Degradation-Conscious Multiobjective Optimal Control of Reconfigurable Li-Ion Battery Energy Storage Systems †

Abstract

1. Introduction

2. Li-Ion Battery Cell Models

2.1. Electrochemical Models

2.2. Reduced-Order Equivalent Circuit Model

3. A Reconfigurable Li-Ion Battery Pack

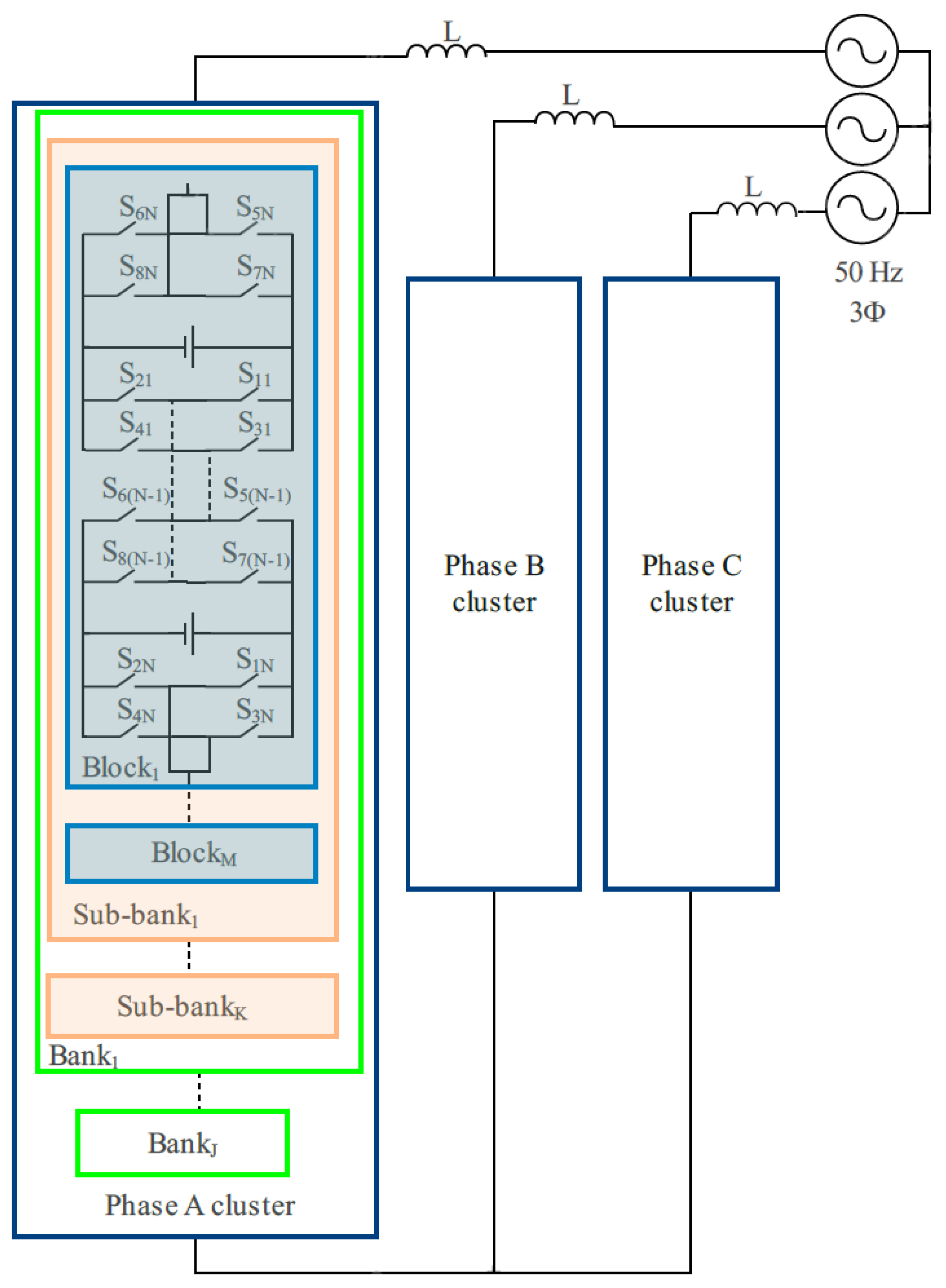

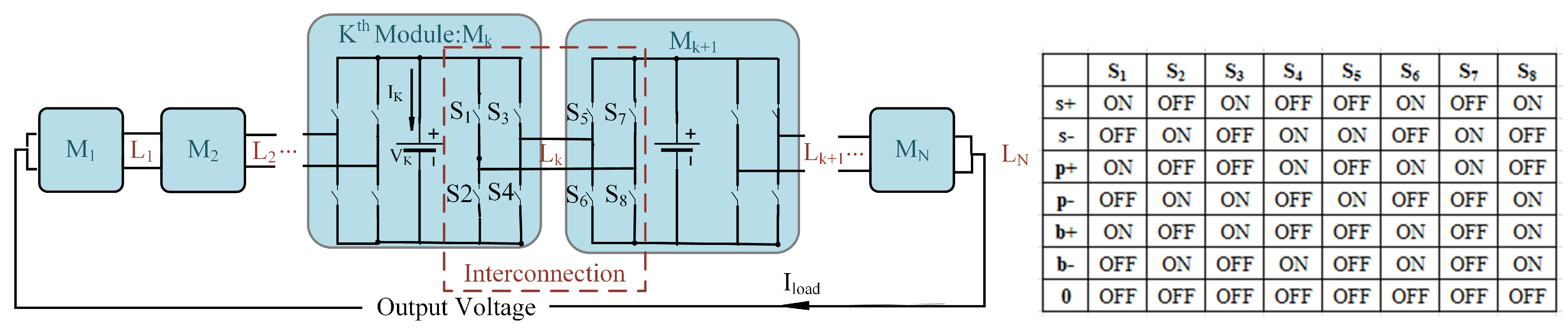

3.1. Topology

3.2. Energy Losses in the Pack

4. Control Mechanism

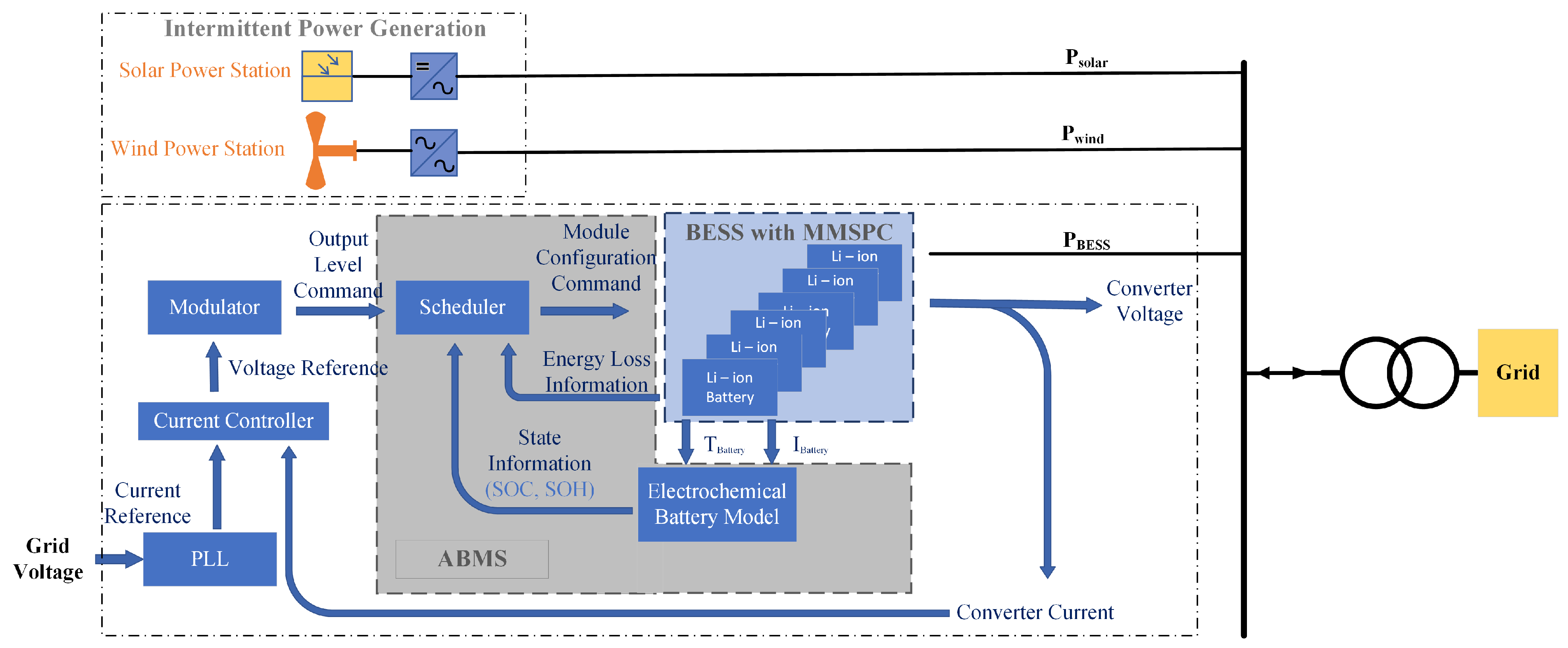

4.1. Scheduler Functionality

4.1.1. Multiobjective Optimization-Based Scheduler

4.1.2. Modified Hierarchical Optimization-Based Scheduler

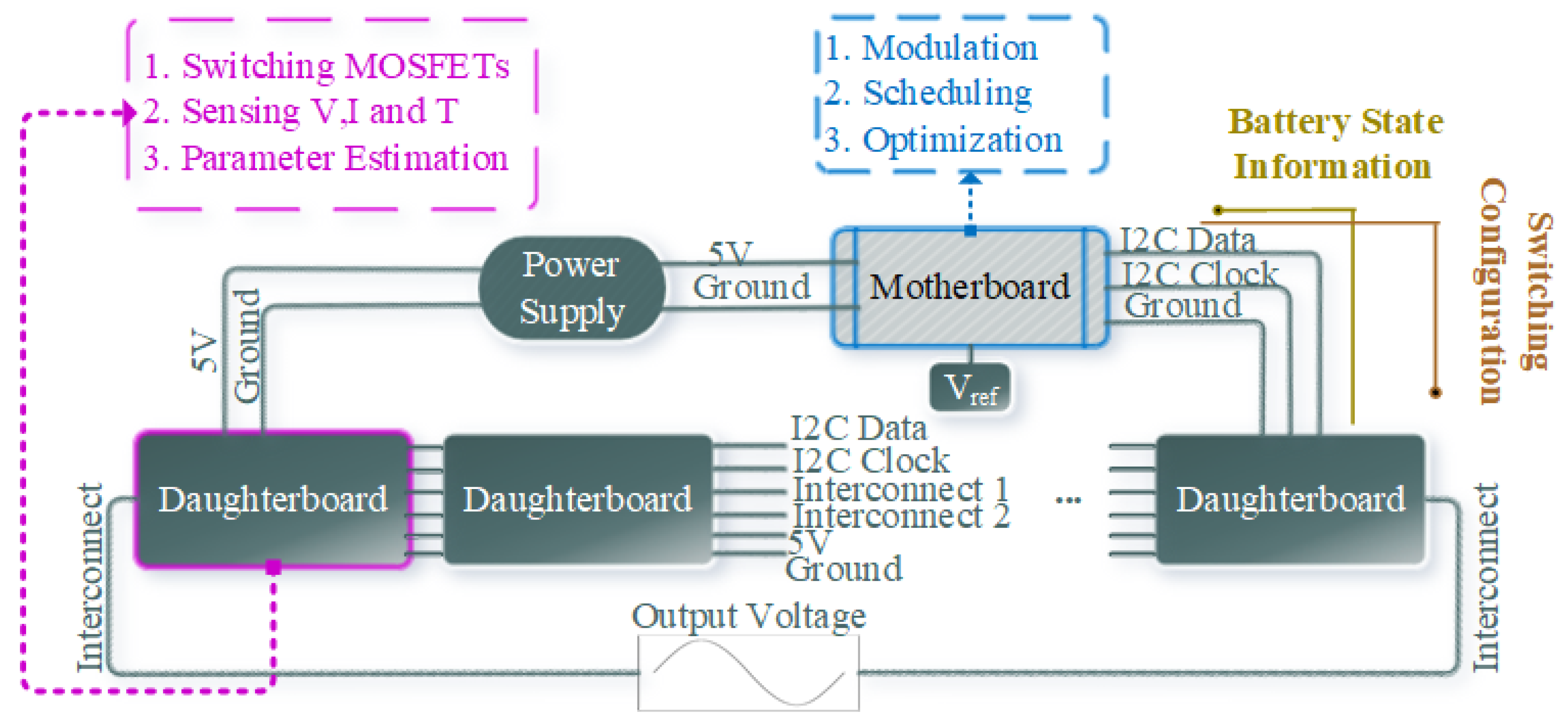

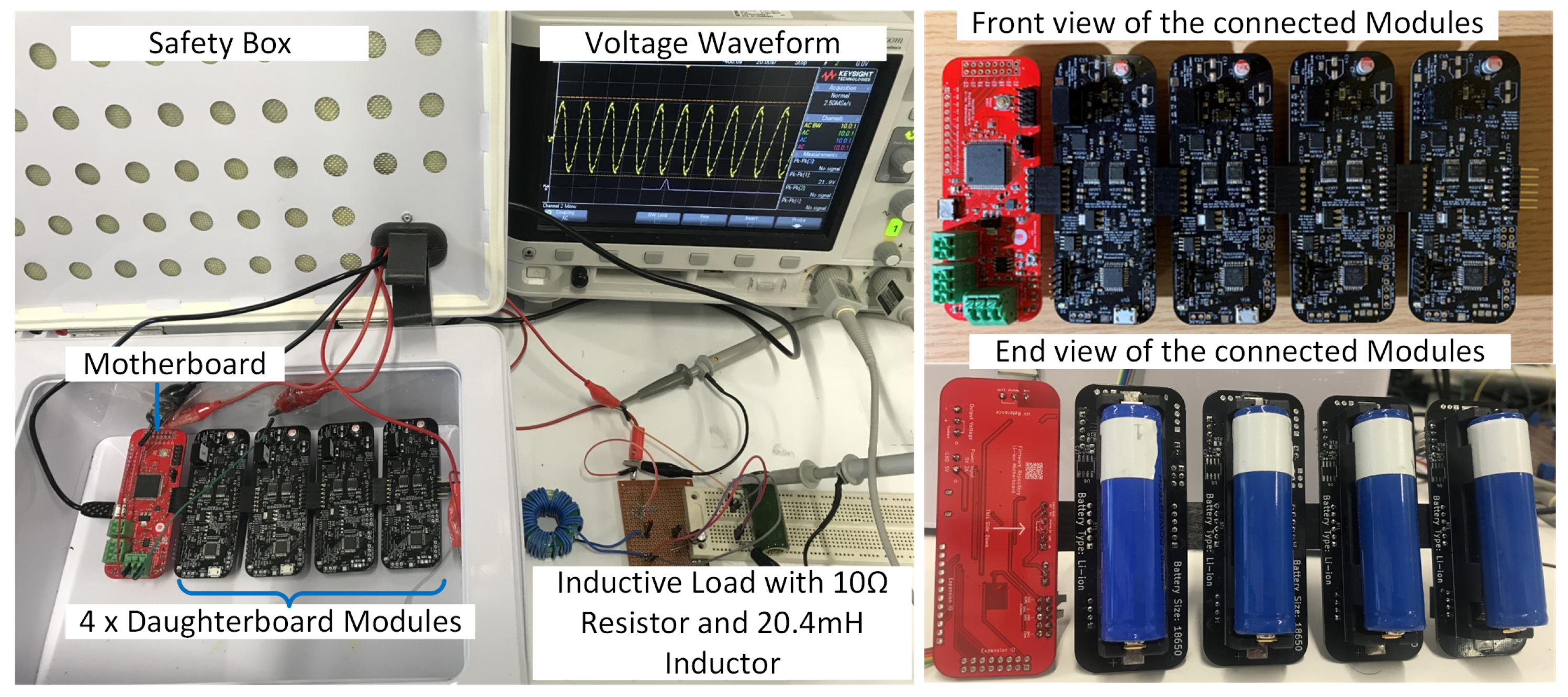

5. Advanced Battery Management System Design

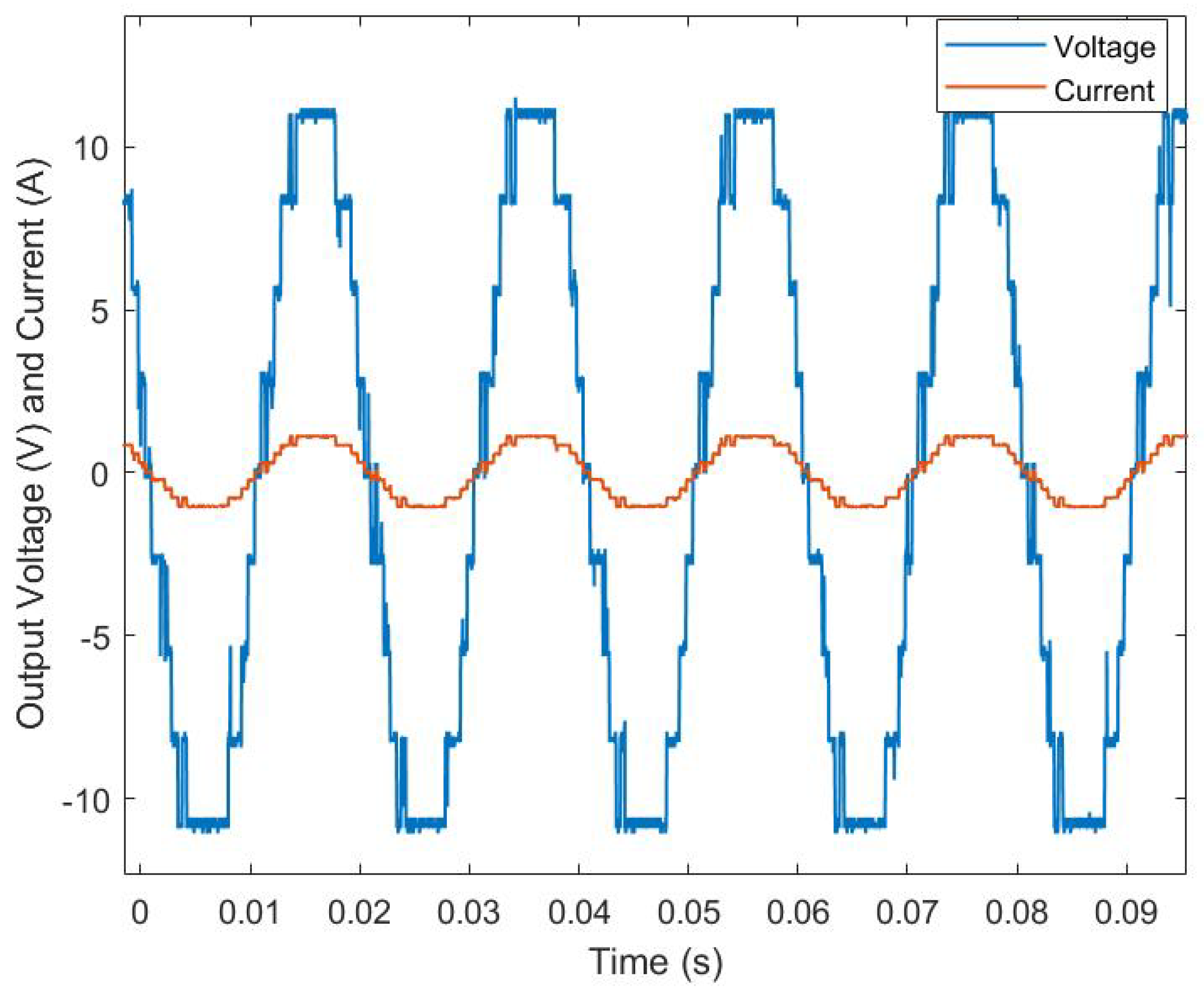

6. Simulation and Experimental Validation

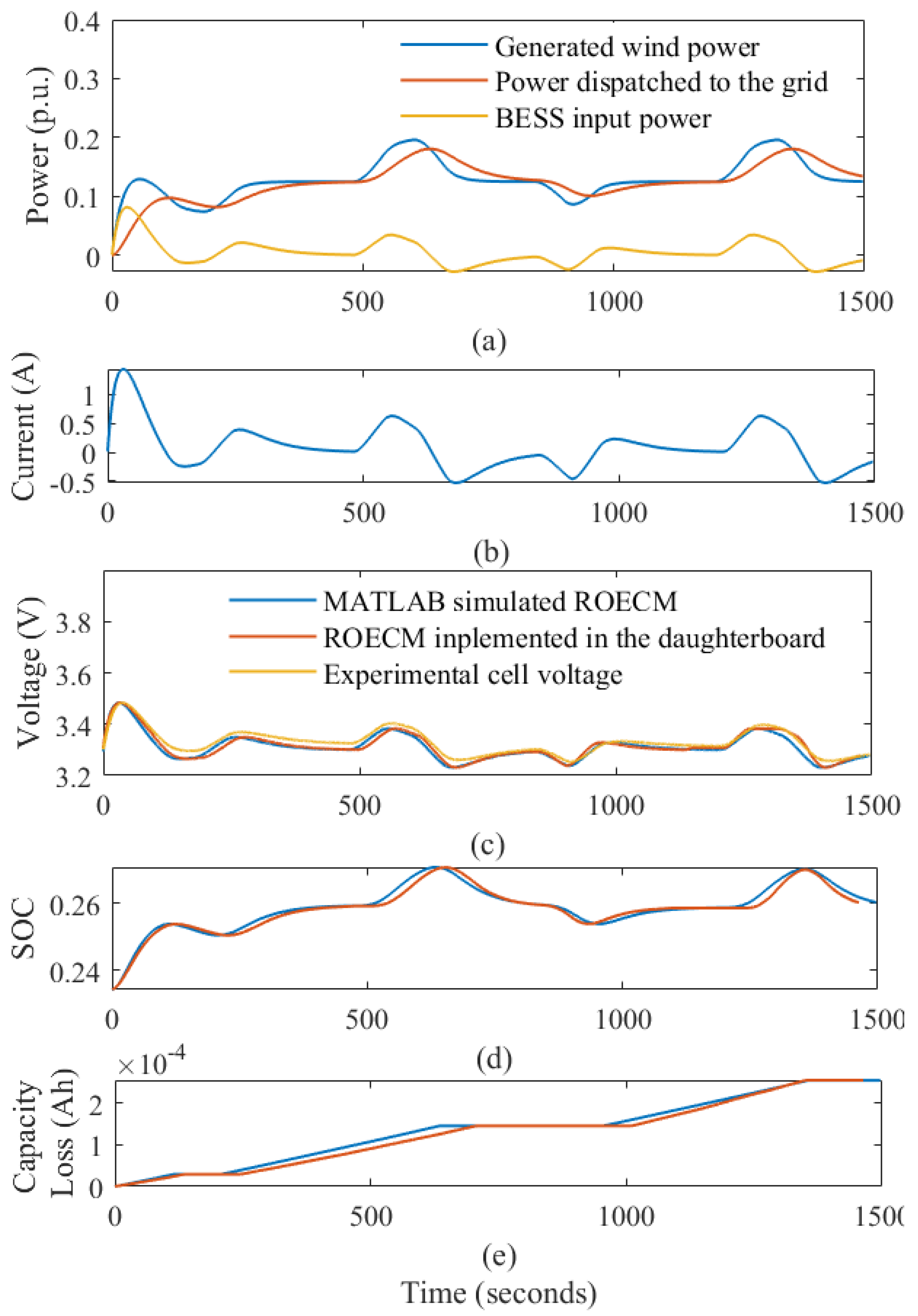

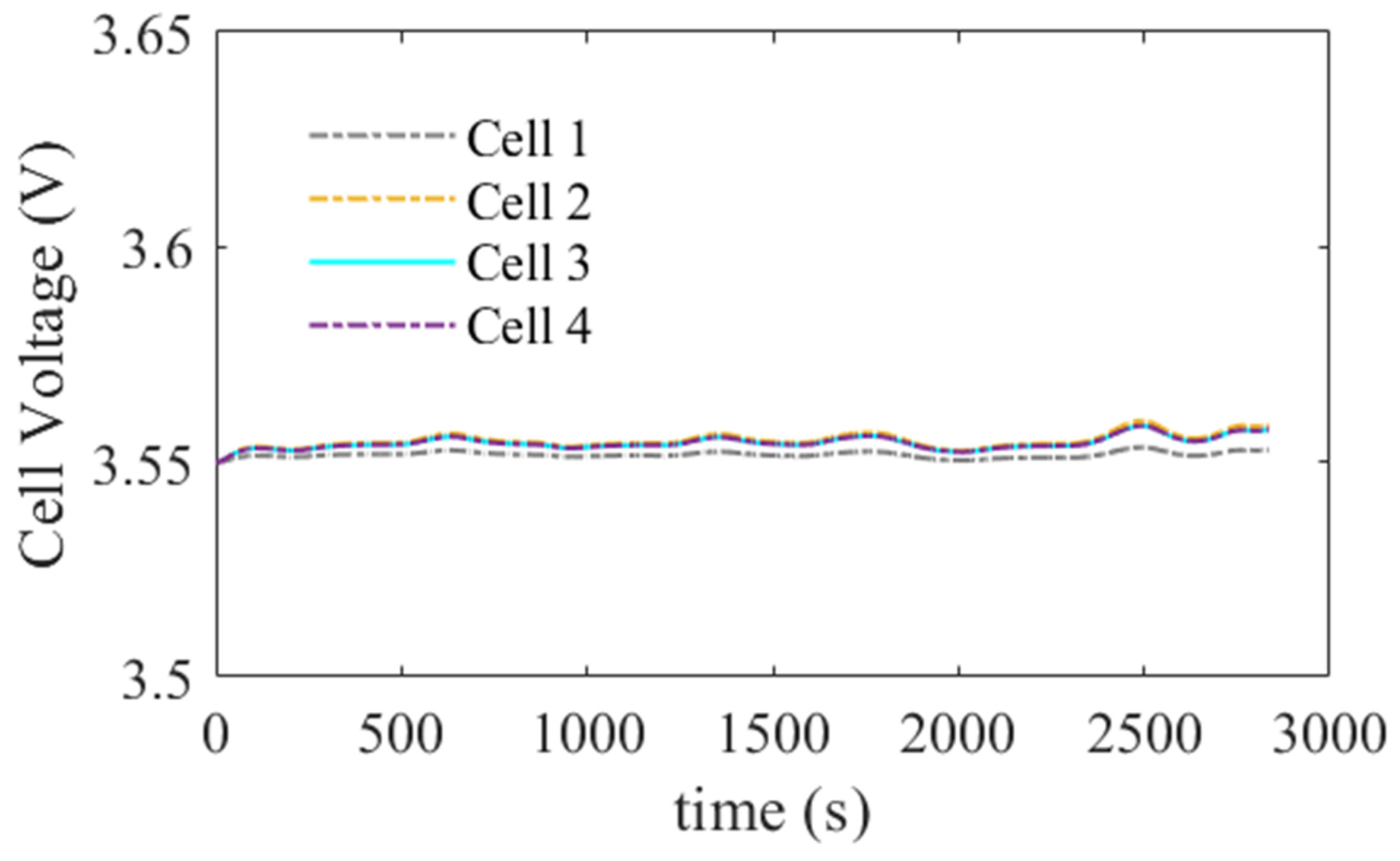

6.1. Electrochemical Battery Model Validation

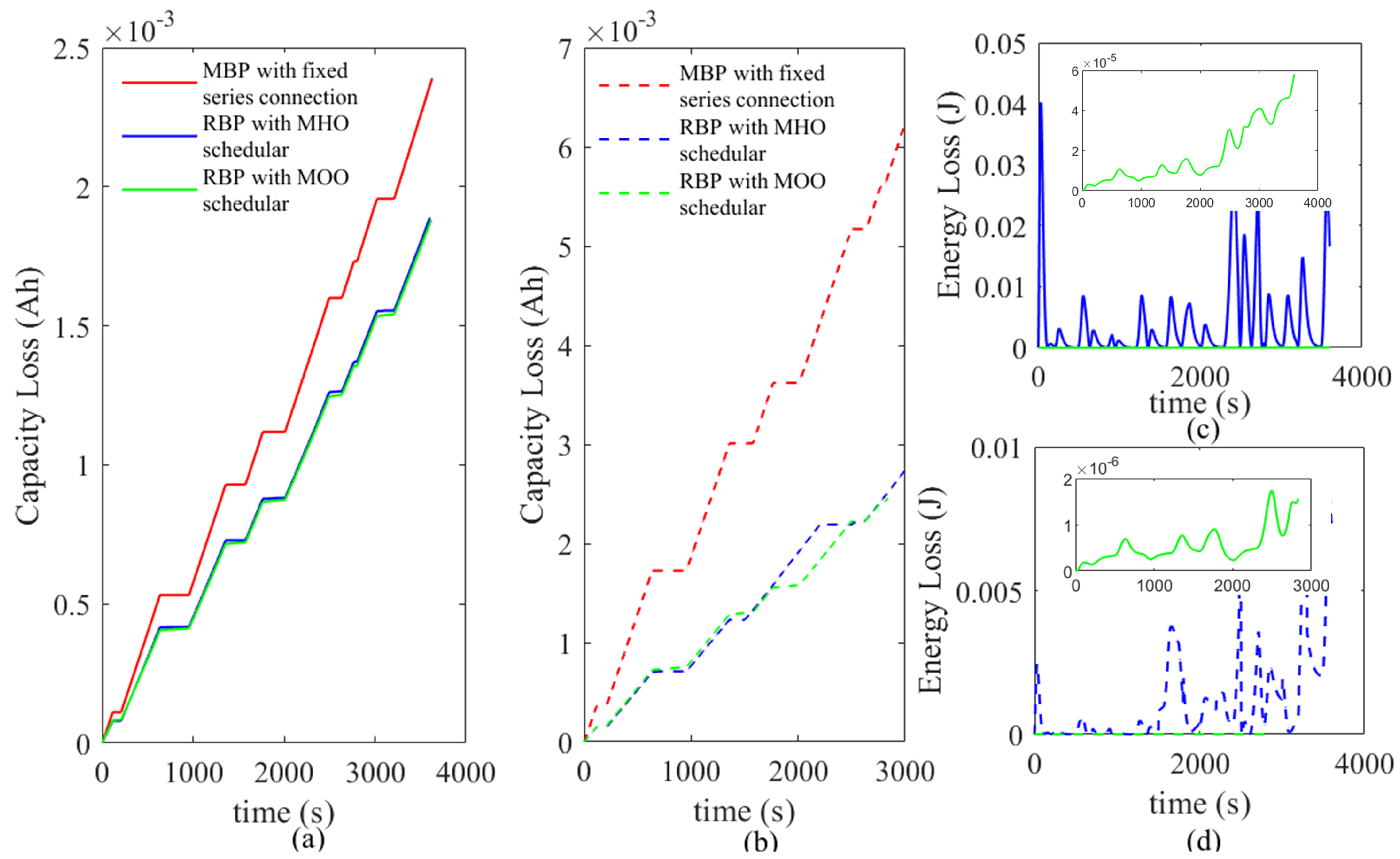

6.2. Scheduler Performances

7. Discussion

- The pack capacity loss is reduced by 28% and 58% for identical and nonidentical scenarios, respectively, compared to MBP, suggesting that the proposed method is ideal for battery packs with cell inconsistencies.

- The energy loss in the converter is reduced by 98% while efficiency is increased by nearly 5% for identical and nonidentical scenarios, respectively, compared to the MHO scheduler.

- The SOC balancing is achieved with a maximum difference of 0.01, indicating that the maximum cell utilization can be achieved without limiting the pack’s performance to its weakest cell due to the adaptive nature of the control mechanism to the changes in the cell condition and dynamic reconfiguration.

- The distribution of computational requirements between the daughterboard and motherboard allows for reduced cost, less time, and increased accuracy. State estimation and ADPE are performed by the daughterboard within 200 and 0.4902 s, respectively. The scheduler function is performed by the motherboard within 0.005 s.

- A feasible hardware design is proposed which ensures a physically small and modular design with a focus on scalability. The daughterboard modularity allows for the system to scale according to the application requirement.

8. Conclusions

- The proposed RBP utilizes a control mechanism that identifies the optimal cell configuration by taking cell inconsistencies and electrochemical parameter variations into account.

- The utilized physics-based battery model is computationally efficient and provides physical interpretation to the circuit parameters and the internal state variables. It allows for the accurate estimation of the battery SOC and SOH.

- The monitoring and control of individual cells is achieved by using MMSPC, which has the ability to dynamically switch battery cells into series, parallel, or a combination of these connections.

- The ABMS proposed has the ability to incorporate cell inconsistencies, accurate online estimation of cell states, and electrochemical parameters.

- A feasible hardware design for the control scheme is presented, and the comparison of the proposed strategies, with simulation and experimental results, is reported and discussed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ABMS | advanced battery management system |

| BESS | battery energy storage system |

| BOL | beginning of life |

| BMS | battery management system |

| CHMMC | cascaded H-bridge modular multilevel converter |

| I2C | interintegrated circuit |

| Li-ion | Lithium-ion |

| MMC | modular multilevel converter |

| MMSPC | modular multilevel series parallel converter |

| MOO | multiobjective optimization |

| MHO | modified hierarchical optimization |

| MBP | monolithic battery pack |

| OCP | open circuit potential |

| OCV | open circuit voltage |

| OLC | output level command |

| PLL | phase-locked loop |

| PS-PWM | phase-shifted pulse width modulation method |

| P2D | pseudo-two-dimensional |

| RBP | reconfigurable battery pack |

| ROECM | reduced order equivalent circuit model |

| SEI | solid electrolyte interface |

| SOE | state of energy |

| SOH | state of health |

| SPM | single particle model |

| SEI | solid electrolyte interface |

| SOC | state of charge |

Appendix A

Appendix A.1. Electrochemical Models and Governing Equations

| SPM | ROECM |

|---|---|

| Potential in the solid phase | Equivalent resistance of the cell |

SEI film resistance | |

| Capacity of the positive electrode | |

| Lithium ion concentration in the solid particles | Capacity of the negative electrode |

| , | |

| Boundary conditions and | Capacity loss of the cell |

| , , | |

| Molar flux | |

| , | |

| Output voltage of the cell | |

| Electric potential in the solid phase | |

| R | Universal gas constant |

| T | Cell temperature |

| a | Specific interfacial area |

| Reaction rate constant | |

| Lithium ion concentration in the electrolyte at t = 0 | |

| Lithium ion concentration in the solid phase particle surface | |

| U | Equilibrium potential of the reaction |

| Lithium ion concentration in the solid phase | |

| r | Radial dimension of the particle |

| Solid phase diffusion coefficient | |

| Molar ion fluxes between the active material in the electrodes and the electrolyte | |

| Irreversible side-reaction current | |

| Equivalent resistance of the cell | |

| Current collectors resistance | |

| Resistance of solid phase over-potential due to Li-ion diffusion | |

| Resistance due to the activation over-potential of the side reactions | |

| Resistance due to the SEI-film formation | |

| Electrolyte resistance | |

| + | Positive electrode |

| − | Negative electrode |

| A | Cross-sectional area of the cell |

| L | Width of the cell |

| F | Faraday constant |

| Volume fraction of the electrode | |

| Theoretical maximum Li-ion concentration | |

| Volume-averaged stoichiometry at time t | |

| Battery volume-averaged stoichiometry of the battery when it is fully discharged | |

| Battery volume-averaged stoichiometry of the battery when it is fully charged | |

| Capacity loss of the battery at the beginning of life (BOL) | |

| Average molecular weight of the electrode | |

| Density of the electrode | |

| Conductivity of the electrode | |

| Initial resistance of the SEI film of the electrode | |

| Irreversible side-reaction current density | |

| Battery volume-averaged stoichiometry of the battery when it is fully discharged | |

| Battery volume-averaged stoichiometry of the battery when it is fully charged | |

| Capacity loss of the battery at the beginning of life (BOL) | |

| Average molecular weight of the electrode | |

| Density of the electrode | |

| Conductivity of the electrode | |

| Initial resistance of the SEI film of the electrode | |

| Irreversible side-reaction current density |

| Physical Meaning (Unit) | Positive Electrode | Negative Electrode |

|---|---|---|

| Particle radius (m) | ||

| Solid phase diffusion coefficient () | ||

| Specific surface area of electrode () | ||

| Length of the electrode (m) | ||

| Volume fraction of the solid phase | ||

| Theoretical maximum concentration in the solid phase () | 51,555 | 30,555 |

| Stoichiometry for an empty battery at BOL | 0.95 | 0.03 |

| Stoichiometry for a full battery at BOL | 0.4870 | 0.8851 |

| Electrode rate constant ( ) | ||

| SEI film resistance at BOL () | 0 | 0.01 |

| Effective electrolyte conductivity () | 0.0045 | 0.0113 |

| Faraday constant (s· A/mol) | 96,487 | |

| Temperature (K) | 298.15 | |

| Universal gas constant [J/(K· mol)] | 8.314 | |

| Current collector resistance () | 0 | |

| Average Li-ion concentration in the electrolyte () | 1000 | |

| Electrode plate area () | 0.05961 | |

| Average molecular weight of the SEI film (kg/mol) | ||

| SEI film density () | ||

| Exchange current density for side reaction () | ||

| Equilibrium potential of the side reaction (V) | 0.4 | |

| Charge capacity at BOL (Ah) | 1.6 | |

| Length of the separator (m) | ||

| Effective electrolyte conductivity of the separator () | 0.0563 | |

References

- De Sisternes, F.J.; Jenkins, J.D.; Botterud, A. The value of energy storage in decarbonizing the electricity sector. Appl. Energy 2016, 175, 368–379. [Google Scholar] [CrossRef]

- Chaturvedi, N.A.; Klein, R.; Christensen, J.; Ahmed, J.; Kojic, A. Algorithms for advanced battery-management systems. IEEE Control. Syst. Mag. 2010, 30, 49–68. [Google Scholar]

- Vetter, J.; Novák, P.; Wagner, M.R.; Veit, C.; Möller, K.C.; Besenhard, J.; Winter, M.; Wohlfahrt-Mehrens, M.; Vogler, C.; Hammouche, A. Ageing mechanisms in lithium-ion batteries. J. Power Sources 2005, 147, 269–281. [Google Scholar] [CrossRef]

- Lawder, M.T.; Suthar, B.; Northrop, P.W.; De, S.; Hoff, C.M.; Leitermann, O.; Crow, M.L.; Santhanagopalan, S.; Subramanian, V.R. Battery energy storage system (BESS) and battery management system (BMS) for grid-scale applications. Proc. IEEE 2014, 102, 1014–1030. [Google Scholar] [CrossRef]

- Li, Y.; Vilathgamuwa, M.; Choi, S.; Xiong, B.; Tang, J.; Su, Y.; Wang, Y. Design of minimum cost degradation-conscious lithium-ion battery energy storage system to achieve renewable power dispatchability. Appl. Energy 2020, 260, 114282. [Google Scholar] [CrossRef]

- Hadigol, M.; Maute, K.; Doostan, A. On uncertainty quantification of lithium-ion batteries: Application to an LiC6/LiCoO2 cell. J. Power Sources 2015, 300, 507–524. [Google Scholar] [CrossRef]

- Meng, J.; Yue, M.; Diallo, D. Nonlinear extension of battery constrained predictive charging control with transmission of Jacobian matrix. Int. J. Electr. Power Energy Syst. 2023, 146, 108762. [Google Scholar] [CrossRef]

- Li, Y.; Vilathgamuwa, M.; Choi, S.; Farrell, T.W.; Tran, N.T.; Teague, J. Development of a degradation-conscious physics-based lithium-ion battery model for use in power system planning studies. Appl. Energy 2019, 248, 512–525. [Google Scholar] [CrossRef]

- Lucia, S.; Torchio, M.; Raimondo, D.M.; Klein, R.; Braatz, R.D.; Findeisen, R. Towards adaptive health-aware charging of li-ion batteries: A real-time predictive control approach using first-principles models. In Proceedings of the 2017 American Control Conference (ACC), Seattle, WA, USA, 24–26 May 2017; pp. 4717–4722. [Google Scholar]

- Lin, X.; Hao, X.; Liu, Z.; Jia, W. Health conscious fast charging of Li-ion batteries via a single particle model with aging mechanisms. J. Power Sources 2018, 400, 305–316. [Google Scholar] [CrossRef]

- Daowd, M.; Omar, N.; Van Den Bossche, P.; Van Mierlo, J. Passive and active battery balancing comparison based on MATLAB simulation. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011; pp. 1–7. [Google Scholar]

- Chatzinikolaou, E.; Rogers, D.J. A comparison of grid-connected battery energy storage system designs. IEEE Trans. Power Electron. 2016, 32, 6913–6923. [Google Scholar] [CrossRef]

- Ahmad, A.B.; Ooi, C.A.; Ishak, D.; Teh, J. State-of-charge balancing control for On/OFF-line internal cells using hybrid modular multi-level converter and parallel modular dual L-bridge in a grid-scale battery energy storage system. IEEE Access 2018, 7, 131–147. [Google Scholar] [CrossRef]

- Quraan, M.; Tricoli, P.; D’Arco, S.; Piegari, L. Efficiency assessment of modular multilevel converters for battery electric vehicles. IEEE Trans. Power Electron. 2016, 32, 2041–2051. [Google Scholar] [CrossRef]

- Goetz, S.M.; Peterchev, A.V.; Weyh, T. Modular multilevel converter with series and parallel module connectivity: Topology and control. IEEE Trans. Power Electron. 2014, 30, 203–215. [Google Scholar] [CrossRef]

- Chatzinikolaou, E.; Rogers, D.J. Hierarchical distributed balancing control for large-scale reconfigurable AC battery packs. IEEE Trans. Power Electron. 2017, 33, 5592–5602. [Google Scholar] [CrossRef]

- Baruschka, L.; Mertens, A. Comparison of cascaded H-bridge and modular multilevel converters for BESS application. In Proceedings of the 2011 IEEE Energy Conversion Congress and Exposition, Phoenix, AZ, USA, 17–22 September 2011; pp. 909–916. [Google Scholar]

- Goetz, S.M.; Li, Z.; Liang, X.; Zhang, C.; Lukic, S.M.; Peterchev, A.V. Control of modular multilevel converter with parallel connectivity—Application to battery systems. IEEE Trans. Power Electron. 2016, 32, 8381–8392. [Google Scholar] [CrossRef]

- Chatzinikolaou, E.; Rogers, D.J. Cell SoC balancing using a cascaded full-bridge multilevel converter in battery energy storage systems. IEEE Trans. Ind. Electron. 2016, 63, 5394–5402. [Google Scholar] [CrossRef]

- He, L.; Kim, E.; Shin, K.G. A case study on improving capacity delivery of battery packs via reconfiguration. ACM Trans.-Cyber-Phys. Syst. 2017, 1–23. [Google Scholar] [CrossRef]

- Kim, Y.; Park, S.; Wang, Y.; Xie, Q.; Chang, N.; Poncino, M.; Pedram, M. Balanced reconfiguration of storage banks in a hybrid electrical energy storage system. In Proceedings of the 2011 IEEE/ACM International Conference on Computer-Aided Design (ICCAD), San Jose, CA, USA, 7–10 November 2011; pp. 624–631. [Google Scholar]

- He, L.; Kong, L.; Lin, S.; Ying, S.; Gu, Y.; He, T.; Liu, C. Reconfiguration-assisted charging in large-scale Lithium-ion battery systems. In Proceedings of the 2014 ACM/IEEE International Conference on Cyber-Physical Systems (ICCPS), Berlin, Germany, 14–17 April 2014; pp. 60–71. [Google Scholar]

- Kumar, P.; Visairo-Cruz, H.; Noble, S. Reconfigurable Battery Pack. U.S. Patent US20090085553A1, 11/906,177, 2 April 2009. [Google Scholar]

- Steinhorst, S.; Shao, Z.; Chakraborty, S.; Kauer, M.; Li, S.; Lukasiewycz, M.; Narayanaswamy, S.; Rafique, M.U.; Wang, Q. Distributed reconfigurable battery system management architectures. In Proceedings of the 2016 21st Asia and South Pacific Design Automation Conference (ASP-DAC), Macao, China, 25–28 January 2016; pp. 429–434. [Google Scholar]

- He, L.; Gu, L.; Kong, L.; Gu, Y.; Liu, C.; He, T. Exploring adaptive reconfiguration to optimize energy efficiency in large-scale battery systems. In Proceedings of the 2013 IEEE 34th Real-Time Systems Symposium, Vancouver, BC, Canada, 3–6 December 2013; pp. 118–127. [Google Scholar]

- Ci, S.; Lin, N.; Wu, D. Reconfigurable battery techniques and systems: A survey. IEEE Access 2016, 4, 1175–1189. [Google Scholar] [CrossRef]

- Morstyn, T.; Momayyezan, M.; Hredzak, B.; Agelidis, V.G. Distributed control for state-of-charge balancing between the modules of a reconfigurable battery energy storage system. IEEE Trans. Power Electron. 2015, 31, 7986–7995. [Google Scholar] [CrossRef]

- Frost, D.F.; Howey, D.A. Completely decentralized active balancing battery management system. IEEE Trans. Power Electron. 2017, 33, 729–738. [Google Scholar] [CrossRef]

- Bouchhima, N.; Schnierle, M.; Schulte, S.; Birke, K.P. Active model-based balancing strategy for self-reconfigurable batteries. J. Power Sources 2016, 322, 129–137. [Google Scholar] [CrossRef]

- Lin, N.; Ci, S.; Wu, D.; Guo, H. An optimization framework for dynamically reconfigurable battery systems. IEEE Trans. Energy Convers. 2018, 33, 1669–1676. [Google Scholar] [CrossRef]

- Han, W.; Wik, T.; Kersten, A.; Dong, G.; Zou, C. Next-generation battery management systems: Dynamic reconfiguration. IEEE Ind. Electron. Mag. 2020, 14, 20–31. [Google Scholar] [CrossRef]

- Doyle, M.; Fuller, T.F.; Newman, J. Modeling of galvanostatic charge and discharge of the lithium/polymer/insertion cell. J. Electrochem. Soc. 1993, 140, 1526. [Google Scholar] [CrossRef]

- Luo, W.; Lyu, C.; Wang, L.; Zhang, L. A new extension of physics-based single particle model for higher charge–discharge rates. J. Power Sources 2013, 241, 295–310. [Google Scholar] [CrossRef]

- Li, Y.; Vilathgamuwa, M.; Choi, S.; Farrell, T.; Tran, N.T.; Teague, J. A physics-based distributed-parameter equivalent circuit model for lithium-ion batteries. Electrochim. Acta 2019, 299, 451–469. [Google Scholar] [CrossRef]

- Karunathilake, D.; Vilathgamuwa, M.; Mishra, Y.; Farrell, T.W. Capacity Loss Reduction using Smart-Battery Management System for Li-ion Battery Energy Storage Systems. In Proceedings of the 2020 IEEE 29th International Symposium on Industrial Electronics (ISIE), Delft, The Netherlands, 17–19 June 2020; pp. 997–1002. [Google Scholar]

- Konidaris, N.; Karunathilake, D.; Vilathgamuwa, M.; Mishra, Y. Modular Multilevel Series Parallel Converter Prototype Design for Li-ion Battery Management Systems. In Proceedings of the 2021 IEEE PES Innovative Smart Grid Technologies-Asia (ISGT Asia), Brisbane, Australia, 5–8 December 2021; pp. 1–5. [Google Scholar]

- Available online: https://mesonet.agron.iastate.edu/request/awos/1min.php (accessed on 28 September 2021).

| Parameter | Symbol |

|---|---|

| Phase voltage | V |

| Energy per cell | E |

| No of cells per block | N |

| Number of blocks | M |

| Number of sub-bank | K |

| Number of bank | J |

| Total cells | 3NMKJ |

| Energy | 3NMKJ E |

| Optimization Methods | Cell Characteristic | Efficiency (%) |

|---|---|---|

| MOO | Identical cells | 99 |

| Nonidentical cells | 99 | |

| MHO | identical cells | 94.5 |

| Nonidentical cells | 94.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karunathilake, D.; Vilathgamuwa, M.; Mishra, Y.; Corry, P.; Farrell, T.; Choi, S.S. Degradation-Conscious Multiobjective Optimal Control of Reconfigurable Li-Ion Battery Energy Storage Systems. Batteries 2023, 9, 217. https://doi.org/10.3390/batteries9040217

Karunathilake D, Vilathgamuwa M, Mishra Y, Corry P, Farrell T, Choi SS. Degradation-Conscious Multiobjective Optimal Control of Reconfigurable Li-Ion Battery Energy Storage Systems. Batteries. 2023; 9(4):217. https://doi.org/10.3390/batteries9040217

Chicago/Turabian StyleKarunathilake, Dulmini, Mahinda Vilathgamuwa, Yateendra Mishra, Paul Corry, Troy Farrell, and San Shing Choi. 2023. "Degradation-Conscious Multiobjective Optimal Control of Reconfigurable Li-Ion Battery Energy Storage Systems" Batteries 9, no. 4: 217. https://doi.org/10.3390/batteries9040217

APA StyleKarunathilake, D., Vilathgamuwa, M., Mishra, Y., Corry, P., Farrell, T., & Choi, S. S. (2023). Degradation-Conscious Multiobjective Optimal Control of Reconfigurable Li-Ion Battery Energy Storage Systems. Batteries, 9(4), 217. https://doi.org/10.3390/batteries9040217