Detailed Characterization of Thermal Runaway Particle Emissions from a Prismatic NMC622 Lithium-Ion Battery

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Cell

2.2. Cell Thermal Runaway Characterization

2.3. Particle Sampling

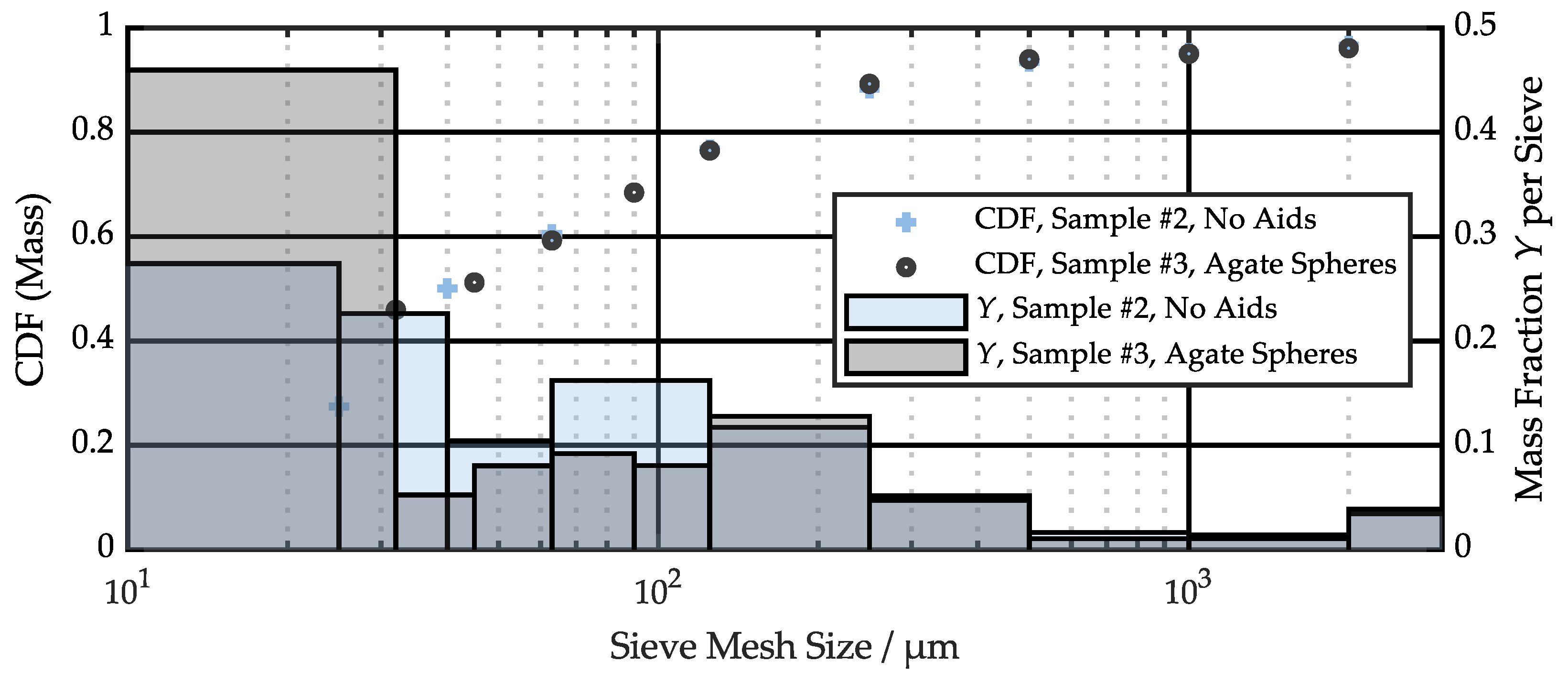

2.4. Sieve Analysis

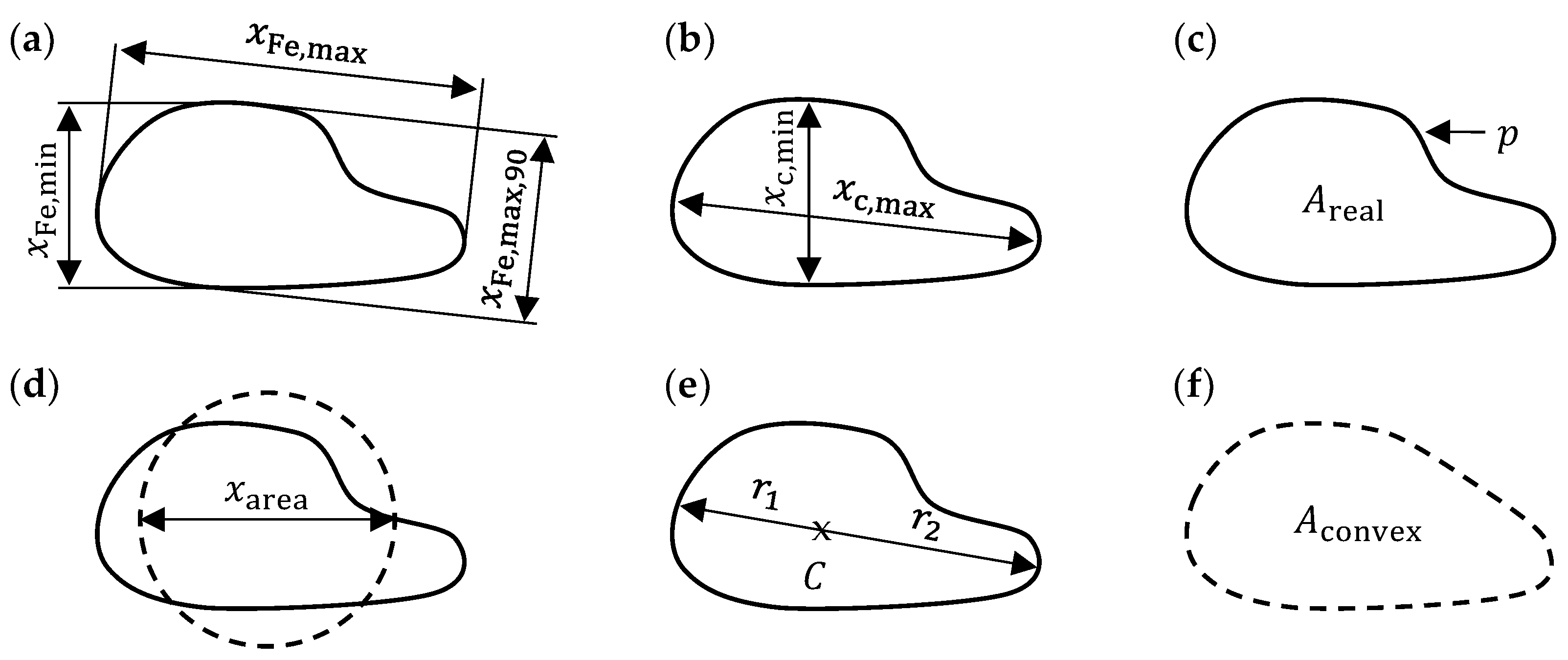

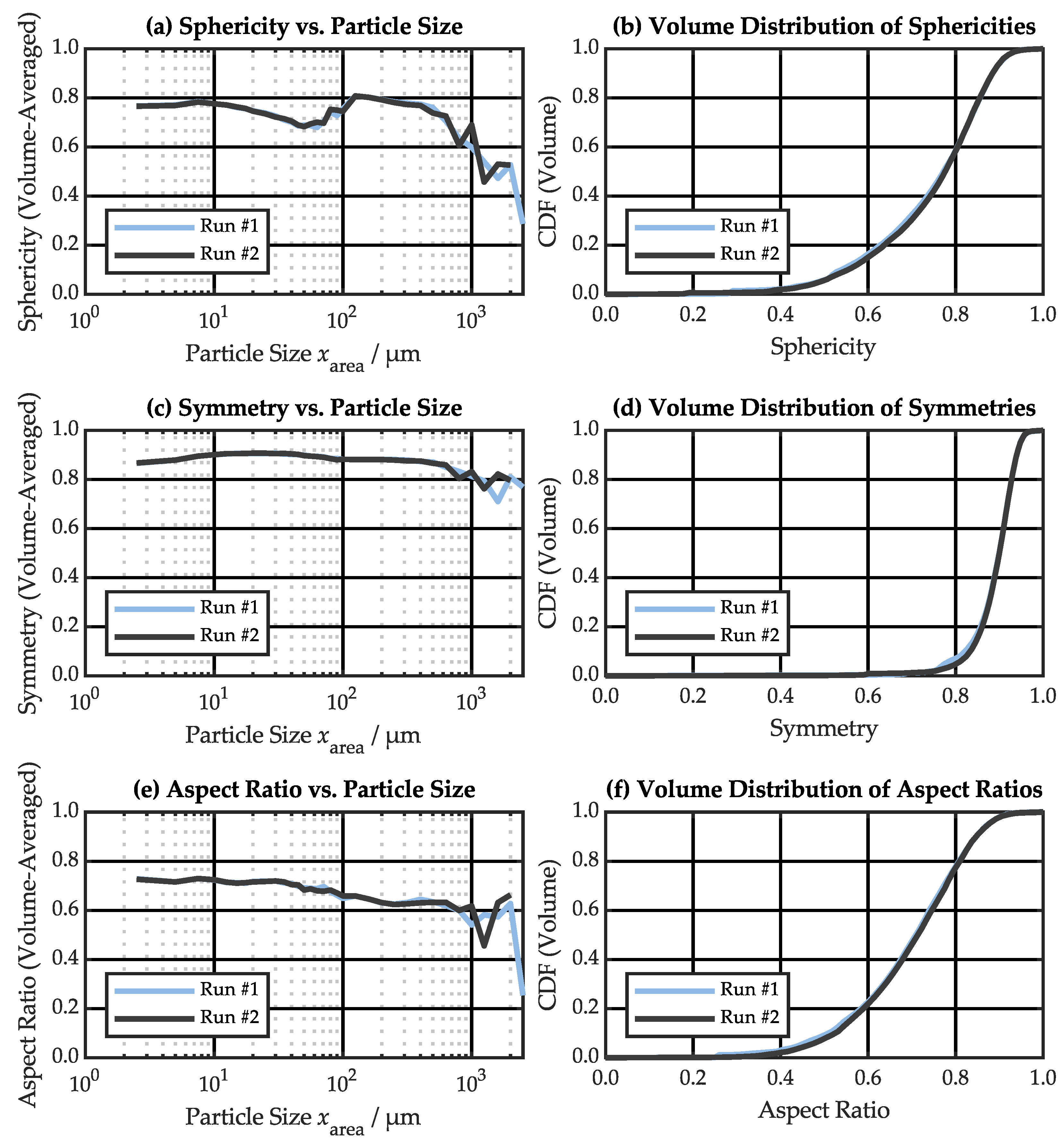

2.5. Dynamic Image Analysis

2.6. Large Particle Image Processing

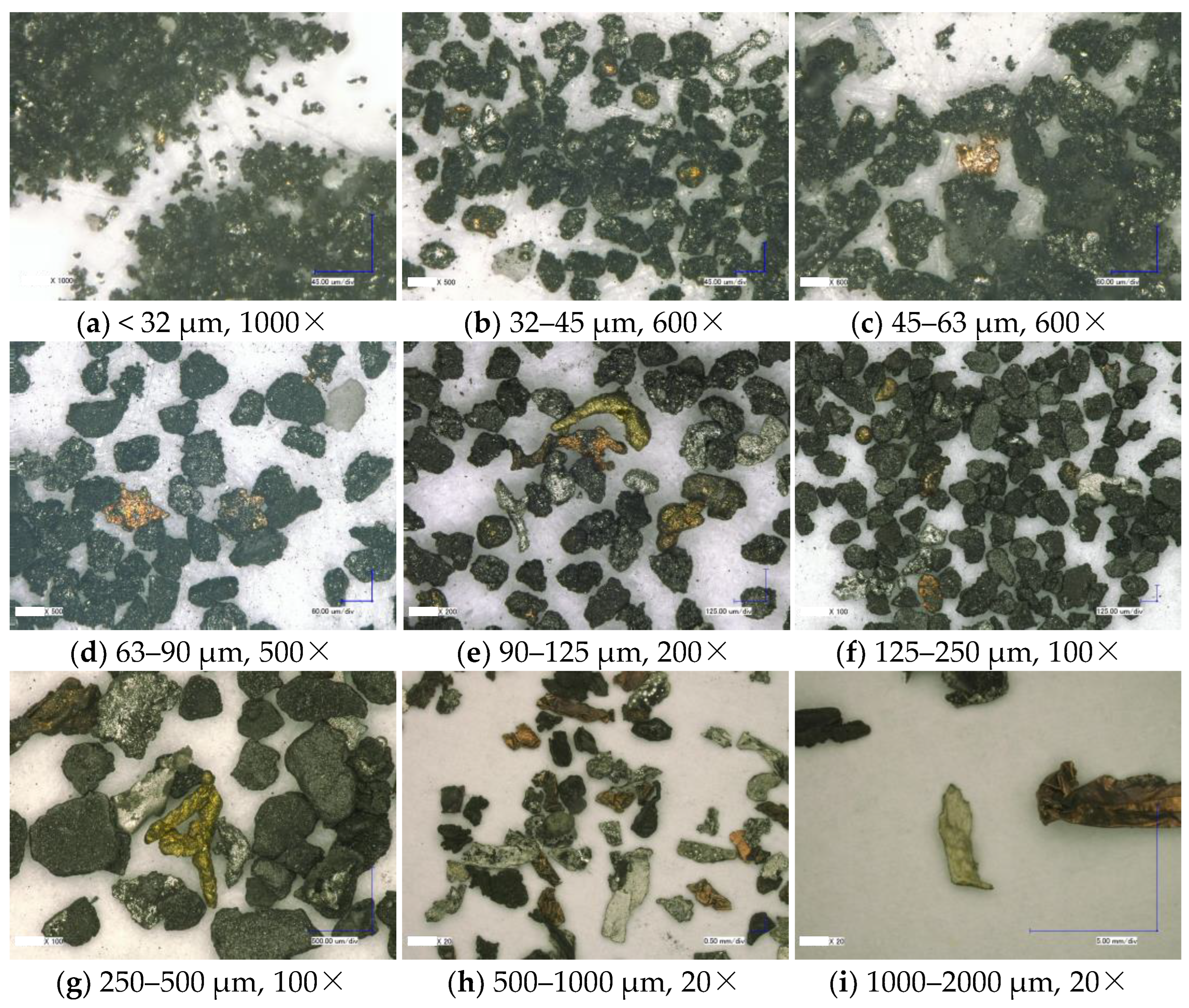

2.7. Light Microscopy

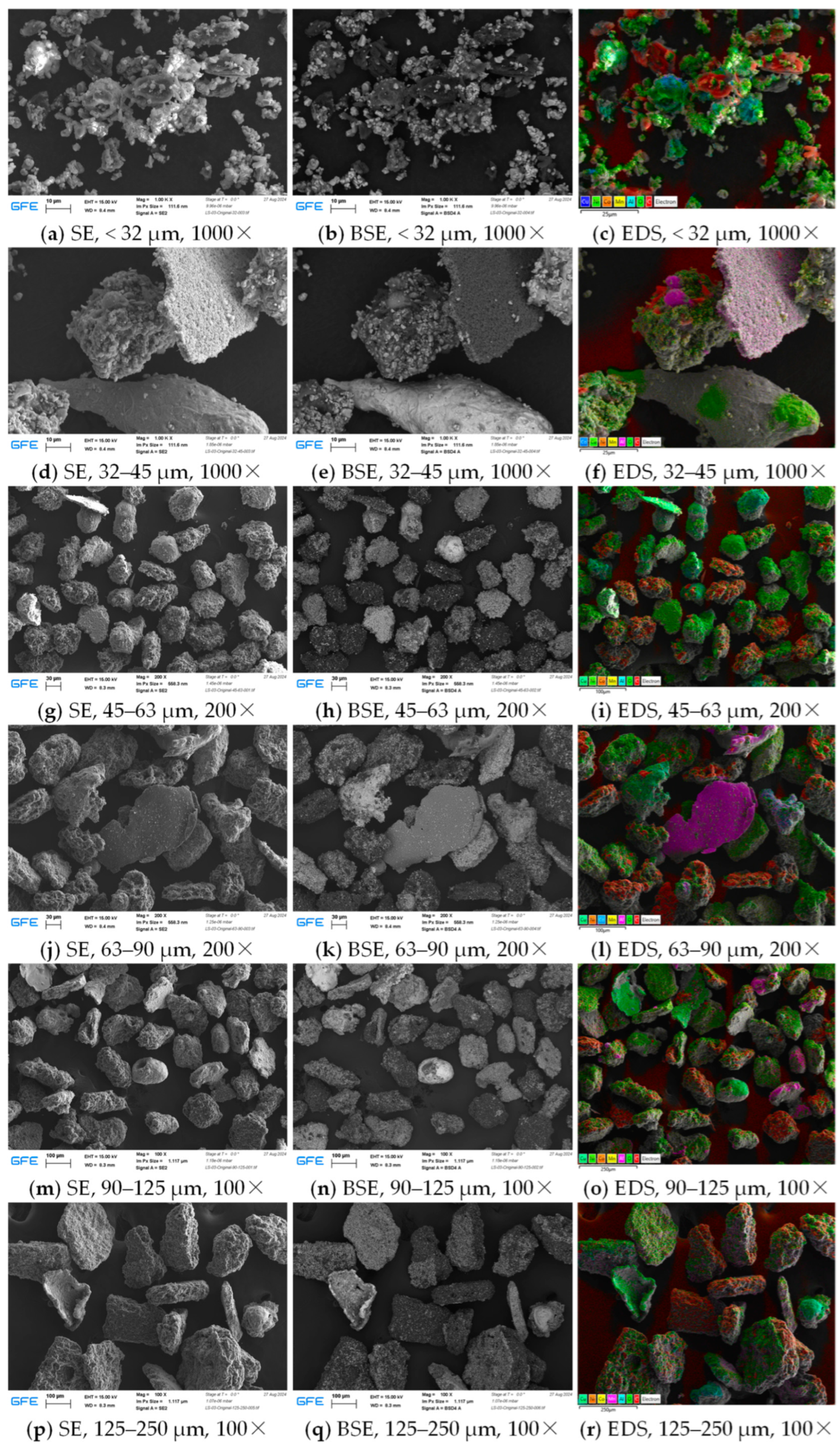

2.8. SEM/EDS Analysis

2.9. Simultaneous Thermal Analysis

3. Results and Discussion

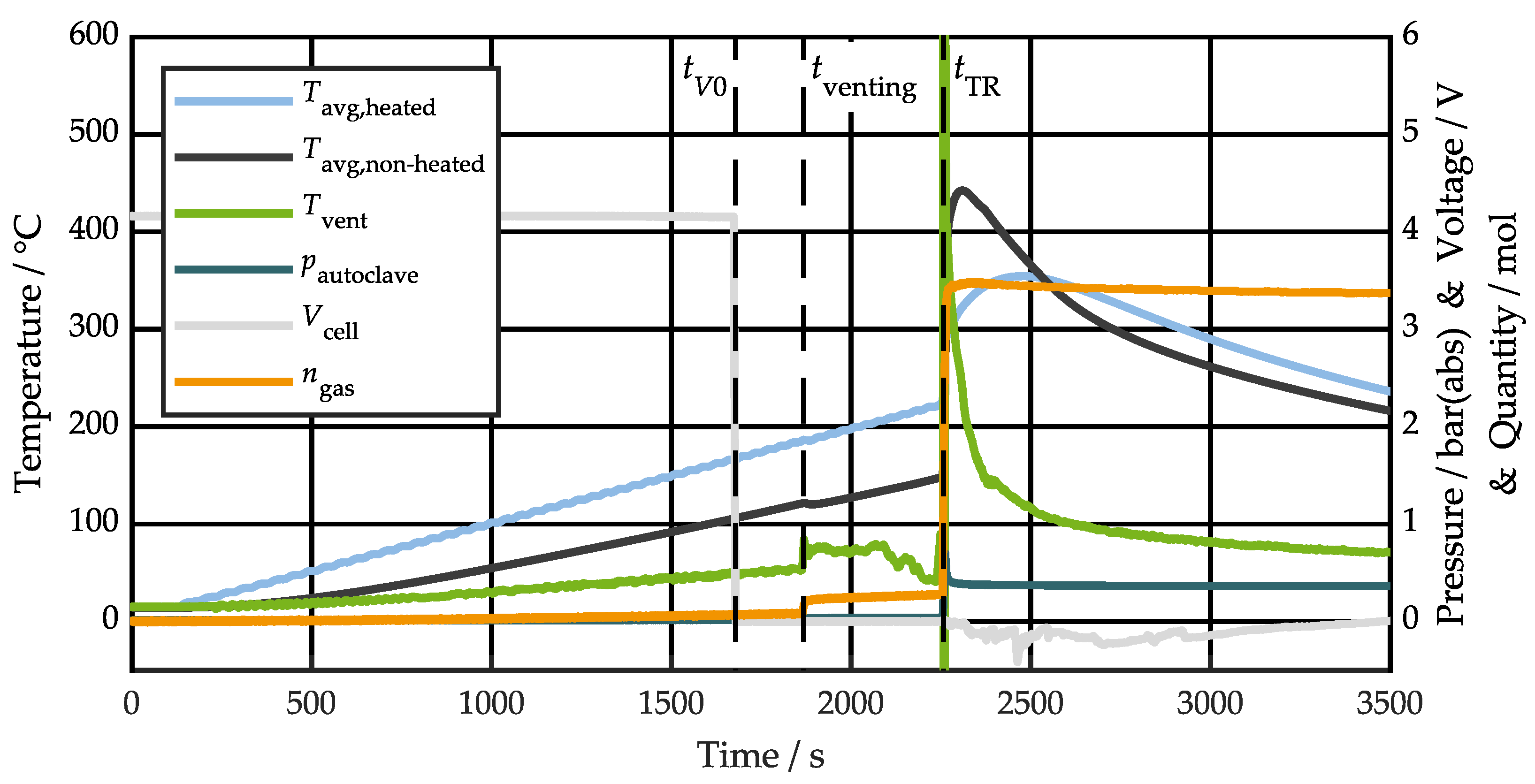

3.1. Cell Thermal Runaway Behavior

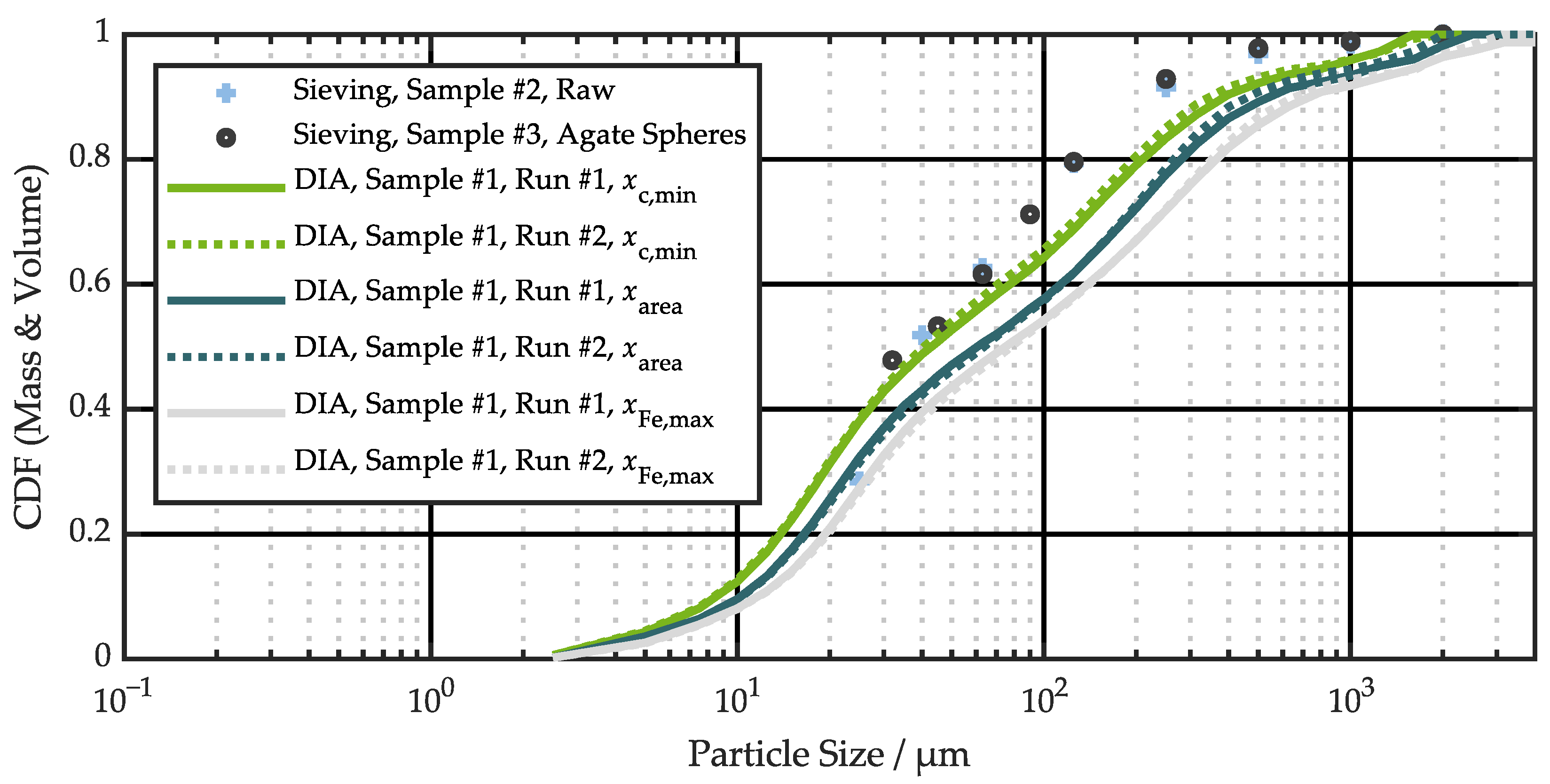

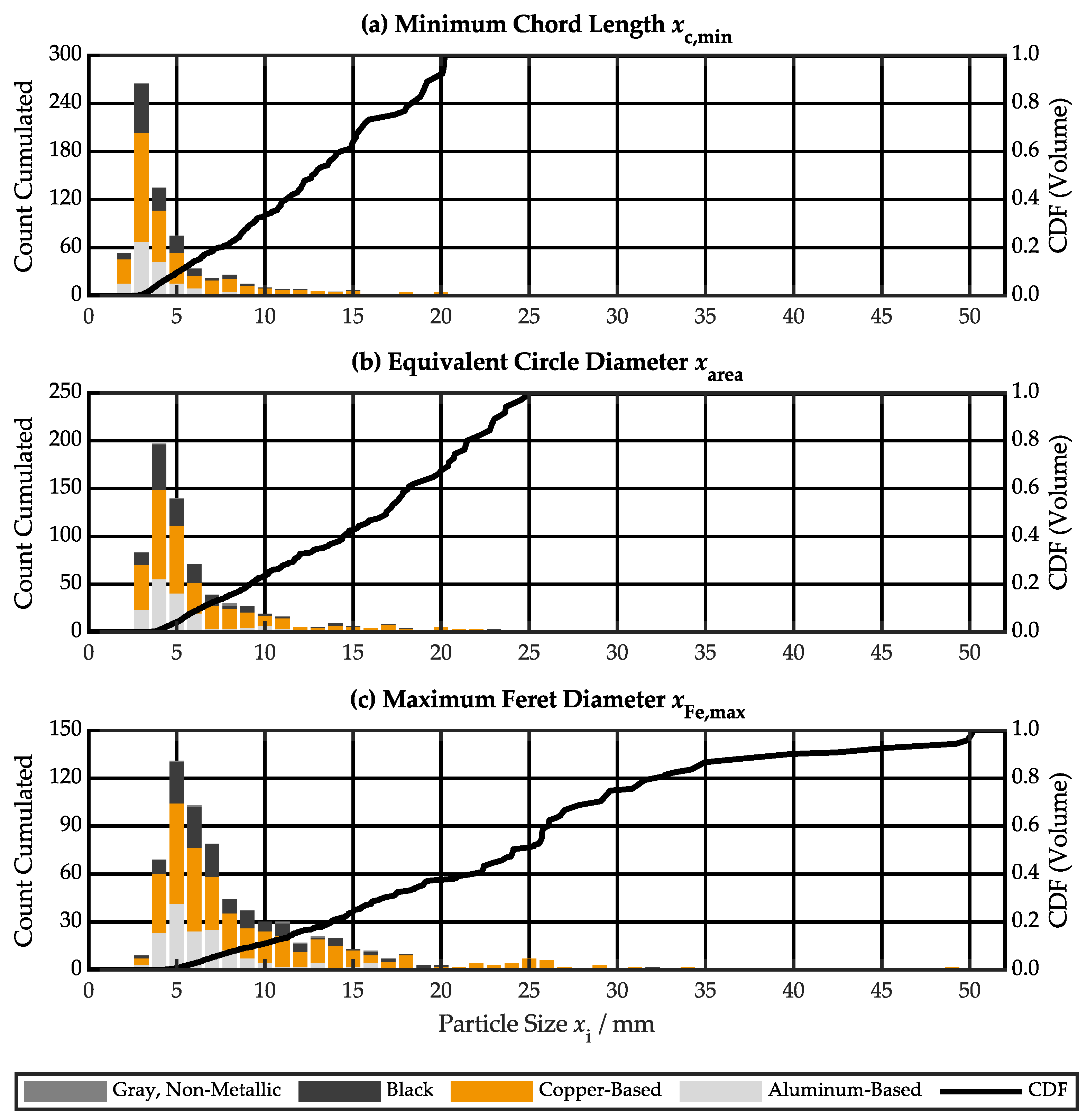

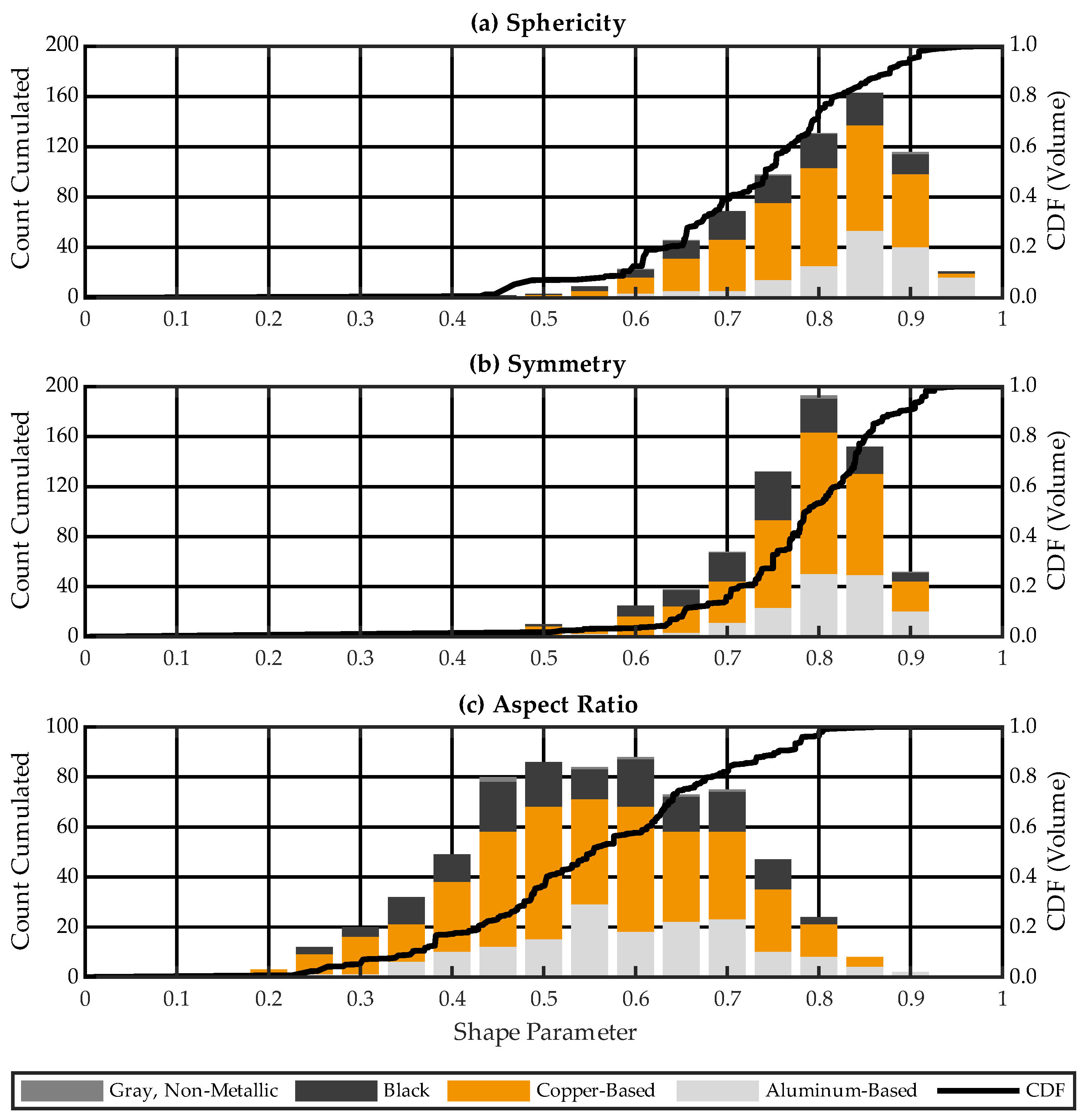

3.2. Particle Size and Shape Distribution

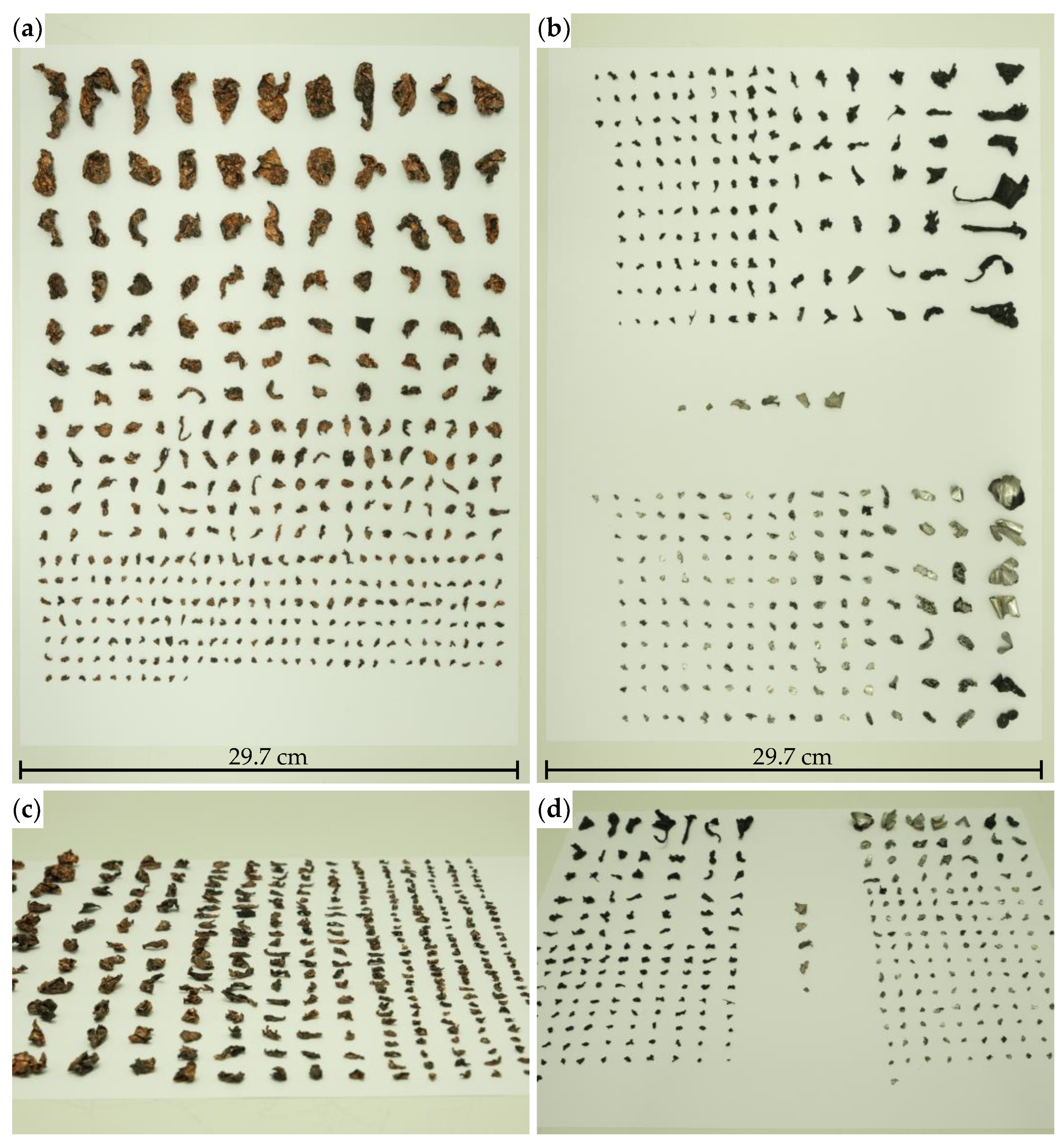

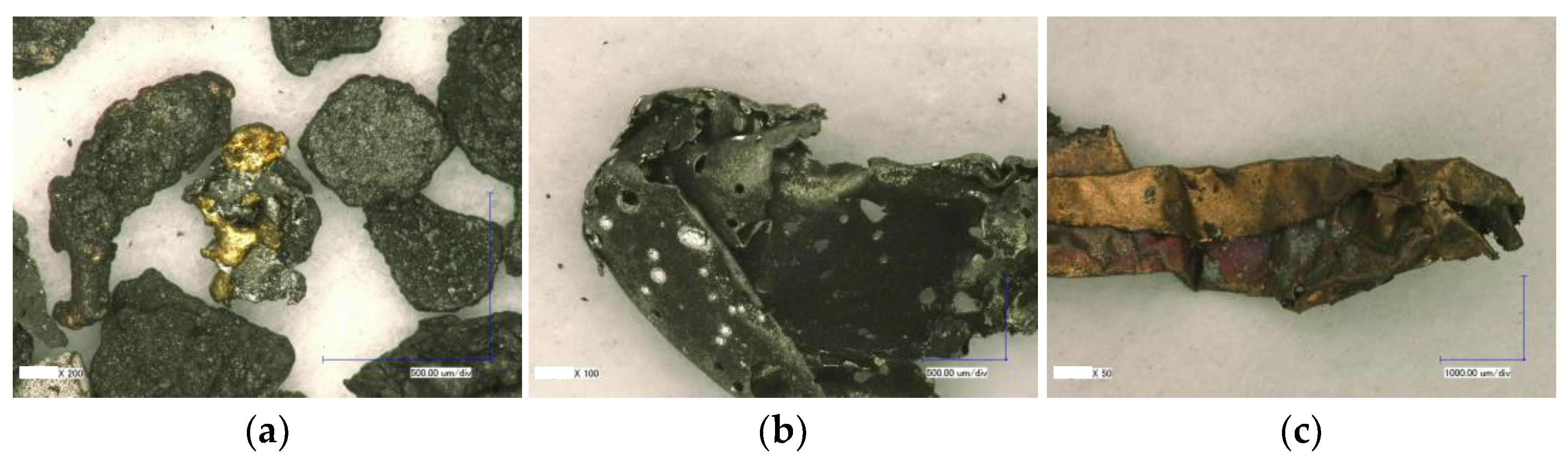

3.3. Large Particle Characteristics

3.4. Microscopic Investigations

3.5. Particle Oxidation Characteristics

4. Conclusions

- The wide range of particle sizes makes it particularly challenging to design appropriate filtration concepts. If a large mesh size is chosen, e.g., 0.1–1 mm, only a small proportion of the particles can be filtered. Reducing the mesh size drastically increases the risk of filter clogging. Alternative filter concepts beyond screening should therefore be investigated.

- Large metallic particles (>2 mm) should be considered as a risk for electrical breakdown of uninsulated high voltage components due to contact–contact shorting. To mitigate arcing within a battery system during TR, high-voltage components should be insulated with a material capable of withstanding the high-temperature, high-velocity particle jet. Alternatively, although impractical, clearance and creepage distances could be designed based on the largest expected pieces of copper or aluminum foil.

- Hot particles can act as an ignition source and are partially combustible themselves. Therefore, the maximum allowable exit temperature of the particles from a battery system into the ambient air should be defined considering the vent gas and particle ignition temperatures, respectively. The reaction onset of the latter was determined to be around 500–600 °C in this study, with peak heat release between 600–750 °C.

- Three-dimensional numerical simulation of particle-laden two-phase flows is a complex task, especially for battery abuse particles. The wide size range requires a wise selection of the right modeling techniques. Non-spherical particle shapes are relevant for proper drag modeling and particle-wall interactions. The wide temperature range has a significant impact on modeling attempts since energy stored in the particles and their material properties vary significantly. This study provides some contribution to these challenges, with further investigation needed.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bloomberg Finance, L.P. Global Energy Storage Market Records Biggest Jump Yet. Available online: https://about.bnef.com/blog/global-energy-storage-market-records-biggest-jump-yet/ (accessed on 15 December 2024).

- Abbas, Q.; Mirzaeian, M.; Hunt, M.R.; Hall, P.; Raza, R. Current State and Future Prospects for Electrochemical Energy Storage and Conversion Systems. Energies 2020, 13, 5847. [Google Scholar] [CrossRef]

- The University of Texas Fire Research Group. Battery Fire and Explosion Incidents: Database Tools. Available online: https://tools.utfireresearch.com/apps/incident_map (accessed on 15 December 2024).

- TÜV-Verband e., V. TÜV Mobility Studie 2024. Available online: https://tuev-verband.de/studien/tuev-mobility-studie-2024 (accessed on 15 December 2024).

- GB 38031-2020; Electric Vehicles Traction Battery Safety Requirements. State Administration for Market Regulation—Standardization Administration of the People’s Republic of China: Beijing, China, 2020.

- United Nations. In Uniform Provisions Concerning the Approval of Vehicles with Regard to Specific Requirements for the Electric Power Train, 3rd ed.; (ECE R100); United Nations: New York, NY, USA, 2022.

- RTCA, Inc. DO-311A—Minimum Operational Performance Standards for Rechargeable Lithium Batteries and Battery Systems; RTCA, Inc.: Washington, DC, USA, 2017. [Google Scholar]

- The European Parliament and the Council of the European Union. Regulation (EU) 2023/1542 of the European Parliament and of the Council of 12 July 2023 Concerning Batteries and Waste Batteries, Amending Directive 2008/98/EC and Regulation (EU) 2019/1020 and Repealing Directive 2006/66/EC; The European Parliament and the Council of the European Union: Brussels, Belgium, 2023. [Google Scholar]

- Zhang, Z.; Dong, H.; Wang, L.; Wang, Y.; He, X. Tracing Root Causes of Electric Vehicle Fires. Energy Technol. 2024, 12, 2400931. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Q.; Xu, L.; Sun, Y.; Feng, X.; Wang, H. A review on mechanisms, characteristics and relating hazards of vent gases from thermally abused Li-ion batteries. J. Energy Storage 2024, 84, 110892. [Google Scholar] [CrossRef]

- Barkholtz, H.M.; Preger, Y.; Ivanov, S.; Langendorf, J.; Torres-Castro, L.; Lamb, J.; Chalamala, B.; Ferreira, S.R. Multi-scale thermal stability study of commercial lithium-ion batteries as a function of cathode chemistry and state-of-charge. J. Power Sources 2019, 435, 226777. [Google Scholar] [CrossRef]

- Essl, C.; Golubkov, A.W.; Fuchs, A. Comparing Different Thermal Runaway Triggers for Two Automotive Lithium-Ion Battery Cell Types. J. Electrochem. Soc. 2020, 167, 130542. [Google Scholar] [CrossRef]

- Essl, C.; Golubkov, A.W.; Fuchs, A. Influence of Aging on the Failing Behavior of Automotive Lithium-Ion Batteries. Batteries 2021, 7, 23. [Google Scholar] [CrossRef]

- Xu, C.; Feng, X.; Huang, W.; Duan, Y.; Chen, T.; Gao, S.; Lu, L.; Jiang, F.; Ouyang, M. Internal temperature detection of thermal runaway in lithium-ion cells tested by extended-volume accelerating rate calorimetry. J. Energy Storage 2020, 31, 101670. [Google Scholar] [CrossRef]

- Willstrand, O.; Pushp, M.; Andersson, P.; Brandell, D. Impact of different Li-ion cell test conditions on thermal runaway characteristics and gas release measurements. J. Energy Storage 2023, 68, 107785. [Google Scholar] [CrossRef]

- Ren, D.; Hsu, H.; Li, R.; Feng, X.; Guo, D.; Han, X.; Lu, L.; He, X.; Gao, S.; Hou, J.; et al. A comparative investigation of aging effects on thermal runaway behavior of lithium-ion batteries. eTransportation 2019, 2, 100034. [Google Scholar] [CrossRef]

- Ohneseit, S.; Finster, P.; Floras, C.; Lubenau, N.; Uhlmann, N.; Seifert, H.J.; Ziebert, C. Thermal and Mechanical Safety As-sessment of Type 21700 Lithium-Ion Batteries with NMC, NCA and LFP Cathodes–Investigation of Cell Abuse by Means of Accelerating Rate Calorimetry (ARC). Batteries 2023, 9, 237. [Google Scholar] [CrossRef]

- Ding, C.; Zhu, N.; Yu, J.; Li, Y.; Sun, X.; Liu, C.; Huang, Q.; Wang, J. Experimental investigation of environmental pressure effects on thermal runaway properties of 21700 lithium-ion batteries with high energy density. Case Stud. Therm. Eng. 2022, 38, 102349. [Google Scholar] [CrossRef]

- Golubkov, A.W.; Scheikl, S.; Planteu, R.; Voitic, G.; Wiltsche, H.; Stangl, C.; Fauler, G.; Thaler, A.; Hacker, V. Thermal runaway of commercial 18650 Li-ion batteries with LFP and NCA cathodes—Impact of state of charge and overcharge. RSC Adv. 2015, 5, 57171–57186. [Google Scholar] [CrossRef]

- Golubkov, A.W.; Fuchs, D.; Wagner, J.; Wiltsche, H.; Stangl, C.; Fauler, G.; Voitic, G.; Thaler, A.; Hacker, V. Thermal-runaway experiments on consumer Li-ion batteries with metal-oxide and olivin-type cathodes. RSC Adv. 2014, 4, 3633–3642. [Google Scholar] [CrossRef]

- Feng, X.; Ouyang, M.; Liu, X.; Lu, L.; Xia, Y.; He, X. Thermal runaway mechanism of lithium ion battery for electric vehicles: A review. Energy Storage Mater. 2018, 10, 246–267. [Google Scholar] [CrossRef]

- Feng, X.; Zheng, S.; He, X.; Wang, L.; Wang, Y.; Ren, D.; Ouyang, M. Time Sequence Map for Interpreting the Thermal Runaway Mechanism of Lithium-Ion Batteries With LiNixCoyMnzO2 Cathode. Front. Energy Res. 2018, 6, 126. [Google Scholar] [CrossRef]

- Zhou, H.; Parmananda, M.; Crompton, K.R.; Hladky, M.P.; Dann, M.A.; Ostanek, J.K.; Mukherjee, P.P. Effect of electrode crosstalk on heat release in lithium-ion batteries under thermal abuse scenarios. Energy Storage Mater. 2022, 44, 326–341. [Google Scholar] [CrossRef]

- Wu, C.; Wu, Y.; Feng, X.; Wang, H.; Zhang, F.; Chen, S.; Li, B.; Deng, T.; Ouyang, M. Ultra-high temperature reaction mechanism of LiNi0.8Co0.1Mn0.1O2 electrode. J. Energy Storage 2022, 52, 104870. [Google Scholar] [CrossRef]

- Kriston, A.; Adanouj, I.; Ruiz, V.; Pfrang, A. Quantification and simulation of thermal decomposition reactions of Li-ion battery materials by simultaneous thermal analysis coupled with gas analysis. J. Power Sources 2019, 435, 226774. [Google Scholar] [CrossRef]

- Hatchard, T.D.; MacNeil, D.D.; Basu, A.; Dahn, J.R. Thermal Model of Cylindrical and Prismatic Lithium-Ion Cells. J. Electrochem. Soc. 2001, 148, A755. [Google Scholar] [CrossRef]

- Kim, G.-H.; Pesaran, A.; Spotnitz, R. A three-dimensional thermal abuse model for lithium-ion cells. J. Power Sources 2007, 170, 476–489. [Google Scholar] [CrossRef]

- Wang, Y.; Ren, D.; Feng, X.; Wang, L.; Ouyang, M. Thermal runaway modeling of large format high-nickel/silicon-graphite lithium-ion batteries based on reaction sequence and kinetics. Appl. Energy 2022, 306, 117943. [Google Scholar] [CrossRef]

- Hoelle, S.; Zimmermann, S.; Hinrichsen, O. 3D Thermal Simulation of Thermal Runaway Propagation in Lithium-Ion Battery Cell Stack: Review and Comparison of Modeling Approaches. J. Electrochem. Soc. 2023, 170, 60516. [Google Scholar] [CrossRef]

- Kim, J.; Mallarapu, A.; Finegan, D.P.; Santhanagopalan, S. Modeling cell venting and gas-phase reactions in 18650 lithium ion batteries during thermal runaway. J. Power Sources 2021, 489, 229496. [Google Scholar] [CrossRef]

- Ostanek, J.K.; Parhizi, M.; Li, W.; Kilaz, G.; Crompton, K.R. CFD-Based Thermal Abuse Simulations including Gas Generation and Venting of an 18650 Li-Ion Battery Cell. J. Electrochem. Soc. 2023, 170, 90512. [Google Scholar] [CrossRef]

- Cellier, A. Simulation aux Grandes Echelles de Feux de Batteries Lithium-Ion pour le Diagnostic de l’Emballement Thermique. Ph.D. Thesis, Institut National Polytechnique de Toulouse—INPT, Toulouse, France, 2023. [Google Scholar]

- Wang, G.; Kong, D.; Ping, P.; Wen, J.; He, X.; Zhao, H.; He, X.; Peng, R.; Zhang, Y.; Dai, X. Revealing particle venting of lithium-ion batteries during thermal runaway: A multi-scale model toward multiphase process. eTransportation 2023, 16, 100237. [Google Scholar] [CrossRef]

- Shen, H.; Wang, H.; Li, M.; Li, C.; Zhang, Y.; Li, Y.; Yang, X.; Feng, X.; Ouyang, M. Thermal Runaway Characteristics and Gas Composition Analysis of Lithium-Ion Batteries with Different LFP and NCM Cathode Materials under Inert Atmosphere. Electronics 2023, 12, 1603. [Google Scholar] [CrossRef]

- Fernandes, Y.; Bry, A.; de Persis, S. Identification and quantification of gases emitted during abuse tests by overcharge of a commercial Li-ion battery. J. Power Sources 2018, 389, 106–119. [Google Scholar] [CrossRef]

- Zou, K.; He, K.; Lu, S. Venting composition and rate of large-format LiNi0.8Co0.1Mn0.1O2 pouch power battery during thermal runaway. Int. J. Heat Mass Transf. 2022, 195, 123133. [Google Scholar] [CrossRef]

- Edge, J.S.; O'Kane, S.; Prosser, R.; Kirkaldy, N.D.; Patel, A.N.; Hales, A.; Ghosh, A.; Ai, W.; Chen, J.; Yang, J.; et al. Lithium ion battery degradation: What you need to know. Phys. Chem. Chem. Phys. 2021, 23, 8200–8221. [Google Scholar] [CrossRef]

- Wang, H.; Xu, H.; Zhang, Z.; Wang, Q.; Jin, C.; Wu, C.; Xu, C.; Hao, J.; Sun, L.; Du, Z.; et al. Fire and explosion characteristics of vent gas from lithium-ion batteries after thermal runaway: A comparative study. eTransportation 2022, 13, 100190. [Google Scholar] [CrossRef]

- Kennedy, R.W.; Marr, K.C.; Ezekoye, O.A. Gas release rates and properties from Lithium Cobalt Oxide lithium ion battery arrays. J. Power Sources 2021, 487, 229388. [Google Scholar] [CrossRef]

- Somandepalli, V.; Marr, K.; Horn, Q. Quantification of Combustion Hazards of Thermal Runaway Failures in Lithium-Ion Batteries. SAE Int. J. Altern. Powertrains 2014, 3, 98–104. [Google Scholar] [CrossRef]

- Tian, X.; Yi, Y.; Fang, B.; Yang, P.; Wang, T.; Liu, P.; Qu, L.; Li, M.; Zhang, S. Design Strategies of Safe Electrolytes for Preventing Thermal Runaway in Lithium Ion Batteries. Chem. Mater. 2020, 32, 9821–9848. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, H.; Li, W.; Li, C. Quantitative identification of emissions from abused prismatic Ni-rich lithium-ion batteries. eTransportation 2019, 2, 100031. [Google Scholar] [CrossRef]

- Wang, K.; Wu, D.; Chang, C.; Zhang, J.; Ouyang, D.; Qian, X. Charging rate effect on overcharge-induced thermal runaway characteristics and gas venting behaviors for commercial lithium iron phosphate batteries. J. Clean. Prod. 2024, 434, 139992. [Google Scholar] [CrossRef]

- Bordes, A.; Marlair, G.; Zantman, A.; Herreyre, S.; Papin, A.; Desprez, P.; Lecocq, A. New insight on the risk profile pertaining to lithium-ion batteries under thermal runaway as affected by system modularity and subsequent oxidation regime. J. Energy Storage 2022, 52, 104790. [Google Scholar] [CrossRef]

- Chen, S.; Wang, Z.; Wang, J.; Tong, X.; Yan, W. Lower explosion limit of the vented gases from Li-ion batteries thermal runaway in high temperature condition. J. Loss Prev. Process Ind. 2020, 63, 103992. [Google Scholar] [CrossRef]

- Zhou, T.; Sun, J.; Li, J.; Wei, S.; Chen, J.; Dang, S.; Tang, N.; Zhu, Y.; Lian, Y.; Guo, J.; et al. Toxicity, Emissions and Structural Damage from Lithium-Ion Battery Thermal Runaway. Batteries 2023, 9, 308. [Google Scholar] [CrossRef]

- Li, W.; Xue, Y.; Feng, X.; Liu, J.; Zhang, F.; Rao, S.; Zhang, T.; Gao, Z.; Du, Z.; Ni, C.; et al. Enhancing understanding of particle emissions from lithium-ion traction batteries during thermal runaway: An overview and challenges. eTransportation 2024, 22, 100354. [Google Scholar] [CrossRef]

- Li, W.; Xue, Y.; Feng, X.; Rao, S.; Zhang, T.; Gao, Z.; Guo, Y.; Zhou, H.; Zhao, H.; Song, Z.; et al. Characteristics of particle emissions from lithium-ion batteries during thermal runaway: A review. J. Energy Storage 2024, 78, 109980. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, H.; Li, W.; Li, C.; Ouyang, M. Size distribution and elemental composition of vent particles from abused prismatic Ni-rich automotive lithium-ion batteries. J. Energy Storage 2019, 26, 100991. [Google Scholar] [CrossRef]

- Chen, S.; Wang, Z.; Yan, W. Identification and characteristic analysis of powder ejected from a lithium ion battery during thermal runaway at elevated temperatures. J. Hazard. Mater. 2020, 400, 123169. [Google Scholar] [CrossRef]

- Liao, Z.; Zhang, S.; Li, K.; Zhao, M.; Qiu, Z.; Han, D.; Zhang, G.; Habetler, T.G. Hazard analysis of thermally abused lithium-ion batteries at different state of charges. J. Energy Storage 2020, 27, 101065. [Google Scholar] [CrossRef]

- Barone, T.L.; Dubaniewicz, T.H.; Friend, S.A.; Zlochower, I.A.; Bugarski, A.D.; Rayyan, N.S. Lithium-ion battery explosion aerosols: Morphology and elemental composition. Aerosol Sci. Technol. 2021, 55, 1183–1201. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, H.; Zhang, Y.; Cheng, L.; Wu, Y.; Feng, X.; Lu, L.; Ouyang, M. Thermal oxidation characteristics for smoke particles from an abused prismatic Li(Ni0.6Co0.2Mn0.2)O2 battery. J. Energy Storage 2021, 39, 102639. [Google Scholar] [CrossRef]

- Niu, H.; Chen, C.; Liu, Y.; Li, L.; Li, Z.; Ji, D.; Huang, X. Mitigating thermal runaway propagation of NCM 811 prismatic batteries via hollow glass microspheres plates. Process Saf. Environ. Prot. 2022, 162, 672–683. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Q.; Jin, C.; Xu, C.; Zhao, Y.; Li, Y.; Zhong, C.; Feng, X. Detailed characterization of particle emissions due to thermal failure of batteries with different cathodes. J. Hazard. Mater. 2023, 458, 131646. [Google Scholar] [CrossRef]

- García, A.; Monsalve-Serrano, J.; Micó, C.; Guaraco-Figueira, C. Detailed characterisation of particle emissions from the thermal runaway of nickel-manganese-cobalt 811 lithium-ion batteries at different states of charge. J. Energy Storage 2024, 96, 112695. [Google Scholar] [CrossRef]

- Ledinski, T.; Golubkov, A.W.; Schweighofer, O.; Erker, S. Arcing in Li-Ion Batteries. Batteries 2023, 9, 540. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Y.; Wang, J.; Lu, L.; Wang, H.; Li, M.; Xu, W.; Shi, C.; Li, C. Characterization of Breakdown Arcs Induced by Venting Particles Generated by Thermal Runaway of Large-Capacity Ternary Lithium-Ion Batteries. Electronics 2024, 13, 3168. [Google Scholar] [CrossRef]

- Claassen, M.; Bingham, B.; Chow, J.C.; Watson, J.G.; Wang, Y.; Wang, X. Characterization of Lithium-Ion Battery Fire Emissions—Part 1: Chemical Composition of Fine Particles (PM2.5). Batteries 2024, 10, 301. [Google Scholar] [CrossRef]

- Claassen, M.; Bingham, B.; Chow, J.C.; Watson, J.G.; Chu, P.; Wang, Y.; Wang, X. Characterization of Lithium-Ion Battery Fire Emissions—Part 2: Particle Size Distributions and Emission Factors. Batteries 2024, 10, 366. [Google Scholar] [CrossRef]

- Ubaldi, S.; Russo, P. Toxicity Assessment of Gas, Solid and Liquid Emissions from Li-Ion Cells of Different Chemistry Subjected to Thermal Abuse. Energies 2024, 17, 4402. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, Y.; Chen, D. Soot formation and its hazards in battery thermal runaway. J. Aerosol Sci. 2024, 181, 106420. [Google Scholar] [CrossRef]

- Yang, Y.; Fang, D.; Maleki, A.; Kohzadi, S.; Liu, Y.; Chen, Y.; Liu, R.; Gao, G.; Zhi, J. Characterization of Thermal-Runaway Particles from Lithium Nickel Manganese Cobalt Oxide Batteries and Their Biotoxicity Analysis. ACS Appl. Energy Mater. 2021, 4, 10713–10720. [Google Scholar] [CrossRef]

- Lejon, C.; Vågberg, D.; Schönfeldt, F.; Liljedahl, B.; Persson, L.; Burman, J.; Elfverson, D.; Rydman, J.E.; Sjöström, J.; Björnham, O. Lagrangian plume rise and dispersion modelling of the large-scale lithium-ion battery fire in Morris, USA, 2021. Air Qual. Atmos. Health 2024, 17, 2077–2089. [Google Scholar] [CrossRef]

- ISO 13322-2:2021; Particle Size Analysis—Image Analysis Methods—Part 2: Dynamic Image Analysis Methods, 2nd ed. International Organization for Standardization: Geneva, Switzerland, 2021.

- Grossetete, T.; Dubourg, S.; Rochard, T.; Marteau, D.; Bengaouer, A. Detailed characterization of solid particles emitted during the thermal runaway of large-scale Lithium-ion cells. J. Energy Storage 2025, 124, 116666. [Google Scholar] [CrossRef]

- Haider, A.; Levenspiel, O. Drag coefficient and terminal velocity of spherical and nonspherical particles. Powder Technol. 1989, 58, 63–70. [Google Scholar] [CrossRef]

- National Institute of Standards and Technology. NIST Chemistry WebBook: NIST Standard Reference Database 69. Available online: https://webbook.nist.gov/chemistry/ (accessed on 27 March 2025).

- Feng, X.; Fang, M.; He, X.; Ouyang, M.; Lu, L.; Wang, H.; Zhang, M. Thermal runaway features of large format prismatic lithium ion battery using extended volume accelerating rate calorimetry. J. Power Sources 2014, 255, 294–301. [Google Scholar] [CrossRef]

- Wang, H.; Xu, H.; Zhao, Z.; Wang, Q.; Jin, C.; Li, Y.; Sheng, J.; Li, K.; Du, Z.; Xu, C.; et al. An experimental analysis on thermal runaway and its propagation in Cell-to-Pack lithium-ion batteries. Appl. Therm. Eng. 2022, 211, 118418. [Google Scholar] [CrossRef]

- Lai, X.; Wang, S.; Wang, H.; Zheng, Y.; Feng, X. Investigation of thermal runaway propagation characteristics of lithium-ion battery modules under different trigger modes. Int. J. Heat Mass Transf. 2021, 171, 121080. [Google Scholar] [CrossRef]

- Yan, H.; Ezekoye, O.A. State of charge effects on active material elemental composition changes between pre-thermal-runaway and post-failure states for 8-1-1 nickel-manganese-cobalt 18650 cells. J. Energy Storage 2023, 63, 106974. [Google Scholar] [CrossRef]

- Hou, J.; Feng, X.; Wang, L.; Liu, X.; Ohma, A.; Lu, L.; Ren, D.; Huang, W.; Li, Y.; Yi, M.; et al. Unlocking the self-supported thermal runaway of high-energy lithium-ion batteries. Energy Storage Mater. 2021, 39, 395–402. [Google Scholar] [CrossRef]

- Bracht, C.; Preitschopf, T.; Schöneich, M.; Neff, T.; Kallfaß, C.; Finze, M. Influence of Crucible Types on Thermal Stability Analysis of Li-Ion Battery Components by Thermogravimetric Analysis–Differential Scanning Calorimetry. Energy Technol. 2024, 12, 2400365. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, R.; Feng, X.; Fang, J.; Xu, J.; Wang, X.; Zhang, J. Thermal Oxidation Characteristics and Kinetics of Micron Aluminum Powder in Different Ambient Oxygen Concentration Atmospheres. Processes 2024, 12, 2408. [Google Scholar] [CrossRef]

- Xiaowei, L.; Jean-Charles, R.; Suyuan, Y. Effect of temperature on graphite oxidation behavior. Nucl. Eng. Des. 2004, 227, 273–280. [Google Scholar] [CrossRef]

| Reference | Cathode Chemistry | Size Distribution | Morphology | Chemical Composition | Reactivity | Parameter Variation |

|---|---|---|---|---|---|---|

| [49] | NMC622 | SA, LD | - | ICP-MS, IC, EA | - | - |

| [42] | NMC622 | SA, LD | - | ICP-MS, IC, EA | - | - |

| [50] | NMC | LD | SEM | EDS, XRD, XRF, FTIR, GC-MS | STA, ERT | SOC, heating temperature, heating power |

| [51] | NMC111 | - | - | EDS, XRD | - | SOC |

| [52] | NMC, LFP, LTO | - | SEM | EDS | - | - |

| [53] | NMC622 | SA, LD | SEM | EDS, ICP-MS | STA-FTIR | - |

| [54] | NMC811 | - | SEM | EDS | - | SOC |

| [55] | NMC111, NMC532, NMC622 | SA, LD | SEM | XRD, ICP-MS, IC, EA | - | - |

| [33] | LFP | SA, LD | SEM, OM | - | - | - |

| [56] | NMC811 | SA, LD | SEM | EDS | DSC, TGA | SOC |

| Property | Value |

|---|---|

| Format | Prismatic |

| Size excl. terminals | 148 × 97.5 × 26.5 mm3 |

| Capacity | 51 Ah |

| Nominal voltage | 3.65 V |

| Mass | 910 ± 35 g |

| Specific energy | 205 Wh/kg |

| Cathode active material | NMC622 |

| Anode active material | Graphite |

| Active material shape | Two wound stacks |

| Electrolyte | in EC:EMC (40:60 wt.%) + additives |

| Separator | ) polymer |

| Parameter | Value |

|---|---|

| Temperature ramps | [5,10,20] K/min |

| Temperature range | 20–1200 °C |

| Crucible type | (no lid) |

| Atmosphere | |

| Particle fractions | [<32, 32–45, 45–63, 63–90, 90–125, 125–250, 250–500] µm |

| Parameter | Test #1 | Test #2 | Test #3 |

|---|---|---|---|

| 915 g | 919 g | 917 g | |

| 526 g (57.5%) | 595 g (64.8%) | 563 g (61.4%) | |

| (in vacuum cleaner filter) | 332 g (36.3%) | 396 g (43.1%) | 403 g (43.9%) |

(gas, residue particles, condensed electrolyte) | 194 g (21.2%) | 199 g (21.6%) | 160 g (17.4%) |

| (sampled from filter) | 319 g (96.1%) | 379 g (95.7%) | 382 g (94.8%) |

| (lost in filter) | 13 g (3.9%) | 17 g (4.3%) | 21 g (5.2%) |

| (pressure based) | 4.8 s | 4.2 s | 4.4 s |

| (ideal gas law) | 3.50 mol (69 mmol/Ah) | 3.95 mol (77 mmol/Ah) | 3.81 mol (75 mmol/Ah) |

| 85 L (1.7 L/Ah) | 96 L (1.9 L/Ah) | 93 L (1.8 L/Ah) | |

| 166 °C | 171 °C | 162 °C | |

| 106 °C | 106 °C | 101 °C | |

| 186 °C | 187 °C | 185 °C | |

| 122 °C | 121 °C | 120 °C | |

| 225 °C | 226 °C | 227 °C | |

| 149 °C | 149 °C | 149 °C | |

| 361 °C | 330 °C | 361 °C | |

| 558 °C | 472 °C | 596 °C | |

| 354 °C | 326 °C | 349 °C | |

| 442 °C | 372 °C | 473 °C | |

| sensor failure | 612 °C | sensor failure | |

| 428 °C | 484 °C | 492 °C | |

| TR heat release (energy balance) | 1008 kJ | 1057 kJ | 992 kJ |

| electrical energy factor | 1.51 | 1.59 | 1.49 |

| Ref. | Cell Shape | Capacity | Cathode | D10 | D50 | D90 | Analysis | Comment |

|---|---|---|---|---|---|---|---|---|

| This | prismatic | 51 Ah | NMC622 | 10 µm | 61 µm | 541 µm | SA, DIA | Sample < 2 mm (96%) |

| 10 µm | 64 µm | 457 µm | Sample < 2 mm (96%) | |||||

| [49] | prismatic | 50 Ah | NMC622 | 23 µm | 198 µm | 475 µm | SA, LD | Sample < 0.85 mm (45%) |

| [42] | prismatic | 50 Ah | NMC622 | 19 µm | 195 µm | 390 µm | SA, LD | Sample < 0.5 mm (90%) |

| [50] | cylindrical | 2.6 Ah | NMC | 147 µm | 182 µm | 200 µm | LD | Average #17–20 |

| 143 µm | 186 µm | 229 µm | Average #21–24 | |||||

| [53] | prismatic | 50 Ah | NMC622 | 8 µm | 179 µm | 663 µm | SA, LD | Read from plot |

| [55] | prismatic | 37 Ah | NMC111 | 29 µm | 109 µm | 214 µm | SA, LD | Sample < 0.85 mm (88%) |

| prismatic | 50 Ah | NMC532 | 30 µm | 184 µm | 600 µm | Sample < 0.85 mm (90%) | ||

| prismatic | 50 Ah | NMC622 | 68 µm | 239 µm | 954 µm | Sample < 0.85 mm (90%) |

| Parameter | Sample # | Copper-Based | Aluminum-Based | “Black” | Gray Non-Metallic | Total |

|---|---|---|---|---|---|---|

| Particle count | 1 | 231 | 111 | 99 | 21 | 462 |

| 2 | 402 | 158 | 122 | 1 | 683 | |

| 3 | 373 | 161 | 144 | 6 | 684 | |

| Particle mass | 1 | 3.99 g | 0.65 g | 3.65 g | 0.12 g | 8.41 g |

| 2 | 6.71 g | 1.59 g | 4.21 g | - | 12.51 g | |

| 3 | 8.14 g | 1.79 g | 4.05 g | 0.02 g | 14.00 g |

| Parameter | Sample # | Copper-Based | Aluminum-Based | “Black” | Gray Non- Metallic |

|---|---|---|---|---|---|

| 1 | 19.0 mm | 13.9 mm | 16.4 mm | 7.3 mm | |

| 2 | 25.6 mm | 17.0 mm | 17.0 mm | 4.7 mm | |

| 3 | 20.2 mm | 20.1 mm | 19.2 mm | 10.7 mm | |

| 1 | 28.8 mm | 18.2 mm | 21.6 mm | 9.0 mm | |

| 2 | 32.0 mm | 20.6 mm | 19.6 mm | 5.3 mm | |

| 3 | 25.1 mm | 22.2 mm | 23.0 mm | 11.7 mm | |

| 1 | 51.4 mm | 26.6 mm | 35.5 mm | 19.1 mm | |

| 2 | 43.3 mm | 27.9 mm | 41.8 mm | 8.8 mm | |

| 3 | 49.9 mm | 26.6 mm | 50.2 mm | 16.1 mm | |

| 1 | 204 (88%) | 100 (90%) | 92 (93%) | 15 (71%) | |

| 2 | 358 (89%) | 136 (86%) | 106 (87%) | 1 (100%) | |

| 3 | 332 (89%) | 135 (84%) | 132 (92%) | 6 (100%) | |

| 1 | 71 (31%) | 21 (19%) | 24 (24%) | 1 (5%) | |

| 2 | 122 (30%) | 30 (19%) | 26 (21%) | 0 (0%) | |

| 3 | 142 (38%) | 26 (16%) | 39 (27%) | 4 (67%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elsner, F.; Gerhards, P.; Berrier, G.; Vincent, R.; Dubourg, S.; Pischinger, S. Detailed Characterization of Thermal Runaway Particle Emissions from a Prismatic NMC622 Lithium-Ion Battery. Batteries 2025, 11, 225. https://doi.org/10.3390/batteries11060225

Elsner F, Gerhards P, Berrier G, Vincent R, Dubourg S, Pischinger S. Detailed Characterization of Thermal Runaway Particle Emissions from a Prismatic NMC622 Lithium-Ion Battery. Batteries. 2025; 11(6):225. https://doi.org/10.3390/batteries11060225

Chicago/Turabian StyleElsner, Felix, Peter Gerhards, Gaël Berrier, Rémi Vincent, Sébastien Dubourg, and Stefan Pischinger. 2025. "Detailed Characterization of Thermal Runaway Particle Emissions from a Prismatic NMC622 Lithium-Ion Battery" Batteries 11, no. 6: 225. https://doi.org/10.3390/batteries11060225

APA StyleElsner, F., Gerhards, P., Berrier, G., Vincent, R., Dubourg, S., & Pischinger, S. (2025). Detailed Characterization of Thermal Runaway Particle Emissions from a Prismatic NMC622 Lithium-Ion Battery. Batteries, 11(6), 225. https://doi.org/10.3390/batteries11060225