Research on External Short Circuit Fault Evaluation Method for Li-Ion Batteries Based on Impedance Spectrum Feature Extraction

Abstract

1. Introduction

1.1. Literature Review

1.2. Paper Contributions

- (1)

- A differential DRT analysis method is proposed for the first time to grade ESC severity. Unlike traditional methods that rely on raw voltage or temperature thresholds, this approach isolates fault-induced electrochemical changes, specifically mass transport limitations from static inconsistencies, thereby establishing a new, high-sensitivity metric for battery safety assessment.

- (2)

- The gap between “black-box” machine learning and “white-box” electrochemical mechanisms is bridged through the construction of physically interpretable feature vectors. By extracting features directly from DRT peaks and optimizing them via differential evolution, the proposed model retains electrochemical interpretability, offering a potential solution to the “trust” problem in AI-based diagnostics.

- (3)

- A robust, model-free diagnostic paradigm is established that operates without the need for complex equivalent circuit modeling or extensive labeled datasets. This unsupervised framework demonstrates strong cross-batch generalization and possesses the potential to be extended for diagnosing other complex failure modes, such as internal short circuits and lithium plating, thereby accelerating the development of next-generation intelligent Battery Management Systems.

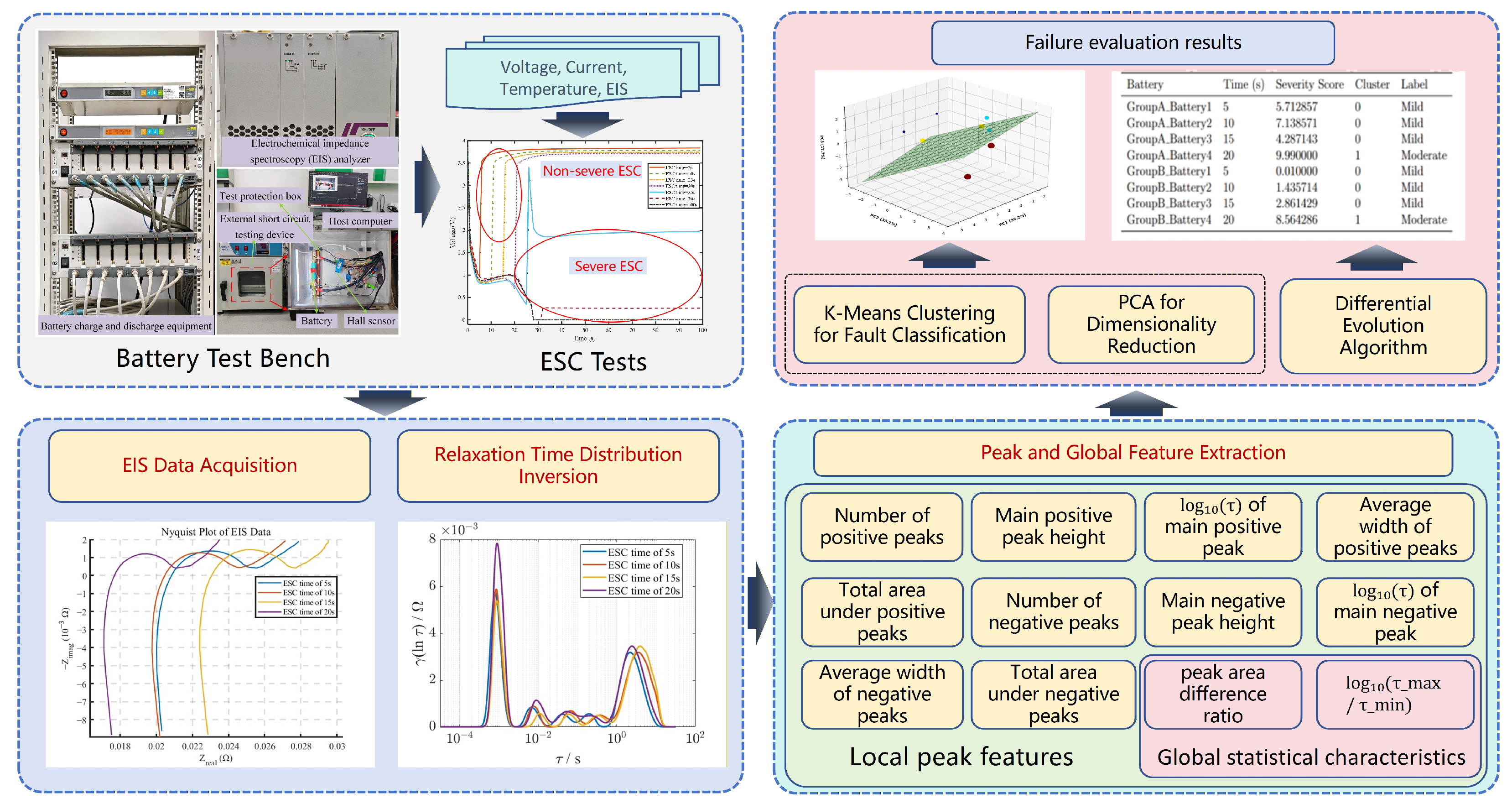

1.3. Paper Structure

2. Test Platform and Dataset

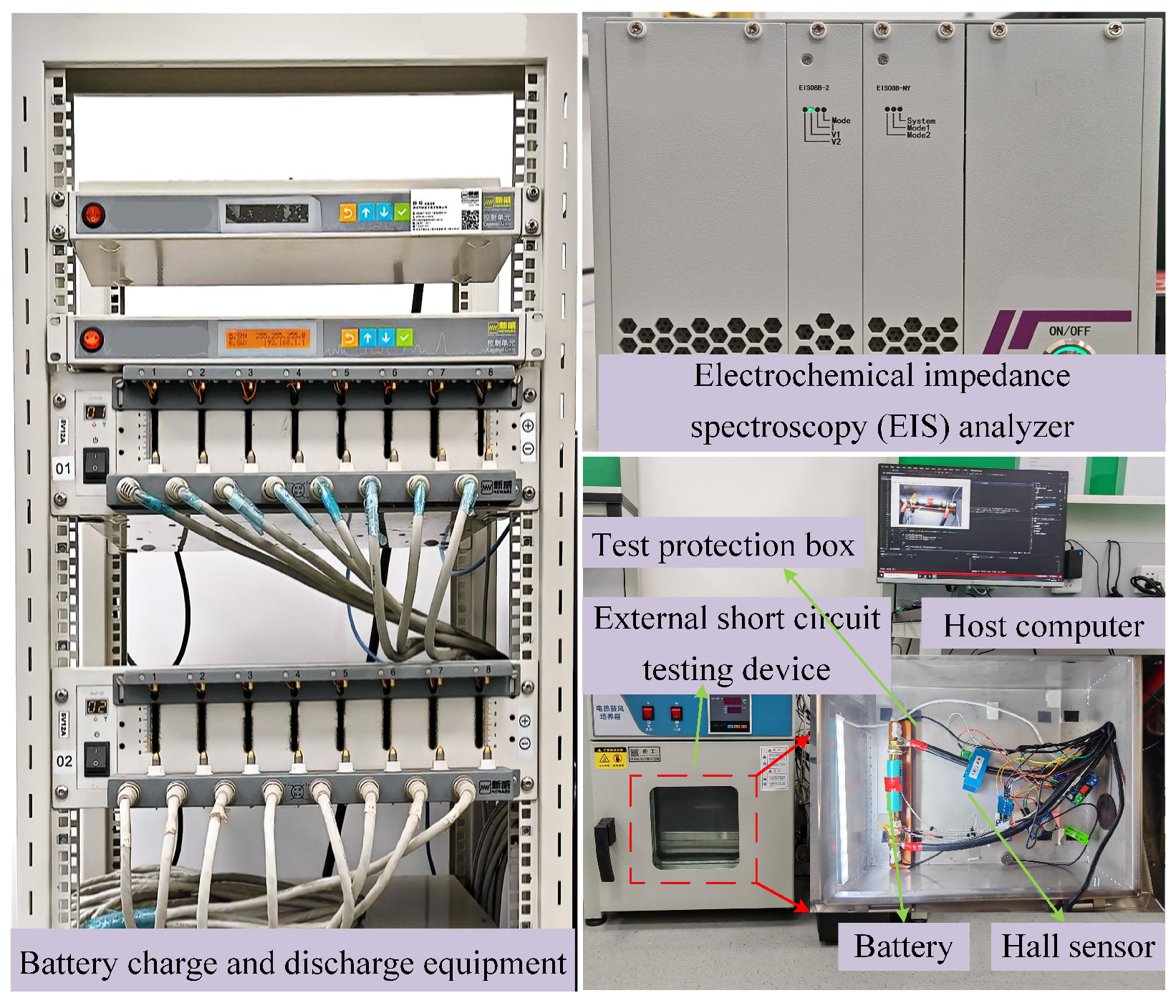

2.1. Test Platform

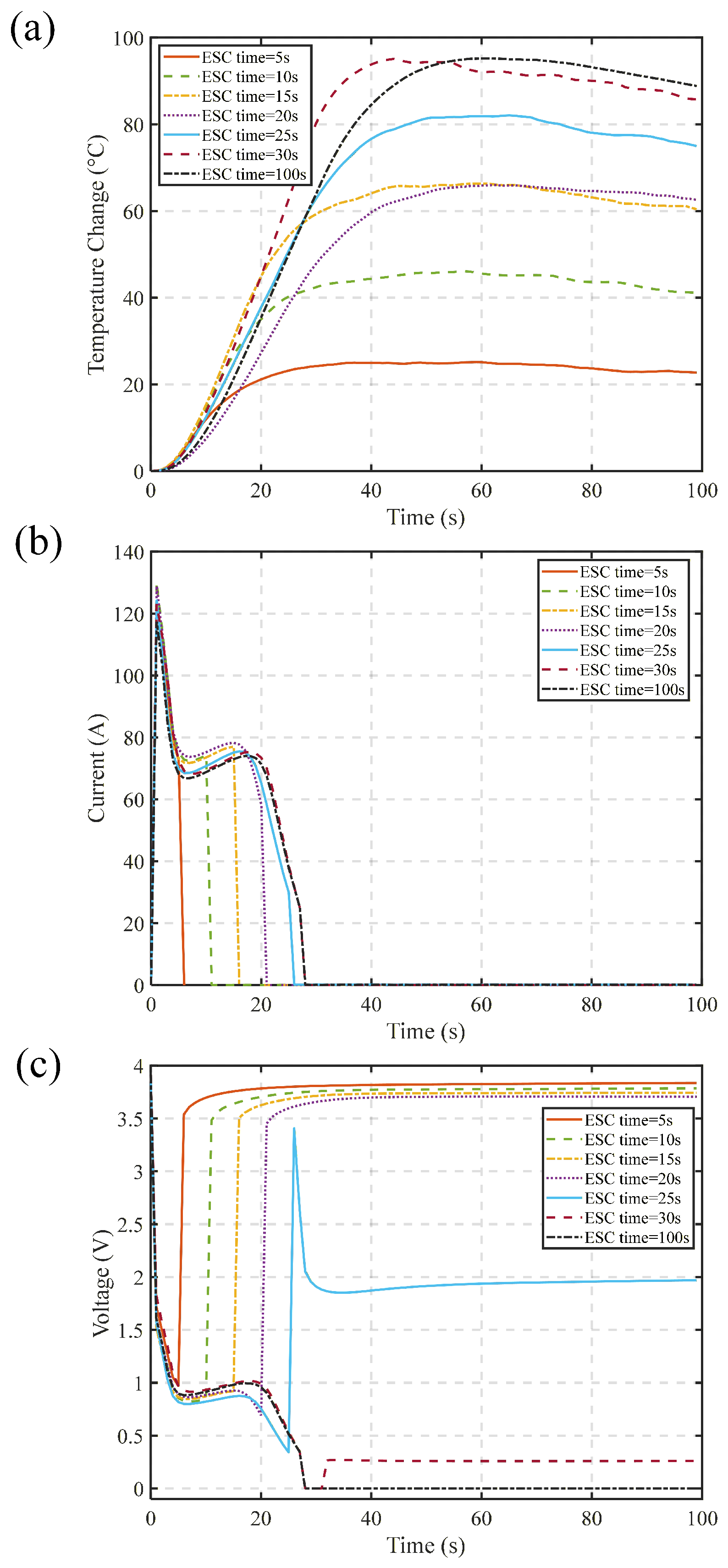

2.2. Experimental Setup

2.3. Battery Dataset

3. ESC Fault Evaluation Method Based on Distribution of Relaxation Times

3.1. Definition and Calculation Method of Relaxation Time

3.2. Feature Extraction of Relaxation Time and Fault Classification Method

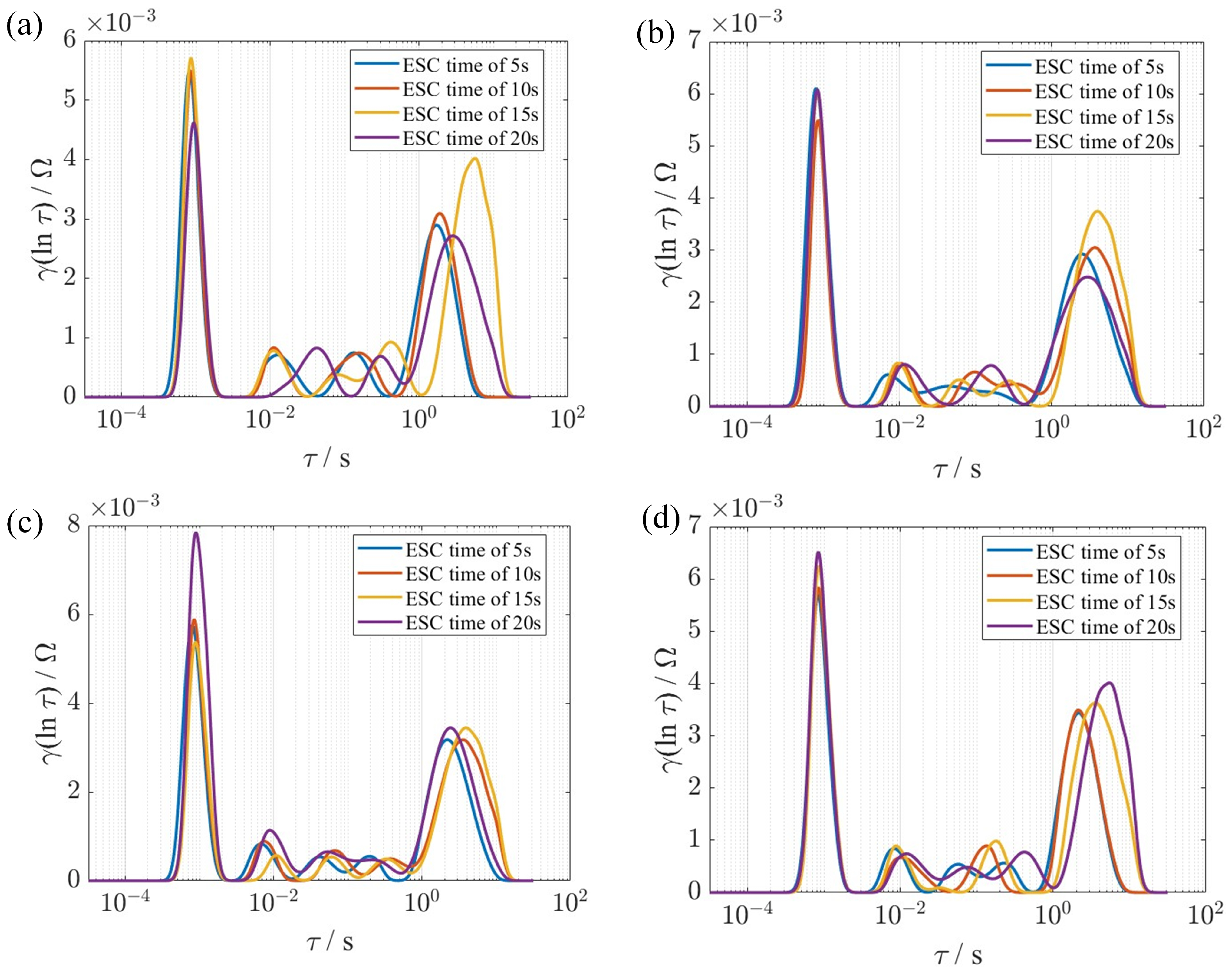

3.2.1. Construction of Difference Distribution

3.2.2. Peak Feature Extraction Method

3.2.3. Dimensionality Reduction and Clustering Analysis

4. Experimental Results Analysis

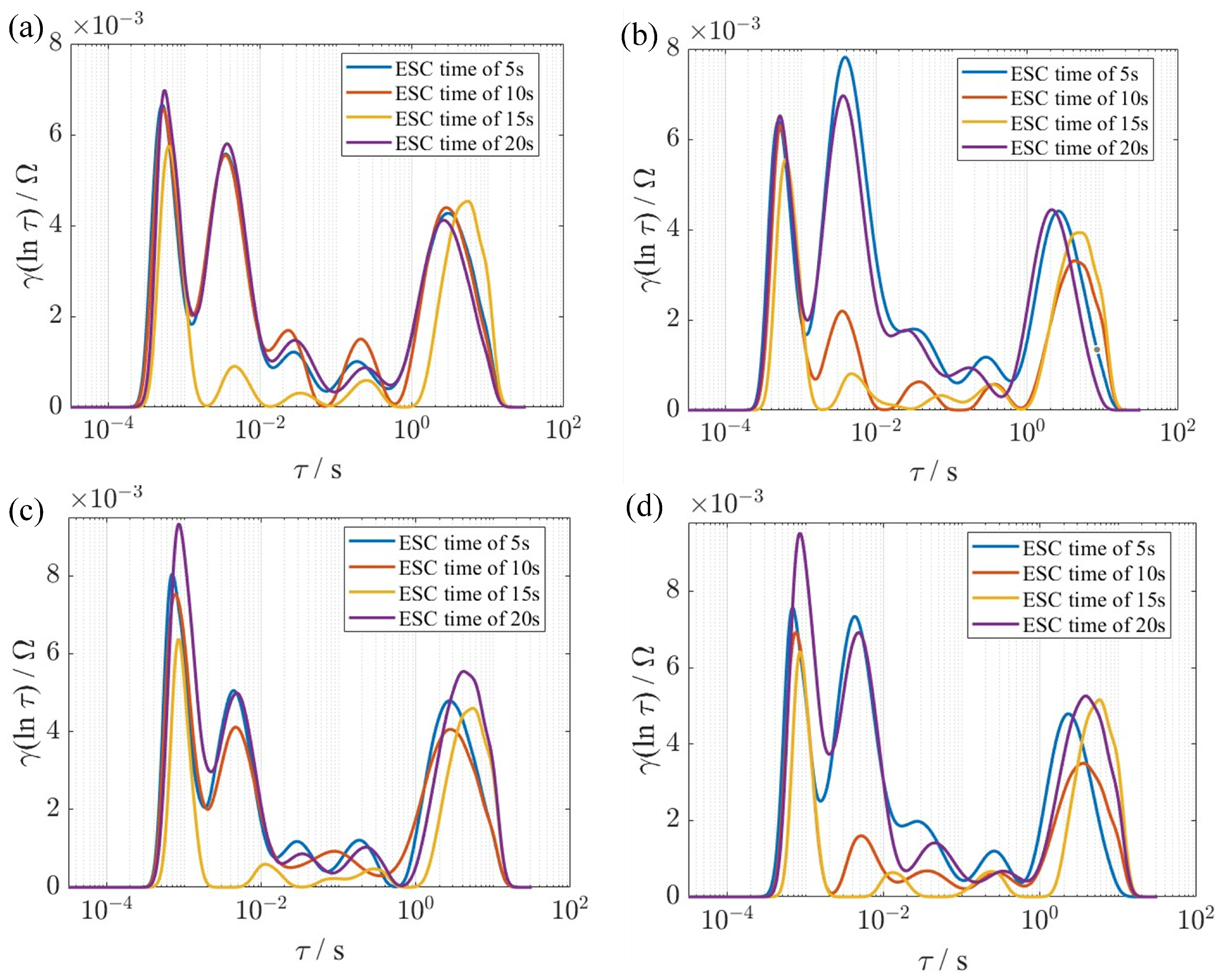

4.1. Relaxation Time Calculation Results

4.2. Clustering Results

4.3. Comparative Analysis with Other Methods

4.4. Fault Severity Evaluation Based on Optimized Feature Weighting

4.5. Fault Severity Evaluation Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yu, J.; Yao, F. Multi-Timescale Estimation of SOE and SOH for Lithium-Ion Batteries with a Fractional-Order Model and Multi-Innovation Filter Framework. Batteries 2025, 11, 372. [Google Scholar] [CrossRef]

- Wang, Y.; Xiang, H.; Soo, Y.Y.; Fan, X. Aging mechanisms, prognostics and management for lithium-ion batteries: Recent advances. Renew. Sustain. Energy Rev. 2025, 207, 114915. [Google Scholar] [CrossRef]

- Lian, Y.; Qiao, D. A Novel Capacity Estimation Method for Lithium-Ion Batteries Based on the Adam Algorithm. Batteries 2025, 11, 85. [Google Scholar] [CrossRef]

- Tran, M.K.; Fowler, M. A review of lithium-ion battery fault diagnostic algorithms: Current progress and future challenges. Algorithms 2020, 13, 62. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, G.; Gao, Y.; Wang, D.; Huang, Q.; Wang, D. Stable Li metal anode by a hybrid lithium polysulfidophosphate/polymer cross-linking film. ACS Energy Lett. 2019, 4, 1271–1278. [Google Scholar] [CrossRef]

- Adasah, S.N.; Wang, Z.; Hu, S.; Capezza, S.; Shao, J.; Chow, M.Y. Review of fault diagnosis based protection mechanisms for battery energy storage systems. In Proceedings of the 2024 IEEE 33rd International Symposium on Industrial Electronics (ISIE), Ulsan, Republic of Korea, 18–21 June 2024; pp. 1–6. [Google Scholar]

- Hu, X.; Zhang, K.; Liu, K.; Lin, X.; Dey, S.; Onori, S. Advanced fault diagnosis for lithium-ion battery systems: A review of fault mechanisms, fault features, and diagnosis procedures. IEEE Ind. Electron. Mag. 2020, 14, 65–91. [Google Scholar] [CrossRef]

- Rao, K.D.; Lakshmi Pujitha, N.N.; Rao Ranga, M.; Manaswi, C.; Dawn, S.; Ustun, T.S.; Kalam, A. Fault mitigation and diagnosis for lithium-ion batteries: A review. Front. Energy Res. 2025, 13, 1529608. [Google Scholar] [CrossRef]

- Madani, S.; Ziebert, C. Beyond limits: A brief exploration of fault detection and balancing in lithium-ion battery technology. J. Phys. Conf. Ser. 2024, 2723, 012012. [Google Scholar] [CrossRef]

- Lin, M.; Hu, D.; Meng, J.; Wu, J. Transfer learning-based lithium-ion battery state of health estimation with electrochemical impedance spectroscopy. IEEE Trans. Transp. Electrif. 2025, 11, 7910–7920. [Google Scholar] [CrossRef]

- Yang, R.; Xiong, R.; Shen, W.; Lin, X. Extreme learning machine-based thermal model for lithium-ion batteries of electric vehicles under external short circuit. Engineering 2021, 7, 395–405. [Google Scholar] [CrossRef]

- Jung, J.B.; Lim, M.G.; Kim, J.Y.; Han, B.G.; Kim, B.; Rho, D.S. Safety assessment for external short circuit of Li-ion battery in ESS application based on operation and environment factors. Energies 2022, 15, 5052. [Google Scholar] [CrossRef]

- An, Z.; Shi, T.; Zhao, Y.; Gong, Q.; Zhang, D.; Bai, J.; Du, X. Study on aging and external short circuit mechanisms of Li-ion cells with different electrode thicknesses. Appl. Energy 2023, 350, 121796. [Google Scholar] [CrossRef]

- Chen, Z.; Xiong, R.; Tian, J.; Shang, X.; Lu, J. Model-based fault diagnosis approach on external short circuit of lithium-ion battery used in electric vehicles. Appl. Energy 2016, 184, 365–374. [Google Scholar] [CrossRef]

- Ma, G.; Xu, S.; Cheng, C. Fault detection of lithium-ion battery packs with a graph-based method. J. Energy Storage 2021, 43, 103209. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, Z.; Tao, Q.; Jiao, M.; Li, P.; Zhou, N. Characterization study on external short circuit for lithium-ion battery safety management: From single cell to module. J. Energy Storage 2024, 99, 113239. [Google Scholar] [CrossRef]

- Yang, R.; Xiong, R.; Ma, S.; Lin, X. Characterization of external short circuit faults in electric vehicle Li-ion battery packs and prediction using artificial neural networks. Appl. Energy 2020, 260, 114253. [Google Scholar] [CrossRef]

- Xiong, R.; Yang, R.; Chen, Z.; Shen, W.; Sun, F. Online fault diagnosis of external short circuit for lithium-ion battery pack. IEEE Trans. Ind. Electron. 2019, 67, 1081–1091. [Google Scholar] [CrossRef]

- Zhang, Y.; Nguyen, R.T.; Liaw, B. Status and gap in rechargeable lithium battery supply chain: Importance of quantitative failure analysis. Proc. IEEE 2021, 109, 1029–1038. [Google Scholar] [CrossRef]

- Wan, T.H.; Saccoccio, M.; Chen, C.; Ciucci, F. Influence of the discretization methods on the distribution of relaxation times deconvolution: Implementing radial basis functions with DRTtools. Electrochim. Acta 2015, 184, 483–499. [Google Scholar] [CrossRef]

- Gao, Z.; Jin, Y.; Zhang, Y.; Zhang, Z.; Li, S.; Liu, J.; Wang, H. Static EIS multi-frequency feature points combined with WOA-BP neural network for Li-ion battery SOH estimation. Measurement 2025, 253, 117780. [Google Scholar] [CrossRef]

- Li, Y.; Ye, M.; Wang, Q.; Lian, G.; Kemény, M.; Xia, B.; Zhang, B. Capacity estimation of lithium-ion battery through interpretation of electrochemical impedance spectroscopy combined with machine learning. Measurement 2025, 243, 116374. [Google Scholar] [CrossRef]

- Meng, J.; Hu, D.; Lin, M.; Peng, J.; Wu, J.; Stroe, D.I. A domain-adversarial neural network for transferable lithium-ion battery state of health estimation. IEEE Trans. Transp. Electrif. 2025, 11, 7732–7742. [Google Scholar] [CrossRef]

- Lai, X.; Deng, C.; Tang, X.; Gao, F.; Han, X.; Zheng, Y. Soft clustering of retired lithium-ion batteries for the secondary utilization using Gaussian mixture model based on electrochemical impedance spectroscopy. J. Clean. Prod. 2022, 339, 130786. [Google Scholar] [CrossRef]

- Yang, B.; Wang, D.; Yu, B.; Wang, F.; Chen, S.; Sun, X.; Dong, H. Research on online passive electrochemical impedance spectroscopy and its outlook in battery management. Appl. Energy 2024, 363, 123046. [Google Scholar] [CrossRef]

- Xia, B.; Qin, Z.; Fu, H. Rapid estimation of battery state of health using partial electrochemical impedance spectra and interpretable machine learning. J. Power Sources 2024, 603, 234413. [Google Scholar] [CrossRef]

- Feng, X.; Ouyang, M.; Liu, X.; Lu, L.; Xia, Y.; He, X. Thermal runaway mechanism of lithium ion battery for electric vehicles: A review. Energy Storage Mater. 2018, 10, 246–267. [Google Scholar] [CrossRef]

- Hong, Z.; Wang, Y.; Jin, Z. Diagnosis of battery external short circuits based on an improved second-order RC fault model and recursive least squares identification method. Energy 2025, 319, 134880. [Google Scholar] [CrossRef]

- Liu, J.; Ciucci, F. The Gaussian process distribution of relaxation times: A machine learning tool for the analysis and prediction of electrochemical impedance spectroscopy data. Electrochim. Acta 2020, 331, 135316. [Google Scholar] [CrossRef]

- La Mantia, F.; Vetter, J.; Novák, P. Impedance spectroscopy on porous materials: A general model and application to graphite electrodes of lithium-ion batteries. Electrochim. Acta 2008, 53, 4109–4121. [Google Scholar] [CrossRef]

- Chowdhury, S.; Barrera, A.; Marinova, M.; Fadel, A.; Bellayer, S.; Hosdez, J.; Vandingenen, C.; Soubhie, F.; Belhache, M.; Supiot, P.; et al. Impact of external short circuit on lithium-ion batteries: A post-mortem case study. J. Mater. Chem. A 2025, 13, 18600–18609. [Google Scholar] [CrossRef]

| Method Category | Required Data | Feature Dimension | Interpretability | Advantages and Disadvantages |

|---|---|---|---|---|

| Voltage Decay Rate Method | Terminal voltage time series | Low | Low | Simple and fast; suitable for preliminary screening; limited resolution |

| Current–Time Integration (I–t) | Current time series | Low | Medium | Quantifies energy impact; ignores structural response details |

| Equivalent Circuit Parameter Variation (e.g., ) | Fitted EIS parameters | Low | Medium | Strong model dependency; less effective for non-typical faults |

| Relaxation Time Difference + Clustering (this work) | Full-frequency EIS response | High | High | No model fitting required; adaptable to complex mechanisms; superior classification performance |

| Specification Parameters | Value |

|---|---|

| Manufacturer | Yiwei Lithium (Huizhou, China) |

| Model | INR18650-20P |

| Nominal Capacity | 2000 mAh |

| Cathode Material | Li(NiCoMn)O2 (NMC) |

| Dimension | mm |

| Mass | 47 g |

| Discharge cut-off voltage | 2.5 V |

| Charge cut-off voltage | 4.2 V |

| Internal resistance | 24 mΩ |

| Algorithm | K-Means | DBSCAN | Logistic Regression | Random Forest |

|---|---|---|---|---|

| Accuracy | 1.00 | 0.50 | 0.75 | 0.75 |

| Battery | Time (s) | Severity Score | Cluster | Label |

|---|---|---|---|---|

| GroupA_Battery1 | 5 | 5.713 | 0 | Mild |

| GroupA_Battery2 | 10 | 7.139 | 0 | Mild |

| GroupA_Battery3 | 15 | 4.287 | 0 | Mild |

| GroupA_Battery4 | 20 | 9.990 | 1 | Moderate |

| GroupB_Battery1 | 5 | 0.010 | 0 | Mild |

| GroupB_Battery2 | 10 | 1.436 | 0 | Mild |

| GroupB_Battery3 | 15 | 2.861 | 0 | Mild |

| GroupB_Battery4 | 20 | 8.564 | 1 | Moderate |

| GroupC_Battery1 | 5 | 0.570 | 0 | Mild |

| GroupC_Battery2 | 10 | 3.979 | 0 | Mild |

| GroupC_Battery3 | 15 | 4.315 | 0 | Mild |

| GroupC_Battery4 | 20 | 10.000 | 1 | Moderate |

| GroupD_Battery1 | 5 | 0.000 | 0 | Mild |

| GroupD_Battery2 | 10 | 2.771 | 0 | Mild |

| GroupD_Battery3 | 15 | 7.634 | 0 | Mild |

| GroupD_Battery4 | 20 | 9.962 | 1 | Moderate |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, Z.; Gao, J.; Wang, Y. Research on External Short Circuit Fault Evaluation Method for Li-Ion Batteries Based on Impedance Spectrum Feature Extraction. Batteries 2025, 11, 437. https://doi.org/10.3390/batteries11120437

Hong Z, Gao J, Wang Y. Research on External Short Circuit Fault Evaluation Method for Li-Ion Batteries Based on Impedance Spectrum Feature Extraction. Batteries. 2025; 11(12):437. https://doi.org/10.3390/batteries11120437

Chicago/Turabian StyleHong, Zhongshen, Jinyuan Gao, and Yujie Wang. 2025. "Research on External Short Circuit Fault Evaluation Method for Li-Ion Batteries Based on Impedance Spectrum Feature Extraction" Batteries 11, no. 12: 437. https://doi.org/10.3390/batteries11120437

APA StyleHong, Z., Gao, J., & Wang, Y. (2025). Research on External Short Circuit Fault Evaluation Method for Li-Ion Batteries Based on Impedance Spectrum Feature Extraction. Batteries, 11(12), 437. https://doi.org/10.3390/batteries11120437