Safety-Critical Influence of Ageing on Mechanical Properties of Lithium-Ion Pouch Cells

Abstract

1. Introduction

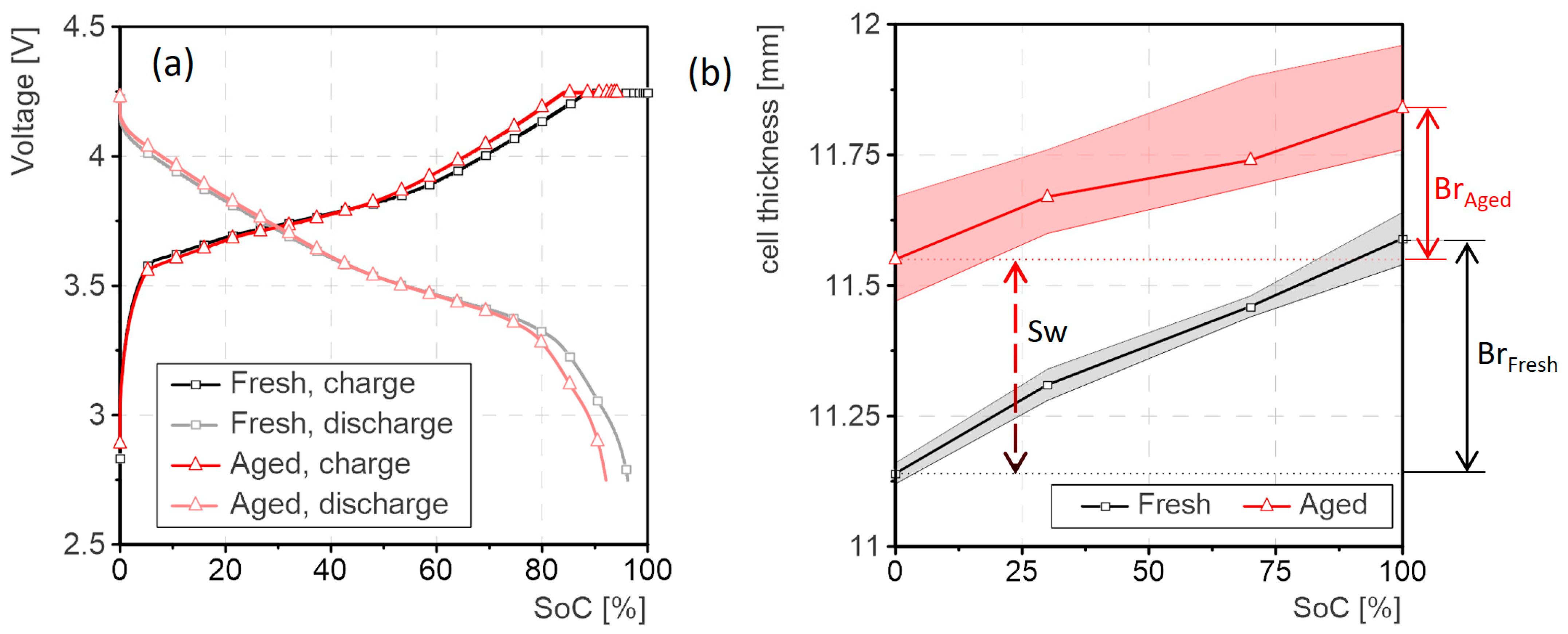

2. Materials and Methods

2.1. Device Under Tests

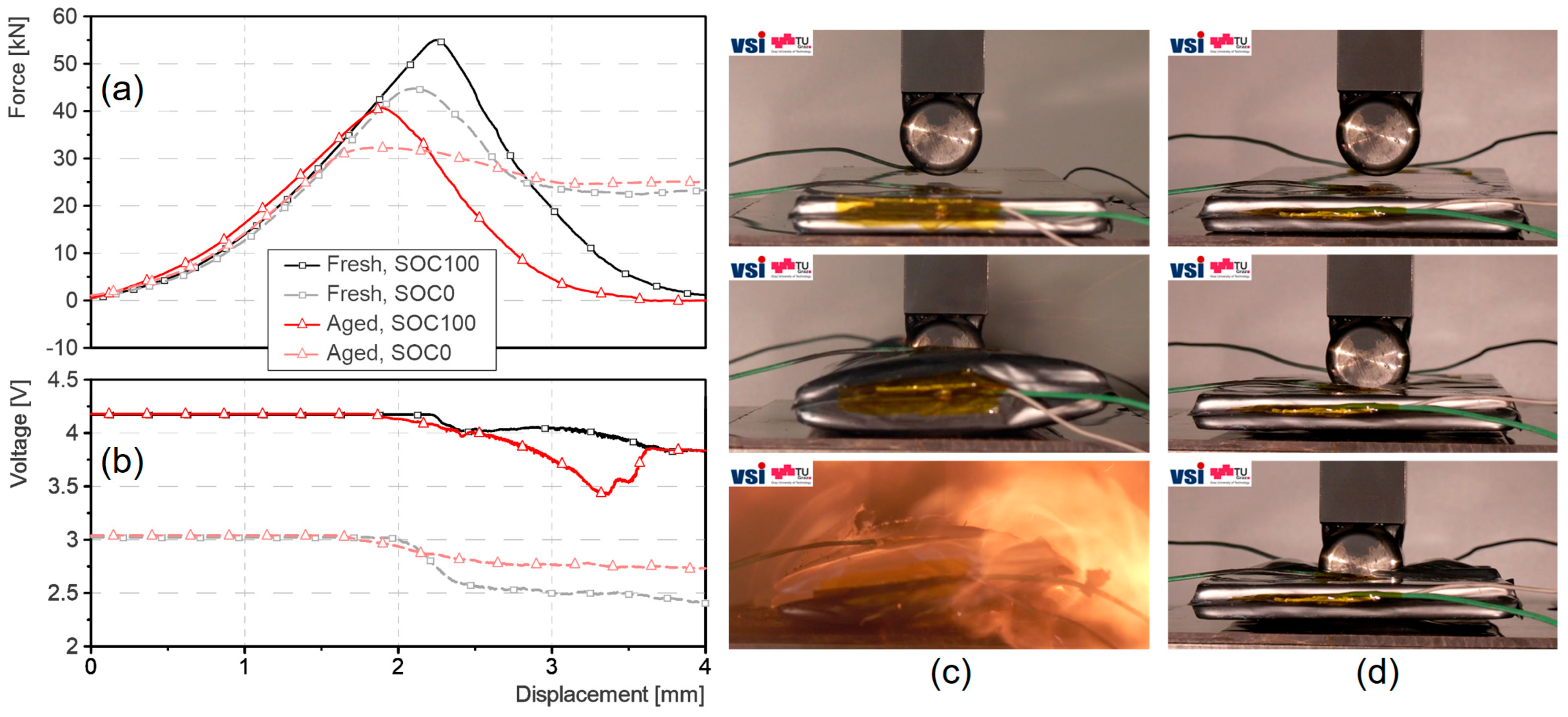

2.2. Mechanical Cell Abuse Test

2.3. Post-Mortem Analysis of Cells

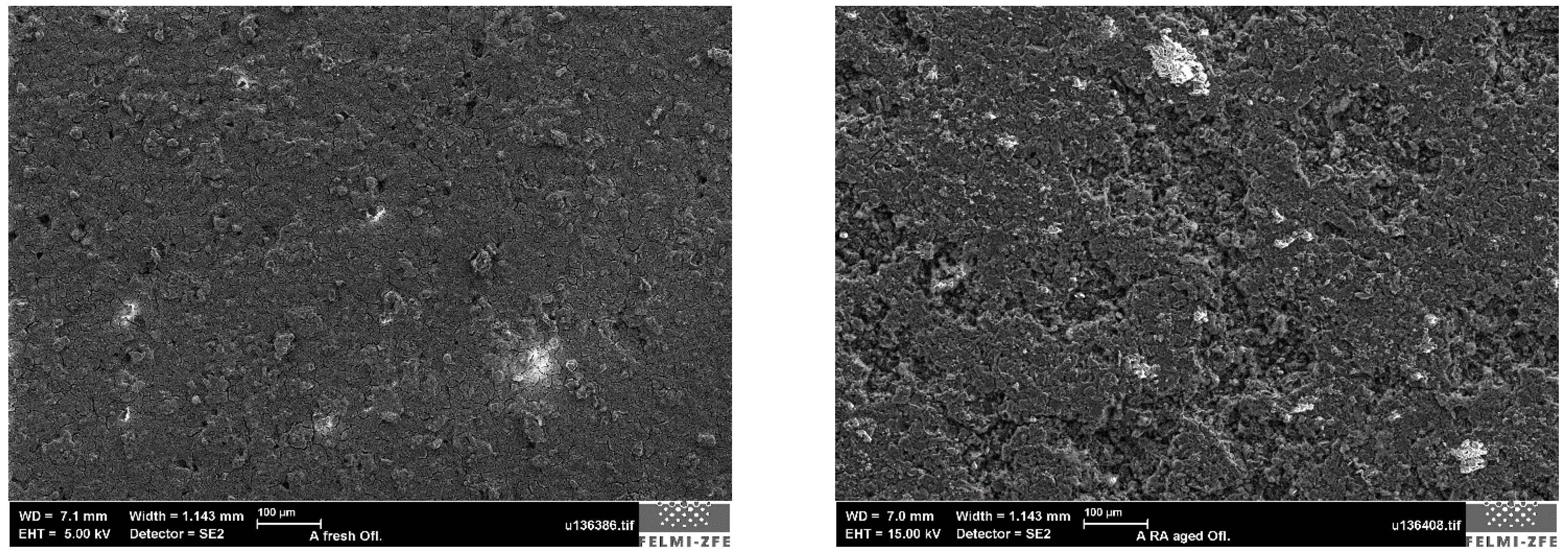

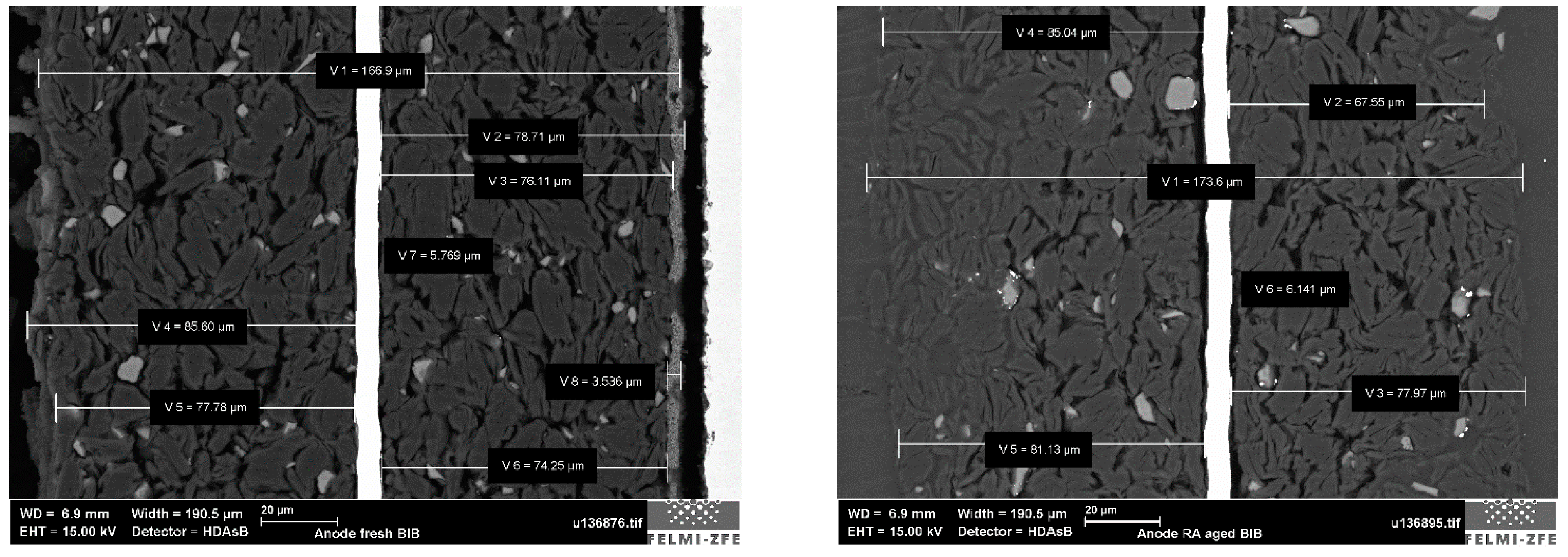

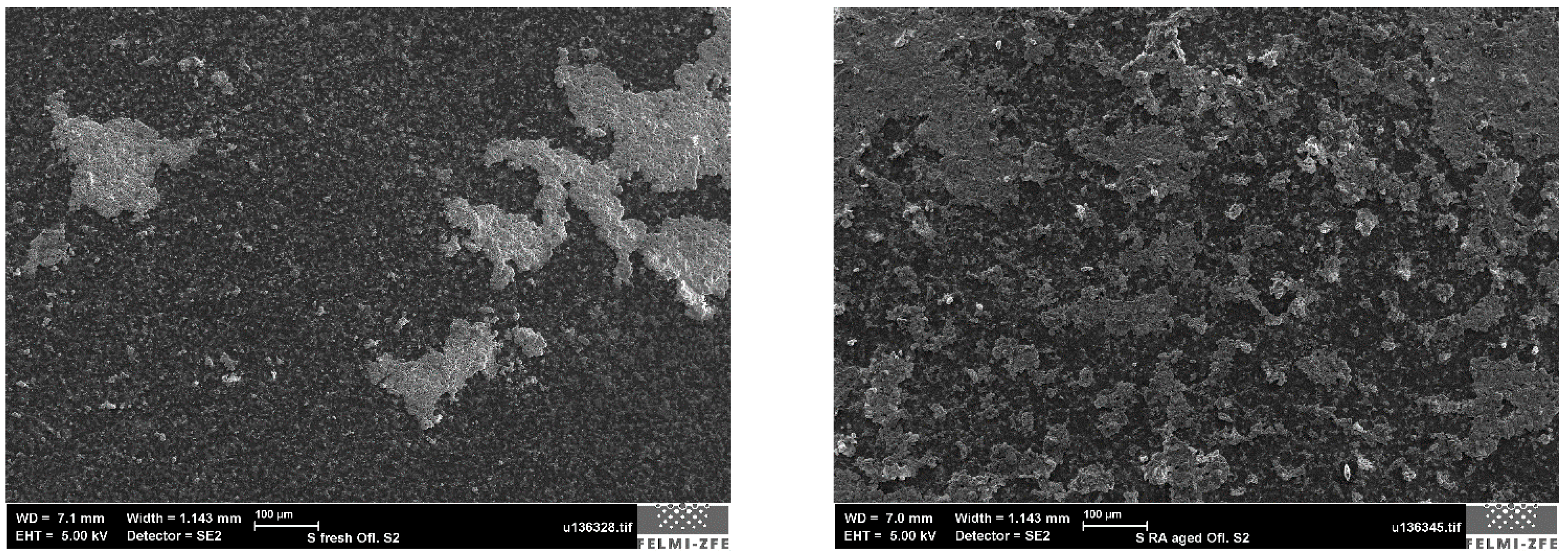

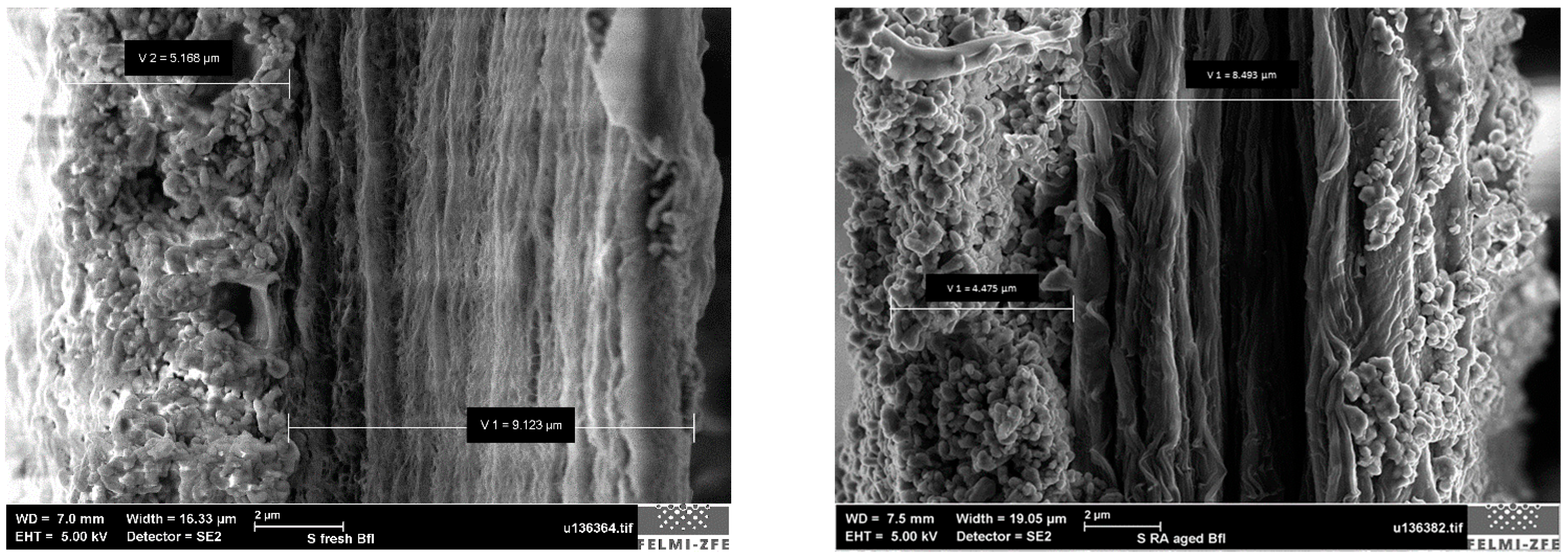

2.3.1. Microscopic Imaging of Cell Components (Surface, Cross-Section) F vs. RA

2.3.2. Mechanical Characterisation of Cell Components

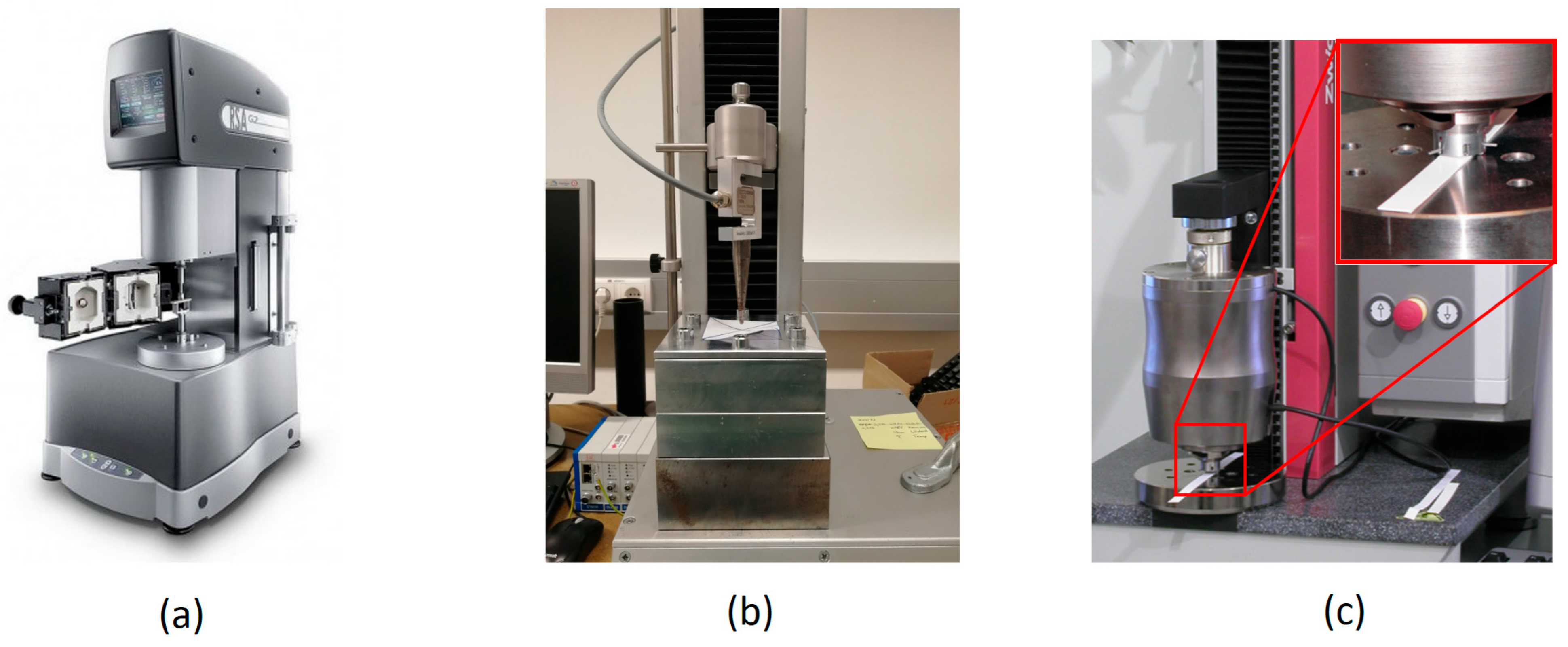

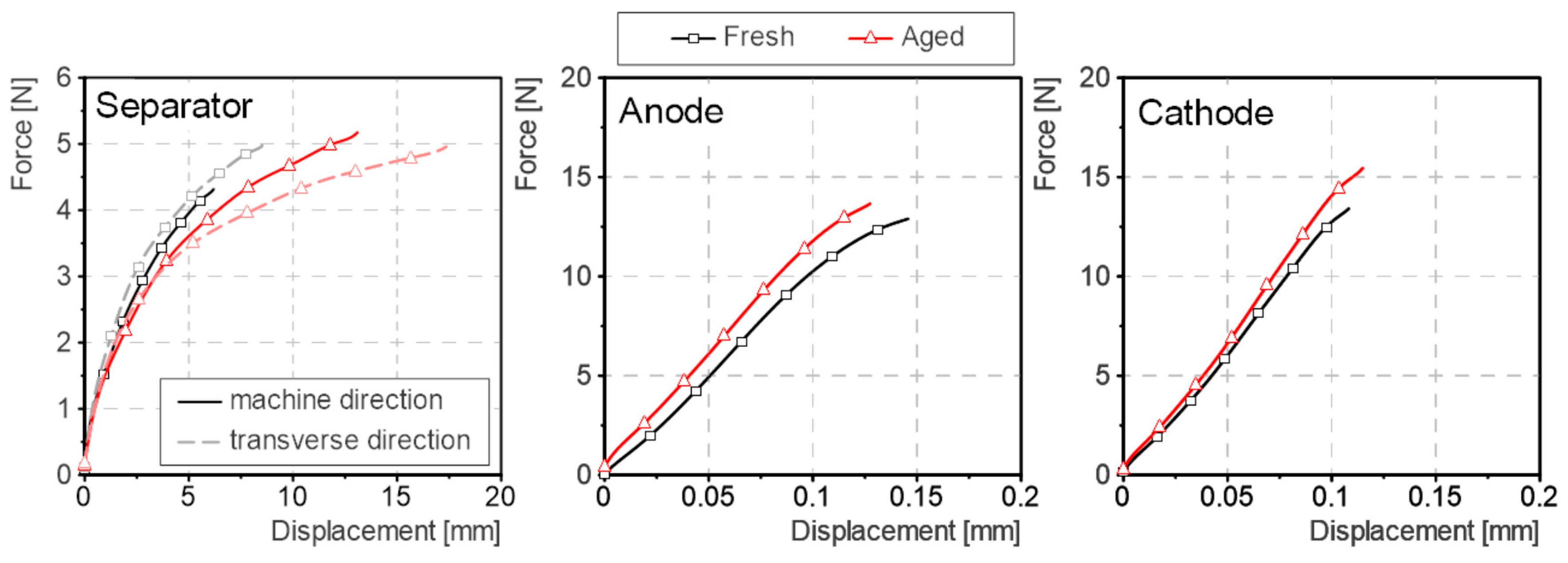

- Uni-axial tensile tests:Tensile tests were conducted to identify possible degradation (e.g., corrosion, cracking [17,21,42]) in the current collectors of the electrodes as well as the properties of the separator. Stripes with a width of 5 mm were cut out of the single components and stored in a replacement electrolyte (dimethyl carbonate DMC). For the separator, samples were created in machine and transverse direction to take into account possible anisotropic behaviour. The samples were clamped with a free length of 15 mm (based on [43]), tested with a speed of 20 mm/min and for each component, five samples were tested. For these tests, a dynamic mechanic analyser (DMA) RSA-G2 (Figure 3a) was used. As results, single force over deflection curves of the five test repetitions as well as respective average data were obtained.

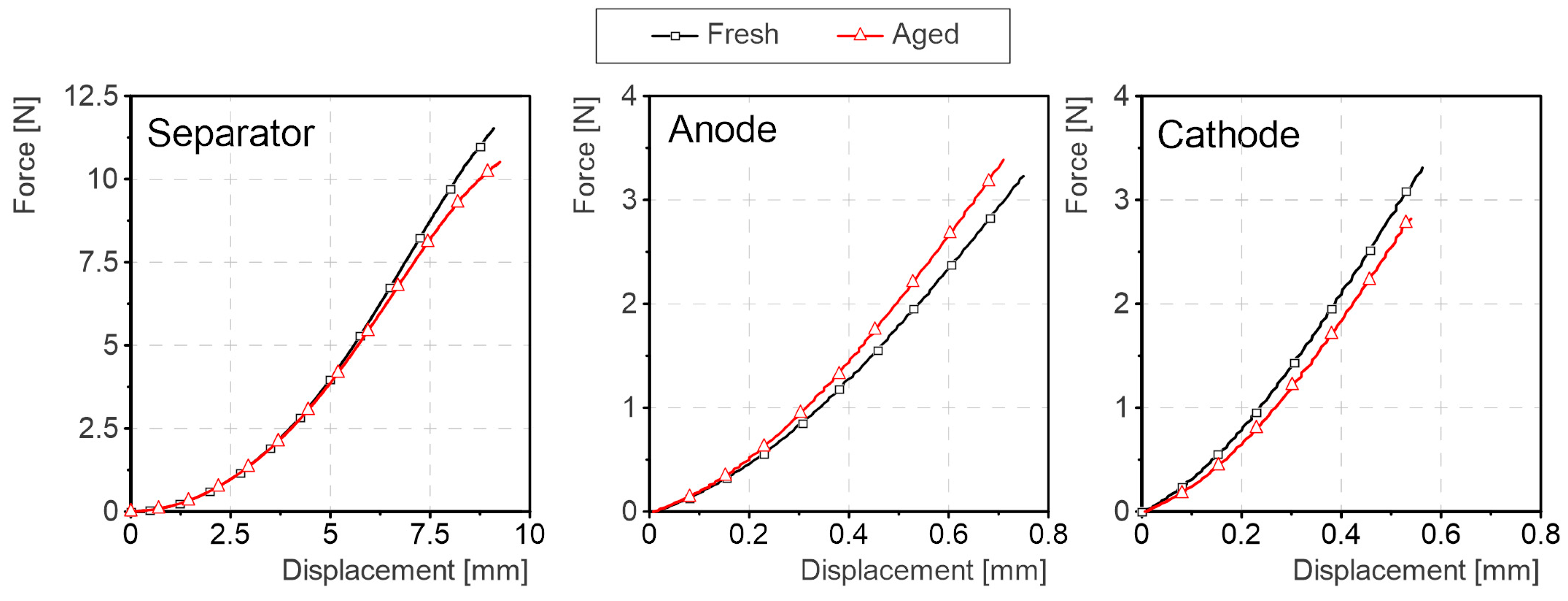

- Puncture penetration tests + SEM cross-section of deformation zone:Puncture penetration tests were carried out in accordance with [44] in order to analyse the effect of localised loading of the active material in combination with bi-axial tension in the current collector. Thereby, a single layer sample (60 × 60 mm) was clamped in a fixture with a circular opening of a 35 mm diameter. A cone with a 3 mm tip radius and an angle of 6° is moved into the sample with a speed of 20 mm/min. This test was carried out with a Z3 universal test machine (displacement resolution of 0.01 mm) equipped with a 20 N (NTT, non-linearity ± 0.02%) load cell (see Figure 3b). As results, force over intrusion curves were generated for the fresh and aged samples of each battery component, with a minimum of five repetitions.In a second step, further cathode samples were loaded up to a force just below the detected failure threshold. Those critically loaded, but not failed samples were then prepared for a subsequent cross-section analysis, as already described above. The aim of this was to visualise the deformation pattern of the fresh and aged cathode active material directly under the tip. The focus, hereby, was laid on a possible reduction in the thickness of the active material, resulting from the local load and on the general curvature of the sample, as an indicator for possible changed shear properties.

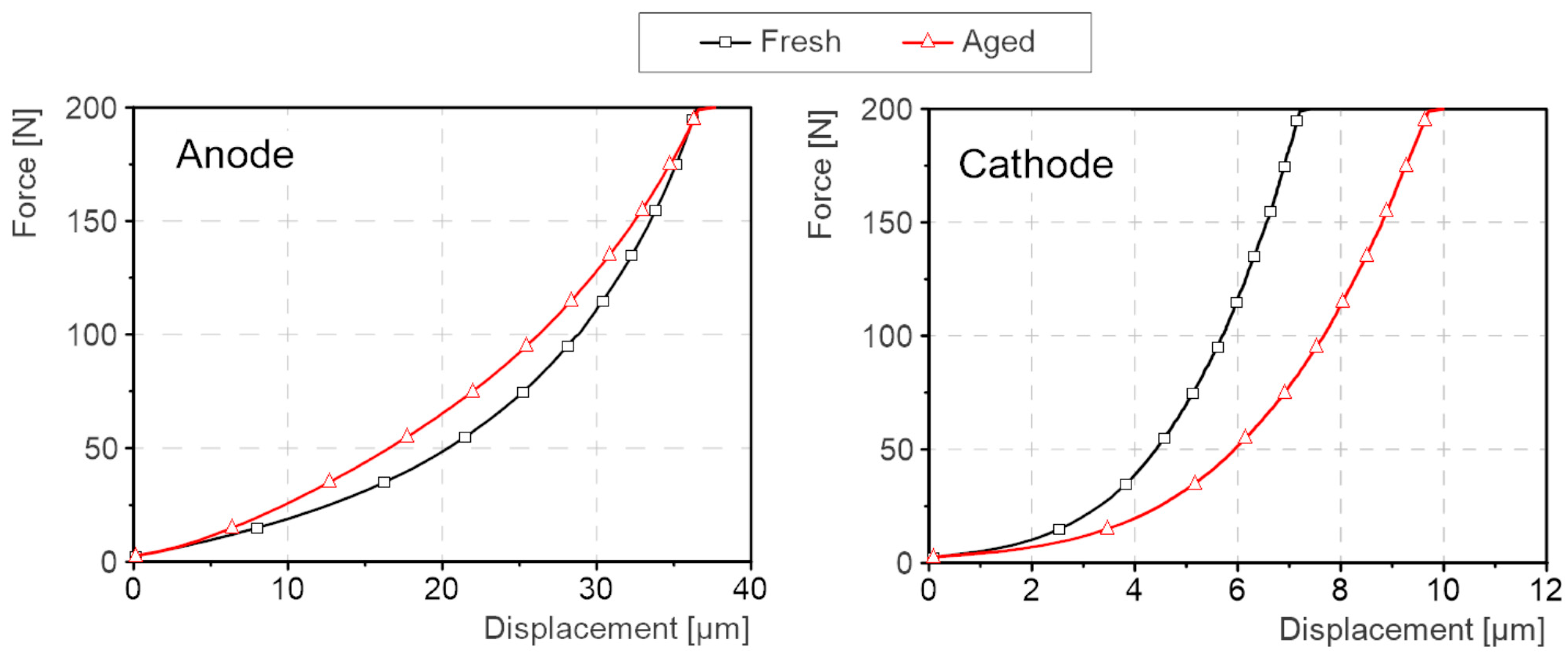

- Compression tests:The puncture penetration tests, in combination with the analysis of the deformation area under the impactor, allowed for a qualitative assessment of different mechanical properties. In order to also quantify the change, complimentary compression tests of the electrode layers were carried out. Due to the very low layer thickness, typically stacked samples are examined in comparative studies in the recent literature. As already shown by [45] for fresh samples, a novel approach was used in this study to examine single electrode layers. Thereby, the possible influence of the mis-alignment of the layer stack, trapped liquid or gas in between layers, or other limitations are ruled out. A testing device of ZwickRoell, which is typically applied for the mechanical characterisation (compressibility) of paper and which features a displacement resolution of 0.04 µm, was adopted for these tests. A flat, circular impactor with a surface of 5 mm2 was pushed into the layer perpendicular to the surface with a speed of 0.2 mm/min and loaded to a maximum allowable peak force of 200 N. Figure 3c shows an exemplary picture of the test-head with a paper sample. For our tests, it was mounted on a ZwickRoell zwickiLine Z2.5 TN universal test machine. For each sample, a minimum of 3 repetitions were tested.

3. Results

3.1. Mechanical Cell Abuse Tests

3.2. Microscopic Imaging of Cell Components’ Structure

3.3. Cell Component Mechanical Characterisation

3.3.1. Tensile Tests of Cell Components

3.3.2. Bi-Axial Tension (Puncture Penetration) + SEM of Deformation Zone

3.3.3. Compression Tests

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Microscopic Imaging

Appendix A.1. Anode

Appendix A.2. Cathode

Appendix A.3. Separator

Appendix B. Component Testing

Appendix B.1. Tensile Test

Appendix B.2. Puncture Penetration Test

Appendix B.3. Compression Tests

References

- European Environment Agency. Transport and Environment Report 2021: Decarbonising Road Transport—The Role of Vehicles, Fuels and Transport Demand; EEA Report No 02/2022 TH-AL-22-004-EN-N; European Environment Agency: Copenhagen, Denmark, 2022. [Google Scholar]

- Parera, N.; Amor, O. Safety Protocols for Electric Vehicles Crash Tests. J. Soc. Automot. Eng. Malays. 2019, 3, 112–122. [Google Scholar] [CrossRef]

- Navale, A.B.; Chippa, S.P.; Chougule, D.A.; Raut, P.M. Crashworthiness aspects of electric vehicle design. Int. J. Crashworthiness 2021, 26, 368–387. [Google Scholar] [CrossRef]

- Birkl, C.R.; Roberts, M.R.; McTurk, E.; Bruce, P.G.; Howey, D.A. Degradation diagnostics for lithium ion cells. J. Power Sources 2017, 341, 373–386. [Google Scholar] [CrossRef]

- Xiong, R.; Pan, Y.; Shen, W.; Li, H.; Sun, F. Lithium-ion battery aging mechanisms and diagnosis method for automotive applications: Recent advances and perspectives. Renew. Sustain. Energy Rev. 2020, 131, 110048. [Google Scholar] [CrossRef]

- Vetter, J.; Novák, P.; Wagner, M.R.; Veit, C.; Möller, K.-C.; Besenhard, J.O.; Winter, M.; Wohlfahrt-Mehrens, M.; Vogler, C.; Hammouche, A. Ageing mechanisms in lithium-ion batteries. J. Power Sources 2005, 147, 269–281. [Google Scholar] [CrossRef]

- Wu, S.; Chen, Y.; Luan, W.; Chen, H.; Huo, L.; Wang, M.; Tu, S.-t. A Review of Multiscale Mechanical Failures in Lithium-Ion Batteries: Implications for Performance, Lifetime and Safety. Electrochem. Energ. Rev. 2024, 7, 35. [Google Scholar] [CrossRef]

- Sun, S.; Xu, J. Safety behaviors and degradation mechanisms of aged batteries: A review. Energy Mater. Devices 2024, 2, 9370048. [Google Scholar] [CrossRef]

- Yang, X.-G.; Leng, Y.; Zhang, G.; Ge, S.; Wang, C.-Y. Modeling of lithium plating induced aging of lithium-ion batteries: Transition from linear to nonlinear aging. J. Power Sources 2017, 360, 28–40. [Google Scholar] [CrossRef]

- Chen, Y.; Luan, W.; Chen, H.; Zhu, X. Multi-scale Failure Behavior of Cathode in Lithium-ion Batteries Based on Stress Field. J. Inorg. Mater. 2022, 777, 918–924. [Google Scholar] [CrossRef]

- Li, J.; Dozier, A.K.; Li, Y.; Yang, F.; Cheng, Y.-T. Crack Pattern Formation in Thin Film Lithium-Ion Battery Electrodes. J. Electrochem. Soc. 2011, 158, A689. [Google Scholar] [CrossRef]

- Yuca, N.; Zhao, H.; Song, X.; Dogdu, M.F.; Yuan, W.; Fu, Y.; Battaglia, V.S.; Xiao, X.; Liu, G. A systematic investigation of polymer binder flexibility on the electrode performance of lithium-ion batteries. ACS Appl. Mater. Interfaces 2014, 6, 17111–17118. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Chen, H.; Luan, W. Shakedown, ratcheting and fatigue analysis of cathode coating in lithium-ion battery under steady charging-discharging process. J. Mech. Phys. Solids 2021, 150, 104366. [Google Scholar] [CrossRef]

- Luo, H.; Zhu, J.; Sahraei, E.; Xia, Y. Adhesion strength of the cathode in lithium-ion batteries under combined tension/shear loadings. RSC Adv. 2018, 8, 3996–4005. [Google Scholar] [CrossRef]

- Xu, R.; Yang, Y.; Yin, F.; Liu, P.; Cloetens, P.; Liu, Y.; Lin, F.; Zhao, K. Heterogeneous damage in Li-ion batteries: Experimental analysis and theoretical modeling. J. Mech. Phys. Solids 2019, 129, 160–183. [Google Scholar] [CrossRef]

- Sun, H.H.; Pollard, T.P.; Borodin, O.; Xu, K.; Allen, J.L. Degradation of High Nickel Li-Ion Cathode Materials Induced by Exposure to Fully-Charged State and Its Mitigation. Adv. Energy Mater. 2023, 13, 2204360. [Google Scholar] [CrossRef]

- Rahe, C.; Kelly, S.T.; Rad, M.N.; Sauer, D.U.; Mayer, J.; Figgemeier, E. Nanoscale X-ray imaging of ageing in automotive lithium ion battery cells. J. Power Sources 2019, 433, 126631. [Google Scholar] [CrossRef]

- Dubarry, M.; Truchot, C.; Liaw, B.Y.; Gering, K.; Sazhin, S.; Jamison, D.; Michelbacher, C. Evaluation of commercial lithium-ion cells based on composite positive electrode for plug-in hybrid electric vehicle applications. Part II. Degradation mechanism under 2C cycle aging. J. Power Sources 2011, 196, 10336–10343. [Google Scholar] [CrossRef]

- Jalkanen, K.; Karppinen, J.; Skogström, L.; Laurila, T.; Nisula, M.; Vuorilehto, K. Cycle aging of commercial NMC/graphite pouch cells at different temperatures. Appl. Energy 2015, 154, 160–172. [Google Scholar] [CrossRef]

- Braithwaite, J.W. Corrosion of Lithium-Ion Battery Current Collectors. J. Electrochem. Soc. 1999, 146, 448. [Google Scholar] [CrossRef]

- Guo, M.; Meng, W.; Zhang, X.; Bai, Z.; Wang, G.; Wang, Z.; Yang, F. Structural Degradation of Cu Current Collector During Electrochemical Cycling of Sn-Based Lithium-Ion Batteries. J. Electron. Mater. 2019, 48, 7543–7550. [Google Scholar] [CrossRef]

- Kalnaus, S.; Wang, Y.; Li, J.; Kumar, A.; Turner, J.A. Temperature and strain rate dependent behavior of polymer separator for Li-ion batteries. Extrem. Mech. Lett. 2018, 20, 73–80. [Google Scholar] [CrossRef]

- Cannarella, J.; Liu, X.; Leng, C.Z.; Sinko, P.D.; Gor, G.Y.; Arnold, C.B. Mechanical Properties of a Battery Separator under Compression and Tension. J. Electrochem. Soc. 2014, 161, F3117–F3122. [Google Scholar] [CrossRef]

- Gor, G.Y.; Cannarella, J.; Leng, C.Z.; Vishnyakov, A.; Arnold, C.B. Swelling and softening of lithium-ion battery separators in electrolyte solvents. J. Power Sources 2015, 294, 167–172. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, J.; Sahraei, E. Degradation of battery separators under charge–discharge cycles. RSC Adv. 2017, 7, 56099–56107. [Google Scholar] [CrossRef]

- Demirocak, D.E.; Bhushan, B. Probing the aging effects on nanomechanical properties of a LiFePO4 cathode in a large format prismatic cell. J. Power Sources 2015, 280, 256–262. [Google Scholar] [CrossRef]

- Chen, Y.; Santhanagopalan, S.; Babu, V.; Ding, Y. Dynamic mechanical behavior of lithium-ion pouch cells subjected to high-velocity impact. Compos. Struct. 2019, 218, 50–59. [Google Scholar] [CrossRef]

- Kermani, G.; Sahraei, E. Review: Characterization and Modeling of the Mechanical Properties of Lithium-Ion Batteries. Energies 2017, 10, 1730. [Google Scholar] [CrossRef]

- Sahraei, E.; Meier, J.; Wierzbicki, T. Characterizing and modeling mechanical properties and onset of short circuit for three types of lithium-ion pouch cells. J. Power Sources 2014, 247, 503–516. [Google Scholar] [CrossRef]

- Feng, X.; Ouyang, M.; Liu, X.; Lu, L.; Xia, Y.; He, X. Thermal runaway mechanism of lithium ion battery for electric vehicles: A review. Energy Storage Mater. 2018, 10, 246–267. [Google Scholar] [CrossRef]

- Abaza, A.; Ferrari, S.; Wong, H.K.; Lyness, C.; Moore, A.; Weaving, J.; Blanco-Martin, M.; Dashwood, R.; Bhagat, R. Experimental study of internal and external short circuits of commercial automotive pouch lithium-ion cells. J. Energy Storage 2018, 16, 211–217. [Google Scholar] [CrossRef]

- Maleki, H.; Wang, H.; Porter, W.; Hallmark, J. Li-Ion polymer cells thermal property changes as a function of cycle-life. J. Power Sources 2014, 263, 223–230. [Google Scholar] [CrossRef]

- Vertiz, G.; Oyarbide, M.; Macicior, H.; Miguel, O.; Cantero, I.; Fernandez de Arroiabe, P.; Ulacia, I. Thermal characterization of large size lithium-ion pouch cell based on 1d electro-thermal model. J. Power Sources 2014, 272, 476–484. [Google Scholar] [CrossRef]

- Richter, F.; Vie, P.J.S.; Kjelstrup, S.; Burheim, O.S. Measurements of ageing and thermal conductivity in a secondary NMC-hard carbon Li-ion battery and the impact on internal temperature profiles. Electrochim. Acta 2017, 250, 228–237. [Google Scholar] [CrossRef]

- Sprenger, M.; Dölle, N.; Schauwecker, F.; Raffler, M.; Ellersdorfer, C.; Sinz, W. Multiscale Analysis and Safety Assessment of Fresh and Electrical Aged Lithium-Ion Pouch Cells Focusing on Mechanical Behavior. Energies 2022, 15, 847. [Google Scholar] [CrossRef]

- Sprenger, M.; Kovachev, G.; Dölle, N.; Schauwecker, F.; Sinz, W.; Ellersdorfer, C. Changes in the Mechanical Behavior of Electrically Aged Lithium-Ion Pouch Cells: In-Plane and Out-of-Plane Indentation Loads with Varying Testing Velocity and State of Charge. Batteries 2023, 9, 67. [Google Scholar] [CrossRef]

- Luo, H.; Xia, Y.; Zhou, Q. Mechanical damage in a lithium-ion pouch cell under indentation loads. J. Power Sources 2017, 357, 61–70. [Google Scholar] [CrossRef]

- Liu, Y.; Xia, Y.; Zhou, Q. Effect of low-temperature aging on the safety performance of lithium-ion pouch cells under mechanical abuse condition: A comprehensive experimental investigation. Energy Storage Mater. 2021, 40, 268–281. [Google Scholar] [CrossRef]

- Kovachev, G.; Ellersdorfer, C.; Gstrein, G.; Hanzu, I.; Wilkening, H.M.R.; Werling, T.; Schauwecker, F.; Sinz, W. Safety assessment of electrically cycled cells at high temperatures under mechanical crush loads. eTransportation 2020, 6, 100087. [Google Scholar] [CrossRef]

- Kovachev, G.; Schröttner, H.; Gstrein, G.; Aiello, L.; Hanzu, I.; Wilkening, H.M.R.; Foitzik, A.; Wellm, M.; Sinz, W.; Ellersdorfer, C. Analytical Dissection of an Automotive Li-Ion Pouch Cell. Batteries 2019, 5, 67. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, J.; Cao, L.; Wu, Z.; Santhanagopalan, S. Constitutive behavior and progressive mechanical failure of electrodes in lithium-ion batteries. J. Power Sources 2017, 357, 126–137. [Google Scholar] [CrossRef]

- Guo, L.; Thornton, D.B.; Koronfel, M.A.; Stephens, I.E.L.; Ryan, M.P. Degradation in lithium ion battery current collectors. J. Phys. Energy 2021, 3, 032015. [Google Scholar] [CrossRef]

- ASTM D882-02; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM F1306-21; Standard Test Method for Slow Rate Penetration Resistance of Flexible Barrier Films and Laminates. ASTM International: West Conshohocken, PA, USA, 2021.

- Schmid, A.; Ellersdorfer, C.; Ewert, E.; Feist, F. Sequential Multi-Scale Modeling Using an Artificial Neural Network-Based Surrogate Material Model for Predicting the Mechanical Behavior of a Li-Ion Pouch Cell Under Abuse Conditions. Batteries 2024, 10, 425. [Google Scholar] [CrossRef]

- Chen, H.; Ling, M.; Hencz, L.; Ling, H.Y.; Li, G.; Lin, Z.; Liu, G.; Zhang, S. Exploring Chemical, Mechanical, and Electrical Functionalities of Binders for Advanced Energy-Storage Devices. Chem. Rev. 2018, 118, 8936–8982. [Google Scholar] [CrossRef] [PubMed]

- Dou, W.; Zheng, M.; Zhang, W.; Liu, T.; Wang, F.; Wan, G.; Liu, Y.; Tao, X. Review on the Binders for Sustainable High-Energy-Density Lithium Ion Batteries: Status, Solutions, and Prospects. Adv. Funct. Mater. 2023, 33, 2305161. [Google Scholar] [CrossRef]

- Iqbal, N.; Ali, Y.; Lee, S. Chemo-mechanical response of composite electrode systems with multiple binder connections. Electrochim. Acta 2020, 364, 137312. [Google Scholar] [CrossRef]

- Orsini, F.; Du Pasquier, A.; Beaudoin, B.; Tarascon, J.M.; Trentin, M.; Langenhuizen, N.; de Beer, E.; Notten, P. In situ Scanning Electron Microscopy (SEM) observation of interfaces within plastic lithium batteries. J. Power Sources 1998, 76, 19–29. [Google Scholar] [CrossRef]

- Sagane, F.; Shimokawa, R.; Sano, H.; Sakaebe, H.; Iriyama, Y. In-situ scanning electron microscopy observations of Li plating and stripping reactions at the lithium phosphorus oxynitride glass electrolyte/Cu interface. J. Power Sources 2013, 225, 245–250. [Google Scholar] [CrossRef]

- Luo, D.; Li, M.; Zheng, Y.; Ma, Q.; Gao, R.; Zhang, Z.; Dou, H.; Wen, G.; Shui, L.; Yu, A.; et al. Electrolyte Design for Lithium Metal Anode-Based Batteries Toward Extreme Temperature Application. Adv. Sci. 2021, 8, e2101051. [Google Scholar] [CrossRef]

- Abbas, S.M.; Gstrein, G.; Jauernig, A.D.; Schmid, A.; Michelini, E.; Hinterberger, M.; Ellersdorfer, C. Influence of Lithium Plating on mechanical properties of commercial LiIon batteries. Batteries 2025. manuscript in preparation. [Google Scholar]

- Michelini, E.; Höschele, P.; Abbas, S.M.; Ellersdorfer, C.; Moser, J. Assessment of Health Indicators to Detect the Aging State of Commercial Second-Life Lithium-Ion Battery Cells through Basic Electrochemical Cycling. Batteries 2023, 9, 542. [Google Scholar] [CrossRef]

- Che, Y.; Guo, J.; Zheng, Y.; Stroe, D.-I.; Liu, W.; Hu, X.; Teodorescu, R. Unlocking Interpretable Prediction of Battery Random Discharge Capacity with Domain Adaptative Physics Constraint. Adv. Energy Mater. 2025, 4, 2405506. [Google Scholar] [CrossRef]

| Peak Force [kN] | Dsp @ Failure [mm] | Difference to F | ||||||

|---|---|---|---|---|---|---|---|---|

| SOC 100% | SOC 0% | SOC 100% | SOC 0% | Peak Force [kN] | Dsp @ Failure [mm] | |||

| F | 55.6 ± 1.2 | 45.2 ± 0.4 | 2.27 ± 0.05 | 2.09 ± 0.03 | SOC 100% | SOC 0% | SOC 100% | SOC 0% |

| RA | 41.4 ± 0.5 | 33.2 ± 0.3 | 1.94 ± 0.04 | 1.79 ± 0.04 | −14.2 (−26%) | −12.0 (−27%) | −0.32 (−14%) | −0.30 (−14%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gstrein, G.; Abbas, S.M.; Ewert, E.; Wenzl, M.; Ellersdorfer, C. Safety-Critical Influence of Ageing on Mechanical Properties of Lithium-Ion Pouch Cells. Batteries 2025, 11, 99. https://doi.org/10.3390/batteries11030099

Gstrein G, Abbas SM, Ewert E, Wenzl M, Ellersdorfer C. Safety-Critical Influence of Ageing on Mechanical Properties of Lithium-Ion Pouch Cells. Batteries. 2025; 11(3):99. https://doi.org/10.3390/batteries11030099

Chicago/Turabian StyleGstrein, Gregor, Syed Muhammad Abbas, Eduard Ewert, Michael Wenzl, and Christian Ellersdorfer. 2025. "Safety-Critical Influence of Ageing on Mechanical Properties of Lithium-Ion Pouch Cells" Batteries 11, no. 3: 99. https://doi.org/10.3390/batteries11030099

APA StyleGstrein, G., Abbas, S. M., Ewert, E., Wenzl, M., & Ellersdorfer, C. (2025). Safety-Critical Influence of Ageing on Mechanical Properties of Lithium-Ion Pouch Cells. Batteries, 11(3), 99. https://doi.org/10.3390/batteries11030099