The Influence of Li4Ti5O12 Preparation Method on Lithium-Ion Capacitor Performance

Abstract

1. Introduction

2. Experimental

2.1. Synthesis of LTO

2.2. Material Characterization

2.3. Electrochemical Measurements

3. Results and Discussion

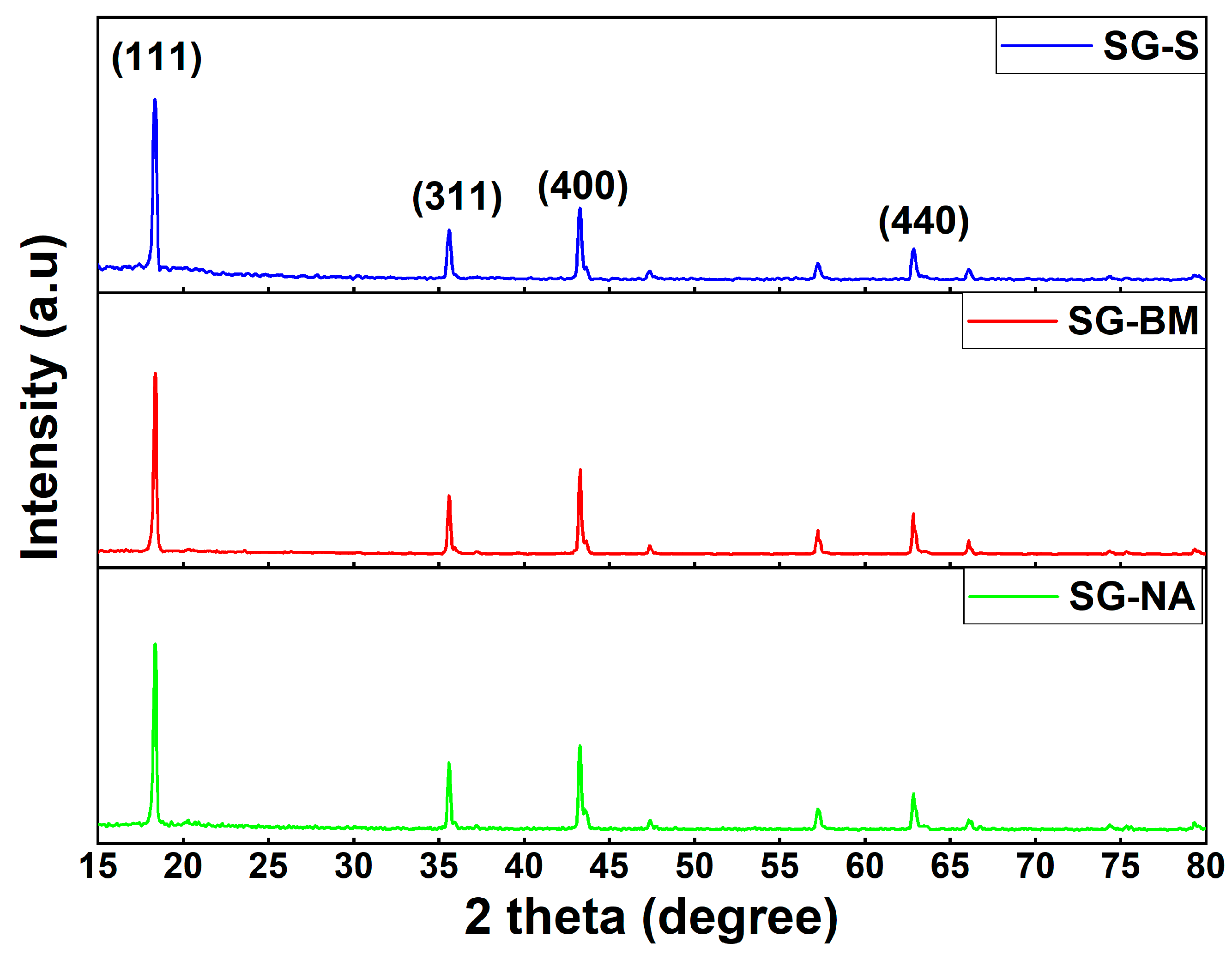

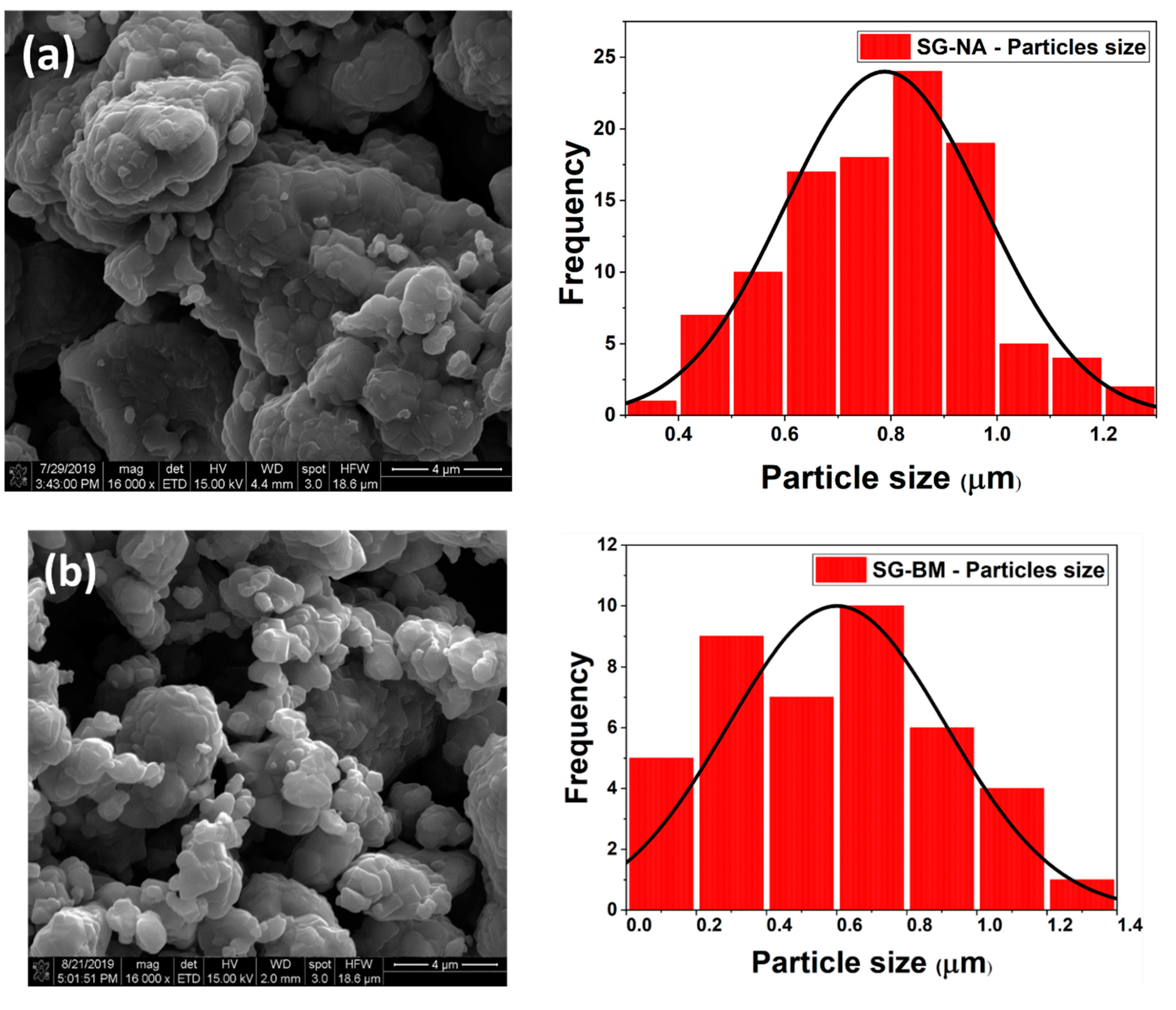

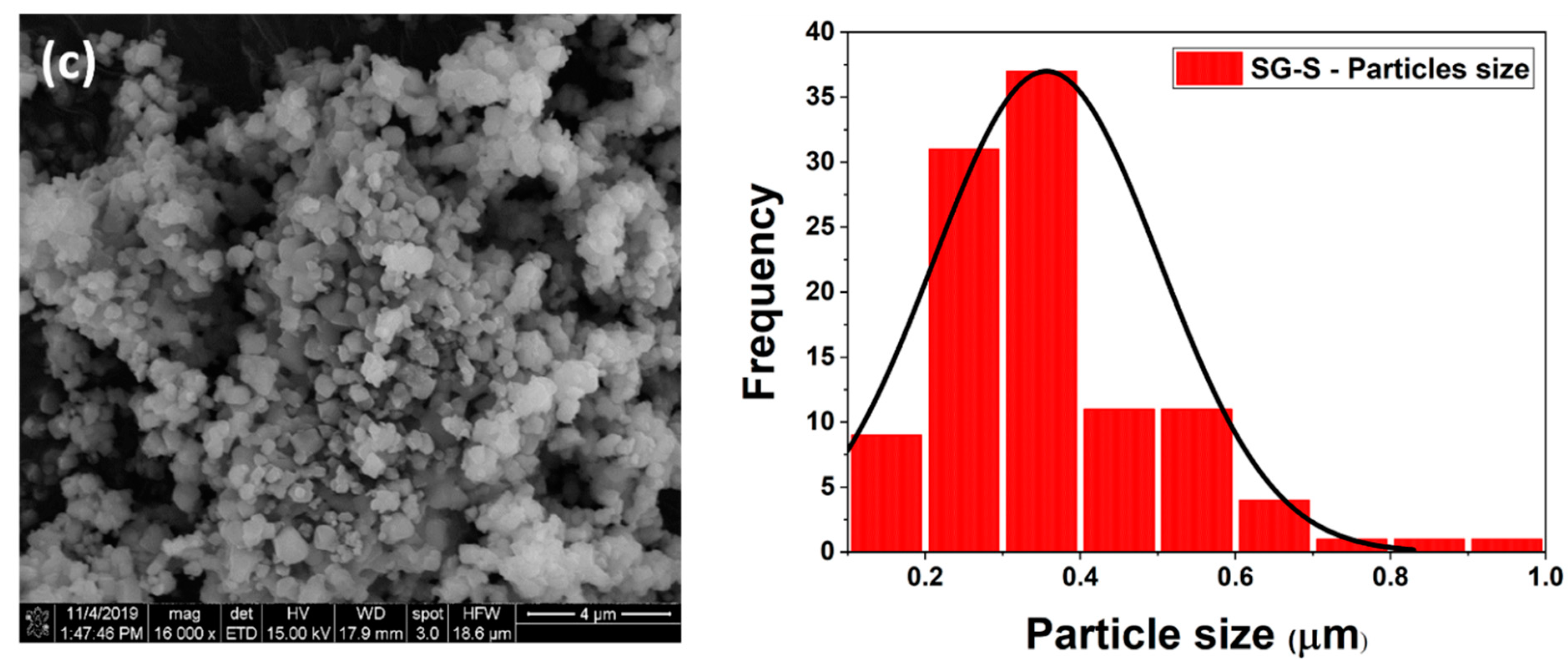

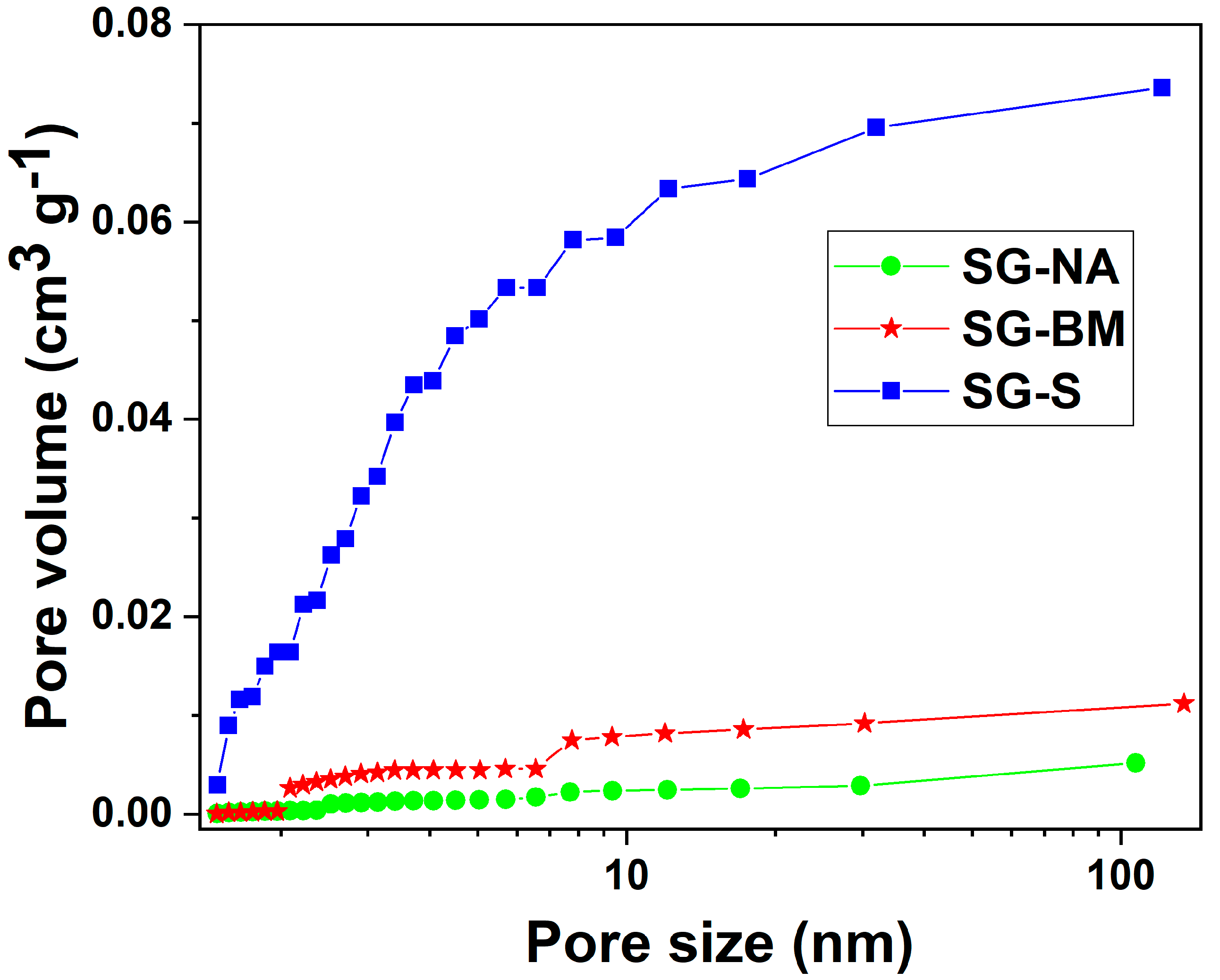

3.1. Structural and Morphological Characterization

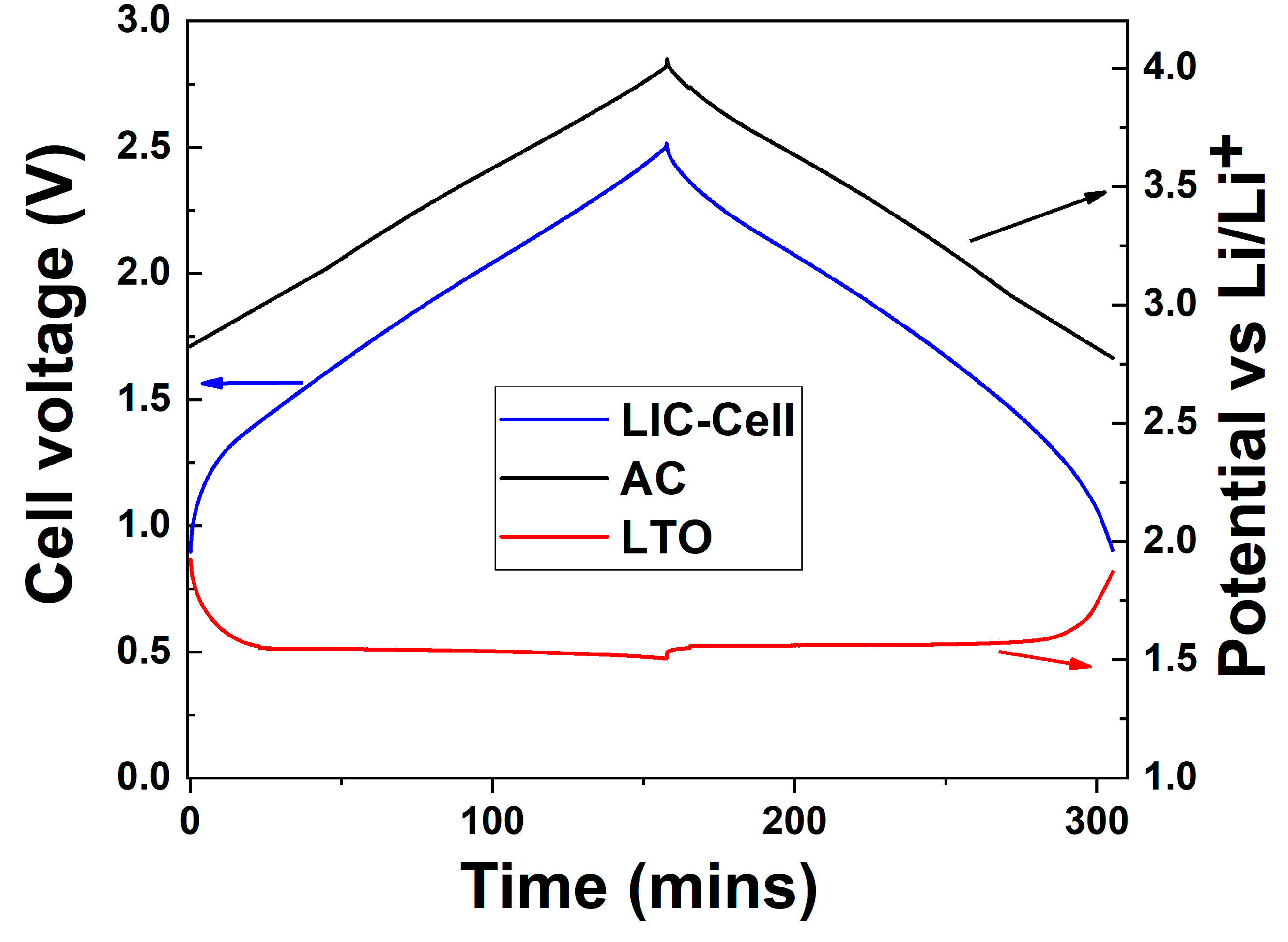

3.2. Electrochemical Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, B.; Zheng, J.; Zhang, H.; Jin, L.; Yang, D.; Lv, H.; Shen, C.; Shellikeri, A.; Zheng, Y.; Gong, R.; et al. Electrode Materials, Electrolytes, and Challenges in Nonaqueous Lithium-Ion Capacitors. Adv. Mater. 2018, 30, e1705670. [Google Scholar] [CrossRef]

- Han, P.; Xu, G.; Han, X.; Zhao, J.; Zhou, X.; Cui, G. Lithium Ion Capacitors in Organic Electrolyte System: Scientific Problems, Material Development, and Key Technologies. Adv. Energy Mater. 2018, 8, 1–30. [Google Scholar] [CrossRef]

- Cao, W.J.; Luo, J.F.; Yan, J.; Chen, X.J.; Brandt, W.; Warfield, M.; Lewis, D.; Yturriaga, S.R.; Moye, D.G.; Zheng, J.P. High Performance Li-Ion Capacitor Laminate Cells Based on Hard Carbon/Lithium Stripes Negative Electrodes. J. Electrochem. Soc. 2016, 164, A93–A98. [Google Scholar] [CrossRef]

- Amatucci, G.G.; Badway, F.; Du Pasquier, A.; Zheng, T. An Asymmetric Hybrid Nonaqueous Energy Storage Cell. J. Electrochem. Soc. 2001, 148, A930–A939. [Google Scholar] [CrossRef]

- Cao, W.; Zheng, J. Li-ion capacitors with carbon cathode and hard carbon/stabilized lithium metal powder anode electrodes. J. Power Sources 2012, 213, 180–185. [Google Scholar] [CrossRef]

- Zheng, J.P. High Energy Density Electrochemical Capacitors without Consumption of Electrolyte. J. Electrochem. Soc. 2009, 156, A500–A505. [Google Scholar] [CrossRef]

- Nitta, N.; Yushin, G. High-capacity anode materials for lithium-ion batteries: Choice of elements and structures for active particles. Part. Part. Syst. Charact. 2014, 31, 317–336. [Google Scholar] [CrossRef]

- Nitta, N.; Wu, F.; Lee, J.T.; Yushin, G. Li-ion battery materials: Present and future. Mater. Today 2015, 18, 252–264. [Google Scholar] [CrossRef]

- Cao, W.; Li, Y.; Fitch, B.; Shih, J.; Doung, T.; Zheng, J. Strategies to optimize lithium-ion supercapacitors achieving high-performance: Cathode configurations, lithium loadings on anode, and types of separator. J. Power Sources 2014, 268, 841–847. [Google Scholar] [CrossRef]

- Hagen, M.; Yan, J.; Cao, W.; Chen, X.; Shellikeri, A.; Du, T.; Read, J.; Jow, T.; Zheng, J. Hybrid lithium-ion battery-capacitor energy storage device with hybrid composite cathode based on activated carbon/LiNi0.5Co0.2Mn0.3O2. J. Power Sources 2019, 433, 126689. [Google Scholar] [CrossRef]

- Bolufawi, O.; Shellikeri, A.; Zheng, J.P. Lithium-Ion Capacitor Safety Testing for Commercial Application. Batteries 2019, 5, 74. [Google Scholar] [CrossRef]

- Naderi, R.; Shellikeri, A.; Hagen, M.; Cao, W.; Zheng, J.P. The Influence of Anode/Cathode Capacity Ratio on Cycle Life and Potential Variations of Lithium-Ion Capacitors. J. Electrochem. Soc. 2019, 166, 2610–2617. [Google Scholar] [CrossRef]

- Ohzuku, T.; Ueda, A.; Nagayama, M. Electrochemistry and Structural Chemistry of LiNiO2 (R3m) for 4 Volt Secondary Lithium Cells. J. Electrochem. Soc. 1993, 140, 1862–1870. [Google Scholar] [CrossRef]

- Ohzuku, T.; Ueda, A.; Yamamota, N. Zero-Strain Insertion Material of Li[Lil/3Ti5/3]O4 for Rechargeable Lithium Cells. J. Electrochem. Soc. 1995, 142, 1431. Available online: http://jes.ecsdl.org/content/142/5/1431.full.pdf (accessed on 2 February 2019). [CrossRef]

- Zhao, B.; Ran, R.; Liu, M.; Shao, Z. A comprehensive review of Li4Ti5O12-based electrodes for lithium-ion batteries: The latest advancements and future perspectives. J. Gen. Microbiol. 2015, 128, 2165–2177. [Google Scholar] [CrossRef]

- Allen, J.; Jow, T.; Wolfenstine, J. Low temperature performance of nanophase Li4Ti5O12. J. Power Sources 2006, 159, 1340–1345. [Google Scholar] [CrossRef]

- Yi, T.-F.; Yang, S.-Y.; Xie, Y. Recent advances of Li4Ti5O12 as a promising next generation anode material for high power lithium-ion batteries. J. Mater. Chem. A 2015, 3, 5750–5777. [Google Scholar] [CrossRef]

- Hao, Y.-J.; Lai, Q.-Y.; Liu, D.-Q.; Xu, Z.-U.; Ji, X.-Y. Synthesis by citric acid sol–gel method and electrochemical properties of Li4Ti5O12 anode material for lithium-ion battery. Mater. Chem. Phys. 2005, 94, 382–387. [Google Scholar] [CrossRef]

- Brinker, C.J.; Scherer, G.W. Sol-Gel Science: The Physics and Chemistry of Sol-Gel Processing; Academic Press: Cambridge, MA, USA, 1990. [Google Scholar]

- Khomane, R.B.; Prakash, A.; Ramesha, K.; Sathiya, M. CTAB-assisted sol–gel synthesis of Li4Ti5O12 and its performance as anode material for Li-ion batteries. Mater. Res. Bull. 2011, 46, 1139–1142. [Google Scholar] [CrossRef]

- Sandhya, C.; John, B.; Gouri, C. Surfactant-assisted solegel route to lithium titanate and its electrochemical properties. J. Alloys Compd. 2016, 655, 238–243. [Google Scholar] [CrossRef]

- Yan, G.; Fang, H.; Zhao, H.; Li, G.; Yang, Y.; Li, L. Ball milling-assisted sol–gel route to Li4Ti5O12 and its electrochemical properties. J. Alloys Compd. 2009, 470, 544–547. [Google Scholar] [CrossRef]

- Wang, G.; Xu, J.; Wen, M.; Cai, R.; Ran, R.; Shao, Z. Influence of high-energy ball milling of precursor on the morphology and electrochemical performance of Li4Ti5O12-ball-milling time. Solid State Ionics 2008, 179, 946–950. [Google Scholar] [CrossRef]

- Jamin, C.; Traina, K.; Eskenazi, D.; Krins, N.; Cloots, R.; Vertruyen, B.; Boschini, F. Effect of freeze-drying and self-ignition process on the microstructural and electrochemical properties of Li4Ti5O12. Mater. Res. Bull. 2013, 48, 4641–4646. [Google Scholar] [CrossRef]

- Mahmoud, A.; Amarilla, J.M.; Lasri, K.; Saadoune, I. Influence of the synthesis method on the electrochemical properties of the Li4Ti5O12 spinel in Li-half and Li-ion full-cells. A systematic comparison. Electrochim. Acta 2013, 93, 163–172. [Google Scholar] [CrossRef]

- Jiang, C.; Ichihara, M.; Honma, I.; Zhou, H. Effect of particle dispersion on high rate performance of nano-sized Li4Ti5O12 anode. Electrochim. Acta 2007, 52, 6470–6475. [Google Scholar] [CrossRef]

- Pohlmann, S.; Balducci, A. A new conducting salt for high voltage propylene carbonate-based electrochemical double layer capacitors. Electrochim. Acta 2013, 110, 221–227. [Google Scholar] [CrossRef]

- Ariyoshi, K.; Yamato, R.; Ohzuku, T. Zero-strain insertion mechanism of Li[Li1/3Ti5/3]O4 for advanced lithium-ion (shuttlecock) batteries. Electrochim. Acta 2005, 51, 1125–1129. [Google Scholar] [CrossRef]

- Deschanvres, A.; Raveau, B.; Sekkal, Z. Mise en evidence et etude cristallographique d’une nouvelle solution solide de type spinelle Li1+xTi2−xO4 0 ≤ x ≤ 0, 333. Mater. Res. Bull. 1971, 6, 699–704. [Google Scholar] [CrossRef]

- Kuo, Y.-C.; Lin, J.-Y. One-pot sol-gel synthesis of Li4Ti5O12/C anode materials for high-performance Li-ion batteries. Electrochim. Acta 2014, 142, 43–50. [Google Scholar] [CrossRef]

- Chauque, S.; Oliva, F.; Visintin, A.; Barraco, D.; Leiva, E.; Cámara, O. Lithium titanate as anode material for lithium ion batteries: Synthesis, post-treatment and its electrochemical response. J. Electroanal. Chem. 2017, 799, 142–155. [Google Scholar] [CrossRef]

- Pohjalainen, E.; Rauhala, T.; Valkeapää, M.; Kallioinen, J.; Kallio, T. Effect of Li4Ti5O12 particle size on the performance of lithium ion battery electrodes at high C-rates and low temperatures. J. Phys. Chem. C 2015, 119, 2277–2283. [Google Scholar] [CrossRef]

- Zukalová, M.; Fabián, M.; Klusáčková, M.; Klementová, M.; Lásková, B.P.; Danková, Z.; Senna, M.; Kavan, L. Li insertion into Li4Ti5O12 spinel prepared by low temperature solid state route: Charge capability vs surface area. Electrochim. Acta 2018, 265, 480–487. [Google Scholar] [CrossRef]

- Zhao, D.; Huo, Q.; Feng, J.; Chmelka, B.F.; Stucky, G.D. Nonionic Triblock and Star Diblock Copolymer and Oligomeric Surfactant Syntheses of Highly Ordered, Hydrothermally Stable, Mesoporous Silica Structures. J. Am. Chem. Soc. 1998, 120, 6024–6036. [Google Scholar] [CrossRef]

- Moss, P.; Au, G.; Plichta, E.; Zheng, J. Investigation of solid electrolyte interfacial layer development during continuous cycling using ac impedance spectra and micro-structural analysis. J. Power Sources 2009, 189, 66–71. [Google Scholar] [CrossRef]

- Lai, C.; Wu, Z.; Zhu, Y.; Wu, Q.; Li, L.; Wang, C. Ball-milling assisted solid-state reaction synthesis of mesoporous Li4Ti5O12 for lithium-ion batteries anode. J. Power Sources 2013, 226, 71–74. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, Z.; Yang, T.; Liao, C.; Wang, Z.; Sun, K. Facile preparation of nanocrystalline Li4Ti5O12 and its high electrochemical performance as anode material for lithium-ion batteries. Electrochem. Commun. 2011, 13, 654–656. [Google Scholar] [CrossRef]

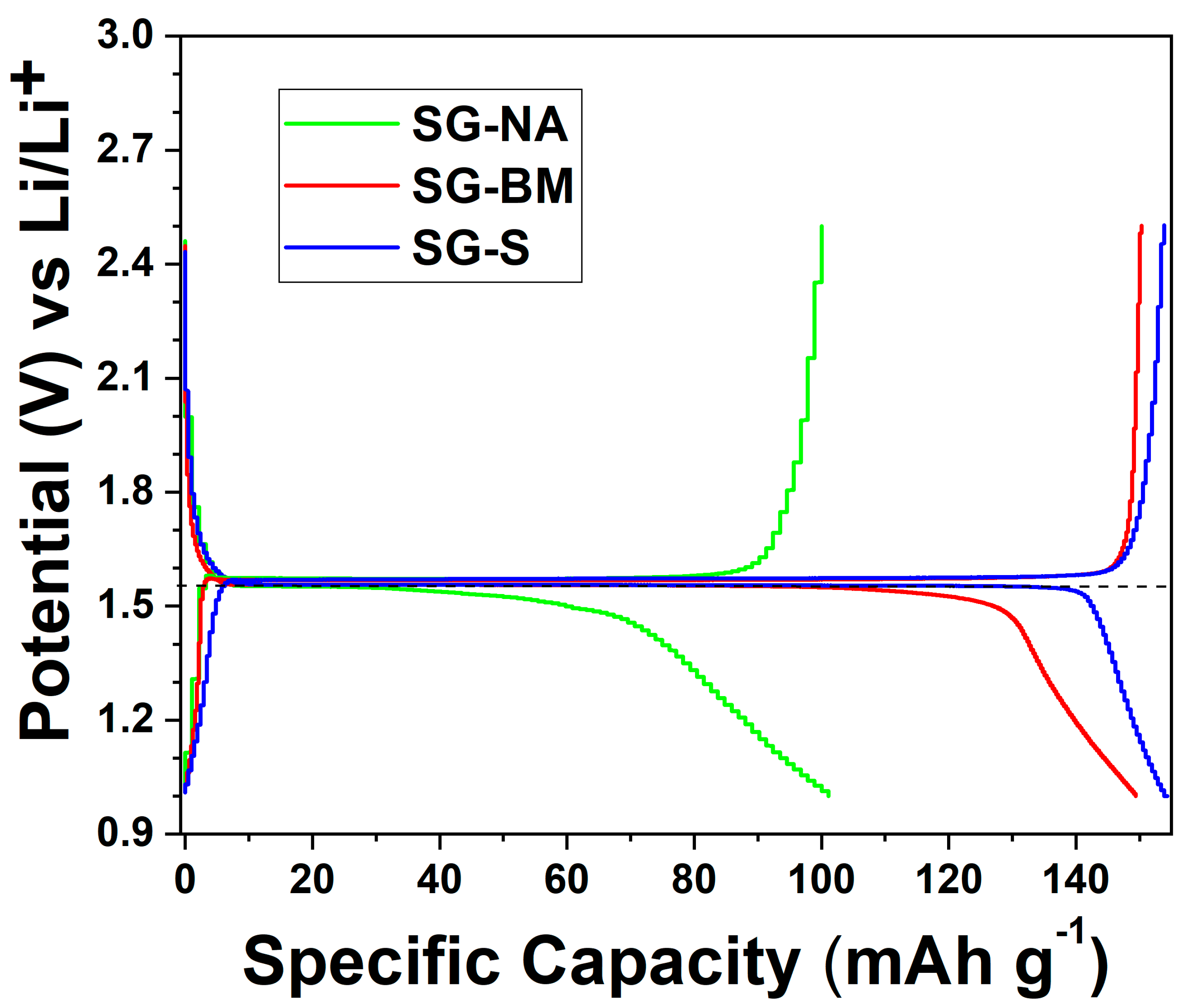

| Sample | ac (nm) | d (nm) | PS (nm) | BET (m2 g−1) | Pore vol. (cm3 g−1) | Td (g cm−3) | Csp (mAh g−1) | CV (mAh cm−3) |

|---|---|---|---|---|---|---|---|---|

| SG-NA | 0.835 | 32 | 900 | 2.20 | 0.005 | 1.6 | 100 | 160 |

| SG-BM | 0.837 | 40 | 600 | 9.60 | 0.011 | 1.0 | 150 | 150 |

| SG-S | 0.836 | 36 | 350 | 55.7 | 0.074 | 1.2 | 154 | 184 |

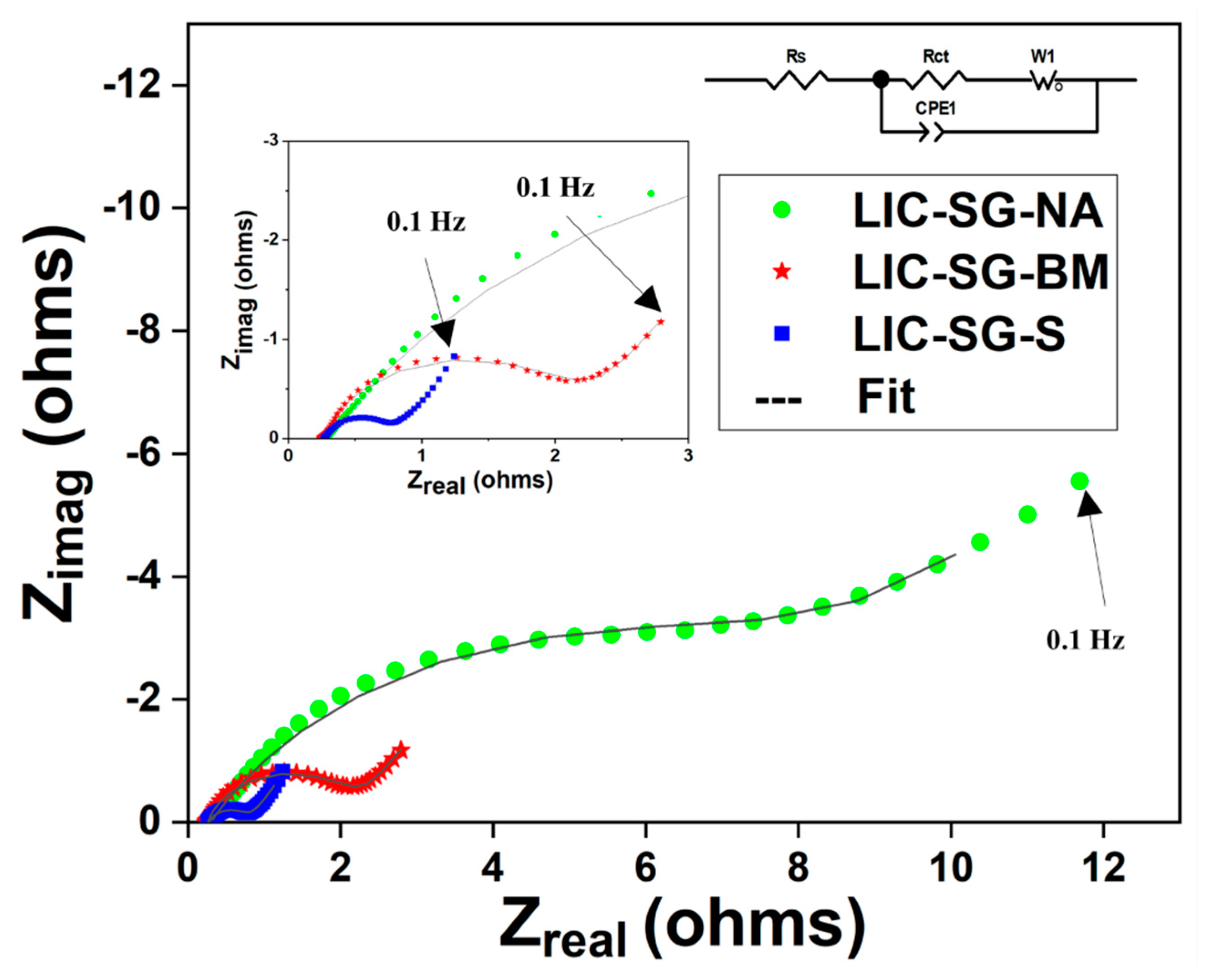

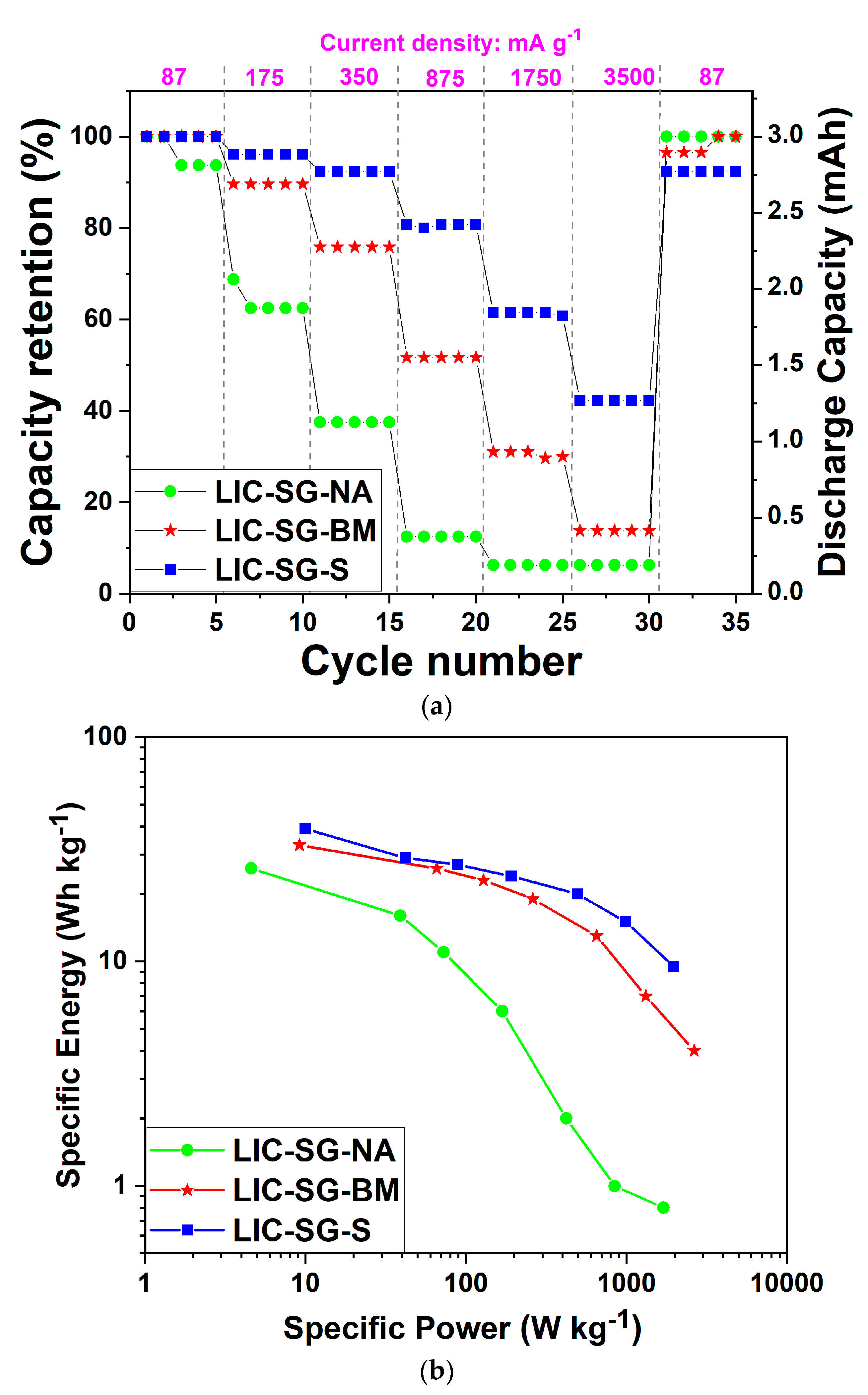

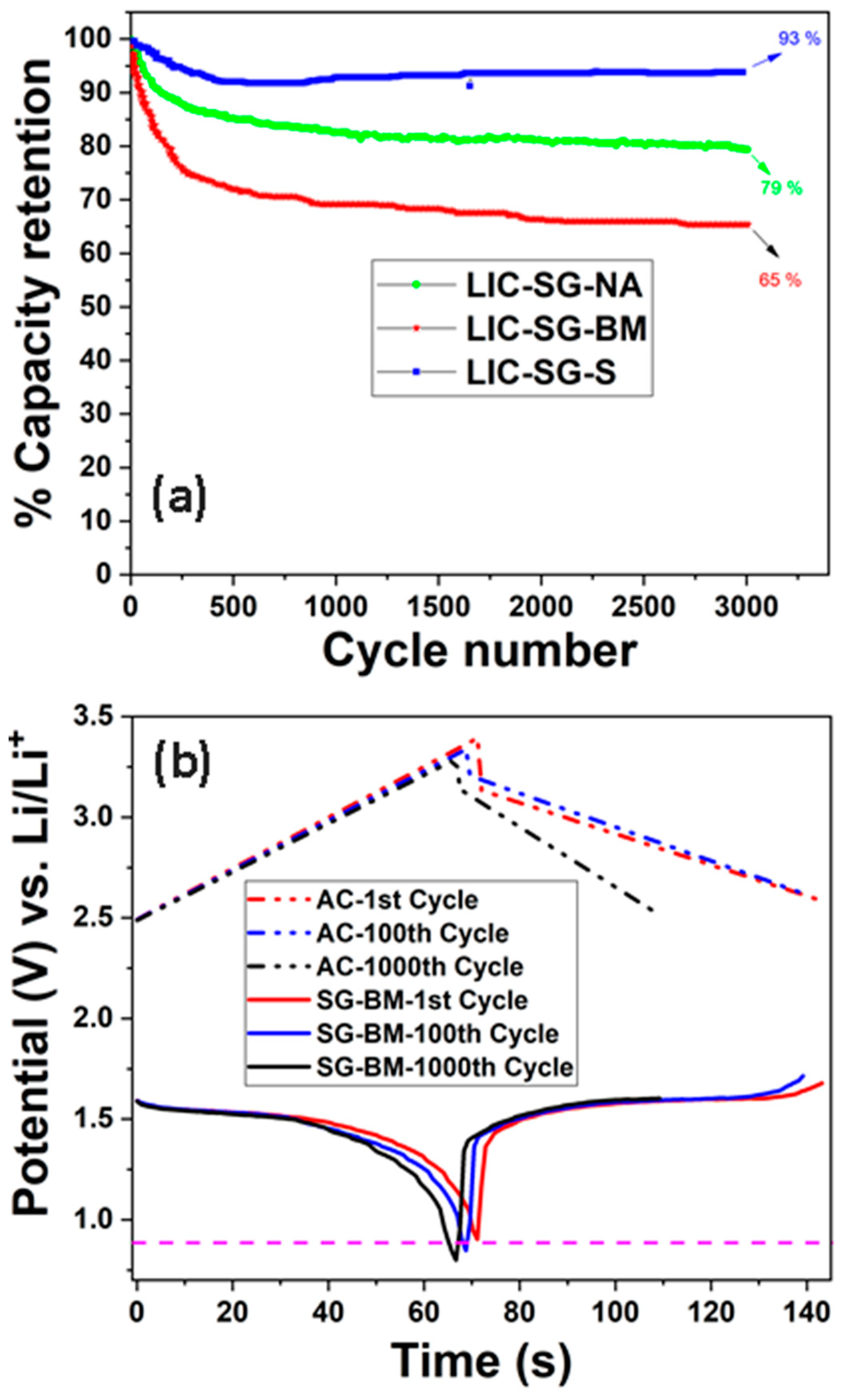

| Parameters | LIC-SG-NA | LIC-SG-BM | LIC-SG-S |

|---|---|---|---|

| Specific energy (Wh kg−1) | 26 | 36 | 39 |

| Max. specific power (kW kg−1) | 0.8 | 2.9 | 8.0 |

| AC-ESR (Ω) @ 0.1 Hz | 12 | 2.8 | 1.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akintola, T.; Shellikeri, A.; Akintola, T.; Zheng, J.P. The Influence of Li4Ti5O12 Preparation Method on Lithium-Ion Capacitor Performance. Batteries 2021, 7, 33. https://doi.org/10.3390/batteries7020033

Akintola T, Shellikeri A, Akintola T, Zheng JP. The Influence of Li4Ti5O12 Preparation Method on Lithium-Ion Capacitor Performance. Batteries. 2021; 7(2):33. https://doi.org/10.3390/batteries7020033

Chicago/Turabian StyleAkintola, Taofeek, Annadanesh Shellikeri, Tawakalt Akintola, and Jim P. Zheng. 2021. "The Influence of Li4Ti5O12 Preparation Method on Lithium-Ion Capacitor Performance" Batteries 7, no. 2: 33. https://doi.org/10.3390/batteries7020033

APA StyleAkintola, T., Shellikeri, A., Akintola, T., & Zheng, J. P. (2021). The Influence of Li4Ti5O12 Preparation Method on Lithium-Ion Capacitor Performance. Batteries, 7(2), 33. https://doi.org/10.3390/batteries7020033