Abstract

In the circular economy, a closed-loop supply chain is essential to guarantee the logistics of raw materials to the correct destination of the end-of-life (EOL) product. This is magnified by hazardous products that can contaminate the environment, such as lead, as well as the people involved in their production processes. Through an exploratory study of multiple cases, we analyzed the Brazilian lead-based vehicle battery chain by investigating two main manufacturers, two recycling companies, and eight distributors/retailers. The aim of the study was to analyze the relationships between the actors in the lead acid battery chain and identify the mechanisms that induce recycling programs, and to propose an explanatory framework. The results indicate that although the sustainability strategies of OEMs are implemented by regulatory mechanisms, the impacts of these strategies cascade among all agents in the supply chain, promoting a convergence between actions and relationships between actors from the perspective of the triple bottom line, highlighting variables for each dimension (economic, social, and environmental). The study contributes to the consolidation of the triple bottom line concepts in the lead acid battery production chain and presents managerial implications for sustainability management.

1. Introduction

The transition from a linear economy to a circular economy involves the reduction and substitution of non-renewable materials and energy, promoting renewable raw materials and energy, and keeping products/materials in use throughout their life cycle [1]. Thus, the life cycle environmental costs associated with the manufacture, use, and disposal of lead acid batteries (LABs) can potentially be reduced through circular economy strategies. In this context, reverse logistics (RL) and closed-loop supply chain (CLSC) play a crucial role. CLSC characteristics, including the products, actors, and interactions, could increase the speed of the transmission from a linear to a circular economy [2]. However, to integrate circular economy (CE) strategies within the supply chain, there are many barriers. One barrier identified by Ayati et al. is the lack of rules and government regulations [3]. In Brazil, the National Solid Waste Policy stipulates that some components (tires, lubricating oils, and batteries) used in the production of a motor vehicle have an environmentally correct destination. The National Environment Council does not allow the final disposal of LABs in any type of sanitary landfill, nor their incineration. Therefore, the LABs (national and imported, used or unusable, received by commercial establishments or in an authorized technical assistance network) must be, in their entirety, sent to an environmentally appropriate destination, under the responsibility of the manufacturer or importer.

In 2019, the Ministry of the Environment signed an agreement with the largest battery manufacturers to implement the RL system of LABs. The agreement sets out goals and responsibilities for manufacturers, importers, distributors, traders, and recyclers, from the collection, packaging, transport, and recycling to the final disposal. The transition to a closed-loop supply chain brings opportunities for stakeholders along the supply chain. To shift from a linear to a circular economy for the lead acid battery supply chain, appropriate regulations and incentives are required to encourage actors along the supply chain to take collaborative actions [4].

Studies on LABs in Greece, Canada, and Turkey suggest that it is important to carry out more research on LAB recycling in other countries [5,6,7]. De Giovanni points out the need to understand the impacts when there is some benefit or incentive in the recovery of LABs [8]. While these studies highlight individual elements of the circular economy, they do not provide a consolidated and comprehensive relationship between automotive original equipment manufacturers (OEMs) and their stakeholders [1]. According to the literature, there is no industry-level circular economy framework for qualifying automotive energy and material flows [1]. However, OEMs have sustainability strategies, and framing them in a broader circular economy lens can capture multiple lifecycles, alternative business models, and feedback loops within a closed-loop system. A circular economy highlights the flows of energy and materials in and out of a system, both upstream and downstream. It can help to create broader and more holistic corporate sustainability strategies [1]. More holistic study of CLSC models is necessary, including sharing mechanisms and reward–penalty mechanisms analysis [2]. Similarly, the authors of [3] point out the need for multi-level research considering the factors involved in studying closed-loop supply chains. Moreover, they argue that there is a lack of understanding of interactions and interdependencies along the chain [3]. Thus, the objective of this manuscript is to analyze the relationships between the actors in the LAB chain and identify the mechanisms that induce recycling programs, and, with that, propose an explanatory framework.

2. Closed-Loop Supply Chain and Reverse Logistics

The closed-loop supply chain (CLSC) has gained attention in the sustainability debate since it is considered one of the most important configurations of the circular economy [3]. It is composed of characteristics that, when identified, studied, and categorized, help not only to promote a better understanding of the current contributions in the literature, but also lead to new models.

The circular economy attempts to close the supply chain loop by reducing the need for virgin materials via the reuse or recycling of existing materials [9]. One of the benefits of a circular economy is to reduce the extraction of virgin materials and extend the lifecycle of resources through reduction, reuse, and recycling [10]. The circular economy is regenerative by design, and a key feature includes the elimination of waste through reverse logistics systems [4].

In a circular economy, the value of products and materials is maintained for as long as possible, and waste and use of resources are minimized. When a battery reaches its end of life (EOL), its materials are kept in the economy to be reused to create more value. In the LAB industry, the product development area designs for recycling and efficiency, anticipating use beyond the end of life.

The purpose of RL is to collect products in EOL that have lost their functionality or become obsolete, regardless of the product line and the producing company [11]. It may involve repair, refurbishment, remanufacturing, recycling, and/or disposal. Recovery options are specific to each product type, depending on the technical feasibility of disassembly and the costs and benefits of the structure needed [12]. Thus, an integrated supply chain approach, considering both forward and reverse supply chains simultaneously, constitutes the concept of the closed-loop supply chain (CLSC).

The CLSC consists of the design, control, and operation of a system to maximize value creation throughout the entire life cycle of a product, with the dynamic recovery of the value of different types and volumes returned over time [13].

In contrast to RL, CLSC involves not only the reverse flows of materials/goods from end-users to manufacturers or facilities, such as collection and recovery centers or disposal sites, but also flows of raw materials/goods from suppliers to manufacturers and then to customers. The establishment of RL and CLSC systems has become a critical requirement of societies in both developed and developing countries [14]. Companies in emerging economies such as Brazil and India need to better understand how their strategic, tactical, and operational decisions affect a CLSC project [15].

An important issue in the CLSC is the reward–penalty mechanism (RPM) to motivate the return process and reduce operating costs. The product return process is complex and usually involves many players, thus creating incentives (financial gains, marketing, promotions, etc.) and penalties (fines, discounts, subsidies reduction).

The focal firm should create an incentive for companies participating in the process [8]. Managers need to adopt a price/return rate policy in the reverse chain to motivate collectors [16].

Retailers do not benefit from the residual value obtained from product returns and recycling. The advantage is exploiting marketing in the return process, increasing the number of visits, consumers remembering the retailer’s contribution to the environment, and consumers’ satisfaction with their participation in environmental preservation and conservation [8].

The government plays a role in encouraging remanufacturing operations and motivating the supply chain to carry out reverse operations [17]. Wang et al. [18] developed models with and without the use of RPM to discuss how to reward intensity and collection targets and their impacts on prices, return percentage, and profit manufacturers and collectors. The collector benefits from the RPM policy and his/her profit increases. For the producer, it depends on the intensity of the incentive and penalty policy and is simultaneously associated with the percentual imposed for collection.

The focus of research on the circular economy is on the environmental dimension because the concept has its origins in industrial symbiosis, ecology, and cradle-to-cradle. Social aspects, including labor practices, human rights, and the well-being of communities, have still been neglected in the operationalization of the circular economy concept [19]. The authors argue that, if society really seeks an alternative to the current economic system, the inclusion of the social sustainability dimension is key. Similarly, society must be considered as building the three pillars of sustainability [20]. The circular economy can play a part in sustainability, where sustainability is the integration of economic performance, social inclusiveness, and environmental resilience, to the benefit of current and future generations. Thus, the impacts of circular economy strategies need to be analyzed so we can understand how they perform considering the triple bottom line and how they contribute to sustainability, especially by slower forms of consumption, i.e., closing resource loops. In this case, the supplier’s participation is essential to achieving triple bottom line (TBL) goals.

Although the three dimensions of sustainability must be considered together, it is noted that trade-offs may occur, as they are not necessarily achieved simultaneously [21]. The integrative view of the aspects of TBL assumes that companies recognize the tensions between them and understand their nature. These tensions can be generated by the conflict of personal interests versus the organization’s interests, short- and long-term visions, current processes versus structural and technological change, and the tension between the organization’s efficiency and socioeconomic system resilience.

The TBL practices are found more frequently in the metal, electro-electronics, and automotive sectors. However, the social dimension receives less attention compared to environmental and economic aspects, even though in many cases it affects the reputation and long-term success of the organization [22]. Some criteria adopted in the social dimension analysis are working conditions, diversity, compliance with human rights, child labor, slavery, employees’ health and safety, quality of life, payment of fair wages, working hours, and impact on the local communities [23].

Lead Acid Batteries Closed-Loop Supply Chain

The largest market for LABs is automotive batteries, which are primarily used as starter ignition (SLI) batteries, followed by industrial batteries for standby power or motive power. The batteries have around 65% of their weight in lead and it can be recovered for later recycling, thus reducing the risks of contamination, and at the same time bringing economic savings. The recycling process of LABs generates losses of lead of about 4.5% of the average 9 kg of lead that each battery contains [24].

In the RL model adopted in major world markets, the end-user delivers the EOL battery to the retailer or dealer. Thus, retailers or resellers are considered initial collection points. In Brazil, the use of secondary lead is economically viable for the LAB manufacturers. Then, battery manufacturers encourage the return of LAB scrap in stores in exchange for discounts on the purchase of new batteries [24].

Next, the batteries are consolidated at distributors and then transported to licensed recycling, where they will be broken down and the main materials (acid, plastic, and lead) separated. The role of the recycler can range from separating the material to transforming it into new raw material, e.g., plastic into granules or lead into ingots. After the recycling process, lead and plastic parts are sent to battery manufacturers as raw materials [25]. This process is well developed, and high efficiencies are achieved. For every ton of battery scrap, around 650 kg of lead is recovered [26]. However, the LAB recycling process has not changed significantly over time [27].

LAB recycling companies worldwide, especially in developing countries, can be considered as one of the sources of soil contamination, especially due to their outdated recycling processes [5,28]. The smelting process is associated with a high emission of carbon dioxide, lead dust, smoke, and hazardous waste, seriously affecting public health [29]. Thus, due to government environmental regulations and a shortage of lead as raw material, companies are under pressure to recover EOL batteries [30].

LABs become dangerous to humans and other species due to their toxic components, especially if disposed of incorrectly or in landfills, as the chemical material can contaminate soil and water. Batteries could have toxic metals such as cadmium, mercury, and lead, so their disposal must be supervised [31]. On the other hand, their recycling cycle is infinite, so they bring opportunities from an environmental, social, and economic perspective. The importance of the recycling process becomes more evident when there is an insufficiency of primary lead sources. Scrap LABs are the major source of secondary lead, accounting for about 85% of the total amount of secondary lead [32]. Adequate EOL management (i.e., refurbishment, reuse, or recycling) of batteries is crucial, not only to mitigate environmental impacts, but also to avoid a shortage of materials in future demands. Effective EOL strategic planning enables the most appropriate material recovery, promoting a circular economy [33]. Thus, an RL, extended producer responsibility (EPR), collection and recycling regulations, and shared responsibility among stakeholders are important to the chain, not only for its accomplishment but for its survival as well [34].

About 95% of LABs are collected and recycled in a closed-loop system (CLSC) in the European Union and the United States [35]. In Brazil, only the main manufacturers aim to recycle between 60% and 80% of the batteries for the replacement market, depending on each region. Legislation and sector agreements do not consider volumes sold to OEMs. On the other hand, informal producers still do not have established goals and their RL is not properly monitored and audited. Reducing tax and offering subsidies to regulated recyclers could help the business shift from the informal to formal sector, which results in a reduction in lead pollution [30].

Treating gaseous emissions is expensive, and environmental legislation continues to become more stringent. For each ton of molten lead, it is necessary to clean 30 to 40 thousand m3 of process gases, which requires the use of expensive equipment [27].

From the point of view of the impact on the social dimension, LAB recycling companies in Bangladesh, China, Kenya, and Brazil were responsible for the contamination of the employees and local community. Contaminations are confirmed through blood lead levels [36,37,38,39]. In these cases, and others reported in the U.S., investigations have demonstrated a link between blood lead levels and lead contamination that persists in topsoil [40].

More than 70% of lead recycling companies in China were closed in 2012 due to production problems and high levels of pollution [41]. In accordance with the new environmental laws and requirements of the Ministry of Industry and Information Technology and the Ministry of Environmental Protection in China, plants with less than 50,000 t per year were shut down and the rest might invest in equipment and environmental controls [42].

The United Nations Environment Assembly (UNEA) also recognized the growing threat of the LAB recycling process to public health and the environment and asked governments to address the issue. However, most countries still rely on general provisions of the environmental laws to monitor the performance of recycling companies and their operational requirements [28].

In South Korea, since 2003, the government has created several obligations for companies producing batteries. Failure to comply with these obligations leads to higher fines than the cost of recycling [43].

New processes are being explored to replace the pyrometallurgical process [33]. The electro-hydrometallurgical technique is one of the alternatives being developed; however, it presents some disadvantages when compared to the pyrometallurgical process. It is less profitable and has higher operating costs, greater consumption of electricity, and requires high investments. Moreover, toxic materials are used in the processes, which increases health risks and maintenance and replacement costs due to severe corrosion of metal components.

3. Methodology

The literature review showed an increase in research related to RL processes and recovery of EOL products, especially for those that contain hazardous components and/or considerable economic value, such as LABs. The literature has shown that several countries have already adopted norms, laws, and regulations for the recovery and recycling of LABs. However, it also pointed to deficiencies in meeting environmental or social regulations in developing countries such as South Africa, China, Brazil, Turkey, and India. In this sense, recent theoretical–conceptual advances have been accompanied by a better understanding of empirical experiences. To contribute to the theoretical generalization, in this research, we took an exploratory qualitative approach, adopting the study of multiple cases as a methodology [44].

Many studies argue that the closed-loop supply chain and RL are acceptable methods to promote the reduction, reuse and recycling of raw materials (circular economic strategy) in order to reach sustainability goals (considering the triple bottom line perspective). We conducted a systematic literature review based on these concepts in the lead acid batteries context. We found some common constructs and variables presented in most of the previous studies of different countries and regions, summarized in Table 1.

Table 1.

Dimensions, constructs, and variables of the research.

Our data collection covered the two largest LAB manufacturers, two recycling companies, and eight distributors and/or retailers, located in four different Brazilian regions (Table 2), all of which had been in business for between 5 and 10 years.

Table 2.

Respondents’ characterization.

The case selection occurred by the snowball sampling process. The first cases were selected for their leadership in the auto parts sector in Brazil [45]. The first company is the largest manufacturer of lead batteries in Latin America and is the supplier of several OEMs and the aftermarket. This company has the recycling process embedded within its own production unit.

The second company exclusively serves the aftermarket. However, it is one of the largest manufacturers in Brazil. This company outsources the recycling process. The two recycling companies that provide services to this manufacturer were interviewed. With these, it is possible to compare leading companies, but with very different production processes, volumes sold, and recycling companies.

We also evaluated how the participation of distributors and retailers affects the RL process. The research was carried out with a sample of eight distributors and/or retailers, distributed in four different Brazilian states. Based on this initial sample of leading companies (seeds) and following the snowball sampling technique, a list of chain actors was generated. Data saturation was reached when there was no new additional information and new interviews became redundant [46].

Data collection took place through semi-structured interviews and through the analysis of documents such as reports, presentations, performance indicators, procedures, and public information. Direct observation of production and management processes enabled data triangulation and validation.

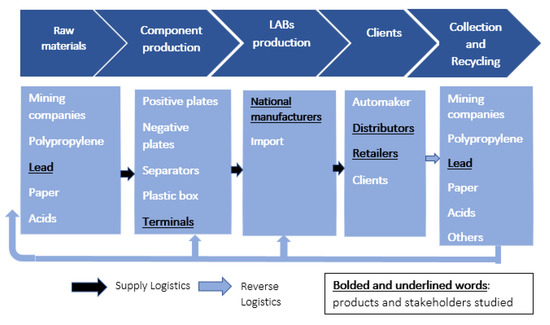

Figure 1 shows the forward and reverse flow of the LAB chain, as well as its main nodes. We have highlighted in bold the elements analyzed.

Figure 1.

LABs supply chain.

4. Results and Discussion

In this section, we present the data gathered in the field, summarizing and highlighting the main findings obtained from the interviewees. We also provide a comparative discussion of previous studies to enrich our analysis.

4.1. Environmental Dimension

The decrease in the use of primary lead is related to the recovery and recycling of batteries. To increase recycling rates, synchronism between the chain is fundamental. The distributors and retailers have their goals for RL and they are encouraged or penalized through commercial policies. The rates of batteries recovered from each manufacturer are audited by an independent agent that validates the relationship between the volume sold in the aftermarket versus the volume of batteries recycled. On a monthly basis, manufacturers send documents evidencing the volumes produced and recycled.

In São Paulo, the region with the highest population density and where automakers are located, the collection and recycling rate reached 104% in 2019. Between 60% and 80% of the lead needed to produce new batteries for the replacement market came from secondary lead. Compared to other studies [10,41,42,43], these results are still lower than the rates of the U.S. and Europe, which have over 80% and 90%, respectively. However, the Brazilian rate is higher than the global average (60%) and much higher than the recycled values in China (29% to 34%) and South Korea (52%).

The COVID-19 pandemic did not affect the sector agreement, as it establishes a relationship between batteries sold to the aftermarket and their recycling. The pandemic brought a reduction in sales volume but maintained the recycling rate. Manufacturers reached more than 100% of the goal.

The federal government enforces the regulation and control of LAB recycling. In 1981, Brazil enacted the National Environmental Policy as the first environmental milestone. In 2010, the National Solid Waste Policy (PNRS) was launched to regulate environmental management and EPR. The National Solid Waste Policy establishes that manufacturers, importers, distributors and traders of batteries are required to structure and implement reverse logistics systems upon return of products after use. Conama Resolution nº 401 establishes maximum limits for lead, cadmium and mercury batteries sold in the national territory and the criteria and standards for their environmentally appropriate management. Finally, Ibama Normative Instruction n° 8, establishes the procedures related to the control of the receipt and the final destination of batteries and subproducts for national manufacturers and importers.

The municipal and/or state environmental agency should be consulted about the existence of any complementary legislation on battery disposal obligations. Enrollment in the Federal Technical Register of Potentially Polluting Activities and Users of Environmental Resources is mandatory for recycling companies, disposal companies and national manufacturers of batteries. Importers and national manufacturers of batteries are required to prepare a Battery Management Plan.

In 2019, a sector agreement was signed between the Ministry of the Environment and the Brazilian Association of Automotive and Industrial Batteries (ABRABAT-BR) to commit the largest battery manufacturers to implement the RL system for lead acid automotive batteries. The agreement sets out goals and responsibilities for manufacturers, importers, distributors, traders, and recyclers, from the collection, packaging, transport, and recycling to the final disposal. With the agreement, more than 16 million lead automotive batteries are expected to be collected and recycled. It expects to recycle more than 153,000 tons of lead every year, thus reducing dependence on lead imports for the manufacture of new batteries.

Brazil is better structured than some other developing countries. For example, the Chinese government still needs to improve the regulations on the battery recycling process, despite having launched the “Standards for emission of industrial pollutants of lead and zinc” in 2013 through its Ministry of Environmental Protection [10]. About 30% to 40% of batteries are recycled by uncertified companies in China [42]. In Africa, few countries regulate operations and emissions in the LAB recycling process [28].

Manufacturers have been improving the production processes and the monitoring and containment of air, soil, or water pollution. However, only one of the manufacturers is ISO 14000 certified.

The recyclers argue that the environmental controls are increasing, thus forcing them to assume expenses to improve the production process and environmental controls, which harms their financial results.

Regarding the risks of the production and recycling of batteries, containment, mitigation, and planning measures were observed for the total elimination of the risks, both in the manufacturers and in the recyclers. Companies discuss and disclose these risks to employees. Both manufacturers and recyclers use the pyrometallurgical process to smelt lead. They argue that the process is safe, more productive, and does not present major environmental risks if considering periodic maintenance and environmental controls. Some methods to replace the pyrometallurgical process are less productive, have higher operating costs and electricity consumption, and need high investments [33,37,47].

The results of the environmental dimension are summarized in Table 3.

Table 3.

Findings on the environmental dimension.

4.2. Social Dimension

Manufacturers and recyclers highlighted the importance of the maintenance and health of their employees and compliance with current legislation. Companies have a schedule for carrying out periodic health checks on their employees at different intervals according to their exposure to risk and, mainly, to contact with lead. Distributors and retailers do not monitor the health of employees associated with battery exposure and movement.

Manufacturers and recyclers do not promote medical examinations in the local community, although they finance social projects. Likewise, the recyclers are not responsible for promoting or monitoring the health of the local community; they comply with the requirements of the legislation.

Law enforcement and social initiatives are better than the findings of Etiang [38] in Kenya, which found significant levels of lead in the blood of children who lived close to a smelting lead company and where high levels of atmospheric, soil, and water contamination were also identified.

The level of contamination in lead manufacturing and recyclers in Africa poses a risk to the health of employees and local communities [28]. In blood samples taken from residents close to a recycler in China, more than 43% had contamination levels above the permitted level [33]. Worse results are found in developing countries [29]. The contamination rates of workers in the U.S. already show better results, thus showing that contamination in this sector is avoidable.

Regarding social responsibility towards the local community, Manufacturer 1 stated that the company’s founders invest in social projects, mainly in education. Manufacturer 2 finances social projects such as access to leisure and entertainment, qualification training, and easy access to business partners, such as schools and doctors. Moreover, Manufacturer 2 supports professional training projects in colleges in the region, hiring this new workforce. Considering the analysis of risks and hazards, manufacturers seek to eliminate or at least mitigate the risks and hazards of production processes, especially the risks of lead contamination.

The risk and hazard matrix for Recycler 1 is outdated and Recycler 2 does not map risks. Distributors and retailers play a crucial role in publicizing the risks and dangers that can be generated by the misuse or incorrect disposal of LABs. Retailers receive more information and training on the technical characteristics of the battery than on sustainability. Training on risks and hazards is normally given by distributors or by a manufacturer’s representative. In all stores, there is information about the RL processes and the importance of recycling. Table 4 presents the main results in relation to the social dimension.

Table 4.

Findings on the social dimension.

Although social aspects are recognized as important, they are not the focus of action. This is in line with previous research [22,48,49], in which it was pointed out that the social dimension receives less attention compared to the environmental and economic aspects, even if this affects the reputation and long-term success of the organization.

4.3. Economic Dimension

The companies point out that there are no government incentives for RL and recycling and that there was an increase in costs to comply with the legislation, harming their operational and financial results. Among the costs involved are RL management and recycling, storage, and transport of EOL batteries. The recycling process requires high investments and equipment maintenance, and environmental control is expensive. From an economic point of view, the direct purchase of primary lead would be more advantageous. Studies carried out in Canada, Turkey, and India [6,7,50] showed that mathematical models considering multiple channels, transportation costs, recycling costs, and return rates determine better economic results for companies.

Most major battery manufacturers do not accept new orders without the equivalent return in battery scrap. Devolution takes place even in the most remote areas, as reverse logistics (the cost of collecting, handling, storing, and transporting) plays an important role in the profitability of this business. This is because Brazil is not a primary lead producer and its scrap price is more competitive than that of primary lead. Economic mechanisms and sectoral agreements (discounts) are fundamental to guarantee the economic viability of the process.

Smaller companies are not part of the sectoral agreement and environmental inspections are less severe. Thus, they have lower process costs. For recyclers, the sector agreement is excellent, as the volume to be recycled tends to increase and, with that, their economic results. Distributors claim that there was an increase in costs due to the complexity of managing RL. Resellers, on the other hand, did not experience an increase in costs, as management is simple, and most distributors have control sheets of what was sold and returned. The economic decision of outsourcing or internalizing the recycling process depends on the manufacturer. Manufacturer 1 internalized the recycling process. The process begins by breaking the batteries, segregating the main materials (sulfuric acid, plastic, and lead), transforming the plastic into granules, and smelting the lead in pyrometallurgical ovens. Manufacturer 2 outsourced the recycling process to three approved companies. The decision to outsource was made at the birth of the company due to the need to reduce investments and the technical and economic uncertainty at the time.

Recycling companies do not recycle sulfuric acid and plastic. The sulfuric acid is resold, and the plastic is shredded, washed, and returned to battery manufacturers. Regarding lead, both companies use pyrometallurgical furnaces to smelt lead into ingots of different weights, according to the client’s requirements. The decision of both manufacturers and recyclers to maintain the pyrometallurgical process is in line with several studies, such as in South Korea, which report that most battery recycling companies use this type of process [43]. Furthermore, as the electricity source is based on fossil fuels, the ecological benefits are less due to emissions. In China, five lead smelting processes, three traditional and two innovative methods, were compared, and the most innovative methods have higher production costs [47]. The pyrometallurgical process is still the main technology used by recyclers in China [42]. New technologies based on hydrometallurgy are rare. The electrolytic technique or electro-hydrometallurgical technique is being studied; however, despite reducing the emission of lead particulates, the technologies require greater consumption of electricity and water and require greater investments in infrastructure [37].

Regarding EOL battery collection, manufacturers adopt similar practices to encourage and secure a better rate from distributors and retailers. These incentives are associated with commercial policies, such as better prices or payment terms. Thus, each manufacturer controls the balance between batteries sold in the aftermarket and batteries returned by each distributor or retailer and establishes prices according to the percentage returned. Another way to encourage distributors and retailers to engage in RL is through training on the importance of recycling and the risks of inappropriate disposal. Then, we can argue that the economic barrier from the perspective of the recovery approach is not seen in the Brazilian case [3].

For distributors and dealers, a better rate of battery return is associated with a better commercial policy. Some customers are unaware of the environmental risks of incorrect disposal and, therefore, retailers offer commercial benefits for battery replacement or take back the old battery for home use or for resale. However, the collection rate is improving annually, due to the law that requires the return of 100% of purchased batteries. The incentive among those involved in the chain increases the rate of return of EOL batteries [8].

Manufacturers suffer from different types of penalties throughout the production process and at RL. In the production process, including the recycling process, companies must meet all environmental requirements in controlling emissions, in addition to labor and tax laws. Regarding RL and recycling, manufacturers must respect the sectoral agreement, with fines in the event of non-compliance with the targets, which may lead to the suspension of their operations. For distributors and resellers, in the case of non-compliance with the return rates, manufacturers reduce discounts and may temporarily or permanently suspend sales contracts.

The country has been an importer of lead since 1960. The Brazilian geological framework is not favorable to the occurrence of deposits of primary lead, as well as zinc, which is currently the main source of lead, as the latter is an element that is derived from zinc extraction. On the other hand, the continuous growth of the automobile industry in the country is translating into a growing demand for lead for the manufacture of automotive batteries. Recycling from scrap has been growing in importance due to several factors, such as the scarcity of rich and/or economically viable mineral deposits, environmental concerns that result in the use of scrap for the production of goods and useful products—thus avoiding their release into ponds or tailings yards—and, finally, the lower energy consumption required for the production of electrolytic lead (which implies a cost reduction).

Brazil does not have a primary lead metallurgy stage, due to the environmental impact generated by this transformation stage. The country is responsible for only 0.1% of the world’s primary lead production [51]. The lead is from the recycling process, especially automotive, industrial and telecommunications batteries. In total, 73% of the consumption of metallic lead contained in lead acid automotive batteries, industrial and motorcycle batteries, and in other uses comes from recycled lead [52]. In an economic context, the exchange rate fluctuation represents an inhibitor of metal imports and an incentive for the recycling process.

Recyclers need to keep their operating licenses valid and ensure they are complying with environmental legislation. If the recyclers exceed the permitted pollution limits, they are fined, must recover the damage caused to the environment and society, and may have their operations closed. Table 5 presents the main findings of the economic dimension.

Table 5.

Findings on the economic dimension.

5. Theoretical and Practical Implications

The sustainability of lead batteries is increasingly being recognized as the world moves rapidly towards electrification. Unlike other battery chemistries, all the main components of a LAB—lead, plastic, and electrolyte—can be recycled and reused to produce new batteries. Recycling makes a supply chain resilient and protected from disruptions arising from economic, social, and environmental contexts. When comparing sustainable practices across all life stages, no other battery chemistry matches the success of remanufacturing as well as LABs. A well-structured recycling infrastructure can achieve a 100% recycling rate. This allows for a constant supply of components, as a new LAB can be composed of more than 80% recycled materials [53].

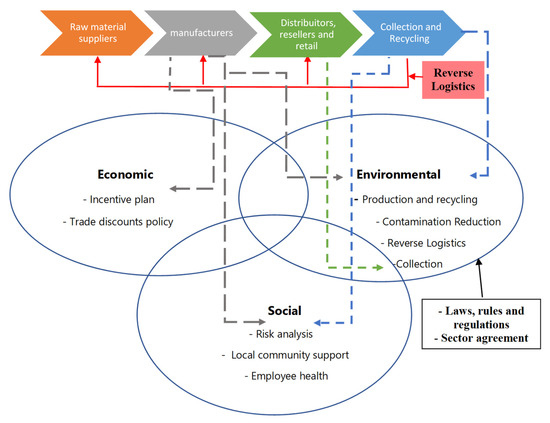

The TBL analysis and discussion serve as a basis for structuring a framework with the main variables that must be observed in the context of the recovery and recycling of EOL LABs. We emphasize that the framework can assume different roles in the understanding, representation, and diffusion of organizational relationships. From the analysis of the various actors involved, it becomes possible to obtain a structure to be used as a reference in the construction of models for the representation and explanation of organizational actions involving the theme of battery recycling. The reference framework seeks to materialize the “organize” function, articulating the spectrum of action, processes, and organizational structures.

The study focused on three key supply chain actors (manufacturers, distributors/dealers/retailers, and recyclers) in the context of recycling. We identified the practices carried out by each actor and how each one works the process in a sustainable way, executing actions that impact the three dimensions of TBL. Sector agreements, laws, and regulations work as RPM that impact the relationships and practices of manufacturers, distributors, and recycling companies in this scenario.

Environmental regulations promote the effect of green technology innovations in polluting industries [54]. In fact, as lead battery manufacturers innovate and design new batteries, they establish cooperative agreements with competitors to design batteries for recycling and resource efficiency. This helps the recycling of key battery components (lead, plastic, acid) for reuse.

As a managerial contribution, the framework can be a guide for managers of different industrial sectors to implement sustainable strategies in their business models. The framework in Figure 2 presents the relationship between the supply chain actors and their actions and practices in each sustainable dimension, and the dashed lines indicate the origin of the actions and practices of the actors in the supply chain. Battery manufacturers adopt practices to encourage and obtain a better collection rate from distributors and retailers through incentive plans and commercial discount policies, also acting in the social and environmental dimensions. The environmental responsibility of manufacturers occurs throughout the product cycle, starting with the purchase of primary or secondary lead to RL for recovery and recycling of EOL batteries. In Brazil, secondary lead is crucial, especially because there is no primary lead production, the lead recovery process presents high loss rates, and there are many small battery-recycling plants not regulated by the government, which can cause lead contamination and an illicit secondary lead recovery market [24].

Figure 2.

Framework for LAB closed-loop supply chain.

Due to the manufacturer’s pricing and discount policy, the distributor, retailer, and reseller assume roles as links in reverse logistics through the collection of EOL batteries. Not all manufacturers will internalize the recycling process; therefore, they have a relevant role in the chain, making the closed-loop supply chain viable.

In relation to the positive and negative effects of the RL design, it is important to note that although there is a reduction in solid waste and contamination through recycling and RL, there is also a negative externality when RL is carried out by road because it leads to fossil fuel consumption and contributes to the increase in pollution levels, especially in Brazil, in which distances are continental. In this sense, the optimization of transport models is necessary in order to mitigate the negative effects related to reverse logistics.

Environmental laws, norms, and regulations are essential for the elaboration of sustainable development programs with impacts on externalities. We show the practicality and usefulness of applying a well-structured empirical approach to understand the effectiveness of environmental law, cascaded to a sector agreement to promote a higher level of recycling of LABs. Our findings are in line with a previous study [55], which found that environmental legal effectiveness depends on the implementation arrangements that establish operational practices such as resourcing of implementation, organizational structures that allow compliance with the law, and mechanisms to ensure the integrity of the governance system.

6. Conclusions

We conducted an exploratory multi-case study of the Brazilian automotive chain involved in the manufacture, sale, reverse logistics, and recycling of LABs. The study was carried out on the largest battery manufacturer in Latin America and on one of the largest Brazilian manufacturers dedicated to the aftermarket. Two companies dedicated to the recycling of LABs and eight commercial companies, including distributors and retailers, also participated. The cases are large companies that have a large market share, being representative companies. Hence, our sample depicts the status of reverse logistics of LABs in the country.

As our study presents an analysis of how the closed-loop supply chain of batteries works in practice, it was possible to identify the relationships between and practices adopted by its actors, from the perspective of TBL. From this, it was possible to design an explanatory framework that could work as a baseline for future sustainability program implementations, and which can also be generalized to other types of batteries. Moreover, we identified the practices and mechanisms that support the development of a sustainable program, as well as potential strategies that could enhance LABs’ value chain sustainability.

The main contribution of our study is the framework proposal, which seeks to materialize the “organize” function, articulating the spectrum of action, processes, and organizational structures in a sustainable perspective. We emphasize that the framework can assume different roles in the understanding, representation, and diffusion of organizational relationships. From the analysis of the various actors involved, it becomes possible to obtain a structure to be used as a reference in the construction of models for the representation and explanation of organizational actions involving the theme of battery recycling.

Our study did not involve the analysis of externalities. Therefore, it is suggested that future research analyze in depth the implementation of these programs seeking to mitigate risks.

Author Contributions

Conceptualization, methodology: W.H. and M.A.; formal analysis, C.M.; investigation, M.A. writing—original draft preparation, G.S.; writing—review and editing, G.S. and C.M.; supervision, W.H., project administration, M.A.; funding acquisition: C.M. All authors have read and agreed to the published version of the manuscript.

Funding

Grant #2019/10142-3, São Paulo Research Foundation (FAPESP).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Aguilar-Esteva, L.C.; Kasliwal, A.; Kinzler, M.S.; Kim, H.C.; Keoleian, G.A. Circular economy framework for automobiles: Closing energy and material loops. J. Ind. Ecol. 2021, 25, 877–889. [Google Scholar] [CrossRef]

- Ayati, M.S.; Shekarian, E.; Majava, J.; Wæhrens, B.V. Toward a circular supply chain: Understanding barriers from the perspective of recovery approaches. J. Clean. Prod. 2022, 359, 131775. [Google Scholar] [CrossRef]

- Shekarian, E. A review of factors affecting closed-loop supply chain models. J. Clean. Prod. 2020, 253, 119823. [Google Scholar] [CrossRef]

- Charles, R.G.; Davies, M.L.; Douglas, P.; Hallin, I.L.; Mabbett, I. Sustainable energy storage for solar home systems in rural Sub-Saharan Africa—A comparative examination of lifecycle aspects of battery technologies for circular economy, with emphasis on the South African context. Energy 2019, 166, 1207–1215. [Google Scholar] [CrossRef]

- Daniel, S.E.; Pappis, C.P.; Voutsinas, T.G. Applying life cycle inventory to reverse supply chains: A case study of lead recovery from batteries. Resour. Conserv. Recycl. 2003, 37, 251–281. [Google Scholar] [CrossRef]

- Subulan, K.; Baykasoglu, A.; Ozsoydan, F.; Tasan, S.; Selim, H. A case-oriented approach to a lead/acid battery closed-loop supply chain network design under risk and uncertainty. J. Manuf. Syst. 2015, 37, 340–361. [Google Scholar] [CrossRef]

- Tosarkani, B.M.; Amin, S.H. A possibilistic solution to configure a battery closed-loop supply chain: Multi-objective approach. Expert Syst. Appl. 2018, 92, 12–26. [Google Scholar] [CrossRef]

- De Giovanni, P. A joint maximization incentive in closed-loop supply chains with competing retailers: The case of spent-battery recycling. Eur. J. Oper. Res. 2018, 268, 128–147. [Google Scholar] [CrossRef]

- Sica, D.; Malandrino, O.; Supino, S.; Testa, M.; Lucchetti, M.C. Management of end-of-life photovoltaic panels as a step towards a circular economy. Renew. Sustain. Energy Rev. 2018, 82, 2934–2945. [Google Scholar] [CrossRef]

- Pan, H.; Geng, Y.; Dong, H.; Ali, M.; Xiao, S. Sustainability evaluation of secondary lead production from spent lead-acid batteries recycling. Resour. Conserv. Recycl. 2019, 140, 13–22. [Google Scholar] [CrossRef]

- Hasanov, P.; Jaber, M.Y.; Tahirov, N. Four-level closed-loop supply chain with remanufacturing. Appl. Math. Model. 2019, 66, 141–155. [Google Scholar] [CrossRef]

- Skinner, L.R.; Bryant, P.T.; Glenn Richey, R. Examining the impact of reverse logistics disposition strategies. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 518–539. [Google Scholar] [CrossRef]

- Guide, V., Jr.; Van Wassenhove, L.N. The evolution of closed-loop supply chain research. Oper. Res. 2009, 57, 10–18. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H. A review of reverse logistics and closed-loop supply chains: A Journal of Cleaner Production focus. J. Clean. Prod. 2017, 142, 371–384. [Google Scholar] [CrossRef]

- Gaur, J.; Mani, V. Antecedents of closed-loop supply chain in emerging economies: A conceptual framework using stakeholder’s perspective. Resour. Conserv. Recycl. 2018, 139, 219–227. [Google Scholar] [CrossRef]

- Masoudipour, E.; Amirian, H.; Sahraeian, R. A novel closed-loop supply chain based on the quality of returned products. J. Clean. Prod. 2017, 151, 344–355. [Google Scholar] [CrossRef]

- Hong, I.H.; Lee, Y.; Chang, P. Socially optimal and fund-balanced advanced recycling fees and subsidies in a competitive forward and reverse supply chain. Resour. Conserv. Recycl. 2014, 82, 75–85. [Google Scholar] [CrossRef]

- Wang, N.; He, Q.; Jiang, B. Hybrid closed-loop supply chains with competition in recycling and product markets. Int. J. Prod. Econ. 2018, 217, 246–258. [Google Scholar] [CrossRef]

- Mies, A.; Gold, S. Mapping the social dimension of the circular economy. J. Clean. Prod. 2021, 321, 128960. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The circular economy: An interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Hahn, T.; Pinkse, J.; Preuss, L.; Figge, F. Tensions in corporate sustainability: Towards an integrative framework. J. Bus. Ethics 2015, 127, 297–316. [Google Scholar] [CrossRef]

- Ghadimi, P.; Wang, C.; Lim, M.K. Sustainable supply chain modeling and analysis: Past debate, present problems and future challenges. Resour. Conserv. Recycl. 2019, 140, 72–84. [Google Scholar] [CrossRef]

- Mani, V.; Agarwal, R.; Gunasekaran, A.; Papadopoulos, T.; Dubey, R.; Childe, S.J. Social sustainability in the supply chain: Construct development and measurement validation. Ecol. Indic. 2016, 71, 270–279. [Google Scholar] [CrossRef]

- Machado Santos, S.; Cabral Neto, J.; Mendonça Silva, M. Forecasting model to assess the potential of secondary lead production from lead acid battery scrap. Environ. Sci. Pollut. Res. 2019, 26, 5782–5793. [Google Scholar] [CrossRef]

- Kannan, G.; Sasikumar, P.; Devika, K. A genetic algorithm approach for solving a closed-loop supply chain model: A case of battery recycling. Appl. Math. Model. 2010, 34, 655–670. [Google Scholar] [CrossRef]

- May, G.J.; Davidson, A.; Monahov, B. Lead batteries for utility energy storage: A review. J. Energy Storage 2018, 15, 145–157. [Google Scholar] [CrossRef]

- Yang, J.; Kumar, R.V.; Singh, D.P. Combustion synthesis of PbO from lead carboxylate precursors relevant to developing a new method for recovering components from spent lead-acid batteries. J. Chem. Technol. Biotechnol. 2012, 87, 1480–1488. [Google Scholar] [CrossRef]

- Gottesfeld, P.; Pokhrel, A.K. Review: Lead exposure in battery manufacturing and recycling in developing countries and among children in nearby communities. J. Occup. Environ. Hyg. 2011, 8, 520–532. [Google Scholar] [CrossRef]

- Gottesfeld, P.; Were, F.; Adogame, L.; Gharbi, S.; San, D.; Nota, M.M.; Kuepouo, F. Soil contamination from lead battery manufacturing and recycling in seven African countries. Environ. Res. 2018, 161, 609–614. [Google Scholar] [CrossRef]

- Joshi, B.V.; Vipin, B.; Ramkumar, J.; Amit, R.K. Impact of policy instruments on lead-acid battery recycling: A system dynamics approach. Resour. Conserv. Recycl. 2021, 169, 105528. [Google Scholar] [CrossRef]

- Espinosa, D.C.R.; Bernardes, A.M.; Tenório, J.A.S. Brazilian policy on battery disposal and its practical effects on battery recycling. J. Power Sources 2004, 137, 134–139. [Google Scholar] [CrossRef]

- Li, M.; Liu, J.; Han, W. Recycling and management of waste lead-acid batteries: A mini-review. Waste Manag. Res. 2016, 34, 298–306. [Google Scholar] [CrossRef] [PubMed]

- Salim, H.K.; Stewart, R.A.; Sahin, O.; Dudley, M. Drivers, barriers and enablers to end-of-life management of solar photovoltaic and battery energy storage systems: A systematic literature review. J. Clean. Prod. 2019, 211, 537–554. [Google Scholar] [CrossRef]

- Ghahremani-Nahr, J.; Kian, R.; Sabet, E. A robust fuzzy mathematical programming model for the closed-loop supply chain network design and a whale optimization solution algorithm. Expert Syst. Appl. 2019, 116, 454–471. [Google Scholar] [CrossRef]

- Battery Council International. Available online: https://batterycouncil.org/ (accessed on 18 March 2020).

- De Freitas, C.U.; De Capitani, E.M.; Gouveia, N.; Simonetti, M.H.; e Silva, M.R.D.P.; Kira, C.S.; de Abreu, M.H. Lead exposure in an urban community: Investigation of risk factors and assessment of the impact of lead abatement measures. Environ. Res. 2007, 103, 338–344. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, J.; Wu, X.; Hu, Y.; Yu, W.; Wang, J.; Dong, J.; Li, M.; Liang, S.; Hu, J.; et al. A critical review on secondary lead recycling technology and its prospect. Renew. Sustain. Energy Rev. 2016, 61, 108–122. [Google Scholar] [CrossRef]

- Etiang, N.; Arvelo, W.; Galgalo, T.; Amwayi, S.; Gura, Z.; Kioko, J.; Omondi, G.; Patta, S.; Lowther, S.; Brown, M. Environmental Assessment and Blood Lead Levels of Children in Owino Uhuru and Bangladesh Settlements in Kenya. J. Health Pollut. 2018, 8, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, K.I.A.; Nurunnahar, S.; Kabir, M.L.; Islam, M.T.; Baker, M.; Islam, M.S.; Forsyth, J.E. Child lead exposure near abandoned lead acid battery recycling sites in a residential community in Bangladesh: Risk factors and the impact of soil remediation on blood lead levels. Environ. Res. 2021, 194, 110689. [Google Scholar] [CrossRef]

- U.S. Department of Health and Human Services, ATSDR. Public Health Assessment for U.S. Smelter and Lead Refinery, Inc.; a/k/a USS Lead Refinery Inc.: East Chicago, IN, USA, 2016. [Google Scholar]

- Tian, X.; Wu, Y.; How, P.; Liang, S.; Qu, S.; Xu, M.; Zuo, T. Environmental impact and economic assessment of secondary lead production: Comparison of main spent lead-acid battery recycling processes in China. J. Clean. Prod. 2017, 144, 142–148. [Google Scholar] [CrossRef]

- Sun, Z.; Cao, H.; Zhang, X.; Lin, X.; Zheng, W.; Cao, G.; Sun, Y.; Zhang, Y. Spent lead-acid battery recycling in China—A review and sustainable analyses on mass flow of lead. Waste Manag. 2017, 64, 190–201. [Google Scholar] [CrossRef]

- Jeong, K.; Kim, J.G. Lead-acid battery recycling and material flow analysis of lead in Korea. J. Mater. Cycles Waste Manag. 2017, 20, 1348–1354. [Google Scholar] [CrossRef]

- Eisenhardt, K.M.; Graebner, M.E. Theory building from cases: Opportunities and challenges. Acad. Manag. J. 2007, 50, 25–32. [Google Scholar] [CrossRef]

- Parker, C.; Scott, S.; Geddes, A. Snowball sampling. In SAGE Research Methods Foundations; SAGE Publications: Thousand Oaks, CA, USA, 2019. [Google Scholar] [CrossRef]

- Naderifar, M.; Goli, H.; Ghaljaie, F. Snowball sampling: A purposeful method of sampling in qualitative research. Strides Dev. Med. Educ. 2017, 14. [Google Scholar] [CrossRef]

- Tian, X.; Gong, Y.; Wu, Y.; Agyeiwaa, A.; Zuo, T. Management of used lead-acid battery in China: Secondary lead industry progress, policies, and problems. Resour. Conserv. Recycl. 2014, 93, 75–84. [Google Scholar] [CrossRef]

- Ahmadi, H.B.; Kusi-Sarpong, S.; Rezaei, J. Assessing the social sustainability of supply chains using Best Worst Method. Resour. Conserv. Recycl. 2017, 126, 99–106. [Google Scholar] [CrossRef]

- Wang, C.; Mu, D.; Zhao, F.; Sutherland, J.W. A parallel simulated annealing method for the vehicle routing problem with simultaneous pickup–delivery and time windows. Comput. Ind. Eng. 2015, 83, 111–122. [Google Scholar] [CrossRef]

- Sasikumar, P.; Haq, A.N. Integration of closed-loop distribution supply chain network and 3PRLP selection for the case of battery recycling. Int. J. Prod. Res. 2011, 49, 3363–3385. [Google Scholar] [CrossRef]

- National Mining Agency. Lead. Available online: https://www.gov.br/anm/pt-br/centrais-de-conteudo/publicacoes/serie-estatisticas-e-economia-mineral/sumario-mineral/pasta-sumario-brasileiro-mineral-2018/chumbo_sm_2018 (accessed on 15 August 2022).

- Iber. Brazilian Institute of Recyclable Energy. Results 2021 Lead-Acid Batteries. Available online: https://www.flipsnack.com/9E57DBDD75E/livreto_iber-2022-flipsnack.html (accessed on 15 August 2022).

- Garche, J.; Moseley, P.T.; Karden, E. Lead–acid batteries for hybrid electric vehicles and battery electric vehicles. In Advances in Battery Technologies for Electric Vehicles; Woodhead Publishing: Sawston, UK, 2015; pp. 75–101. [Google Scholar]

- Cai, X.; Zhu, B.; Zhang, H.; Li, L.; Xie, M. Can direct environmental regulation promote green technology innovation in heavily polluting industries? Evidence from Chinese listed companies. Sci. Total Environ. 2020, 746, 140810. [Google Scholar] [CrossRef]

- Martin, P.; Boer, B.; Slobodian, L. Framework for Assessing and Improving Law for Sustainability: A Legal Component of a Natural Resource Governance Framework; IUCN: International Union for Conservation of Nature: Gland, Switzerland, 2016. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).