Failure Analysis of Fire in Lithium-Ion Battery-Powered Heating Insoles: Case Study

Abstract

1. Introduction

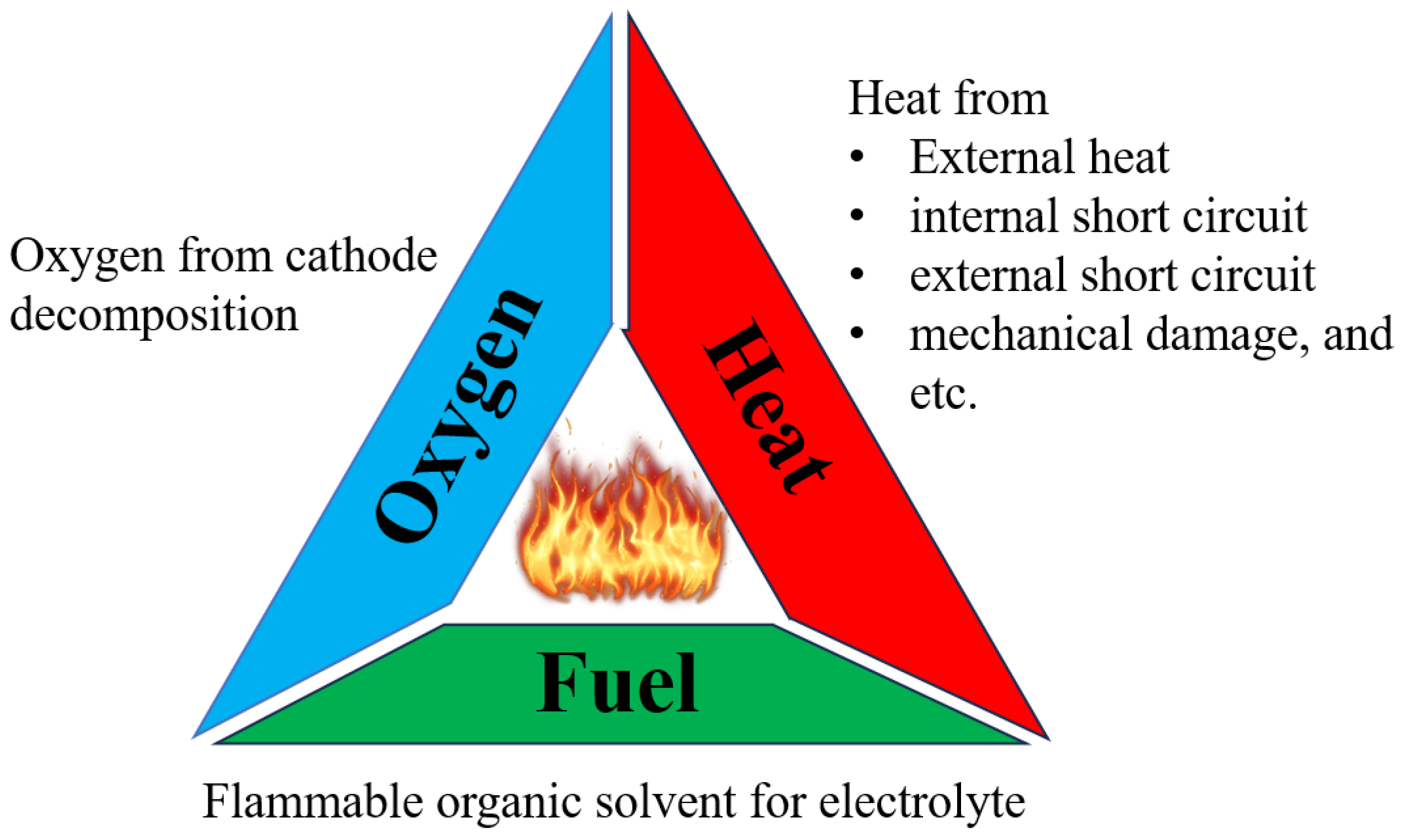

1.1. Safety Concerns

- 1.

- Energy applications with high capacity and low current: cell phones, laptops, cameras, and power banks.

- 2.

- Power drive applications with moderate current: electric vehicles, e-bikes, scooters, etc.

- 3.

- Power tool applications with high current output: power tools.

1.2. Wearables with LIBs

2. Materials and Methods

2.1. Background

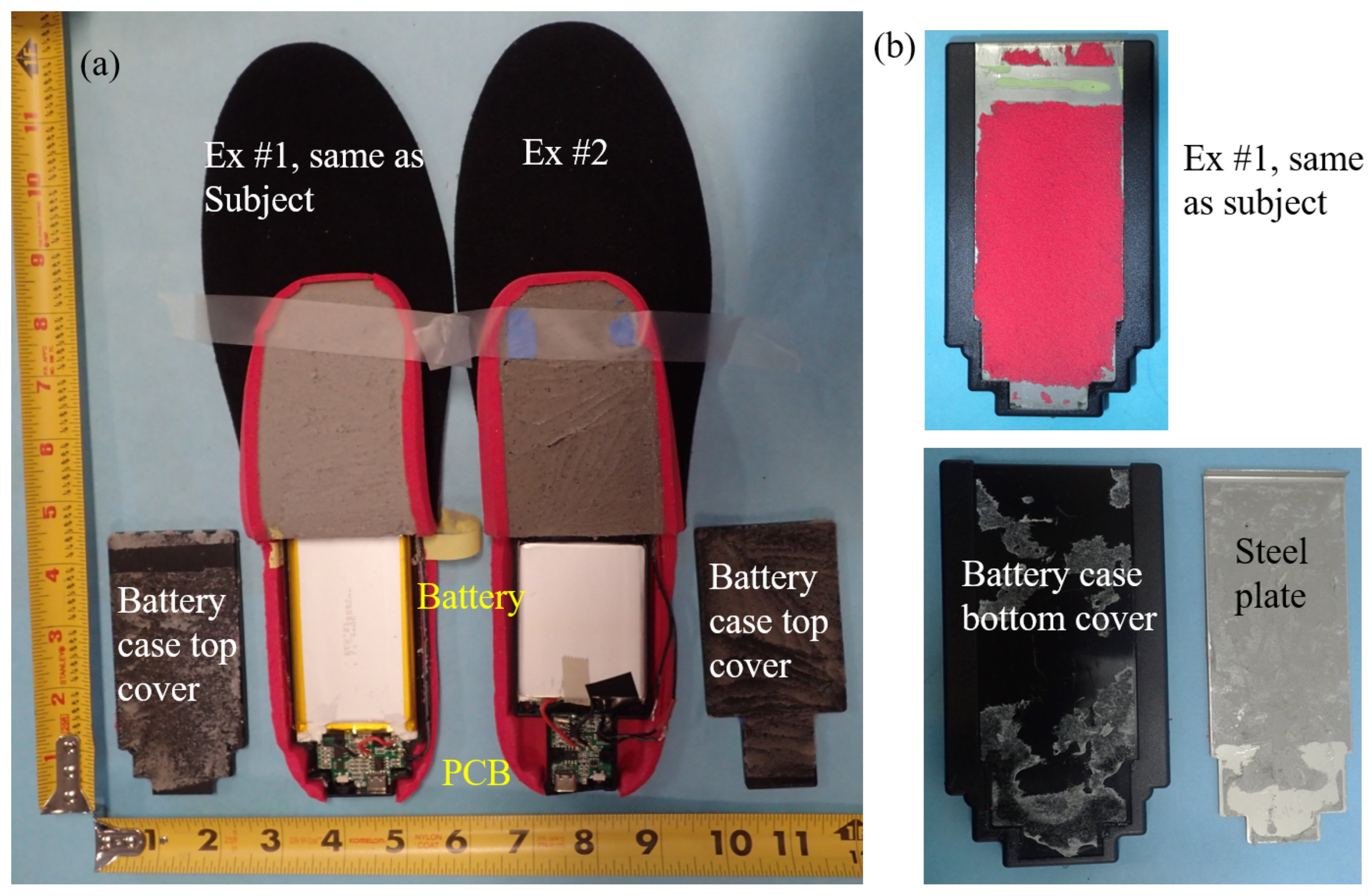

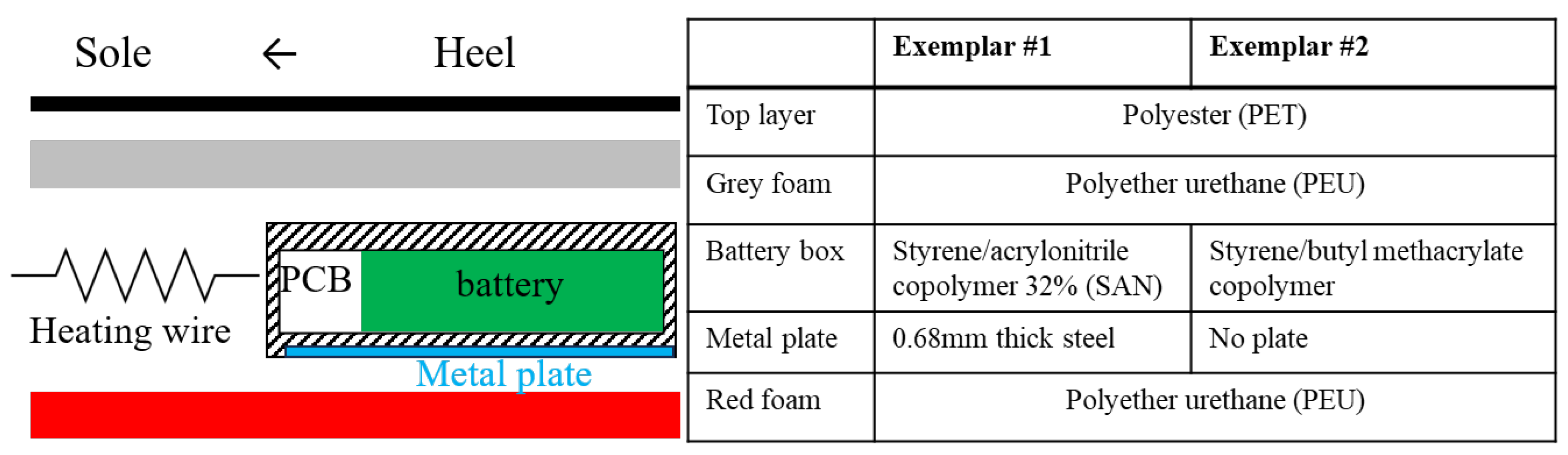

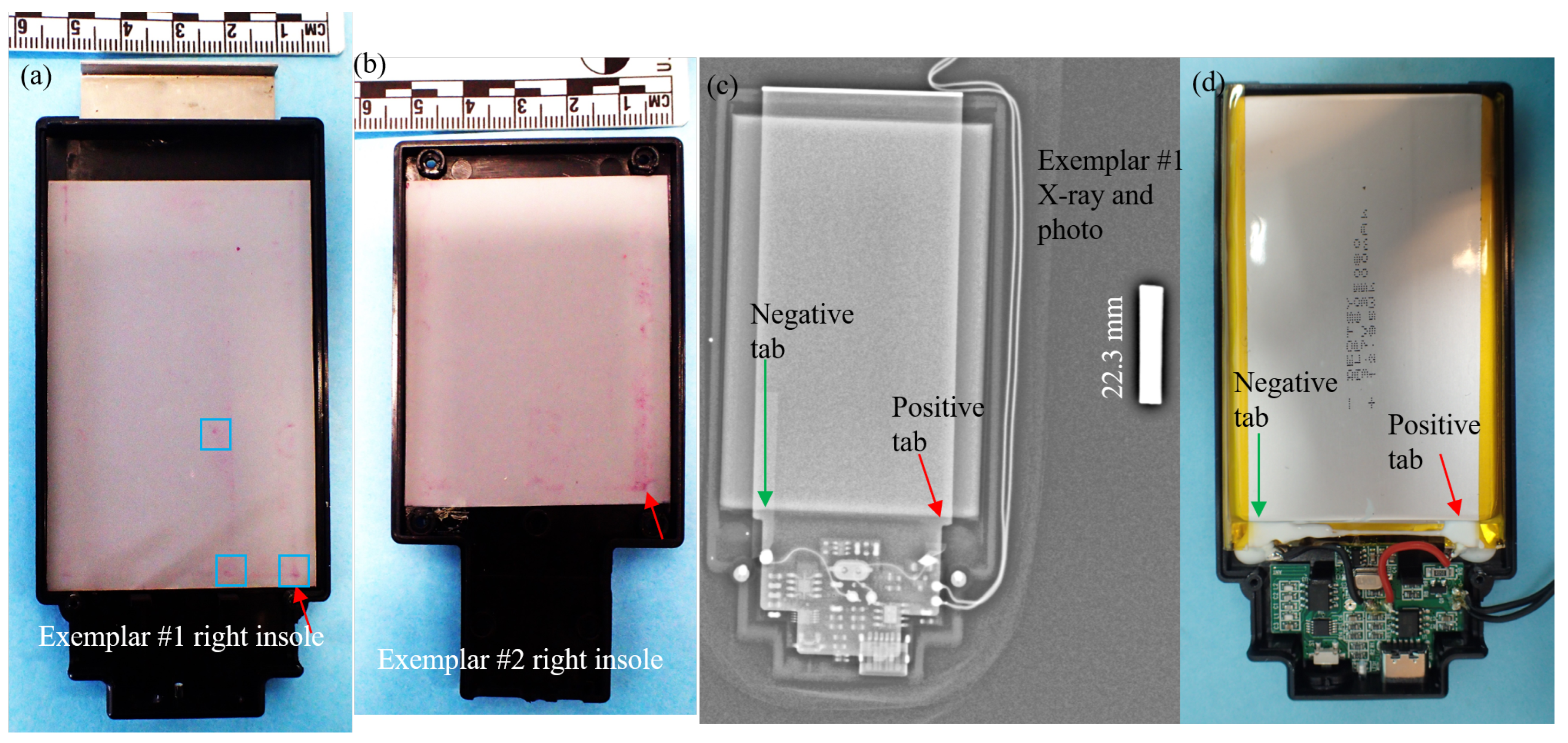

2.2. Materials

2.3. Testing

3. Results

3.1. Insole Material

3.2. Battery Cell Composition

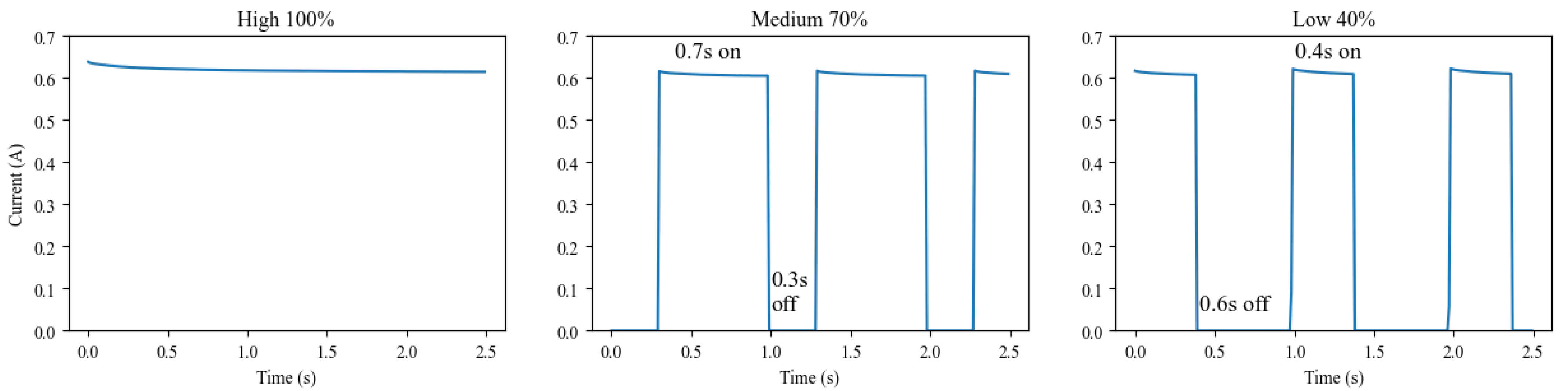

3.3. Electrical Performance

3.4. Insole Heating Test

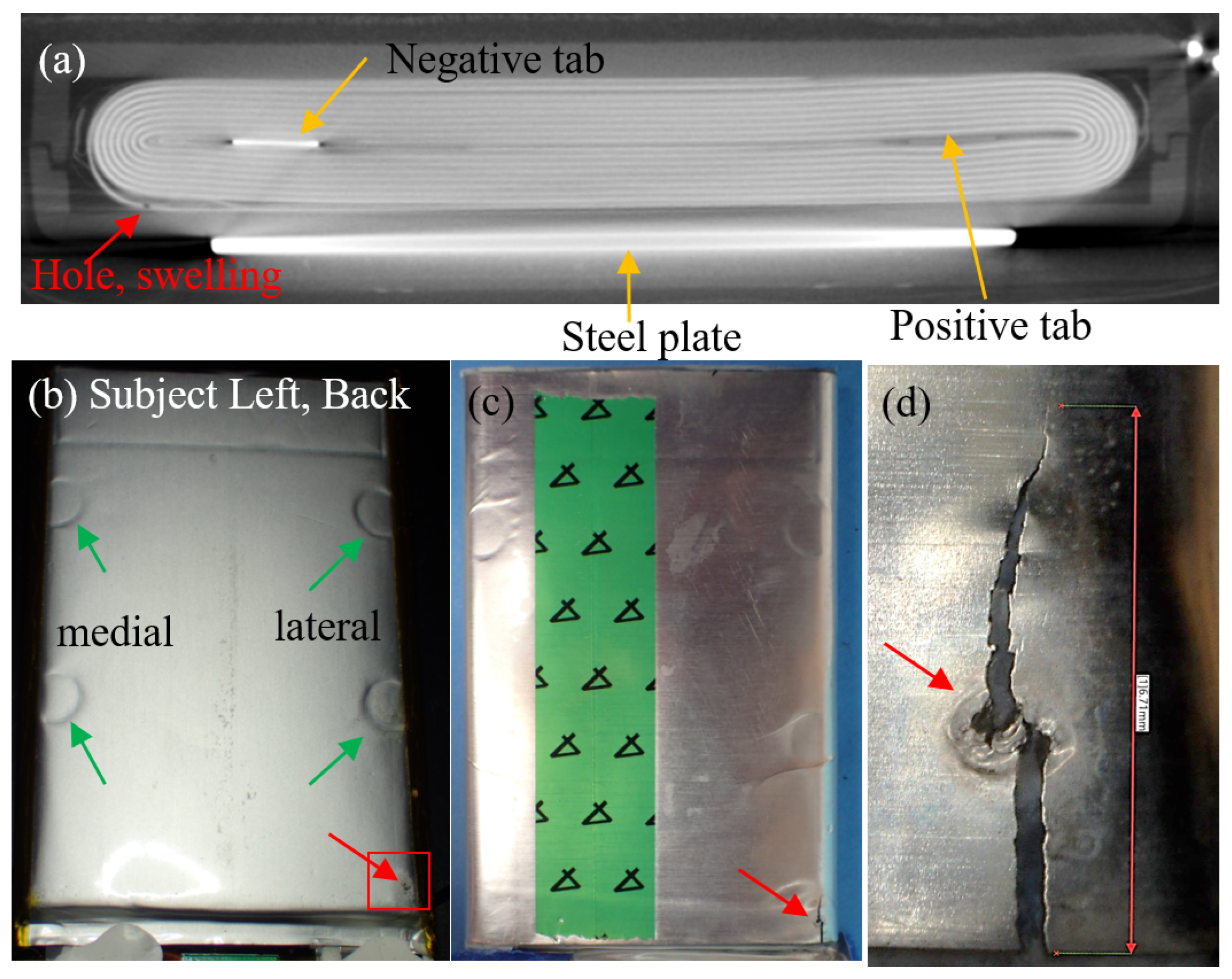

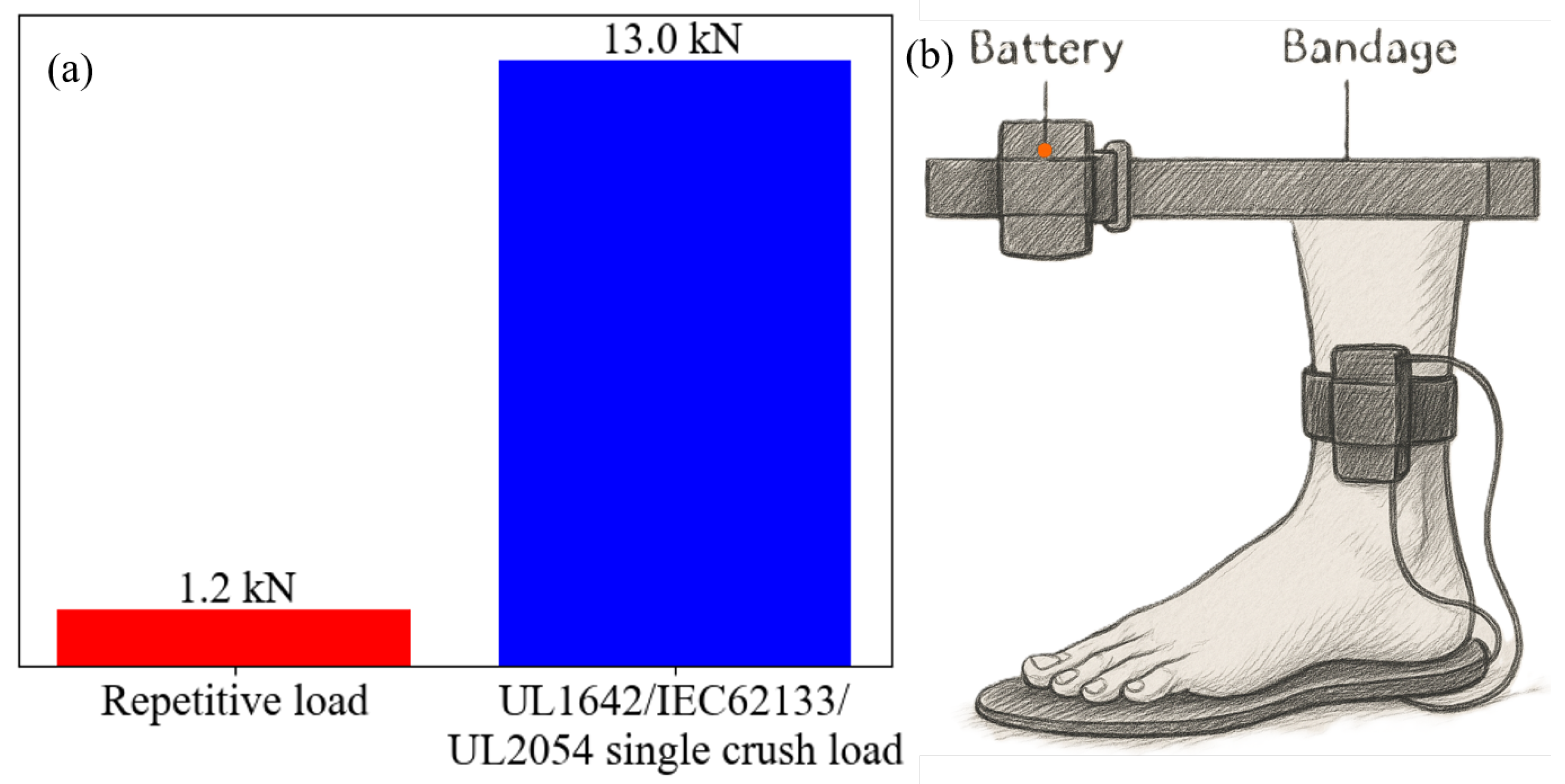

3.5. Battery Pressure Test

3.6. Charge-Discharge Cycle Test

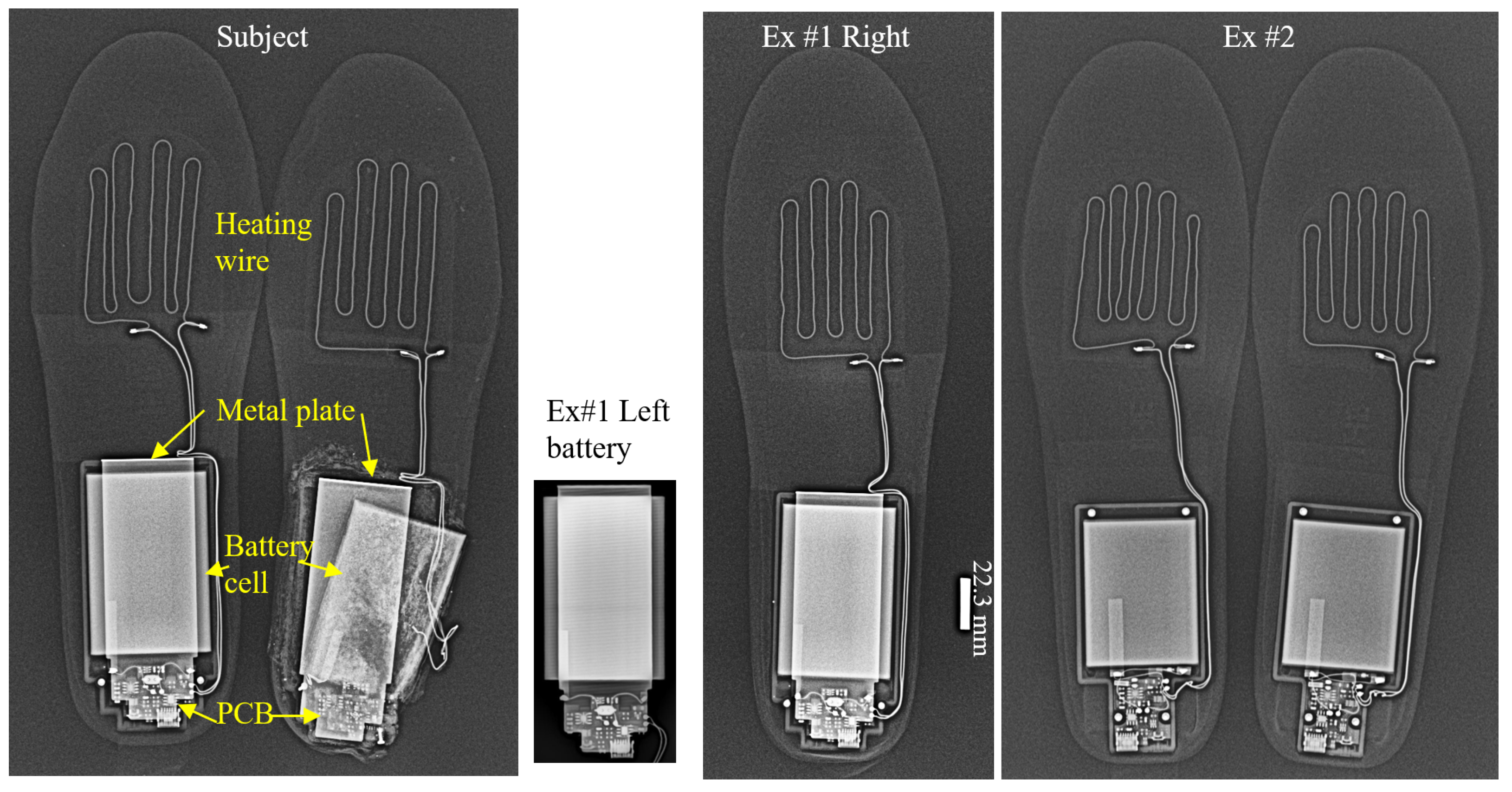

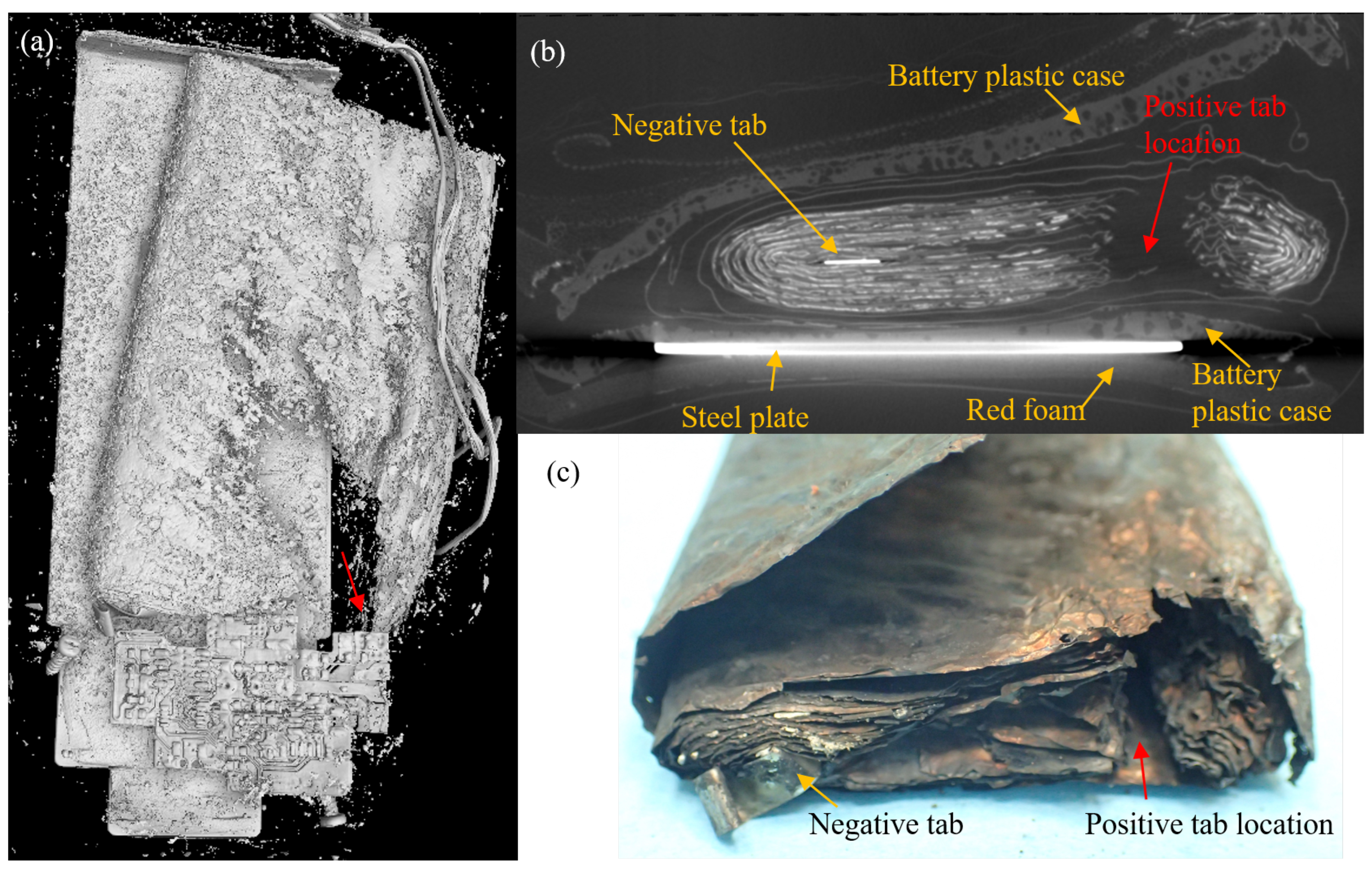

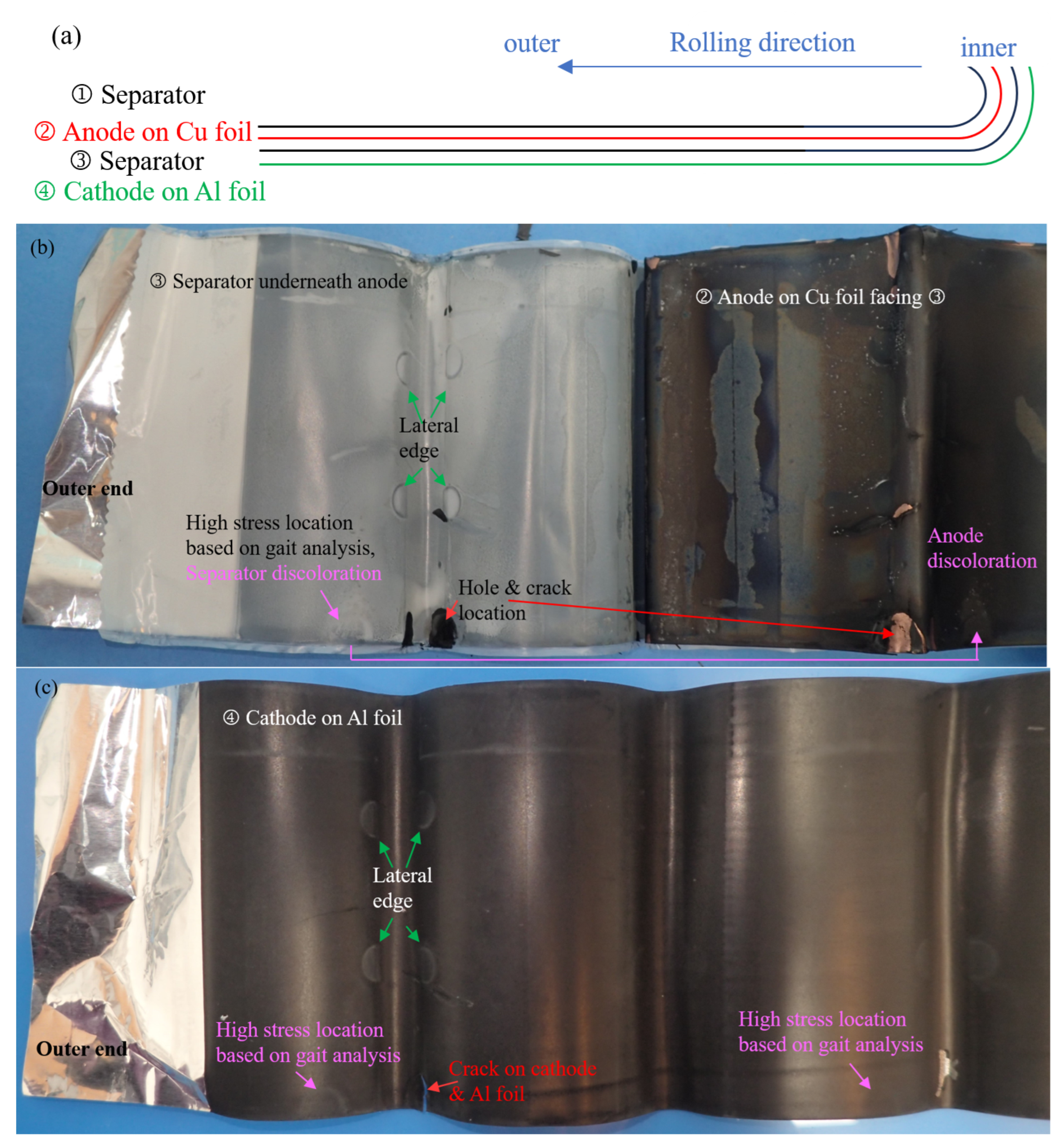

3.7. Subject Insole CT and Disassembly

4. Root Cause Analysis and Design Concerns

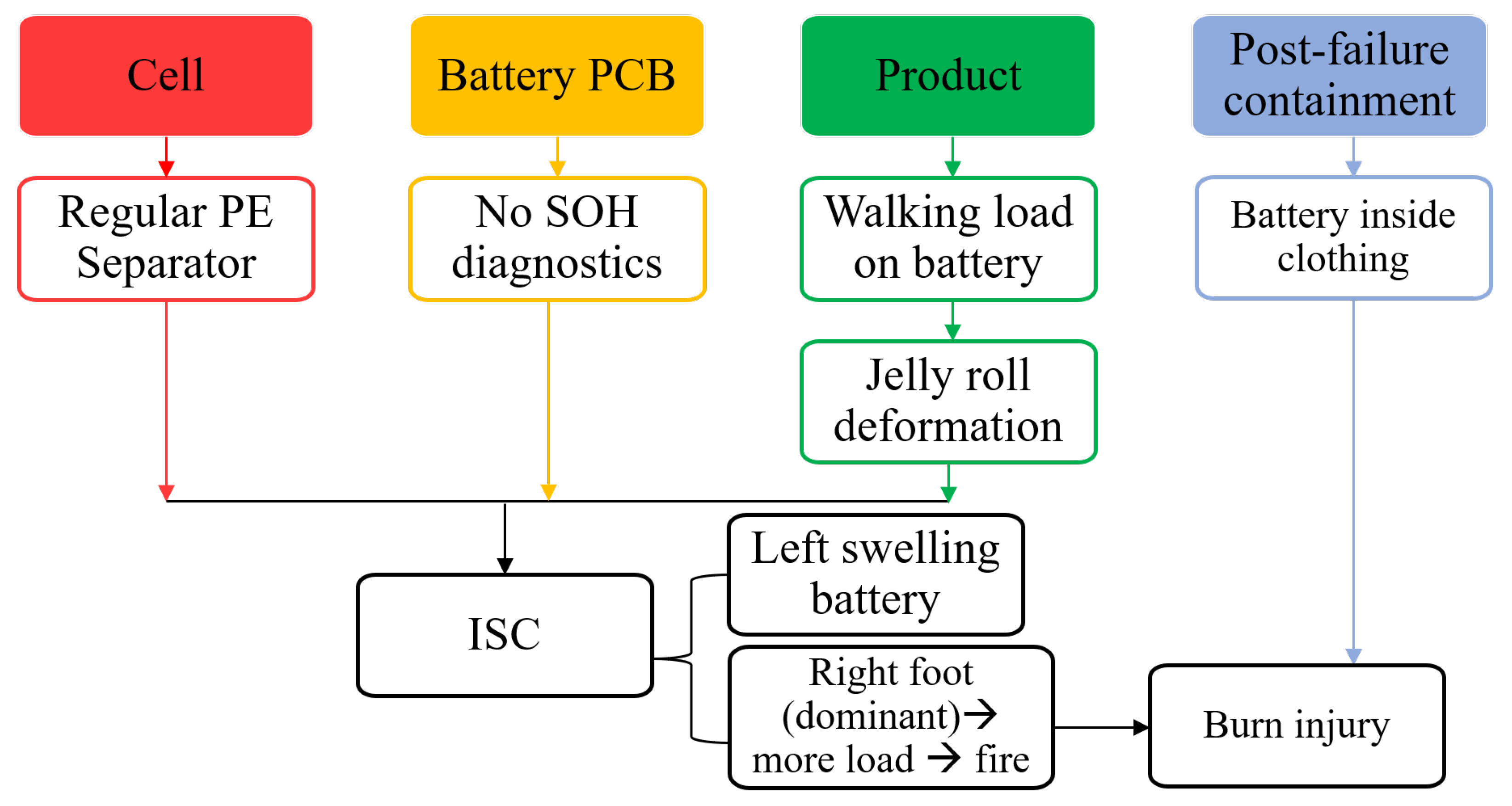

4.1. Root Cause Analysis

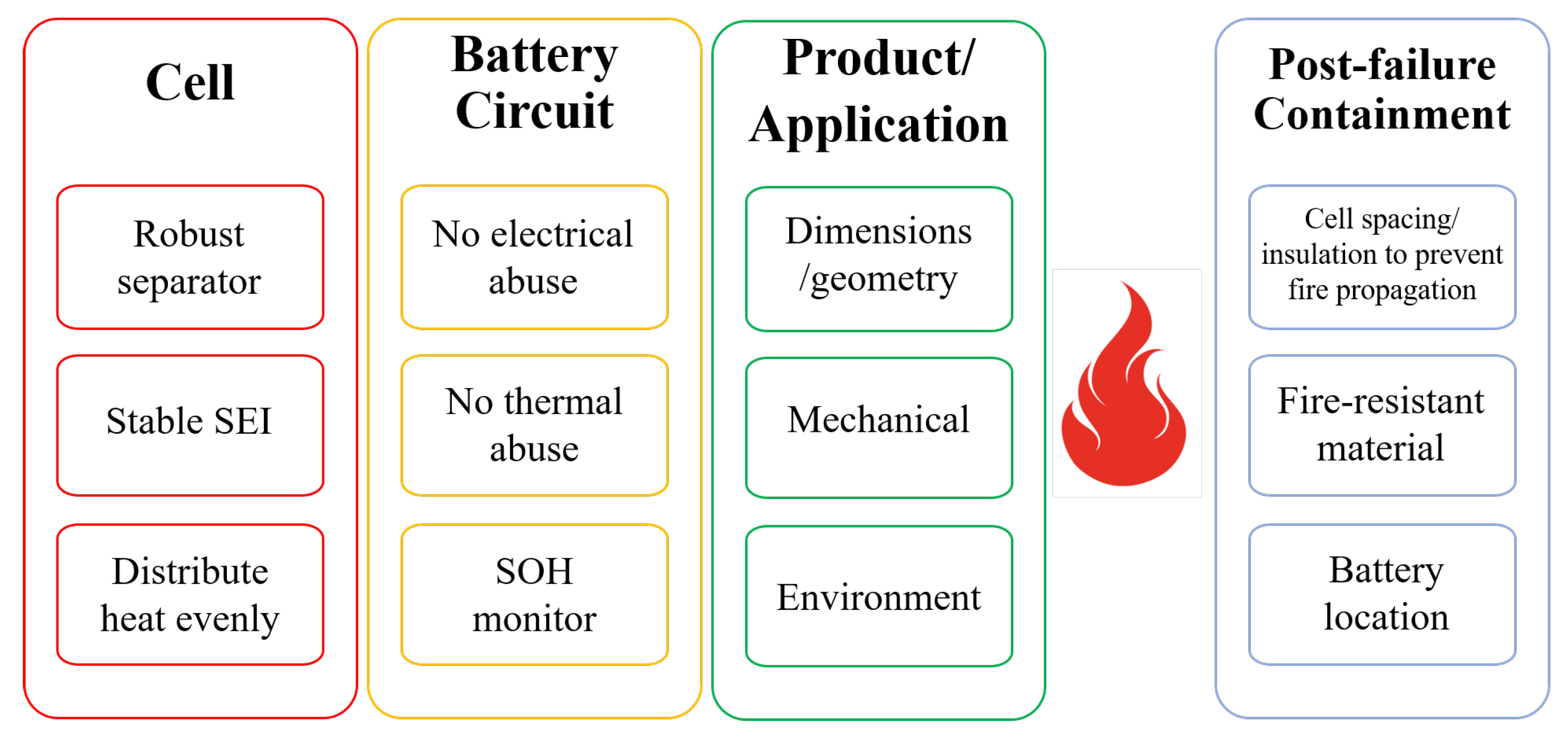

4.2. Battery Design Concerns

4.3. Additional Consideration

4.3.1. Exemplar #2 Battery Safety Assessment

4.3.2. Study Limitations

5. Conclusions

- 1.

- Cell-level robustness: Implementation of ceramic-coated separators, stable SEI formulations, and designs ensuring homogeneous heat distribution to prevent internal shorts.

- 2.

- Smart circuit architectures: Mandatory integration of health monitoring systems to detect early degradation while preventing electrical/thermal abuse.

- 3.

- Product specific consideration: Rigorous evaluation of placement and environmental stresses during product design.

- 4.

- Fail-safe containment: Strategic use of fire-retardant materials, isolation designs to prevent thermal runaway propagation, and exterior placement away from skin contact.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LIB | Lithium-ion battery |

| ISC | Internal short circuit |

| NiMH | Nickel-metal hydride |

| BMS | Battery management system |

| PCB | Protection circuit board (sometimes printed circuit board) |

| SOH | State of health |

| CT | Computed tomography |

| SEM | Scanning electron microscopy |

| EDS | Energy dispersive spectroscopy |

| FTIR | Fourier transform infrared spectroscopy |

| OCV | Open-circuit voltage |

| PET | Polyester |

| PEU | Polyether urethane |

| NCM | Nickel-cobalt-manganese |

| LCO | Lithium cobalt oxide |

| PE | Polyethylene |

| IC | Integrated circuit |

| PWM | Pulse-width modulation |

| SEI | Solid electrolyte interphase |

References

- Nishi, Y.; Wakihara, M. Performance of the First Lithium Ion Battery and Its Process Technology. In Lithium Ion Batteries: Fundamentals and Performance; Kodansha Ltd.: Tokyo, Japan, 1998; pp. 181–198. [Google Scholar] [CrossRef]

- Whittingham, M.S. Lithium batteries and cathode materials. Chem. Rev. 2004, 104, 4271–4301. [Google Scholar] [CrossRef] [PubMed]

- Mikolajczak, C.; Kahn, M.; White, K.; Long, R.T. Lithium-Ion Batteries Hazard and Use Assessment Final Report. Technical Report, The Fire Protection Research Foundation. 2011. Available online: https://www.nfpa.org/education-and-research/research/fire-protection-research-foundation/projects-and-reports/lithium-ion-batteries-hazard-and-use-assessment (accessed on 15 May 2025).

- Xu, K. Nonaqueous liquid electrolytes for lithium-based rechargeable batteries. Chem. Rev. 2004, 104, 4303–4417. [Google Scholar] [CrossRef] [PubMed]

- Lai, X.; Jin, C.; Yi, W.; Han, X.; Feng, X.; Zheng, Y.; Ouyang, M. Mechanism, modeling, detection, and prevention of the internal short circuit in lithium-ion batteries: Recent advances and perspectives. Energy Storage Mater. 2021, 35, 470–499. [Google Scholar] [CrossRef]

- Kim, C.S.; Yoo, J.S.; Jeong, K.M.; Kim, K.; Yi, C.W. Investigation on internal short circuits of lithium polymer batteries with a ceramic-coated separator during nail penetration. J. Power Sources 2015, 289, 41–49. [Google Scholar] [CrossRef]

- CPSC Issues Consumer Safety Warning: Serious Injury or Death Can Occur if Lithium-Ion Battery Cells Are Separated from Battery Packs and Used to Power Devices. Available online: https://www.cpsc.gov/Newsroom/News-Releases/2021/CPSC-Issues-Consumer-Safety-Warning-Serious-Injury-or-Death-Can-Occur-if-Lithium-Ion-Battery-Cells-Are-Separated-from-Battery-Packs-and-Used-to-Power-Devices (accessed on 18 September 2023).

- ANSI/CAN/UL 8139:2020; Electrical Systems of Electronic Cigarettes and Vaping Devices. ULSE: Evanston, IL, USA, 2020. Available online: https://www.shopulstandards.com/ProductDetail.aspx?productId=UL8139_2_S_20240426 (accessed on 15 May 2025).

- CPSC Warns Consumers to Immediately Stop Using WOTOTIC and Ackpair Heated Socks Due to Risk of Serious Burn Injury and Fire Hazard; Sold on Amazon.com. 2024. Available online: https://www.cpsc.gov/Warnings/2025/CPSC-Warns-Consumers-to-Immediately-Stop-Using-WOTOTIC-and-Ackpair-Heated-Socks-Due-to-Risk-of-Serious-Burn-Injury-and-Fire-Hazard-Sold-on-Amazon-com (accessed on 21 June 2025).

- Choi, M.S.S.; Lee, H.J.; Lee, J.H. Early intervention for Low-Temperature burns: Comparison between early and late hospital visit patients. Arch. Plast. Surg. 2015, 42, 173–178. [Google Scholar] [CrossRef] [PubMed]

- Columbia Sportswear Recalls Batteries Sold With Jackets Due to Fire Hazard. 2011. Available online: https://www.cpsc.gov/Recalls/2011/columbia-sportswear-recalls-batteries-sold-with-jackets-due-to-fire-hazard (accessed on 21 June 2025).

- BRP Recalls Ski Doo and Can Am Lithium Ion Rechargeable Batteries and Heated Gloves. 2014. Available online: https://www.cpsc.gov/Recalls/2014/BRP-Recalls-Ski-Doo-and-Can-Am-Lithium-ion-Rechargeable-Batteries-and-Heated-Gloves (accessed on 21 June 2025).

- Tech Gear 5.7 Recalls Performance Heated Socks Due to Fire and Burn Hazards. Technical Report. 2019. Available online: https://www.cpsc.gov/Recalls/2019/Tech-Gear-5-7-Recalls-Performance-Heated-Socks-Due-to-Fire-and-Burn-Hazards (accessed on 21 June 2025).

- Wilford, D. Burlington Man Suffers Burns After Amazon Insoles Catch Fire. 2023. Available online: https://torontosun.com/news/local-news/burlington-man-suffers-burns-after-amazon-insoles-catch-fire#comments-area (accessed on 21 June 2025).

- Heated Insole Burn Injury. Available online: https://www.jasonturchin.com/practice-areas/product-liability-attorneys/consumer-product-liability/heated-insole-burn-injury/ (accessed on 21 June 2025).

- Hajebian, H.; chambers, C.; Murota, D.; Lodescar, R.; Turkowski, J. 647 Full Thickness Burn Injuries from Heated Insole Device Explosions: First Case Series. J. Burn. Care Res. 2025, 46, S212. [Google Scholar] [CrossRef]

- George, G. An Unexpected Burn. 2025. Available online: https://www.adirondackalmanack.com/2025/01/an-unexpected-burn.html (accessed on 21 June 2025).

- Cole-Price, A.K.; Silverman, E.; Sienko, P.; Molvik, H.; Vercruysse, G.A. An Initial Report of Thermal Runaway Resulting in Full-Thickness Foot Burns From Lithium-Ion Battery-Powered Insole. J. Burn. Care Res. 2024, 45, 1636–1640. [Google Scholar] [CrossRef] [PubMed]

- Quttaineh, R. Electronically Heated Insoles Leave MN Man with Third-Degree Burns, Medical Professionals Say to Stay Away from Similar Products. 2024. Available online: https://www.kare11.com/article/news/local/heated-rechargeable-apparel-products-insole-electronic-burns-hospital-center/89-78bb1397-2b41-464b-9018-c35b5308a499 (accessed on 20 June 2025).

- Quttaineh, R. Minnesota Man Suffers Burns After Rechargeable Insoles Explode Inside Boots. 2024. Available online: https://www.valleynewslive.com/2024/12/17/minnesota-man-suffers-burns-after-rechargeable-insoles-explode-inside-boots/ (accessed on 20 June 2025).

- Johnson, S. Warning: Heated Insole Malfunction, 2024. Available online: https://www.wjfw.com/news/warning-heated-insole-malfunction/article_4d0b1872-bd9b-11ef-9742-2f91c3dd4431.html (accessed on 20 June 2025).

- Koech, A.K.; Mwandila, G.; Mulolani, F.; Mwaanga, P. Lithium-ion battery fundamentals and exploration of cathode materials: A review. S. Afr. J. Chem. Eng. 2024, 50, 321–339. [Google Scholar] [CrossRef]

- UMW TP4056 1A Standalone Linear Li-Ion Battery Charger. Available online: https://www.umw-ic.com/static/pdf/493f603e988f83ce21e556bca0c516fd.pdf (accessed on 8 May 2025).

- UMW TP4057 1A Standalone Linear Li-Ion Battery Charger. Available online: https://www.umw-ic.com/static/pdf/a62b0c86d7543da6d2ba82f8104549b0.pdf (accessed on 16 May 2025).

- DW06 One Cell Lithium-Ion/Polymer Battery Protection IC Datasheet. Available online: http://www.pingjingsemi.com/UploadFile/pdf/DW06.pdf (accessed on 28 March 2025).

- DW07D One Cell Lithium-Ion/Polymer Battery Protection IC Datasheet. Available online: https://lcsc.com/datasheet/lcsc_datasheet_2202252130_Shenzhen-Fuman-Elec-DW07D_C89497.pdf (accessed on 28 March 2025).

- Cui, B.; Wang, H.; Li, R.; Xiang, L.; Du, J.; Zhao, H.; Li, S.; Zhao, X.; Yin, G.; Cheng, X.; et al. Long-sequence voltage series forecasting for internal short circuit early detection of lithium-ion batteries. Patterns 2023, 4, 100732. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, L.; Li, D.; Wang, K. State-of-health estimation of lithium-ion batteries based on electrochemical impedance spectroscopy: A review. Prot. Control Mod. Power Syst. 2023, 8, 41. [Google Scholar] [CrossRef]

- Messing, M.; Shoa, T.; Habibi, S. Estimating battery state of health using electrochemical impedance spectroscopy and the relaxation effect. J. Energy Storage 2021, 43, 103210. [Google Scholar] [CrossRef]

- Dostal, C. (Ed.) Engineered Materials Handbook: Engineering Plastics; ASM International: Almere, The Netherlands, 1988; Volume 2. [Google Scholar]

- ASM International (Ed.) ASM Handbook Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys, 10th ed.; ASM International: Almere, The Netherlands, 1990; Volume 1. [Google Scholar]

- Lee, S.Y. IoT-Based Sensor Shoes System for Gait Correction. Int. J. Electr. Electron. Res. 2022, 10, 62–68. [Google Scholar] [CrossRef]

- Keslar, D. DOT/FAA/TCTN-22/27 An Analysis of State of Charge in Lithium-Ion Batteries. Technical Report, Federal Aviation Administration. 2022. Available online: https://www.fire.tc.faa.gov/pdf/tctn22-27.pdf (accessed on 18 May 2025).

- Zhang, W.; Wei, Y.C.; Cheng, M.X.; Liu, Y.M.; Sun, H. The in-situ testing and modeling on sealing strength deterioration of lithium-ion pouch cell. Eng. Fail. Anal. 2021, 120, 105036. [Google Scholar] [CrossRef]

- UL 1642; Lithium Batteries, 6th Edition. ULSE: Evanston, IL, USA, 2020. Available online: https://www.shopulstandards.com/ProductDetail.aspx?productId=UL1642_6_S_20200929 (accessed on 19 September 2023).

- UL 2054; Household and Commercial Batteries, 3rd Edition. ULSE: Evanston, IL, USA, 2022. Available online: https://www.shopulstandards.com/ProductDetail.aspx?UniqueKey=40907 (accessed on 29 June 2025).

- IEC 62133-2; Secondary Cells and Batteries Containing Alkaline or Other Non-Acid Electrolytes: Safety Requirements for Portable Sealed Secondary Cells, and for Batteries Made from Them, for Use in Portable Applications. Part 2, Lithium Systems. IEC: Geneva, Switzerland, 2017. Available online: https://webstore.iec.ch/en/publication/32662 (accessed on 15 May 2025).

- UN 38.3; Lithium metal, lithium ion and sodium ion batteries. In Manual of Tests and Criteria, 8th Edition. UNECE: New York, NY, USA, 2023; pp. 426–442. Available online: https://unece.org/sites/default/files/2024-09/ST_SG_AC.10_11_Rev.8e_WEB.pdf (accessed on 29 June 2025).

- UL 2271; Batteries for Use In Light Electric Vehicle (LEV) Applications, 3rd Edition. ULSE: Evanston, IL, USA, 2023. Available online: https://www.shopulstandards.com/ProductDetail.aspx?UniqueKey=45051 (accessed on 29 June 2025).

- UL 2580; Batteries for Use In Electric Vehicles, 3rd Edition. ULSE: Evanston, IL, USA, 2020. Available online: https://www.shopulstandards.com/ProductDetail.aspx?UniqueKey=48504 (accessed on 29 June 2025).

| Date | Warning No. | Product | Reason | Outcome |

|---|---|---|---|---|

| 16 November 2011 [11] | 12-705 | LIBs for heating jackets | One report of a battery overheating at a distribution facility in France. No incidents or injuries. | Renounced |

| 25 February 2014 [12] | 14-115 | Heated gloves and replacement LIBs | Three reports of batteries overheating while charging. No injuries. | Recalled 1650 units |

| 14 March 2019 [13] | 19-082 | Heated socks | Four reports of batteries overheating, melting or igniting. No injuries. | Recalled 4000 units |

| 24 October 2024 [9] | 25-022 | Heated socks | Seven reports: four reports of fire and three reports of sparking or malfunctioning. |

| Date of Incidence | Gender | Use History | Device on? | Activity | Side of Injury |

|---|---|---|---|---|---|

| 22 December 2023 [14] | Male | Off | Walking at work | Left | |

| 28 December 2023 [15] | Male | Off | Construction work at job site | Left | |

| 14 January 2024 a [14] | Off | ||||

| 25 January 2024 (this case) | Male | New, used fewer than 10 times over 13 workdays | Off | Stepping down at work | Right |

| December 2023 to February 2024 [16] | Male | Operating cons- truction vehicle | Right | ||

| Male | Using lawn mower | Right | |||

| Male | Fire in snow boot | Right | |||

| 5 April 2024 [17] | Male | Several pairs used for 2 years | Off | Walking to chicken coop | Right |

| 10 August 2024 b [18] | Male | New, used a few times | Off | At football game tailgate party | Right |

| 30 November 2024 [19] | Male | Purchased in November 2023; used for winter 2023; first use in winter 2024. | Sitting during hunting | Left | |

| 12 December 2024 [20] | Male | Purchased in 2023, used in winter 2023 for hunting and fishing. | Off | Preparing to put a fish house on lake | Right |

| 14 December 2024 [21] | Male | Christmas gift in 2023, used in winter 2023 for ice fishing. | Off | Packing up fishing gear |

| Dimension | Electrical | Material | |||||

|---|---|---|---|---|---|---|---|

| Form Factor | Nominal Voltage (V) | Capacity (mAh) | Internal Resistance (mΩ) | Cathode | Anode | Separator | |

| Ex #1 | 605080 | 3.7 | 3500 | 26 | NCM 40/15/45 | Graphite | PE |

| Ex #2 | 535265 | 3.8 | 3000 | 45 | LCO | Graphite | PE |

| Cell Properties | PCB IC | Test Result | ||||

|---|---|---|---|---|---|---|

| Cathode | Nominal Voltage (V) | Battery Protection IC | Charging Module IC | Charge Max OCV (V) | Cutoff OCV (V) | |

| Ex #1 | NMC 40/15/45 | 3.7 | DW06D [25] 2.4∼4.3 V | UMW TP4056 [23] 1 A, 4.242 V | 4.22 | 3.17 |

| Ex #2 | LCO | 3.8 | DW07D [26] 2.9∼4.4 V | UMW TP4057 [24] 0.5 A, 4.282 V | 4.30 | 3.31 |

| Starting @ 19 °C | Setting | Insulation | Duration (Hours) | Insole Max Temperature (°C) | Cell Max Temperature (°C) | Cell Internal Impedance (m) |

|---|---|---|---|---|---|---|

| Ex #1 | Medium | Yes | 0.35 | 74.2 | 20.5 | 26 |

| High | No | 5.9 | 57.6 | 26.6 | ||

| Ex #2 | High | No | 4.6 | 55.9 | 30.1 | 45 |

| Insole | Test | Initial Impedance (mΩ) | Final Impedance (mΩ) | Swelling? |

|---|---|---|---|---|

| Subject Left | Walking, <10 cycles | Should be the same as Ex #1, ∼25 | 36 | Yes |

| Ex #1 | 12 steps, 10 cycles | 26 | 28 | No |

| Ex #2 | 12 steps, 10 cycles | 45 | 48 | No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, R.; Jin, S.; Stevick, G. Failure Analysis of Fire in Lithium-Ion Battery-Powered Heating Insoles: Case Study. Batteries 2025, 11, 271. https://doi.org/10.3390/batteries11070271

Yuan R, Jin S, Stevick G. Failure Analysis of Fire in Lithium-Ion Battery-Powered Heating Insoles: Case Study. Batteries. 2025; 11(7):271. https://doi.org/10.3390/batteries11070271

Chicago/Turabian StyleYuan, Rong, Sylvia Jin, and Glen Stevick. 2025. "Failure Analysis of Fire in Lithium-Ion Battery-Powered Heating Insoles: Case Study" Batteries 11, no. 7: 271. https://doi.org/10.3390/batteries11070271

APA StyleYuan, R., Jin, S., & Stevick, G. (2025). Failure Analysis of Fire in Lithium-Ion Battery-Powered Heating Insoles: Case Study. Batteries, 11(7), 271. https://doi.org/10.3390/batteries11070271