Abstract

Battery thermal runaway (TR) is usually accompanied by a large amount of heat release, as well as a jet of flame. This not only causes harm to the surrounding environment but even exacerbates thermal runaway propagation (TRP). At this stage, many types of materials are used to suppress TRP, and people tend to focus on improving one characteristic of the material while ignoring other properties of the material. This may leave potential pitfalls for TRP suppression, suggesting the need to study multiple properties of multiple materials. In order to better weigh the advantages and disadvantages of different types of materials when suppressing TRP, we compared three typical materials for suppressing TRP behavior in lithium-ion batteries (LIBs). These materials are phase change materials (PCM), ceramic fibers, and glass fibers. They are all available in two different thicknesses, 2 mm and 3 mm. The experiments started with a comparative analysis of the TR experimental phenomena in the presence of the different materials. Then, the temperature and mass loss of the battery module during TR were analyzed separately and comparatively. The 3 mm glass fiber showed the best inhibition effect, which extended the TR interval between cells 1 and 2 to 894 s and successfully inhibited the TR of cell 3. Compared with the blank group, the total mass loss decreased from 194.3 g to 182.2 g, which is a 6.2% reduction. Subsequently, we comprehensively analyzed the performance of the three materials in suppressing TRP by combining their suppressing mechanisms. The experimental results show that glass fiber has the best effect in suppressing TRP due to its excellent thermal insulation and mechanical properties. This study may provide new insights into how to trade-off material properties for TRP suppression in the future.

1. Introduction

In recent years, lithium-ion batteries (LIBs) have been widely used in electric vehicles (EVs) and energy storage plants due to their high energy density, environmental friendliness, and long life [1,2,3]. However, thermal runaway (TR) can occur in batteries for a variety of reasons, and TR can create thermal runaway propagation (TRP) in battery modules [4,5]. The flames and toxic gases produced during the TRP process are extremely hazardous to the surrounding environment [6]. Therefore, it is necessary to improve the safety of battery modules by adding materials that can suppress TRP between battery modules when carrying out the design of battery modules.

There are many causes of battery TR, including thermal, electrical, and mechanical abuse [7]. Therefore, it is better to prevent these three dimensions when we choose materials for the design of the battery module. From the thermal point of view, continuous and discontinuous heating affects the behavior of the battery TR. Zhou et al. [8] investigated the effects of continuous and discontinuous heating on battery TR. They found that continuous heating leads to a faster accumulation of heat inside the battery, which makes the battery TR more drastic, emphasizing the importance of heat dissipation and insulation in the battery module. From an electrical point of view, once an internal short circuit occurs in a battery, it is highly likely to cause TR [9,10]. This emphasizes the importance of the insulating properties of the material. Many times, batteries are short-circuited from external shocks [11]. Zhang et al. [12] illustrated the relationship between the pinning depth and the TR due to a short circuit inside the battery. The results, in conjunction with the battery structure, point out that the faster the pinning speed is, the more the battery is damaged and the higher the TRP rate is. Therefore, the mechanical properties of the material must also be taken into account. There is a lot of existing research on materials to suppress TRP, which will be further described below.

There are many studies on mitigating thermal behavior of LIBs under TR conditions by using phase change materials (PCMs). PCMs, with an excellent ability of absorbing heat, are widely used in the field of energy storage [13]. Chen et al. [14] conducted research on suppressing TR using different kinds of PCMs. Their findings reveal that, compared with natural convection cooling, PCM cooling can effectively decrease a battery’s surface temperature. The combination of aerogel felt (AEGF) and PCM can greatly mitigate TR behavior. Unlike the mechanism of PCM on suppressing TR, the AEGF is remarkable for its good thermal insulation characteristic [15]. Thus, plenty of scholars put thermal insulation materials, like AEGF, into use to suppress TR. Niu et al. [16] prepared ultra-light hollow glass microsphere (HGM) plates with low thermal conductivity to suppress TRP. It was found that the plates, characterized by low thermal conductivity and excellent fireproof performance, can slow down the TRP rate, thereby enhancing the safety of high-energy battery systems. Zou et al. [17] investigated the TRP behavior of battery modules under conditions with three types of thermal insulation materials and without insulation materials. Thet found that all of the materials suppressed TRP, although they did not inhibit TRP completely. By analyzing the thermophysical properties of these materials, it was revealed that the thermal diffusion coefficient and maximum service temperature are critical parameters for the selection of thermal insulation materials. Some research has considered various factors to prepare barrier material. Bausch et al. [18] presented an eco-friendly endothermic barrier, characterized for its low conductivity and high compressive strength, to suppress TRP. The study shows that the thermal barrier material can not only delay TRP but also can avoid damage to the cells adjacent to the cell processing TR. However, at this stage, there are very limited comparative studies on TRP suppression by differently characterized materials. Based on this, we will carry out a comparative research work on TRP suppression with different materials and elaborate the mechanisms behind it.

This study addresses a key research gap by studying the suppression effect of three typical materials with advantages and disadvantages, respectively. With the analysis of battery surface temperature, TRP interval, and absolute mass loss, we deeply clarify the mechanism of these materials’ functions. After analyzing the mechanism by which these materials suppress TRP, we used a radar chart to elaborate, in detail, how to weigh the advantages and disadvantages of materials that suppress TRP from multiple indicators. It is demonstrated that glass fiber has the best ability to suppress TRP, as it not only has a good command of thermal insulation but is also remarkable for its excellent mechanical properties. By comparing the differences underlying TRP suppression while systematically examining the critical balance among various excellent material properties, this paper provides valuable insights for the selection of materials for battery thermal management systems.

2. Methodology

2.1. Battery Sample

The battery sample chosen for this experiment is a square pouch battery with a cathode made of LiNixCoyMn1−x−yO2 and an anode composed of graphite. The battery is designed to be able to cycle over 1000 times, and the electrolyte of the battery consists of lithium salts and a polymer matrix. The nominal battery voltage is 3.7 V, the charge cut-off voltage is 4.2 V, and the discharge limit voltage is 2.8 V. Its overall dimensions are 132 × 65 × 13.5 mm. The physical diagram of the battery is as shown in Figure 1.

Figure 1.

Physical battery diagram: (a) front view, (b) reverse view.

2.2. Material Characterization

2.2.1. PCM Sample

The PCM material used in this study is a new type of solid–solid phase change material (SSPCM), aiming to achieve strong mechanical properties and leak resistance. Hexamethylene diisocyanate (HDI) and polyethylene glycol (PEG) were used as precursors. Meanwhile, a hybrid heat transfer network was designed, including carbon nanotubes (CNT), expanded graphite (EG), and advanced ceramic materials, such as boron nitride (BN) and silicon carbide (SiC). HDI and a dibutyltin dilaurate (DBTDL) catalyst were purchased from Aikang Biotechnology Development Co., Ltd. (Zhenjiang, China). PEG and CNT (specification: 98 wt%, outer diameter 20 nm, length 10–30 μm) were purchased from Heowns Opde Technologies Co., Ltd. (Tianjin, China). H-BN (specification: 99 wt%, 1–2 μm) was purchased from Merck Biochemical Co., Ltd. (Shanghai, China). EG (purity: 99 wt%) was purchased from Tengshengda Carbon Graphite Co., Ltd. (Qingdao, China). SiC (specification: 99 wt%, 1–3 μm) was purchased from Dewei Chemical Co., Ltd. (Zhenjiang, China). The specific synthesis process can be found in a previous work [19].

2.2.2. Ceramic Fiber Sample

The ceramic fiber was purchased from Hebei Hualuo Sealing Materials Co., Ltd. (Cangzhou, China). The main component of the ceramic fiber is aluminum silicate (with an alumina content of 45–46% and a silica content of 51–52%). It also contains a small amount of zirconia. Its bulk density is approximately 200 kg/m3, and the thermal conductivity is about 0.12 W/mK.

2.2.3. Glass Fiber Sample

The glass fiber material was purchased from Hebei Caike Thermal Insulation Materials Co., Ltd. (Langfang, China). The glass fiber is a non-woven fabric composed of high-purity silica (SiO2, ~52–54 wt%), alumina (Al2O3, ~14–16 wt%), calcium oxide (CaO, ~17–19 wt%), and trace amounts of magnesium oxide (MgO) and boron oxide (B2O3). The fibers exhibit an average diameter of 8–12 μm.

2.3. Experimental Setup

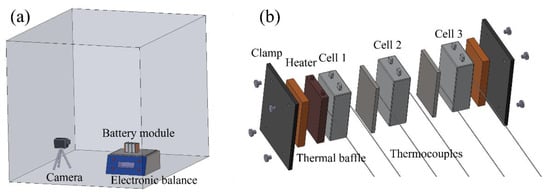

The layout of the experiment is shown in Figure 2a. An electronic balance with 0.1 g accuracy was used to record the mass change during the TR process of the battery module, and a heat baffle between it and the battery module was used to protect the electronic balance. A high-definition video camera was placed at the front side of the TR battery module to record the experimental phenomena during the TR process. The exact layout of the battery module is shown in Figure 2b, with the corresponding TRP-suppressing material sandwiched between the cells. A heater was used to heat the first cell to TR. The heater was separated from the sandwich plate by a heat shield. Thermocouples (accuracy: 0.5 °C, temperature measurement range: 0–1300 °C) were used to record the surface temperatures at the center of the cells on the left and right sides, and the data were transferred to a computer via an ICPCON 7018 module. The TRP test was conducted in winter, when the ambient temperature was approximately (10 ± 5) °C. The air pressure was about one standard atmosphere. The battery modules were arranged horizontally, with the heating plate tightly attached to the leftmost battery’s side. The heating plate was turned off immediately after the battery was heated to TR. During the test, the weather was either sunny or cloudy, and the battery was kept dry to prevent accidental short circuits.

Figure 2.

Layout of the experiment: (a) overall schematic; (b) specific layout in TR test.

2.4. Experimental Arrangement

The materials used to suppress TRP in the experiment were PCMs, glass fiber, and ceramic fiber. They are composed of two thicknesses, 2 mm and 3 mm. A multifunctional thermal conductivity tester (Xiangtan Dra-III type, accuracy: ±3%) (Dre-III, Xiangtan Xiangyi Instruments Co., Ltd., Xiangtan, China) was used to measure the thermal conductivity of the PCM, which is around 0.61 W/m∙K. A Q500 thermogravimetric analyzer (TGA, Q500, TA Instruments Inc., Shanghai, China) was used to analyze the thermal stability of the PCM. Details can be found in the previous work of our subject group [19]. The physical properties of the glass and ceramic fibers are provided by the merchant. Their thermal conductivity is around 0.018 W/m∙K and 0.12 W/m∙K, respectively. The specific arrangement of the experiment is shown in Table 1, which is divided into a blank group and six other groups, with different thicknesses and materials. The purpose of this arrangement is to better compare the effect of TRP suppression between different materials. By setting up different thicknesses of the same materials, the internal mechanism of the corresponding materials to suppress TRP can be better explored.

Table 1.

Specific arrangements of experiment.

3. Experimental Results and Analyses

3.1. Comparative Analysis of TR Behavior Through Experimental Phenomenon

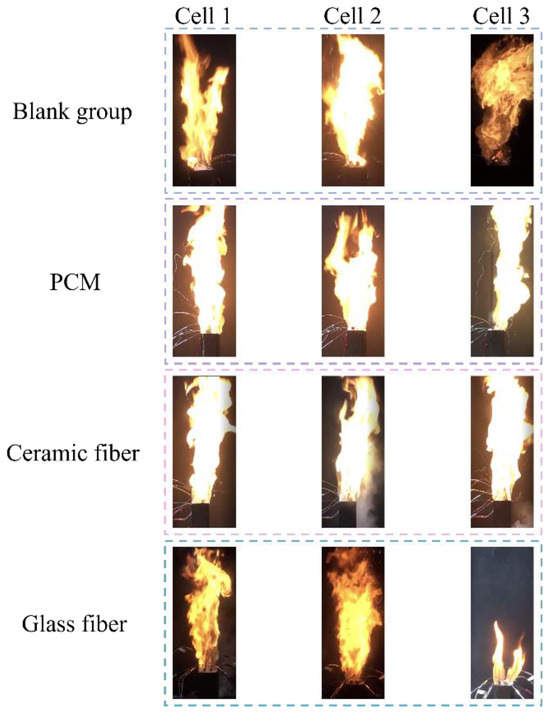

The three materials selected in the experiment all have the potential to suppress TRP, and their mechanisms for suppressing TRP are not completely the same. For the PCM, during the phase change process, it can absorb a large amount of heat, effectively suppressing the rise in battery temperature and thus achieving the purpose of suppressing TRP. Ceramic fiber is an excellent thermal insulation material. It can effectively prevent the heat of the TR battery from spreading to the surrounding batteries, thereby suppressing TRP. Glass fiber also has good thermal insulation performance. At the same time, due to its high porosity, while suppressing heat conduction, its structure with high porosity restrains the gas flow, and the low thermal conductivity reduces the heat transfer in the gas, effectively suppressing the occurrence of thermal convection. All these characteristics endow glass fiber with the potential to suppress TRP. In order to compare the effect of TRP suppression by the three materials more intuitively, we compared the experimental phenomena during the TRP suppression process. Figure 3 shows the typical experimental phenomena of cell 1, cell 2, and cell 3 during the TRP process of the blank group, as well as the three materials of 3 mm, respectively. It can be clearly observed that only the 3 mm glass fiber successfully inhibited the TRP of cell 3. The other three groups did not inhibit the TRP of cell 3. Overall, there was no significant difference in the flame behavior of the cells, except for cell 3 of the 3 mm glass fiber set. This is because the three materials themselves cannot directly act on the flame; they can only play a role as a flame retardant but cannot mitigate the intensity of the flame directly. A PCM can absorb heat and dissipate heat in the process of phase change, but due to its inability to insulate the heat, it is unable to successfully inhibit the TRP at a thickness of 3 mm. Ceramic fibers and glass fibers have a good ability to insulate heat. However, from the experimental phenomenon, compared to the glass fiber, the ceramic fiber failed to inhibit the violent flame jet of cell 3 as successfully as the glass fiber. The success of the glass fiber in inhibiting the TR of cell 3 may be attributed to the better mechanical and insulating properties of glass fiber. This allowed the glass fiber to not only act as a thermal insulator but also provide some cushioning and insulation during the expansion process of the pouch cells. This avoided the occurrence of short-circuiting between neighboring cells, which prevented the TR of cell 3 from bursting into flames, resulting in only a small fire emanating from cell 3.

Figure 3.

Experimental phenomena of TR under blank group and different material suppression.

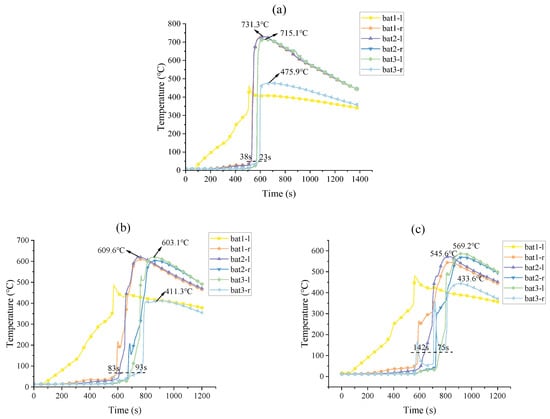

3.2. Comparative Analysis of TR Behavior by Battery Temperature Characteristic

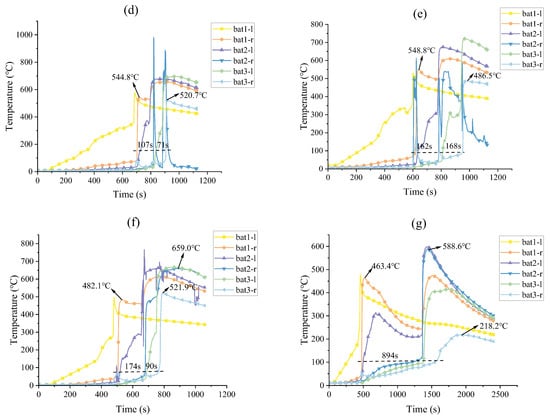

The temperature–time images of the seven groups of the TRP tests are shown in Figure 4. First of all, compared to the blank group, regardless of the PCM, ceramic fiber or glass fiber, they all effectively reduced the maximum temperature of the cell surface and prolonged the TRP interval. It is noteworthy that only the 3 mm glass fibers successfully inhibited the TRP of cell 3. Considering the material thickness dimension, it is obvious that, regardless of the material, the 3 mm material further prolonged the interval between the TRP of the cell compared to the 2 mm one and further reduced the maximum temperature of the cell surface. This is attributed to better heat dissipation and insulation, respectively. For the PCM, except for the material at 3 mm, it better suppressed the temperature rise of the battery compared to the insulating material, ceramic fiber. However, the total time it suppressed TRP was not as good as the ceramic fiber in both thickness cases. It can be concluded that although PCM material has certain heat absorption and dissipation ability, it can be well used in the thermal management of battery modules. However, in suppressing TRP, PCM alone does not suppress heat diffusion well. For glass fiber, with a thickness of 3 mm, it successfully blocks the TR of cell 3. Glass fiber has a strong balance of mechanical strength and flexibility, and its tensile strength is much greater than aluminum silicate ceramic fiber [20,21]. As a thermal insulation material, it has better insulation and mechanical properties than ceramic fiber, which may be the reason why it is more prominent than ceramic fiber in suppressing TRP. Glass fiber has good thermal and mechanical properties. Many scholars use it to improve the thermal and mechanical properties of materials. Chen et al. [22] incorporated glass fibers into graphene oxide, and the results show that glass fibers play an important role in enhancing strength and toughness. Feng et al. [23] used glass fibers to improve the mechanical and thermal properties of thermal insulation materials. The results show that the glass fibers effectively dispersed the external stresses of the material and significantly improved the thermal insulation ability of the material at high temperatures. The PCM used in this paper is a PCM with a low leakage rate and high mechanical strength, synthesized in the previous work of our group [19]. This PCM was synthesized via a polyurethane crosslinking reaction, using polyethylene glycol (PEG) and hexamethylene diisocyanate (HDI) as precursors. This approach chemically integrates the phase change molecular chains into the thermoset polymer matrix via PEG, enhancing the thermal stability and mechanical properties of the material while effectively mitigating the leakage problem commonly found in PCM composites. Nonetheless, the experimental results show that with increasing temperature, this PCM undergoes a slight decomposition at around 250 °C, which corresponds to the rupture of the polyurethane bonds. Subsequently, the PEG chain breakage rapidly degraded in the temperature range of 340 °C to 450 °C. This corresponds to a rapid phase transition of the PCM, with the maximum rate of mass loss occurring at about 400 °C. This is much lower than the surface temperature of the cell at TR, when the PCM is already undergoing phase transition. At the same time, the large amount of heat released by the cell makes it impossible to achieve a rapid temperature control and cooling of the already phase-transformed PCM. Therefore, as the results of this experiment show, the PCM alone cannot successfully block TRP at a relatively thin thickness (2 mm or 3 mm). From this, we can conclude that simple heat absorbing materials, such as PCMs, cannot successfully inhibit TRP at a relatively thin thickness, and how to design a heat absorbing material that can effectively inhibit TRP at a thinner thickness is a breakthrough point worthy of research in the future. As for the thermal insulation material, when choosing the material, not only should its thermal conductivity be taken into account but also its own mechanical properties and insulating properties are also very important.

Figure 4.

Comparison of battery module temperatures: (a) blank group, (b) 2 mm PCM, (c) 3 mm PCM, (d) 2 mm ceramic fiber, (e) 3 mm ceramic fiber, (f) 2 mm glass fiber, (g) 3 mm glass fiber.

3.3. Comparative Analysis of TR Behavior by Mass Loss of Battery Module

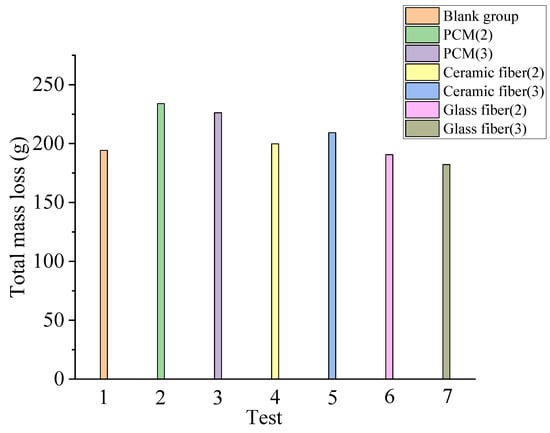

We have analyzed the mass loss of the battery module and discuss it in the following section. Figure 5 summarizes the total mass loss of the battery module for several cases. Compared with the 194.3 g of the blank group, the mass loss of the PCM group increased to 233.9 g and 226.2 g, respectively, which may be due to the loss of PCM by phase change melting when encountering high temperatures. The 3 mm thick PCM provides relatively better heat absorption and insulation, reducing the intensity of TR, which makes the total mass loss of the battery module slightly lower than that of the 2 mm PCM group at this time. The ceramic fiber mass loss in both thickness cases is higher than that of the blank group, 199.8 g and 209.3 g, respectively, even though it is more effective in suppressing the TRP of the battery module than both PCM groups. This may be due to the unstable chemical composition of the selected ceramic fiber materials, which led to the thermal decomposition of the materials and increased mass loss during TR. Through a thorough analysis of the experimental process and results, it was found that the layered stripping of aluminum silicate ceramic fiber paper at high temperatures is one of the main reasons for the decline and even failure of its barrier performance. When the ceramic fiber paper is exposed to a high-temperature environment, the internal fiber structure will undergo a series of changes. Under the action of high temperatures, the binding force between the fibers inside the ceramic fiber paper gradually weakens, and the originally closely arranged fiber layer begins to separate, forming the phenomenon of layered peeling. This is because ceramic fiber paper is usually made of fibers that are combined with each other by physical or chemical interactions. At high temperatures, these binding forces are disrupted and the friction between the fibers decreases, leading to easy separation of the fiber layer. Layer stripping will make the structure of ceramic fiber paper become loose, forming many gaps inside, thus greatly reducing its ability to block heat and gas. Heat can be transferred more easily through these voids, and the gas generated by TR can penetrate the ceramic fiber paper more smoothly, resulting in the TR transmission being unable to be effectively suppressed. The total mass loss of both glass fiber groups is smaller than that of the blank group, 190.6 g and 182.2 g. On the one hand, this is attributed to the good thermal stability of the glass fiber material itself. On the other hand, the good thermal insulation of the glass fibers reduced the intensity of TR, even at 3 mm, inhibiting the fierce ejection of cell 3. This resulted in a minimum mass loss of 182.2 g in the battery module with 3 mm glass fiber.

Figure 5.

Comparison of total mass loss of battery packs in different cases.

3.4. Comprehensive Comparative Analysis of the Inhibition Effect of Different Materials

In the case of ceramic fibers, the internal fiber structure is destroyed at high temperatures, consequently resulting in a weakened blocking effect on conductive heat, as well as radiant heat from neighboring cells. At the same time, the relatively weak mechanical properties make it further extruded to the neighboring soft pack cells. Thus, a good TRP inhibition effect cannot be achieved in both thicknesses.

PCMs have relatively high thermal conductivity, which enhances the longitudinal heat transfer in the TR process. When a lithium-ion battery is experiencing TR, a lot of heat is generated inside the battery, which needs to be transmitted through the material inside the battery and the surrounding barrier materials. Due to the relatively high thermal conductivity of the PCM, the heat can be quickly transferred along the axial direction inside the PCM, that is, the longitudinal transmission. Inside the battery, when TR occurs in a certain part, the heat will be quickly transferred to other parts through the PCM, resulting in the rapid spread of TR inside the battery. The relatively high thermal conductivity of the PCM also enables the rapid transfer of heat to adjacent batteries or other components, further exacerbating TRP. Although the PCM has a strong heat dissipation capability, it cannot balance the heat that is quickly transferred to neighboring cells by its own strong thermal conductivity. Therefore, the effect of simply using thinner PCMs to inhibit TRP is not significant.

Glass fiber has extremely high porosity, up to 92%. This porous structure allows for the formation of many tiny pores inside the glass fiber wool, which are connected with each other and constitute a complex network of gas channels. During the process of TR, the heat is mainly transmitted through heat conduction, heat convection, and thermal radiation. For glass fiber, the tiny pores inside it can greatly hinder the progress of heat conduction. As the thermal conductivity of gas is far lower than that of solid materials, the heat needs to be continuously reflected and scattered in many tiny pores when passing through glass fiber, which greatly increases the path and difficulty of heat transfer and effectively slows down the speed of heat conduction. These tiny pores are also able to inhibit the occurrence of thermal convection. Glass fiber also has very low thermal conductivity of only around 0.018 W/mK. Thermal conductivity is an important index to measure the thermal insulation ability of a material. The lower the thermal conductivity, the better the thermal insulation ability of the material, and the stronger the ability to block heat transfer. There is a synergistic effect between the porosity and the low thermal conductivity to inhibit thermal diffusion. The structure of high porosity provides a good basis for the performance of low thermal conductivity, which results in the obstruction of heat transfer inside the glass fiber. During the heat conduction process, the transfer of heat is required not only in the solid skeleton but also in a large number of gas pores, which makes heat conduction much more difficult. The low thermal conductivity further limits the heat transfer speed in the solid skeleton and gas pores, so that the glass fiber can inhibit the heat diffusion more effectively. In terms of thermal convection, the structure of high porosity suppresses the gas flow, while the low thermal conductivity reduces the transfer of heat in the gas, which effectively prevents the occurrence of thermal convection. Therefore, the porosity and low thermal conductivity of glass fiber cooperate with each other, making it show excellent performance in blocking TRP.

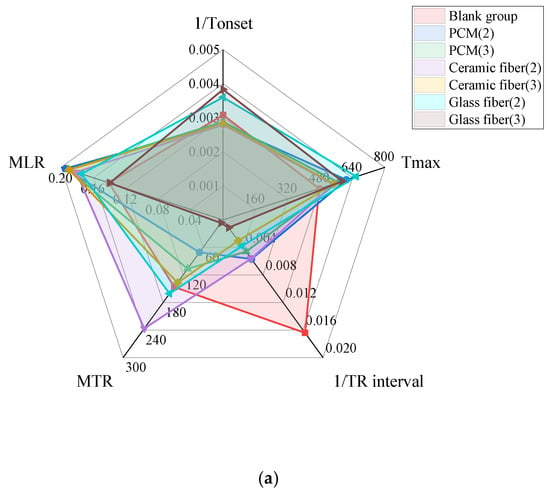

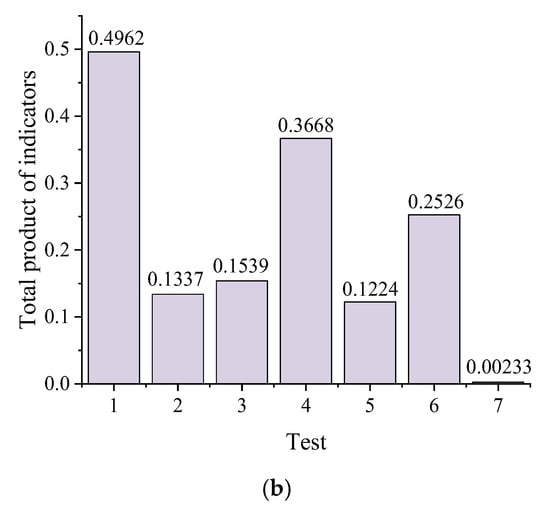

4. Evaluation of the Effectiveness of Different Materials for TRP Inhibition

Based on the analysis above, we evaluated the effectiveness of TRP inhibition in the blank group, as well as in different materials with different thicknesses. This will help relevant personnel to better weigh the benefits of the materials, as well as the material properties. First of all, the higher the effectiveness of the material to inhibit TRP, the lower the risk of the battery module. In this paper, the effectiveness of materials to inhibit TRP is qualitatively evaluated from the perspective of inhibition effectiveness, and five key indicators are selected. They are battery TR trigger temperature Tonset, maximum temperature within the battery module Tmax, total interval time for TR propagation, maximum temperature rise rate (MTR) of the battery, and mass loss rate (MLR) of the battery.

Tmax: peak temperature of the battery after TR. The higher the maximum temperature of the battery after TR, the higher the risk of potential harm to other batteries [24], i.e., the lower the effectiveness of material inhibition to suppress TRP.

TR interval: the longer the time interval of TRP of the battery, the lower the harm of TR, and the higher the effectiveness of material inhibition to suppress TRP. In order to maintain consistency with the data above, the inverse of the TR interval is taken as the observation index in this paper.

MTR: the maximum temperature rise rate of the battery. The greater the maximum temperature rise rate of the battery, the greater the potential harm to the surrounding environment [24], that is, the less effective the material is in suppressing TRP. In order to make the results of MTR more representative, we chose the right-hand side temperature rise rate of battery 3 as the observation index.

MLR: the mass loss rate of the battery. The larger the mass loss rate of the battery module during the whole TRP process, the more completely it represents the loss of the battery, and the more harmful it is to the surrounding environment [25], that is, the lower the effectiveness of material to inhibit TRP.

Tonset: The higher the temperature at which the battery triggers TRP, the lower the risk of TRP in the battery [26], that is, the higher the effectiveness of material to inhibit TRP. In order to keep consistency with the data above, the inverse of Tonset is taken as the observation index in this paper.

The evaluation model data are shown in Figure 6a. We can clearly see that the total area of 3 mm glass fiber is the smallest. This indicates that the riskiness of the battery module under the action of 3 mm glass fibers is the smallest, i.e., the effectiveness of 3 mm glass fibers in suppressing TRP is the best. In order to visualize these areas, we use the value of the product of the five metrics as the final metric that qualitatively represents the effectiveness of the material to inhibit TRP. The smaller the product, the more effective the material is in inhibiting TRP. As we can see from Figure 6b, all the materials have smaller indices than the blank group, proving that the inhibition is all positive. Especially, the value of 3 mm glass fiber is only 0.00233, which is much smaller than the other materials. It is proved that the 3 mm glass fiber group attained the best ability in inhibiting TRP. Overall, the effectiveness of TRP inhibition is, in descending order, 3 mm glass fiber, 3 mm ceramic fiber, 2 mm PCM, 3 mm PCM, 2 mm glass fiber, and 2 mm ceramic fiber. In practical applications, the cost and weight of the materials also need to be taken into account. As can be known from the above evaluation, the glass fiber has the best effect in inhibiting TRP, and its manufacturing cost is lower than that of the aluminum silicate ceramic fiber, but it is heavier than the aluminum silicate ceramic fiber. Therefore, it is suitable for application in fixed-energy storage systems. For mobile battery packs, such as the battery packs in electric vehicles, considering the factor of weight, ceramic fiber is more suitable for application in this scenario. However, compared with glass fiber, the effect of ceramic fiber in inhibiting TRP is not good, and it is necessary to make a trade-off between safety and cost at this time. For the PCM, its thermal management performance is the most excellent. However, it has a high cost, a high density, and the effect of inhibiting TRP is not good. Therefore, when choosing it, it is recommended to use it in combination with thermal insulation materials.

Figure 6.

(a) A radar chart for the evaluation of the effectiveness of material suppression of TRP; (b) total product of indicators.

5. Conclusions

This project takes LIBs as the object, compares and analyzes the influence of different isolation layer materials on the TRP of LIBs, analyzes the influence law of different isolation layer materials on the TRP, and analyzes the blocking effect and influencing factors of different materials. The test results show that glass fiber has the best inhibiting effect on TRP. This is due to its high thermal stability, insulating properties, and good mechanical properties, along with its strong insulating ability. In the case of purely heat absorbing materials, such as PCMs, it is not possible to block TRP at a relatively thin thickness. In the case of ceramic fiber, despite its good insulating ability, its thermal stability is not up to the mark, making it ultimately unsuccessful in blocking TRP. Overall, the physical properties, chemical properties, structural properties, and use environment of the material will have an impact on the barrier effect of the material. Based on the comparison of the phenomena, temperatures, and mass losses of different materials in suppressing the TRP of battery packs, this study innovatively conducts a comprehensive evaluation of relevant indicators in a radar chart. In combination with practical situations, it is explained that when people select materials for suppressing TRP, they should not only focus on a single property of the material. Instead, they need to consider the application scenarios and make trade-offs among various advantages and disadvantages of the materials, such as thermal insulation performance, mechanical properties, heat dissipation performance, cost, and weight. The research results of this project will have important guiding significance for the selection and application of TR protection materials for LIBs.

Author Contributions

Investigation, Y.C. (Yaoyu Chen); resources, Y.C. (Yin Chen); data curation, Y.Y.; writing—original draft, Y.M. and Y.C. (Yaoyu Chen); writing—review & editing, Y.M. and M.C.; supervision, M.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (52204213).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Ali, S.; Ahmad, T.; Tahir, M.Y.; Usman, M.; Chhattal, M.; Hussain, I.; Khan, S.; Hassan, A.M.; Assiri, M.A.; Rosaiah, P.; et al. The emergence of density functional theory for supercapacitors: Recent progress and advances. J. Energy Storage 2023, 73, 109100. [Google Scholar] [CrossRef]

- Mao, Y.; Chen, Y.; Chen, M. Review of Flame Behavior and Its Suppression during Thermal Runaway in Lithium-Ion Batteries. Batteries 2024, 10, 307. [Google Scholar] [CrossRef]

- Jiangyi, H.; Fan, W. Design and testing of a small orchard tractor driven by a power battery. Eng. Agríc. 2023, 43, e20220195. [Google Scholar] [CrossRef]

- Börger, A.; Mertens, J.; Wenzl, H. Thermal runaway and thermal runaway propagation in batteries: What do we talk about? J. Energy Storage 2019, 24, 100649. [Google Scholar] [CrossRef]

- Quan, Y.-Z.; Liu, Q.-S.; Liu, M.-C.; Zhu, G.-R.; Wu, G.; Wang, X.-L.; Wang, Y.-Z. Flame-retardant oligomeric electrolyte additive for self-extinguishing and highly-stable lithium-ion batteries: Beyond small molecules. J. Energy Chem. 2023, 84, 374–384. [Google Scholar] [CrossRef]

- Sun, P.; Bisschop, R.; Niu, H.; Huang, X. A Review of Battery Fires in Electric Vehicles. Fire Technol. 2020, 56, 1361–1410. [Google Scholar] [CrossRef]

- Feng, X.; Ren, D.; He, X.; Ouyang, M. Mitigating Thermal Runaway of Lithium-Ion Batteries. Joule 2020, 4, 743–770. [Google Scholar] [CrossRef]

- Zhou, G.; Yang, S.; Liu, Y.; Zhang, Q.; Li, Y.; Lu, H.; Wei, Z.; Huang, Q.; Zhou, W. Thermal runaway response and flame eruption dynamics of lithium-ion batteries under continuous/intermittent heating mode of dual heat sources. Appl. Therm. Eng. 2024, 249, 123363. [Google Scholar] [CrossRef]

- Zhang, G.; Wei, X.; Tang, X.; Zhu, J.; Chen, S.; Dai, H. Internal short circuit mechanisms, experimental approaches and detection methods of lithium-ion batteries for electric vehicles: A review. Renew. Sustain. Energy Rev. 2021, 141, 110790. [Google Scholar] [CrossRef]

- Salloum, R.; Rabuel, F.; Abada, S.; Morcrette, M. Investigating the internal short-circuit in 18650 cells under thermal abuse conditions. J. Power Sources 2025, 628, 235905. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, N.; Jiang, L.; Wei, Z.; Zhang, Y.; Yu, Y.; Song, L.; Wang, L.; Duan, Q.; Sun, J.; et al. Assessment of the complete chain evolution process of LIBs from micro internal short circuit failure to thermal runaway under mechanical abuse conditions. Process Saf. Environ. Prot. 2024, 185, 296–306. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.; Huang, X.; Huang, X. Intra-cell thermal runaway propagation within a cylindrical battery induced by nail penetration. Int. J. Therm. Sci. 2025, 210, 109633. [Google Scholar] [CrossRef]

- Chen, M.; Yu, Y.; Ouyang, D.; Weng, J.; Zhao, L.; Wang, J.; Chen, Y. Research progress of enhancing battery safety with phase change materials. Renew. Sustain. Energy Rev. 2024, 189, 113921. [Google Scholar] [CrossRef]

- Chen, M.; Zhu, M.; Zhang, S.; Ouyang, D.; Weng, J.; Wei, R.; Chen, Y.; Zhao, L.; Wang, J. Experimental investigation on mitigation of thermal runaway propagation of lithium-ion battery module with flame retardant phase change materials. Appl. Therm. Eng. 2023, 235, 121401. [Google Scholar] [CrossRef]

- Ren, M.; Fakayode, O.A.; Kong, F.; Zhou, C.; Chen, L.; Fan, X.; Liang, J.; Li, H. Characterization of cellulose nanocrystals prepared by different delignification methods and application of ultra-light, hydrophobic aerogels as oil absorbent in food systems. Ind. Crops Prod. 2023, 197, 116653. [Google Scholar] [CrossRef]

- Niu, H.; Chen, C.; Liu, Y.; Li, L.; Li, Z.; Ji, D.; Huang, X. Mitigating thermal runaway propagation of NCM 811 prismatic batteries via hollow glass microspheres plates. Process Saf. Environ. Prot. 2022, 162, 672–683. [Google Scholar] [CrossRef]

- Zou, K.; Xu, J.; Zhao, M.; Lu, S. Effects and mechanism of thermal insulation materials on thermal runaway propagation in large-format pouch lithium-ion batteries. Process Saf. Environ. Prot. 2024, 185, 1352–1361. [Google Scholar] [CrossRef]

- Bausch, B.; Frankl, S.; Becher, D.; Menz, F.; Baier, T.; Bauer, M.; Böse, O.; Hölzle, M. Naturally-derived thermal barrier based on fiber-reinforced hydrogel for the prevention of thermal runaway propagation in high-energetic lithium-ion battery packs. J. Energy Storage 2023, 61, 106841. [Google Scholar] [CrossRef]

- Chen, M.; Gong, Y.; Zhao, L.; Chen, Y. Phase change material with outstanding thermal stability and mechanical strength for battery thermal management. J. Energy Storage 2024, 104, 114565. [Google Scholar] [CrossRef]

- Gupta, A.K.; Kiran, R.; Zafar, S.; Pathak, H. Effect of hygrothermal ageing on the mechanical properties of glass fiber reinforced polymer composite: Experimental and numerical approaches. Mater. Today Commun. 2024, 41, 111060. [Google Scholar] [CrossRef]

- Xu, C.; Liu, X.; Wang, L.; Gan, X.; Li, T.; Feng, X.; Yue, X.; Lv, Y.; Wang, X. Structural morphology evolution and characterization of electrospun magnesium aluminum silicate ceramic micro-nanofibers: A study. Mater. Today Commun. 2024, 39, 108816. [Google Scholar] [CrossRef]

- Chen, L.; Liu, J.; Liu, H.; Liu, Z.; Song, Q. Synergistic effect of graphene oxide and glass fiber on mchanical and thermal properties of composites: Experimental and simulation investigations. React. Funct. Polym. 2025, 210, 106201. [Google Scholar] [CrossRef]

- Feng, R.; Yang, Q.; Dai, H.; Deng, M.; Wang, H.; Hou, C.; Cheng, Z.; Gao, H. Effect of glass fiber on the mechanical and thermal insulation performances of kaolinite-based thermal insulator. Case Stud. Constr. Mater. 2024, 21, e03879. [Google Scholar] [CrossRef]

- Zhu, X.; Sun, Z.; Wang, Z.; Wang, H.; Lin, N.; Shan, C. Thermal runaway in commercial lithium-ion cells under overheating condition and the safety assessment method: Effects of SoCs, cathode materials and packaging forms. J. Energy Storage 2023, 68, 107768. [Google Scholar] [CrossRef]

- Wang, Z.; Yuan, J.; Zhu, X.; Wang, H.; Huang, L.; Wang, Y.; Xu, S. Overcharge-to-thermal-runaway behavior and safety assessment of commercial lithium-ion cells with different cathode materials: A comparison study. J. Energy Chem. 2021, 55, 484–498. [Google Scholar] [CrossRef]

- Mao, N.; Gadkari, S.; Wang, Z.; Zhang, T.; Bai, J.; Cai, Q. A comparative analysis of lithium-ion batteries with different cathodes under overheating and nail penetration conditions. Energy 2023, 278, 128027. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).