1. Introduction

The limited fossil fuel resources and their harmful impacts on the environment have been the main motivations for researchers to find alternative solutions [

1]. At the moment, the prime mover for most vehicles and power plants is based on combustion engines that use fossil fuels [

2]. Renewable energies such as wind and solar are recently being widely used for power plants and buildings, while hydrogen and methane have shown promising results to be used for mobile applications [

3]. These two fuels can be either directly injected into modified combustion engines or be used in fuel cells, which utilize electrochemical reactions to generate electricity [

4]. The usage of fuel cells in power plants and charging stations ensures a continuous and environmentally friendly generation of electricity for different types of applications [

5].

The most commercialized types of fuel cells are the Solid Oxide Fuel Cell (SOFC) [

6] and Proton Exchange Membrane Fuel Cell (PEMFC) [

7], which operate in high- and low- temperatures, respectively. PEMFC only uses hydrogen as the fuel [

8], while SOFC can utilize methane, methanol, bio-methanol, natural gas, and biogas in addition to hydrogen [

9]. SOFC is considered to be more suitable for stationary applications such as power plants and charging stations, either standalone [

10] or combined with other renewable resources such as wind [

11], solar [

12], and geothermal [

13]. As the operating temperature of the SOFC is high, the exhaust gases from the stack may still have the energy to be recovered [

14]. In this regard, it is common to integrate the SOFC units with different types of bottoming cycles [

15]. The selection of the bottoming cycle mainly depends on the temperature of the output flow from the afterburner of the SOFC unit. In high-temperature cases, the usage of gas turbines is suggested [

16], while the Kalina cycle and Organic Rankine Cycle (ORC) have shown promising results in low exhaust temperatures [

17]. The waste heat recovery of the SOFC unit also leads to higher efficiencies of the system while improving the environmental performance of the SOFC units by reducing the waste heat to the atmosphere.

Thus far, the usage of ORCs has been recognized in more than 690 power plants with more than 2.6 Gigawatts of installed capacity [

18]. The most important application of the ORCs is to recover the waste heat by different types of units, in addition to being used in biomass, solar, wind-thermal, and geothermal power plants [

19]. In the operation of the ORCs, the selection of the working fluid is of importance and the efficiency of the system is highly dependent on the thermodynamic characteristics of the utilized working fluid [

20]. The ideal properties for the ORC’s working fluids are isentropic vapor saturation curve, low freezing point, safety, low cost, and low environmental impacts [

21]. Although there have been studies to indicate the better performance of the combined systems from energetic and exergetic aspects, there is a research gap on the environmental impacts of using the integrated systems of the SOFC and ORC.

Instead of characterizing the environmental impacts of the SOFC’s operation, a detailed analysis should be deployed to consider all the processes to manufacture the SOFC and all the other components of the hybrid system in addition to the processes needed for the SOFC’s operation, i.e., maintenance [

22]. In this regard, a comprehensive study should be conducted to evaluate the supply chain of the components and their life cycles, which is known as a life-cycle assessment (LCA) [

23]. Using LCA, all the environmental effects of the combined system are obtained during the entire lifetime from the extraction of the raw materials to the manufacturing of the components of the integrated system and the disposal of waste and emissions to the environment at each stage of the life cycle [

24]. This study aims to suggest an integrated system to provide electricity for a charging station for electric vehicles using fuel cell technology that is environmentally friendly. However, the processes of the whole operation of the charging station should be further analyzed using the LCA method to make a logical comparison to the conventional fossil-fuel-based systems.

Furthermore, as a method to reduce the possible harmful impacts on the environment and improve the efficiency of the integrated system, the usage of batteries is suggested [

25]. Therefore, partial operation of the system becomes feasible, which means lower disposal of heat to the environment and a higher lifetime of the system. In this condition, the efficiency of the system will be improved as well [

26]. Although there has been implementation of different types of storage systems in an integrated system to improve the overall performance, a detailed dynamic evaluation [

27] of the combined battery in the proposed system should be performed in addition to the energy, exergy, and environmental studies to prove the suitability of the system to be established as a charging station for the electric cars.

Due to the harmful impacts of fossil fuels on the environment, the main aim of this study is to propose an integrated system using the four SOFC stacks as the energy provider. The system is designed to provide the required electricity for a charging station that is dedicated to electric vehicles. To better improve the efficiency of the system, the exhaust heat of the SOFC stacks is recovered by an ORC unit considering R134a as the working fluid. As the power demand of the electric cars may vary during the day, it is assumed that the four SOFC stacks will operate full-load (100%) during the day from 6 a.m. to 10 p.m., while three of the SOFC stacks will change to partial-load (30%) operation from 10 p.m. to 6 a.m. to reduce waste to the environment and to improve the efficiency of the combined system. The fourth SOFC stack will remain at full-load operation. Since there is still a possibility of having fluctuations in the power demand by the electric cars, a LiMn2O4 type of Lithium-Ion battery is integrated to the SOFC stacks, and the ORC unit is to be charged during the full-load operation and act as a backup system for the possible lack of electricity during the partial operation of the SOFC stacks. A dynamic study of the battery considering three different power demands was performed to better analyze the performance of the dedicated battery in the system. Energy and exergy characterizations were performed to obtain the thermodynamic properties in all the state points and to calculate the overall efficiencies and exergy destructions. Additionally, the LCA method was used to figure out the impacts of the current suggested design on the environment. Comparisons were also made between the environmental impacts of different input fuels for the SOFC stacks and ORC’s working fluids.

2. Problem Description

At the current stage, there are power plants, which are fueled by fossil fuels to produce power for different applications. However, this study aims to find a suitable alternative for fossil-fueled power plants to act as a charging station for electric vehicles. In this regard, four SOFC stacks are devised to use methane as the fuel and produce the main share of the required electricity. To operate the SOFC, the fuel, air, and water are compressed to reach the desired pressure followed by pre-heating to obtain the required temperature. Then, the steam and the fuel are mixed in a mixer before entering the SOFC stack. During the operation of the SOFC, electricity is generated that is transferred to the inverter, and the exhaust gases are transported to the afterburner. The reason behind using the afterburner is the existence of gases which have not participated in the electrochemical reactions and still have enough chemical energy to be converted. After the combustion in the afterburner, the exhaust gases from this unit have a noticeable amount of heat to be recovered by a bottoming cycle. The temperature of the exhaust streams from the SOFC stacks remains higher than 1000 K after passing through the water and fuel pump heat exchanger, however, the exhaust temperature decreases rapidly through the air pump heat exchanger to temperature below 500 K. The mass flow is large and stays constant during the heat exchange process. To recover the exhaust heat of the SOFC stacks, ORC with R134a as the working fluid is utilized to further generate electricity for the proposed charging station. It should be mentioned that a basic ORC unit is used for heat recovery purposes, and advanced ORC units such as cascaded ORC and ORC with regenerator will obviously further recover the exhaust heat from the SOFC stacks.

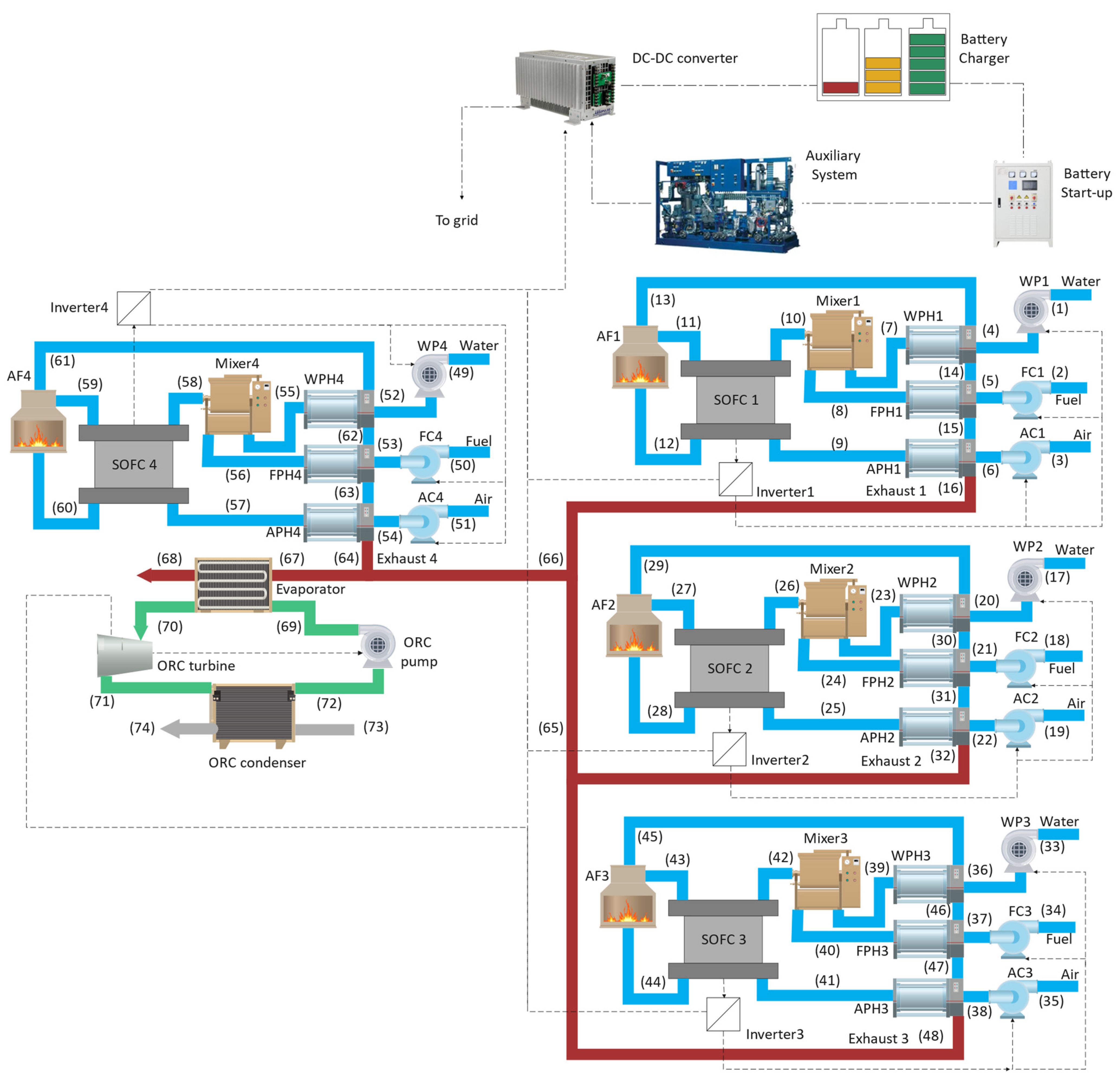

Figure 1 shows a schematic of the proposed design to provide electricity for electric vehicles. In

Figure 1, WP, FC, AC, WPH, FPH, APH, AF, ORC, and SOFC are the respective abbreviations for the water pump, fuel compressor, water pre-heater, fuel pre-heater, air pre-heater, afterburner, Organic Rankine Cycle, and Solid Oxide Fuel Cell.

To improve the efficiency of the system and reduce the amount of required fuel for the system’s operation, the SOFC stacks operate full-load (100%) during the day from 6 a.m. to 10 p.m. while SOFC1, SOFC2, and SOFC3 work partial-load (30%) from 10 p.m. to 6 a.m. considering that SOFC4 continues full-load operation. The reason behind this strategy is that there are fewer electric cars at night requiring to be charged, hence, it is better to decrease the system’s operation and fuel utilization. However, it is possible that a sudden peak in the power demand occurs, either during the day or at night. In this regard, it is suggested to use batteries to store the electricity once the power demand is lower than the generated electricity by the SOFC stacks and the ORC unit, hence, the battery can act as a backup unit in high power demand scenarios.

In addition to a dynamic performance needed to analyze the response of the battery to different power load demands, the performance of the system should be characterized by a detailed thermodynamic analysis to obtain the energetic and exergetic characteristics in addition to the overall efficiencies. Although the usage of methane and fuel cells seems to be more environmentally friendly than fossil fuels, a detailed life-cycle assessment is still needed to figure out the corresponding impacts of this charging station considering eighteen parameters based on ReCiPe 2016 v1.03 Midpoint (H).

5. Conclusions

The current paper evaluated a state-of-the-art design for the electric vehicle charging station using SOFC, ORC, and battery units. Thermodynamic modeling and simulation were developed to obtain the characteristics of the system in each state point. Having these characteristics enabled the calculation of the output power, overall efficiencies, and exhaust heat. Results indicated that the system is able to produce 246.02 kWh electricity using 3.35 g/s of methane. The respective overall energy and exergy efficiencies were also calculated to be 48.96% and 48.51%. The changes in the current density of the SOFC stacks resulted in noticeable changes in the output power of the SOFC stacks and ORC unit, followed by changes in the overall efficiencies. Although higher current densities resulted in higher output powers, the efficiencies are reduced since the operation of SOFC stacks at high current densities leads to higher exergy values and exhaust heat. The results of the exergy destructions in each component also indicated the low exergy destruction values between the ORC’s components, while the SOFC’s air pre-heater had the highest share among all the analyzed components.

The dynamic response of the LiMn2O4 battery by three different power load profiles was analyzed, and it was concluded that the battery unit is capable enough to act as a backup/storage unit for the possible fluctuations in the power demand of the electric vehicles. Results of the life-cycle assessment also showed the impacts of the current suggested design of the charging station on the environment using the ReCiPe 2016 v1.03 Midpoint (H). A comparison was made to analyze the effects of five different SOFC fuels, which resulted in the conclusion of selecting pure hydrogen as the most environmentally friendly fuel for the SOFC. However, the LCA results also indicated the promising results of bio-methanol, biogas, and methane to be used as the SOFC’s fuel once pure hydrogen is not available. The second comparison among the impacts of the different ORC’s working fluid on the environment revealed the advantages of using R245fa. The LCA results suggested against using R227ea based on the ReCiPe 2016 v1.03 Midpoint (H). Although the current study covered important gaps in the literature, the following topics can be interesting for future studies:

The current study performed a detailed energy, exergy, and environmental study to characterize the overall performance of the suggested design for the charging station. In addition to this study, it is suggested to perform an economic evaluation to further characterize this novel design using thermo-economic or exergo-economic methodologies.

This study considered the usage of a LiMn2O4 Lithium-Ion battery to act as the backup/storage unit. Although the LiMn2O4 battery has shown promising results in different applications, other types of batteries and storage systems can be further analyzed and integrated into the system. LCA studies can be conducted for each type of battery and the obtained simulation results can facilitate the determination of the best type of battery to be used in the suggested design.