Echelon Utilization of Retired Power Lithium-Ion Batteries: Challenges and Prospects

Abstract

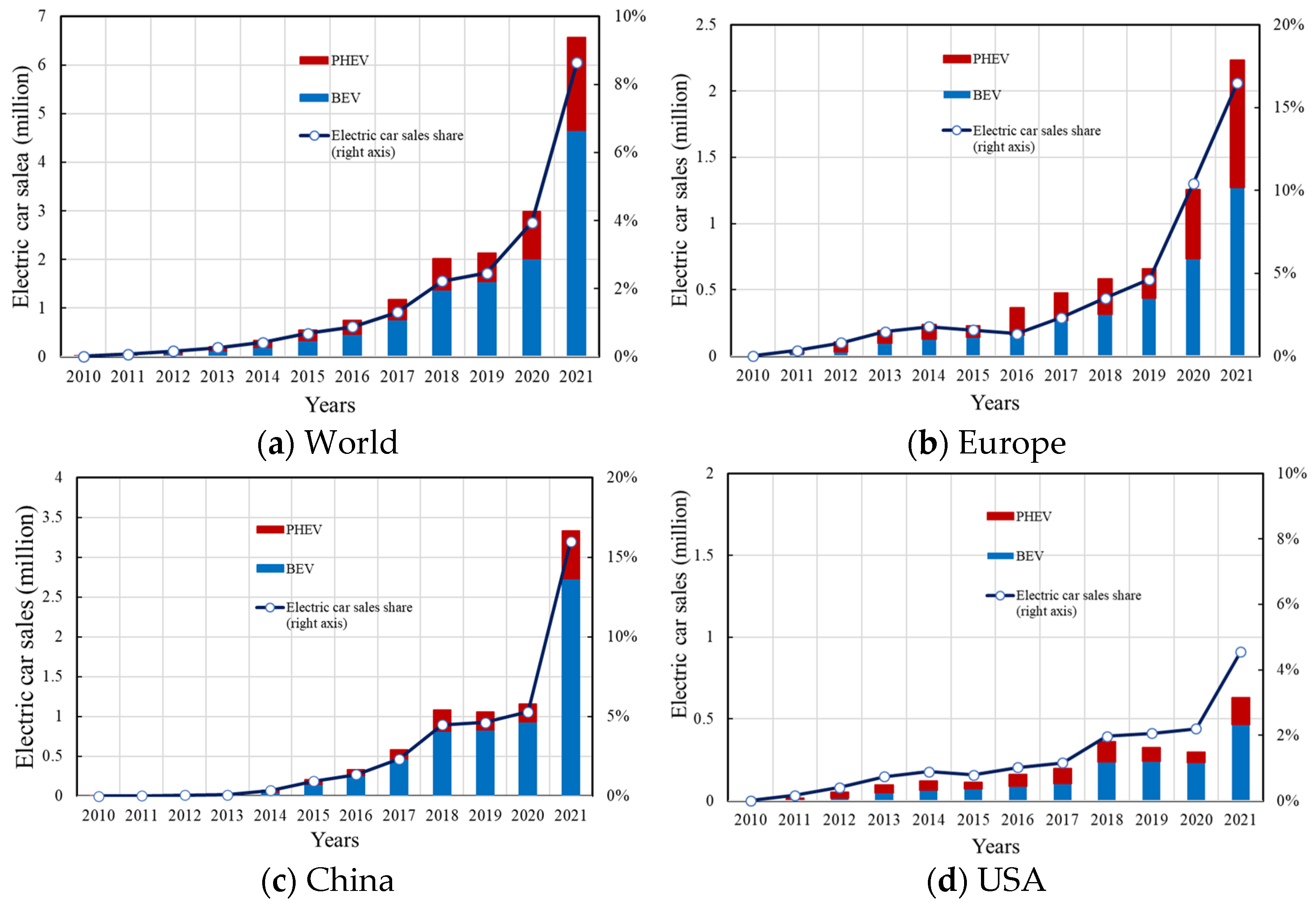

:1. Introduction

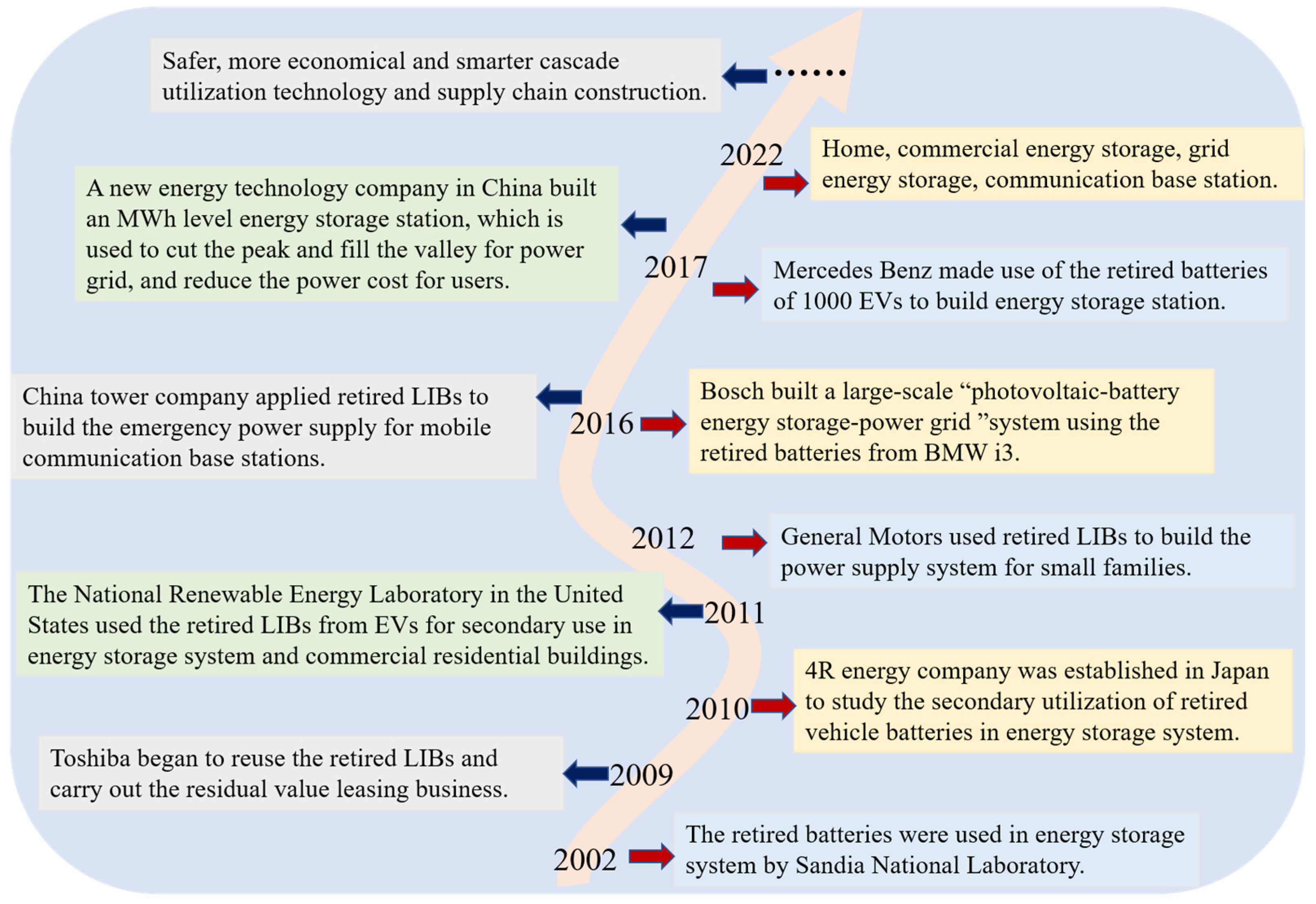

2. Treatment of Retired Power LIBs

2.1. Battery Materials Recycling

2.2. Echelon Utilization

3. Status of Echelon Utilization of Retired Power LIBs

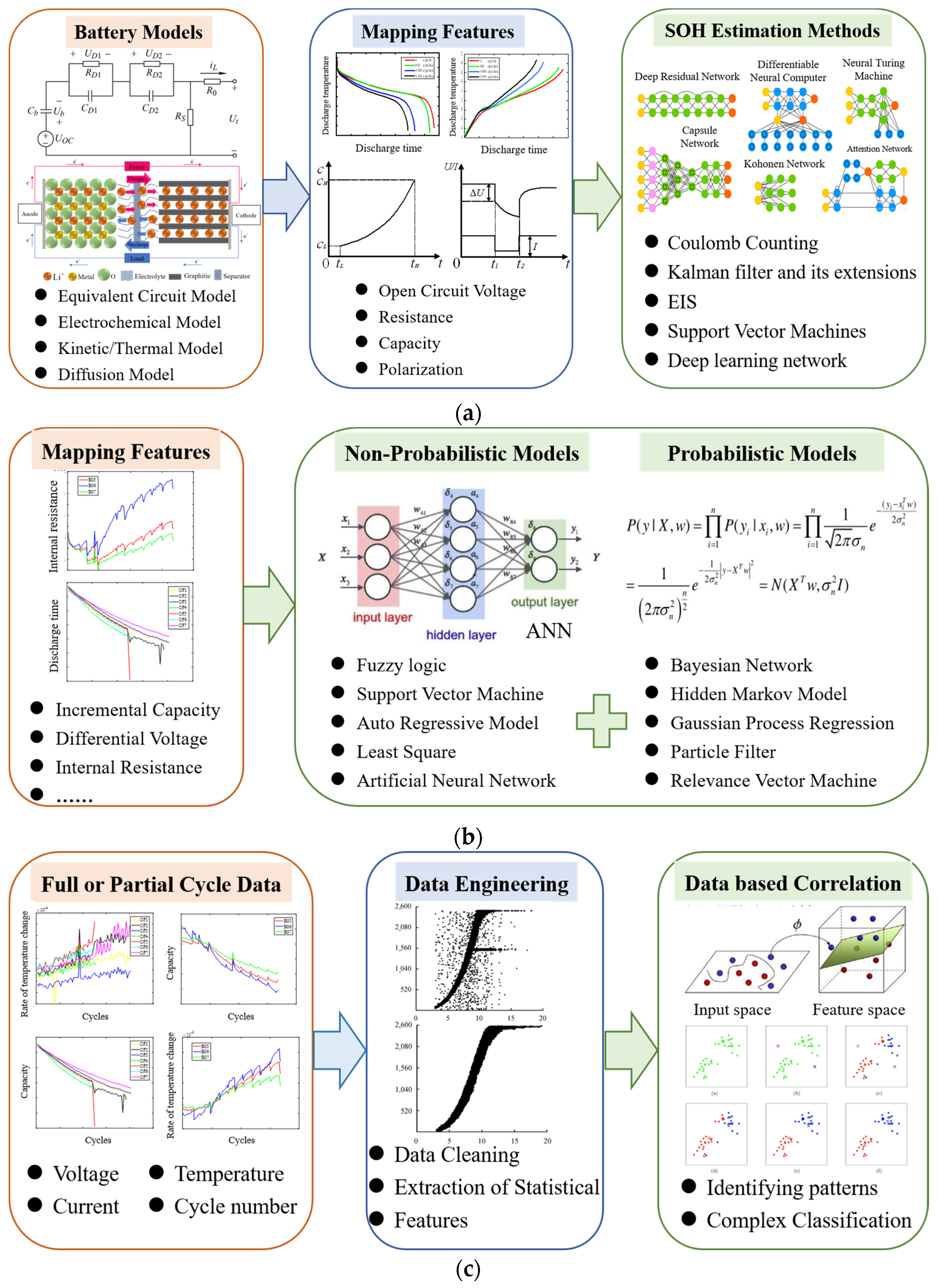

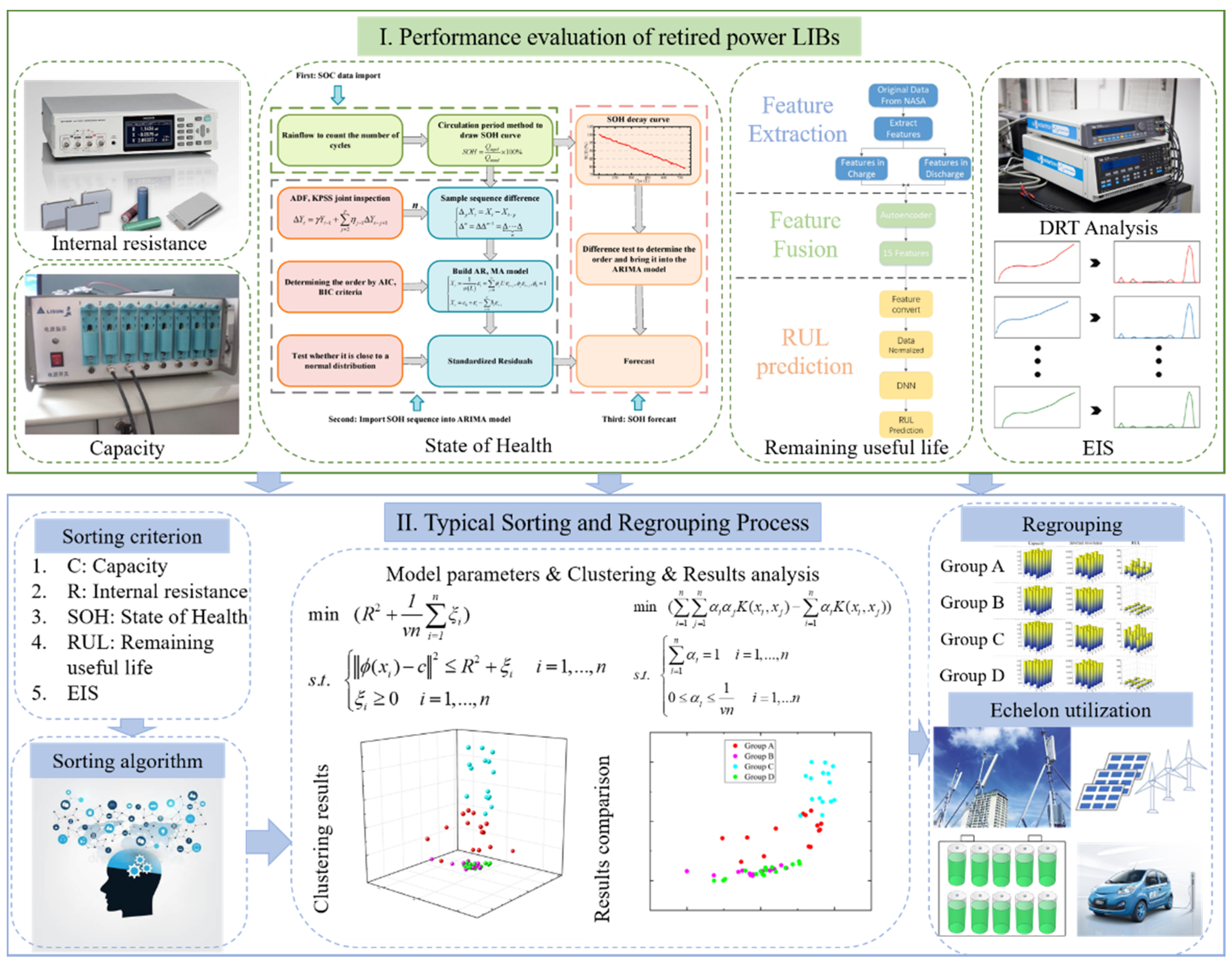

3.1. Performance Evaluation of Retired Power LIBs

3.1.1. SOH Estimation

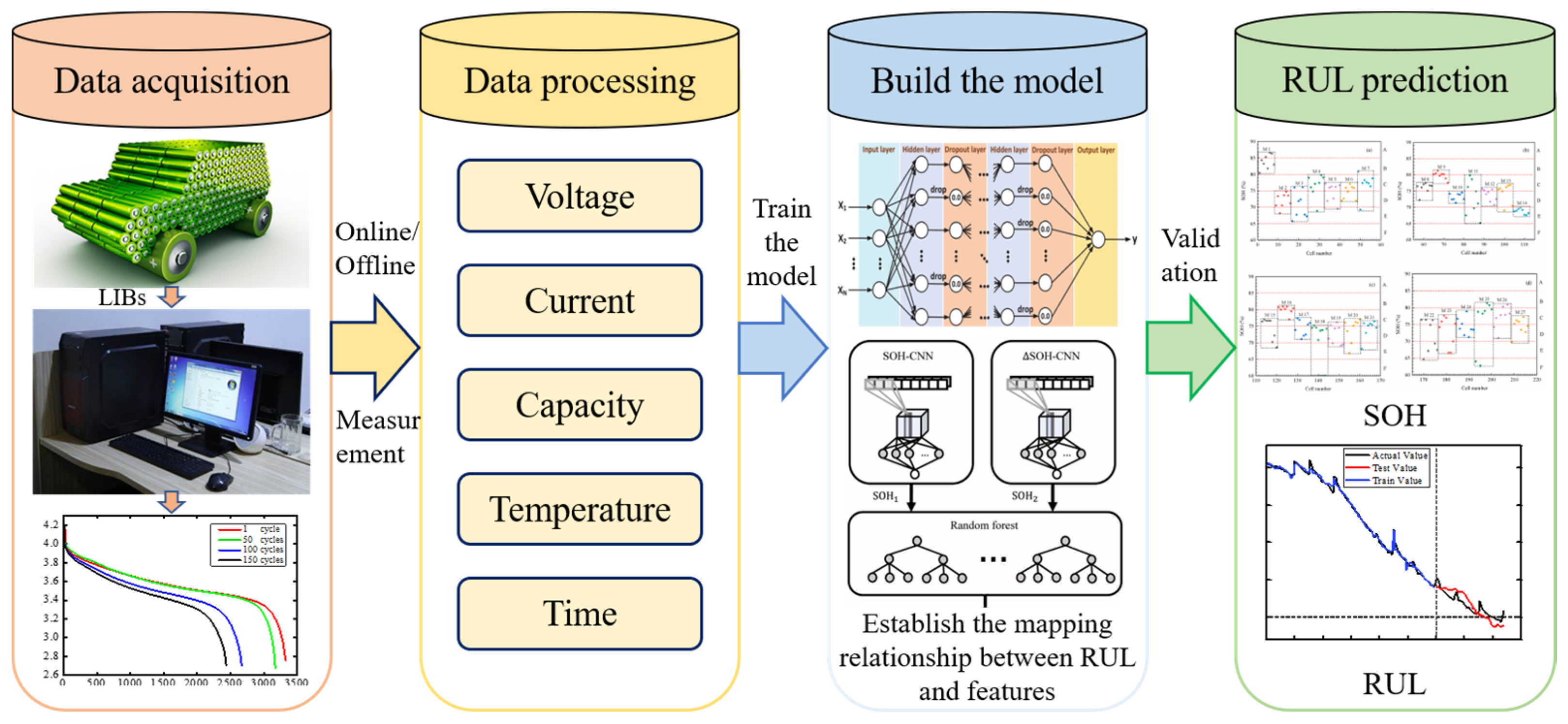

3.1.2. RUL Prediction

3.1.3. EIS

3.2. Sorting and Regrouping Methods of Retired Power LIBs

4. Echelon Utilization Scenarios and Economy of Retired Power LIBs

4.1. Echelon Utilization Scenarios of Retired Power LIBs

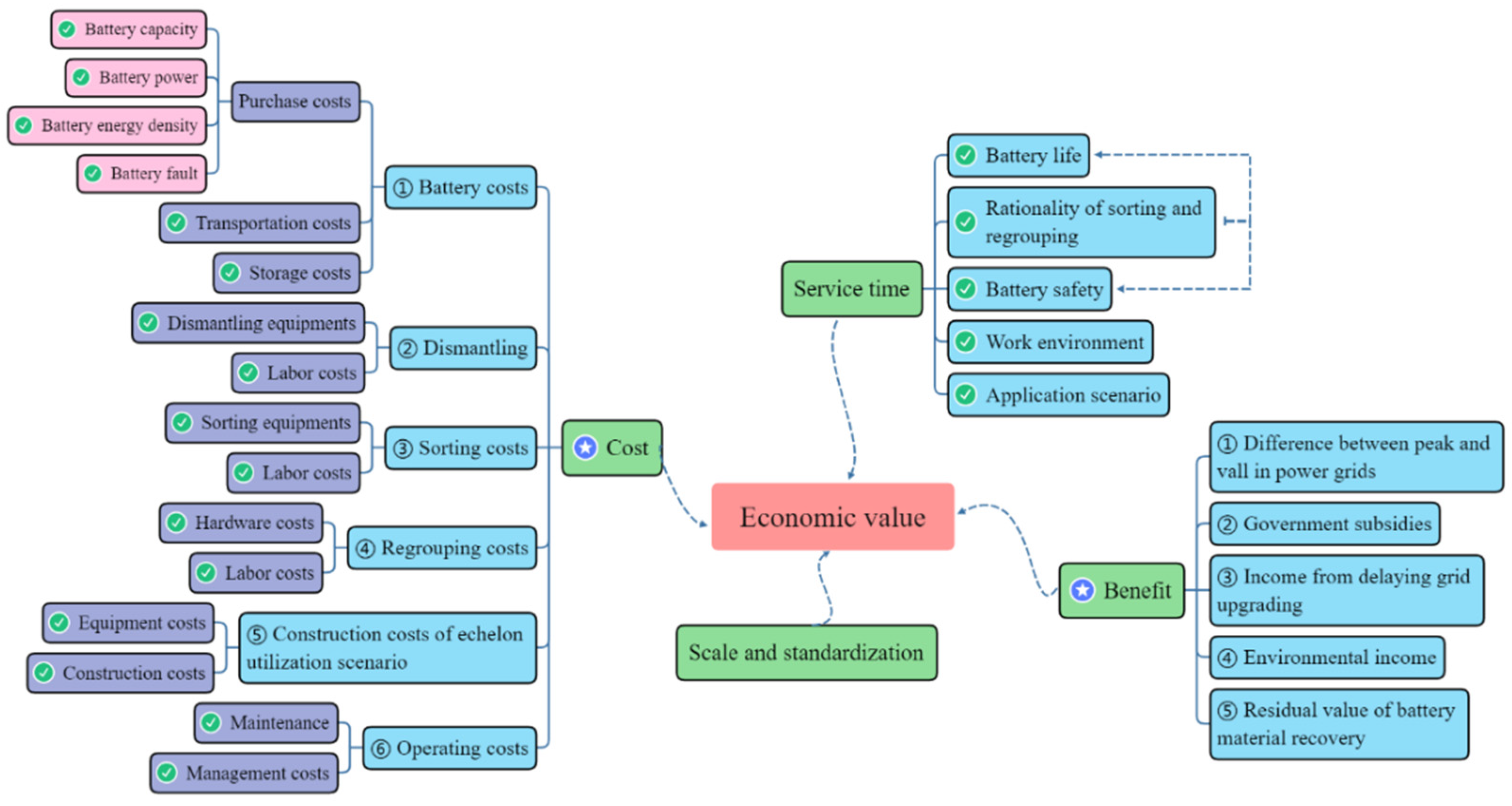

4.2. Echelon Utilization Economy of Retired Power LIBs

5. Technical Challenges of Echelon Utilization

5.1. Safety Issues

5.2. Performance Evaluation Methods

5.3. Supply Chain Construction

5.4. Regulation and Certification

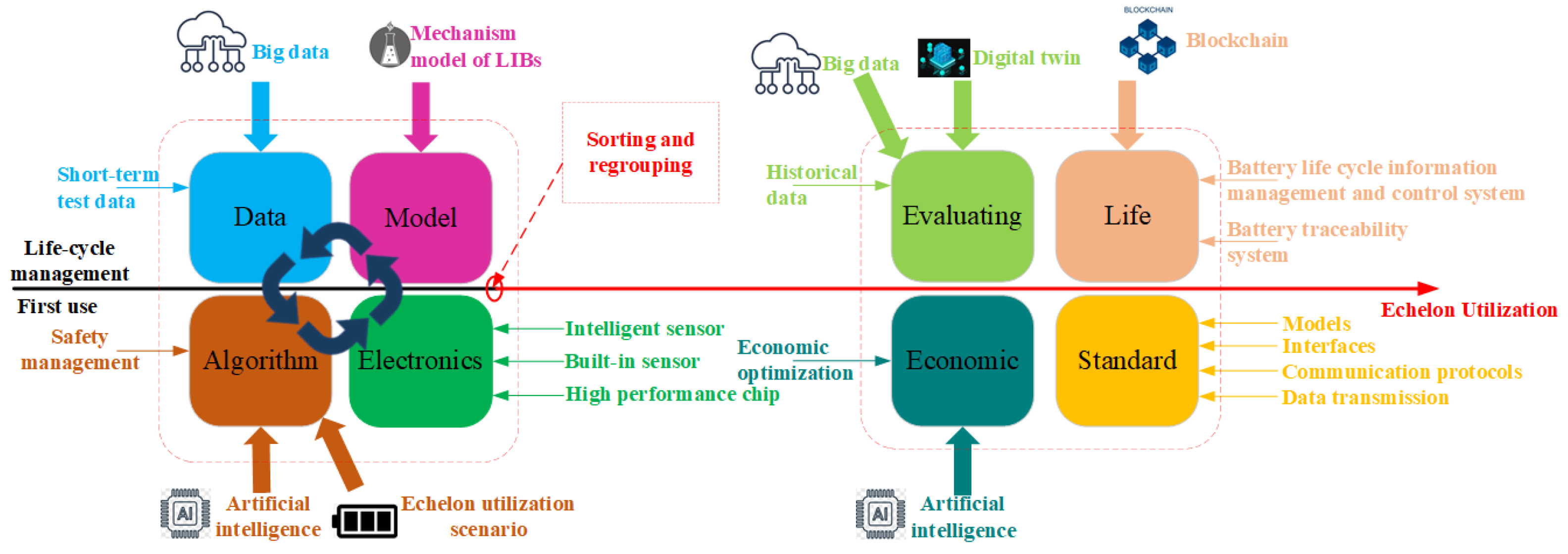

6. Future Research Outlooks

- (1)

- Full life cycle battery management system for LIBs based on the digital twin and big data. The collection of historical data through communication technology during the service life of LIBs can provide resources for evaluating retired power LIBs. For retired power LIBs, key data that can be used to evaluate or predict LIBs can be mined from massive historical data using big data and machine learning. A key technical problem is how to quickly mine variable state quantities from massive and diverse data and use prediction functions to build accurate sorting models.

- (2)

- Scenario planning method for echelon utilization of retired power LIBs. Combining the characteristics of the echelon utilization requirements of different scenarios and the evolution law of the performance state of retired power LIBs, a definition mechanism of retired power LIBs and application scenarios is constructed through fuzzy theory, and then the scenarios are pre-allocated.

- (3)

- Economic research on echelon utilization of retired power LIBs. Considering the cost and benefit differences of retired power LIBs in different application scenarios, a high-fidelity model of the cost and benefits of retired power LIBs in different application scenarios is established. Based on the artificial intelligence algorithm, the economic optimization model of the echelon utilization of retired power LIBs is optimized.

- (4)

- The battery life cycle information management and control system based on blockchain technology creates a true, transparent, comprehensive battery traceability system. Solve the problems in constructing battery recycling channels, constructing the whole life cycle recycling evaluation system, and establishing the service system. Combining the characteristics of decentralization and information traceability of blockchain technology. A recycling system for retired power LIBs based on blockchain technology constructed from the aspects of the recycling system framework, recycling operation process, and implementation methods.

- (5)

- To promote the recovery and reuse of retired power LIBs, the production and manufacture of LIBs should be facilitated. LIB models, interfaces, communication protocols, data transmission, etc., should be standardized to facilitate the echelon utilization of large-scale retired power LIBs. An important trend in the future is that the design, production, and manufacturing of LIBs will also become part of battery life cycle management.

7. Conclusions

- (1)

- In many scenarios, echelon utilization is more attractive for both the government and investors than direct recycling of materials in retired power LIBs. The echelon utilization of retired power LIBs still faces many difficulties and has been in a state of difficulty in implementation and control. The government should introduce more policies to encourage echelon utilization, and more importantly, it is necessary to break through the cardinal technology of echelon utilization of retired power LIBs.

- (2)

- The purpose of evaluating the performance of retired power LIBs is to judge whether they have the value of echelon utilization and to apply them to different echelon utilization scenarios according to their performance. Commonly used methods are mainly model-based, data-driven, and data-model hybrid. With the development of big data and artificial intelligence, data-based methods are being widely used.

- (3)

- The echelon utilization scenarios of retired power LIBs are also diverse, and this study summarizes them into static and dynamic application scenarios. The cost and economy of echelon utilization are related to whether it can be applied in large-scale industrialization. The economic analysis of the echelon utilization of large-scale retired power LIBs needs to be carried out from multiple dimensions and aspects, and the current research is rarely involved.

- (4)

- The main technical challenges of echelon utilization include safety issues, performance evaluation methods, economic feasibility, supply chain construction, and regulation and certification. Breaking through these key technical challenges can promote the commercialization of echelon utilization.

- (5)

- In the foreseeable future, the development direction of echelon utilization includes: (i) A complete life cycle battery management system for LIBs based on digital twin and big data. (ii) Scenario planning method for echelon utilization. (iii) Economic research on echelon utilization. (iv) A battery life cycle information management and control system based on blockchain technology. (v) Standardization of the models, interfaces, communication protocols, data transmission, etc., of LIBs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fan, E.; Li, L.; Wang, Z.; Lin, J.; Huang, Y.; Yao, Y.; Chen, R.; Wu, F. Sustainable Recycling Technology for Li-Ion Batteries and Beyond: Challenges and Future Prospects. Chem. Rev. 2020, 120, 7020–7063. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Xiao, M.; Peng, X.; Garg, A.; Gao, L. A surrogates thermal modeling and parametric optimization of battery pack with air cooling for EVs. Appl. Therm. Eng. 2019, 147, 90–100. [Google Scholar] [CrossRef]

- Chen, X.; Shuai, C.; Wu, Y.; Zhang, Y. Analysis on the carbon emission peaks of China’s industrial, building, transport, and agricultural sectors. Sci. Total Environ. 2020, 709, 135768. [Google Scholar] [CrossRef]

- Li, Y.; Li, C.; Garg, A.; Gao, L.; Li, W. Heat dissipation analysis and multi-objective optimization of a permanent magnet synchronous motor using surrogate assisted method. Case Stud. Therm. Eng. 2021, 27, 101203. [Google Scholar] [CrossRef]

- International Energy Agency. Global EV Outlook 2022. Available online: www.iea.org (accessed on 12 August 2022).

- Li, W.; Peng, X.; Xiao, M.; Garg, A.; Gao, L. Multi-objective design optimization for mini-channel cooling battery thermal management system in an electric vehicle. Int. J. Energy Res. 2019, 43, 3668–3680. [Google Scholar] [CrossRef]

- Huang, B.; Pan, Z.; Su, X.; An, L. Recycling of lithium-ion batteries: Recent advances and perspectives. J. Power Sources 2018, 399, 274–286. [Google Scholar] [CrossRef]

- QYRESEARCH. 2019–2025 Global and China Automotive Repair and Maintenance Services Market Status and Forecast Report. Available online: https://www.qyresearch.com/index/detail/1294434/2019-2025-global-and-china-automotive-repair-and-maintenance-services-market-status-and-forecast-report (accessed on 12 August 2022).

- Yu, K.; Gong, Y. Exploration on Ecological Restoration Model for the Improvement of Ecosystem Services of Yellow River Floodplains -A Case Study of Zhengzhou Yellow River Floodplain Park Planning and Design. Landsc. Archit. Front. 2021, 9, 86–97. [Google Scholar] [CrossRef]

- Zhang, X.; Li, L.; Fan, E.; Xue, Q.; Bian, Y.; Wu, F.; Chen, R. Toward sustainable and systematic recycling of spent rechargeable batteries. Chem. Soc. Rev. 2018, 47, 7239–7302. [Google Scholar] [CrossRef]

- Jo, C.-H.; Myung, S.-T. Efficient recycling of valuable resources from discarded lithium-ion batteries. J. Power Sources 2019, 426, 259–265. [Google Scholar] [CrossRef]

- Lv, W.; Wang, Z.; Cao, H.; Sun, Y.; Zhang, Y.; Sun, Z. A Critical Review and Analysis on the Recycling of Spent Lithium-Ion Batteries. Acs Sustain. Chem. Eng. 2018, 6, 1504–1521. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Guarino, F.; Longo, S.; Mistretta, M.; Cellura, M. Reuse of electric vehicle batteries in buildings: An integrated load match analysis and life cycle assessment approach. Energy Build. 2019, 186, 339–354. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.; Yang, W. Optimal design of electric vehicle battery recycling network—From the perspective of electric vehicle manufacturers. Appl. Energy 2020, 275, 115328. [Google Scholar] [CrossRef]

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S.; et al. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 75–86. [Google Scholar] [CrossRef]

- Sathre, R.; Scown, C.D.; Kavvada, O.; Hendrickson, T.P. Energy and climate effects of second-life use of electric vehicle batteries in California through 2050. J. Power Sources 2015, 288, 82–91. [Google Scholar] [CrossRef]

- Wakihara, M. Recent developments in lithium ion batteries. Mater. Sci. Eng. R Rep. 2001, 33, 109–134. [Google Scholar] [CrossRef]

- Zhang, T.; He, Y.; Wang, F.; Ge, L.; Zhu, X.; Li, H. Chemical and process mineralogical characterizations of spent lithium-ion batteries: An approach by multi-analytical techniques. Waste Manag. 2014, 34, 1051–1058. [Google Scholar] [CrossRef] [PubMed]

- Gaines, L.; Richa, K.; Spangenberger, J. Key issues for Li-ion battery recycling. Mrs Energy Sustain. 2018, 5, 12. [Google Scholar] [CrossRef]

- Arshad, F.; Li, L.; Amin, K.; Fan, E.; Manurkar, N.; Ahmad, A.; Yang, J.; Wu, F.; Chen, R. A comprehensive review of the advancement in recycling the anode and electrolyte from spent lithium ion batteries. ACS Sustain. Chem. Eng. 2020, 8, 13527–13554. [Google Scholar] [CrossRef]

- Song, Q.; Li, A.; Shi, L.; Qian, C.; Feric, T.G.; Fu, Y.; Zhang, H.; Li, Z.; Wang, P.; Li, Z.; et al. Thermally stable, nano-porous and eco-friendly sodium alginate/attapulgite separator for lithium-ion batteries. Energy Storage Mater. 2019, 22, 48–56. [Google Scholar] [CrossRef]

- Ordoñez, J.; Gago, E.J.; Girard, A. Processes and technologies for the recycling and recovery of spent lithium-ion batteries. Renew. Sustain. Energy Rev. 2016, 60, 195–205. [Google Scholar] [CrossRef]

- Wang, X.; Gaustad, G.; Babbitt, C.W. Targeting high value metals in lithium-ion battery recycling via shredding and size-based separation. Waste Manag. 2016, 51, 204–213. [Google Scholar] [CrossRef] [PubMed]

- Yun, L.; Linh, D.; Shui, L.; Peng, X.; Garg, A.; Le, M.L.P.; Asghari, S.; Sandoval, J. Metallurgical and mechanical methods for recycling of lithium-ion battery pack for electric vehicles. Resour. Conserv. Recycl. 2018, 136, 198–208. [Google Scholar] [CrossRef]

- Winslow, K.M.; Laux, S.J.; Townsend, T.G. A review on the growing concern and potential management strategies of waste lithium-ion batteries. Resour. Conserv. Recycl. 2018, 129, 263–277. [Google Scholar] [CrossRef]

- Diaz, L.A.; Strauss, M.L.; Adhikari, B.; Klaehn, J.R.; McNally, J.S.; Lister, T. Electrochemical-assisted leaching of active materials from lithium ion batteries. Resour. Conserv. Recycl. 2020, 161, 104900. [Google Scholar] [CrossRef]

- Siqi, Z.; Guangming, L.; Wenzhi, H.; Juwen, H.; Haochen, Z. Recovery methods and regulation status of waste lithium-ion batteries in China: A mini review. Waste Manag. Res. 2019, 37, 1142–1152. [Google Scholar] [CrossRef]

- Ferreira, D.A.; Prados, L.M.Z.; Majuste, D.; Mansur, M.B. Hydrometallurgical separation of aluminium, cobalt, copper and lithium from spent Li-ion batteries. J. Power Sources 2009, 187, 238–246. [Google Scholar] [CrossRef]

- Chen, M.; Ma, X.; Chen, B.; Arsenault, R.; Karlson, P.; Simon, N.; Wang, Y. Recycling End-of-Life Electric Vehicle Lithium-Ion Batteries. Joule 2019, 3, 2622–2646. [Google Scholar] [CrossRef]

- Georgi-Maschler, T.; Friedrich, B.; Weyhe, R.; Heegn, H.; Rutz, M. Development of a recycling process for Li-ion batteries. J. Power Sources 2012, 207, 173–182. [Google Scholar] [CrossRef]

- Chagnes, A.; Pospiech, B. A brief review on hydrometallurgical technologies for recycling spent lithium-ion batteries. J. Chem. Technol. Biotechnol. 2013, 88, 1191–1199. [Google Scholar] [CrossRef]

- Pollmann, K.; Raff, J.; Merroun, M.; Fahmy, K.; Selenska-Pobell, S. Metal binding by bacteria from uranium mining waste piles and its technological applications. Biotechnol. Adv. 2006, 24, 58–68. [Google Scholar] [CrossRef]

- Mishra, D.; Kim, D.-J.; Ralph, D.; Ahn, J.-G.; Rhee, Y.-H. Bioleaching of metals from spent lithium ion secondary batteries using Acidithiobacillus ferrooxidans. Waste Manag. 2008, 28, 333–338. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Chen, G.; Chen, Z. Effective regeneration of LiCoO2 from spent lithium-ion batteries: A direct approach towards high-performance active particles. Green Chem. 2018, 20, 851–862. [Google Scholar] [CrossRef]

- Shi, Y.; Chen, G.; Liu, F.; Yue, X.; Chen, Z. Resolving the Compositional and Structural Defects of Degraded LiNixCoyMnzO2 Particles to Directly Regenerate High-Performance Lithium-Ion Battery Cathodes. ACS Energy Lett. 2018, 3, 1683–1692. [Google Scholar] [CrossRef]

- Accurec Battery Recycling Division Home Page. Available online: http://accurec.de/nimh (accessed on 12 August 2022).

- Recupyl Battery Recycling Division Home Page. Available online: www.recupyl.com (accessed on 12 August 2022).

- Umicore Recycling Division Home Page. Available online: https://www.umicore.com/en/industries/recycling (accessed on 12 August 2022).

- Neubauer, J.; Smith, K.; Wood, E.; Pesaran, A. Identifying and Overcoming Critical Barriers to Widespread Second Use of PEV Batteries; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2015. [CrossRef]

- Li, C.; Wang, N.; Li, W.; Yi, Q.; Qi, D. A battery centralized scheduling strategy for battery swapping of electric vehicles. J. Energy Storage 2022, 51, 104327. [Google Scholar] [CrossRef]

- Martinez-Laserna, E.; Gandiaga, I.; Sarasketa-Zabala, E.; Badeda, J.; Stroe, D.I.; Swierczynski, M.; Goikoetxea, A. Battery second life: Hype, hope or reality? A critical review of the state of the art. Renew. Sustain. Energy Rev. 2018, 93, 701–718. [Google Scholar] [CrossRef]

- Neubauer, J.; Pesaran, A. The ability of battery second use strategies to impact plug-in electric vehicle prices and serve utility energy storage applications. J. Power Sources 2011, 196, 10351–10358. [Google Scholar] [CrossRef]

- Viswanathan, V.V.; Kintner-Meyer, M. Second use of transportation batteries: Maximizing the value of batteries for transportation and grid services. IEEE Trans. Veh. Technol. 2011, 60, 2963–2970. [Google Scholar] [CrossRef]

- Song, Z.; Feng, S.; Zhang, L.; Hu, Z.; Hu, X.; Yao, R. Economy analysis of second-life battery in wind power systems considering battery degradation in dynamic processes: Real case scenarios. Appl. Energy 2019, 251, 113411. [Google Scholar] [CrossRef]

- Chen, X.; Tang, J.; Li, W.; Xie, L. Operational reliability and economy evaluation of reusing retired batteries in composite power systems. Int. J. Energy Res. 2020, 44, 3657–3673. [Google Scholar] [CrossRef]

- Wang, N.; Li, C.; Li, W.; Chen, X.; Li, Y.; Qi, D. Heat dissipation optimization for a serpentine liquid cooling battery thermal management system: An application of surrogate assisted approach. J. Energy Storage 2021, 40, 102771. [Google Scholar] [CrossRef]

- Lai, X.; Huang, Y.; Gu, H.; Deng, C.; Han, X.; Feng, X.; Zheng, Y. Turning waste into wealth: A systematic review on echelon utilization and material recycling of retired lithium-ion batteries. Energy Storage Mater. 2021, 40, 96–123. [Google Scholar] [CrossRef]

- Li, Y.; Garg, A.; Shevya, S.; Li, W.; Gao, L.; Lee Lam, J.S. A Hybrid Convolutional Neural Network-Long Short Term Memory for Discharge Capacity Estimation of Lithium-Ion Batteries. J. Electrochem. Energy Convers. Storage 2021, 19, 030901. [Google Scholar] [CrossRef]

- Qi, D.; Li, C.; Wang, N.; Huang, M.; Hu, Z.; Li, W. A Novel Approach Investigating the Remaining Useful Life Predication of Retired Power Lithium-Ion Batteries Using Genetic Programming Method. J. Electrochem. Energy Convers. Storage 2021, 18, 030904. [Google Scholar] [CrossRef]

- Yang, J.; Gu, F.; Guo, J. Environmental feasibility of secondary use of electric vehicle lithium-ion batteries in communication base stations. Resour. Conserv. Recycl. 2020, 156, 104713. [Google Scholar] [CrossRef]

- Sabet, P.S.; Stahl, G.; Sauer, D.U. Non-invasive investigation of predominant processes in the impedance spectra of high energy lithium-ion batteries with Nickel-Cobalt-Aluminum cathodes. J. Power Sources 2018, 406, 185–193. [Google Scholar] [CrossRef]

- Weng, C.; Cui, Y.; Sun, J.; Peng, H. On-board state of health monitoring of lithium-ion batteries using incremental capacity analysis with support vector regression. J. Power Sources 2013, 235, 36–44. [Google Scholar] [CrossRef]

- Basia, A.; Simeu-Abazi, Z.; Gascard, E.; Zwolinski, P. Review on State of Health estimation methodologies for lithium-ion batteries in the context of circular economy. Cirp J. Manuf. Sci. Technol. 2021, 32, 517–528. [Google Scholar] [CrossRef]

- Wang, Q.-K.; He, Y.-J.; Shen, J.-N.; Ma, Z.-F.; Zhong, G.-B. A unified modeling framework for lithium-ion batteries: An artificial neural network based thermal coupled equivalent circuit model approach. Energy 2017, 138, 118–132. [Google Scholar] [CrossRef]

- Hu, C.; Jain, G.; Zhang, P.; Schmidt, C.; Gomadam, P.; Gorka, T. Data-driven method based on particle swarm optimization and k-nearest neighbor regression for estimating capacity of lithium-ion battery. Appl. Energy 2014, 129, 49–55. [Google Scholar] [CrossRef]

- Patil, M.A.; Tagade, P.; Hariharan, K.S.; Kolake, S.M.; Song, T.; Yeo, T.; Doo, S. A novel multistage Support Vector Machine based approach for Li ion battery remaining useful life estimation. Appl. Energy 2015, 159, 285–297. [Google Scholar] [CrossRef]

- Ng, S.S.Y.; Xing, Y.; Tsui, K.L. A naive Bayes model for robust remaining useful life prediction of lithium-ion battery. Appl. Energy 2014, 118, 114–123. [Google Scholar] [CrossRef]

- Galeotti, M.; Cinà, L.; Giammanco, C.; Cordiner, S.; Di Carlo, A. Performance analysis and SOH (state of health) evaluation of lithium polymer batteries through electrochemical impedance spectroscopy. Energy 2015, 89, 678–686. [Google Scholar] [CrossRef]

- Song, L.; Zhang, K.; Liang, T.; Han, X.; Zhang, Y. Intelligent state of health estimation for lithium-ion battery pack based on big data analysis. J. Energy Storage 2020, 32, 101836. [Google Scholar] [CrossRef]

- Jia, J.; Liang, J.; Shi, Y.; Wen, J.; Pang, X.; Zeng, J. SOH and RUL Prediction of Lithium-Ion Batteries Based on Gaussian Process Regression with Indirect Health Indicators. Energies 2020, 13, 375. [Google Scholar] [CrossRef]

- Kaur, K.; Garg, A.; Cui, X.; Singh, S.; Panigrahi, B.K. Deep learning networks for capacity estimation for monitoring SOH of Li-ion batteries for electric vehicles. Int. J. Energy Res. 2021, 45, 3113–3128. [Google Scholar] [CrossRef]

- Eddahech, A.; Briat, O.; Bertrand, N.; Delétage, J.-Y.; Vinassa, J.-M. Behavior and state-of-health monitoring of Li-ion batteries using impedance spectroscopy and recurrent neural networks. Int. J. Electr. Power Energy Syst. 2012, 42, 487–494. [Google Scholar] [CrossRef]

- Hu, X.; Xu, L.; Lin, X.; Pecht, M. Battery Lifetime Prognostics. Joule 2020, 4, 310–346. [Google Scholar] [CrossRef]

- Wang, N.; Li, C.; Li, W.; Huang, M.; Qi, D. Effect analysis on performance enhancement of a novel air cooling battery thermal management system with spoilers. Appl. Therm. Eng. 2021, 192, 116932. [Google Scholar] [CrossRef]

- Liao, L.; Köttig, F. Review of Hybrid Prognostics Approaches for Remaining Useful Life Prediction of Engineered Systems, and an Application to Battery Life Prediction. IEEE Trans. Reliab. 2014, 63, 191–207. [Google Scholar] [CrossRef]

- Pattipati, B.; Sankavaram, C.; Pattipati, K. System Identification and Estimation Framework for Pivotal Automotive Battery Management System Characteristics. IEEE Trans. Syst. Man Cybern. Part C (Appl. Rev.) 2011, 41, 869–884. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, L.; Su, X.; Ma, P. Prognostics of Lithium-Ion Batteries Based on Battery Performance Analysis and Flexible Support Vector Regression. Energies 2014, 7, 6492–6508. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, M.; Chen, Y.; Tao, Y. A novel health indicator for on-line lithium-ion batteries remaining useful life prediction. J. Power Sources 2016, 321, 1–10. [Google Scholar] [CrossRef]

- Richardson, R.R.; Osborne, M.A.; Howey, D.A. Gaussian process regression for forecasting battery state of health. J. Power Sources 2017, 357, 209–219. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, R.; He, H.; Pecht, M.G. Long Short-Term Memory Recurrent Neural Network for Remaining Useful Life Prediction of Lithium-Ion Batteries. IEEE Trans. Veh. Technol. 2018, 67, 5695–5705. [Google Scholar] [CrossRef]

- Liu, D.; Xie, W.; Liao, H.; Peng, Y. An Integrated Probabilistic Approach to Lithium-Ion Battery Remaining Useful Life Estimation. IEEE Trans. Instrum. Meas. 2015, 64, 660–670. [Google Scholar] [CrossRef]

- Pang, X.; Huang, R.; Wen, J.; Shi, Y.; Jia, J.; Zeng, J. A Lithium-ion Battery RUL Prediction Method Considering the Capacity Regeneration Phenomenon. Energies 2019, 12, 2247. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, Z.; Ren, J.; Zhai, Z.; Wang, S.; Chen, X. A transferable lithium-ion battery remaining useful life prediction method from cycle-consistency of degradation trend. J. Power Sources 2022, 521, 230975. [Google Scholar] [CrossRef]

- Mao, L.; Xu, J.; Chen, J.; Zhao, J.; Wu, Y.; Yao, F. A LSTM-STW and GS-LM Fusion Method for Lithium-Ion Battery RUL Prediction Based on EEMD. Energies 2020, 13, 2380. [Google Scholar] [CrossRef]

- Martínez, M.; Teliz, E.; Zinola, C.F.; Díaz, V. EIS study on metal hydride electrodes using a porous model: Fitting methodology and SOC effects. J. Energy Storage 2020, 27, 101067. [Google Scholar] [CrossRef]

- Häcker, J.; Danner, C.; Sievert, B.; Biswas, I.; Zhao-Karger, Z.; Wagner, N.; Friedrich, K.A. Investigation of Magnesium–Sulfur Batteries using Electrochemical Impedance Spectroscopy. Electrochim. Acta 2020, 338, 135787. [Google Scholar] [CrossRef]

- Murbach, M.D.; Hu, V.W.; Schwartz, D.T. Nonlinear electrochemical impedance spectroscopy of lithium-ion batteries: Experimental approach, analysis, and initial findings. J. Electrochem. Soc. 2018, 165, A2758. [Google Scholar] [CrossRef]

- Tröltzsch, U.; Kanoun, O.; Tränkler, H.-R. Characterizing aging effects of lithium ion batteries by impedance spectroscopy. Electrochim. Acta 2006, 51, 1664–1672. [Google Scholar] [CrossRef]

- Schuster, S.F.; Brand, M.J.; Campestrini, C.; Gleissenberger, M.; Jossen, A. Correlation between capacity and impedance of lithium-ion cells during calendar and cycle life. J. Power Sources 2016, 305, 191–199. [Google Scholar] [CrossRef]

- Guo, D.; Yang, G.; Zhao, G.; Yi, M.; Feng, X.; Han, X.; Lu, L.; Ouyang, M. Determination of the Differential Capacity of Lithium-Ion Batteries by the Deconvolution of Electrochemical Impedance Spectra. Energies 2020, 13, 915. [Google Scholar] [CrossRef]

- Mingant, R.; Bernard, J.; Sauvant-Moynot, V. Novel state-of-health diagnostic method for Li-ion battery in service. Appl. Energy 2016, 183, 390–398. [Google Scholar] [CrossRef]

- Oldenburger, M.; Bedürftig, B.; Gruhle, A.; Grimsmann, F.; Richter, E.; Findeisen, R.; Hintennach, A. Investigation of the low frequency Warburg impedance of Li-ion cells by frequency domain measurements. J. Energy Storage 2019, 21, 272–280. [Google Scholar] [CrossRef]

- Wang, Q.K.; He, Y.J.; Shen, J.N.; Hu, X.S.; Ma, Z.F. State of Charge-Dependent Polynomial Equivalent Circuit Modeling for Electrochemical Impedance Spectroscopy of Lithium-Ion Batteries. IEEE Trans. Power Electron. 2018, 33, 8449–8460. [Google Scholar] [CrossRef]

- Wang, L.-F.; Geng, M.-M.; Ding, X.-N.; Fang, C.; Zhang, Y.; Shi, S.-S.; Zheng, Y.; Yang, K.; Zhan, C.; Wang, X.-D. Research progress of the electrochemical impedance technique applied to the high-capacity lithium-ion battery. Int. J. Miner. Metall. Mater. 2021, 28, 538–552. [Google Scholar] [CrossRef]

- Meddings, N.; Heinrich, M.; Overney, F.; Lee, J.-S.; Ruiz, V.; Napolitano, E.; Seitz, S.; Hinds, G.; Raccichini, R.; Gabers, M.; et al. Application of electrochemical impedance spectroscopy to commercial Li-ion cells: A review. J. Power Sources 2020, 480, 228742. [Google Scholar] [CrossRef]

- Li, W.; Chen, S.; Peng, X.; Xiao, M.; Gao, L.; Garg, A.; Bao, N. A Comprehensive Approach for the Clustering of Similar-Performance Cells for the Design of a Lithium-Ion Battery Module for Electric Vehicles. Engineering 2019, 5, 795–802. [Google Scholar] [CrossRef]

- Gong, X.; Xiong, R.; Mi, C.C. Study of the Characteristics of Battery Packs in Electric Vehicles With Parallel-Connected Lithium-Ion Battery Cells. IEEE Trans. Ind. Appl. 2015, 51, 1872–1879. [Google Scholar] [CrossRef]

- Lee, K.; Kum, D. Development of cell selection framework for second-life cells with homogeneous properties. Int. J. Electr. Power Energy Syst. 2019, 105, 429–439. [Google Scholar] [CrossRef]

- Li, C.; Wang, N.; Li, W.; Li, Y.; Zhang, J. Regrouping and Echelon Utilization of Retired Lithium-ion Batteries based on A Novel Support Vector Clustering Approach. IEEE Trans. Transp. Electrif. 2022, 8, 3648–3658. [Google Scholar] [CrossRef]

- Liao, Q.; Mu, M.; Zhao, S.; Zhang, L.; Jiang, T.; Ye, J.; Shen, X.; Zhou, G. Performance assessment and classification of retired lithium ion battery from electric vehicles for energy storage. Int. J. Hydrog. Energy 2017, 42, 18817–18823. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Tan, X. Research on the Classification Method for the Secondary Uses of Retired Lithium-ion Traction Batteries. Energy Procedia 2017, 105, 2843–2849. [Google Scholar] [CrossRef]

- Lai, X.; Qiao, D.; Zheng, Y.; Ouyang, M.; Han, X.; Zhou, L. A rapid screening and regrouping approach based on neural networks for large-scale retired lithium-ion cells in second-use applications. J. Clean. Prod. 2019, 213, 776–791. [Google Scholar] [CrossRef]

- Yan, J.; Yukun, W.; Caiping, Z.; Guangning, S.; Jun, L. Research on group methods of second-use Li-ion batteries based on k-means clustering model. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Lai, X.; Deng, C.; Li, J.; Zhu, Z.; Han, X.; Zheng, Y. Rapid Sorting and Regrouping of Retired Lithium-Ion Battery Modules for Echelon Utilization Based on Partial Charging Curves. IEEE Trans. Veh. Technol. 2021, 70, 1246–1254. [Google Scholar] [CrossRef]

- Zhou, Z.; Duan, B.; Kang, Y.; Shang, Y.; Cui, N.; Chang, L.; Zhang, C. An efficient screening method for retired lithium-ion batteries based on support vector machine. J. Clean. Prod. 2020, 267, 121882. [Google Scholar] [CrossRef]

- Garg, A.; Yun, L.; Gao, L.; Putungan, D.B. Development of recycling strategy for large stacked systems: Experimental and machine learning approach to form reuse battery packs for secondary applications. J. Clean. Prod. 2020, 275, 124152. [Google Scholar] [CrossRef]

- Fengxian, H.; Shen, W.X.; Qiang, S.; Kapoor, A.; Honnery, D.; Dayawansa, D. Clustering LiFePO4 cells for battery pack based on neural network in EVs. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 1–5. [Google Scholar] [CrossRef]

- Yang, H.; Chen, J.; Tang, Z. Screening decommissioned power batteries based on K-means algorithm and genetic algorithm. Chin. J. Power Sources 2019, 43, 2001–2004. [Google Scholar] [CrossRef]

- Tong, S.; Fung, T.; Klein, M.P.; Weisbach, D.A.; Park, J.W. Demonstration of reusing electric vehicle battery for solar energy storage and demand side management. J. Energy Storage 2017, 11, 200–210. [Google Scholar] [CrossRef]

- Li, L.; Zhang, X.; Li, M.; Chen, R.; Wu, F.; Amine, K.; Lu, J. The Recycling of Spent Lithium-Ion Batteries: A Review of Current Processes and Technologies. Electrochem. Energy Rev. 2018, 1, 461–482. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, Z.; Li, J.; Zhou, Y.; Han, F. A physical model experiment for investigating into temperature redistribution in surrounding rock of permafrost tunnel. Cold Reg. Sci. Technol. 2018, 151, 47–52. [Google Scholar] [CrossRef]

- Ambrose, H.; Gershenson, D.; Gershenson, A.; Kammen, D. Driving rural energy access: A second-life application for electric-vehicle batteries. Environ. Res. Lett. 2014, 9, 094004. [Google Scholar] [CrossRef]

- Lai, X.; Qiao, D.; Zheng, Y.; Yi, W. A Novel Screening Method Based on a Partially Discharging Curve Using a Genetic Algorithm and Back-Propagation Model for the Cascade Utilization of Retired Lithium-Ion Batteries. Electronics 2018, 7, 399. [Google Scholar] [CrossRef]

- Li, W.; Garg, A.; Le, M.L.P.; Ruhatiya, C.; Gao, L.; Tran, V.M. Electrochemical performance investigation of LiFePO4/C0.15-x (x = 0.05, 0.1, 0.15 CNTs) electrodes at various calcination temperatures: Experimental and Intelligent Modelling approach. Electrochim. Acta 2020, 330, 135314. [Google Scholar] [CrossRef]

- Song, Z.; Feng, X.; Lal, R.; Fan, M.; Ren, J.; Qi, H.; Qian, C.; Guo, J.; Cai, H.; Cao, T.; et al. Chapter Five—Optimized agronomic management as a double-win option for higher maize productivity and less global warming intensity: A case study of Northeastern China. Adv. Agron. 2019, 157, 251–292. [Google Scholar] [CrossRef]

- Lai, X.; Huang, Y.; Deng, C.; Gu, H.; Han, X.; Zheng, Y.; Ouyang, M. Sorting, regrouping, and echelon utilization of the large-scale retired lithium batteries: A critical review. Renew. Sustain. Energy Rev. 2021, 146, 111162. [Google Scholar] [CrossRef]

- Hua, Y.; Liu, X.; Zhou, S.; Huang, Y.; Ling, H.; Yang, S. Toward Sustainable Reuse of Retired Lithium-ion Batteries from Electric Vehicles. Resour. Conserv. Recycl. 2021, 168, 105249. [Google Scholar] [CrossRef]

- Zhan, S.; Hou, P.; Enevoldsen, P.; Yang, G.; Zhu, J.; Eichman, J.; Jacobson, M.Z. Co-optimized trading of hybrid wind power plant with retired EV batteries in energy and reserve markets under uncertainties. Int. J. Electr. Power Energy Syst. 2020, 117, 105631. [Google Scholar] [CrossRef]

- Canals Casals, L.; Barbero, M.; Corchero, C. Reused second life batteries for aggregated demand response services. J. Clean. Prod. 2019, 212, 99–108. [Google Scholar] [CrossRef]

- Gur, K.; Chatzikyriakou, D.; Baschet, C.; Salomon, M. The reuse of electrified vehicle batteries as a means of integrating renewable energy into the European electricity grid: A policy and market analysis. Energy Policy 2018, 113, 535–545. [Google Scholar] [CrossRef]

- Lih, W.C.; Yen, J.H.; Shieh, F.H.; Liao, Y.M. Second Use of Retired Lithium-ion Battery Packs from Electric Vehicles: Technological Challenges, Cost Analysis and Optimal Business Model. In Proceedings of the 2012 International Symposium on Computer, Consumer and Control, Washington, DC, USA, 4–6 June 2012; pp. 381–384. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, Q.; Li, Y.; Li, H.; Pan, X.; McLellan, B. The social-economic-environmental impacts of recycling retired EV batteries under reward-penalty mechanism. Appl. Energy 2019, 251, 113313. [Google Scholar] [CrossRef]

- Pan, Y.-W.; Hua, Y.; Zhou, S.; He, R.; Zhang, Y.; Yang, S.; Liu, X.; Lian, Y.; Yan, X.; Wu, B. A computational multi-node electro-thermal model for large prismatic lithium-ion batteries. J. Power Sources 2020, 459, 228070. [Google Scholar] [CrossRef]

- Yang, S.-C.; Hua, Y.; Qiao, D.; Lian, Y.-B.; Pan, Y.-W.; He, Y.-L. A coupled electrochemical-thermal-mechanical degradation modelling approach for lifetime assessment of lithium-ion batteries. Electrochim. Acta 2019, 326, 134928. [Google Scholar] [CrossRef]

- Feng, X.; Ren, D.; He, X.; Ouyang, M. Mitigating Thermal Runaway of Lithium-Ion Batteries. Joule 2020, 4, 743–770. [Google Scholar] [CrossRef]

- Li, W.; Garg, A.; Wang, N.; Gao, L.; Le Phung, M.L.; Tran, V.M. Computational Fluid Dynamics-Based Numerical Analysis for Studying the Effect of Mini-Channel Cooling Plate, Flow Characteristics, and Battery Arrangement for Cylindrical Lithium-Ion Battery Pack. J. Electrochem. Energy Convers. Storage 2022, 19, 041003. [Google Scholar] [CrossRef]

- Li, W.; Garg, A.; Xiao, M.; Peng, X.; Le Phung, M.L.; Tran, V.M.; Gao, L. Intelligent optimization methodology of battery pack for electric vehicles: A multidisciplinary perspective. Int. J. Energy Res. 2020, 44, 9686–9706. [Google Scholar] [CrossRef]

- Wang, Q.; Mao, B.; Stoliarov, S.I.; Sun, J. A review of lithium ion battery failure mechanisms and fire prevention strategies. Prog. Energy Combust. Sci. 2019, 73, 95–131. [Google Scholar] [CrossRef]

- Lai, H.F.; Kuo, C.Y.; Cheng, S.P. Significance of telomerase reverse-transcriptase promoter mutations in differentiated thyroid cancer. Formos. J. Surg. 2021, 54, 171–176. [Google Scholar] [CrossRef]

- Li, W.; Garg, A.; Xiao, M.; Gao, L. Optimization for Liquid Cooling Cylindrical Battery Thermal Management System Based on Gaussian Process Model. J. Therm. Sci. Eng. Appl. 2020, 13, 021015. [Google Scholar] [CrossRef]

- Li, W.; Jishnu, A.K.; Garg, A.; Xiao, M.; Peng, X.; Gao, L. Heat Transfer Efficiency Enhancement of Lithium-Ion Battery Packs by Using Novel Design of Herringbone Fins. J. Electrochem. Energy Convers. Storage 2020, 17, 021108. [Google Scholar] [CrossRef]

- Xiong, R.; Li, L.; Tian, J. Towards a smarter battery management system: A critical review on battery state of health monitoring methods. J. Power Sources 2018, 405, 18–29. [Google Scholar] [CrossRef]

- Alamerew, Y.A.; Brissaud, D. Modelling reverse supply chain through system dynamics for realizing the transition towards the circular economy: A case study on electric vehicle batteries. J. Clean. Prod. 2020, 254, 120025. [Google Scholar] [CrossRef]

- Catton, J.W.A.; Walker, S.B.; McInnis, P.; Fowler, M.; Fraser, R.A.; Young, S.B.; Gaffney, B. Design and Analysis of the Use of Re-Purposed Electric Vehicle Batteries for Stationary Energy Storage in Canada. Batteries 2019, 5, 14. [Google Scholar] [CrossRef]

| Metals | Cathode Material | Prices | ||||

|---|---|---|---|---|---|---|

| LiCoO2 (Mass%) [22] | LiFePO4(LFP) (Mass%) [23] | LiMn2O4 (Mass%) [23] | LiNi1/3Mn1/3Co1/3O2 (NMC) (Mass%) [24] | LiNi0.8Co0.15Al0.05O2 (NCA) (Mass%) [25] | ||

| Aluminum | 5.2 | 6.5 | 21.7 | 22.72 | 21.9 | 2.36 |

| Cobalt | 17.3 | 0.0 | 0.0 | 8.45 | 2.3 | 49.81 |

| Copper | 7.3 | 8.2 | 13.5 | 16.60 | 13.3 | 9.456 |

| Iron/steel | 16.5 | 43.2 | 0.1 | 8.79 | 0.1 | 0.73 |

| Lithium | 2.0 | 1.2 | 1.4 | 1.28 | 1.9 | 11.75 |

| Manganese | 0.0 | 0.0 | 10.7 | 5.86 | 0.0 | 2.30 |

| Nickel | 1.2 | 0.0 | 0.0 | 14.84 | 12.1 | 16.16 |

| Binder | 2.4 | 0.9 | 3.7 | 1.39 | 3.8 | N/A |

| Electrolyte | 14.0 | 14.9 | 11.8 | 11.66 | 11.7 | N/A |

| Plastic | 4.8 | 4.4 | 4.5 | 3.29 | 4.2 | N/A |

| Study | Recycle Method | Advantages | Disadvantages |

|---|---|---|---|

| Refs [29,30] | Pyrometallurgical | Relatively mature technology, simple process | Low recovery rate, high cost, large environmental pollution |

| Refs [15,31] | Hydrometallurgical | High recovery rate, high efficiency, low power consumption | Relatively complex process, high resource consumption, low efficiency, long production time |

| Refs [32,33] | Bioleaching | Low cost, low environmental pollution, low energy consumption | Relatively complex process, long time cultivation |

| Refs [34,35] | Direct recycling | Simple process, low cost, low environmental pollution | Immature technology, difficult to commercialize |

| Related Company | Battery Type | Recycle Method | Recovered Product | Country |

|---|---|---|---|---|

| Accurec-recycling Gmbh | Except Pb and Hg | Pyrometallurgy | Co, Li | Germany |

| AEA | All | Hydrometallurgy | Co2O3, LiOH | UK |

| AkkuSer Oy | All | Pro-and hydrometallurgy | Meal powder | Finland |

| Batrec industrie AG | Li-based, Hg-based | Pyrometallurgy | Co, MnO2, Ni | Switzerland |

| Brunp recycling | Li-based, Ni-based | Hydrometallurgy | Cathode | China |

| GEM | Li-based, Ni-based | Hydrometallurgy | Cathode | China |

| Glencore Plc | Li-based | Pro-and hydrometallurgy | Co, Ni, Cu | Switzerland |

| IME | Li-based, Ni-based | Pro-and hydrometallurgy | Li2CO3, Co | Germany |

| International Metals Reclamation Company | Li-based, Ni-based | Pyrometallurgy | Ni alloys | US |

| JX Nippon Mining & Metals | Li-based | Hydrometallurgy | Ni, Co, Mn, Li | Japan |

| Mitsubishi | Li-based, Pb-acid | Pyrometallurgy | LiCoO2 | Japan |

| Xstrata | Li-based, Ni-based | Pro-and hydrometallurgy | Cu, Ni, Zn | Switzerland |

| Onto technology LLC | Li-based | Direct recycling | Cathode | US |

| Recupyl | Li-based, Zn-based | Hydrometallurgy | Co(OH)2, Li2CO3 | France |

| Retriev Technologies | All | Hydrometallurgy | Co, Li2CO3 | US, Canada |

| Campine | Pb-acid | Pyrometallurgy | Pb | Belgium |

| Rockwood Lithium | Li-based | Hydrometallurgy | Oxide (Co, Li) | Germany |

| Sumitomo and Sony | All | Pro-and hydrometallurgy | Co, Ni, Fe alloy, CoO | Japan |

| Umicore | Li-based, NiMH | Pro-and hydrometallurgy | CoCl2, Ni(OH)2 | US |

| SNAM | Li-based, Ni-based | Pyrometallurgy | Ni, Co, Cd | France |

| Study | Battery Type | Methods | Mode of Operation | Category |

|---|---|---|---|---|

| Wang et al. [54] | LIBs | Artificial neural network and equivalent circuit model | Offline | I |

| Hu et al. [55] | LIBs | K-means algorithm and particle swarm optimization | Offline/Online | II |

| Patil et al. [56] | LIBs | Support vector machines | Offline/Online | III |

| Ng et al. [57] | LIBs | Naïve Bayes model | Online | II |

| Galeotti et al. [58] | Lithium polymer batteries | EIS | Offline | I |

| Song et al. [59] | LIBs | Artificial neural network | Offline | III |

| Jia et al. [60] | LIBs | Gaussian process regression | Online | II |

| Kaur et al. [61] | LIBs | Feed-forward neural network and convolutional neural network, and long short-term memory neural network | Online/Offline | III |

| Eddahech et al. [62] | LIBs | EIS and Neural Network | Offline/Online | I |

| Study | Battery Type | Health Index | Methods | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Ng et al. [57] | LIBs | Capacity | Naive Bayes | Concise | Based on attribute independence assumption |

| Pattipati et al. [66] | Rechargeable battery | Capacity, internal resistance | Support vector machine | Unaffected by nonlinearities and small samples | Need to satisfy Mercer criterion |

| Wang et al. [67] | LIBs | Energy efficiency, temperature | Support vector regression | Fewer dimensions | Lack of sparseness |

| Zhou et al. [68] | LIBs | Mean voltage drop | Relevance vector machine | Avoids overfitting and underfitting | Not suitable for long-term prediction |

| Richardson et al. [69] | LIBs | Capacity | Gaussian process regression | Unaffected by high-dimension and small samples | Parameter and kernel function selection is sensitive |

| Zhang et al. [70] | LIBs | Capacity | Long short-term memory recurrent neural network | Avoids overfitting and underfitting | Requires sufficient historical data |

| Liu et al. [71] | LIBs | Capacity, discharging voltage difference | Monotonic echo state networks | Strong nonlinear processing ability | High computational complexity |

| Pang et al. [72] | LIBs | Capacity | Wavelet decomposition technology and neural network | Not affected by prediction starting points | Relatively complex model |

| Wang et al. [73] | LIBs | Capacity and 13 features | Bayesian model averaging | High prediction accuracy | An encoding network is required |

| Mao et al. [74] | LIBs | Capacity | Machine learning algorithms | Not affected by prediction starting points | Complex model fusion |

| Study | Battery Type | Parameters | Sorting/Regrouping Methods | Validation Methods | Advantages |

|---|---|---|---|---|---|

| Liao et al. [90] | Li-ion phosphate batteries | Capacity, voltage, resistance, EIS | Capacity, pulse discharge voltage, charge transfer resistance, and lithium-ion diffusion coefficient | Experiment | No special equipment, high economy |

| Li et al. [91] | Li-ion phosphate batteries | Capacity, equivalent resistance spectrum | Difference of 2% of the maximum capacity | Experiment | Convenient and efficient |

| Lai et al. [92] | LIBs | Capacity, voltage, internal resistance | Neural network model and the piecewise linear fitting model | Experiment | High efficiency |

| Jiang et al. [93] | LIBs | Capacity, resistance | K-means algorithm | Simulation | Preferable consistency, high capacity utilization |

| Li et al. [89] | LIBs | Capacity, internal resistance, RUL | Novel equal-number support vector clustering algorithm | Simulation | Equal-number, preferable consistency |

| Lai et al. [94] | LIBs | Capacity | K-means algorithm | Simulation, Experiment | High precision and consistency |

| Zhou et al. [95] | LiFePO4 battery | Capacity, resistance | Support vector machine | Experiment | High classification accuracy |

| Garg et al. [96] | All | Capacity, internal resistance | Self-organizing maps | Experiment | Reduced inconsistencies within the battery pack |

| He et al. [97] | LiFePO4 battery | Temperature, capacity | Self-organizing maps | Simulation | High consistency |

| Yang et al. [98] | Power battery | Resistance, open circuit voltage, capacity | Combination of k-means and genetic algorithm | Experiment | Better applicability |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, N.; Garg, A.; Su, S.; Mou, J.; Gao, L.; Li, W. Echelon Utilization of Retired Power Lithium-Ion Batteries: Challenges and Prospects. Batteries 2022, 8, 96. https://doi.org/10.3390/batteries8080096

Wang N, Garg A, Su S, Mou J, Gao L, Li W. Echelon Utilization of Retired Power Lithium-Ion Batteries: Challenges and Prospects. Batteries. 2022; 8(8):96. https://doi.org/10.3390/batteries8080096

Chicago/Turabian StyleWang, Ningbo, Akhil Garg, Shaosen Su, Jianhui Mou, Liang Gao, and Wei Li. 2022. "Echelon Utilization of Retired Power Lithium-Ion Batteries: Challenges and Prospects" Batteries 8, no. 8: 96. https://doi.org/10.3390/batteries8080096

APA StyleWang, N., Garg, A., Su, S., Mou, J., Gao, L., & Li, W. (2022). Echelon Utilization of Retired Power Lithium-Ion Batteries: Challenges and Prospects. Batteries, 8(8), 96. https://doi.org/10.3390/batteries8080096