1. Introduction

The development of batteries, especially their prolonged lifetime, increased capacity and high current charge/discharge abilities has accelerated the use of battery applications in many electronic and mechatronic devices. In the last decades, battery applications have been applied to areas of telecommunication devices, electric drives for electric and hybrid cars, as well as space probes. Battery management systems (BMS) [

1,

2,

3,

4] have played a crucial role in the safe and sound use of battery applications by (1) preventing the overcharging and overdischarging of batteries, (2) as well as monitoring and informing users regarding the state of the charge (SOC) and state of the health (SOH) of the battery cells. The two battery characteristics, i.e., the SOC and SOH, have been rigorously studied recently. The following methods are currently among the state-of-the-art for their determination and estimation:

Direct measurement methods. These are as follows: the ampere-hour integral SOC estimation [

5,

6], open circuit voltage method, internal resistant method, electrochemical impedance spectroscopy, load voltage method, discharge test method, etc.

Estimation method based on the black box battery model. Typical applications here involve machine learning (ML) methods, such as artificial neural networks (ANNs), support vector machines, genetic algorithms (GA), particle swarm optimization algorithms, fuzzy algorithms, deep learning methods, etc., to obtain the battery model from a large amount of input data for SOC estimation [

7].

Estimation method based on the state-space battery cell model. The original and adaptive Kalman filter (KF) versions are frequently found, such as extended KF [

8], dual KF [

9], unscented KF [

10], adaptive KF [

11], sigma-point KF [

12]. Also, particle filters have been utilized in the past to adapt the model parameters due to battery cell temperature fluctuations and measurement noises [

13].

Direct measurement methods do not require any modeling, as all necessary data are acquired through physical measurement. Some of these methods are invasive and irreversible, potentially causing permanent damage to the battery cell, while others are non-harmful. Black box battery models, based on statistical learning, are powerful and effective but traditionally require large amounts of data. These methods can also pose significant resource challenges when run on embedded hardware. In contrast, state-space battery cell models typically demand fewer resources. It is important to note that both black box and state-space battery models require some degree of measurement to run and monitor the surrogate model. Surrogate model-based methods are indirect; they need to be evaluated to estimate the SOC, unlike direct measurement methods, which provide the SOC directly. The following battery cell models are well-known among practitioners [

7]:

Electrochemical mechanism models (pseudo-two-dimensional models [

14] and its simplified models, single-particle models [

15], and the newest model, the most accurate model, the full homogenized macroscale model [

16]).

Equivalent circuit models (Rint model [

17], RC model [

17], Thevenin model [

5,

17], PNGV model [

17], dual polarisation model [

17], enhanced self-correcting model (ECM) [

17,

18], etc.).

Data-driven models which mainly include neural network models, autoregressive models, and support vector machine models [

7].

Despite their very high accuracy, electrochemical mechanism models have not been widely used in engineering applications for two main reasons: (1) the high complexity of the non-linear system with partial differential equations that lack analytical solutions, requiring significant computational power for numerical solutions, and (2) poor adaptability to certain working conditions. Equivalent circuit models have gained popularity for SOC engineering applications over the past decade due to their simple structure and parameter adaptability, despite their questionable accuracy and inability to reflect the internal characteristics of the battery cell. The popularity of data-driven models is rising, but they still require a large amount of input data to learn the battery cell model and achieve at least moderate accuracy.

Coulomb counting (CC) [

17,

19] is a widely used method for estimating the state of charge (SOC) of batteries due to its simplicity. It is reliable, but susceptible to integrator drift over time and variations in charging efficiency. The problem of integrator drift is traditionally addressed by frequent recalibrations at the battery’s maximum or minimum voltage when fully charged or discharged. However, such an approach is not always feasible as batteries may run without achieving these two extremes. Another problem of the CC is the charging efficiency. Namely, when charging, excessive heat may generated which can cause less than 100 percent of the charging energy to be stored into the battery. The enhanced Coulomb counting (ECC) method addresses this problem by introducing a parameter known as charging efficiency, denoted by

. The ECC will be used in the continuation of the study.

The Thevenin model is the most commonly employed ECM [

20]. However, the Thevenin model is unable to address the nature of cell hysteresis due to the effects of charging and discharging. Hence, new versions of models like the Equivalent Circuit Model (ECM) emerged, with the Enhanced Self-Correcting (ESC) model being one of the most widely used ECMs today. Typically, two parallel pairs of RC circuits (2RC) are utilized rather than one pair (1RC), to capture the rapid and complex cell dynamics better. Identifying the ESC parameters is called parameterization. To identify these parameters, the battery cell (or group of cells) needs to undergo a specific experimental test with numerous consecutive charging and discharging periods. This activates both the static and dynamic nature of the battery, varying its Open Circuit Voltage (OCV). The measured time lags in OCV can then be used to estimate the RC parameters. Knox et al. [

20] compared several test profile identification methods. The more well-known non-invasive methods include the Galvanostatic Intermittent Titration Technique (GITT), Hybrid Pulse Power Characterization (HPPC), and Electrochemical Impedance Spectroscopy (EIS). In GITT, the cell undergoes a profile of short current pulses followed by relaxation periods [

21]. Temperature, voltage, and current are monitored, and their dynamics are used for the parameterization of the ESC model. The most fundamental method of parameter identification is the non-linear least-square curve fitting method, where a higher-order polynomial is fitted. Customized test profiles are frequently practiced among researchers. A more coherent method is the Iterative Parameter Identification Algorithm (IPIA) [

20]. Often, fitting is conducted using metaheuristic methods, where the penalty function is set as the squared deviation between actual and ESC-predicted voltage. HPPC involves monitoring the ratio of voltage drop to the current load applied,

, and deriving ohmic parameters from voltage drops. EIS, on the other hand, is a frequency-based identification method, rather than a time-based one like GITT and HPPC, making it somewhat more complex [

22].

The Linear Kalman Filter (LKF) is another computation method for estimating the SOC, although its linear nature imposes several drawbacks. Practice shows that extreme values of SOC, i.e., below 10% and above 90%, are often difficult to estimate due to the very nonlinear nature of the cell (except 100%, which is called a maximum end voltage and is hence utilized for calibration purposes). This is because basic LKF is suitable only for linear systems with white and Gaussian noises, which is clearly not the case for the highly non-linear ESC model of a battery cell. The Extended Kalman Filter (EKF) corrects the cell nonlinearities to some degree by performing linearizations. Hence, EKFs are more suitable for such problems, contributing to their popularity among researchers [

18,

23]. A sample of these includes [

24,

25,

26]. A drawback of the EKF is sometimes a burdensome convergence of the learning algorithm, as stated in He et al. [

27]. As a result, various hybridizations of EKF emerged, such as adapting the battery parameters or covariance matrices. Yun et al. presented the idea of adapting the battery parameters in [

28]. The authors adapted the battery’s internal resistance as well as the parameters of RC elements. Underlying various simulations have shown more accurate estimations compared to the classic EKF. Zhang et al. [

29] implemented an adaptive EKF named AEKF, in which they adapted the measurement noise covariance and error covariance matrices. The authors reported that the estimation accuracy was better than using the classical EKF. Alternatively, ref. [

30] implemented a hierarchical adaptive EKF, i.e., the HAEKF, where they split the state-space equation into two different submodels with two different sampling rates. One of these was intended to capture the lower dynamics, the other the faster dynamics. Experiments have shown greater reliability of such a method compared to the classic EKF.

The Sigma Point Kalman Filter (SPKF) [

31] and Particle Filter (PF) [

32] are other examples of a KF for estimating the SOC, even more advanced than the EKF. Furthermore, the SPKF can be easily adapted to enhance its performance below the SOC of 10% by including an H infinity filter [

5]. This may be an accurate method. Authors in [

16] compared the accuracies of two electrochemical mechanism models, i.e., the Doyle–Fuller–Newman model (DFN) and the full homogenized macroscale model (FHM). Parameters of both the models were obtained using particle swarm optimization (PSO), where 18 variables per model were involved. The FHM was shown to overcome the limitations of the DFN regarding the prediction of voltage responses at high temperatures. Another example of combining the PSO with the PF was published by Pang et al. [

33].

The recursive least squares (RLS) is another example of a battery parameter estimator. It is a type of adaptive filter that rests on a weighted least squares regression method. Initially, the covariance matrix is initialized to a high value, and identified parameters are equal to 0. The forgetting factor is introduced, where values close to 1 represent a focus on the new data points, and values close to 0 focus on the old data points. As the RLS recursively runs each time step, the identified parameters adapt in the way that the cost function, which represents the error between actual and predicted values, minimizes.

Ren et al. [

34] show an application of the RLS for parameter identification of the lithium-ion battery. Authors argue that as the battery parameters are continuously adapted, the predicted value of a terminal voltage continuously approaches its true value. Liu et al. [

35] employ a variable and adaptable window size within which the battery parameters are identified. The authors argue that too many data points too far away in the past may cause data saturation, which can act negatively on the correctness of identified parameters. Interestingly, they use RLS only for online parameter identification, while for estimating the SOC, they employ an unscented Kalman filter that runs in parallel. Ge et al. [

36] employ an adaptation of the forgetting factor. They argue that the so-called improved forgetting factor RLS makes the parameter identification less prone to jitter and divergence under complex conditions. Li et al. [

37] employed an RLS parameter identification under strong electromagnetic interference. Both the SOC and SOH were co-estimated using the UKF, here the SOH has been expressed as a ratio between estimated and rated capacities.

Recent trends within the state-of-the-art methodologies in the field include machine learning and deep learning approaches towards both the SOC and SOH predictions. Chen et al. [

38] proposed the self-attention long short-term memory (LSTM-SA) for reliable and robust SOC estimations on different current profiles, temperatures and aging levels. Empirical experiments have shown clear LSTM-SA convergence to the unbiased estimate of the SOC with average errors within 2%. Li et al. [

39] implemented a digital twin involving the LSTM and the convolutional neural network (CNN) for predicting the SOH. Predicted capacity errors of less than 3 mAh were observed. Reza et al. [

40] implemented a hybrid LSTM where its hyperparameters are optimized using the lightning search algorithm (LSA). The authors argued that the hybrid LSTM-LSA outperformed the standard LSTM on the problem of remaining useful life (RUL) prediction. Dineva [

41] and Madani et al. [

42] published a thorough review of deep learning approaches toward reliable SOH predictions.

Our inspiration for this work was the ESC model, parameterized on an experimental training cycle, and utilizing the metaheuristic nature-inspired optimization algorithm (in our case, GA). The novelties of the paper are as follows:

In the first proposed framework, a self-correcting feedback loop with an adaptable gain is proposed to obtain an unbiased estimate of the SOC. Initially, a biased initial condition of SOC0 is input externally, which then gradually with time converges to an unbiased estimate.

The second proposed framework does not utilize a feedback loop as a first framework to realize the initial condition of SOC0 but rather estimates it as an additional GA dimension. The dimensionality of the GA problem thus increases from 9 to 10 independent variables.

The adaptation of mutation probability (mutation rate ) is implemented. An average fitness performance is measured for the last generations and if no significant improvements are realized, the mutation probability is increased for the . If no further improvements are realized the mutation probability is increased further, each time by .

The proposed ESC model is realized in practice in less time than the classic ESC, as knowing the initial condition of SOC0 is not needed. This means that the operator does not have to run experimental tests to find one. Also, due to the existence of the feedback loop, the ESC performs in a more reliable way. Even if the initially set SOC0 is not correct and the bias exists, such bias is decreased automatically over time.

The structure of the paper is as follows: First, the materials and methods, including all three proposed techniques are presented. Next, the experiments and results follow. A reader may find practical evidence regarding the visual and statistical analyses of the results. Finally, the discussion is supplied.

2. Materials and Methods

Lithium Titanate Oxide cell (LTO) batteries are a type of battery with low self-discharge characteristics, high energy density, and relatively opportunistic recycling options [

43]. The LTO is a graphite-free cell with anode chemistry formulae

(titanate oxide nanocrystals). Lithium salt

dissolved in an organic solvent acts as an electrolyte. Their working principle lies in a cathode full of lithium ions which are moved through the electrolyte to a titanate anode [

44]. Charging the battery is called oxidation, and discharging reduction (lithiation of titanate oxide) [

44]. Both the charging and discharging form a so-called redox cycle, with voltage (or SOC) slightly changing between minimal, nominal and fully charged. The OCV varies with respect to the SOC [

1], the higher the SOC, the higher the OCV, and vice versa. Experiments and testings in this paper were executed utilizing the LTOs, with specification tag LTO1865-13, purchased from the company GWL a. s., Prague, Czech Republic. Crucial parameters of the LTO battery are presented in

Table 1.

The proposed work was based on three distinctive tasks (yellow, blue, and red), as outlined in

Figure 1. The first task involved the identification of the battery cell, as suggested by [

1]. Two different identification procedures were conducted: static and dynamic identifications, both represented by yellow rectangles. The OCV-SOC relationship was recorded as a static battery relationship, implying that the identification experiments of charging and discharging were carried out at a very low reference current rate, typically

or below [

1]. The motivation for keeping the current that low was to avoid exciting dynamic elements within the battery. Next, the dynamic identification of the battery cell followed. This included rapid current changes while monitoring the transient phenomena. Extensive and durable battery tests and measurements were conducted for this first task. Following this, the training (or tuning) of the ESC model was performed. The objective of ESC tuning was to seek and find the optimal ESC parameters. Frequently, this was conducted using an optimization algorithm; we chose the Genetic Algorithm (GA). Here, three different frameworks of the ESC model were proposed and implemented, all utilizing the GA. These were named GA-ESC, GA-ESC+FB, and GA-(ESC+SOC0), where FB stood for feedback. Finally, laboratory experiments and testing were conducted to check the validity of the frameworks.

2.1. Static OCV Relationship of the Battery Cell

The identification of a static relationship OCV-SOC was conducted in a controllable test temperature chamber. The process was executed as suggested in [

1]. First, the battery cell was placed at the ambient temperature of

and was fully charged. Next, the OCV-SOC nonlinear characteristics were recorded at discharging reference rate

until the battery was fully discharged. The ambient temperature was then increased by

and the process was repeated. We continued this process until the ambient temperature reached

(see Algorithm 1). Here,

represents reference (desired) current.

Figure 2 depicts how the battery was connected to the testing platform.

| Algorithm 1 SOC-OCV Recording with Temperature Variation |

- 1:

Initialize empty lists and monitor each time step: , , 0 - 2:

Set initial temperature: - 3:

Set temperature increment: - 4:

Set maximal ambient temperature - 5:

Start of SOC-OCV recording - 6:

while

do - 7:

Set and record temperature - 8:

Relax for 2 h ▹ Remark: Relaxing the battery means A. - 9:

Discharge at for 10 min - 10:

Charge at till then relax for 2 h - 11:

Discharge at till then relax for 2 h - 12:

Charge at for 10 min - 13:

Discharge at till then relax for 2 h - 14:

Charge at till - 15:

Record corresponding SOC and OCV values at all times - 16:

Increase temperature: - 17:

end while - 18:

End of SOC-OCV recording - 19:

Output: , ,

|

The following OCV relationship was established [

1] as shown in the following Equation (

1):

where

k represents the time sample and the

is a temperature correction factor of

[

1]. Essentially, this equation calculates the OCV0 for a given SOC and corrects it for the underlying temperature (so that the calculation is valid for any underlying temperature).

2.2. Dynamic Relationship of the Battery

The dynamic relationship of the battery focuses on realizing the dynamics of the battery when undergoing abrupt and rapid changes in load.

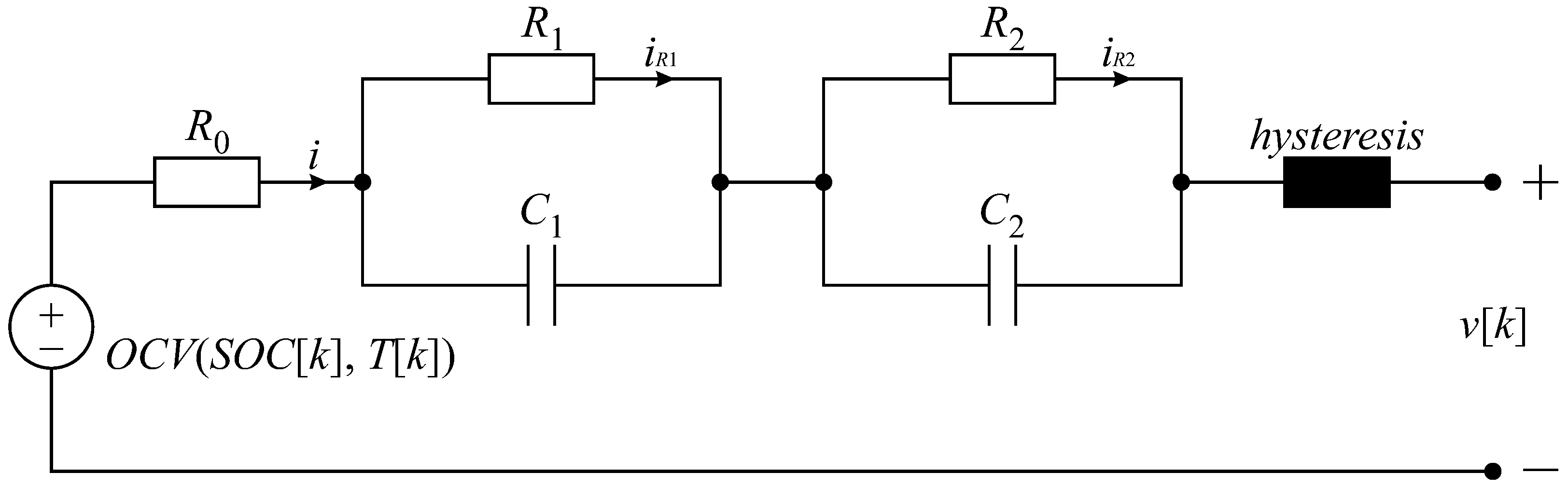

Figure 3 shows an equivalent RC circuit of the battery. The static relationship considers the voltage generator

and the resistor

. The dynamic relationship considers the

n-th parallel pairs of the RC elements and a hysteresis element [

1]. The equivalent series resistance

represents the voltage drop if the battery is being discharged and the voltage rise if the battery is being charged. The

n-th RC parallel elements, which are wired in series, represent diffusion voltages that correspond to transient responses. Each RC element incorporates its time constant by capacitor

being discharged through resistor

. A hysteresis element (black box in

Figure 3) symbolizes the terminal voltage difference, depending on whether the battery has been recently charged or discharged. Several different types of battery hysteresis exist, among others voltage hysteresis, due to first-order phase transitions and kinetic pathways [

45], battery resistance hysteresis due to aging [

46], and temperature-dependent hysteresis due to ambient temperature

[

47]. Plett et al. [

1] in the classic ESC model consider the voltage hysteresis only in two different types, i.e., the SOC-varying hysteresis

and instantaneous hysteresis

. The first type describes changes in hysteresis with respect to the SOC, while the second type describes voltage jumps at a constant SOC if the direction of current flow changes. Two additional dimensionless parameters to be tuned were supplied here, i.e.,

M and

, where the final hysteresis voltage, denoted as

in

Figure 3, is calculated as their sum.

2.3. Synthesis of the ESC Model

The ECC model is defined as follows in Equation (

2) [

1]:

where

represents the total capacity,

the time sample,

the Coulombic (charge) efficiency,

the current in given

k-th time step. The direction of the current

can be either positive or negative, where positive current represents discharging and negative current represents charging the battery cell [

1].

Let the

represent the rate factor of the

j-th RC circuit as

, where

, and let the

represent the current vector of currents flowing through each RC element. Let the

be a current (scalar quantity) flowing through the

. Then, a forthcoming state of the current vector

can be predicted as follows:

where

and

represent a diagonal matrix of rate factors and a vector of elements

, respectively.

Let the

represent the dynamic behavior of the battery. Then, the dynamic hysteresis voltage

is calculated as follows (Equation (

3)):

and the instantaneous hysteresis voltage

is calculated as follows (Equation (

4)):

The overall hysteresis voltage

is defined as (Equation (

5)):

Finally, a vector of forthcoming

,

j-th RC element current

and dynamic hysteresis voltage

can be defined in the form of a state-space equation, as follows [

1]:

Here, the

,

a is a vector of

n-sized zeros

, and

. Then, the estimated voltage

from a Vbatt block (see

Figure 4,

Figure 5 and

Figure 6) as a third task can be calculated as follows [

1]. Finally, the predicted voltage equation can be calculated as follows, see Equation (

7),

where the

resembles the predicted voltage which is compared with the actual voltage

and the deviation between the two can be calculated

. The term

includes the temperature correction.

2.3.1. ECC: Enhanced Coulomb Counting Method to Estimate the SOC

The ECC method is the simplest method for estimating the SOC (Equation (

2)). SOC estimation using ECC is quite accurate under certain conditions [

16,

17,

19]: (1) the parameter coulomb efficiency

of the ECC model must exactly match the real battery parameter, (2) the initial SOC must be known, (3) frequent recalibrations at SOCs of either 100 or 0% must be performed, and (4) the measurement of

must be very accurate with noise filtered. Such conditions can typically be maintained for a short time only, i.e., the first few discharging/charging cycles, due to the expected drift induced by integrating the current. However, its simplicity makes it a very suitable benchmark method.

2.3.2. EKF: Extended Kalman Filter Based on the ESC, Initial SOC0 Is Known

The implemented EKF is based on the underlying ESC model in state space. The benefit of the EKF compared to the ESC is that the EKF is capable of filtering process and sensor noises, which either come from measurement noise or sporadic disturbances. The EKF procedure is divided into six steps, which Plett et al. [

18] further divide into (step 1a) state-prediction time update

, (step 1b) error-covariance time update

, (step 1c) predicting system output

, (step 2a) calculating estimator gain matrix

, (step 2b) state-estimate measurement update

, and finally (step 2c) error-covariance measurement update

. Four non-measurable states are estimated as follows: 2RC-pair currents, dynamic hysteresis voltage, and SOC, i.e.,

(as shown in

Figure 1). The state-space model is in the discrete form defined as (see Equation (

8)):

where four matrices, i.e., the

,

,

, and

, are defined as follows (see Equation (

9)):

where

where

represents the index of hysteresis within the estimated state-space vector

, i.e.,

if indexing starts with 0 or

if indexing starts with 1. Additionally, the

term is approximated by real measurement data from the SOC-OCV curve as an interpolated derivative of the OCV at a given SOC point [

1].

The Kalman estimator gain is calculated as

where

represents the estimated variance of sensor noise, and residual (estimation error) is calculated as

. A six-step Kalman procedure is implemented as listed in Algorithm 2.

| Algorithm 2 Extended Kalman Filter with an underlying ESC model [1] |

- 1:

Initialize empty matrices: - 2:

for n do - 3:

(A-priori estimate) State-prediction time update and update - 4:

(A-priori estimate) Error-covariance time update - 5:

Predict system output - 6:

Calculate and Kalman gain - 7:

(A-posteriori estimate) State-estimate measurement update - 8:

(A-posteriori estimate) Error-covariance measurement update - 9:

end for

|

2.3.3. GA-ESC: Initial SOC0 Is Known, ESC Parameters Determined by GA

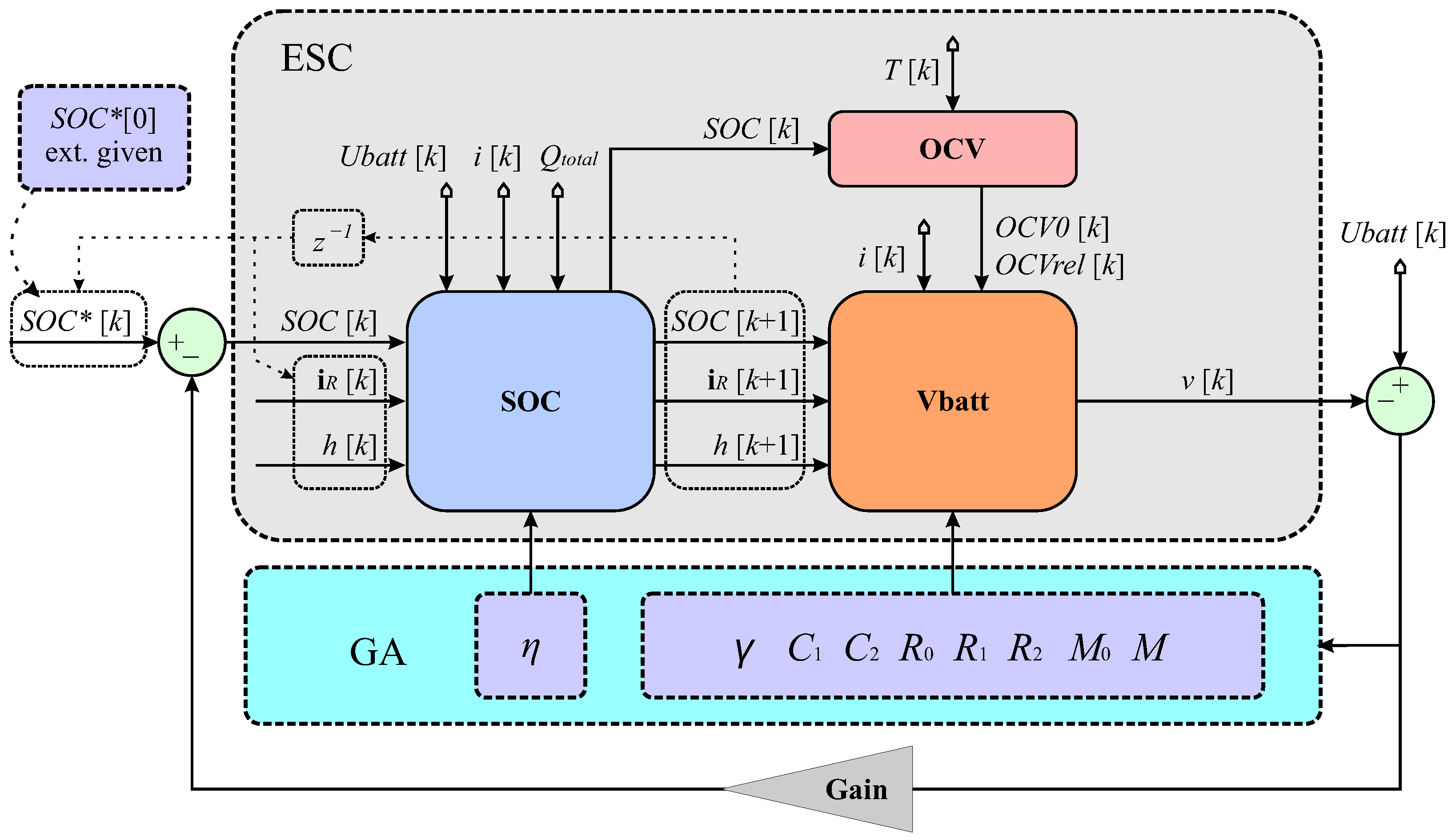

The GA-ESC framework, depicted in

Figure 4, utilizes a classical ESC model, of which parameters (in cyan color in

Figure 4) are tuned using the GA as trial solutions. An underlying experimental training cycle is recorded, involving voltages, currents and temperatures. The objective of the ESC model is to predict actual voltage, denoted as

, given the state vector

,

, and

. The objective of GA is to tune the ESC parameters such that the mean squared error between the predicted voltage

and actual voltage

is minimized for the complete experimental training cycle.

The initial SOC0 is externally given, as the classical ESC is unable to determine it. The initial SOC needs to be measured. The blue-colored “SOC” block represents the calculation of the predicted forthcoming state of the , , and from current , , and . Predicted forthcoming states are input into the orange-colored “Vbatt” block which calculates predicted voltage . Predicted voltage is compared to the and the difference between the two is an indicator of fitness of a trial solution (the fittest trial solution is being searched for). As mentioned, the GA-ESC is unable to determine the initial condition SOC0, still it is involved here as an individual framework as a benchmark.

2.3.4. GA-ESC+FB: Initial SOC0 Set to Arbitrary Value and Corrected by FB, ESC Parameters Determined by GA

The GA-ESC+FB framework utilizes a modified ESC model with an additional feedback loop and parameter. The GA-ESC+FB tuning of ESC parameters is similar to the GA-ESC. A set of trial solutions is given to the ESC and the mean squared error using these ESC parameters on the underlying experimental training cycle is calculated. The lower the mean squared error, the better the fitness.

Again, the initial SOC0 (denoted as

in

Figure 5) is given externally. However, this time the initial SOC0 can be externally given as an arbitrary number between 0% and 100%. There is no need to measure it, which is the benefit of using GA-ESC+FB compared to the GA-ESC. The feedback loop with the variable

parameter then acts as a correction mechanism to correct the error between uncorrected

and actual

as follows. If

overreads the

, the error

becomes negative and the

is reduced. If

underreads the

, the error

becomes positive and the

is increased. Such correction does not take place in a single step, but rather gradually with time (we expect that the largest error will be at the beginning). The adaptation of the

parameter controls allowed corrections. The equation that follows represents the feedback loop mechanism numerically.

The advantage of GA-ESC+FB lies in the constant self-correcting action. While the GA is run once only to determine the proper ESC parameters during the GA training period, the FB mechanism is run constantly during the testing period (and also during the remaining life cycle of the battery cell) as well. Still, the FB is not able to compensate for diminishing SOH due to aging. To address the aging of the battery cell, new ESC model parameters should be recalculated recurrently every now and then (based on the underlying time period).

2.3.5. GA-(ESC+SOC0): ESC Parameter and Initial SOC0 Both Determined by GA

The GA-(ESC+SOC0) is similar to the GA-ESC method. The main difference between the two is that besides seeking the optimal ESC model parameters it seeks the initial condition of SOC0 as well. Practically this means that the dimension of the problem is incremented by +1.

Figure 6 exhibits the GA-(ESC+SOC0) method.

GA-(ESC+SOC0) is a simple yet effective hack of the fundamental GA-ESC. Instead of realizing the initial condition SOC0 by hand, it is being found automatically during the ESC model parameters searching.

4. Discussion

Three different underlying designs for predicting the state-of-charge given its uncertain initial conditions were implemented and tested. The simplest of all was the direct method called enhanced Coulomb counter which was only able to predict SOC without estimating the state space vector. Two other designs, the extended Kalman filter and enhanced self-correcting mechanism, optimized by a genetic algorithm, estimated the state space vector too. Given appropriate settings, both of these designs should have ensured unbiased estimates of the state of charge of a lithium-ion battery cell.

The enhanced Coulomb counter functioned as expected. In the short term, it was seen as a reliable indicator. In the long term, integral drift with respect to time prevented it from making unbiased estimates. Soon after the last recalibration at a state-of-charge equal to 100%, it began predicting a negative state-of-charge. The extended Kalman filter performed with more stability. Minimal bias, possibly an offset, was spotted in the long term and caused the Kalman filter to overread the actual state-of-charge by approximately four percentage points. Further analysis would be necessary to determine the exact cause.

One of the proposed frameworks, i.e., the enhanced self-correction model with a feedback loop, seemed the best option. The variable of the feedback loop tends to control the convergence rate to the unbiased estimate of state-of-charge. Some experiments were necessary to properly determine the parameter, if set to high it may have caused instabilities; if set to low, the convergence rate was slow. This framework functioned well even if an arbitrary value of the state-of-charge initial condition was input. The other two alternatives of the enhanced self-correcting model without the feedback loop needed prior knowledge of the state-of-charge initial condition.

In the future, it would be crucial to address the changing battery parameters due to aging. Keeping the identified model constant may induce bias in state-of-charge predictions. Battery parameters are not obliged to be updated continuously, as there is no need for this, but they should be updated every now and then at underlying update times. These update times may be either (1) fixed, for example, after five discharging/charging cycles, or (2) adaptive after the battery cell was misused due to over-charging/-discharging or discharging with too high currents, etc. A time window with all the necessary data needs to be recorded and a “silent” genetic algorithm execution, where in each time step only a single generation is executed (or even less) to prevent non-real-time microcontroller behavior, would need to be implemented.