Topographical Optimization of a Battery Module Case That Equips an Electric Vehicle

Abstract

1. Introduction

- The development of the energy capacity of cells through other technologies;

- The functional optimization of the components of a battery cell;

- High-performance and energy-efficient battery management systems (BMS);

- The reduction of mechanical losses by reducing the number of components in the electric powertrain;

- The development of energy flow management systems at the level of the entire vehicle;

- The protection, safety, and security assurances in the use of energy sources.

- Mechanical: impact, deformation, penetration, free fall, mechanical shock, vibrations, and immersion.

- Electrical: overload, overloading, forced download, and high C-rate.

- Thermal: heating, overheating, and thermal runaway.

2. Materials and Methods

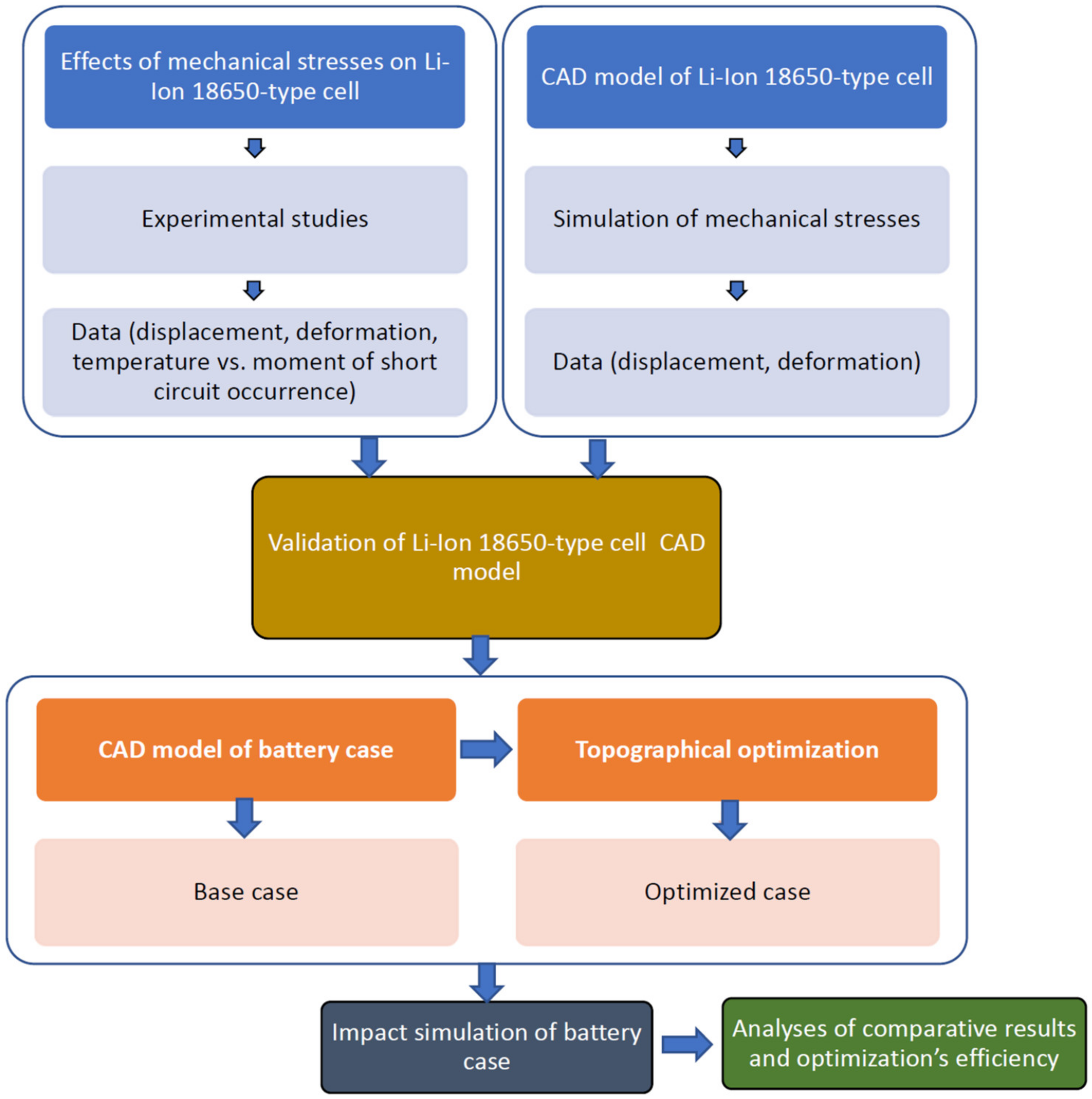

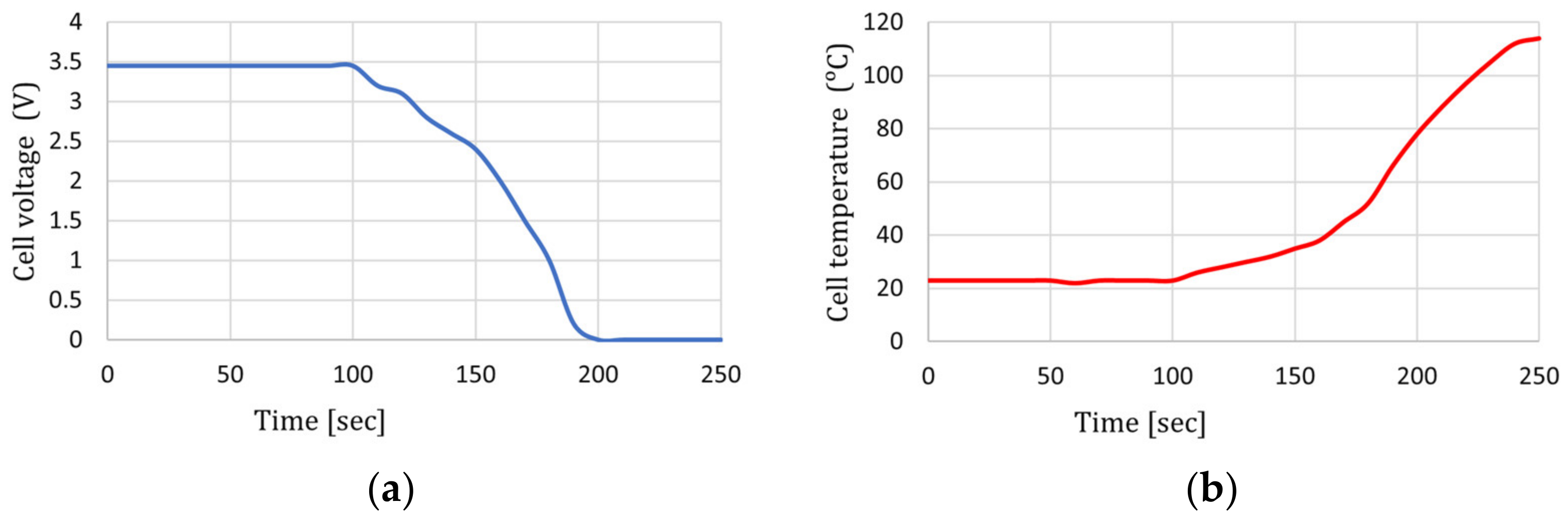

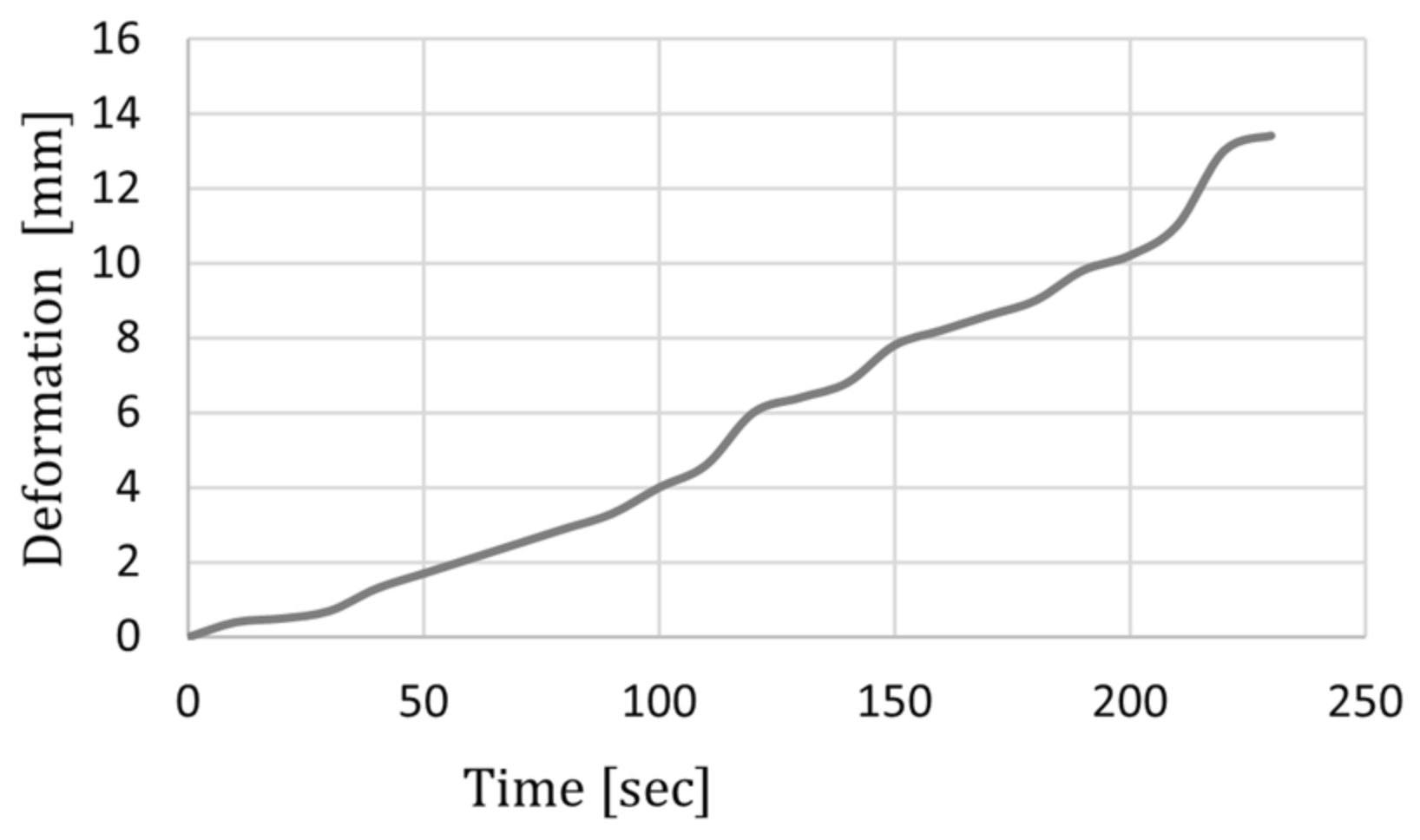

- Experimental research—The first direction of research was an experimental one and aimed to identify the point where (following mechanical deformation stresses on a Samsung 18650-type cell, with an 80% state of charge) the short-circuit occurs, and the cell becomes unusable.

- Numerical CAD modelling of a 18650-type cell—the creation of a CAD model considering the cell’s complex construction/design.

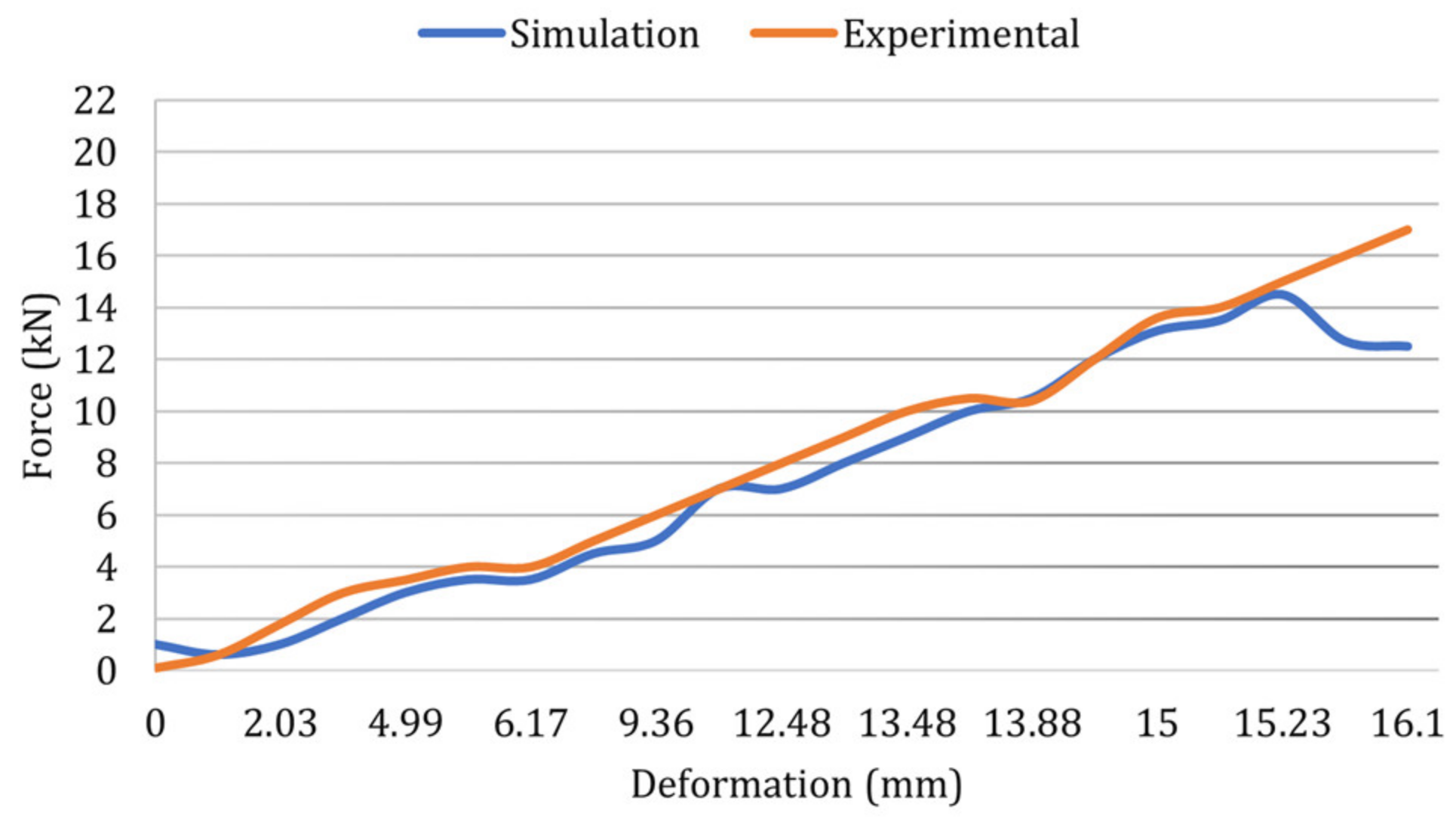

- Validation of a 18650-type cell CAD model—using experimentally obtained data.

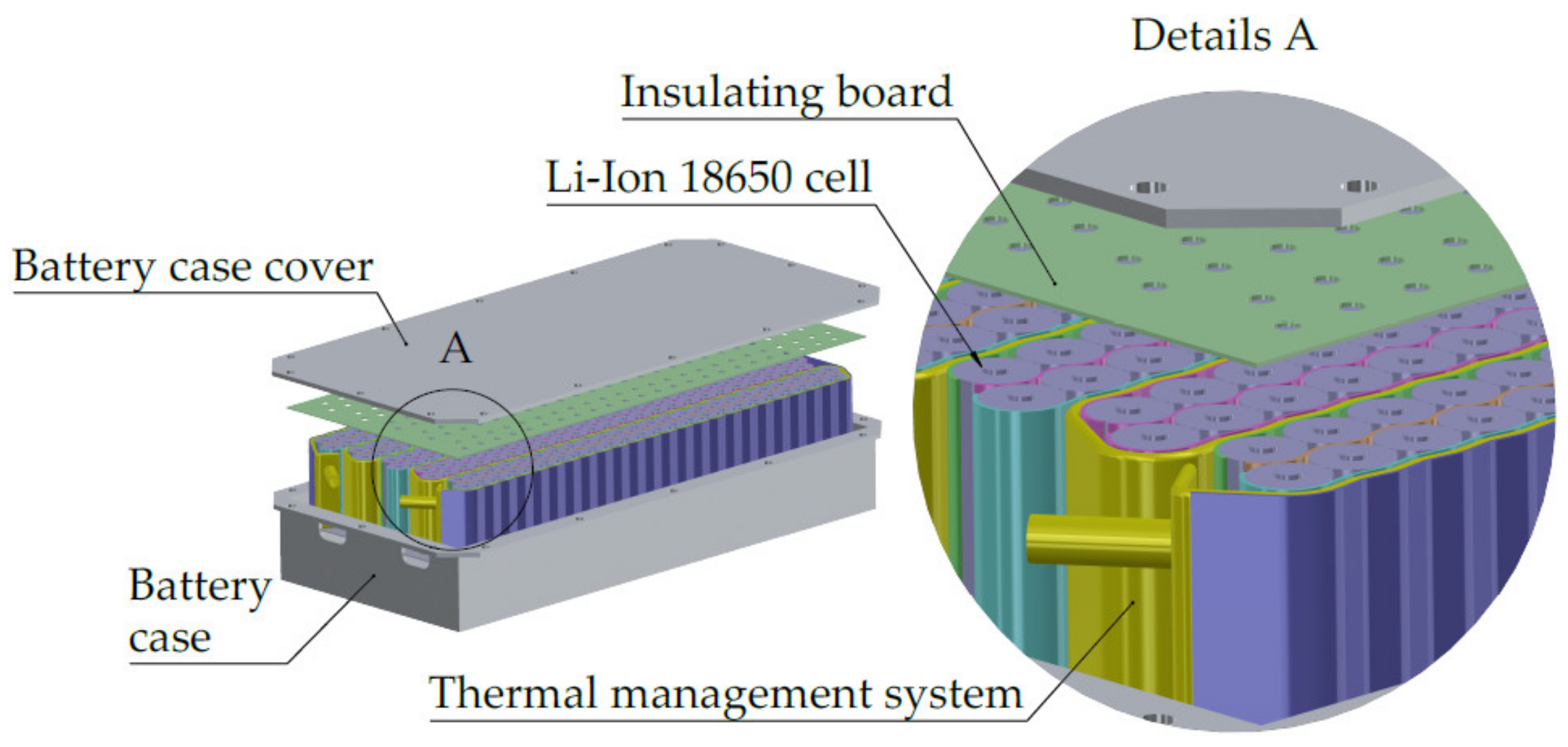

- Numerical CAD modelling of a battery case—the creation of a CAD model for a battery (including the internal thermal management system), consisting of 12 modules (a total number of 5760 cells, where each module is made of 480 cells).

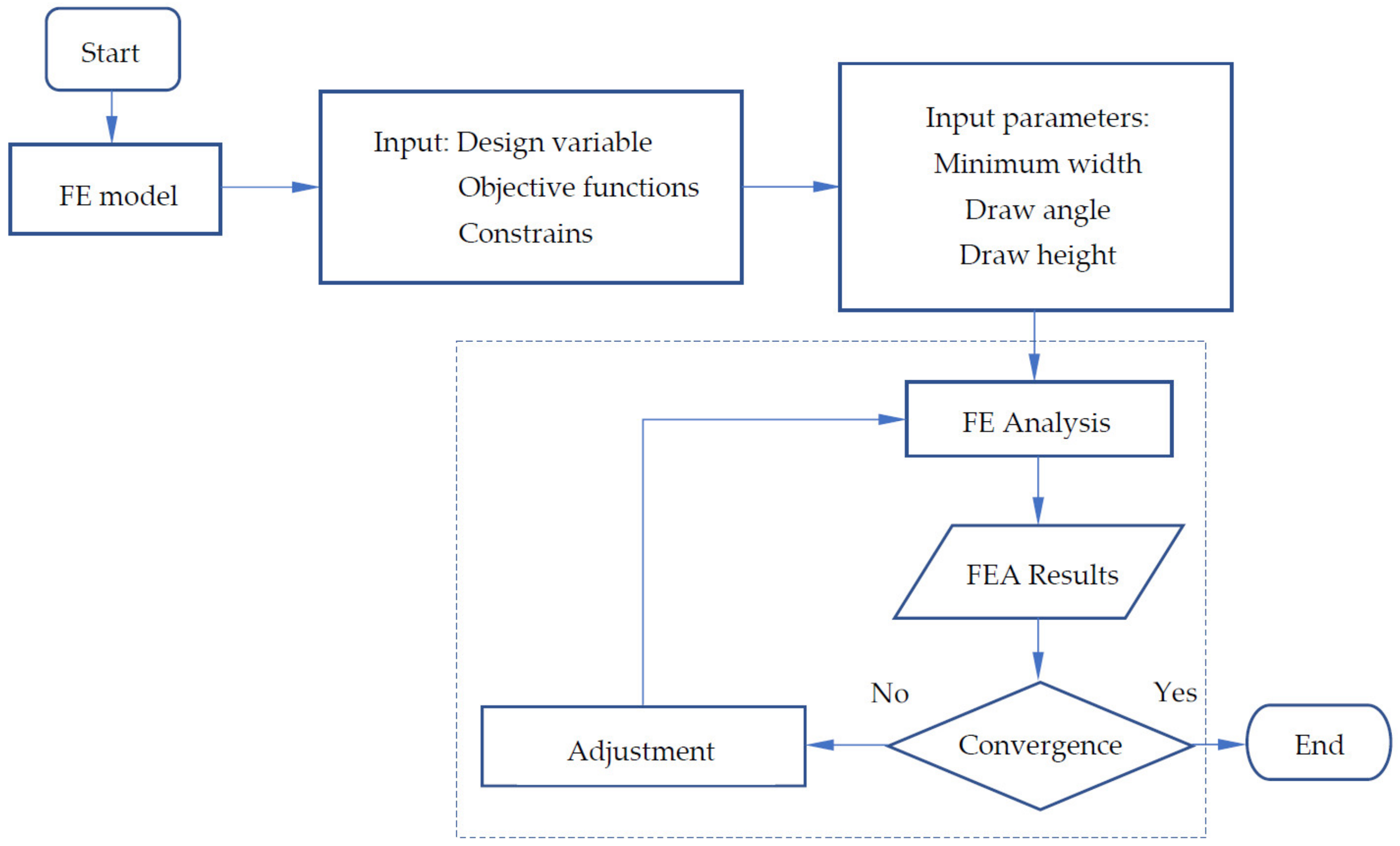

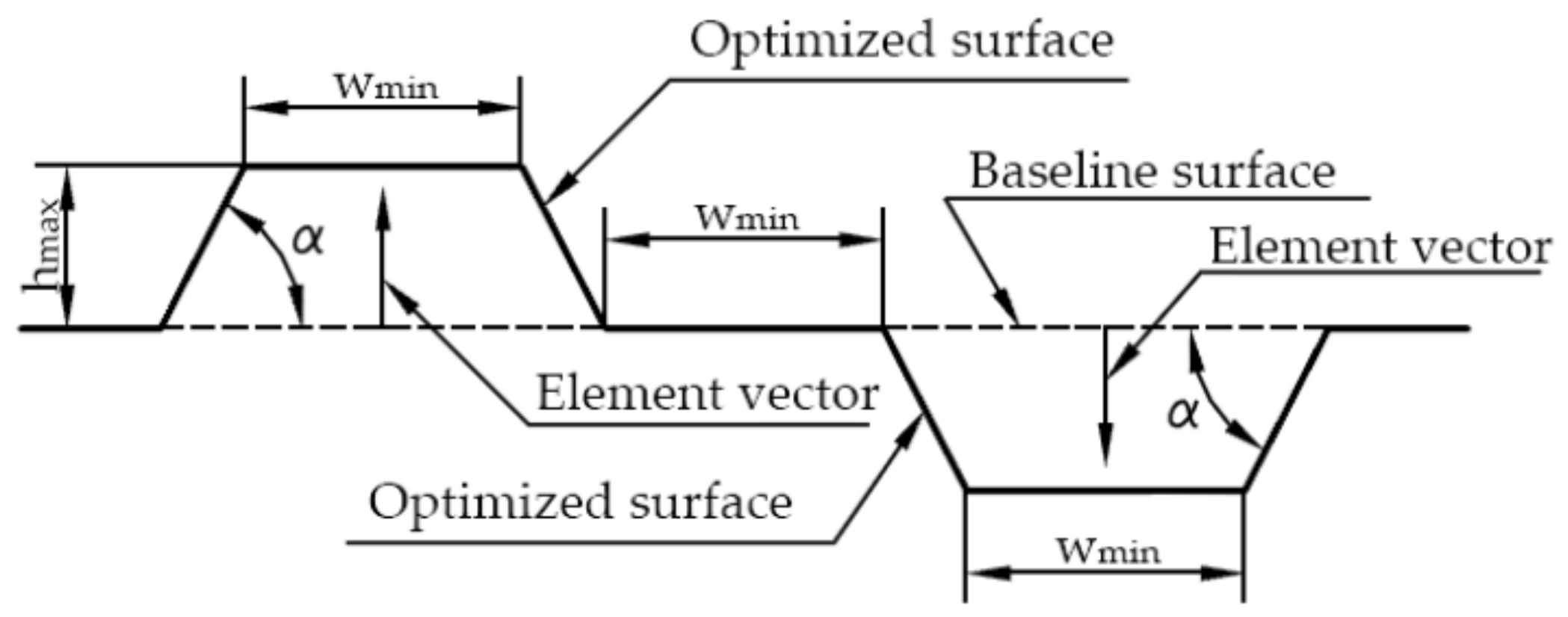

- Topographical optimization—the idea of a topographical optimization of the upper and lower surface of the battery case was approached by imposing a restriction relating to the real-world conditions of an electric vehicle. The considered restriction was the range of frequencies (vibrations) due to the tire–road interaction, which are transmitted to the vehicle chassis (and implicitly to the mechanical structure of the battery).

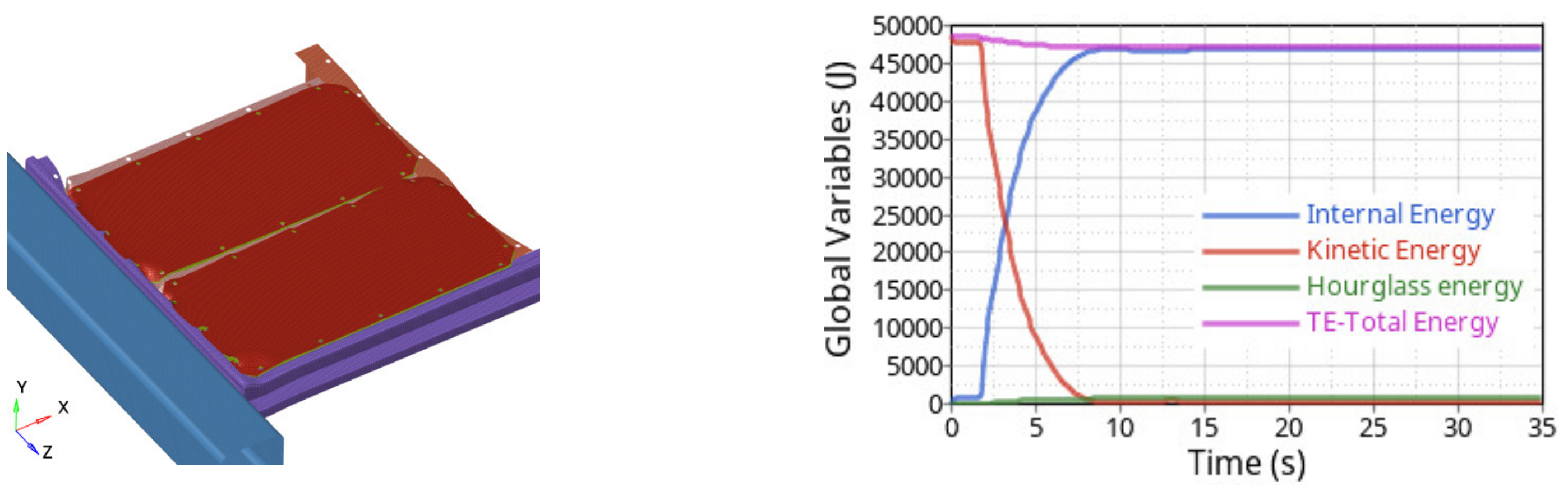

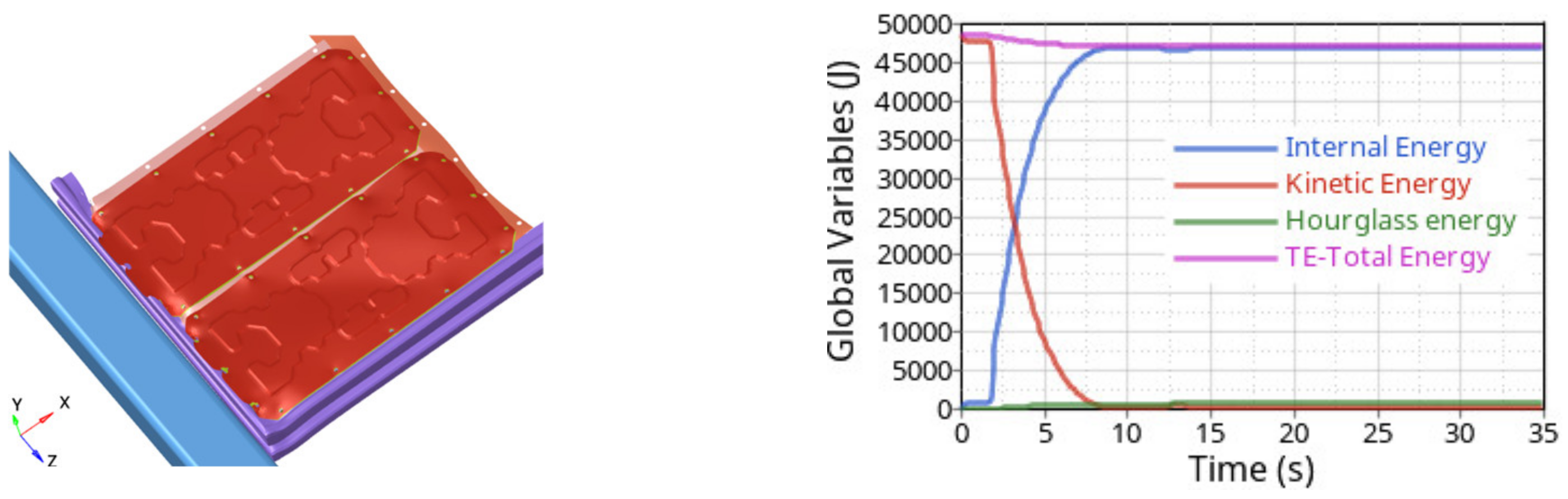

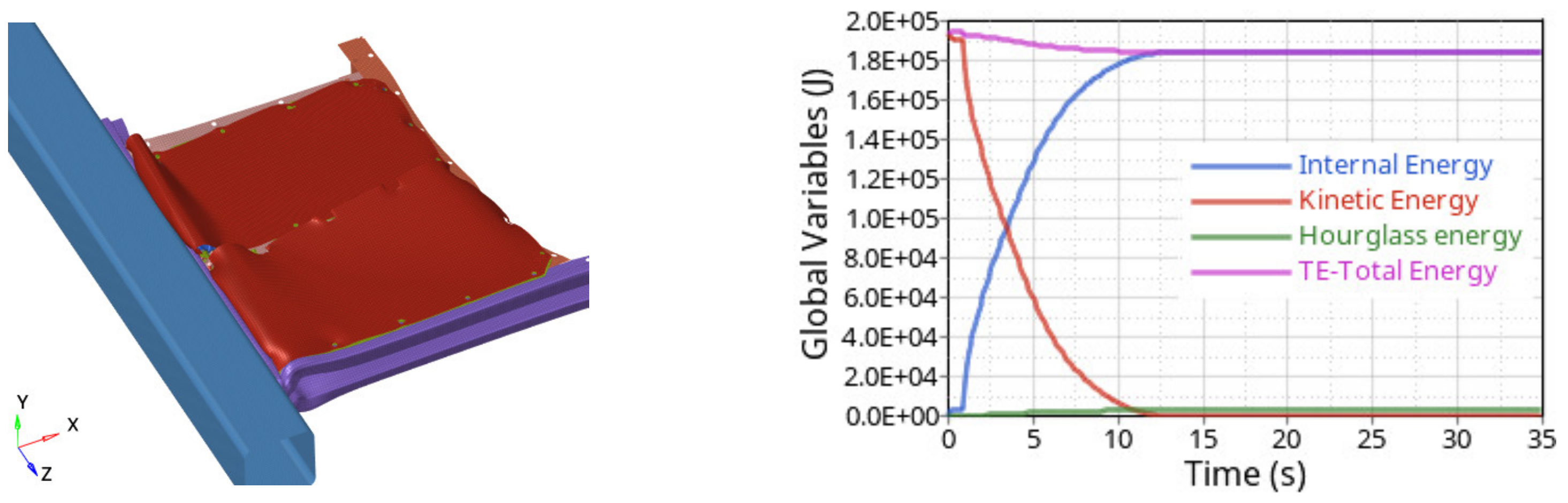

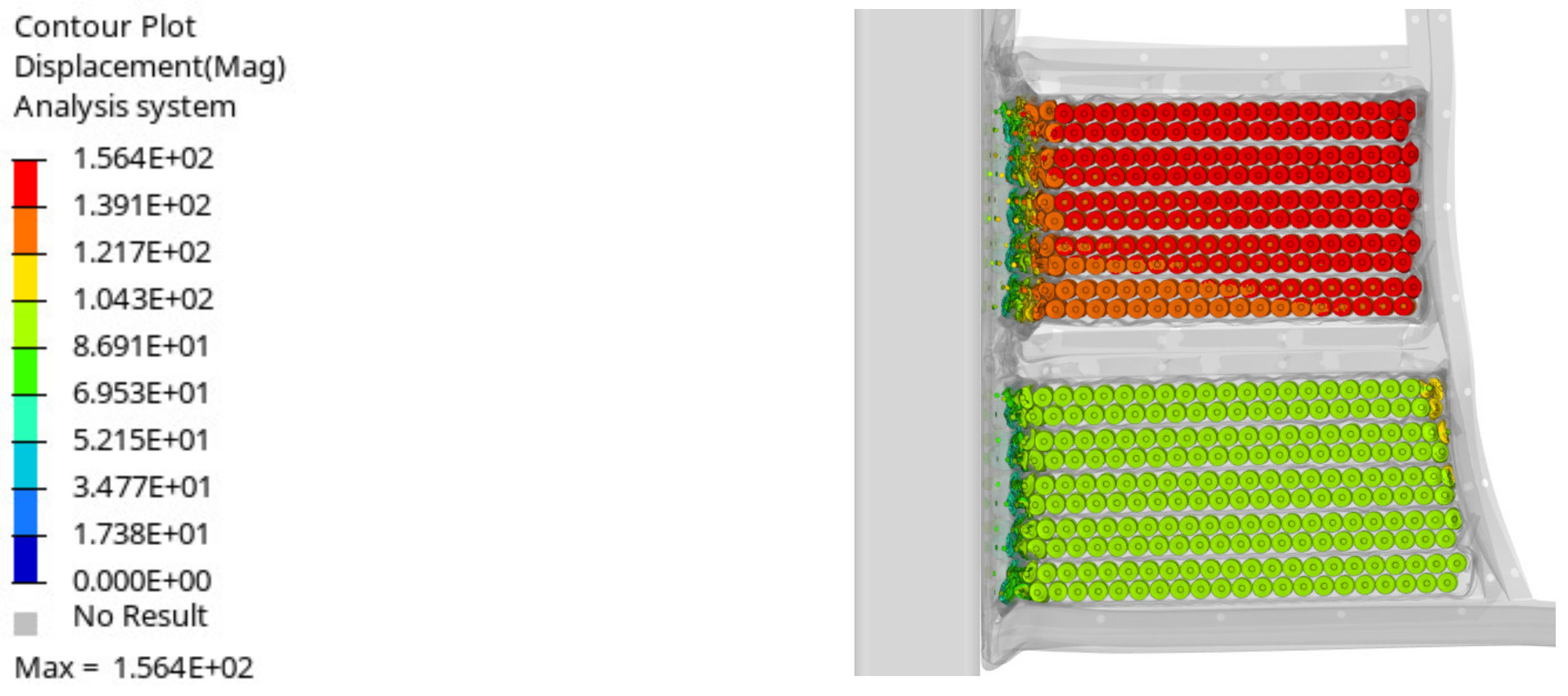

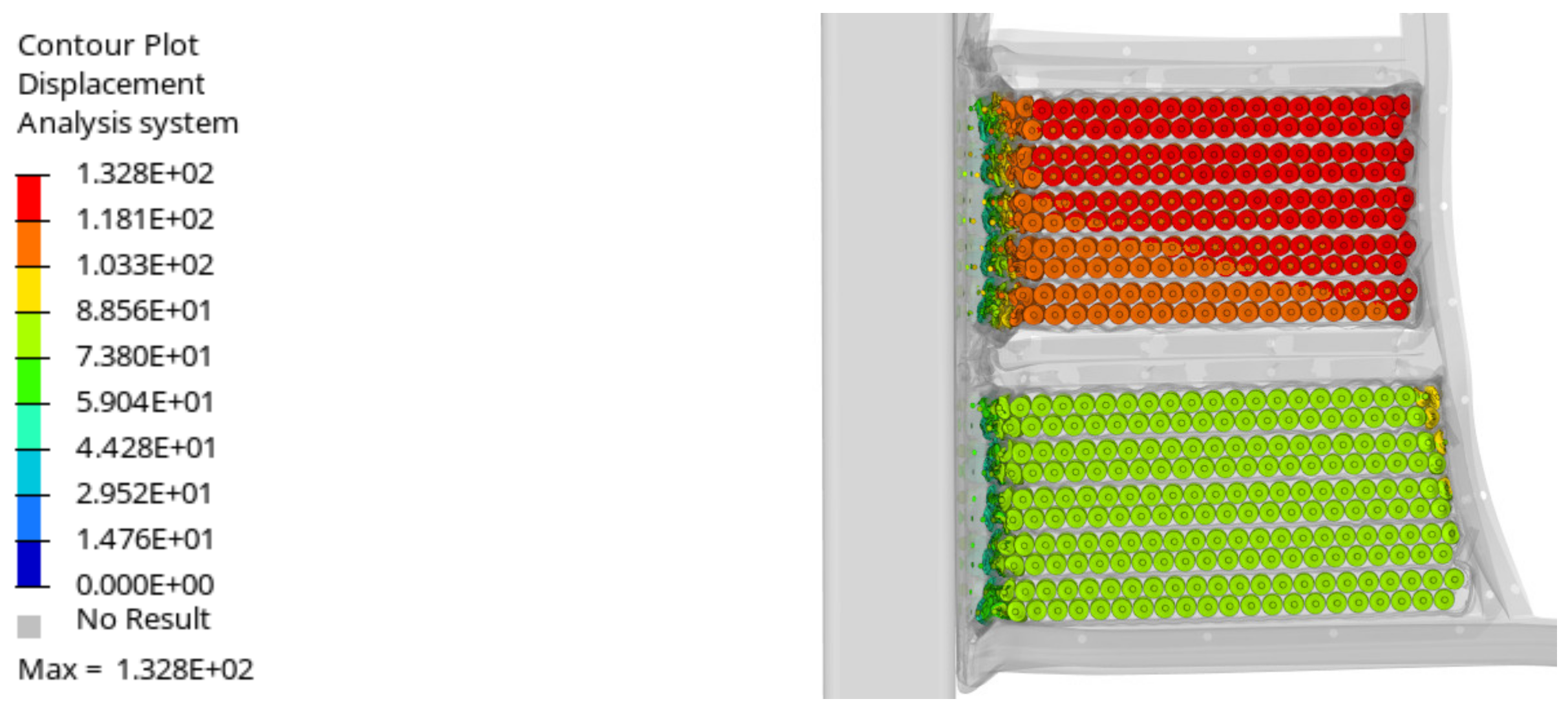

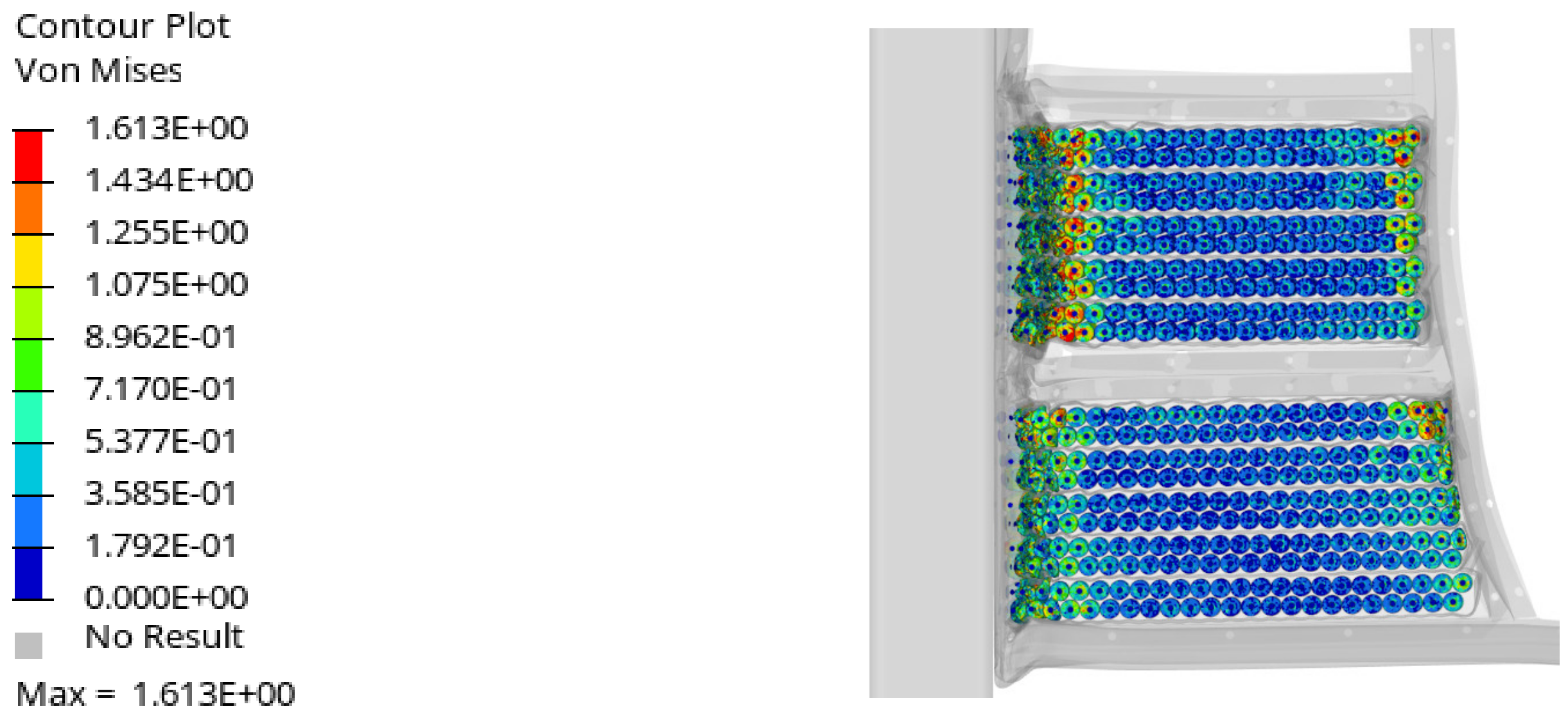

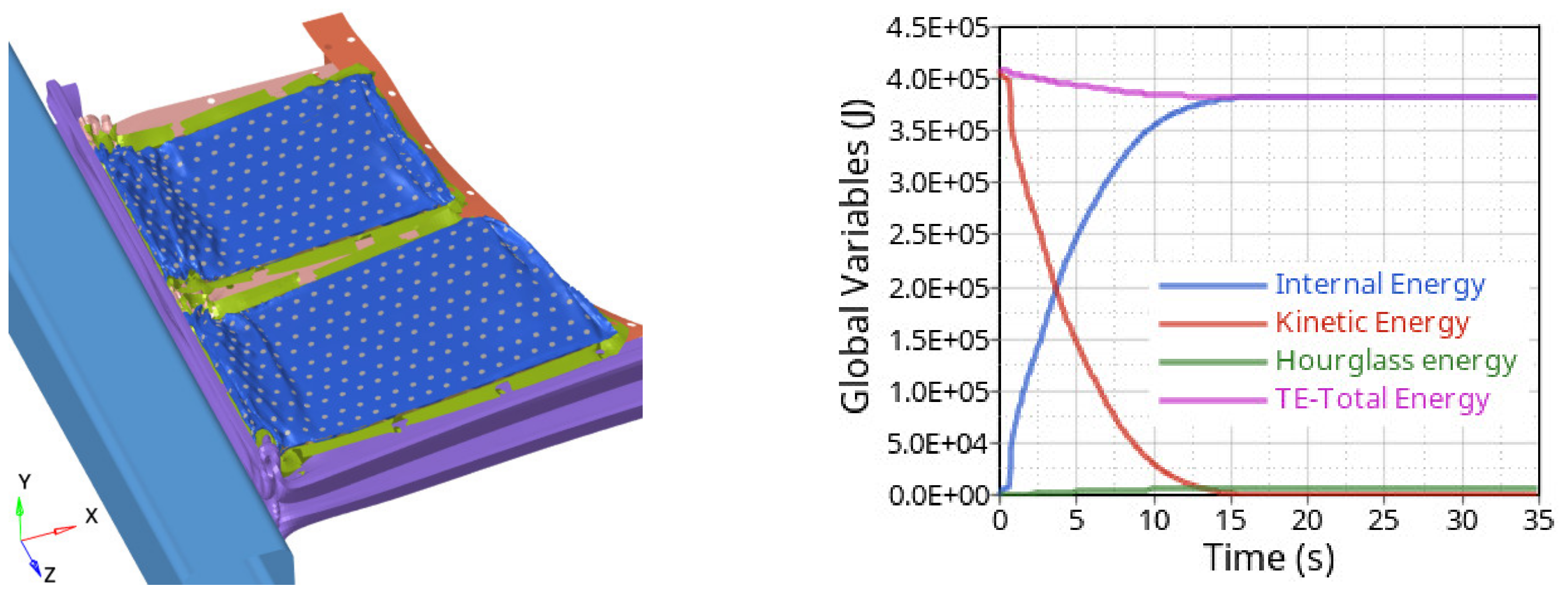

- Numerical simulation of base and optimized cases.

- Comparative analysis of data and conclusions on the efficiency.

2.1. Experimental Research

2.2. Numerical Modelling and Simulation

2.2.1. Numerical Modelling and Simulation of the 18650-Type Cell

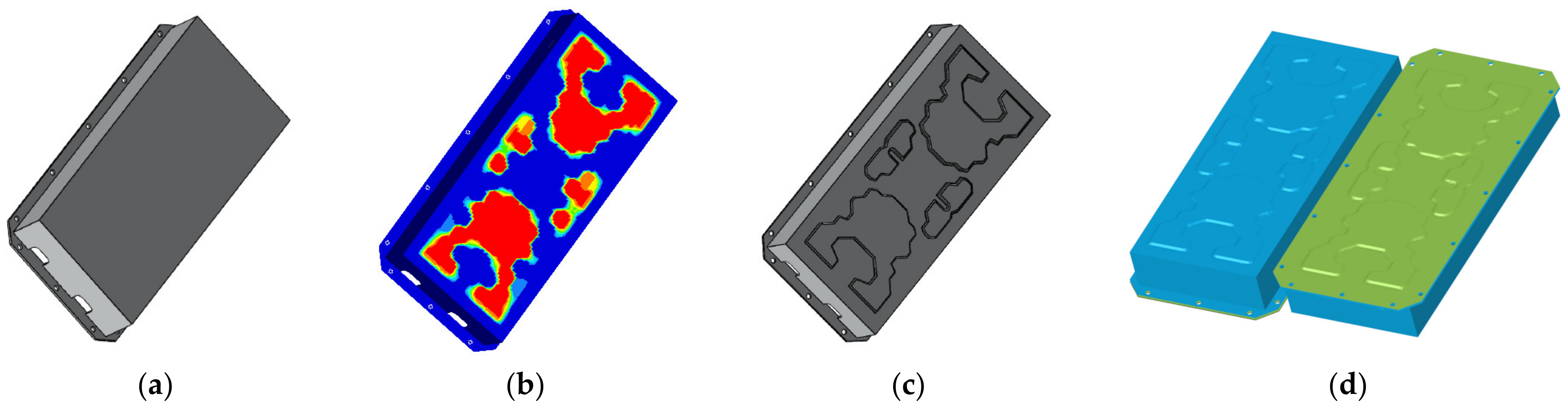

2.2.2. Topographical Optimization of the Battery Module Case

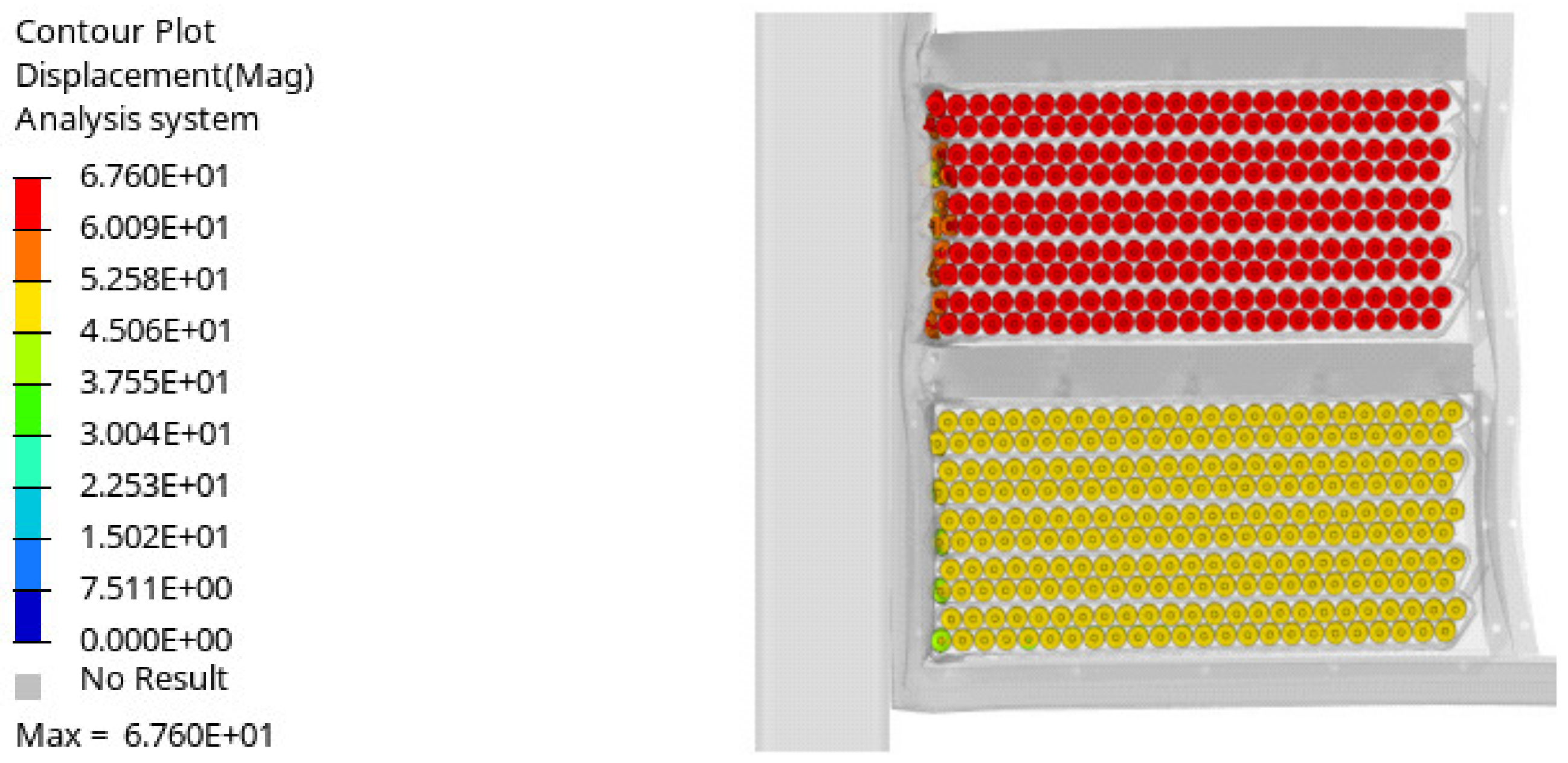

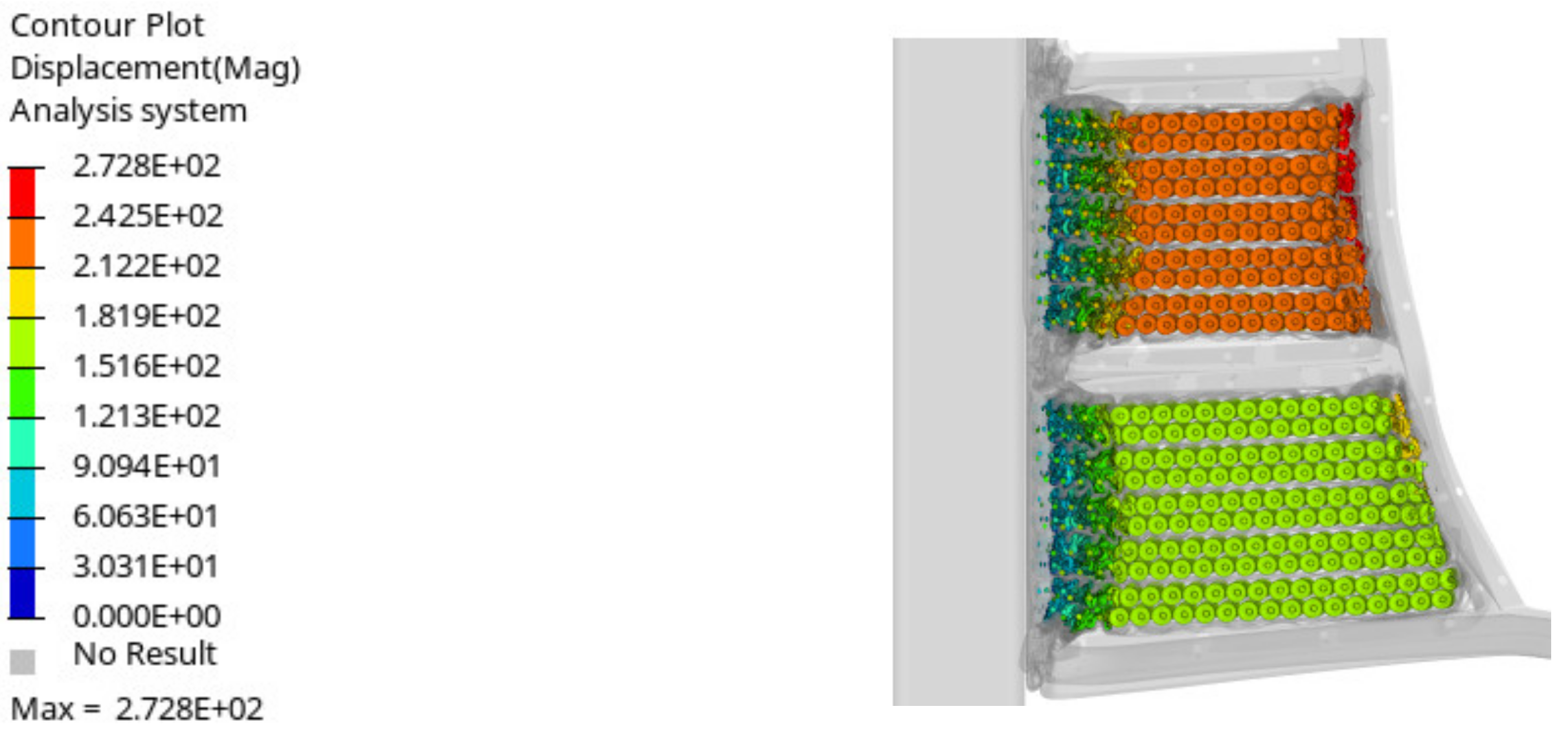

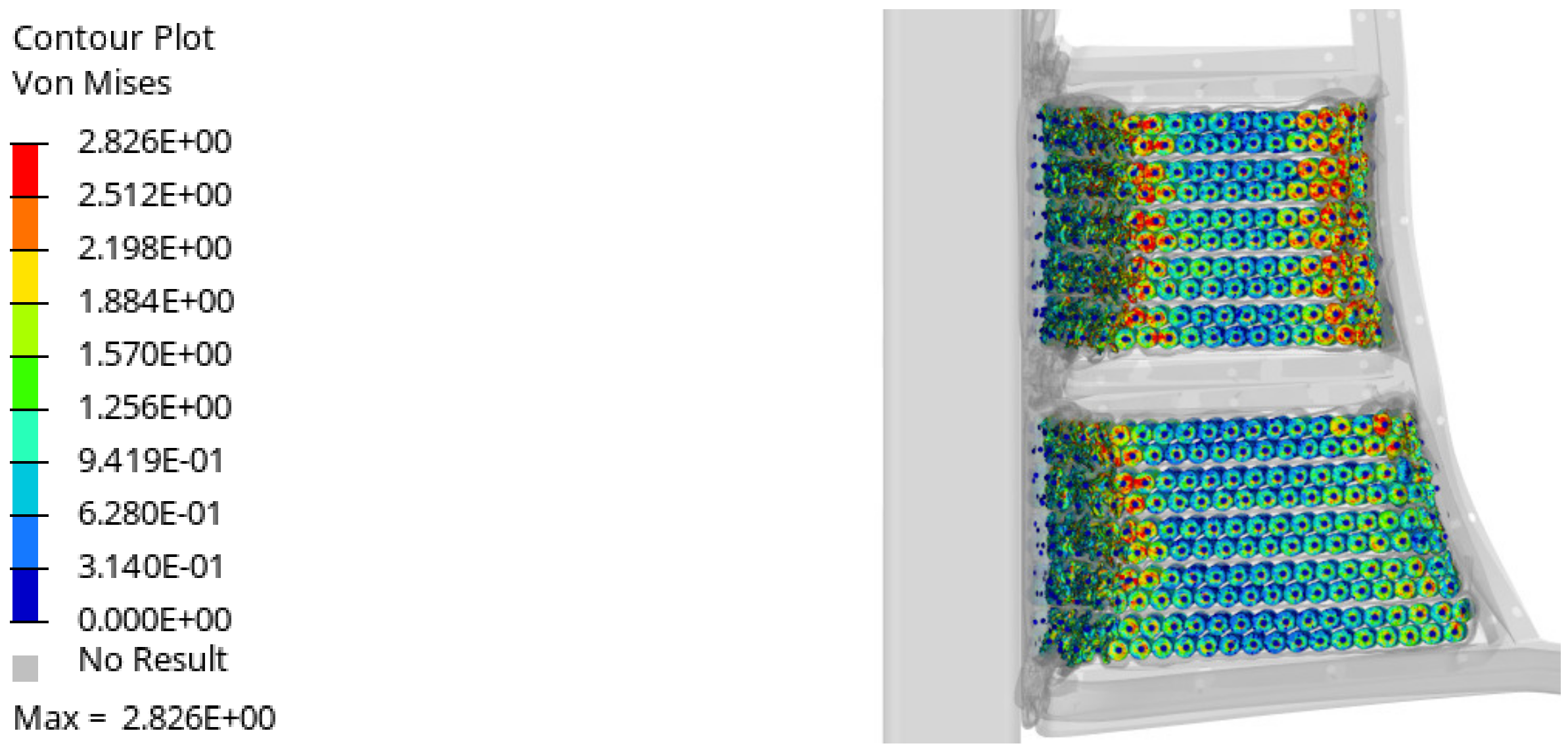

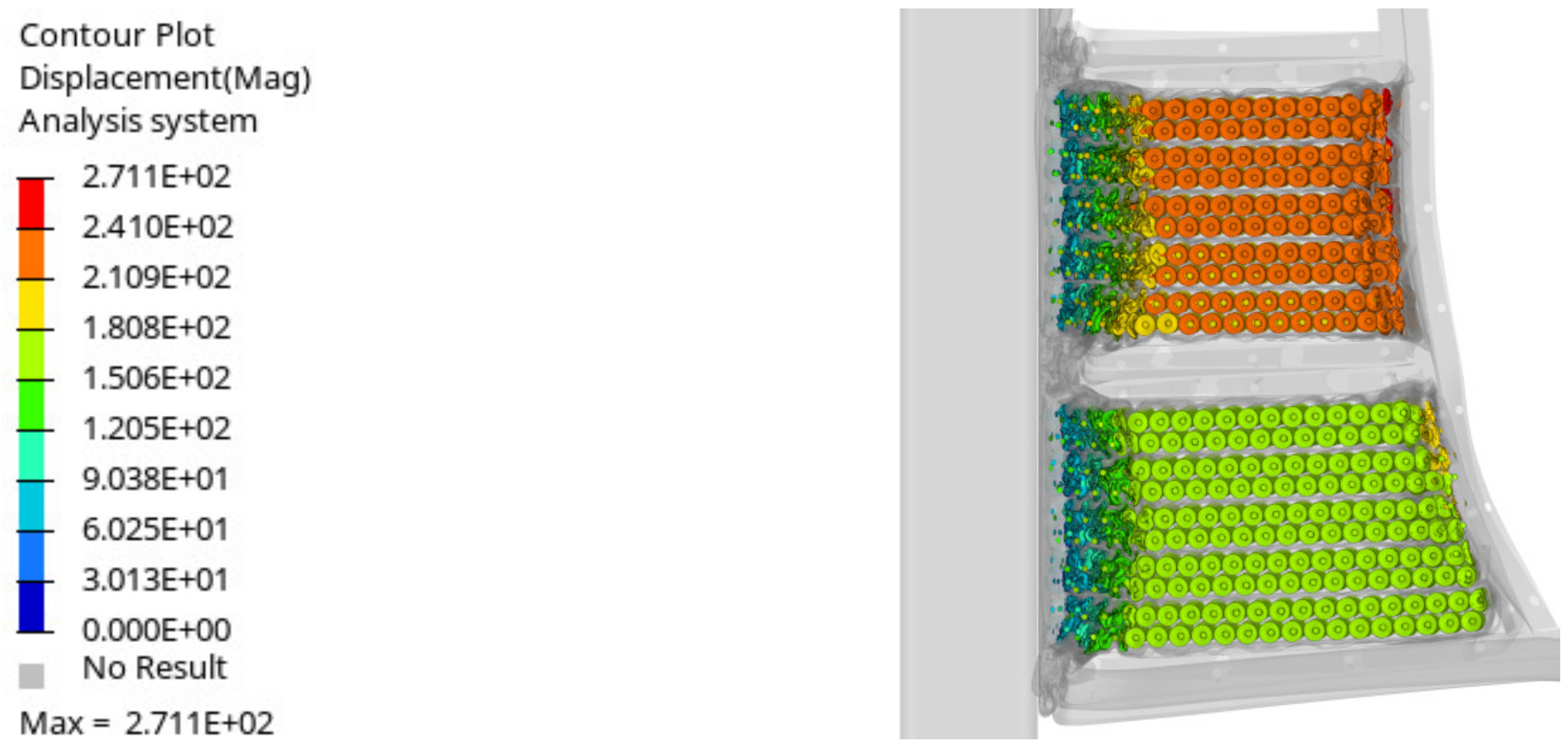

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Winkler, S.L.; Anderson, J.E.; Garza, L.; Ruona, W.C.; Vogt, R.; Wallington, T.J. Vehicle criteria pollutant (PM, NOx, CO, HCs) emissions: How low should we go? Clim. Atmos. Sci. 2018, 1, 26. [Google Scholar] [CrossRef]

- Abdel-Rahman, A.A. On the emissions from internal-combustion engines: A review. Int. J. Energy Res. 1998, 22, 489–513. [Google Scholar] [CrossRef]

- Adeyanju, A. Effects of Vehicular Emissions on Human Health. J. Clean Energy Technol. 2018, 6, 411–420. [Google Scholar] [CrossRef]

- Kim, B.-G.; Lee, P.-H.; Lee, S.-H.; Kim, Y.-E.; Shin, M.-Y.; Kang, Y.; Bae, S.-H.; Kim, M.-J.; Rhim, T.; Park, C.-S.; et al. Long-Term Effects of Diesel Exhaust Particles on Airway Inflammation and Remodeling in a Mouse Model. Allergy Asthma Immunol. Res. 2016, 8, 246–256. [Google Scholar] [CrossRef]

- European Environmental Agency (EEA). Greenhouse Gas Emissions from Transport in Europe. 2020. Available online: https://www.eea.europa.eu/data-and-maps/indicators/transport-emissions-of-greenhouse-gases/transport-emissions-of-greenhouse-gases-12 (accessed on 15 September 2022).

- Chau, K.T.; Chan, C.C. Emerging Energy-Efficient Technologies for Hybrid Electric Vehicles. Proc. IEEE 2007, 95, 821–835. [Google Scholar] [CrossRef]

- Amamra, S.-A.; Tripathy, Y.; Barai, A.; Moore, A.D.; Marco, J. Electric Vehicle Battery Performance Investigation Based on Real World Current Harmonics. Energies 2020, 13, 489. [Google Scholar] [CrossRef]

- Kim, J.-S.; Lee, D.-C.; Lee, J.-J.; Kim, C.-W. Optimization for maximum specific energy density of a lithium-ion battery using progressive quadratic response surface method and design of experiments. Sci. Rep. 2020, 10, 15586. [Google Scholar] [CrossRef] [PubMed]

- Lei, Y.; Zhang, C.; Gao, Y.; Li, T. Charging Optimization of Lithium-ion Batteries Based on Capacity Degradation Speed and Energy Loss. Energy Procedia 2018, 152, 544–549. [Google Scholar] [CrossRef]

- Li, R.; Wei, X.; Sun, H.; Sun, H.; Zhang, X. Fast Charging Optimization for Lithium-Ion Batteries Based on Improved Electro-Thermal Coupling Model. Energies 2022, 15, 7038. [Google Scholar] [CrossRef]

- Liu, K.; Kang Li, K.; Peng, Q.; Zhang, C. A brief review on key technologies in the battery management system of electric vehicles. Front. Mech. Eng. 2019, 14, 47–64. [Google Scholar] [CrossRef]

- Buidin, T.I.C.; Mariasiu, F. Battery Thermal Management Systems: Current Status and Design Approach of Cooling Technologies. Energies 2021, 14, 4879. [Google Scholar] [CrossRef]

- Lai, W.-J.; Ali, M.Y.; Pan, J. Mechanical behavior of representative volume elements of lithium-ion battery modules under various loading conditions. J. Power Source 2014, 248, 789–808. [Google Scholar] [CrossRef]

- Abada, S.; Marlair, G.; Lecocq, A.; Petit, M.; Sauvant-Moynot, V.; Huet, F. Safety focused modeling of lithium-ion batteries: A review. J. Power Source 2016, 306, 178–192. [Google Scholar] [CrossRef]

- Feng, X.; Ouyang, M.; Liu, X.; Lua, L.; Xia, Y.; He, X. Thermal runaway mechanism of lithium ion battery for electric vehicles: A review. Energy Storage Mater. 2018, 10, 246–267. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, X.; Xiao, Y.; Gao, H.; Wang, H.; Piao, C. Influence of Low-Temperature Charge on the Mechanical Integrity Behavior of 18650 Lithium-Ion Battery Cells Subject to Lateral Compression. Energies 2019, 12, 797. [Google Scholar] [CrossRef]

- Sahraei, E.; Meier, J.; Wierzbicki, T. Characterizing and modeling mechanical properties and onset of short circuit for three types of lithium-ion pouch cells. J. Power Source 2014, 247, 503–516. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, X.; Sahraei, E.; Wierzbicki, T. Deformation and failure mechanisms of 18650 battery cells under axial compression. J. Power Source 2016, 336, 332–340. [Google Scholar] [CrossRef]

- Xu, J.; Ma, J.; Zhao, X.; Chen, H.; Xu, B.; Wu, X. Detection Technology for Battery Safety in Electric Vehicles: A Review. Energies 2020, 13, 4636. [Google Scholar] [CrossRef]

- Evarts, E.C. Lithium batteries: To the limits of lithium. Nature 2015, 526, 93–95. [Google Scholar] [CrossRef]

- Chombo, P.V.; Laoonual, Y. A review of safety strategies of a Li-ion battery. J. Power Source 2020, 478, 228649. [Google Scholar] [CrossRef]

- Klink, J.; Hebenbrock, A.; Grabow, J.; Orazov, N.; Nylén, U.; Benger, R.; Beck, H.-P. Comparison of Model-Based and Sensor-Based Detection of Thermal Runaway in Li-Ion Battery Modules for Automotive Application. Batteries 2022, 8, 34. [Google Scholar] [CrossRef]

- Ruiz, V.; Pfrang, A.; Kriston, A.; Omar, N.; Van den Bossche, P.; Boon-Brett, L. A review of international abuse testing standards and regulations for lithium ion batteries in electric and hybrid electric vehicles. Renew. Sustain. Energy Rev. 2018, 81, 1427–1452. [Google Scholar] [CrossRef]

- Ahn, Y.J.; Lee, Y.-S.; Cho, J.-R. Multi-Layered Numerical Model Development of a Standard Cylindrical Lithium-Ion Battery for the Impact Test. Energies 2022, 15, 2509. [Google Scholar] [CrossRef]

- Muresanu, A.D.; Dudescu, M.C. Numerical and Experimental Evaluation of a Battery Cell under Impact Load. Batteries 2022, 8, 48. [Google Scholar] [CrossRef]

- Shui, L.; Chen, F.; Garg, A.; Peng, X.; Bao, N.; Zhang, J. Design optimization of battery pack enclosure for electric vehicle. Struct. Multidiscip. Optim. 2018, 58, 331–347. [Google Scholar] [CrossRef]

- An, Y.; Wang, X.; Dou, N.; Wu, Z. Strength analysis of the lightweight-designed power battery boxes in electric vehicle. E3S Web Conf. 2022, 341, 01025. [Google Scholar] [CrossRef]

- Ruan, G.; Yu, C.; Hu, X.; Hua, J. Simulation and optimization of a new energy vehicle power battery pack structure. J. Theor. Appl. Mech. 2021, 59, 565–578. [Google Scholar] [CrossRef]

- Qiao, W.; Yu, L.; Zhang, Z.; Pan, T. Study on the Battery Safety in Frontal Collision of Electric Vehicle. J. Phys.: Conf. Ser. 2021, 2137, 012008. [Google Scholar] [CrossRef]

- Pan, Y.; Xiong, Y.; Wu, L.; Diao, K.; Guoa, W. Lightwieght design of an automotive battery-pack enclosure via advanced high-strength steels and size optimization. Int. J. Automot. Technol. 2021, 22, 1279–1290. [Google Scholar] [CrossRef]

- Dong, S.; Lv, J.; Wang, K.; Li, W.; Tian, Y. Design and Optimization for a New Locomotive Power Battery Box. Sustainability 2022, 14, 12810. [Google Scholar] [CrossRef]

- Biharta, M.A.S.; Santosa, S.P.; Widagdo, D.; Gunawan, L. Design and Optimization of Lightweight Lithium-Ion Battery Protector with 3D Auxetic Meta Structures. World Electr. Veh. J. 2022, 13, 118. [Google Scholar] [CrossRef]

- Pratama, L.K.; Santosa, S.P.; Dirgantara, T.; Widagdo, D. Design and Numerical Analysis of Electric Vehicle Li-Ion Battery Protections Using Lattice Structure Undergoing Ground Impact. World Electr. Veh. J. 2022, 13, 10. [Google Scholar] [CrossRef]

- European Commission. Green Deal: Sustainable Batteries for a Circular and Climate Neutral Economy. 2020. Available online: https://digital-strategy.ec.europa.eu/fr/node/475/printable/pdf (accessed on 15 September 2022).

- Kehl, D.; Jennert, T.; Lienesch, F.; Kurrat, M. Electrical Characterization of Li-Ion Battery Modules for Second-Life Applications. Batteries 2021, 7, 32. [Google Scholar] [CrossRef]

- Szabo, I.; Sirca, A.A.; Scurtu, L.; Kocsis, L.; Hanches, I.N.; Mariasiu, F. Comparative study of Li-ion 18650 cylindrical cell under pinch indentation. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1256, 012022. [Google Scholar] [CrossRef]

- Weber, J. Automotive Development Process; Springer: Berlin, Germany, 2009; pp. 142–143. [Google Scholar]

| Battery’s Component | Material [-] | Density [kg/m3] | Elasticity Modulus [GPa] | Poisson’s Coefficient [-] | Single-Layer Thickness [μm] |

|---|---|---|---|---|---|

| Cathode | LiFePO4 | 4000 | 100 | 0.35 | 90 |

| Anode | Graphite | 2300 | 110 | 0.23 | 130 |

| Positive collector | Aluminium | 2700 | 180 | 0.35 | 20 |

| Negative collector | Copper | 7980 | 210 | 0.34 | 10 |

| Separator | Polyethylene (PE) | 1500 | 20 | 0.3 | 10 |

| Case | Steel | 7850 | 210 | 0.3 | 560 |

| Range of Cells Deformation [mm] | Base Battery Module Case | Optimized Battery Module Case | Difference (Base vs. Optimized) [%] | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Impact Velocity [m/s] | ||||||||||

| 10 | 20 | 30 | 10 | 20 | 30 | 10 | 20 | 30 | ||

| Deformed cells (pcs) | <0.5 | 5 | 8 | 12 | 2 | 4 | 8 | −60.0 | −50.0 | −33.3 |

| 0.5–1.0 | 6 | 9 | 19 | 3 | 5 | 13 | −50.0 | −44.4 | −31.6 | |

| 1.0–1.5 | 8 | 18 | 22 | 4 | 11 | 16 | −50.0 | −38.9 | −27.3 | |

| 1.5–2.0 | 9 | 25 | 29 | 5 | 16 | 22 | −44.4 | −36.0 | −24.1 | |

| 2.0–2.5 | 13 | 35 | 49 | 8 | 24 | 38 | −38.5 | −31.4 | −22.4 | |

| >2.5 | 18 | 122 | 265 | 13 | 91 | 221 | −27.8 | −25.4 | −16.6 | |

| Total affected cells | 59 | 217 | 396 | 35 | 151 | 318 | −40.7 * | −30.4 * | −19.7 * | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szabo, I.; Scurtu, L.I.; Raboca, H.; Mariasiu, F. Topographical Optimization of a Battery Module Case That Equips an Electric Vehicle. Batteries 2023, 9, 77. https://doi.org/10.3390/batteries9020077

Szabo I, Scurtu LI, Raboca H, Mariasiu F. Topographical Optimization of a Battery Module Case That Equips an Electric Vehicle. Batteries. 2023; 9(2):77. https://doi.org/10.3390/batteries9020077

Chicago/Turabian StyleSzabo, Ioan, Liviu I. Scurtu, Horia Raboca, and Florin Mariasiu. 2023. "Topographical Optimization of a Battery Module Case That Equips an Electric Vehicle" Batteries 9, no. 2: 77. https://doi.org/10.3390/batteries9020077

APA StyleSzabo, I., Scurtu, L. I., Raboca, H., & Mariasiu, F. (2023). Topographical Optimization of a Battery Module Case That Equips an Electric Vehicle. Batteries, 9(2), 77. https://doi.org/10.3390/batteries9020077