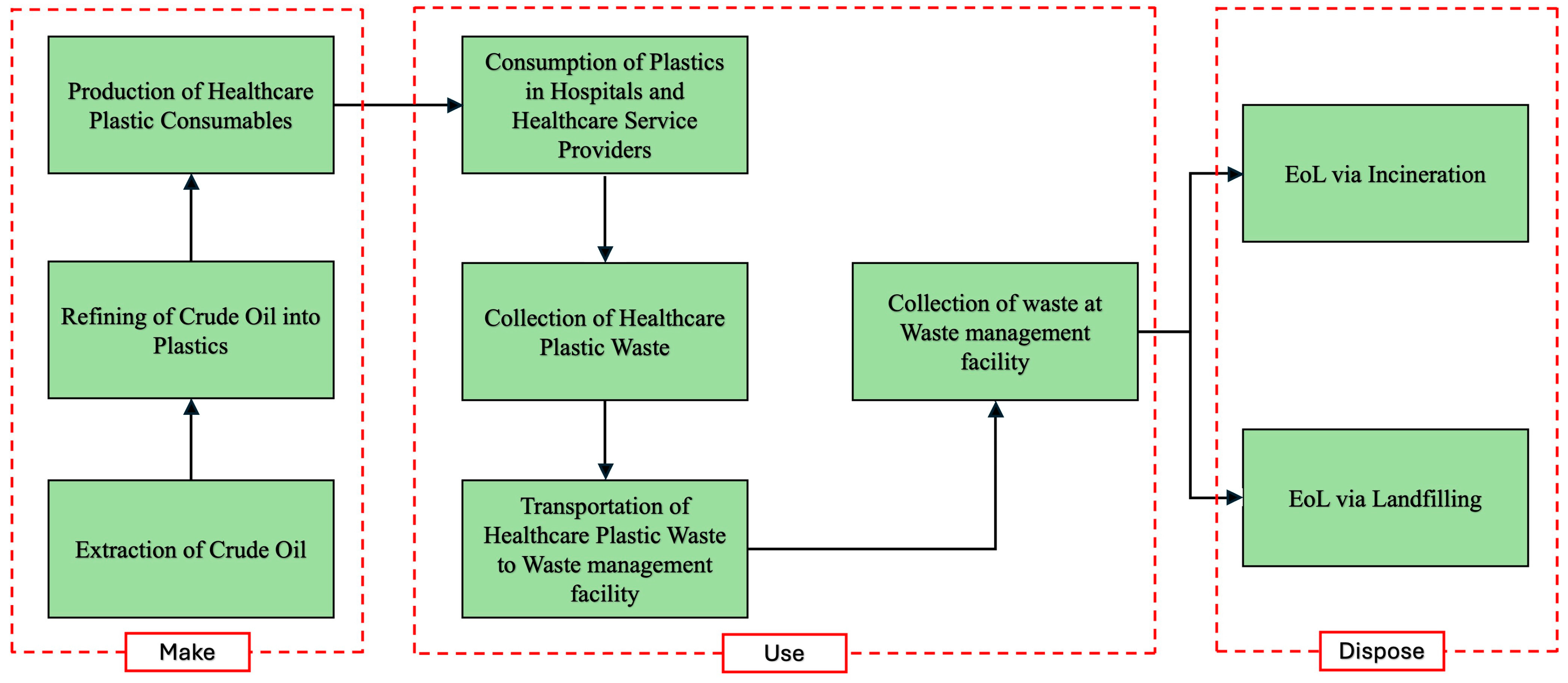

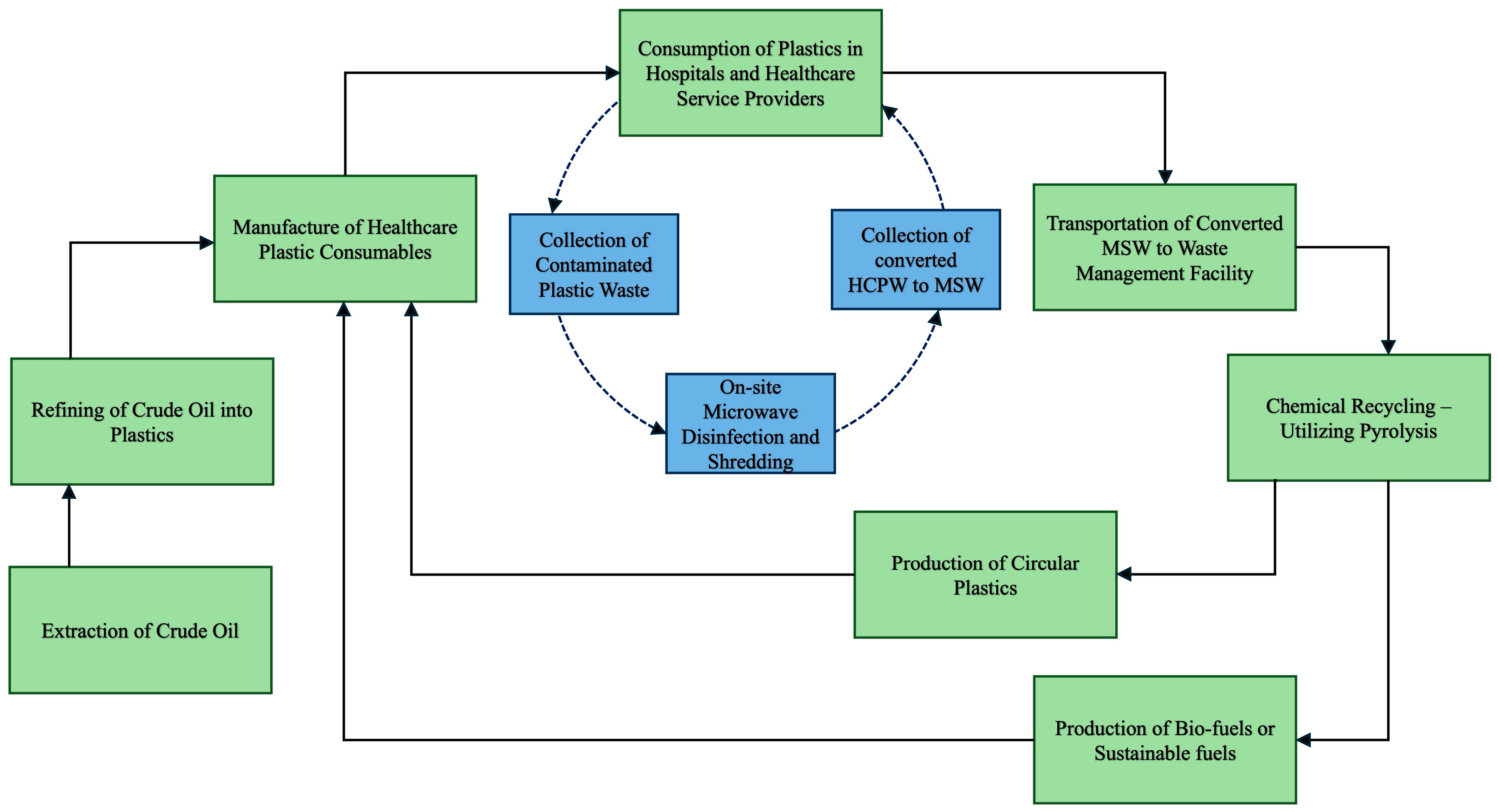

4. Proposal of a Circular Solution for Healthcare Plastic Waste

5. Prospects and Future Challenges

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| EU | European Union |

| HCPW | Healthcare plastic waste |

| PPE | Personal protective equipment |

| PU | Polyurethane |

| PP | Polypropylene |

| PC | Polycarbonate |

| LDPE | Low-density polyethylene |

| PVC | Poly-vinyl chloride |

| PS | Polystyrene |

| MSW | Municipal solid waste |

| HSPs | Healthcare service providers |

| PAHs | Polycyclic aromatic hydrocarbons |

| PCBs | Polychlorinated biphenyls |

| PCDD/Fs | Polychlorinated dibenzo-p-dioxin and dibenzofurans |

| LCA | Lice-cycle assessment |

References

- Modjarrad, K. Introduction. In Handbook of Polymer Applications in Medicine and Medical Devices; Elsevier: Amsterdam, The Netherlands, 2014; pp. 1–7. ISBN 978-0-323-22805-3. [Google Scholar]

- Medical Plastics Market Size, Share & Growth Report. 2030. Available online: https://www.grandviewresearch.com/industry-analysis/medical-plastics-market (accessed on 31 July 2024).

- Rizan, C.; Mortimer, F.; Stancliffe, R.; Bhutta, M.F. Plastics in Healthcare: Time for a Re-Evaluation. J. R. Soc. Med. 2020, 113, 49–53. [Google Scholar] [CrossRef]

- McGain, F.; Story, D.; Hendel, S. An Audit of Intensive Care Unit Recyclable Waste. Anaesthesia 2009, 64, 1299–1302. [Google Scholar] [CrossRef] [PubMed]

- Gadhave, R.V.; Vineeth, S.K.; Gadekar, P.T. Polymers and Polymeric Materials in COVID-19 Pandemic: A Review. Open J. Polym. Chem. 2020, 10, 66–75. [Google Scholar] [CrossRef]

- Burki, T. Global Shortage of Personal Protective Equipment. Lancet Infect. Dis. 2020, 20, 785–786. [Google Scholar] [CrossRef]

- Dharmaraj, S.; Ashokkumar, V.; Hariharan, S.; Manibharathi, A.; Show, P.L.; Chong, C.T.; Ngamcharussrivichai, C. The COVID-19 Pandemic Face Mask Waste: A Blooming Threat to the Marine Environment. Chemosphere 2021, 272, 129601. [Google Scholar] [CrossRef]

- Arikan, E.B.; Ozsoy, H.D. A Review: Investigation of Bioplastics. J. Cent. Eur. Agric. 2015, 9, 188–192. [Google Scholar] [CrossRef]

- Sastri, V.R. Introduction. In Plastics in Medical Devices; Elsevier: Amsterdam, The Netherlands, 2014; pp. 1–8. ISBN 978-1-4557-3201-2. [Google Scholar]

- Joseph, B.; James, J.; Kalarikkal, N.; Thomas, S. Recycling of Medical Plastics. Adv. Ind. Eng. Polym. Res. 2021, 4, 199–208. [Google Scholar] [CrossRef]

- Gibbens, S. Can Medical Care Exist Without Plastic? Available online: https://www.nationalgeographic.com/science/article/can-medical-care-exist-without-plastic (accessed on 31 July 2024).

- Su, M.; Wang, Q.; Li, R. How to Dispose of Medical Waste Caused by COVID-19? A Case Study of China. Int. J. Environ. Res. Public Health 2021, 18, 12127. [Google Scholar] [CrossRef]

- Hu, X.; Davies, R.; Morrissey, K.; Smith, R.; Fleming, L.E.; Sharmina, M.; Clair, R.; Hopkinson, P. Single-Use Plastic and COVID-19 in the NHS: Barriers and Opportunities. J. Public Health Res. 2022, 11, jphr.2021.2483. [Google Scholar] [CrossRef]

- Okunola, A.A.; Kehinde, I.O.; Oluwaseun, A.; Olufiropo, E.A. Public and Environmental Health Effects of Plastic Wastes Disposal: A Review. J. Toxicol. Risk Assess. 2019, 5, 2. [Google Scholar] [CrossRef]

- Vanapalli, K.R.; Sharma, H.B.; Ranjan, V.P.; Samal, B.; Bhattacharya, J.; Dubey, B.K.; Goel, S. Challenges and Strategies for Effective Plastic Waste Management during and Post COVID-19 Pandemic. Sci. Total Environ. 2021, 750, 141514. [Google Scholar] [CrossRef]

- Ilyas, S.; Srivastava, R.R.; Kim, H. Disinfection Technology and Strategies for COVID-19 Hospital and Bio-Medical Waste Management. Sci. Total Environ. 2020, 749, 141652. [Google Scholar] [CrossRef] [PubMed]

- Bendjoudi, Z.; Taleb, F.; Abdelmalek, F.; Addou, A. Healthcare Waste Management in Algeria and Mostaganem Department. Waste Manag. 2009, 29, 1383–1387. [Google Scholar] [CrossRef]

- Hossain, M.S.; Santhanam, A.; Nik Norulaini, N.A.; Omar, A.K.M. Clinical Solid Waste Management Practices and Its Impact on Human Health and Environment—A Review. Waste Manag. 2011, 31, 754–766. [Google Scholar] [CrossRef] [PubMed]

- Kheirabadi, S.; Sheikhi, A. Recent Advances and Challenges in Recycling and Reusing Biomedical Materials. Curr. Opin. Green Sustain. Chem. 2022, 38, 100695. [Google Scholar] [CrossRef] [PubMed]

- WHO Health-Care Waste. Available online: https://www.who.int/news-room/fact-sheets/detail/health-care-waste (accessed on 22 October 2024).

- Zaman, A.; Newman, P. Plastics: Are They Part of the Zero-Waste Agenda or the Toxic-Waste Agenda? Sustain Earth 2021, 4, 4. [Google Scholar] [CrossRef]

- Mager, M.; Traxler, I.; Fischer, J.; Finger, D.C. Potential Analysis of the Plastics Value Chain for Enhanced Recycling Rates: A Case Study in Iceland. Recycling 2022, 7, 73. [Google Scholar] [CrossRef]

- Abhilash; Inamdar, I. Recycling of Plastic Wastes Generated from COVID-19: A Comprehensive Illustration of Type and Properties of Plastics with Remedial Options. Sci. Total Environ. 2022, 838, 155895. [Google Scholar] [CrossRef]

- Ganesh, B.; Temsamani, I. A Circular Solution for Plastic Waste Within Healthcare: A Fully Implementable Solution for Creating a Circular End-of-Life Option for Plastic Waste Using Chemical Recycling [Internet] [Dissertation]. 2023. (TRITA-ITM-EX). Available online: https://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-337664 (accessed on 9 February 2025).

- European Union. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance); European Union: Maastricht, The Netherlands, 2008; Volume 312. [Google Scholar]

- European Union. Council Directive 91/689/EEC of 12 December 1991 on Hazardous Waste; European Union: Maastricht, The Netherlands, 1991; Volume 377. [Google Scholar]

- European Union. 2000/532/EC: Commission Decision of 3 May 2000 Replacing Decision 94/3/EC Establishing a List of Wastes Pursuant to Article 1(a) of Council Directive 75/442/EEC on Waste and Council Decision 94/904/EC Establishing a List of Hazardous Waste Pursuant to Article 1(4) of Council Directive 91/689/EEC on Hazardous Waste (Notified under Document Number C(2000) 1147) (Text with EEA Relevance); European Union: Maastricht, The Netherlands, 2000; Volume 226. [Google Scholar]

- European Union. Regulation (EC) No 1013/2006 of the European Parliament and of the Council of 14 June 2006 on Shipments of Waste; European Union: Maastricht, The Netherlands, 2006; Volume 190. [Google Scholar]

- European Union. Directive 2000/76/EC of the European Parliament and of the Council of 4 December 2000 on the Incineration of Waste; European Union: Maastricht, The Netherlands, 2000; Volume 332. [Google Scholar]

- Olsson, O. Så Styrs Sjukvården i Sverige. Available online: https://skr.se/skr/halsasjukvard/vardochbehandling/ansvarsfordelningsjukvard.64151.html (accessed on 27 September 2024).

- Arbetsmiljöverket Smittrisker (AFS 2018:4), Föreskrifter—Arbetsmiljöverket. Available online: https://www.av.se/globalassets/filer/publikationer/foreskrifter/smittrisker_afs_2018_4.pdf (accessed on 5 August 2024).

- Marinković, N.; Vitale, K.; Holcer, N.J.; Džakula, A.; Pavić, T. Management of Hazardous Medical Waste in Croatia. Waste Manag. 2008, 28, 1049–1056. [Google Scholar] [CrossRef]

- NHS. NHS England NHS Clinical Waste Strategy. Available online: https://www.england.nhs.uk/long-read/nhs-clinical-waste-strategy/ (accessed on 22 October 2024).

- Windfeld, E.S.; Brooks, M.S.-L. Medical Waste Management—A Review. J. Environ. Manag. 2015, 163, 98–108. [Google Scholar] [CrossRef]

- Mühlich, M.; Scherrer, M.; Daschner, F.D. Comparison of Infectious Waste Management in European Hospitals. J. Hosp. Infect. 2003, 55, 260–268. [Google Scholar] [CrossRef] [PubMed]

- McGain, F.; White, S.; Mossenson, S.; Kayak, E.; Story, D. A Survey of Anesthesiologists’ Views of Operating Room Recycling. Anesth. Analg. 2012, 114, 1049–1054. [Google Scholar] [CrossRef]

- McGain, F.; Hendel, S.A.; Story, D.A. An Audit of Potentially Recyclable Waste from Anaesthetic Practice. Anaesth. Intensive Care 2009, 37, 820–823. [Google Scholar] [CrossRef]

- Olawade, D.B.; Fapohunda, O.; Wada, O.Z.; Usman, S.O.; Ige, A.O.; Ajisafe, O.; Oladapo, B.I. Smart Waste Management: A Paradigm Shift Enabled by Artificial Intelligence. Waste Manag. Bull. 2024, 2, 244–263. [Google Scholar] [CrossRef]

- Adarsh, U.K.; Kartha, V.B.; Santhosh, C.; Unnikrishnan, V.K. Spectroscopy: A Promising Tool for Plastic Waste Management. TrAC Trends Anal. Chem. 2022, 149, 116534. [Google Scholar] [CrossRef]

- Lubongo, C.; Alexandridis, P. Assessment of Performance and Challenges in Use of Commercial Automated Sorting Technology for Plastic Waste. Recycling 2022, 7, 11. [Google Scholar] [CrossRef]

- Kenny, C.; Priyadarshini, A. Review of Current Healthcare Waste Management Methods and Their Effect on Global Health. Healthcare 2021, 9, 284. [Google Scholar] [CrossRef]

- Singh, N.; Tang, Y.; Zhang, Z.; Zheng, C. COVID-19 Waste Management: Effective and Successful Measures in Wuhan, China. Resour. Conserv. Recycl. 2020, 163, 105071. [Google Scholar] [CrossRef] [PubMed]

- IVL More Secure Recycling of Plastic in Healthcare. Available online: https://www.ivl.se/english/ivl/press/press-releases/2022-05-20-more-secure-recycling-of-plastic-in-healthcare.html (accessed on 22 October 2024).

- Dehghani, M.H.; Ahrami, H.D.; Nabizadeh, R.; Heidarinejad, Z.; Zarei, A. Medical Waste Generation and Management in Medical Clinics in South of Iran. MethodsX 2019, 6, 727–733. [Google Scholar] [CrossRef]

- Saeidi-Mobarakeh, Z.; Tavakkoli-Moghaddam, R.; Navabakhsh, M.; Amoozad-Khalili, H. A Bi-Level and Robust Optimization-Based Framework for a Hazardous Waste Management Problem: A Real-World Application. J. Clean. Prod. 2020, 252, 119830. [Google Scholar] [CrossRef]

- Barcelo, D. An Environmental and Health Perspective for COVID-19 Outbreak: Meteorology and Air Quality Influence, Sewage Epidemiology Indicator, Hospitals Disinfection, Drug Therapies and Recommendations. J. Environ. Chem. Eng. 2020, 8, 104006. [Google Scholar] [CrossRef] [PubMed]

- Datta, P.; Mohi, G.; Chander, J. Biomedical Waste Management in India: Critical Appraisal. J. Lab. Physicians 2018, 10, 6–14. [Google Scholar] [CrossRef] [PubMed]

- Kollu, V.K.R.; Kumar, P.; Gautam, K. Comparison of Microwave and Autoclave Treatment for Biomedical Waste Disinfection. Syst. Microbiol. Biomanuf. 2022, 2, 732–742. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Pali, H.S.; Kumar, M. A Comprehensive Review on the Production of Alternative Fuel through Medical Plastic Waste. Sustain. Energy Technol. Assess. 2023, 55, 102924. [Google Scholar] [CrossRef]

- Rowan, N.J.; Laffey, J.G. Challenges and Solutions for Addressing Critical Shortage of Supply Chain for Personal and Protective Equipment (PPE) Arising from Coronavirus Disease (COVID19) Pandemic—Case Study from the Republic of Ireland. Sci. Total Environ. 2020, 725, 138532. [Google Scholar] [CrossRef]

- Rutala, W.A.; Weber, D.J. Disinfection, Sterilization, and Control of Hospital Waste. In Mandell, Douglas, and Bennett’s Principles and Practice of Infectious Diseases; Elsevier: Amsterdam, The Netherlands, 2015; pp. 3294–3309.e4. ISBN 978-1-4557-4801-3. [Google Scholar]

- Singh, N.; Tang, Y.; Ogunseitan, O.A. Environmentally Sustainable Management of Used Personal Protective Equipment. Environ. Sci. Technol. 2020, 54, 8500–8502. [Google Scholar] [CrossRef] [PubMed]

- Su, G.; Ong, H.C.; Ibrahim, S.; Fattah, I.M.R.; Mofijur, M.; Chong, C.T. Valorisation of Medical Waste through Pyrolysis for a Cleaner Environment: Progress and Challenges. Environ. Pollut. 2021, 279, 116934. [Google Scholar] [CrossRef]

- Wang, J.; Shen, J.; Ye, D.; Yan, X.; Zhang, Y.; Yang, W.; Li, X.; Wang, J.; Zhang, L.; Pan, L. Disinfection Technology of Hospital Wastes and Wastewater: Suggestions for Disinfection Strategy during Coronavirus Disease 2019 (COVID-19) Pandemic in China. Environ. Pollut. 2020, 262, 114665. [Google Scholar] [CrossRef] [PubMed]

- Singh, H. Harnessing the Foundation of Biomedical Waste Management for Fostering Public Health: Strategies and Policies for a Clean and Safer Environment. Discov. Appl. Sci. 2024, 6, 89. [Google Scholar] [CrossRef]

- Liu, J.; Li, H.; Liu, Z.; Meng, X.; He, Y.; Zhang, Z. Study on the Process of Medical Waste Disinfection by Microwave Technology. Waste Manag. 2022, 150, 13–19. [Google Scholar] [CrossRef]

- Capoor, M.R. Current Perspectives of Biomedical Waste Management in Context of COVID-19. Indian J. Med. Microbiol. 2021, 39, 171–178. [Google Scholar] [CrossRef] [PubMed]

- Satti, S.; Hashmi, M.; Subhan, M.; Shereen, M.; Fayad, A.; Abbasi, A.; Shah, A.; Ali, H. Bio-Upcycling of Plastic Waste: A Sustainable Innovative Approach for Circular Economy. Water Air Soil Pollut. 2024, 235, 171–178. [Google Scholar] [CrossRef]

- Grigore, M. Methods of Recycling, Properties and Applications of Recycled Thermoplastic Polymers. Recycling 2017, 2, 24. [Google Scholar] [CrossRef]

- Anuar Sharuddin, S.D.; Abnisa, F.; Wan Daud, W.M.A.; Aroua, M.K. Energy Recovery from Pyrolysis of Plastic Waste: Study on Non-Recycled Plastics (NRP) Data as the Real Measure of Plastic Waste. Energy Convers. Manag. 2017, 148, 925–934. [Google Scholar] [CrossRef]

- Anuar Sharuddin, S.D.; Abnisa, F.; Wan Daud, W.M.A.; Aroua, M.K. A Review on Pyrolysis of Plastic Wastes. Energy Convers. Manag. 2016, 115, 308–326. [Google Scholar] [CrossRef]

- Kumar, R. Tertiary and Quaternary Recycling of Thermoplastics by Additive Manufacturing Approach for Thermal Sustainability. Mater. Today Proc. 2021, 37, 2382–2386. [Google Scholar] [CrossRef]

- Merrild, H.; Larsen, A.W.; Christensen, T.H. Assessing Recycling versus Incineration of Key Materials in Municipal Waste: The Importance of Efficient Energy Recovery and Transport Distances. Waste Manag. 2012, 32, 1009–1018. [Google Scholar] [CrossRef] [PubMed]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and Chemical Recycling of Solid Plastic Waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of Plastic Solid Waste: A State of Art Review and Future Applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Solis, M.; Silveira, S. Technologies for Chemical Recycling of Household Plastics—A Technical Review and TRL Assessment. Waste Manag. 2020, 105, 128–138. [Google Scholar] [CrossRef]

- Khan, B.A.; Cheng, L.; Khan, A.A.; Ahmed, H. Healthcare Waste Management in Asian Developing Countries: A Mini Review. Waste Manag. Res. 2019, 37, 863–875. [Google Scholar] [CrossRef] [PubMed]

- Chu, Y.T.; Zhou, J.; Wang, Y.; Liu, Y.; Ren, J. Current State, Development and Future Directions of Medical Waste Valorization. Energies 2023, 16, 1074. [Google Scholar] [CrossRef]

- Paraschiv, M.; Kuncser, R.; Tazerout, M.; Prisecaru, T. New Energy Value Chain through Pyrolysis of Hospital Plastic Waste. Appl. Therm. Eng. 2015, 87, 424–433. [Google Scholar] [CrossRef]

- Liu, S.; Kots, P.A.; Vance, B.C.; Danielson, A.; Vlachos, D.G. Plastic Waste to Fuels by Hydrocracking at Mild Conditions. Sci. Adv. 2021, 7, eabf8283. [Google Scholar] [CrossRef] [PubMed]

- Gabbar, H.; Aboughaly, M.; Stoute, C.A. DC Thermal Plasma Design and Utilization for the Low Density Polyethylene to Diesel Oil Pyrolysis Reaction. Energies 2017, 10, 784. [Google Scholar] [CrossRef]

- Sharifzadeh, M.; Sadeqzadeh, M.; Guo, M.; Borhani, T.N.; Murthy Konda, N.V.S.N.; Garcia, M.C.; Wang, L.; Hallett, J.; Shah, N. The Multi-Scale Challenges of Biomass Fast Pyrolysis and Bio-Oil Upgrading: Review of the State of Art and Future Research Directions. Prog. Energy Combust. Sci. 2019, 71, 1–80. [Google Scholar] [CrossRef]

- Ding, Z.; Chen, H.; Liu, J.; Cai, H.; Evrendilek, F.; Buyukada, M. Pyrolysis Dynamics of Two Medical Plastic Wastes: Drivers, Behaviors, Evolved Gases, Reaction Mechanisms, and Pathways. J. Hazard. Mater. 2021, 402, 123472. [Google Scholar] [CrossRef] [PubMed]

- Som, U.; Rahman, F.; Jahangirnagar University, Bangladesh; Hossain, S.; Khulna University of Engineering and Technology, Bangladesh. Recovery of Pyrolytic Oil from Thermal Pyrolysis of Medical Waste. J. Eng. Sci. 2018, 5, H5–H8. [Google Scholar] [CrossRef]

- Qin, L.; Han, J.; Zhao, B.; Wang, Y.; Chen, W.; Xing, F. Thermal Degradation of Medical Plastic Waste by In-Situ FTIR, TG-MS and TG-GC/MS Coupled Analyses. J. Anal. Appl. Pyrolysis 2018, 136, 132–145. [Google Scholar] [CrossRef]

- Ullah, F.; Zhang, L.; Ji, G.; Irfan, M.; Ma, D.; Li, A. Experimental Analysis on Products Distribution and Characterization of Medical Waste Pyrolysis with a Focus on Liquid Yield Quantity and Quality. Sci. Total Environ. 2022, 829, 154692. [Google Scholar] [CrossRef]

- Vellaiyan, S. Optimization of Pyrolysis Process Parameters for a Higher Yield of Plastic Oil with Enhanced Physicochemical Properties Derived from Medical Plastic Wastes. Sustain. Chem. Pharm. 2023, 36, 101310. [Google Scholar] [CrossRef]

- Wan Mahari, W.A.; Awang, S.; Zahariman, N.A.Z.; Peng, W.; Man, M.; Park, Y.-K.; Lee, J.; Sonne, C.; Lam, S.S. Microwave Co-Pyrolysis for Simultaneous Disposal of Environmentally Hazardous Hospital Plastic Waste, Lignocellulosic, and Triglyceride Biowaste. J. Hazard. Mater. 2022, 423, 127096. [Google Scholar] [CrossRef]

- Allende, S.; Brodie, G.; Jacob, M.V. Microwave Pyrolysis of Various Wastes and Analysis of Energy Recovery. Bioresour. Technol. Rep. 2024, 26, 101821. [Google Scholar] [CrossRef]

- Rai, P.K.; Sonne, C.; Song, H.; Kim, K.-H. Plastic Wastes in the Time of COVID-19: Their Environmental Hazards and Implications for Sustainable Energy Resilience and Circular Bio-Economies. Sci. Total Environ. 2023, 858, 159880. [Google Scholar] [CrossRef]

- Munir, D.; Irfan, M.F.; Usman, M.R. Hydrocracking of Virgin and Waste Plastics: A Detailed Review. Renew. Sustain. Energy Rev. 2018, 90, 490–515. [Google Scholar] [CrossRef]

- Liu, Y.; Zhai, Y.; Li, S.; Liu, X.; Liu, X.; Wang, B.; Qiu, Z.; Li, C. Production of Bio-Oil with Low Oxygen and Nitrogen Contents by Combined Hydrothermal Pretreatment and Pyrolysis of Sewage Sludge. Energy 2020, 203, 117829. [Google Scholar] [CrossRef]

- European Environment Agency Average Yearly Price of Plastic Scrap (EUR/Tonne). Available online: https://www.eea.europa.eu/en/circularity/sectoral-modules/plastics/average-yearly-price-of-plastic-scrap-eur-tonne (accessed on 31 August 2024).

- Brunn, M. EU Legislative Approach to Chemical Recycling Will Shape Future of the Pyrolysis Oil Sector. Available online: https://www.recycling-magazine.com/2023/10/25/eu-legislative-approach-to-chemical-recycling-will-shape-future-of-the-pyrolysis-oil-sector/ (accessed on 9 February 2025).

- Pettersson, M.; Olofsson, J.; Börjesson, P.; Björnsson, L. Reductions in Greenhouse Gas Emissions through Innovative Co-Production of Bio-Oil in Combined Heat and Power Plants. Appl. Energy 2022, 324, 119637. [Google Scholar] [CrossRef]

- Gao, W.; Kirilyuk, M.; Ramanurthi, R.; Wallach, J. Scaling Investments in Plastics Circularity|McKinsey. Available online: https://www.mckinsey.com/industries/chemicals/our-insights/a-unique-moment-in-time-scaling-plastics-circularity#/ (accessed on 22 August 2024).

- Sørmo, E.; Krahn, K.M.; Flatabø, G.Ø.; Hartnik, T.; Arp, H.P.H.; Cornelissen, G. Distribution of PAHs, PCBs, and PCDD/Fs in Products from Full-Scale Relevant Pyrolysis of Diverse Contaminated Organic Waste. J. Hazard. Mater. 2024, 461, 132546. [Google Scholar] [CrossRef] [PubMed]

| Stakeholder Group | Successive Interviews | Number of Attendees | Positions Held by Interviewees | Size of Enterprise | On-Site Visit and Discussion |

|---|---|---|---|---|---|

| Hospital | 4 | 3 | Environmental Strategist, Environmental Coordinator, Environment Manager | Large | Yes |

| Chemical Recycling Technology Provider-Company A | 4 | 3 | Process Manager, LCA Engineer, Process Specialist | Large | |

| Chemical Recycling Technology Provider-Company B | 1 | 2 | Procurement Engineer, Process Manager | Large | |

| Waste Management Logistics Company | 1 | 2 | Head of Hazardous Waste, Operations Coordinator | Large | |

| On-site Disinfection-Company C | 2 | 1 | Sales Representative | SME | |

| On-site Disinfection-Company D | 3 | 2 | Sales Manager, Design Engineer | SME | Yes |

| On-site Disinfection-Company E | 1 | 2 | Sales Engineer, Director of Sales | SME | Yes |

| Licensor–Consultant | 1 | 1 | R&D Process Engineering Consultant | SME | |

| Healthcare Consumable Manufacturer | 4 | 3 | ESG Manager, Sustainability Director, Head of ESG | Large | Yes |

| Regulations | Aim and Scope of the Regulation |

|---|---|

| Environmental Code—SFS 1998:808 | The legal foundation for environmental protection, including waste management. |

| Waste Ordinance—SFS 2020:614 | Specification of general waste management protocols. |

| Regulations for Contagious Waste—SOSFS 2005:26 | Dictates the handling, storage, and transportation of contagious waste. |

| Infection Risks—AFS 2018:4 | Addresses infection control measures and categorizes infection risks based on four risk groups. |

| Transporting Waste—NFS 2005:3 | Provides guidelines for the transportation of waste. |

| Reporting and Documenting Dangerous Waste—NFS 2020:5 | Mandates the reporting and documentation of hazardous waste. |

| Transport Regulation of Dangerous Waste—MSBFS 2020:9 | Governs the transportation of hazardous goods. |

| Waste for Landfill—SFS 2001:512 | Pertains to landfill waste management. |

| Disinfection Technology | About the Rrocess | Advantage | Limitations |

|---|---|---|---|

| Autoclave—On-site | The use of pressurized steam at high temperatures to sterilize healthcare plastic waste, ensuring the destruction of all microbial life. | Good sterilization; technologically mature process; good efficiency. | Produces toxic gasses; bad odor; cannot reduce volume of waste; increased mass and moisture in waste. |

| Chemical Disinfection—On-Site | The use of chemical agents to destroy or deactivate pathogens in healthcare plastic waste, rendering it safe for disposal or recycling. | High efficiency; high sterilization; broad sterilization spectrum; can destroy spores and fungi along with bacteria and viruses. | High operational cost; cannot reduce volume of waste; increased mass and moisture in waste. |

| Microwave Disinfection—On-Site | The application of microwave radiation to heat and disinfect HCPW, effectively killing pathogens through thermal effects. | High efficiency; high sterilization; broad sterilization spectrum; can destroy most bacteria and viruses; low pollution; low operational cost; mass reduction; moisture reduction. | Moderately high capital expenditure. |

| On-site Pyrolysis/Gasification and Other Valorization Methods | The thermal decomposition of healthcare plastic waste in the absence or limited presence of oxygen to produce valuable by-products such as syngas, bio-oil, and char, while simultaneously eliminating pathogens. | Reduction in mass and volume; generation of value-added products; high efficiency. | Extremely high capital expenditure; requires pre-treatment and upcycling of plastic waste. |

| Disinfection Technology | Chemical Disinfection | Microwave-Assisted Disinfection | Microwave and Resistance Disinfection | Autoclave |

|---|---|---|---|---|

| Company | Company C | Company D | Company E | Current Method |

| Capacity per cycle (Kg) | 8 kg | 10 kg–44 kg | 75 kg–250 kg | 2.5 kg–88 kg |

| Working principle | Chemical agents (biocides) and shredding | Microwave and shredding | Microwave, electrical resistance, and shredding | Pressurized steam |

| Cycle time | 15 min | 30 min | 60 min | 30 min |

| Cycle time per kg | 1.9 min/kg | From 3 min/kg to 0.68 min/kg | From 1.25 min/kg to 0.24 min/kg | From 12 min/kg |

| Running cost per kg | 5.18 SEK per kg | 1.24 SEK per kg | 1 SEK per kg | 11.45 SEK per kg |

| Initial cost | Low | Low | High | Low |

| Energy per hour | Low (3.9 kW/h) | Low (3 Kw/h) | High (20 kW/h) | Medium (6 kW/h) |

| Energy per kg (small) | 0.49 kW/h | 0.3 kW/h | 0.27 kW/h | 2.4 kW/h |

| Weight reduction | No | Yes, approx. 20% | Yes, approx. 20% | No |

| Volume reduction | Yes 80% | Yes, 80% | Yes, 80% | No |

| Sterilization level | High (also for spores) | High | High | High |

| Sterilization capacity | 6Log10 | 6Log10 | 6Log10 | 5Log10 |

| Consumables | Yes | No | No | No |

| Water consumption | High | Low | Low | Yes |

| Maintenance needs | Medium (filters) | Low | Low | Yes |

| Regulations compliance | Medium | High | High | Very High |

| Automatic sorting (add-on) | No | No | Yes | No |

| Self-cleaning | Yes | No | No | Semi-self-cleaning |

| Labor skill level | Unskilled | Unskilled | Semi-skilled | Skilled |

| Recycling Method | Definition | Advantages | Limitations |

|---|---|---|---|

| Primary Recycling or Closed-Loop Recycling | Reuse of plastic scraps to produce items with similar properties and characteristics to the original material. | Most suitable for discarding waste within production processes; established process. | Not suitable for contaminated, non-homogeneous, or mixed plastic streams; |

| Secondary Recycling or Mechanical Recycling | Recovery of plastics through mechanical processes that downgrade the recycled material, resulting in reduced quality. | Less energy consumption; established process. | mixed plastic cannot be used and requires extensive sorting; output of the process leads to loss in physical, chemical, and mechanical properties. |

| Tertiary Recycling or Chemical Recycling | Recovery and upcycling of plastics through thermochemical processes, breaking down polymers into monomers with quality recovery of the recycled material. | Well-established processes; feedstock is mixed plastic with lower moisture content; output is usually upcycled into circular plastics having up to 100% of virgin plastic characteristics. | Feedstock must not have moisture content; very expensive for small-scale setups. |

| Quatenary Recycling or Energy Recovery | Energy recovery through incineration. | Current method for value recovery through incineration of plastic waste; cheap process; established process. | Toxic gas emissions; air pollution; smoke, ash, tar, and dust formation. |

| Hospital and HSP (1) | On-Site Disinfection Machine Manufacturers (2) | Waste Management Company (3) | Chemical Recycling Company (4) | |

|---|---|---|---|---|

| Hospitals and HSP (A) | N.A. |

|

| N.A. |

| On-site Disinfection Machine Manufacturers (B) |

| N.A. |

| N.A. |

| Waste Management Company (C) |

|

| N.A. |

|

| Chemical Recycling Company (D) | N.A. | N.A. |

| N.A. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ganesh, B.; Shoaib-ul-Hasan, S.; Temsamani, I.; Salehi, N. Towards a Circular Solution for Healthcare Plastic Waste: Understanding the Legal, Operational, and Technological Landscape. Recycling 2025, 10, 27. https://doi.org/10.3390/recycling10010027

Ganesh B, Shoaib-ul-Hasan S, Temsamani I, Salehi N. Towards a Circular Solution for Healthcare Plastic Waste: Understanding the Legal, Operational, and Technological Landscape. Recycling. 2025; 10(1):27. https://doi.org/10.3390/recycling10010027

Chicago/Turabian StyleGanesh, Bharghav, Sayyed Shoaib-ul-Hasan, Iliass Temsamani, and Niloufar Salehi. 2025. "Towards a Circular Solution for Healthcare Plastic Waste: Understanding the Legal, Operational, and Technological Landscape" Recycling 10, no. 1: 27. https://doi.org/10.3390/recycling10010027

APA StyleGanesh, B., Shoaib-ul-Hasan, S., Temsamani, I., & Salehi, N. (2025). Towards a Circular Solution for Healthcare Plastic Waste: Understanding the Legal, Operational, and Technological Landscape. Recycling, 10(1), 27. https://doi.org/10.3390/recycling10010027