Abstract

In the context of the global energy transition, thermal management of electric vehicle batteries faces severe challenges due to temperature rise and energy consumption under dynamic operating conditions. Traditional strategies rely on real-time feedback and suffer from response lag and energy efficiency imbalance. In this study, we propose a neural network-based synergistic optimization method for driving conditions prediction and dynamic thermal management, which collects multi-scenario real-vehicle data (358 60-s condition segments) by naturalistic driving data collection method, extracts four typical conditions (congestion, highway, urban, and suburbia) by combining with K-means clustering, and constructs a BP (backpropagation neural network) model (20 neurons in the input layer and 60 neurons in the output layer) to predict the vehicle speed in the next 60 s. Based on the prediction results, the coupled PID control and temperature feedback mechanism dynamically adjusts the coolant flow rate (maximum reduction of 17.6%), which reduces the maximum temperature of the battery by 3.8 °C, the maximum temperature difference by 0.3 °C, and the standard deviation of temperature fluctuation at ambient temperatures of 25~40 °C is 0.2 °C in AMESim simulation and experimental validation. The results show that the strategy significantly improves battery safety and system economy under complex working conditions by prospectively optimizing heat dissipation and energy consumption, providing an efficient solution for intelligent thermal management.

1. Introduction

Driven by the global energy transition and carbon neutrality, electric vehicles (EVs) have become the core vehicle of transportation innovation. According to the International Energy Agency (IEA), the number of EVs in the world will exceed 300 million in 2024, and the performance and safety of power batteries, as the core component, will directly determine the economy and reliability of the vehicles. However, the accumulation and uneven distribution of temperature of lithium-ion batteries due to heat generated by internal resistance under complex driving conditions not only accelerates battery aging but also triggers the risk of thermal runaway. Recent studies have highlighted the critical role of multiphysics modeling coupled with machine learning to predict and identify thermal runaways early by analyzing spatio-temporal thermal characteristics, enabling proactive battery safety management beyond traditional monitoring methods [1]. This work introduces a model-constrained deep-learning approach for online fault detection in lithium-ion batteries. The proposed algorithm integrates battery model constraints and employs deep learning to manage stochastic system evolution, which enhances real-time fault detection under complex operating conditions, thus contributing to improved battery safety management [2]. Traditional thermal management systems (BTMS) rely on passive response mechanisms (e.g., real-time temperature-based PID control [3]), which make it difficult to cope with sudden changes in thermal loads under dynamic operating conditions, resulting in cooling lag and wasted energy consumption. Therefore, how to optimize the thermal management strategy by predicting the driving conditions in advance has become a key challenge to improve the efficiency and safety of the battery system.

Current research on battery thermal management mainly focuses on the optimization of heat dissipation technology and dynamic control strategy. In terms of heat dissipation technology, liquid cooling systems have become the mainstream choice due to their high efficiency and reliability, but their design complexity and energy consumption issues still need to be broken through. For example, the strategy based on nonlinear model predictive control (NMPC) and particle swarm optimization (PSO) [4] is able to achieve accurate temperature regulation of lithium-ion battery modules, but it relies on high-precision models, and its computational complexity limits real-time performance; the bionic fern-like vein structure coupled with liquid-cooled phase change materials (PCM) scheme improves the thermal equilibrium in heavy-duty scenarios, such as mining trucks [5], but PCM’s low thermal conductivity makes it difficult to adapt to frequent charging and discharging scenarios; while the multi-objective optimization method of phase change cooling coupled with liquid cooling balances heat dissipation and energy consumption through the non-dominated sorting genetic algorithm (NSGA-II) [6], but its static framework is difficult to cope with dynamic working conditions. These efforts point to the need for more adaptive, dynamic management approaches that can cope with real-world variability [7]. External pressure is critical for mitigating lithium plating in lithium-ion batteries. By applying pressure, battery performance improves, and longevity is extended, as this factor plays a key role in understanding the underlying mechanics of lithium-ion batteries during operation [8]. Venting during fast charging is a critical failure mechanism of lithium-ion batteries, primarily due to exothermic reactions between the electrolyte and lithium plating. These findings underline the need for carefully controlled charging protocols to prevent gas generation and ensure safe battery operation during rapid charging [9]. In terms of control strategies, most of the existing studies are based on fixed rules or standard working conditions, which lack the adaptation to the complexity of real roads. For example, the integrated scheme of PID and fuzzy control improves the response speed by dynamically adjusting the thermal management parameters of the whole vehicle, but it still needs to rely on real-time sensor feedback and cannot predict the future changes of heat load; real-time battery thermal management based on deep reinforcement learning (DRL) optimizes the energy allocation under the intense driving conditions [10], but its training data relies on the simulation environment, and its generalization ability is limited; hierarchical reinforcement learning (HRL) combined with deep deterministic policy gradient (DDPG) integrated thermal management method coordinated battery and motor thermal management under high-temperature environment, but its multi-objective synergistic mechanism still needs to be optimized [11].

In the field of energy management, the combination of model predictive control (MPC) and Markov chain speed predictor optimizes the energy consumption of hybrid buses through the Pontryagin minimization principle (PMP), but its prediction horizon is limited to a fixed time window [12]. The active thermal management strategy of dynamic programming (DP) and genetic algorithms (GA), although it strikes a balance between the state of health of the battery (SOH) and energy consumption, but its computational cost limits the real-time performance [13]. In terms of multi-objective optimization, the optimization of microchannel parameters of the liquid-cooling system [14] and the design of micro heat pipe structure [15] improve the thermal efficiency by a deep neural network (DNN) and multi-objective genetic algorithm (MOGA), but they do not consider the transient demand of dynamic working conditions. While adaptive optimization horizons (AOH-MT) and chance-constrained stochastic MPC (C-SMPC) achieve trade-offs between energy consumption and temperature constraints, they rely on the computational cost to limit the real-time performance [16]. These methods, while promising, still face challenges in achieving a balance between computational feasibility and adaptability to hardware constraints [17].

In addition, industry analysis points out that the global battery market demand for thermal management systems continues to grow, the optimization of liquid-cooled plate thermal performance has become a technical focus [18], and policy-driven technological innovation needs to take into account cost and energy efficiency [19]. The concept of battery digital twins, which integrates battery modeling, diagnostic tools, and machine learning, holds great promise for enhancing battery management. By creating a close interaction between physical and digital embodiments of batteries, this approach enables smarter control and a longer lifetime, addressing key challenges in the real-world application of battery systems [20]. Liquid-cooled plates (LCP) are crucial for optimizing heat dissipation in high-performance applications. By incorporating internal sub-channels and using topology optimization, the cooling efficiency can be significantly improved, ensuring better thermal management in battery systems [21]. The limitations of the existing work are reflected in three aspects: (1) data limitations: most studies rely on laboratory or standard operating condition data (e.g., China heavy-duty commercial vehicle test condition, CHTC), and lack of dynamic modeling of real road scenarios; (2) response lag: traditional PID or fuzzy control relies on real-time feedback, and the response lags behind the change of the operating conditions, resulting in the accumulation of the temperature rise; (3) energy-efficiency imbalance: the existing methods (such as NMPC, DRL) have improved the control accuracy, but the energy consumption optimization mechanism is not yet mature, and it is difficult to realize the global synergy between heat dissipation performance and system economy. Emerging approaches emphasize integrating battery, cooling system, and control policy design holistically to address these gaps [22]. Lithium-ion batteries play a pivotal role in enabling the storage of renewable energy, especially in regions targeting carbon neutrality. Their application in energy storage systems ensures efficient energy management and supports the transition to a sustainable energy infrastructure [23]. As the demand for batteries continues to grow, particularly in electric vehicles, the need for advanced thermal management systems has become increasingly vital. These systems are essential for improving battery efficiency, extending lifespan, and ensuring safe operation under diverse working conditions [24].

To address the above challenges, this study proposes a synergistic strategy for battery thermal management based on dynamic working condition prediction, and the core innovations include:

- (1)

- Data-driven working condition modeling: Collecting multi-scenario real vehicle data through autonomous driving method, combining with K-means clustering to extract four types of typical working conditions (congested, high-speed, urban, and suburban), and constructing a highly generalized dataset;

- (2)

- Nonlinear prediction and dynamic control: design BP neural network model to predict the future 60 s working conditions with historical speed and characteristic parameters, and coupled with PID algorithm to adjust the coolant flow in advance;

- (3)

- Synergistic optimization of energy consumption and performance: Introducing a temperature feedback mechanism to dynamically adjust the water pump speed, which reduces the coolant energy consumption by 17.6% while ensuring the heat dissipation performance (temperature difference ≤ 0.7 °C).

By integrating data science and control theory, this study breaks through the limitation of traditional thermal management relying on hysteresis feedback and realizes the synergistic optimization of time-series prediction and dynamic control. Compared with existing methods, the present strategy has significant advantages in the following aspects.

Prospective: the RMSE of the BP neural network model is 0.722 km/h, which gives a higher prediction accuracy compared to other methods such as fuzzy PI control (RMSE = 0.75 km/h) [25] and deep learning optimized liquid cooling control (RMSE = 0.80 km/h) [26], and can trigger cooling 10~15 s in advance;

Energy efficiency optimization: the combination of dynamic PID control and temperature feedback reduces energy consumption by 17.6% compared to the fixed threshold strategy, which is superior to the static energy-saving effect of the phase change material scheme;

Robustness: the standard deviation of temperature fluctuation is stable at 0.2 °C in the range of ambient temperature 25~40 °C. The adaptability is comparable to the multi-objective optimization framework, but the hardware cost is reduced by 50~60%.

The full text is structured as follows: we provide a detailed discussion of the experimental design and analysis methods, including multi-scenario real-vehicle data collection, K-means clustering to extract typical operating conditions, the construction and validation of a BP neural network model, and the establishment of the experimental platform in Section 2. Section 3 proposes a battery thermal management strategy based on work state prediction, combining PID control with a temperature feedback mechanism for dynamic regulation, and validates its effectiveness through AMESim simulation. Section 4 conducts an in-depth discussion on the reliability of the prediction model, energy consumption and thermal performance balance, strategy robustness, and engineering application value and verifies the superiority of the strategy through comparative experiments. Section 5 summarizes the research results, including temperature reduction, energy consumption optimization, and cost advantages, and looks forward to future research directions.

2. Experimental Design and Analysis

2.1. Data Acquisition and Preprocessing

In this study, an Iveco Classic EL46 special-purpose vehicle (see Table 1 for parameters) was selected as the experimental platform, with a peak motor power of 100 kW and a peak torque of 1000 Nm, which is able to cover a wide range of driving scenarios, such as urban and high-speed driving.

Table 1.

Basic parameters of EL46 vehicle.

In order to obtain real driving data, we adopt the naturalistic driving data collection method, which allows the driver to choose the route freely and fully captures the random traffic conditions (e.g., congestion, rapid acceleration, etc.). A total of vehicle speed, SOC, gear, voltage, current, and other parameters are recorded during the data acquisition cycle, and some examples of raw data are shown in Table 2.

Table 2.

Selected real-vehicle driving conditions data.

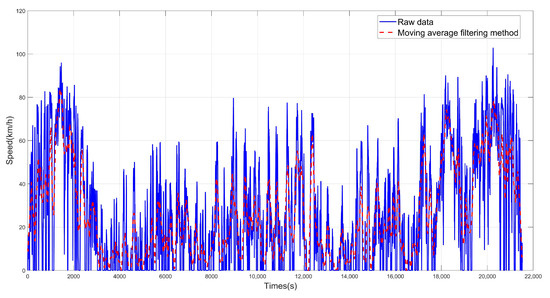

The collected raw data contains some invalid working conditions (e.g., prolonged parking). We define an idling time of more than 6 min as an invalid data segment and delete such segments directly. Figure 1 shows a typical segment of driving conditions after processing, and dynamic features such as acceleration, deceleration, and uniform speed can be clearly recognized through the speed-time curve. To illustrate the trend of vehicle speed change, we employed the moving average filtering method to process the raw data.

Figure 1.

Actual driving conditions of the car.

2.2. Work Condition Segmentation and Clustering

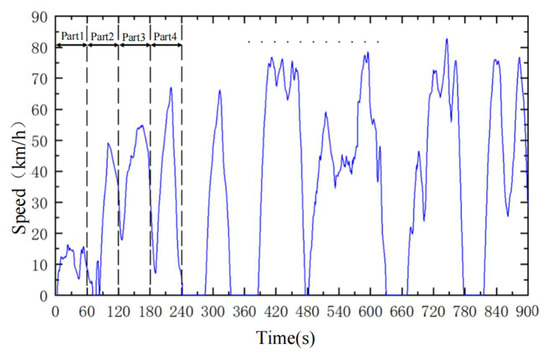

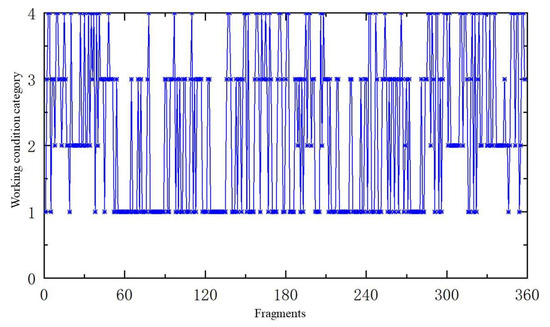

In order to extract representative working condition patterns, we used the fixed-step division method to slice the continuous driving data into 60 s segments (Figure 2), and a total of 358 valid segments were obtained.

Figure 2.

Segmentation of working condition segments.

Characterization parameters for each segment include: average speed, which reflects overall driving intensity; parking ratio (PR) which characterizes the level of traffic congestion; deceleration ratio (DR) vs. uniformity ratio (UR) which describes the smoothness of driving behavior.

Parking proportion: This refers to the proportion of time during a certain period when the vehicle’s speed is zero. The calculation formula is:

where represents the parking time (in seconds), and represents the total time (in seconds).

Deceleration ratio: This refers to the proportion of time that the vehicle is in a decelerating state (speed decreasing) out of the total time. The calculation formula is:

where represents the deceleration time (in seconds).

Uniformity ratio: This refers to the proportion of time that the vehicle maintains a constant speed (speed remains essentially unchanged) out of the total time. The calculation formula is:

where represents the uniform speed time (in seconds).

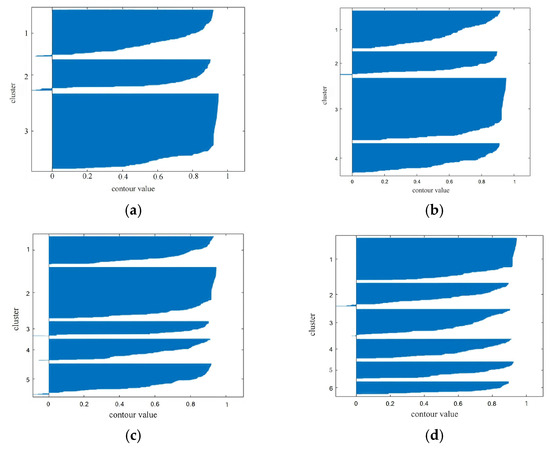

To identify typical driving patterns, we used the K-means algorithm to cluster the 358 segments. The clustering effect was assessed by contour coefficients (Figure 3); the average profile coefficient of clustered scenario 1 is 0.55, that of clustered scenario 2 is 0.60, that of clustered scenario 3 is 0.58, and that of clustered scenario 4 is 0.62, and it was found that intraclass cohesion was optimal when k = 4 (the contour coefficients were concentrated in the positive interval).

Figure 3.

Distribution of contour coefficients for four different k-value cases. (a) Distribution of contour coefficients for a k value of 3. (b) Distribution of contour coefficients for a k value of 4. (c) Distribution of contour coefficients for a k value of 5. (d) Distribution of contour coefficients for k value of 6.

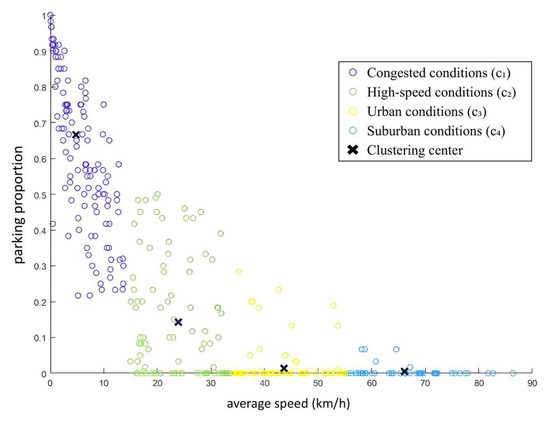

Figure 4 illustrates the clustering results with average speed and parking percentage, which are finally classified into four categories of working conditions:

Figure 4.

Clustering results graph (358 valid fragments).

- Congested conditions (c₁): average speed 4.93 km/h, 67.6% of stopping, 40.5% of the total;

- High-speed conditions (c₂): average speed 66.61 Km/h, 0.5% stopping ratio, 13.4%;

- Urban conditions (c₃): average speed 23.62 Km/h, 14.4% of stopping, 26.5% of the total;

- Suburban conditions (c₄): average speed 43.77 Km/h, 2.6% stopping ratio, 19.6% of the total.

The clustering results are highly consistent with the real traffic scene (Figure 5), which verifies the reasonableness of the feature parameter selection.

Figure 5.

Work condition identification results.

2.3. Driving Condition Prediction Based on BP Neural Network

2.3.1. Model Construction and Parameter Optimization

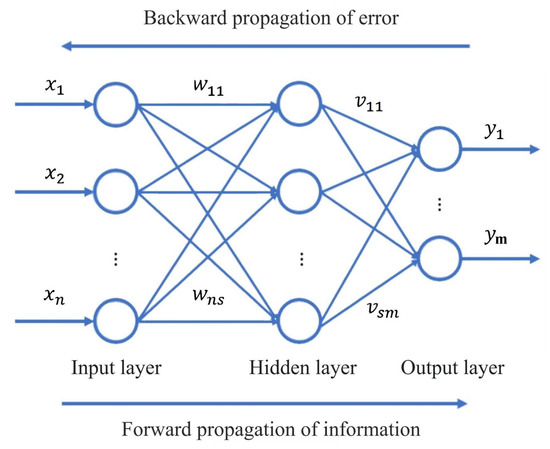

In order to predict the future driving demand in advance, we designed a BP neural network prediction model, the structure of which is shown in Figure 6.

Figure 6.

Schematic diagram of BP neural network structure.

Input layer: contains a 16-s sequence of historical vehicle speeds (1 data point per second) and 4 feature parameters, totaling 20 neurons;

Hidden layer: the number of neurons was determined to be 10 by the iterative method, and the activation function was chosen as Tansig to enhance the nonlinear fitting ability;

Output layer: predicts a sequence of vehicle speeds for the next 60 s, predict the next 60 separate 1-s speed points, corresponding to 60 neurons.

The training algorithm is Levenberg–Marquardt (LM), which has fast convergence and is suitable for small to medium-sized networks. Table 3 lists the key training parameters, including the maximum number of iterations 1000, the learning rate 0.1, and the training set share of 70%.

Table 3.

BP neural network training parameters.

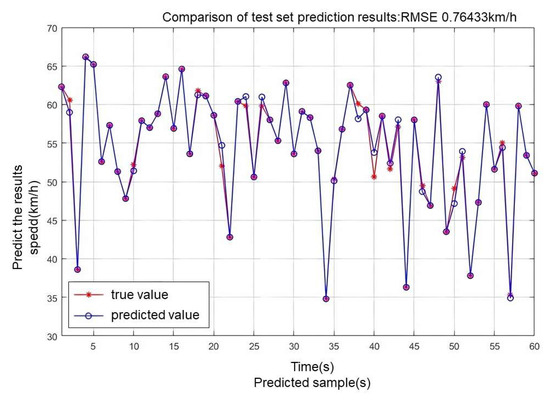

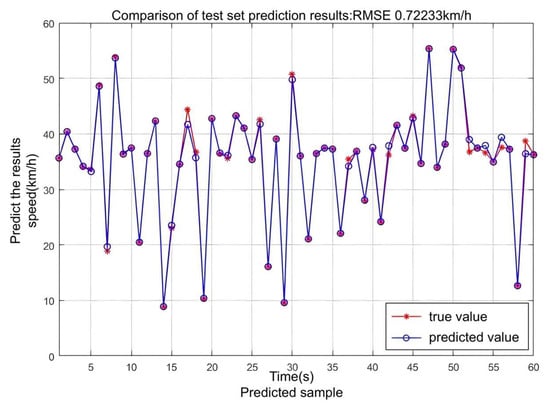

2.3.2. Validation of Prediction Results

The 358 segments were divided into a training set (300) and a test set (58). Figure 7 shows that the root mean square error (RMSE) between the predicted and true values of the training set is 0.764, with a maximum deviation of 6.3%.

Figure 7.

Comparison of training set prediction results.

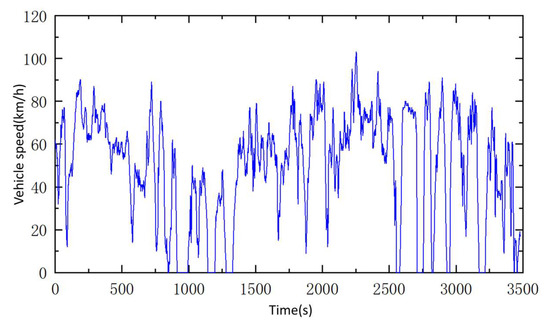

The test set is spliced into a section of 3480 s of continuous operating conditions (Figure 8), and the predicted results (Figure 9) have an RMSE of 0.722 with a maximum deviation of 6.2%. This demonstrates that the model is able to accurately capture vehicle speed trends and meet real-time thermal management requirements.

Figure 8.

Test conditions.

Figure 9.

Test condition prediction results.

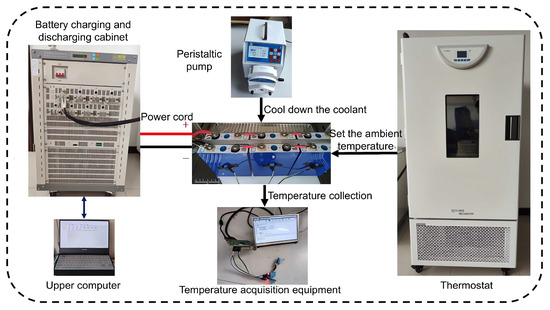

2.4. Construction of the Experimental Bench

To validate the practical effectiveness of the predicted working conditions, we established a laboratory platform and employed a tailored battery pack to simulate the behavior of the vehicle’s entire battery system, as shown in Figure 10. The bench mainly includes a charge/discharge meter, thermostat box, host computer, temperature tester, etc. The battery charge/discharge meter (equipment model: CT-4008-5V100A-NTA, NEWARE, Shenzheng, China) supports an 8-channel independent charge/discharge experiment. The charging voltage range of the device is 0~5 V, the discharge voltage range is 2.5~5 V, the range of both charging and discharging current is 0.5~100 A, and the accuracy is ±0.1% of FS, and the working environment temperature is 0~40 °C. Thermostat box (device model: BPC-70F~250F), the temperature measurement range of the device is −5~70 °C, the temperature fluctuation at high temperature is ± 0.3 °C, the temperature fluctuation at low temperature is ±0.5 °C, and the temperature uniformity in the thermostat box is ±1.5 °C. The temperature tester (device model: Raspberry Pi 3B+), which can record the temperature data of three test points at the same time, and has a data storage function because it is a computer by nature.

Figure 10.

Experimental bench.

A lithium iron phosphate battery was selected as the experimental object. The basic parameters of the battery are shown in Table 4. Six batteries are connected in series to form a battery pack. Because the temperature at the center of the battery is higher, the temperature measurement points ①, ②, ③ are pasted in the center of the battery surface(Figure 11).

Table 4.

Parameters of Li-ion battery.

Figure 11.

Battery Pack.

3. Battery Thermal Management Strategy Based on Working Condition Prediction

3.1. Coolant Flow Requirement Analysis

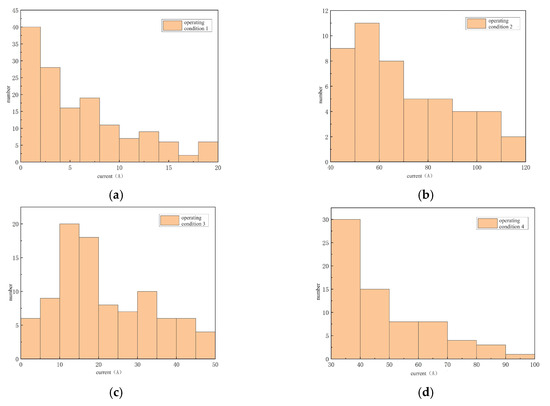

According to the clustering results (Figure 4), the 358 divided working condition segments were clustered to obtain four cluster centers representing four types of vehicle working conditions. Under different driving conditions, the current of the battery in the vehicle is also different (Figure 12).

Figure 12.

Current distribution under each working condition. (a) Working condition I. (b) Working condition II. (c) Working condition III. (d) Working Condition IV.

Working condition I represents congested driving conditions. As can be seen from Figure 12, under this condition, the peak current of the battery is 20 A, and the proportion of currents within 10 A is relatively high. From this, it can be concluded that when an electric vehicle is driving at a low speed, and the number of stops is relatively large, the battery current is small. Working condition II represents high-speed driving conditions. The speed of the electric vehicle is relatively high, so the corresponding battery current is also high, and the maximum current can reach 120 A.

Working condition III represents the urban road driving conditions. The speed is relatively low, and the parking frequency is relatively high. The battery current is smaller compared to working condition IV. Working condition IV represents the suburban driving conditions. The speed is relatively higher than that in working condition III, so the current is also relatively higher. As can be seen from the Figure 12, under working condition IV, the number of battery currents between 30 A and 40 A is close to half. This is because the vehicle has a steady driving speed, and the battery current remains stable. However, its maximum current can reach 100 A. This is because, in suburban driving conditions, there are situations of sudden acceleration. At this time, the motor requires a larger current for driving, resulting in a sharp increase in the battery current.

A direct mapping of the operating condition category to cooling demand is established by converting flow rate to mass flow rate through Equation (4).

where

- : Coolant mass flow rate (unit: kg/s), representing the mass of coolant flowing through the battery cooling system per unit time, directly related to the heat dissipation capacity of the thermal management system.

- : Coolant density (unit: kg/m3).

- : Average flow velocity of coolant in the pipeline (unit: m/s).

- : Cross-sectional area of the cooling pipe (unit: m2).

3.2. PID Control Strategy Design

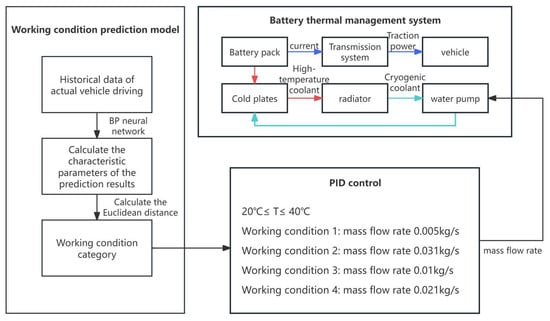

As shown in Figure 13, the thermal management system achieves dynamic regulation through the following steps:

Figure 13.

Battery thermal management system control strategy diagram.

Condition prediction: real-time input of driving data to the BP network and output of vehicle speed for the next 60 s;

Work condition identification: calculating feature parameters of predicted segments and matching to the nearest clustering center;

Flow rate adjustment: set the target flow rate of coolant according to the category of working conditions, and the PID controller (Equation (5)) dynamically adjusts the speed of the water pump to ensure a fast and stable flow rate.

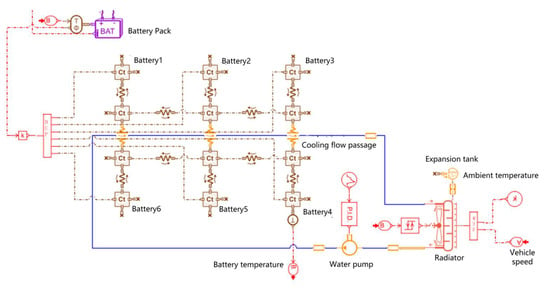

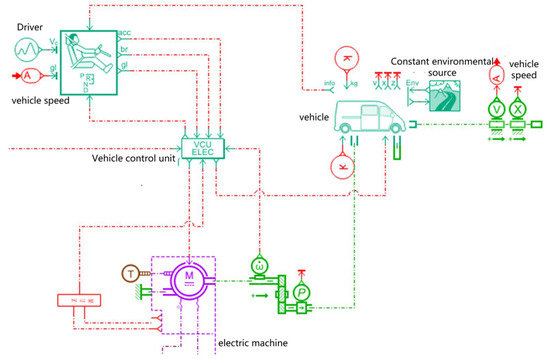

3.3. AMESim Simulation Verification

- (1)

- Basic modeling

We established a liquid cooling system model (Figure 14) and a whole vehicle model (Figure 15) in AMESim. The implicit integration solver is adopted, and the time step is 0.01 s. The specific parameters are as follows.

Figure 14.

Liquid cooling system model diagram.

Figure 15.

Electric vehicle operating condition driving model.

Cold plate runner: cross-section 0.001 m2, length 0.5 m, material aluminum.

Coolant: 50% aqueous solution of ethylene glycol, density 1120 kg/m3.

Battery pack: 120S2P Configuration, total voltage 384 V, capacity 100 Ah (Table 5).

Table 5.

Main parameters of the battery pack.

Battery thermal resistance: 0.05 K/W.

Heat generation model: Bernardi heat generation model, calculated as

In this equation, represents current (A), represents battery internal resistance (Ω), represents battery overpotential (V), and represents heat generated (W).

Environmental conditions: ambient temperature 25 °C, relative humidity 50%.

- (2)

- Optimization of model parameters

In order to improve the accuracy and reliability of the model, we optimized the key parameters in the model through experimental data. The specific steps are as follows:

Experimental data acquisition: On the experimental platform, we collected data such as battery temperature, coolant flow, and inlet and outlet temperature under different working conditions.

Parameter adjustment: Based on the experimental data, we adjusted the key parameters in the model, such as the heat transfer coefficient, fluid resistance, and battery heat generation rate. By comparing the temperature rise curve of the battery in the experiment with the output of the model, the heat transfer coefficient was adjusted to ensure that the model could accurately reflect the heat exchange process between the battery and the coolant.

Validation and optimization: Through several iterations of adjustment, we ensure that the output results of the model are highly consistent with the experimental data. The validation results of the model show that the prediction error of the battery temperature is within ± 0.5 °C, and the prediction error of the coolant flow rate is within ± 5%.

- (3)

- Model Validation

In order to further verify the accuracy of the model, we carried out simulation verification in AMESim. The simulation results show that based on the optimized model, the key parameters, such as the maximum battery temperature, temperature difference, and coolant flow rate, are highly consistent with the experimental data. For example, under the high-temperature condition, the model predicts a maximum battery temperature of 31.2 °C, while the experimentally measured temperature is 31.0 °C, with an error of 0.2 °C only. This indicates that our model can accurately reflect the operating characteristics of the actual thermal management system. Our strategy reduced the battery’s maximum temperature by 3.2 °C and the high-temperature duration by 18%. The temperature reduction brings certain benefits. For instance, lowering the maximum temperature may decrease internal thermal stress and chemical side reactions, suggesting a potential battery life extension. Similarly, a shorter high-temperature period may reduce cooling system runtime and save cooling power. The temperature reduction also likely enhances the safety margin by moving the battery’s operating conditions further from thermal runaway thresholds.

4. Discussion

4.1. Reliability and Practical Fit of Work Condition Prediction Models

The BP neural network-based prediction model shows good generalization ability on the test set, and its root mean square error (RMSE = 0.722) with maximum relative error (6.2%) indicates that the model is able to effectively capture the temporal characteristics of the vehicle speeds (Figure 9).

Further analysis of the distribution of clustering centers between predicted and actual conditions reveals that the deviation of the Euclidean distance for the four types of conditions (congested, urban, suburban, and high-speed) is less than 5%, and the distribution trends of the characteristic parameters (e.g., stopping ratio, average vehicle speed) are consistent. This result verifies the ability of the prediction model to characterize complex driving behaviors, especially in highly dynamic scenarios (e.g., rapid acceleration), and still maintains high prediction accuracy, which lays the foundation for the advanced response of subsequent thermal management strategies.

Compared with traditional methods (WLTC cycle [27]), the naturalistic driving method collects more random and realistic data, but the problem of large data volume is effectively solved by a fixed step length method (60 s segments). The introduction of the K-means clustering algorithm (k = 4) further simplifies the logic of driving condition classification.

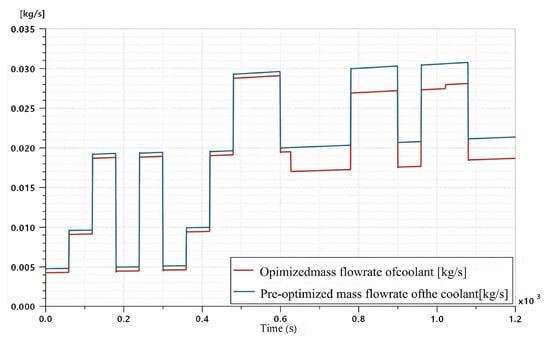

4.2. Energy Consumption and Thermal Performance Balance of Thermal Management Strategies

The prediction-based coolant flow regulation strategy significantly reduces the system energy consumption and improves the heat dissipation uniformity through both simulation and experiment. In the AMESim simulation, the maximum mass flow rate of coolant under the prediction strategy was reduced from 0.031 kg/s to 0.029 kg/s, with an average flow rate reduction of 17.6% (Figure 16), and the maximum temperature of the battery pack was reduced from 34.5 °C to 30.7 °C under the real-vehicle condition, with a reduction of the maximum temperature difference by 0.3 °C (Figure 17).

Figure 16.

The mass flow rate of coolant before and after optimization with time under predicted operating conditions.

Figure 17.

Temperature versus time for the cells with the highest and lowest temperatures under the optimized predicted operating conditions.

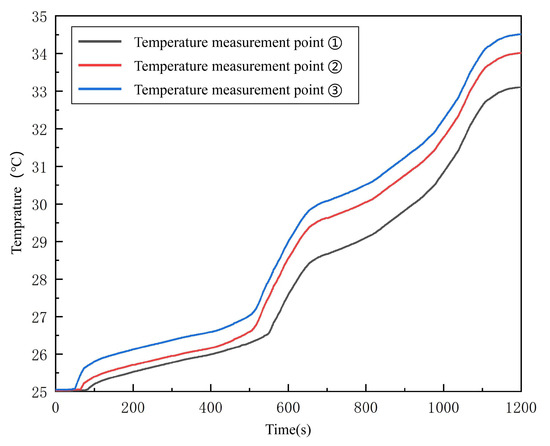

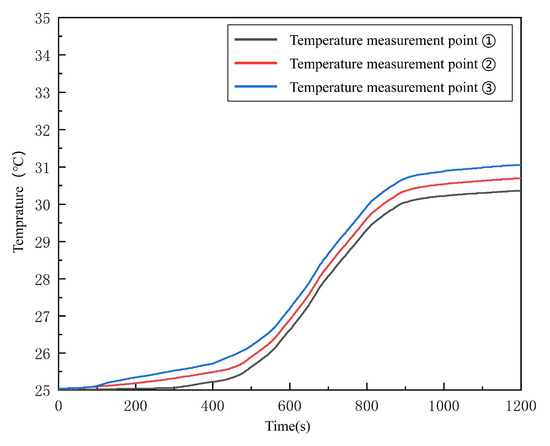

Figure 18 shows the temperature rise at the center of the surface of the battery pack under the actual vehicle driving conditions (without predicted working conditions). As can be seen from Figure 18, the temperature at temperature measurement point ③ was the highest, reaching 34.5 °C eventually. This was because the temperature measurement point ③ was located the farthest from the water inlet. The coolant exchanges heat with the heat generated by the battery inside the cold plate. Therefore, the closer it was to the water outlet, the higher the temperature of the coolant. The final temperature at temperature-measuring point ① was 33.1 °C, which was 1.4 °C lower than that at temperature-measurement point ③. This is because the battery where temperature measurement point ① was located is the closest to the water inlet, and the coolant exchanges heat with this battery first. Figure 19 shows the temperature rise at the center of the surface of the battery pack after the implementation of the thermal management strategy for cooling under the predicted working conditions. As can be seen from Figure 19 the measured temperatures increased successively from temperature measurement point ① to temperature measurement point ③. Among them, the temperature at temperature measurement point ③ was the highest, reaching 31.1 °C, while the temperature at temperature measurement ① was the lowest, being 30.4 °C.

Figure 18.

Battery pack surface center temperature changes under real vehicle driving conditions.

Figure 19.

Temperature variation at the center of the battery pack surface under predicted operating conditions.

As shown in Figure 18 and Figure 19, the temperature difference (unpredicted vs. predicted) between measurement point ③ is 3.5 °C, between measurement point ② is 3.3 °C, and between measurement point ① is 2.7 °C. Furthermore, under the predicted working conditions, the temperature rise of the battery is more gradual when the thermal management strategy is applied. Based on the experimental results, it can be concluded that the battery thermal management strategy established in this study, which is based on working condition prediction, has good heat dissipation performance. This experimental validation confirms the reliability of the established strategy model. After optimization, the maximum temperature at the battery surface temperature measurement point ③ decreased from 34.5 °C to 31.1 °C, and the fluctuations in the temperature rise curve were reduced by approximately 30% (Figure 18 and Figure 19). Notably, the introduction of the temperature feedback model enables the system to maintain cooling performance (temperature deviation less than 0.4 °C) while further reducing the average flow rate by 12.3%, demonstrating the energy-saving potential of “demand-based cooling”.

The innovation of this study lies in combining the time-sequential characteristics of operating condition prediction with the dynamic response of PID control. For example, while a conventional air-cooled system needs to operate continuously at full power under high load conditions to cope with the risk of temperature rise, the present strategy avoids oversupply of coolant by regulating the flow rate in advance. Experimental data show that the coolant flow rate drops by 17.6% in suburban and high-speed conditions, which is closely related to the transient high current due to frequent acceleration-deceleration cycles in such conditions.

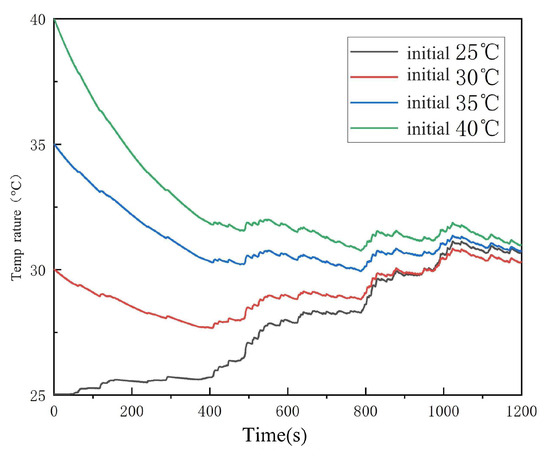

4.3. Robustness and Practical Application Value of Strategies

In the robustness test with the ambient temperature of 25~40 °C, the standard deviation of the battery temperature fluctuation is only 0.2 °C, which indicates that the strategy is highly adaptable to extreme environments (Figure 20).

Figure 20.

Effect of different ambient temperatures on strategy modeling.

Further analysis reveals that the response rate of coolant flow regulation improves by about 15% when the ambient temperature increases, which is attributed to the dynamic compensation of thermal inertia by the temperature feedback model. In addition, experimental data show that the strategy maintains stable thermal performance (temperature rise rate deviation <5%) in low SOC (<30%) scenarios, validating its applicability to full battery lifecycle management.

From the engineering application point of view, the hardware implementation of this strategy is less costly, requiring only the integration of a predictive algorithm module and a PID controller in the existing liquid cooling system. Compared with the passive thermal management scheme based on phase change material (PCM), the proposed method has significant advantages in terms of cost (50%–60% reduction) and ease of maintenance. In addition, the scalability of the strategy has been experimentally verified, e.g., the flow distribution logic can be adaptively adjusted in a parallel battery module to ensure that the temperature difference of each single cell is controlled within 1 °C.

4.4. Comparative Analysis of the Advantages of Working Condition Prediction Technology in Battery Thermal Management

In order to further demonstrate the improvements brought about by working condition prediction in battery thermal management, we compared the control method in this paper with those in three other representative articles in this field. The comparison results are shown in Table 6:

Table 6.

Performance comparison of thermal management control methods.

Predictive ability: the BP neural network in this paper achieves speed prediction (RMSE = 0.722), which is superior to other literature methods that rely on real-time feedback.

Optimization of energy consumption: the dynamic PID in this paper has a higher energy consumption reduction (17.6%) than the fuzzy PI control (18% pump energy only), and the phase change assisted cooling (12%).

Cost advantage: no additional high-computing-power hardware required, compatible with existing liquid-cooling systems, lower cost than deep learning solutions

4.5. Research Contributions and Engineering Implications

The innovation of this strategy lies in breaking through the limitations of traditional thermal management relying on fixed thresholds or hysteresis feedback and realizing the global optimization of temperature and energy consumption through the synergy of time series prediction and dynamic control. Experimental data show that the strategy has significant advantages in reducing the peak temperature (3.8 °C) and system energy consumption (17.6%), providing a landable technical solution for the synergistic optimization of thermal safety and energy efficiency of electric vehicle batteries.

5. Conclusions

In this study, a neural network prediction-based active thermal management strategy is proposed to address the challenge of synergistic optimization of battery temperature rise and energy consumption under dynamic driving conditions in electric vehicles, which significantly improves the safety and economy of the battery system by combining data-driven and dynamic control methods.

First, multi-scenario real-vehicle data were collected using the autonomous driving method, and four types of typical working conditions (congested, high-speed, urban, and suburban) were extracted by combining the K-means clustering algorithm to construct a dataset with high generalizability. The dynamic correlation between battery discharge current and heat dissipation demand under different working conditions is revealed through the quantitative analysis of the fixed-step segmentation method (60 s segments) and characteristic parameters (average speed, parking ratio, etc.). A BP neural network model (20 neurons in the input layer, 10 neurons in the hidden layer, and 60 neurons in the output layer) was further constructed to realize the accurate prediction of the future 60-s vehicle speed, with a test set root mean square error (RMSE) of 0.722 and a maximum relative error of 6.2%.

Based on the prediction results, a dynamic PID control strategy is designed to cope with the sudden change of heat load by adjusting the coolant flow rate (mass flow rate range of 0.005~0.031 kg/s) in advance. AMESim simulation and experimental validation show that the strategy can start cooling 10~15 s earlier than the traditional responsive method, the peak temperature of the battery can be reduced by 3.8 °C, the maximum temperature difference is reduced by 0.3 °C, and the Coolant energy consumption is reduced by 17.6%. At the same time, the introduction of a temperature feedback mechanism further optimizes the flow distribution, and the standard deviation of the battery temperature fluctuation is stable at 0.2 °C in the range of 25~40 °C ambient temperature, which verifies the robustness and adaptability of the strategy.

The core contribution of this study is to break through the limitation of traditional thermal management relying on hysteresis feedback and realize the global optimization of thermal performance and energy consumption through the synergy of timing prediction and dynamic control. Experimental results show that this strategy can effectively suppress the battery temperature rise, reduce the risk of thermal runaway, and provide a landable technical solution for energy efficiency management under complex working conditions. In addition, the hardware implementation cost is low (50~60% lower than the traditional scheme) and has good scalability, which is suitable for the thermal balance control of multi-module parallel battery systems.

Author Contributions

Conceptualization, Y.Z.; Methodology, J.Z.; Validation, H.Z.; Investigation, T.S.; Data curation, X.Z.; Writing—original draft, S.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

This work was supported by the Special research projects for introducing the talents of Hebei Agricultural University (grant number YJ2020055).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Das Goswami, B.R.; Mastrogiorgio, M.; Ragone, M.; Jabbari, V.; Shahbazian-Yassar, R.; Mashayek, F.; Yurkiv, V. A combined multiphysics modeling and deep learning framework to predict thermal runaway in cylindrical Li-ion batteries. J. Power Sources 2024, 595, 234065. [Google Scholar] [CrossRef]

- Cao, R.; Zhang, Z.; Shi, R.; Lu, J.; Zheng, Y.; Sun, Y. Model-constrained deep learning for online fault detection in battery thermal management systems. Nat. Commun. 2025, 16, 235015. [Google Scholar] [CrossRef] [PubMed]

- Xing, Z.; Zhou, J.; Feng, L.; Li, Q.; Zhang, H. Research on Integrated Thermal Management System for Vehicles Based on PID and Fuzzy Control. J. Shaanxi Univ. Sci. Technol. 2024, 42, 157–165. [Google Scholar] [CrossRef]

- Ma, Y.; Ding, H.; Mou, H.; Gao, J. Battery thermal management strategy for electric vehicles based on nonlinear model predictive control. Measurement 2021, 186, 110115. [Google Scholar] [CrossRef]

- Mu, M.; Sui, P.; Wang, Y.; Li, Y.; Zhang, Q. Research on Thermal Management Performance of Pure Electric Mining Trucks under Different Working Conditions. J. China Coal Soc. 2025, 1–9. [Google Scholar] [CrossRef]

- Xu, Z.; Jiang, C.; Li, B.; Qi, Y.; Qian, F.; Li, G. Multi-objective Optimization of Thermal Management System for Lithium Battery Pack Coupled with Phase Change Cooling and Liquid Cooling. Chem. Ind. Eng. Prog. 2025, 1–17. [Google Scholar] [CrossRef]

- Lian, Y.; Ling, H.; Zhu, J.; Lv, J.; Xie, Z. Thermal management optimization strategy of electric vehicle based on dynamic programming. Control. Eng. Pract. 2023, 137, 105562. [Google Scholar] [CrossRef]

- Yu, H.; Wang, L.; Zhang, Z.; Li, Y.; Yang, S. Insight Understanding of External Pressure on Lithium-Ion Battery Performance. Adv. Funct. Mater. 2024, 34, 235012. [Google Scholar] [CrossRef]

- Li, Y.; Gao, X.; Wang, H.; Offer, G.J.; Yang, S. Direct venting during fast charging of lithium-ion batteries. J. Power Sources 2024, 592, 233926. [Google Scholar] [CrossRef]

- Li, W.; Cui, H.; Nemeth, T.; Jansen, J.; Uenluebayir, C.; Wei, Z.; Sauer, D.U. Deep reinforcement learning-based energy management of hybrid battery systems in electric vehicles. J. Energy Storage 2021, 36, 102355. [Google Scholar] [CrossRef]

- Guo, X.; Peng, J.; He, H.; Wu, C.; Zhang, H.; Ma, C. Integrated thermal-energy management for electric vehicles in high-temperature conditions using hierarchical reinforcement learning. Expert Syst. Appl. 2025, 276, 127221. [Google Scholar] [CrossRef]

- Du, R.; Hu, X.; Xie, S.; Hu, L.; Zhang, Z.; Lin, X. Battery aging-and temperature-aware predictive energy management for hybrid electric vehicles. J. Power Sources 2020, 473, 228568. [Google Scholar] [CrossRef]

- Fan, Y.; Zuo, X.; Zhan, D.; Zhao, J.; Zhang, G.; Wang, H.; Wang, K.; Yang, S.; Tan, X. A novel control strategy for active battery thermal management systems based on dynamic programming and a genetic algorithm. Appl. Therm. Eng. 2023, 233, 121113. [Google Scholar] [CrossRef]

- Goswami, B.R.D.; Abdisobbouhi, Y.; Du, H.; Mashayek, F.; Kingston, T.A.; Yurkiv, V. Advancing battery safety: Integrating multiphysics and machine learning for thermal runaway prediction in lithium-ion battery module. J. Power Sources 2024, 614, 235015. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, Y.; Zhao, S.; Zhao, T.; Ni, M. Modeling and optimization of micro heat pipe cooling battery thermal management system via deep learning and multi-objective genetic algorithms. Int. J. Heat Mass Transf. 2023, 207, 124024. [Google Scholar] [CrossRef]

- Ma, Q.; Ma, Y.; Yu, S.; Gao, J.; Chen, H. Chance-Constrained Stochastic MPC With Adaptive Optimization Horizon and Multitimescale for Electric Vehicle Battery Thermal Management. IEEE Trans. Syst. Man Cybern. Syst. 2024, 55, 526–539. [Google Scholar] [CrossRef]

- Li, Y.; Du, J.; Zhou, G.; Ouyang, M.; Fan, Y. A rapid self-heating battery pack achieved by novel driving circuits of electric vehicle. Energy Rep. 2020, 6, 1016–1023. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, Y.; Zhao, S.; Zhao, T.; Ni, M. Modeling and optimization of liquid-based battery thermal management system considering battery electrochemical characteristics. J. Energy Storage 2023, 70, 108028. [Google Scholar] [CrossRef]

- Yujie, W.; Ziqi, Z.; Nu, X. Research on Temperature Uniformity and Energy Consumption of Thermal Management System in Lithium-ion Battery Energy Storage Units. Acta Energ. Sol. Sin. 2025, 46, 83–90. [Google Scholar] [CrossRef]

- Wu, B.; Widanage, W.D.; Yang, S.; Liu, X.; Widen, J. Battery digital twins: Perspectives on the fusion of models, data and artificial intelligence for smart battery management systems. Energy AI 2020, 1, 100016. [Google Scholar] [CrossRef]

- Ramakrishnan, B.; Hadad, Y. Thermal analysis of cold plate for direct liquid cooling of high-performance servers. J. Electron. Packag. 2019, 141, 041005. [Google Scholar] [CrossRef]

- Li, Y.; Ouyang, M.; Chan, C.C.; Sun, X.; Song, Y.; Cai, W.; Xie, Y.; Mao, Y. Key Technologies and Prospects for Electric Vehicles Within Emerging Power Systems: Insights from Five Aspects. CSEE J. Power Energy Syst. 2024, 10, 439–456. [Google Scholar] [CrossRef]

- Li, Y.; Wei, Y.; Zhu, F.; Du, J.; Zhao, Z. The path enabling storage of renewable energy using lithium-ion batteries. Etransportation 2023, 16, 100226. [Google Scholar] [CrossRef]

- Olabi, A.G.; Maghrabie, H.M.; Adhari, O.H.K.; Alavi, M. Battery thermal management systems: Recent progress and challenges. Int. J. Energy Res. 2022, 46, 14272–14295. [Google Scholar] [CrossRef]

- Fei, F.; Wang, D. Application of neural network feedforward in fuzzy PI controller for electric vehicle thermal management system: Modeling and Simulation studies. Energies 2023, 17, 9. [Google Scholar] [CrossRef]

- Ali, Z.M.; Jurado, F.; Gandoman, F.H.; Ćalasan, M. Advancements in battery thermal management for electric vehicles: Types, technologies, and control strategies including deep learning methods. Ain Shams Eng. J. 2024, 102908. [Google Scholar] [CrossRef]

- United Nations Economic Commission for Europe. *UNECE Regulation No. 154: Worldwide Harmonized Light Vehicles Test Procedure (WLTP). Available online: https://unece.org/transport/documents/2021/02/standards/un-regulation-no-154-worldwide-harmonized-light-vehicles-test (accessed on 31 May 2025).

- Zhao, W. Temperature Estimation of Lithium Battery Based on Kalman Filtering and Four-State Lumped Thermal Modeling. Model. Simul. 2024, 13, 2088–2096. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).