Abstract

In the literature, the hierarchy of value retention strategies (R-strategies) is utilized to describe the impacts on various circular economy (CE) factors. However, this approach is not suitable for batteries, such as the vanadium flow battery (VFB), due to its technical complexity. The presented model primarily focuses on VFBs, as a deep technical understanding is identified as a fundamental prerequisite for a comprehensive CE analysis. Based on the R-strategies, a new model called the dynamic multi-dimensional value retention strategy model (DDS) is developed accordingly. The DDS divides the R-strategies into three dimensions, as changes in the studied object each have a unilateral influence on the underlying dimensions. In addition, interactions among the R-strategies within the dimensions are observed. Moreover, the model enables the transparent and comprehensible examination of various CE objective factors. Through the model, future adjustments to CE for batteries can be analyzed and quantified. In particular, the analysis yields new insights into individual end-of-life (EoL) strategies, based on new findings regarding the VFB. Consequently, important new perspectives on the VFB are also illuminated. The DDS model is applicable to other complex technologies as well as simple product systems.

1. Introduction

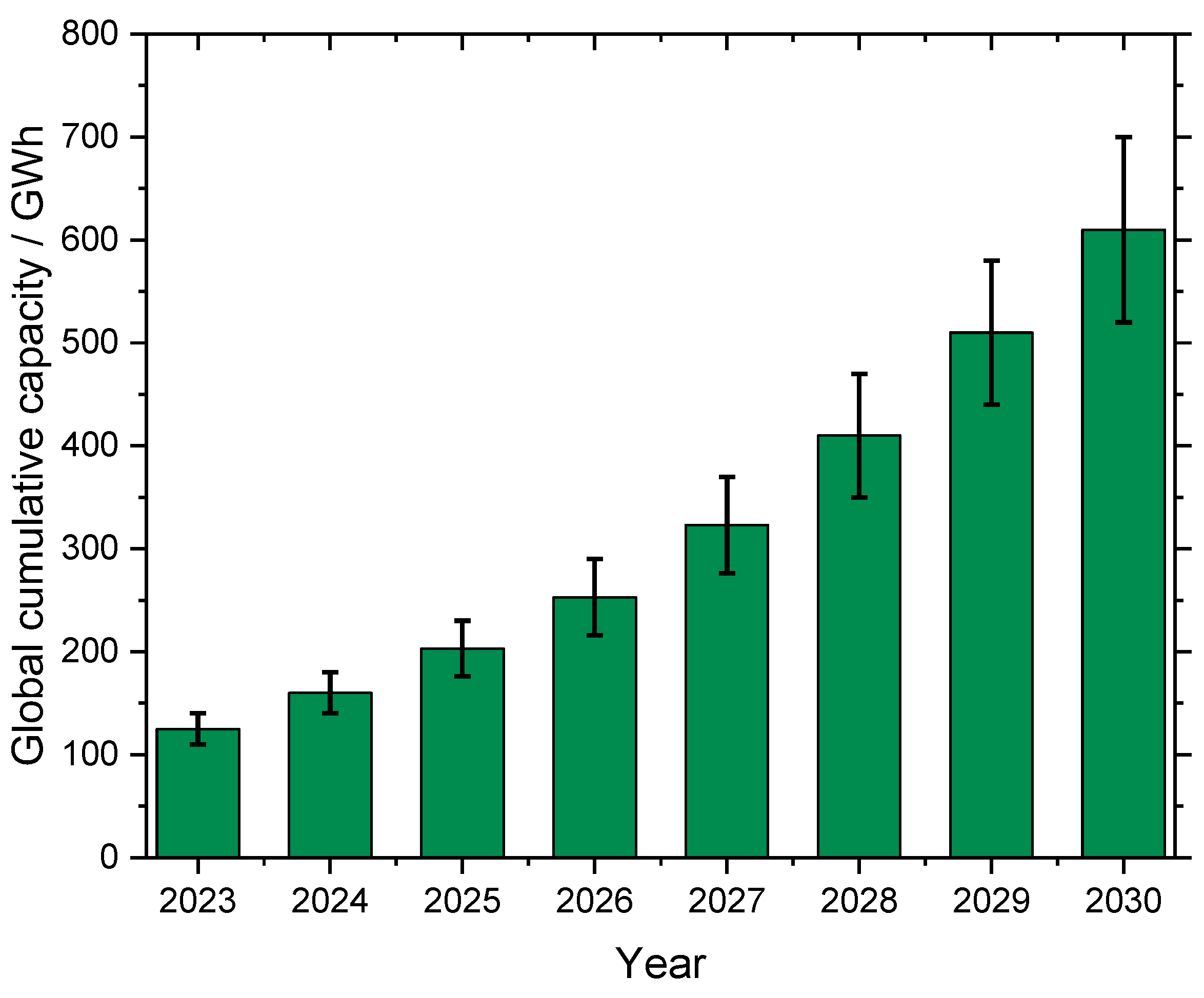

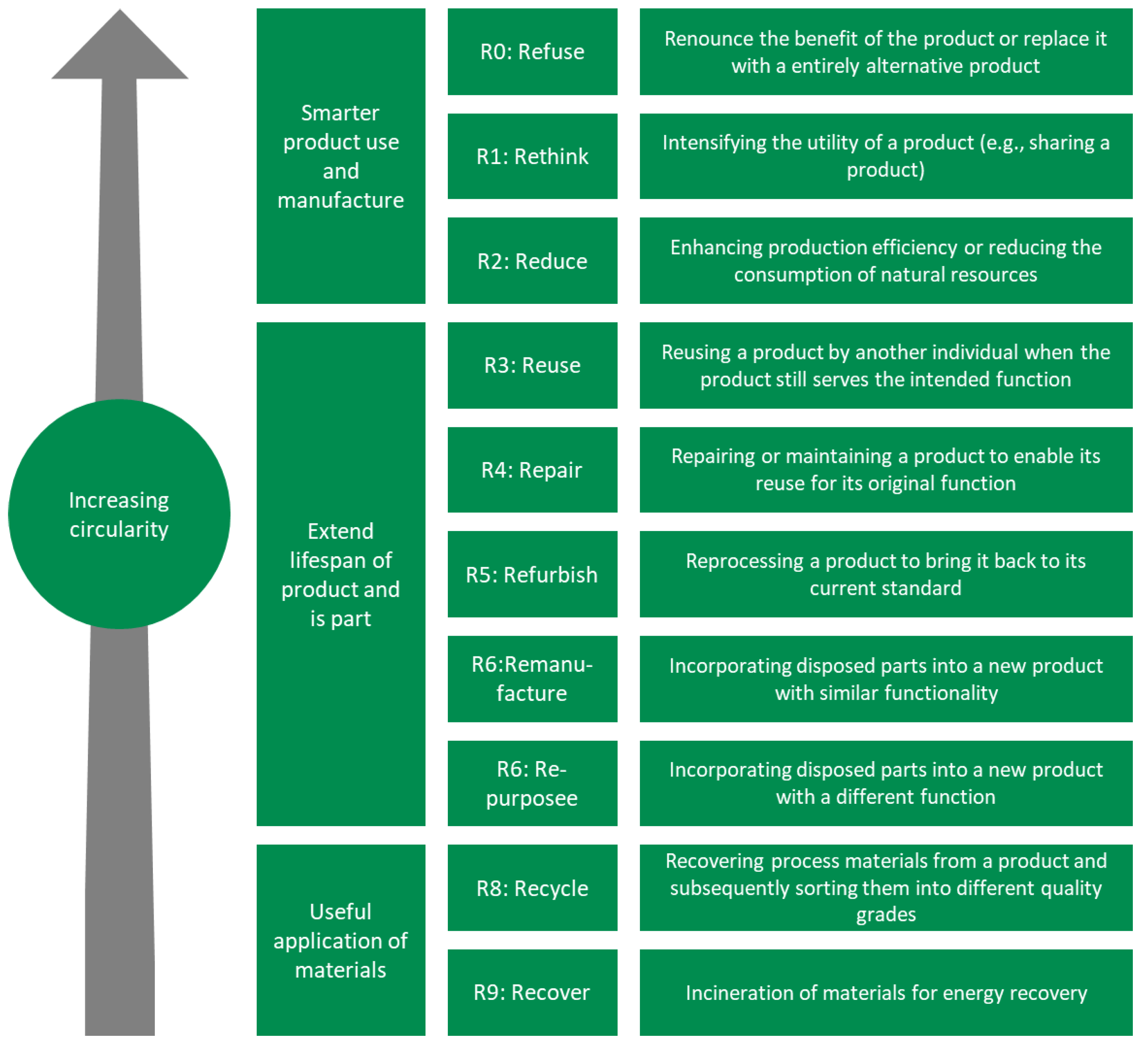

Throughout Europe, 75% of greenhouse gas (GHG) emissions are generated by the energy sector. Therefore, the EU’s objective is to promote the expansion of renewable energies to reduce GHG emissions by at least 55% by 2030 compared to 1990 levels. This includes a mandatory target of at least 42.5% renewable energy by 2030 [1]. However, energy derived from renewable sources is highly volatile, uncertain, and location-dependent. Consequently, the integration of energy systems necessitates flexibility to ensure the security of supply. Flexibility can be understood as the ability to balance the emerging residual load. The residual load is defined as the electricity demand reduced by the energy provided by renewable sources. As the proportion of renewable energy in the electricity mix increases, conventional power generation will increasingly need to align with the residual load. The flexibility can be provided through three components. Firstly, supply side provision is facilitated by transmission and distribution networks via flexible power plants. Secondly, demand-side utilization involves the introduction of new loads as part of electrification. The third component comprises energy storage [2]. The expansion of stationary storage systems is therefore becoming one of the most crucial strategies for reducing CO2 emissions in the long term. Figure 1 illustrates the increasing demand and significance of storage systems based on the expected global and cumulative amount of installed battery capacity (in GWh) by 2030. The Figure 1 is based on the model proposed by Jarbratt et al. [3]. Consequently, a significant surge in resources for the production of storage systems is expected.

Figure 1.

Annual average expected installation of battery storage capacities. Based on Jarbratt et al. [3].

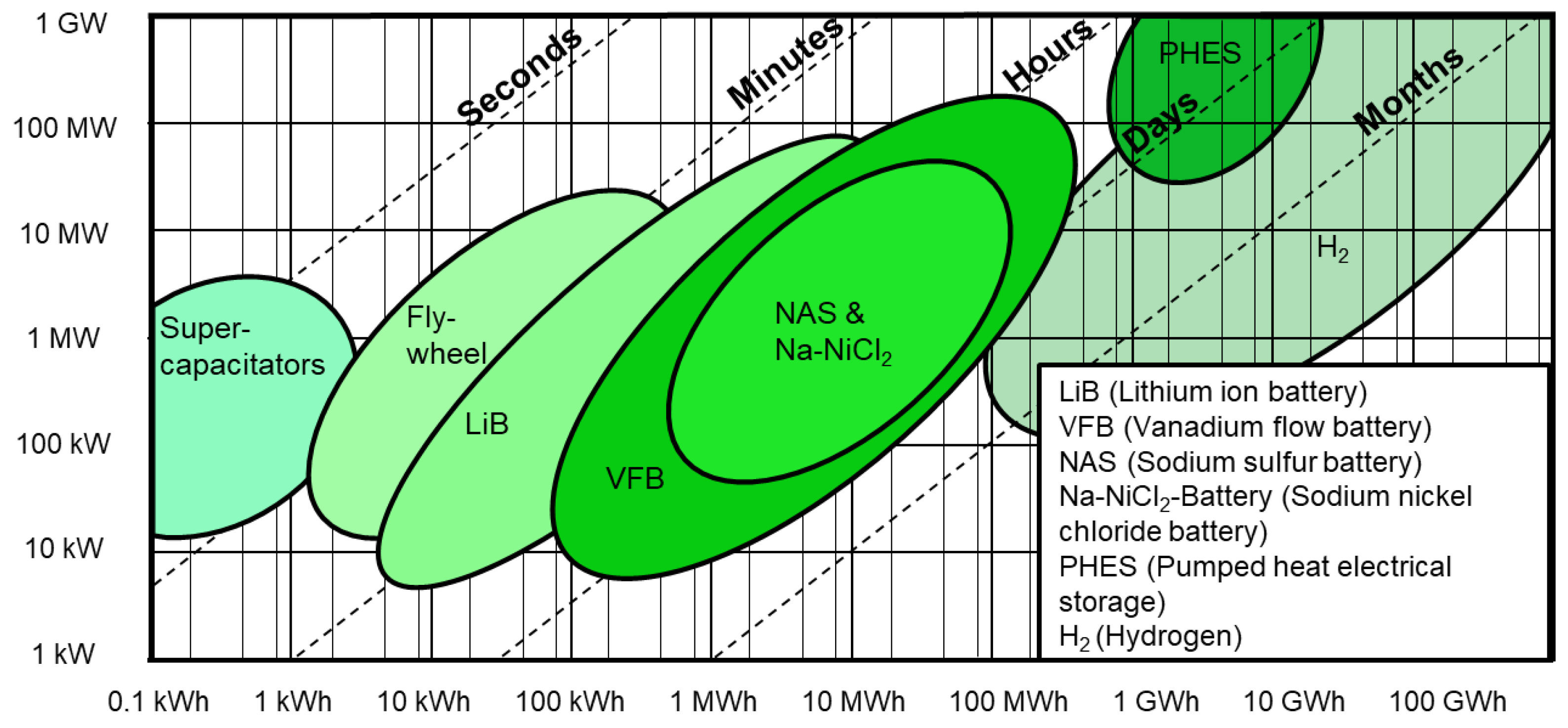

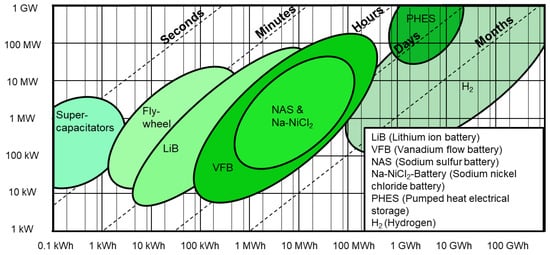

Figure 2 schematically illustrates several technologies for energy storage based on Thielmann et al. [4]. Due to the multitude of possibilities for storage, the figure depicts the dependency of storage on the required capacity and power on the axes. Additionally, the optimal charge/discharge durations of the technologies are indicated in the figure. However, these factors, including capacity and power, are not fixed boundaries and can vary significantly depending on the situation.

Figure 2.

Schematic representation of different storage technologies with the typical capacities and power ranges. Based on Thielmann et al. [4].

The vanadium flow battery (VFB) presents a viable alternative as a medium-term storage solution, positioned between short-term lithium-ion batteries (LiB) and hydrogen as long-term storage technologies. The VFB also boasts unique properties such as high turnover efficiencies, unaffected by geographical restrictions and independent scalability of power and capacity compared to other systems [5]. However, the battery is often characterized as heavy and material-intensive due to its low energy density. Nevertheless, the literature lacks an assessment of the VFB concerning a circular economy (CE) approach and potential recycling pathways.

In this paper, for the first time in the literature, the VFB is examined within a CE framework. During the examination of the R-strategies, it became clear that the framework can be used for simple product systems and the statements are valid. For complex product systems, especially stationary storage technologies, the definitions and statements are sometimes misleading. We hypothesize that this is a problem of efficient CE. Also, this newly developed dynamic multi-dimensional value retention strategy model (DDS) is based on the linear R-strategies approach, also called value retention strategies, and can accordingly be extended to other battery storage systems. This approach accommodates the complexity of batteries for the CE framework and provides transparent insights on the adaptation of various R-strategies.

2. Vanadium Flow Battery

By 2030, power generation will become increasingly volatile, highlighting the crucial advantages of stationary battery systems as storage solutions. For reliable, renewable-based electricity supply, both decentralized and centralized stationary storage technologies play an important, if not decisive, role [6]. Their primary task is to ensure grid stability and reliability to prevent blackouts. Additionally, stationary storage systems significantly improve the integration of renewable energies into the grid.

Stationary storage systems can also contribute to resolving the “energy trilemma” in the future, as energy can be reliably provided, is sustainable, and offers economic benefits through intermediate storage. The VFB, with its efficient coupling with other storage systems and unique characteristics, can contribute to realizing these points. The all-vanadium flow battery (VFB) was introduced by Skyllas-Kazacos in 1988 to address issues related to crossover and self-discharge stated for other redox pairs [7]. This battery type later became known as the G1 RFB [8]. Building on this development, VFBs, alongside LiBs, have become prominent in grid-scale energy storage, especially in the MWh range. The battery can be particularly suitable as a stationary storage system on an industrial scale and thus make a significant contribution to the energy transition [9].

2.1. Technical Description

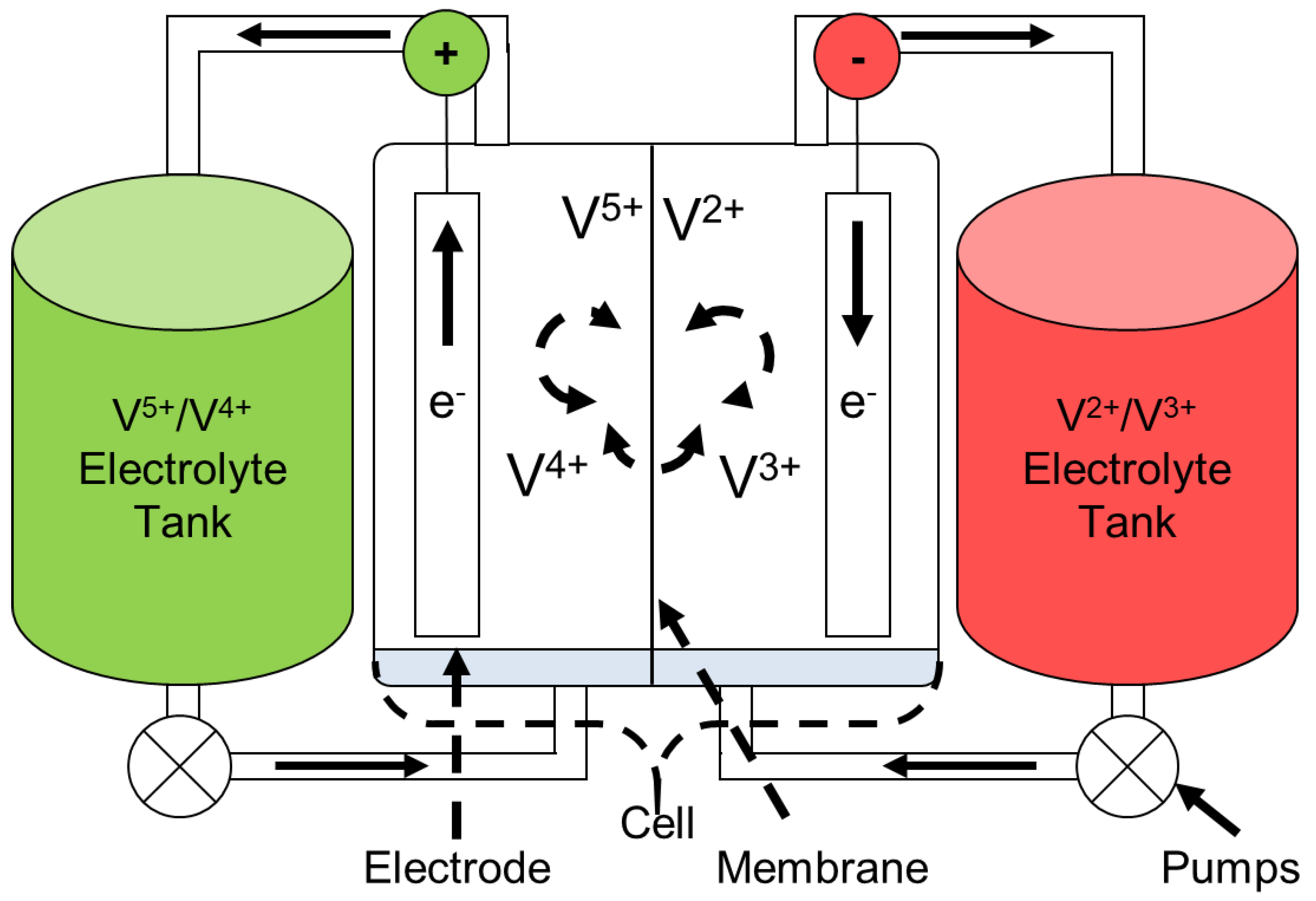

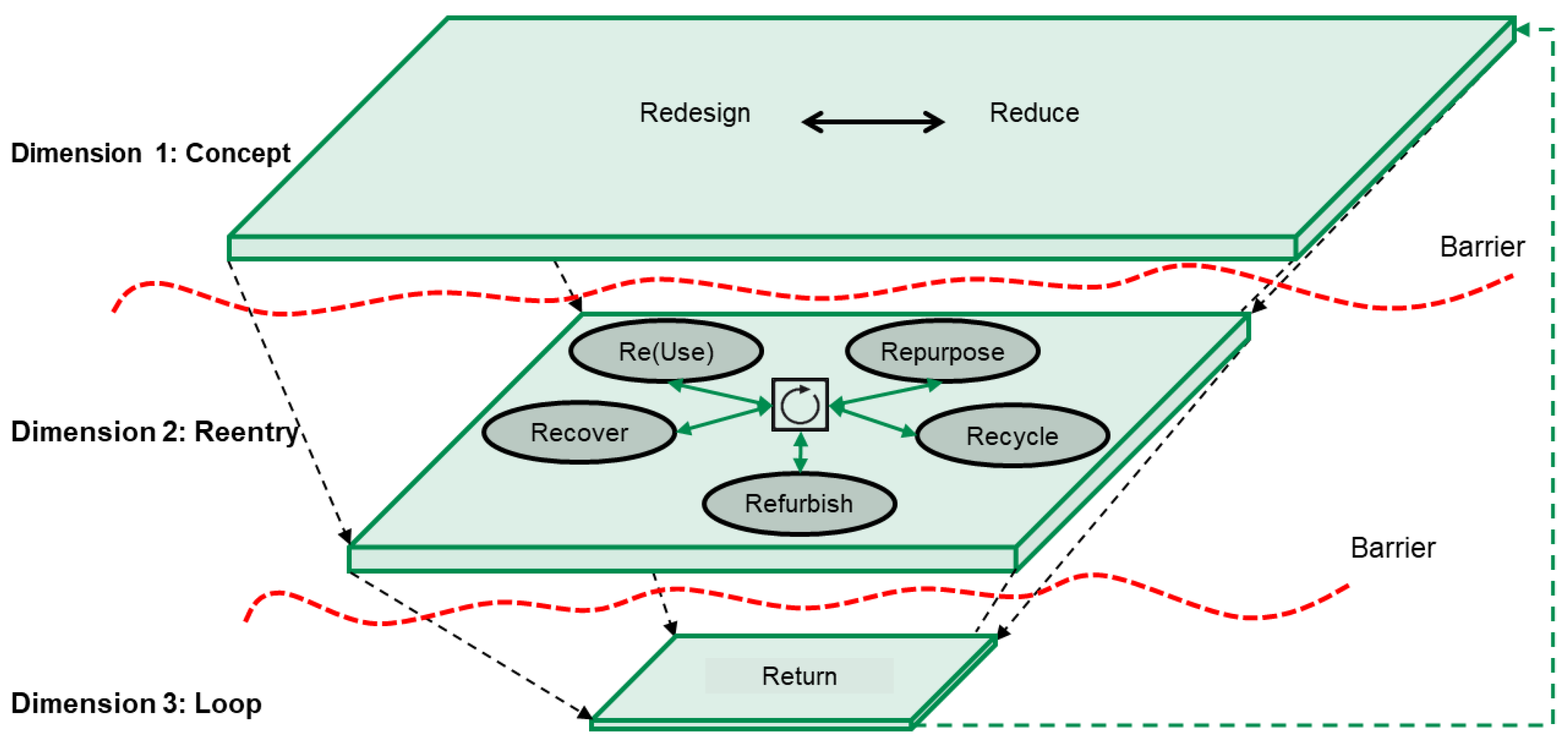

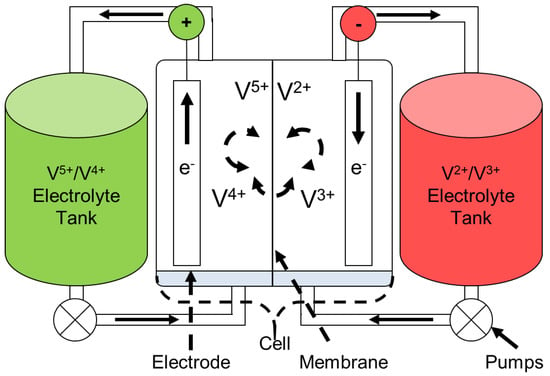

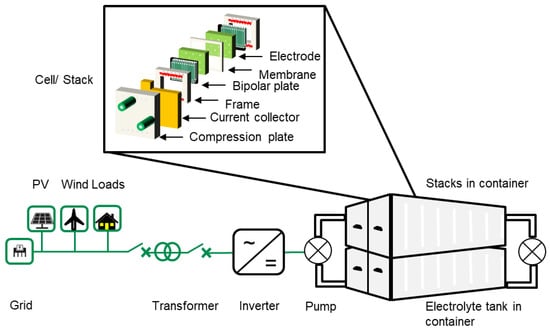

In order to analyze the factors of the circular economy, a profound understanding of VFB is a fundamental prerequisite. The battery design exhibits similarities to fuel cells [10]. As illustrated in Figure 3, the VFB comprises at least one stack and two tanks. The conversion of energy occurs within the stacks, and the energy is stored in the aqueous electrolyte in external tanks. Accordingly, the number or size of the active areas in the stacks determines the battery’s power, while the quantity of the electrolyte determines the battery’s capacity. Consequently, the power and capacity of the battery can be scaled independently, allowing the battery to be constructed according to the required specifications [11,12]. As shown in Figure 3, the electrolyte and the stack, the reaction site, are locally separated.

Figure 3.

Schematic structure of a VFB.

An advantage of the VFB is the high cycle numbers of 20,000. The high cycle number can be achieved notably due to the resulting crossover being balanced through rebalancing, made possible by both vanadium forming the active species in both the positive and negative electrolytes [12,13].

The efficiency of the battery is described in the literature as between 75% and 90% [14]. However, the realistic value is rather around 75–80%. At high voltages, losses due to cell overpotential dominate. In the context of cell overpotential, an example to mention is the overvoltage losses [15]. The internal resistances of the cell are mainly attributed to the ohmic losses at the membrane and have the greatest influence on efficiency [16]. The losses due to the pumping power of the VFB are generally low in industrial operations due to the high efficiency of the pumps, up to 90% [15]. Equally important, however, is the design of the VFB, as well as the reduction of shunt currents [16]. For precise efficiency losses during operation, we refer to the work of Trovò et al. [15] and Li et al. [17].

2.2. Relevant Aspects for the Circular Economy

The relevant points for VFB are summarized below for assessing CE factors. This information is crucial for making statements regarding CE and the importance of these factors later on. Accordingly, the electrolyte factors for CE are initially addressed, followed by the mass balances of the VFB and the stack.

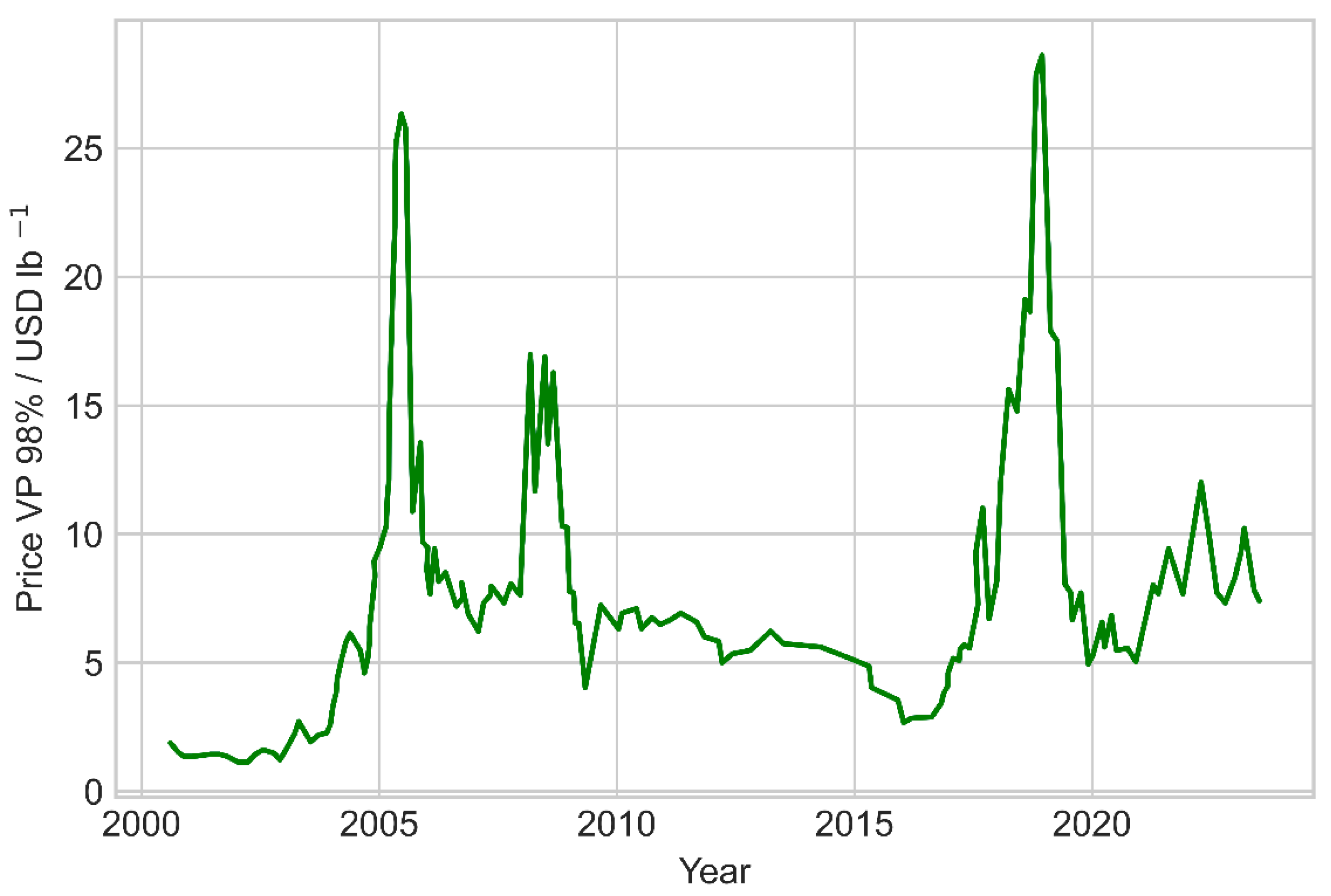

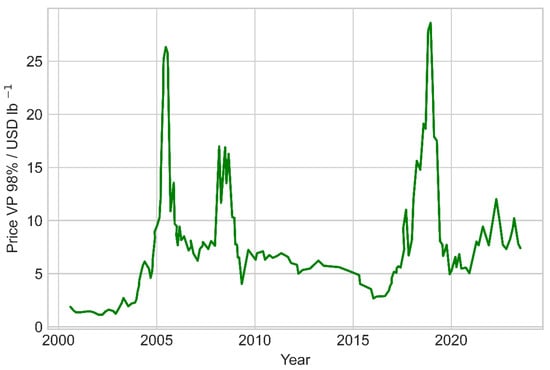

Depending on the energy-to-power (E/P) ratio of the battery, the electrolyte contributes approximately half of the system costs [11]. As shown in Figure 4, the price of vanadium pentoxide (VP) is extremely volatile, leading to little planning security for industrial applications. Moreover, the VP, depending on the exact design and other variables, is responsible for a large portion of emissions. The global warming potential (GWP) emissions of the primary electrolyte of the VFB cause approximately 70% of the GWP emissions [12,18]. However, this statement must be contextualized with the latest insights, as the electrolyte, depending on the critical contamination in the electrolyte, can be recycled. Through the treatment of the electrolyte, the GWP of the electrolyte can be reduced by up to 99.8% [19]. This also implies significant cost savings for the electrolyte and consequently for the VFB. This significantly enhances the planning security for VFB systems as well.

Figure 4.

Price trend for vanadium pentoxide with a purity of 98%. Based on [20].

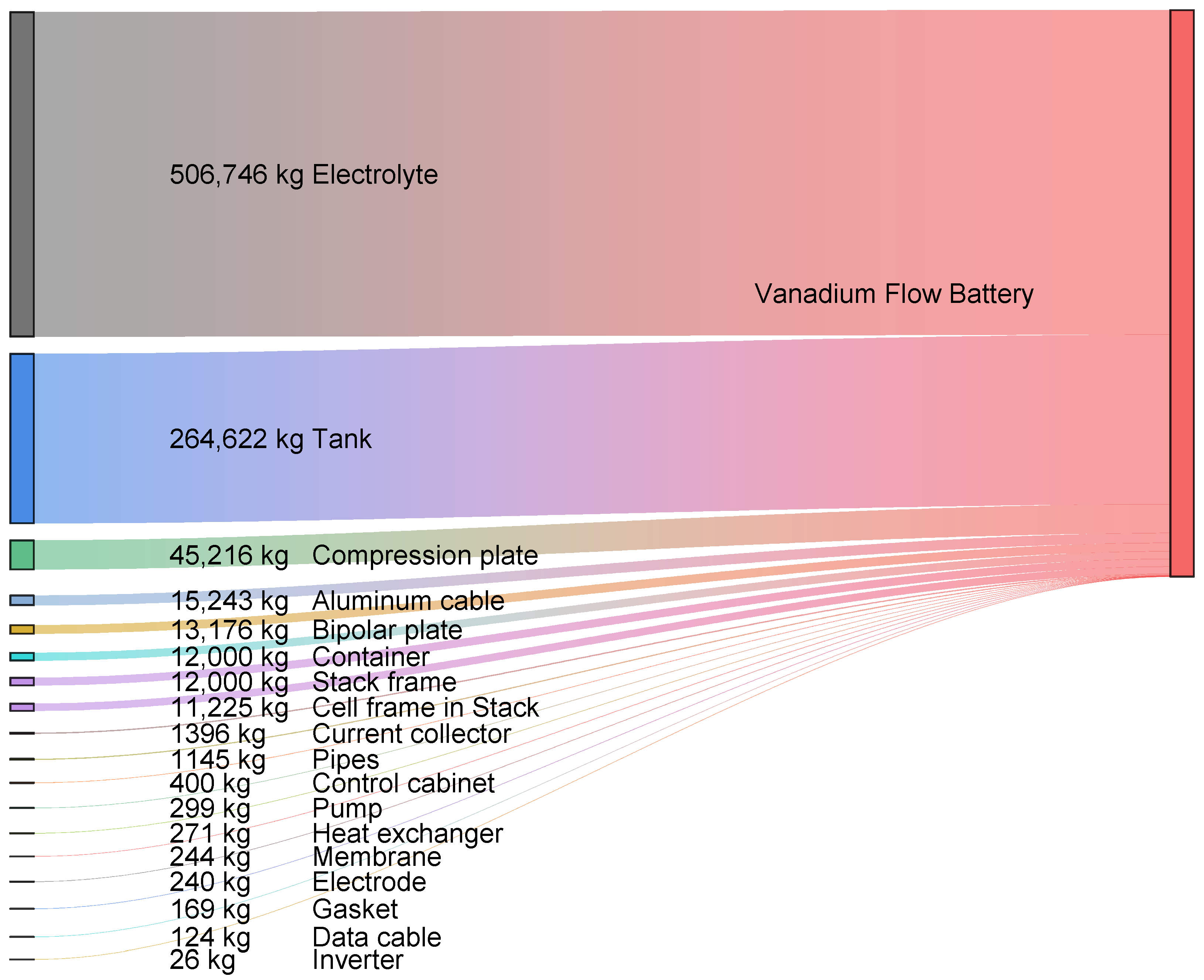

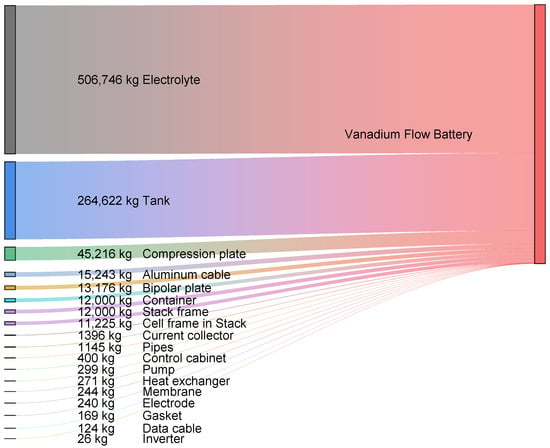

Another advantage is that significantly less of the critical compound VP is required through treatment [19]. To understand the mass ratios and resource utilization of the VFB, the ratios are depicted in Figure 5. The absolute masses provided are based on our own previous work [12], with the corresponding capacity of the VFB being 8 MWh and a power of 1 MW. The electrolyte weighs approximately 500 t, accounting for 57% of the weight of the VFB. Whereas the electrolyte consists of water to 60.2% and only 11% of VP. Furthermore, the electrolyte contains sulfuric acid (28.5%) and phosphoric acid (0.3%).

Figure 5.

Mass ratios of a VFB with 1 MW and 8 MWh. Based on Blume et al. [12].

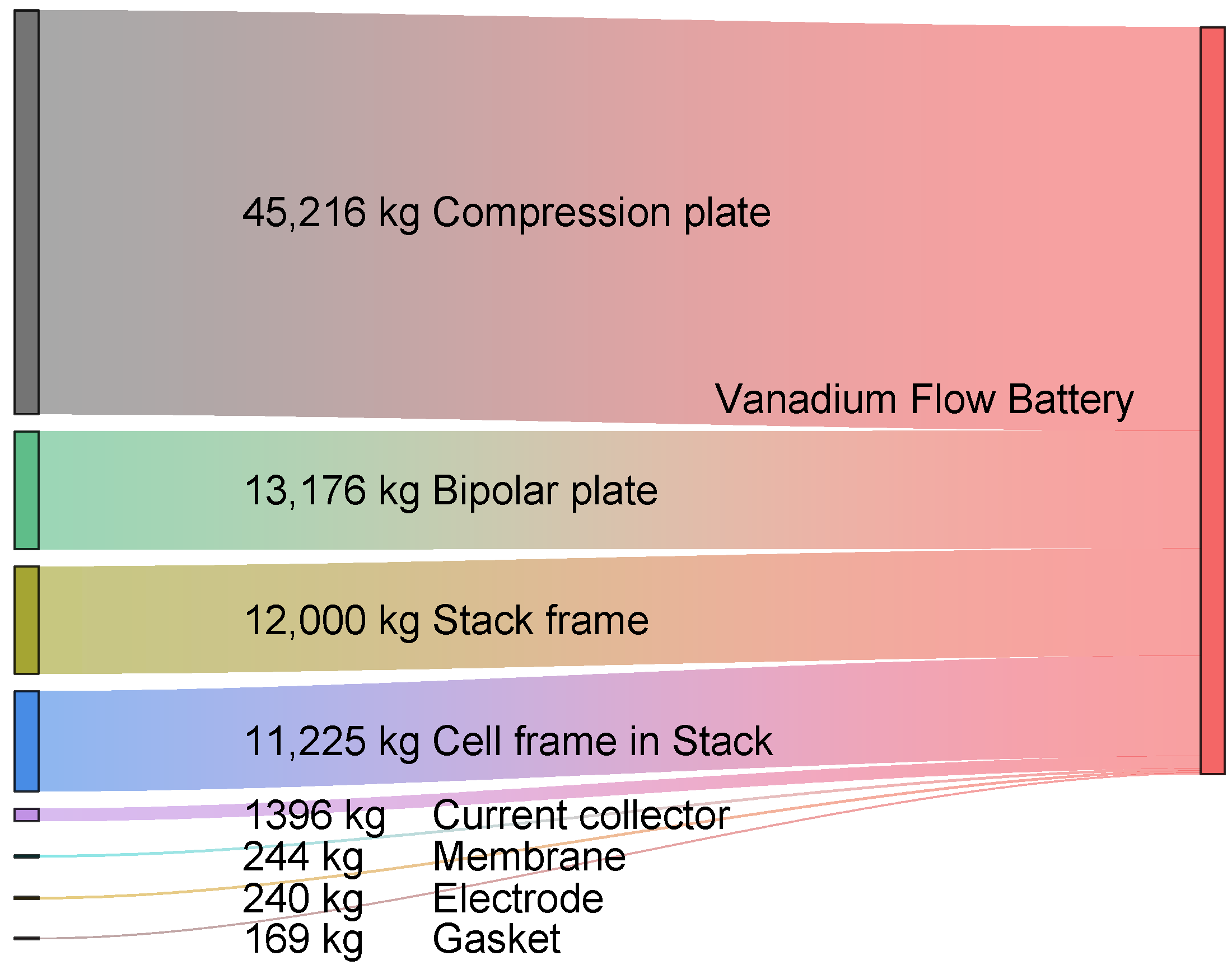

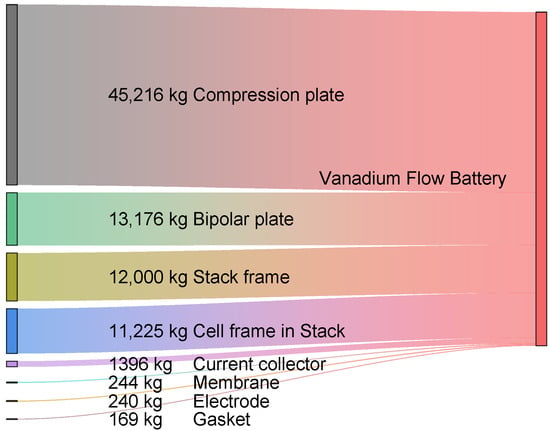

The absolute mass ratios of the stack are provided in Figure 6. The compression plate significantly dominates the mass ratios, accounting for 54% of the total weight of the stack.

Figure 6.

Mass ratio of a stack of a VFB with 1 MW. Based on Blume et al. [12].

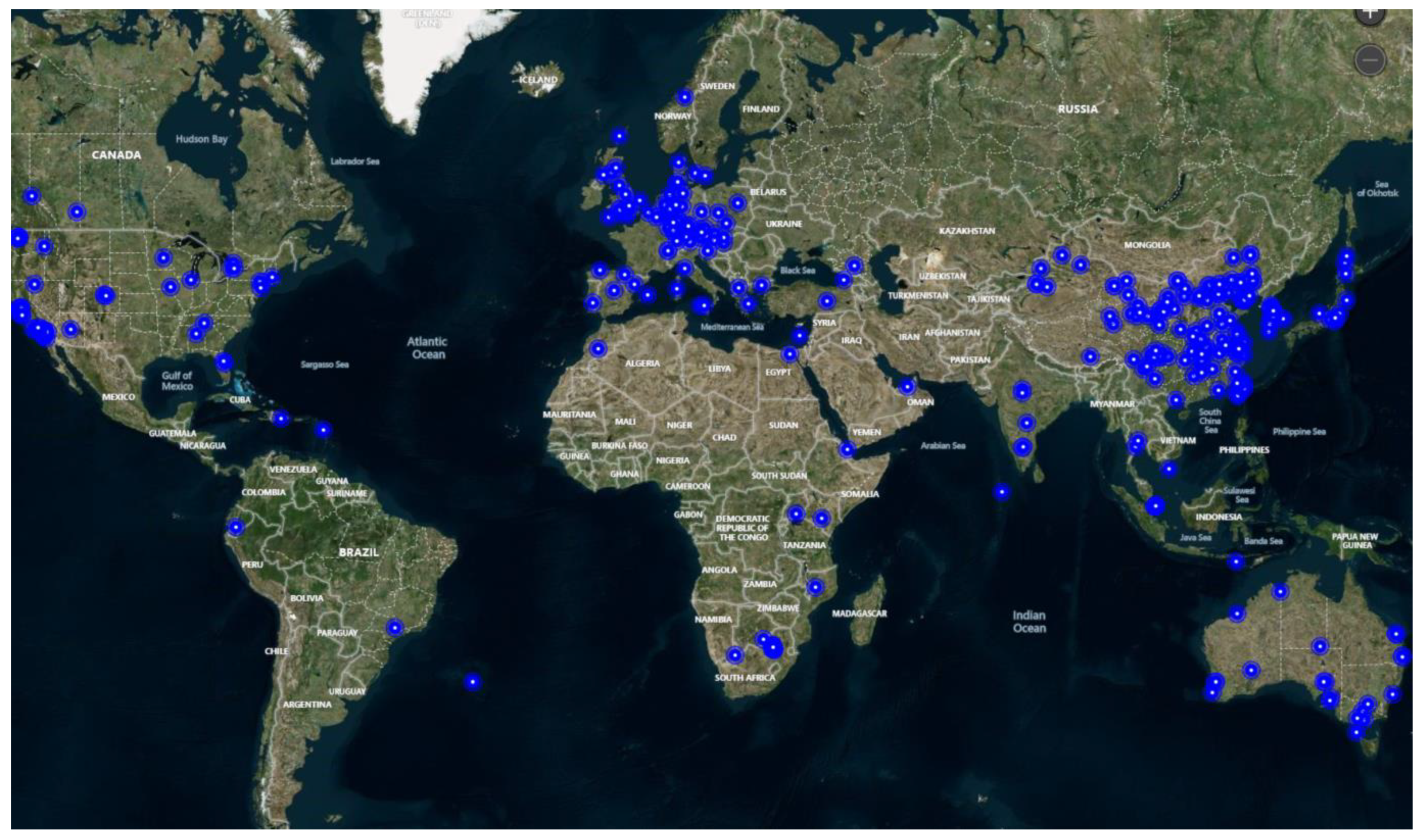

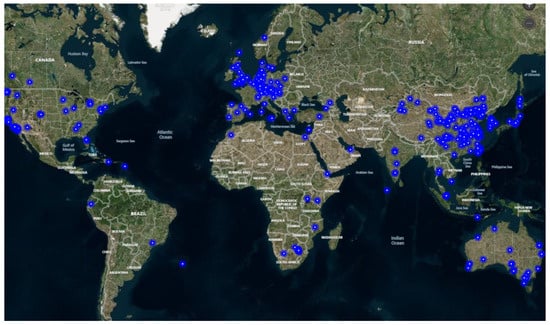

However, it must be noted that the E/P ratio of 8:1 is the standard value for VFBs, and the mass ratios do not result from a percentage-wise higher capacity compared to the power. The latest projects in China, however, have a lower E/P ratio, as this can be flexibly adjusted to the respective requirements with the VFB. The two largest VFB projects are both located in China, one in Dalian City with 100 MW/400 MWh capacity and the other in Xiangyang with 100 MW/500 MWh capacity [6]. China currently dominates and is expected to continue dominating the VFB market. For the year 2023, VFB projects in China with a capacity of 4.5 GWh were announced, more than doubling the capacity from the previous year. However, the implementation of these projects needs to be monitored [21]. Figure 7 illustrates over 300 VFB projects worldwide, depicting those that have been implemented, announced, contractually secured, or are currently under construction.

Figure 7.

Global Vanadium Flow Battery Projects (Screenshot Vanitec Ltd. [22]).

3. Circular Economy

The following paragraph explains the basic idea and development of the CE, as the field is very broad and there are various approaches and definitions. Subsequently, the different R-strategies (linear value retention strategies) are elucidated, as a new approach is being developed using this methodology.

3.1. Circular Economy in General

The UN [23] expects a population of 9.8 billion people on the planet by 2050. A growing population, coupled with increasing prosperity, leads to an exponential increase in demand, particularly for finite resources, resulting in a corresponding 70% increase in waste by 2050 [24]. In the long term, the linear economic model is ecologically and economically problematic, inefficient, and unsustainable due to resource depletion. The transition to a CE is understood as an approach to sustainable development.

For this reason, the concept of the CE is steadily gaining importance and significance in politics, media, consumer behavior, businesses, and academia to enable sustainable development with high resource efficiency and reduced waste over the long term [25,26,27]. In politics and businesses, the idea of CE is often touted as new and revolutionary. However, the concept of systemic thinking dates back to the 18th century in the field of agriculture and human metabolism [28,29,30]. Reike et al. [28] emphasize that several authors, including Quesnay with his “Tableau Economique” in 1758, made initial assumptions about the added value of cyclical inputs [28,31]. It is also essential to mention the publication of the Club of Rome [32] in 1972. Also, the Brundtland Report in 1987 [33], calling for “A global agenda for change”, which was advocated by the World Commission on Environment and Development must be mentioned in this context.

Reike et al. [28] view CE as an evolution in three phases. The first phase spans from 1970 to 1990, and the second phase ends in 2010. The third phase started around 2010 and focuses on maximizing value retention in light of resource decline. It urged the design of sustainable development where future generations could meet their needs without compromising the ability of future generations to meet their own needs. Furthermore, it aimed to understand and explain the interrelationships between social equity, economic growth, and environmental problems, seeking political solutions and concepts to reconcile development and the environment [33]. It was recognized early that the traditional linear economy model of “take, make, and throw away” cannot be sustainable, especially when considering long-term parameters [34,35,36].

CE promotes sustainable development by reducing material consumption and production [27,31,37,38]. Given the complexity of the CE concept, successful implementation requires collaboration among all stakeholders along the value chain and a fundamental rethinking by all involved parties. CE aims to prevent waste, decouple economic activity from consumption, conserve resources, and address global challenges [31,39,40]. Although the topic is gaining relevance and importance, there are various interpretations and definitions of CE in the literature [28,41,42,43,44]. The definition by the Ellen MacArthur Foundation [39] is the most widespread, while Kirchherr’s definition [45] is omnipresent in the scientific community. Kirchherr et al. [45] describe CE as an economic system that retains materials throughout their lifecycle, thereby avoiding the concept of end-of-life (EoL). Furthermore, they list and discuss 114 definitions of CE, indicating that there is no consensus on models, criteria, barriers, or methods of CE in the literature. There are also various tools for circular decision-making, such as waste hierarchy, R-strategies, life cycle assessment (LCA), multi-criteria decision analysis (MCDA), and social life cycle assessment (S-LCA). Consequently, quantifying or ranking the CE concept is not feasible. It is clear that all relevant points cannot be captured with a single model or indicator. R-strategies in particular are repeatedly used in the literature to depict various EoL processes and to rank them in terms of the CE concept.

The R-strategies, or value retention strategies, derive their name from the prefix “R” meaning “back” or “again” in Latin. There are various manifestations of R-strategies in the literature, generally representing measures to efficiently use products and resources. Reike et al. [28] examined 69 peer-reviewed papers and identified the use of 38 different “re” words. These strategies operate on three levels and serve sustainable development. The first level is the microeconomic level, focusing on products, companies, and consumers. The second level is the mesoeconomic level, primarily concerning eco-industrial parks and the supply chain. In contrast, the third level, the macro level, considers cities, regions, countries, and beyond, aiming to create long-term environmental quality, economic prosperity, and social justice. These three core factors should be preserved for the current generation while being attainable for future generations [45].

Through our extensive literature review, we realized that these issues are being addressed in various areas and products with value retention strategies. However, these approaches and models are only partially applicable to emerging technologies or highly technical complex systems. Therefore, in this work, we further developed existing models for applications in stationary storage systems, focusing on VFBs.

3.2. CE Framework for Stationary Batteries

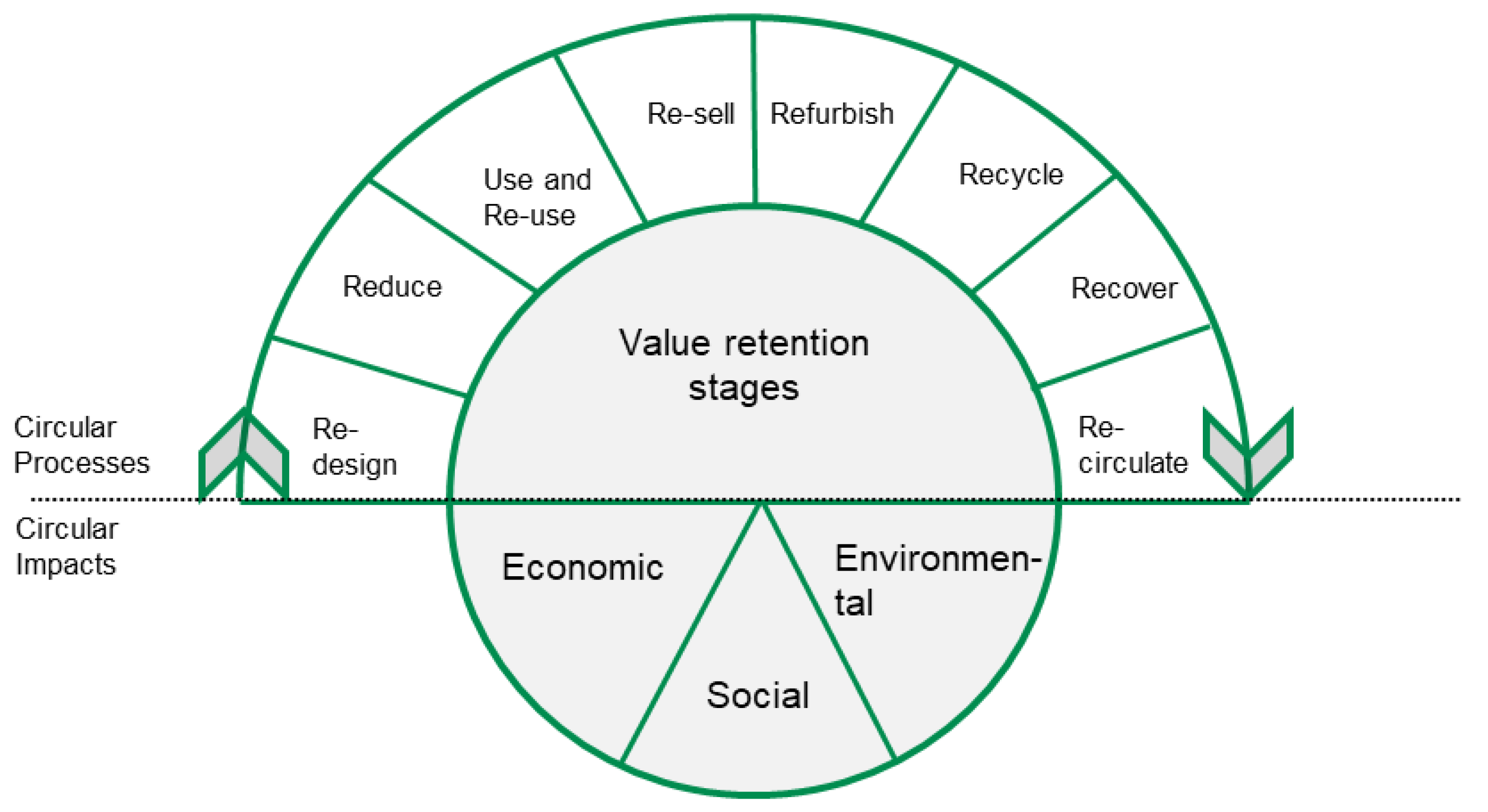

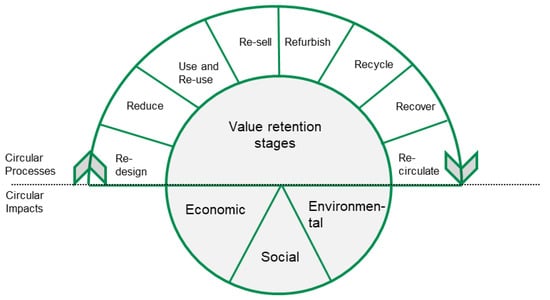

Garcia-Saravia Ortiz-de-Montellano and van der Meer [46] summarize the points mentioned above in a so-called CE framework. The method is illustrated in Figure 8. In this model, CE consists of circular impacts and circular processes. The circular impacts comprise the ultimate goals of CE, which encompass social, economic, and environmental influences. The circular processes consist of eight R-strategies. Upon reviewing the literature, it becomes evident that the circular impacts have already been adequately addressed, whereas the circular processes, specifically concerning the R-strategies for stationary battery systems, have not been discussed in detail.

Figure 8.

CE framework based on Garcia-Saravia Ortiz-de-Montellano and van der Meer [46].

The costs for VFBs have been extensively discussed in various life cycle costing (LCC) studies [11,47,48,49,50,51,52,53,54,55], and the S-LCA has been transparently elucidated in Koese et al. [56]. The environmental impacts of VFB have also been adequately and transparently described through LCAs [12,18,57,58,59,60,61,62]. However, the circular processes have not been fully addressed in the literature. Before the circular processes can be transparently applied to circular impacts, the value retention stages must first be analyzed. Various approaches to combining these factors exist.

One particularly promising approach is the circular life cycle sustainability assessment (C-LCSA) framework proposed by Luthin et al. [63]. This approach combines LCA, LCC, S-LCA, and circularity assessment (CA). The uniqueness of the approach lies in the selection of relevant indicators and consideration beyond the lifecycle. The material circularity indicator, product circularity indicator, and longevity indicator have been identified as relevant. The approach aims to integrate technical circularity into LCSA [63]. There are various approaches, which are always built to combine different sustainability factors. The coupling of these methods is usually based on the analysis of a certain field and combining the various factors specifically in that area. Often, the material-intensive construction sector [64,65,66,67,68,69,70,71,72,73,74,75] is used in the literature to link LCA with CE. Therefore, we use the same approach, initially considering a certain area to be able to make generally valid statements about different fields in the long term. However, it is also questionable to what extent a universally applicable approach for the quantification of different sustainability factors can be established.

In the next subchapter, the concept of value retention stages is analyzed in detail. Therefore, in the next chapter, the “linear” model of R-strategies is presented in general terms. Subsequently, the acquired knowledge is explained in connection with the dynamic multi-dimensional value retention strategy model (DDS), mainly focusing on the VFB. However, other battery systems are also discussed.

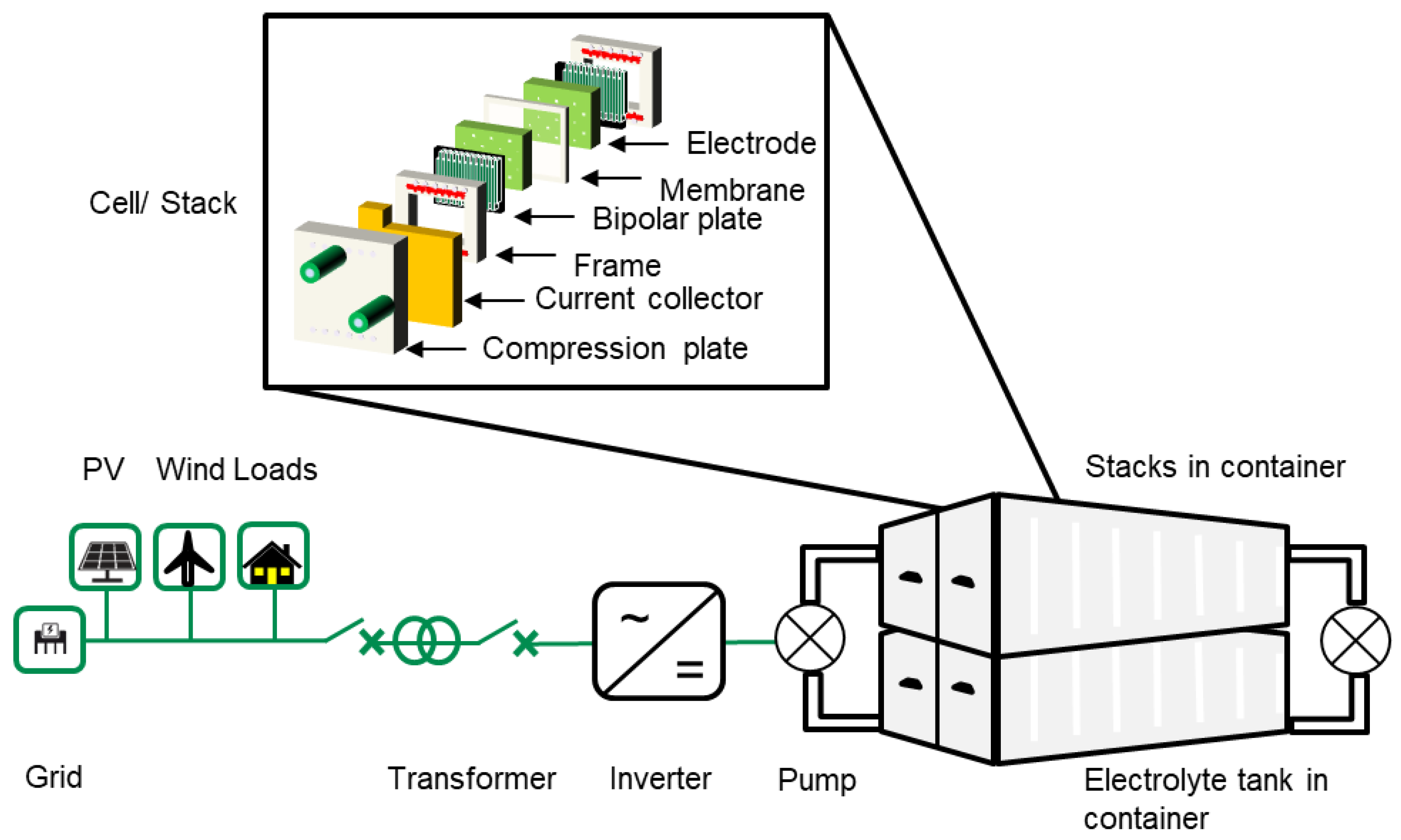

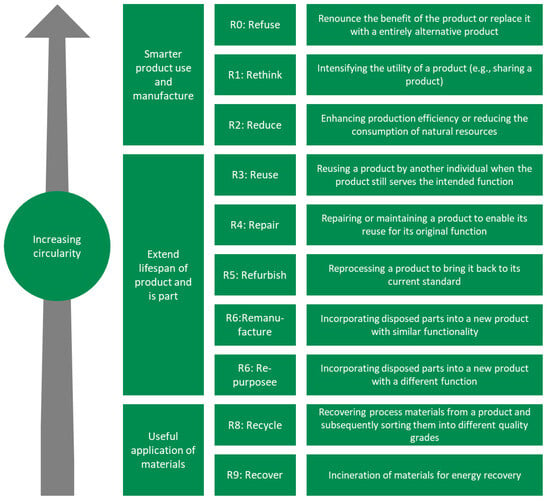

3.3. Idea of Linear Value Retention Strategies

Based on the fundamental ideas of Blomsma and Brennan [29] or the definitions provided by Kirchherr et al. [45], the concept of CE is primarily dominated by the implementation of the 3R-strategies (reduce, reuse, and recycle) [41,76,77,78,79,80,81,82]. The extension of this concept leads to the nine R-strategies or even ten R-strategies, which are structured as the value chain of consumers and businesses [28,83,84]. Figure 9 illustrates the nine R-Strategies according to Potting et al. [83]. The graphic also includes corresponding explanations for the various strategies. Fundamentally, Potting’s thesis suggests that a lower R number of strategies has a greater CE impact and is generally preferable. However, Potting et al. also emphasize the weaknesses of the concept, as increased energy or material demands can arise, for instance, through recycling. Consequently, additional weaknesses of the model are also highlighted. Reike et al. [28] further examine the weaknesses of the model and provide various reasons. For a comprehensive explanation and investigation of the basic model, we refer to Reike et al. [28]. Blomsma and Brennan [29] also emphasize that the theoretical and paradigmatic clarity and transparency of the CE concept have not yet been fully elaborated. This assertion is reinforced by Elia et al. [85] or the Circular Economy Action Plan of the European Commission [86], which claims that the CE concept is a new idea and how it can be strengthened. While Reike et al. [28] define the concept of CE more as refurbished than a completely new concept.

Figure 9.

Value retention strategies based on the methodology of Potting et al. [83].

Additional statements can be found in the literature [28,29,85,87,88] where the concept of CE is criticized due to the lack of framework conditions, and the call for new approaches from the scientific community [28,63,89,90] is becoming increasingly louder. This is the motivation for us to introduce a new model based on the nine R-Strategies in the next chapter that considers the technical requirements of the CE concept as well as multiple life cycles. This is intended to serve as a starting point for further approaches to new CE concepts. Therefore, the basic model of the nine R-Strategies is first explained in Section 3.3 followed by the transparent presentation of the new concept.

3.4. Linear Value Retention Strategies

In the following chapter, reference is made to a product to be manufactured. Furthermore, definitions in the literature are interpreted differently, and the transitions are sometimes fluid. Consequently, a strategy cannot always be clearly assigned. For further examples and a detailed listing of individual R-strategies, we recommend the work of Garcia-Saravia Ortiz-de-Montellano and van der Meer [46].

3.4.1. Refuse

The refuse strategy pertains not only to the non-use of the product from the customer’s side but also applies to the manufacturer’s side. For customers, it involves either a complete or reduced consumption or demand for a product. On the manufacturer’s side, it often entails the avoidance of using hazardous substances in production or the omission of packaging, for instance [28]. Additionally, replacing the product with a new one serving the same function is considered [45].

3.4.2. Rethink

Rethink is here interpreted synonymously with redesign. Generally, both customers and manufacturers should strengthen their adherence to CE behaviors. This can be achieved through communication or strategies with customers. Moreover, manufacturers should reconsider the choice of raw materials for the product. Furthermore, the altered design aims to enable reuse levels or facilitate easier processing. New innovations related to the product fall under this category [46].

3.4.3. Reduce

Reduce involves, for example, higher efficiency in manufacturing, resulting in the need for fewer raw materials and reduced waste during production. Additionally, product complexity can be decreased to reduce emissions [46].

3.4.4. Reuse

The concept of reuse also encompasses the concept of resell, as both sides of the market are required, the supply side, and the demand side. Reselling is sometimes considered a separate strategy because costs and energy expenditure for transfer or transportation must be considered when transferring to a second user [46]. However, the general perception in the literature is that reuse always refers to a second new individual or customer [28]. Generally, reuse strongly relates to the usage phase, this does not mean the use of partial products. Furthermore, it is a consensus that the product does not need further processing or repair. Therefore, the product’s functionality must be the same as in the original state. Minor repairs, inspections, and cleanings are often described as legitimate in the literature [28,91,92].

3.4.5. Repair

Repair refers to the restoration of a product, extending its lifespan or restoring its original function. Various interpretations exist for this seemingly straightforward definition. Generally, it involves replacing smaller defective parts. The literature also emphasizes who performs the repair and where the repair takes place [28].

3.4.6. Refurbish

Refurbish or reconditioning involves refurbishing an old product, which may be partially damaged or have reduced functionality, to possess the performance or characteristics of a new product. By replacing individual components, the function of a product is modernized or improved. The product is upgraded, reaching a satisfactory quality standard [93].

3.4.7. Remanufacture

Remanufacture involves the dismantling of a product or product system, allowing one or more components to be used to create a product with the same functions for reuse. Desired quality standards can be achieved through inspection, cleaning, refurbishment, or testing [94].

3.4.8. Repurpose

This strategy is defined by using a used or discarded product for a new product system with a different function compared to the original product [95].

3.4.9. Recycle

Recycling involves extracting materials from an existing product system, whereby the original structure of the materials is not preserved. The recovered raw materials often exhibit altered quality compared to the primary material and can subsequently be used in open-loop or closed-loop systems [28].

3.4.10. Recover

When no further value can be obtained from the product or materials, or the composition of the product or individual substances does not permit recycling technically or economically, recovery can retrieve individual substances or energy from the waste product [83].

3.5. R-Strategies as a Solution Approach

First, it must be questioned to what extent a comparison of different EoL strategies for a product system is desired within the context of the R-strategies. It is also questionable which of the numerous indicators should be considered. The literature does not provide a clear answer to this, but it becomes evident that, particularly through phases such as rethink/redesign or reduce, it is implicitly assumed that all changed aspects and consequences can be anticipated, thus enabling an assessment of how a product system behaves in line with the CE concept through a change. Due to the numerous definitions and methods, this may hardly be feasible even for simple product systems. Consider the same question for highly complex systems, and the answer should therefore be that this is not valid. Any change in a component within stationary battery systems leads to further system changes, resulting in additional adjustments. These points will be discussed in detail in Section 4.

Even with simple product systems, the effects and consequences are often debated, and opinions vary greatly. When considering a theoretical concept like the R-strategies, the question arises as to whether only the theoretical outcome should be considered or also the actual results. The working hypothesis of this study is:

Hypothesis 1.

Mapping and quantifying a circular value chain with a linear approach is only limitedly possible for complex systems.

Based on this hypothesis, the concept of linear strategies is used to develop the DDS.

4. Introducing the Dynamic Multi-Dimensional Value Retention Strategy

The following chapter begins with an explanation of the basic model in general. Subsequently, the model is explained based on the VFB. Accordingly, the previously discussed R-strategies with the respective modifications are also elucidated.

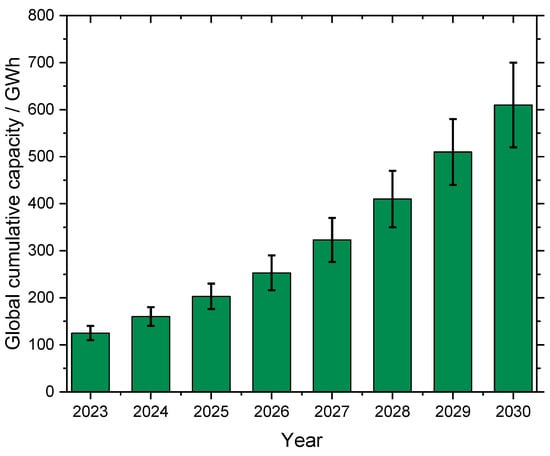

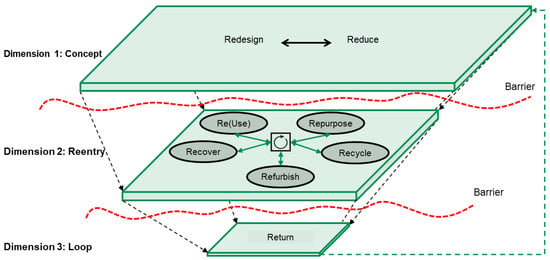

The DDS is based on the R-strategies and is divided into three dimensions. Each dimension is further subdivided into various levels as appropriate. The individual dimensions are concept (D1), reentry (D2), and loop (D3), which are shown in Figure 10.

Figure 10.

Structure of the dynamic multi-dimensional value retention strategy model (DDS).

The dimensions are unilaterally dependent, extending from the concept dimension to the reentry dimension, and correspondingly, the loop dimension is unilaterally dependent on the reentry dimension. The interdependence is illustrated by the connection arrows in Figure 10. The corresponding levels are the corresponding R-Strategies for the respective dimension. The mapping of the R-strategies is given by the model and cannot be varied. The different levels are interrelated and thus mutually dependent. The arrows between the levels represent an interrelationship. It can be assumed that a level has long-term consequences on other levels within the respective dimension. These interrelationships will be transparently elaborated throughout the chapter.

The individual dimensions are divided by barriers, as shown in Figure 10. To reach the next dimension through the barrier, one of the indicators of the barriers must be significantly improved, or the overall sum of factors must be better. The criteria of the barriers must first be defined. The choice of indicators depends on the product system and the research question. Accordingly, the conditions of the barriers can be freely defined. Nevertheless, general statements about the barrier functions can also be defined. It is generally advisable to consider the economic impact, and furthermore, any CE factors can be selected. The barriers separate the individual dimensions and ensure that the new concepts or approaches are realistic and/or feasible. Individual examples of the barriers are also mentioned in the following sections.

4.1. Step 1: Definition of the Product System

For complex products/emerging products, the R-strategies cannot be considered due to various factors, as the scope of functions of usage and the product must be examined on different levels or dimensions. This is particularly evident when examining batteries in detail. Linear strategies are excellent for simple product systems; however, in complex products, the facts are often presented in conflicting ways. Simple products do not have significantly different marginal utility, their functionality is nearly binary, and wear and tear minimally affect the product’s function or have no impact on the use phase. In complex product systems, these assumptions or R-strategies primarily lead to a modified use phase.

Therefore, the product system must first be understood and clearly categorized accordingly. For battery systems, it must be transparently explained whether it involves a new type of battery or a redesign. For example, whether the organic flow battery (OFB) is simply a redesign and flow batteries, in general, constitute a product system, or whether it represents a completely independent product system, where, for instance, different electrolytes define a redesign. Particularly crucial is the determination of the goal and investigation scope. Especially during the rethink or redesign level, a redefinition of the investigation scope can be conducted. In this case, the model must be fully traversed again, starting from the concept dimension. Likewise, the reason for conducting the study and the addressed as well as investigated target group must be defined. Also important is the depth of the product and the development status of the battery. For this, reference can be made to the technical readiness level (TRL)—laboratory scale, etc. A good overview for classifying TRLs can be found in Moni et al. [96].

4.2. Step 2: Adjustment of the Barriers

In Figure 10, the two barriers between the dimensions are depicted. The results for each barrier are analyzed separately for D1–D2 and D2–D3. The objectives or definitions of the barriers should be transparently discussed and defined beforehand. This includes whether the focus should be specifically limited to one factor of the barriers. Ultimately, any of the multiple indicators in the barrier can be used. Especially in the EoL of a product, a distinction must be made between actual implementation and technical, economic, and ecological feasibility. The barriers ensure that the examined strategies are not merely theoretical concepts. Furthermore, R-strategies in batteries and the energy sector are strongly influenced by political decisions and framework conditions. In several tests, the criteria of cost, effective performance, policy, or sustainability factors show the realistic results of the model. Therefore, these barriers are assumed for both explanation purposes and in the actual model.

In order for the next dimension to be reached, at least one of the factors must be improved, even if other factors may be negatively influenced. As seen in Equations (1) and (2), the formula is composed of the following values. The conditions for the barrier function will be further elucidated in the subsequent chapters with additional examples for various scenarios.

With: K = effective costs

Barrier function U(K, Pe, Po, S) = K + Pe + Po + S ≥ 1

K, Pe, Po, S1 ∈ {0,1}

Pe = Performance

Po = Politics

S = Sustainability

Similar to the weighting of the dimensions, a weighting of the factors is also possible (Equations (3)–(6)). Thus, a factor is no longer either fulfilled or not fulfilled; instead, a factor between 0 and 1 can be calculated. Accordingly, the value is no longer binary; instead, the factor is assigned a value between 0 and 1, reflecting the degree of change. The quantification depends on the chosen barrier. The following function can be used for this purpose.

U(K, Pe, Po, S) = wa × K + wb × Pe + wc × Po + wd × S ≥ 1

wa + wb + wc + wd = 1

0 ≤ wa; wb; wc; wd ≤ 1

0 ≤ K; Pe; Po; S ≤ 1

5. Case Study: DDS Applied to VFB

There is generally no consensus on the specific definitions of R-strategies. Accordingly, the presented definitions of the classical R-strategies refer to those already introduced. In the following section, we present the corresponding R-strategies in connection with the DDS, with examples for stationary storage technologies. The R-strategy “Refuse” is not considered, as in the battery domain, abstaining (Refuse) from stationary storage systems generally under certain conditions is not advisable. One of the conditions for not considering the refuse level is efficient coupling of all storage systems with the grid. This includes, in particular, considering optimal charging and discharging cycles.

5.1. Step 1: Definition of the Product System VFB

The focus of the study lies on the flow battery (FB). The most widespread type of flow battery is the VFB, which is why the focus is placed on this type. The defined product system is a VFB with an E/P ratio of 1 MW/8 MWh. This is relevant for the definition, as this chapter also uses battery masses to clarify the dimensions and importance of certain assumptions. The TRL of the battery is 9; it is used worldwide in various fields and environmental conditions. Production is largely automated, and various batteries have completed the full lifecycle and met requirements. Furthermore, research and development are largely completed.

The focus of the case study is primarily on the components of the power and capacity of the system. The supporting components of the systems are only considered in simplified form. Therefore, inverters, pumps, etc., are not fully considered in the DDS. In Figure 11, the VFB is depicted within a grid. In our previous work [12], the individual components, technical requirements, and material properties are extensively described.

Figure 11.

Schematic diagram of a vanadium flow battery in the grid.

Through the isolated consideration of the product system, renewable energies and network structures are also not considered; however, the impacts on these systems are examined in simplified form. Since various R-strategies, for example, can have a significant impact on the efficiency of the battery, other non-considered components for stationary battery systems must also be included. In this case, renewable energies, when coupled with the decreasing efficiency of the VFB, exert a negative influence on the CE factors on the product system.

Furthermore, different stack designs are considered when analyzing the stack components. This means that different assumptions are made with regard to the active areas of the stack. As a result, different components of the stack must be considered.

5.2. Step 2: Adjustment of the Barriers

Multiple factors of the barriers are deliberately selected in the model to examine and process various scenarios transparently. For instance, the sustainability aspect could be further explored in various specifications. For the sake of clarity, this aspect is simplified in the present discussion. In practice, the focus could be placed on the CO2 emissions caused by every stored kWh throughout the lifecycle. It is essential to consider the lifespan in this example. The same applies to pricing. The defined unit would be the incurred costs to store one kWh throughout the battery’s lifecycle, not the costs for the capacity of 1 kWh. The factors of the barriers in this consideration consist of meeting the criteria of cost, effective performance, policy, or sustainability factors. The selection of these four factors of the barriers is also made because they represent the most relevant options.

5.3. Dimension 1

In Figure 10, the two levels, “reduce” and “redesign”, are depicted. These levels belong to the first dimension, namely the D1 concept. The figure also illustrates the interaction between the two levels. Both levels hold equal rank in the model, hence neither of the levels is prioritized. In the following chapter, these two levels will be elucidated with examples.

5.3.1. Redesign

Redesign or rethink constitutes the initial level within the concept dimension. The requirements of redesign and rethink are relevant for this purpose. In the following chapter, this level is simply referred to as redesign. As depicted in Figure 10, redesign is interrelated with only one level, namely reduce. Consequently, both levels are interdependent.

In general, depending on the definition of the term, in the DSS, theoretically, most factors for improving the CE factors can be found in redesign. Thus, the dimension serves as the cornerstone for the underlying levels and unilaterally influences the second dimension. However, it is crucial to understand that the improvements in the CE concept of the product system are significantly determined here, and thus, the improvements must also be attributed to “Redesign”.

For all types of batteries, advancements in technology and new components allow for higher cycle counts and better battery performance, thereby significantly enhancing the battery’s sustainability in many aspects. There is substantial potential in these areas within the battery sector. Particularly, higher power densities, energy densities, system efficiencies, and cycle counts have a significant impact. These factors often exert a relatively high influence on the sustainability of batteries compared to other product systems, but the primary reason for the changes is based on significant cost reductions. For example, in the case of VFB, doubling the power density nearly halves the required number of cell stacks, resulting in significant material, emission, and cost savings. This statement only applies under certain conditions, above all the same maximum number of cycles and the same system efficiency [12,57].

However, innovations are a primary driver for a more sustainable development of batteries; technological progress can also deteriorate sustainability or the circular economy concept for certain indicators. For example, the membrane is frequently reinforced to ensure higher cycle stability but may also render recycling nearly impossible. Nevertheless, the VFB offers significant potential due to its stack design, as the components are partially in pure form, requiring only the disassembly of the stack. The screwing of the system is another advancement in redesign. Previously, stacks were partially welded or cast in plastic to ensure stack tightness. With technological progress, the establishment of stack screwing was implemented, leading to a reduction in complexity, which is a very exciting prospect for recycling and also for repair and refurbishment levels in D2.

However, the technical implementation of these factors is dependent on the altered stack design, which must be attributed to the redesign level. This enables much easier and more cost-effective separation of the components. These overlaps of different levels often occur in battery systems. However, a mutually negative effect like in the case of the reinforced membrane may also occur.

Depending on the size of the active area, a design without gaskets can be realized, although to our knowledge, gasket-less stack design is only possible with small active areas [18]. Whether the concept can also be used with large active areas is unclear. Since VFB gaskets often contain fluorine, this is a significant advantage despite the low weight of the gaskets. The gaskets account for 0.2% of the stack’s weight and only 0.02% of the total VFB weight. Currently, Solvay is researching the so-called NFS (non-fluoro surfactant), which eliminates the use of fluoro surfactants [97].

This phenomenon could also fall under “Reduce”. The same applies to the next generation of bipolar plates (BPP), which could be a bipolar foil. The foil can potentially reduce material requirements. Additionally, the foil can be continuously produced by extrusion, enabling efficient manufacturing. In some cases, a continuously produced BPP is also possible. However, the use of recyclates in the foil is questionable due to the significantly lower thickness of the films compared to BPP. Therefore, these factors, the lifetime and the performance parameters of the components must be considered in the decision-making process. The use of a flow field in the BPP to optimize flow behavior must also be considered. The more complex manufacturing process can positively influence the flow behavior [98,99]. On the other hand, more waste is generated during production, and depending on the design, a thicker BPP may need to be used. Contrary to general opinion, even in a closed-loop recycling scenario, a tendency toward a high recycling rate must be attributed to the redesign level. Closed-loop recycling, without contaminants, usually leads to altered material characteristics, affecting the product system. If the goal with the BPP is, for example, a high recycling rate, this must be considered in the stack assembly. Shredding and extruding the material create altered mechanical properties and various conductivities of the compound, potentially leading to thicker BPP and increased material input overall. These altered properties are frequently observed in battery-relevant components. For components with the same material properties, such as in the case of insulated aluminum recycling, it would still fall into the redesign level if aluminum is considered in the product’s design due to its recycling properties. However, in the future, new recycling, separation, or processing methods could shift the relevance toward the recycling level, necessitating a reevaluation of these levels.

A significant development is also observed in housing. VFBs are manufactured in standardized 40’ ISO HC containers in industrial applications (Sumitomo Electric, Enerox), resulting in efficient transport, economic advantages, and overall CE benefits [18]. Generally, by improving the tank design using polypropylene (PP) tanks and containers in the first lifecycle, approximately 78% of materials can be saved. The calculation is based on three containers and tanks for 2 MWh of electrolyte, requiring interpolation of the value. The calculation is compared to a reinforced concrete tank, which is also much more difficult to recycle. However, a significantly longer lifespan than 20 years could also be argued for reinforced concrete tanks. Moreover, very efficient transport is possible due to the container setup, and the facilities can be set up elsewhere with minimal effort.

Regarding transport, electrolytes are particularly notable due to their weight. In our previous work [18], it was shown that CO2 emissions, even in the worst-case scenario, are in the lower percentile range compared to the complete VFB. The electrolyte could be mixed on-site, but primarily due to the lower hazard level during transport, the electrolyte is mixed completely at the factory. The high water content in the electrolyte (approximately 60%) and the relatively low energy density make transport highly inefficient. New approaches exist that are attributed to redesign. Converting the liquid electrolyte into low-crystallinity gel can make transport more economical and ecologically efficient, reducing the electrolyte’s weight by approximately 36% [100]. Thus, some of the water is refilled on-site. Another research focus regarding the electrolyte is the utilization of a less pure electrolyte. Producing less pure vanadium results in not significantly fewer emissions, but significant cost advantages can still be achieved [12]. In the long term, it is crucial to understand how the maximum cycle count, efficiency loss, capacity loss, corrosion, and changes in cell parameters will change. The potential detrimental effects and the long-term cell performance associated with slightly impure electrolytes still need to be examined [12,101].

A core theme of the redesign level, as with the points mentioned above, is the electrolyte consisting of VP, which is a crucial subject. However, through indirect effects or advances in other product systems, a product can also benefit in terms of the CE concept. In the case of VFBs, one possibility is to obtain primary VP with fewer emissions. Vanadium, the element contained in VP, is a byproduct of the steel industry and is accordingly obtained to 80% from the processing of magnetites [102]. Through the decarbonization of the steel process via direct reduction with green hydrogen, the byproduct VP is also produced in a significantly less environmentally unfriendly manner [12,103,104]. Our calculated dataset [12] clearly indicates that 97.7% of the CO2e emissions from the electrolyte occur during conventional steel production. To ensure the performance and efficiency of the battery over 20 years, regular rebalancing must be performed in VFBs to correct the imbalance of the electrolyte. This effect has various physical and chemical causes [105,106,107]. While rebalancing is essential for the battery, it does not have a direct impact on CE strategies. Additionally, rebalancing cannot be assigned to a specific level, as it is a standard procedure. Therefore, this point is not discussed in detail in this work.

As mentioned at the beginning, there are also different types of flow batteries. The objectives are, for example, a higher energy density or to replace the entire electrolyte with a “more sustainable” alternative, which should also be the more cost-effective option in the long term. In recent years, the OFB has been widely discussed. In the realm of flow batteries, the OFB falls under the category of redesign since it deliberately avoids the critical material VP and replaces it with an organic electrolyte. However, as of the present time, the battery is still not cheaper, and labeling the OFB as a less emission-intensive alternative has yet to be demonstrated [54]. This is primarily due to the uncertain cycle stability of the electrolyte. Another advantage of the OFB is that a perfluorinated membrane is not necessarily required. Nevertheless, the impact on cycle life and efficiency must also be considered with respect to the membrane. Finding a suitable alternative membrane remains a significant challenge for the OFB. Consequently, choosing a membrane that is not stable over the long term has a negative impact on emissions and CE. Often, perfluorinated polymer ion exchange membranes (PEM), such as Nafion, are used in VFBs [108]. Consequently, the membrane dominates the stratospheric ozone depletion potential emissions of the VFB [12]. In addition to the PEM, an anion exchange membrane (AEM) can also be utilized for VFBs [109]. A separator as a membrane replacement for OFBs can tend to save emissions under certain circumstances (same lifetime, performance, etc.). However, the OFB remains an intriguing alternative to the VFB. Particularly, with the increasingly intensive utilization of artificial intelligence in science and battery research, the research pace can be significantly accelerated [110]. This would also represent a substantial advancement in the quest for suitable organic substance pairs for the electrolyte since far fewer electrolytes need to be tested in the laboratory. In recent years, another flow battery has also emerged at the forefront, marketed by various companies under different names. Essentially, these systems are based on an iron flow battery (IFB). Initially, the electrolyte, significantly cheaper due to the active species of iron in the electrolyte, appears to be less expensive. However, it remains unclear how this will evolve over the battery’s lifespan; nevertheless, a longer duration (discharge time) is generally sought for IFBs. The commissioning of a 50 MW/500 MWh IFB is also planned in Germany for 2027 [111].

In the literature, redesign especially highlights the design for cascading, with relatively little emphasis on the factor of innovation currently being addressed. This is another indication of the need for a new analysis structure for R-Strategies. Similarly, in the classic model, communication and behavior between the manufacturer and customer are emphasized. This approach will be further promoted from 2026 by the introduction of the Battery Passport in the European Union [112]. However, the specific advantages of batteries are currently only promoted at conferences, websites, and in customer interactions. From the customer’s perspective, the pros and cons regarding CE strategies are still challenging to discern.

5.3.2. Reduce

As observed in the previous chapter, the overlaps between reduce and redesign are significant in this section as well. If the stack is generally intended to be less material-intensive, individual components can be made thinner. However, particular attention must be paid to the boundary conditions, as this can have a negative impact on cycle life and performance. Furthermore, the inlet channel in the stack must then be designed to be narrower, which would result in altered pressure and flow fields in the stack. Therefore, the factor of material savings in battery systems is complex because, in general, batteries are already designed to be efficient for cost reasons. The same applies to transportation; the more cost-effective alternatives usually have a lower CO2 footprint. For stationary batteries, it makes no economic sense to transport components, for example, by airplane. It is also evident in this area that the design has changed due to optimal transport requirements. Constructing within a container creates optimal transport conditions.

Regarding the emission-intensive and critical material vanadium, which can also be obtained from fly ash from crude oil-fired boilers instead of from iron ore [57]. The development of these new sources of vanadium has three advantages. Primary VP dependency is eliminated, anticipating emission reduction, while also processing a waste product. However, it is unclear to what extent the necessary purity of VP can be achieved. Volkov et al. [113] describe the production of high-purity pentoxide through subsequent hydrometallurgical processing. However, it is unclear whether this meets the required purity of 99.8%. Bakkar et al. [114] also describe acidic leaching, alkaline leaching, and roasting for the extraction of VP. However, the purity is not specified. As with the extraction of VP from ores, the purity that can be technically and economically produced will also strongly depend on the raw material [12]. Hakimi et al. [115] report a recovery rate of VP ranging from 92.9 to 99.6%, which is a very good result, but again depends on the starting material. However, conclusive statements regarding CE require both a life cycle costing (LCC) and an LCA. Another alternative to reduce vanadium emissions is a transparent supply chain to trace vanadium back to its source. One way to implement this is through blockchain, allowing third parties to trace the data, which cannot be altered. Volvo already uses a similar concept for cobalt traceability [116].

The increased efficiency in the production of the BPP or bipolar foil has already been addressed. Particularly noteworthy is the advantageous manufacturing through a continuous production process rather than injection molding. With injection molding, significant manufacturing losses occur due to the mold, resulting in the need for considerably more raw material. This aligns closely with the previous definition of the classical r-strategies. However, contrary to the classical definition, we do not observe a reduction in product complexity; rather, the trend, driven in part by 3D printing, tends towards increasingly complex shapes to enhance battery efficiency through new cell characteristics [117,118]. While certain product systems may be simplified and designed for recyclability, the general trend in accumulators, as well as in the hydrogen sector, leans towards more complex systems.

5.3.3. Barrier from the D1 Concept to the D2 Reentry

The significance of the new barrier element has already been extensively explained. Nonetheless, in this section, the fundamental idea of this condition is reiterated through various elements. The fundamental thesis is that the next dimension can only be reached if one of the factors of the barriers is met. The self-imposed factors of the barriers are:

- -

- Effective costs;

- -

- Effective performance;

- -

- Sustainability factors;

- -

- Policies/laws.

The barrier factors are defined in such a way that only realistic scenarios are considered, thereby advancing into the next dimension accordingly. The simplest case to explain the barriers is when an alternative, while less emission-intensive, is significantly more expensive, resulting in a low probability of adoption. Upon closer examination, it becomes apparent that the various barrier factors also have interrelationships. The battery performance also influences the effective costs. As mentioned earlier, it is not just the installed capacity that matters, but the costs for storage over the entire lifecycle. In the future, pricing will become even more complicated due to CO2 levies (sustainability factors) as well as subsidies (policies/laws).

Another more complex example is if a manufacturer decides not to use per- and polyfluorinated chemicals (PFAS) in the VFB, then the analysis would halt at that point. None of the conditions would be met at this time. Effective costs would not be supported due to poorer performance, and lower stack cycle counts, among other factors. The interrelationship between the cost and performance barrier factors becomes evident. The factor is also linked to sustainability. If stacks need to be replaced much more frequently due to altered membranes, it has negative consequences for emissions. Likewise, a lower efficiency can lead to more emissions in the usage phase through renewable energies. As long as policies do not incentivize or ban PFAS, this point is not valid. Consequently, significant advantages in the following dimensions would counteract these disadvantages. Following the same line of argumentation, a bipolar foil would not be analyzed. Another example is the funding from the California Energy Commission for the largest zinc-based flow battery with 20 MWh [119]. Initially, none of the barrier factors except the political decision favors the zinc flow battery (ZFB). For a detailed analysis of the ZFB, we recommend the work of Tarroja et al. [120].

5.4. Dimension 2

As shown in Figure 10, reuse, recycle, repair, repurpose, recover, and refurbish are in an unranked order. These seven levels constitute D2 or reentry.

These factors are dependent on the changes achieved in D1 of the product or service. In the following section, the interactions of the factors will also become evident. For example, further reuse, despite a long lifespan, directly impacts remanufacture or recycling. If a VFB continues to be operated, the components contained within it degrade, reducing the economically viable expansion of the components. The same applies to recycling, as there is a risk of contamination or decomposition of the components due to the electrolyte. These points will be explained in more detail in the following.

5.4.1. Reuse

For FBs, a classical reuse level does not exist as defective or performance-diminishing components can be replaced. However, due to the definition of reuse as an R-strategy, the battery can be resold and transported to another customer with minimal effort owing to its containerized construction. This case, to our knowledge, is mainly observed in research facilities. However, for a reuse level, the altered efficiency must always be considered, as it may no longer be economically or ecologically viable to continue operating a VFB without repair. These and other factors are ensured through barrier functions, especially as repairs in VFBs are relatively easy to carry out. In the realm of traditional accumulators, the so-called second life is frequently defined as reuse in new applications for LiBs. In this scenario, old batteries, partly from electric vehicles, are utilized as stationary batteries. LiBs in the automotive sector are only used until a capacity loss of 20–30%; however, under certain conditions, these batteries can still be reused in stationary applications [121,122]. Hence, reuse is sensible because the battery may have too high a capacity loss for electric vehicles but is less problematic for stationary batteries, and refurbishing or repairing LiBs is not practical. However, in the case of automotive batteries, it could also be considered a repurpose level. The reuse level is excellent for addressing the interrelationships in D2. The following discusses the shipping of used batteries from electric vehicles, such as LiBs, to developing countries in a simplified manner. This highlights the various factors, uncertainties, and interactions involved. Several theses are formulated:

- A lower efficiency can effectively lead to more emissions: It should be noted that the converted energy, e.g., from photovoltaics, is also associated with a significant amount of emissions. With lower efficiency, efficient coupling between renewable energy and storage is not possible. This thesis would need to be precisely calculated using LCA, for instance. Our previous work [12] is suitable for the losses incurred during the use phase of batteries.

- Due to different recycling strategies, batteries and components in developing countries tend to be recycled less effectively. Furthermore, fewer components are typically extracted or reused, impacting material recovery significantly. Also, various materials may be disposed of or incinerated in a more environmentally harmful manner due to lax regulations. This thesis is not always valid but must be thoroughly investigated in each case. As described in the model, this affects the return level accordingly.

- Additionally, this could potentially circumvent costly recycling paths. Consequently, companies are no longer obliged to concern themselves with less emission-intensive EoL strategies.

However, such a scenario could be excluded through a proper definition of barrier factors. This example can be further elaborated. Similar efforts to support developing countries led to the export of old computers around 2000. However, this resulted in ecologically and socially adverse effects [123].

5.4.2. Repair

The typical repair level is a relatively small area for flow batteries in comparison. Although leaks in flow batteries represent the most common failure rates, these leaks need to be repaired in the piping [124]. The main reason is the few mechanical parts in the VFB system. Generally, the pump systems are the only mechanical parts that can be repaired [12,125]. The greatest potential for repair lies definitely in the area of stacks. The repair of the VFB can be divided into two different steps. On the one hand, the stack can be repaired, but the entire stack can also be replaced, which also belongs to the repair level [12,126]. Depending on the definition of repair, small repair steps are generally meant in the literature. This also applies to the replacement of the stacks, as the effort required to replace a stack in the overall system can be relatively low. To what extent a repair of the stack is actually implemented in practice generally depends on the different cell sizes. In the case of small cells, repair of the cells is to be excluded because the stacks are only replaced. In the case of large cells, repair is generally possible and also sensible. The repair depends on which stack component is defective and what damage is caused in the stack as a result. The runtime or cycle life the stack has undergone at the time of the defect is also relevant. At a certain point, repair or replacement of an element in the stack is no longer practical, as it is highly likely that the other components may have also reached the EoL. Nevertheless, repair of the stack is possible by replacing individual components. The economic point must also be considered for repairing the stack, as this may result in a longer downtime compared to a complete replacement. The choice of the appropriate method is also covered by the previously mentioned barrier function (cost function).

Repairing the VFB by replacing the stacks can be implemented with little effort. The downtimes of the VFB are also relatively short. The advantage is also that the on-site personnel can be trained to perform the replacement on-site. This point is becoming increasingly relevant as the integration of personnel from the respective location becomes more important for grants or applications. This point will become increasingly important, especially in developing countries, as a requirement for the approval of a project. The exclusion of complete outsourcing of a service is also taken into account by the barrier function.

5.4.3. Refurbish/Remanufacture

Refurbish and remanufacture are consolidated in this chapter due to the various definitions provided in the literature [28,40,46,93,94,127,128,129,130,131,132]. Singhal et al. [131] consider refurbishment as part of remanufacture. Moreover, these definitions often pertain to individual products rather than complex product systems like the VFB. Additionally, the question arises as to the relevance of the quality of the new product. Quality requirements for refurbished products are sometimes contradictory in the literature [46,93,94,128,133]. Strictly speaking, refurbishment does not apply to the VFB if it is considered a complete system since not all parts of the VFB are replaced. For example, when the electrolyte is refurbished, the tank or piping is not necessarily replaced simultaneously. This is due to the advantage of the VFB being able to refurbish individual components. Furthermore, the refurbished parts are not used in the same VFB system because it may lead to longer performance and capacity losses or the VFB may need to be taken out of service entirely. However, conflicting definitions exist in the literature regarding whether it is relevant for the parts to be used in the same product system or a different one. For simplification, refurbish and remanufacture are referred to as refurbish in the following. As in previous chapters, pumps, inverters, and peripherals are not part of the VFB system and therefore not included in the scope of investigation.

In general, the VFB with its unique properties is highly suitable for various refurbish/remanufacture levels. First and foremost, as previously discussed, a distinction must be made between the electrolytes and the stack. In the case of the electrolyte, it is not only the most economically and ecologically relevant component in the VFB but also a crucial component, constituting 57.2% of the mass in the predefined VFB [12]. Depending on the level of contamination, the electrolyte can be fully refurbished, leading to significant reductions in emissions and primary materials. Various scenarios were assessed in our previous work [19], and corresponding emission reductions were calculated. Depending on the level of contamination, up to 99.8% CO2e can be saved compared to primary electrolytes [19]. Consequently, the refurbish level is one of the most important levels for the successful implementation of a CE regarding emissions. Downtime of the VFB is generally not relevant, as the systems are designed for 20 years of operation, and the electrolyte has a lifespan of 20 years [126].

Regarding the stack, the most relevant components for refurbishment are the BPP, membrane, and current collector. However, refurbishment must be balanced with the lifespan of the components and their intended use. For instance, if a BPP is to be refurbished, it must be ensured that it can still reach approximately 10 years of lifespan in the VFB. If the BPP cannot reach the 10-year mark of a stack’s lifespan, it can have a significant impact, as sometimes the entire stack may need to be replaced prematurely, leading to significantly more emissions than expected over the 10-year period.

Thus, not only do the established barriers have implications, but also the R-strategies of the D2, which indirectly influence the D3. To describe the interrelationships between the different levels, the refurbishment of the BPP is mentioned as an example. If the probability of breakage of this plate is only minimally increased by refurbishment of the BPP, it has a significant impact on the various levels. For instance, the current collector would no longer be recyclable or would be recycled poorly, as it would come into contact with the electrolyte. Consequently, the current collector, usually made of copper, would degrade. Similarly, this would also affect the possibility of processing the electrolyte. With high copper contamination in the electrolyte, processing becomes increasingly unrealistic. As a result, precipitation of the VPs in the electrolyte would occur. This alternative is more emission-intensive and cost-intensive than processing [19].

In the stack area, it is usually not just defective components that are replaced, but the entire stack. This thesis depends on various factors. The functionality of different components is not binary; rather, performance fluctuates between 0 and 100%, and the lifespan can be roughly estimated based on operating time. The number of cells and the size of the active area also play a role. In larger systems, it is generally more economically feasible to replace individual stack components. Consequently, in the small stack area, all components may be replaced even if they still show good performance. Therefore, refurbishment is always possible, but it also carries significant risks. Thus, the risk must be assessed based on various factors, with ecological and economic factors being particularly important. In another scenario, the entire stack can be reused if it was put into operation only a few years before the complete decommissioning of the VFB. In this scenario, the higher probability of compatibility with other already installed systems is also given due to its age.

Furthermore, technological progress and changes in design must be considered. It can be assumed that the stack design changes during the stack’s lifetime, rendering the parts unusable for the new generation of stacks. Also, the installed global capacity of a company is relevant because refurbishment is only meaningful if the refurbished parts previously came from another facility. If, simplistically speaking, all stacks are removed and refurbished after 10 years of operation, the resulting maintenance work would lead to very long downtimes and cost issues. This problem would particularly affect smaller stacks because they are not replaced exactly after 10 years of operation but are iteratively replaced once a certain increase in resistance or capacity loss is observed. However, the assured capacity for the customer must still be guaranteed. Therefore, a certain level of scalability and maturity of the company is advisable, especially if there is an actual change in stack design and the old generation of stacks may still need to be manufactured.

In general, it becomes evident from the classical definition of refurbishment that only partial components need to be refurbished; however, this still leads to the VFB not functioning as planned. Additionally, downtime due to refurbishment work on individual parts leads to significant cost disadvantages, necessitating the development of a sophisticated logistics system to coordinate parts from different facilities and guarantee minimal downtime.

5.4.4. Repurpose

The repurpose level is of little relevance for the VFB. The complete system cannot be repurposed for another use. Only partial components can be reused. In particular, the container offers high potential for this purpose. There is a high probability that the container can be reused in other applications for up to 80 additional years after 20 years [18,134]. The extent to which the container can be reused for the second lifecycle of the VFB depends on many internal and external factors. In general, existing subsystems could also be adopted and, under certain conditions, used with a modified electrolyte. For example, if a longer duration is needed, the system could be equipped with more tanks and converted into an IFB. However, the realism of this scenario is questionable.

5.4.5. Recycling

The VFB offers excellent recycling opportunities due to its stack construction and the design described earlier [12]. However, in the field of stationary storage or emerging technologies, several points need to be considered. The following section discusses various recycling strategies, but it has already been explained why recycling of relevant stack components must also be attributed to redesign. Relevant stack components in this case include all components that have a significant impact on the performance or cycle life of the VFB.

In recycling, actual rates should be assumed because recycling rates depend on many different parameters. Economic, ecological, material composition, resource criticality, infrastructure, technological developments, location factors, legal frameworks, and the effort involved in separating various components must all be considered. In practice, it is also not sufficient to quantify recycling rates based on the material or the product alone because recycling rates of the product depend on additional factors. An important factor here is again the size of the active area. Complex cleaning and disassembly of stacks are more economically viable for larger components than for smaller active areas. The failure probabilities of stack components are also relevant, as these parts sometimes degrade or require extensive cleaning due to contamination by the electrolyte. Consequently, a simplified analysis of recycling rates for individual components is only conditionally valid. For the analysis of recycling, the assumption of bolted stacks is also made, allowing components to be dismantled with little effort.

In the literature, however, even for complex components, general recycling rates of a material are assumed, a practice that is not realistic and should be avoided. This point is particularly relevant for compact battery systems such as LiB. The recycling rates in compact battery systems may significantly differ from the pure material recycling rate. It is advisable to examine the components and recycling structures more closely for hotspots regarding various indicators in order to make statements. This approach was investigated in the BMWK 03ET6156 project. The focus was on BPP due to the sometimes high manufacturing losses during extrusion. Membrane recycling was also examined in the project. With BPP, manufacturing losses of up to 50% can occur due to production defects and edge trimming [12]. However, this value decreases drastically under better production conditions. Even a lower percentage of recycled material has an impact on the relevant requirements for BPP, although it only needs to be shredded and extruded. In particular, conductivity, mechanical stability, chemical stability, and structured surface change compared to the original material, and these factors must be considered for the recycled product. However, the influence of the redesign level on the recycling level is also evident here because if the bipolar foil is used, closed-loop recycling would no longer be possible.

Although mechanical recycling without significant foreign substances is, depending on the material, one of the most advantageous recycling strategies, especially since the complex sorting, which is normally very complex, is eliminated in this scenario [135]. Furthermore, the performance of the recycled material must also be distinguished between manufacturing losses and materials already installed and in operation.

In the case of the membrane, a distinction must generally be made between AEM and PEM during recycling. It is also relevant whether the membrane is reinforced, which significantly complicates recycling. With a reinforced membrane, manufacturing losses are also higher. With an unreinforced membrane, one can assume about 5%. Generally, there are also various sources in the literature [136,137,138,139,140] on membrane recycling; however, it is not clear how the performance parameters develop over the life cycles. Chemours, the manufacturer of the Nafion membrane, also confirmed in 2022 [141] that research on ionomer recycling is still in its early stages. However, if a closed-loop recycling rate is to be assumed, long-term stability must be demonstrated, and the very complex and energy-intensive as well as material-intensive recycling path must be very precisely included in the corresponding balances. However, the assumption of membrane recycling is questionable.

In the VFB, a fluoro rubber gasket (FKM) is also usually installed, but despite its importance, there is relatively little research. With a Web of Science search using the keyword “FKM recycling”, the first article was published in 2002, whereas only one article was published in 2021. No research was published on this topic in 2022, and in 2023, there were only two publications. A good overview of the exact recycling steps was summarized by Schuster et al. [142]. Schuster et al. mainly develop two strategies for recycling: grinding FKM with subsequent mixing of original FKM material and mechanical devulcanization of FKM with subsequent mixing of primary FKM. The mixing ratios and long-term stability are not clearly determinable. As explained in the redesign section, there are also initial stack designs without gaskets.

In contrast, other stack components such as the compression plate, current collector, or frame are available in pure form and can accordingly be assumed to have ideal recycling rates for the material. However, it must be noted how the recycling rates in the literature are composed because the materials are sometimes in pure form. This can result in a significantly higher recycling rate being realized than that indicated in the literature for the material. The recycling data from the literature often do not refer to pure forms. Sometimes, however, due to the vanadium electrolyte, prior cleaning is required. A general distinction must therefore also be made between contaminated materials, materials that have already been used, and production losses. These components fall under the classic recycling level of the R-strategies. The reason for this is that while a change in material properties is to be expected through recycling, these changes do not affect the lifespan or performance of the VFB. However, this only applies to the “other stack components”.