Synthesis Methods of Si/C Composite Materials for Lithium-Ion Batteries

Abstract

1. Introduction

2. Synthesis Methods

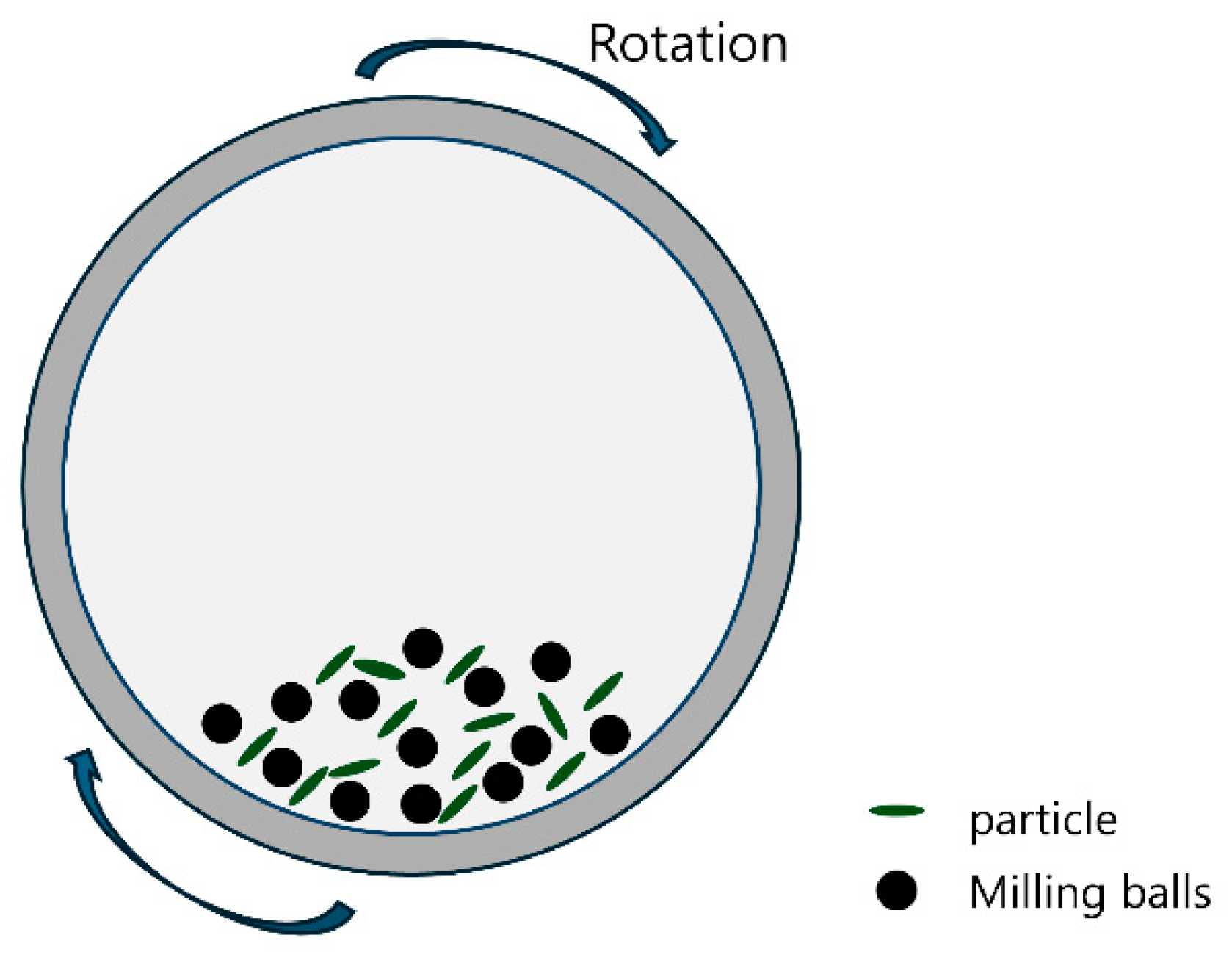

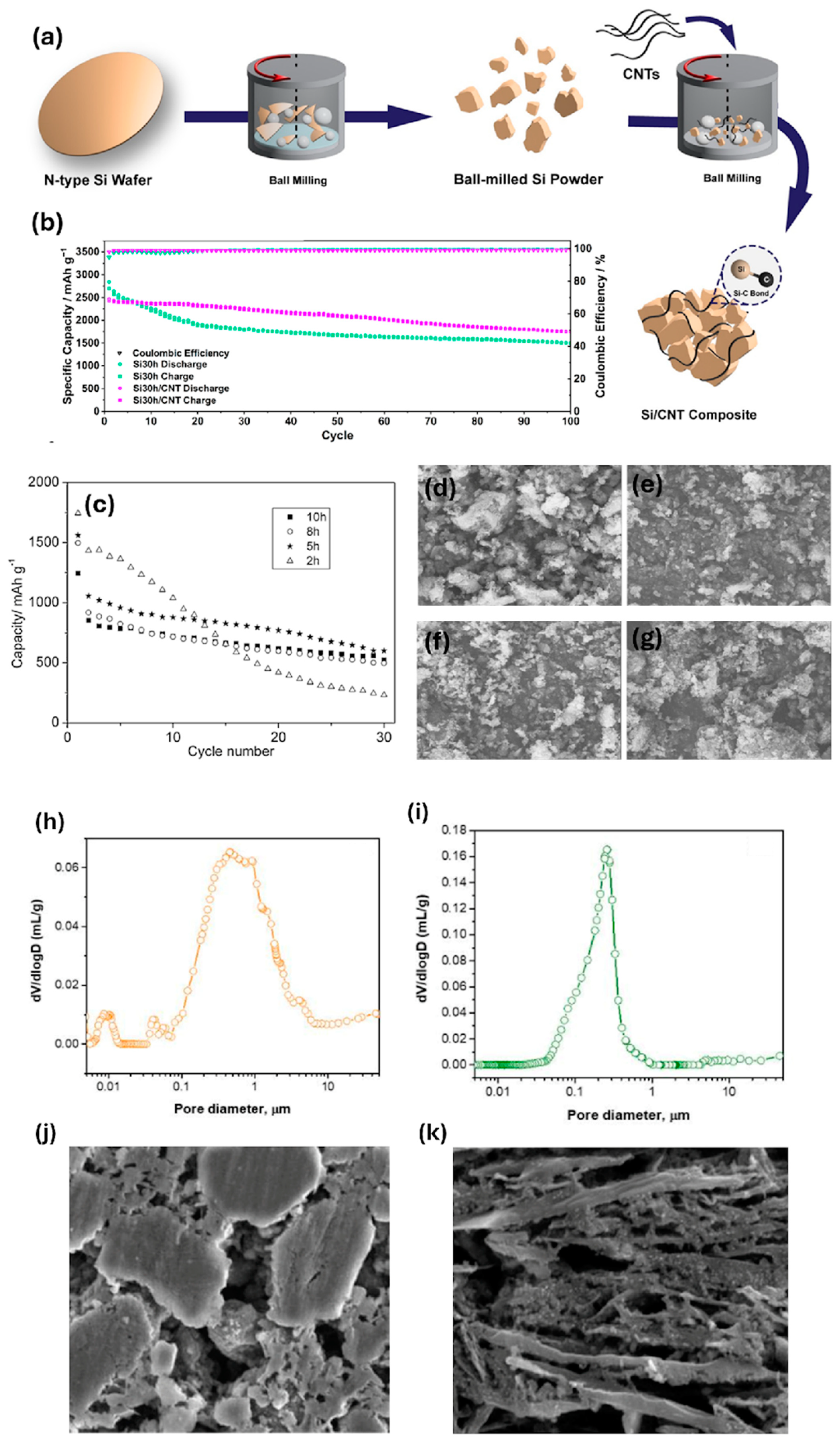

2.1. Ball Milling

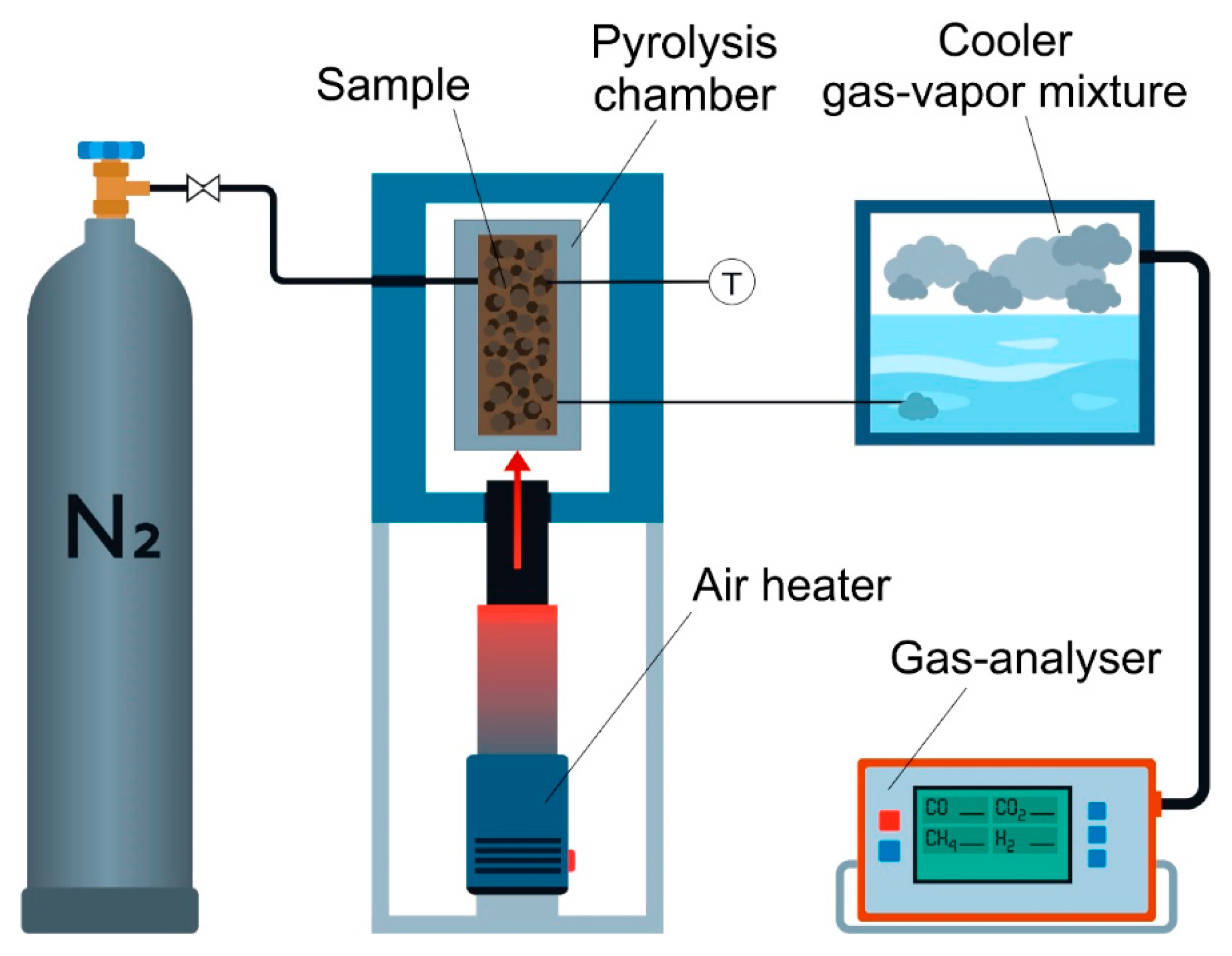

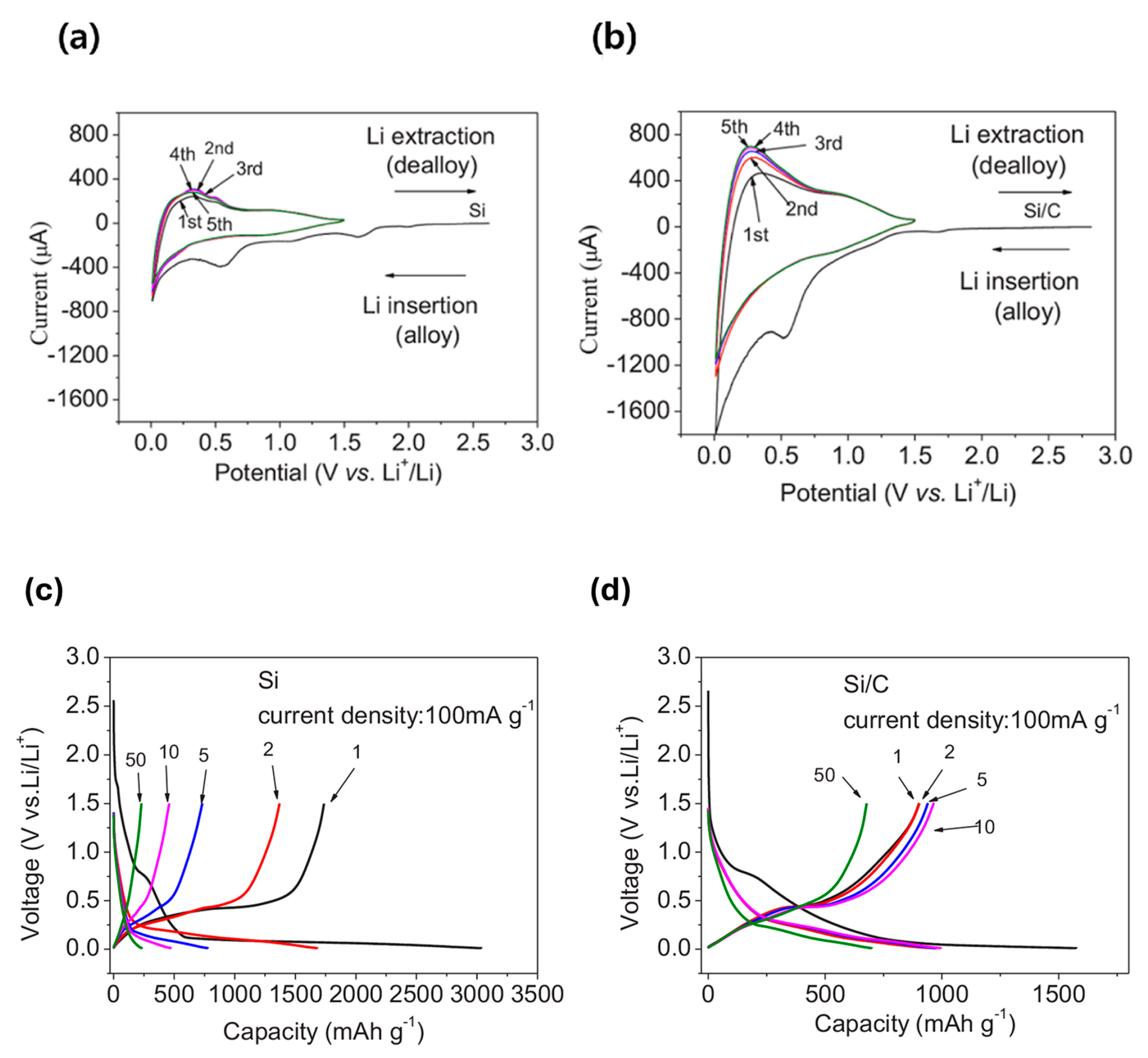

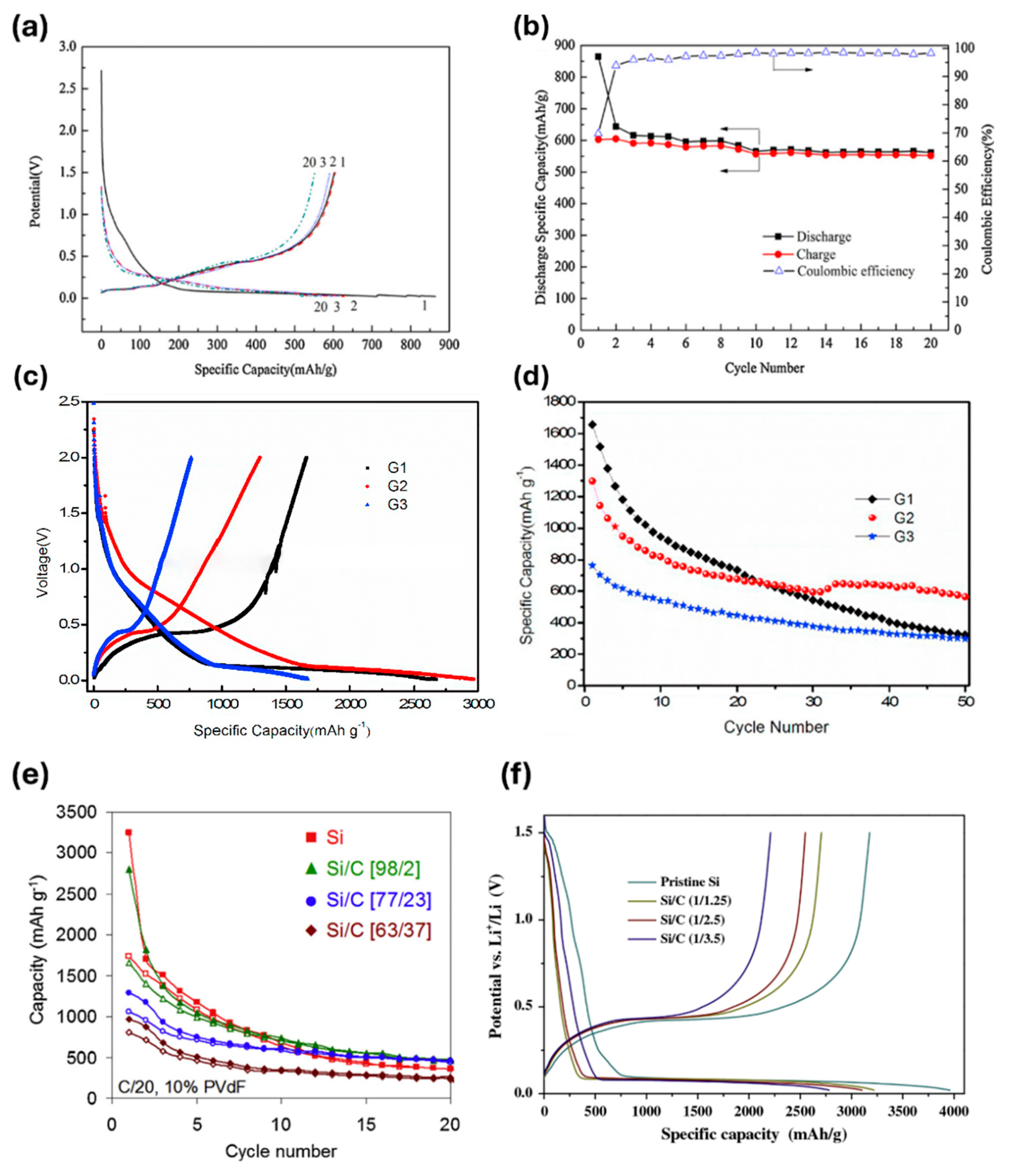

2.2. Pyrolysis

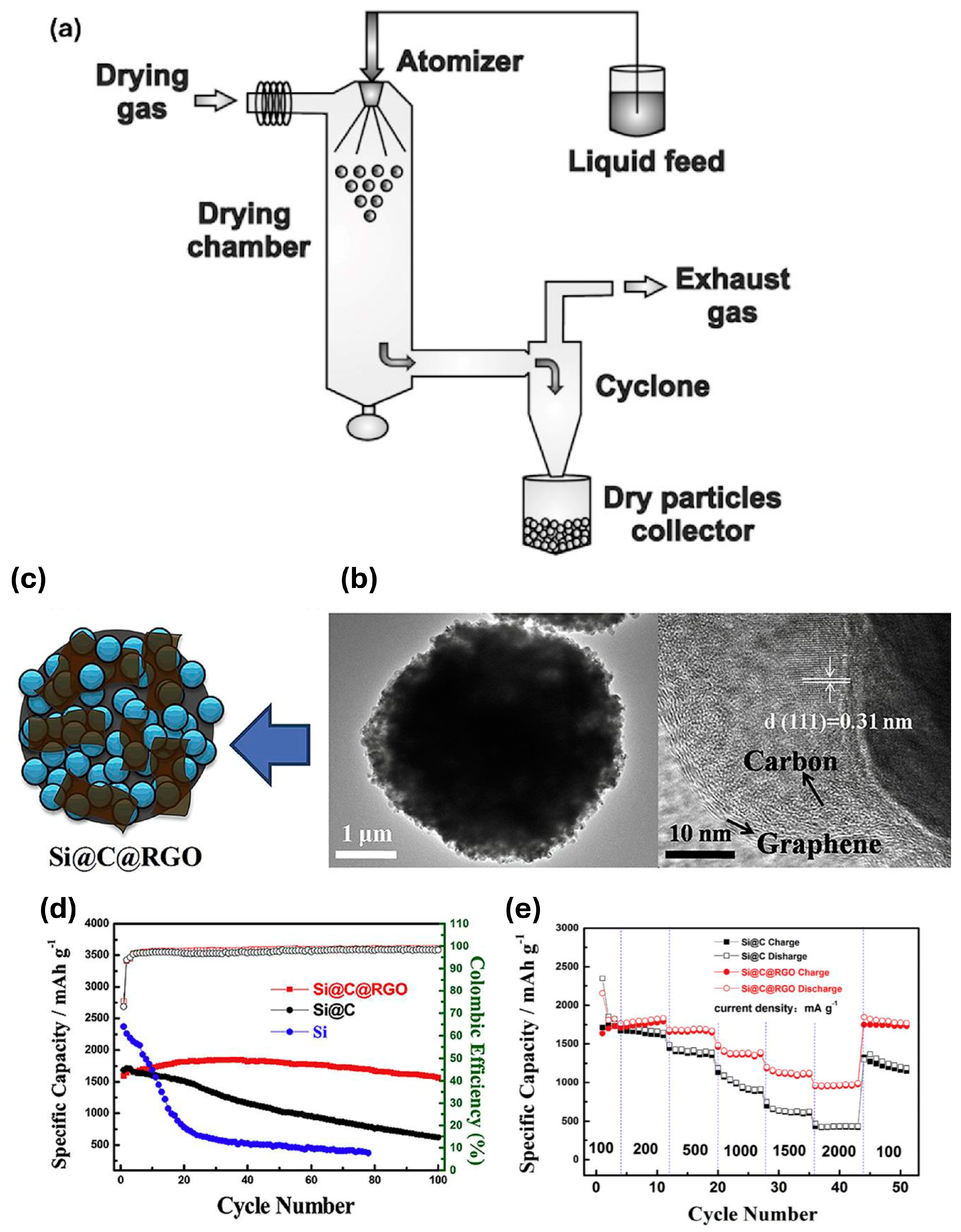

2.3. Spray Drying

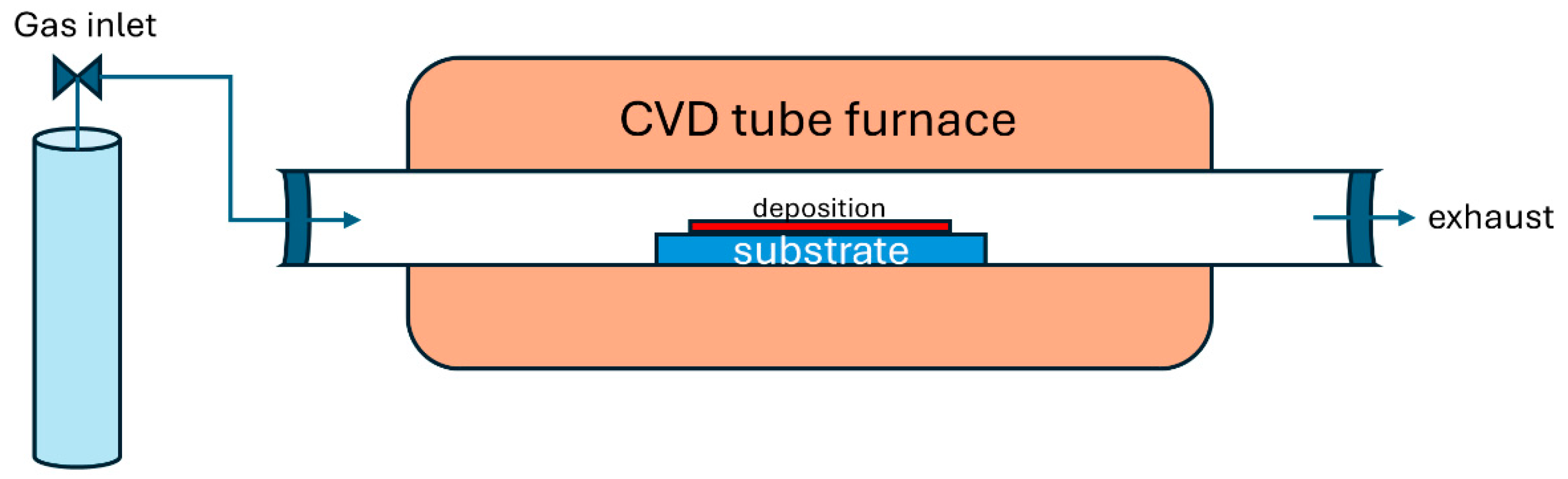

2.4. Chemical Vapor Deposition

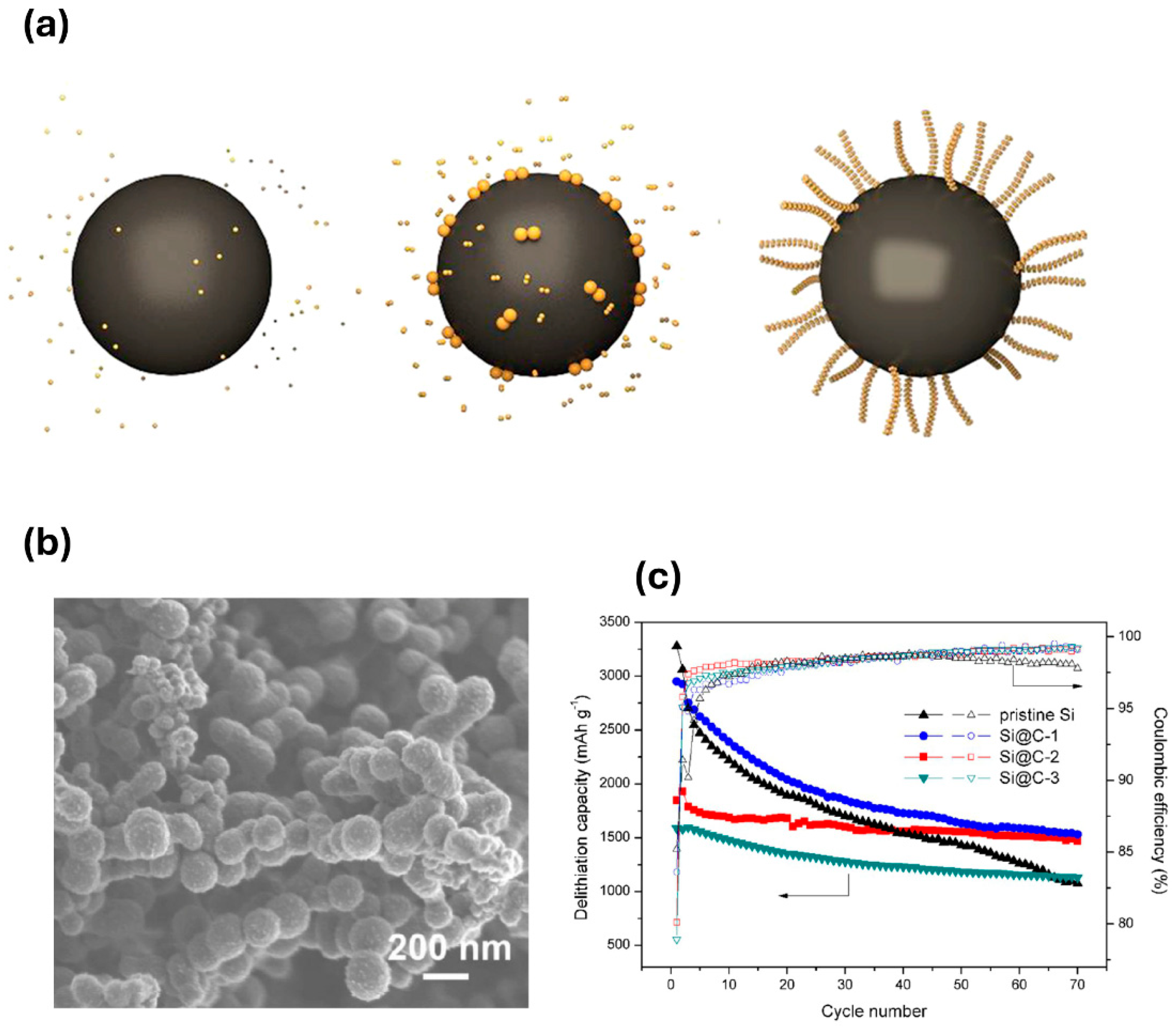

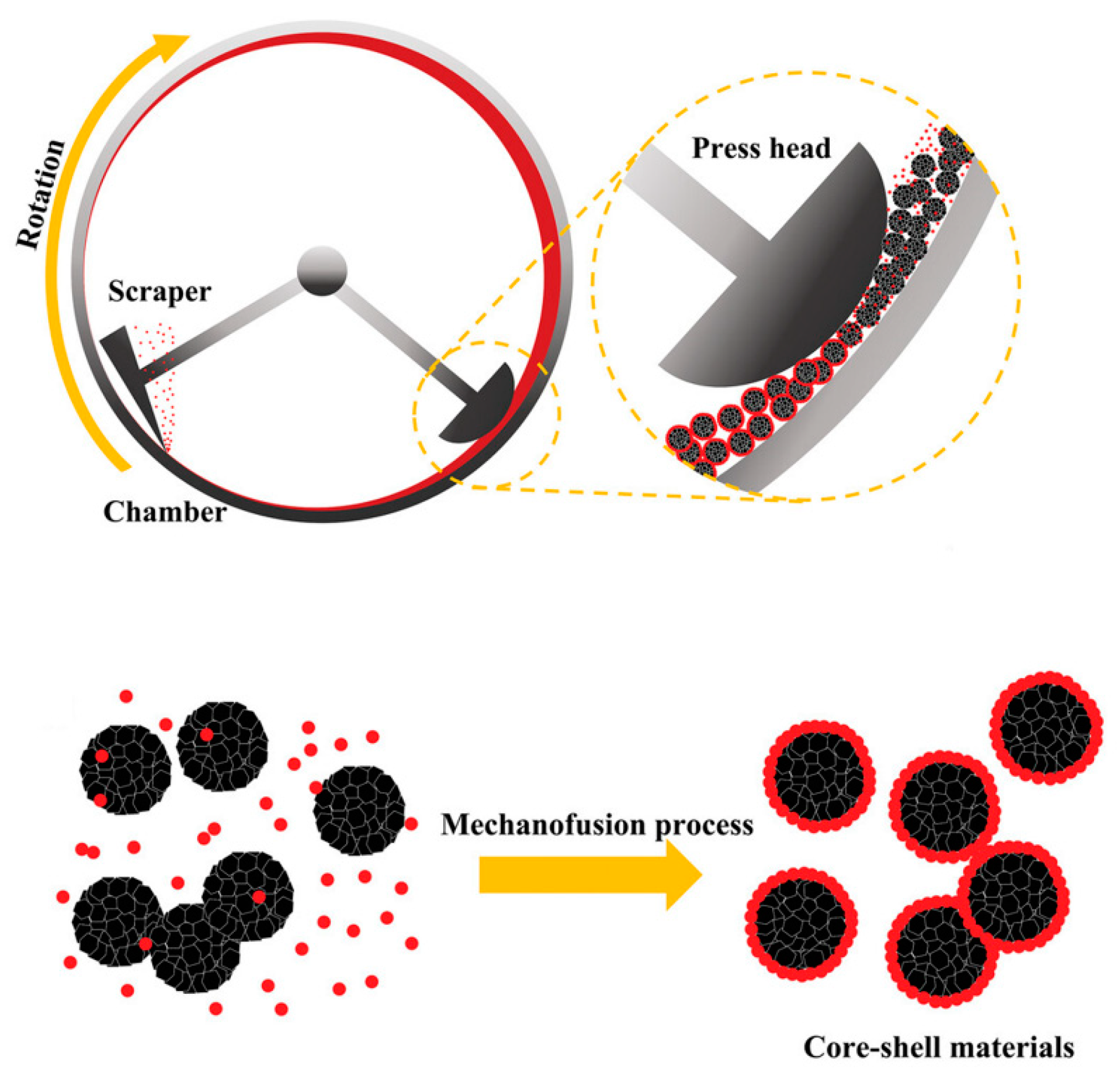

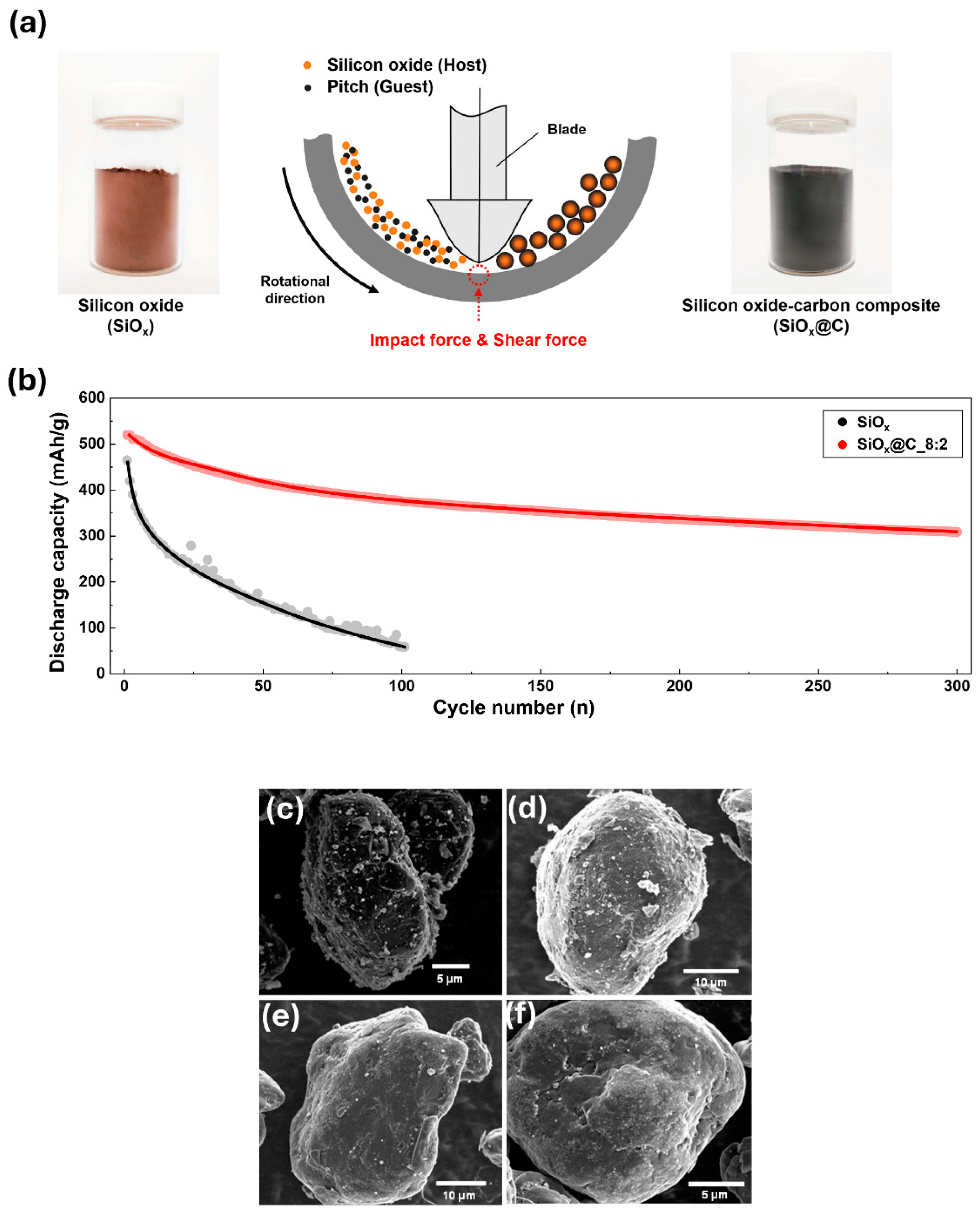

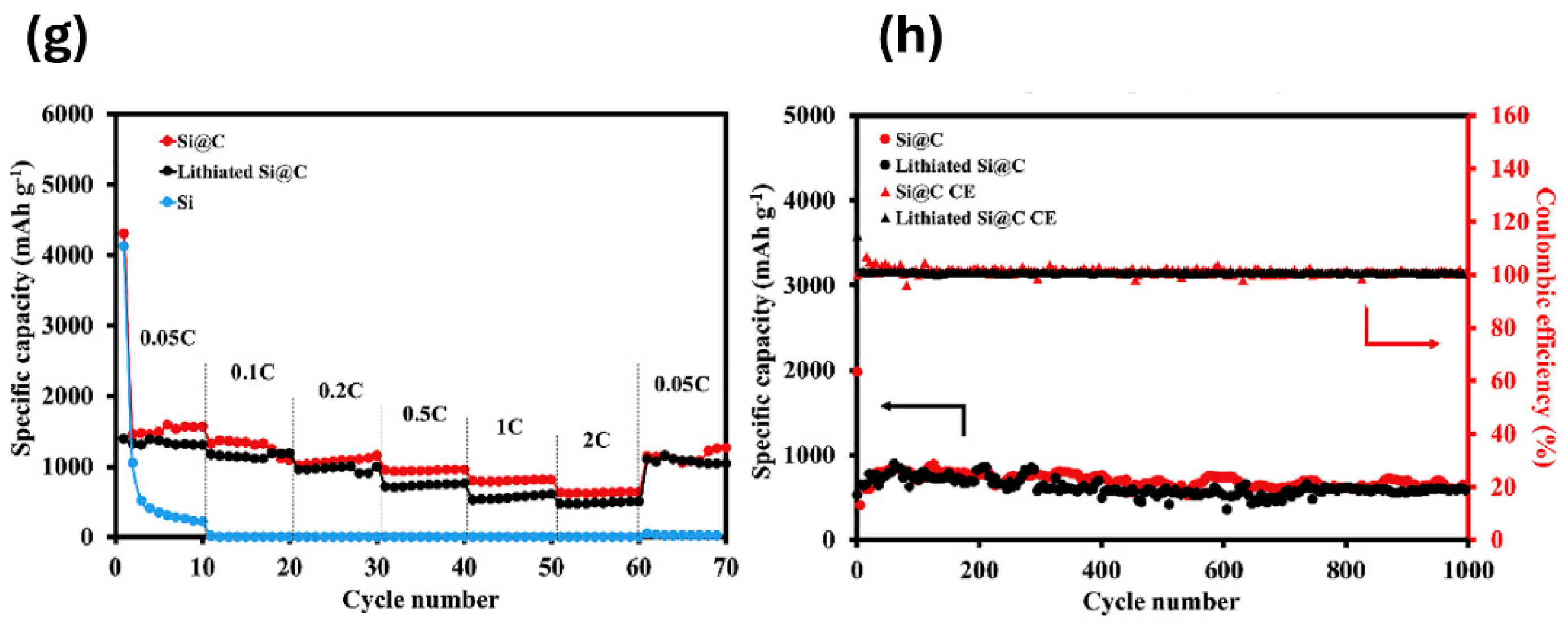

2.5. Mechanofusion

3. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dou, F.; Shi, L.Y.; Chen, G.R.; Zhang, D.S. Silicon/Carbon Composite Anode Materials for Lithium-Ion Batteries. Electrochem. Energy Rev. 2019, 2, 149–198. [Google Scholar] [CrossRef]

- Li, M.; Lu, J.; Chen, Z.W.; Amine, K. 30 Years of Lithium-Ion Batteries. Adv. Mater. 2018, 30, 1800561. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Lee, S.; Jung, D.S.; Roh, K.C.; Seo, J.; Kim, J.; Kim, K.; Kim, P.J.; Choi, J. Synergistically enhanced LiF-rich protective layer for highly stable silicon anodes. Appl. Surf. Sci. 2024, 661, 160023. [Google Scholar] [CrossRef]

- Lee, H.; Yoon, T.; Chae, O. Strategies for Enhancing the Stability of Lithium Metal Anodes in Solid-State Electrolytes. Micromachines 2024, 15, 453. [Google Scholar] [CrossRef]

- Su, H.P.; Barragan, A.A.; Geng, L.X.; Long, D.H.; Ling, L.C.; Bozhilov, K.N.; Mangolini, L.; Guo, J.C. Colloidal Synthesis of Silicon-Carbon Composite Material for Lithium-Ion Batteries. Angew. Chem. Int. Ed. 2017, 56, 10780–10785. [Google Scholar] [CrossRef]

- Nzereogu, P.U.; Omah, A.D.; Ezema, F.I.; Iwuoha, E.I.; Nwanya, A.C. Anode materials for lithium-ion batteries: A review. Appl. Surf. Sci. Adv. 2022, 9, 100233. [Google Scholar] [CrossRef]

- Ko, J.; So, S.; Kim, M.; Kim, I.; Ahn, Y.N.; Hur, J. Promoting Zn2+ migration through polar perovskite dielectric layer on Zn metal anode for the enhanced aqueous Zn-ion batteries. Chem. Eng. J. 2023, 462, 142308. [Google Scholar] [CrossRef]

- Nam, G.; Hwang, J.; Kang, D.H.; Oh, S.; Chae, S.; Yoon, M.; Ko, M.S. Mechanical densification synthesis of single-crystalline Ni-rich cathode for high-energy lithium-ion batteries. J. Energy Chem. 2023, 79, 562–568. [Google Scholar] [CrossRef]

- Song, W.; Chae, O.B.; Ryu, J.H. Surface Nitridation of Nano-sized Anatase TiO2 using Urea and Thiourea for Enhanced Electrochemical Performance in Lithium-ion Batteries. J. Electrochem. Sci. Technol. 2024, 15, 512–520. [Google Scholar] [CrossRef]

- Kim, J.; Yoon, T.; Chae, O.B. Behavior of NO3−-Based Electrolyte Additive in Lithium Metal Batteries. Batteries 2024, 10, 135. [Google Scholar] [CrossRef]

- Phan Nguyen, T.; Thi Giang, T.; Tae Kim, I. Restructuring NiO to LiNiO2: Ultrastable and reversible anodes for lithium-ion batteries. Chem. Eng. J. 2022, 437, 135292. [Google Scholar] [CrossRef]

- Sui, D.; Liu, J. Constriction-susceptible lithium support for fast cycling of solid-state lithium metal battery. Chin. Chem. Lett. 2024, 110417. [Google Scholar] [CrossRef]

- Goodenough, J.B.; Park, K.S. The Li-Ion Rechargeable Battery: A Perspective. J. Am. Chem. Soc. 2013, 135, 1167–1176. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.Y.; Chae, O.B.; Kim, G.; Peterson, A.A.; Wu, M.; Jung, H.T. Long-Range Uniform Deposition of Ag Nanoseed on Cu Current Collector for High-Performance Lithium Metal Batteries. Small 2024, 20, e2307200. [Google Scholar] [CrossRef] [PubMed]

- Park, K.; Myeong, S.; Lee, D.; Yoo, H.E.; Kim, J.; Kim, C.; Kim, J.; Sun, S.; Kwon, J.; Kim, S.C.; et al. Improved Li-ion kinetics of the anode by kneading process of binder for lithium-ion batteries with high energy density. Electrochim. Acta 2023, 464, 142900. [Google Scholar] [CrossRef]

- de las Casas, C.; Li, W.Z. A review of application of carbon nanotubes for lithium ion battery anode material. J. Power Sources 2012, 208, 74–85. [Google Scholar] [CrossRef]

- Chan, C.K.; Peng, H.L.; Liu, G.; McIlwrath, K.; Zhang, X.F.; Huggins, R.A.; Cui, Y. High-performance lithium battery anodes using silicon nanowires. Nat. Nanotechnol. 2008, 3, 31–35. [Google Scholar] [CrossRef]

- Chae, O.B.; Rynearson, L.; Lucht, B.L. Distance-Dependent Solid Electrolyte Interphase Control by Electrochemical Pretreatment. ACS Energy Lett. 2022, 7, 3087–3094. [Google Scholar] [CrossRef]

- Nguyen, T.P.; Kim, I.T. Self-Assembled Few-Layered MoS on SnO Anode for Enhancing Lithium-Ion Storage. Nanomaterials 2020, 10, 2558. [Google Scholar] [CrossRef]

- Lee, G.; Kim, I.; Hur, J. Highly conductive and robust telluride-carbon hybrid matrix for enhanced copper diphosphide anode in Li-ion batteries. J. Alloys Compd. 2023, 950, 169914. [Google Scholar] [CrossRef]

- So, S.; Ko, J.; Ahn, Y.N.; Kim, I.; Hur, J. Unraveling improved electrochemical kinetics of In2Te3-based anodes embedded in hybrid matrix for Li-ion batteries. Chem. Eng. J. 2022, 429, 132395. [Google Scholar] [CrossRef]

- Feng, K.; Li, M.; Liu, W.W.; Kashkooli, A.G.; Xiao, X.C.; Cai, M.; Chen, Z.W. Silicon-Based Anodes for Lithium-Ion Batteries: From Fundamentals to Practical Applications. Small 2018, 14, 1702737. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.C.; Uono, H.; Satou, T.; Fuse, T.; Ishihara, T.; Ue, M.; Senna, M. Cyclic properties of Si-Cu/carbon nanocomposite anodes for Li-ion secondary batteries. J. Electrochem. Soc. 2005, 152, A523–A526. [Google Scholar] [CrossRef]

- Zhang, Y.X.; Wu, B.R.; Mu, G.; Ma, C.W.; Mu, D.B.; Wu, F. Recent progress and perspectives on silicon anode: Synthesis and prelithiation for LIBs energy storage. J. Energy Chem. 2022, 64, 615–650. [Google Scholar] [CrossRef]

- Quilty, C.D.; Wu, D.R.; Li, W.Z.; Bock, D.C.; Wang, L.; Housel, L.M.; Abraham, A.; Takeuchi, K.J.; Marschilok, A.C.; Takeuchi, E.S. Electron and Ion Transport in Lithium and Lithium-Ion Battery Negative and Positive Composite Electrodes. Chem. Rev. 2023, 123, 1327–1363. [Google Scholar] [CrossRef]

- Choi, W.S.; Kim, M.; Kim, I.T. Te-rP-C Anodes Prepared Using a Scalable Milling Process for High-Performance Lithium-Ion Batteries. Micromachines 2023, 14, 2156. [Google Scholar] [CrossRef]

- Kidanu, W.G.; Hur, J.; Kim, I.T. Gallium-Indium-Tin Eutectic as a Self-Healing Room-Temperature Liquid Metal Anode for High-Capacity Lithium-Ion Batteries. Materials 2022, 15, 168. [Google Scholar] [CrossRef]

- Luo, F.; Liu, B.N.; Zheng, J.Y.; Chu, G.; Zhong, K.F.; Li, H.; Huang, X.J.; Chen, L.Q. Review-Nano-Silicon/Carbon Composite Anode Materials Towards Practical Application for Next Generation Li-Ion Batteries. J. Electrochem. Soc. 2015, 162, A2509–A2528. [Google Scholar] [CrossRef]

- Roy, P.; Srivastava, S.K. Nanostructured anode materials for lithium ion batteries. J. Mater. Chem. A 2015, 3, 2454–2484. [Google Scholar] [CrossRef]

- Bärmann, P.; Diehl, M.; Göbel, L.; Ruttert, M.; Nowak, S.; Winter, M.; Placke, T. Impact of the silicon particle size on the pre-lithiation behavior of silicon/carbon composite materials for lithium ion batteries. J. Power Sources 2020, 464, 228224. [Google Scholar] [CrossRef]

- Shi, C.; Wang, T.; Liao, X.; Qie, B.; Yang, P.; Chen, M.; Wang, X.; Srinivasan, A.; Cheng, Q.; Ye, Q.; et al. Accordion-like stretchable Li-ion batteries with high energy density. Energy Storage Mater. 2019, 17, 136–142. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Y.; Ren, D.; Wang, L.; He, X. Graphite as anode materials: Fundamental mechanism, recent progress and advances. Energy Storage Mater. 2021, 36, 147–170. [Google Scholar] [CrossRef]

- Li, P.; Kim, H.; Myung, S.T.; Sun, Y.K. Diverting Exploration of Silicon Anode into Practical Way: A Review Focused on Silicon-Graphite Composite for Lithium Ion Batteries. Energy Storage Mater. 2021, 35, 550–576. [Google Scholar] [CrossRef]

- Gonzalez, A.F.; Yang, N.H.; Liu, R.S. Silicon Anode Design for Lithium-Ion Batteries: Progress and Perspectives. J. Phys. Chem. C 2017, 121, 27775–27787. [Google Scholar] [CrossRef]

- Yoshio, M.; Wang, H.Y.; Fukuda, K.; Umeno, T.; Dimov, N.; Ogumi, Z. Carbon-coated Si as a lithium-ion battery anode material. J. Electrochem. Soc. 2002, 149, A1598–A1603. [Google Scholar] [CrossRef]

- Sun, L.; Liu, Y.X.; Shao, R.; Wu, J.; Jiang, R.Y.; Jin, Z. Recent progress and future perspective on practical silicon anode-based lithium ion batteries. Energy Storage Mater. 2022, 46, 482–502. [Google Scholar] [CrossRef]

- Preman, A.N.; Vo, T.N.; Choi, S.; Lee, H.; Lim, Y.E.; Kim, I.; Ahn, S.K. Self-Healable Poly(Acrylic Acid) Binder toward Optimized Electrochemical Performance for Silicon Anodes: Importance of Balanced Properties. ACS Appl. Energy Mater. 2024, 7, 749–759. [Google Scholar] [CrossRef]

- Gu, M.; He, Y.; Zheng, J.M.; Wang, C.M. Nanoscale silicon as anode for Li-ion batteries: The fundamentals, promises, and challenges. Nano Energy 2015, 17, 366–383. [Google Scholar] [CrossRef]

- Chen, X.; Li, H.X.; Yan, Z.H.; Cheng, F.Y.; Chen, J. Structure design and mechanism analysis of silicon anode for lithium-ion batteries. Sci. China Mater. 2019, 62, 1515–1536. [Google Scholar] [CrossRef]

- Liu, X.Y.; Zhu, X.J.; Pan, D. Solutions for the problems of silicon-carbon anode materials for lithium-ion batteries. R. Soc. Open Sci. 2018, 5, 172370. [Google Scholar] [CrossRef]

- Park, E.; So, S.; Hur, J. Carbon-free hydrated cobalt vanadium oxide as a promising anode for lithium-ion batteries. Appl. Surf. Sci. 2022, 579, 152182. [Google Scholar] [CrossRef]

- Li, P.; Zhao, G.Q.; Zheng, X.B.; Xu, X.; Yao, C.H.; Sun, W.P.; Dou, S.X. Recent progress on silicon-based anode materials for practical lithium-ion battery applications. Energy Storage Mater. 2018, 15, 422–446. [Google Scholar] [CrossRef]

- Ozanam, F.; Rosso, M. Silicon as anode material for Li-ion batteries. Mater. Sci. Eng. B-Adv. 2016, 213, 2–11. [Google Scholar] [CrossRef]

- Jin, Y.; Zhu, B.; Lu, Z.D.; Liu, N.; Zhu, J. Challenges and Recent Progress in the Development of Si Anodes for Lithium-Ion Battery. Adv. Energy Mater. 2017, 7, 1700715. [Google Scholar] [CrossRef]

- Shen, T.; Yao, Z.J.; Xia, X.H.; Wang, X.L.; Gu, C.D.; Tu, J.P. Rationally Designed Silicon Nanostructures as Anode Material for Lithium-Ion Batteries. Adv. Eng. Mater. 2018, 20, 1700591. [Google Scholar] [CrossRef]

- Szczech, J.R.; Jin, S. Nanostructured silicon for high capacity lithium battery anodes. Energy Environ. Sci. 2011, 4, 56–72. [Google Scholar] [CrossRef]

- Wu, H.; Cui, Y. Designing nanostructured Si anodes for high energy lithium ion batteries. Nano Today 2012, 7, 414–429. [Google Scholar] [CrossRef]

- Rahman, M.A.; Song, G.S.; Bhatt, A.I.; Wong, Y.C.; Wen, C.E. Nanostructured Silicon Anodes for High-Performance Lithium-Ion Batteries. Adv. Funct. Mater. 2016, 26, 647–678. [Google Scholar] [CrossRef]

- Teki, R.; Datta, M.K.; Krishnan, R.; Parker, T.C.; Lu, T.M.; Kumta, P.N.; Koratkar, N. Nanostructured Silicon Anodes for Lithium Ion Rechargeable Batteries. Small 2009, 5, 2236–2242. [Google Scholar] [CrossRef]

- Cao, Z.; Zheng, X.Y.; Qu, Q.T.; Huang, Y.H.; Zheng, H.H. Electrolyte Design Enabling a High-Safety and High-Performance Si Anode with a Tailored Electrode-Electrolyte Interphase. Adv. Mater. 2021, 33, 2103178. [Google Scholar] [CrossRef]

- Zhang, S.; He, M.N.; Su, C.C.; Zhang, Z.C. Advanced electrolyte/additive for lithium-ion batteries with silicon anode. Curr. Opin. Chem. Eng. 2016, 13, 24–35. [Google Scholar] [CrossRef]

- Xu, C.; Lindgren, F.; Philippe, B.; Gorgoi, M.; Björefors, F.; Edström, K.; Gustafsson, T. Improved Performance of the Silicon Anode for Li-Ion Batteries: Understanding the Surface Modification Mechanism of Fluoroethylene Carbonate as an Effective Electrolyte Additive. Chem. Mat. 2015, 27, 2591–2599. [Google Scholar] [CrossRef]

- Liu, H.B.; Sun, Q.; Zhang, H.Q.; Cheng, J.; Li, Y.Y.; Zeng, Z.; Zhang, S.; Xu, X.; Ji, F.J.; Li, D.P.; et al. The application road of silicon-based anode in lithium-ion batteries: From liquid electrolyte to solid-state electrolyte. Energy Storage Mater. 2023, 55, 244–263. [Google Scholar] [CrossRef]

- He, Y.; Jiang, L.; Chen, T.W.; Xu, Y.B.; Jia, H.P.; Yi, R.; Xue, D.C.; Song, M.; Genc, A.; Bouchet-Marquis, C.; et al. Progressive growth of the solid-electrolyte interphase towards the Si anode interior causes capacity fading. Nat. Nanotechnol. 2021, 16, 1113–1120. [Google Scholar] [CrossRef]

- Xu, Z.X.; Yang, J.; Li, H.P.; Nuli, Y.N.; Wang, J.L. Electrolytes for advanced lithium ion batteries using silicon-based anodes. J. Mater. Chem. A 2019, 7, 9432–9446. [Google Scholar] [CrossRef]

- Li, Z.H.; Zhang, Y.P.; Liu, T.F.; Gao, X.H.; Li, S.Y.; Ling, M.; Liang, C.D.; Zheng, J.C.; Lin, Z. Silicon Anode with High Initial Coulombic Efficiency by Modulated Trifunctional Binder for High-Areal-Capacity Lithium-Ion Batteries. Adv. Energy Mater. 2020, 10, 1903110. [Google Scholar] [CrossRef]

- Gao, S.L.; Sun, F.Y.; Brady, A.; Pan, Y.Y.; Erwin, A.; Yang, D.D.; Tsukruk, V.; Stack, A.G.; Saito, T.; Yang, H.B.; et al. Ultra-efficient polymer binder for silicon anode in high-capacity lithium-ion batteries. Nano Energy 2020, 73, 104804. [Google Scholar] [CrossRef]

- Magasinski, A.; Zdyrko, B.; Kovalenko, I.; Hertzberg, B.; Burtovyy, R.; Huebner, C.F.; Fuller, T.F.; Luzinov, I.; Yushin, G. Toward Efficient Binders for Li-Ion Battery Si-Based Anodes: Polyacrylic Acid. ACS Appl. Mater. Interfaces 2010, 2, 3004–3010. [Google Scholar] [CrossRef]

- Liu, D.; Zhao, Y.; Tan, R.; Tian, L.L.; Liu, Y.D.; Chen, H.B.; Pan, F. Novel conductive binder for high-performance silicon anodes in lithium ion batteries. Nano Energy 2017, 36, 206–212. [Google Scholar] [CrossRef]

- Preman, A.N.; Lee, H.; Yoo, J.; Kim, I.; Saito, T.; Ahn, S.K. Progress of 3D network binders in silicon anodes for lithium ion batteries. J. Mater. Chem. A 2020, 8, 25548–25570. [Google Scholar] [CrossRef]

- Luo, W.; Chen, X.Q.; Xia, Y.; Chen, M.; Wang, L.J.; Wang, Q.Q.; Li, W.; Yang, J.P. Surface and Interface Engineering of Silicon-Based Anode Materials for Lithium-Ion Batteries. Adv. Energy Mater. 2017, 7, 1701083. [Google Scholar] [CrossRef]

- Jiang, C.L.; Xiang, L.; Miao, S.J.; Shi, L.; Xie, D.H.; Yan, J.X.; Zheng, Z.J.; Zhang, X.M.; Tang, Y.B. Flexible Interface Design for Stress Regulation of a Silicon Anode toward Highly Stable Dual-Ion Batteries. Adv. Mater. 2020, 32, e1908470. [Google Scholar] [CrossRef]

- Lv, Y.Y.; Han, Z.B.; Jia, R.R.; Shi, L.Y.; Yuan, S. Porous interface for fast charging silicon anode. Battery Energy 2022, 1, 20220009. [Google Scholar] [CrossRef]

- Wang, L.; Lu, J.J.; Li, S.Y.; Xi, F.S.; Tong, Z.Q.; Chen, X.H.; Wei, K.X.; Ma, W.H. Controllable Interface Engineering for the Preparation of High Rate Silicon Anode. Adv. Funct. Mater. 2024, 34, 2403574. [Google Scholar] [CrossRef]

- Wang, L.; Yu, J.; Li, S.Y.; Xi, F.S.; Ma, W.H.; Wei, K.X.; Lu, J.J.; Tong, Z.Q.; Liu, B.; Luo, B. Recent advances in interface engineering of silicon anodes for enhanced lithium-ion battery performance. Energy Storage Mater. 2024, 66, 103243. [Google Scholar] [CrossRef]

- Zuo, X.X.; Zhu, J.; Müller-Buschbaum, P.; Cheng, Y.J. Silicon based lithium-ion battery anodes: A chronicle perspective review. Nano Energy 2017, 31, 113–143. [Google Scholar] [CrossRef]

- Andersen, H.F.; Foss, C.E.L.; Voje, J.; Tronstad, R.; Mokkelbost, T.; ErikVullum, P.; Ulvestad, A.; Kirkengen, M.; Mæhlen, J.P. Silicon-Carbon composite anodes from industrial battery grade silicon. Sci. Rep. 2019, 9, 14814. [Google Scholar] [CrossRef]

- Liu, Y.; Hanai, K.; Yang, J.; Imanishi, N.; Hirano, A.; Takeda, Y. Silicon/carbon composites as anode materials for Li-ion batteries. Electrochem. Solid-State Lett. 2004, 7, A369–A372. [Google Scholar] [CrossRef]

- Wang, J.Z.; Zhong, C.; Chou, S.L.; Liu, H.K. Flexible free-standing graphene-silicon composite film for lithium-ion batteries. Electrochem. Commun. 2010, 12, 1467–1470. [Google Scholar] [CrossRef]

- Mhadhbi, M. Modelling of the High-Energy Ball Milling Process. Adv. Mat. Phys. Chem. 2021, 11, 31–44. [Google Scholar] [CrossRef]

- Yu, S.X.; Guo, B.B.; Zeng, T.B.; Qu, H.Q.; Yang, J.L.; Bai, J.M. Graphene-based lithium-ion battery anode materials manufactured by mechanochemical ball milling process: A review and perspective. Compos. Pt. B-Eng. 2022, 246, 110232. [Google Scholar] [CrossRef]

- Bhagyaraj, S.M.; Oluwafemi, O.S.; Kalarikkal, N.; Thomas, S. Synthesis of Inorganic Nanomaterials: Advances and Key Technologies; Woodhead Publishing: Duxford, UK; Cambridge, MA, USA, 2018; p. 12. 300p. [Google Scholar]

- Zhang, Y.; Cheng, Y.; Song, J.; Zhang, Y.; Shi, Q.; Wang, J.; Tian, F.; Yuan, S.; Su, Z.; Zhou, C.; et al. Functionalization-assistant ball milling towards Si/graphene anodes in high performance Li-ion batteries. Carbon 2021, 181, 300–309. [Google Scholar] [CrossRef]

- Wang, D.; Gao, M.; Pan, H.; Wang, J.; Liu, Y. High performance amorphous-Si@SiOx/C composite anode materials for Li-ion batteries derived from ball-milling and in situ carbonization. J. Power Sources 2014, 256, 190–199. [Google Scholar] [CrossRef]

- Qian, L.; Lan, J.-L.; Xue, M.; Yu, Y.; Yang, X. Two-step ball-milling synthesis of a Si/SiOx/C composite electrode for lithium ion batteries with excellent long-term cycling stability. RSC Adv. 2017, 7, 36697–36704. [Google Scholar] [CrossRef]

- Koraag, P.Y.E.; Firdaus, A.M.; Hawari, N.H.; Refino, A.D.; Dempwolf, W.; Iskandar, F.; Peiner, E.; Wasisto, H.S.; Sumboja, A. Covalently Bonded Ball-Milled Silicon/CNT Nanocomposite as Lithium-Ion Battery Anode Material. Batteries 2022, 8, 165. [Google Scholar] [CrossRef]

- Cu, P.; Cai, R.; Zhou, Y.K.; Shao, Z.P. Si/C composite lithium-ion battery anodes synthesized from coarse silicon and citric acid through combined ball milling and thermal pyrolysis. Electrochim. Acta 2010, 55, 3876–3883. [Google Scholar]

- Cabello, M.; Gucciardi, E.; Herrán, A.; Carriazo, D.; Villaverde, A.; Rojo, T. Towards a High-Power Si@graphite Anode for Lithium Ion Batteries through a Wet Ball Milling Process. Molecules 2020, 25, 2494. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.G.; Zhang, H.L.; Zhao, Z.G.; Li, F.; Liu, C.; Cheng, H.M. Composite anode material of silicon/graphite/carbon nanotubes for Li-ion batteries. Electrochim. Acta 2006, 51, 4994–5000. [Google Scholar] [CrossRef]

- Han, J.; Zhao, C.C.; Wang, L.; Song, J.; Yang, D.; Tian, Q.H. Simple ball milling-assisted method enabling N-doped carbon embedded Si for high performance lithium-ion battery anode. J. Alloys Compd. 2023, 966, 171668. [Google Scholar] [CrossRef]

- Gorshkov, A.; Berezikov, N.; Kaltaev, A.; Yankovsky, S.; Slyusarsky, K.; Tabakaev, R.; Larionov, K. Analysis of the Physicochemical Characteristics of Biochar Obtained by Slow Pyrolysis of Nut Shells in a Nitrogen Atmosphere. Energies 2021, 14, 8075. [Google Scholar] [CrossRef]

- Kaur, R.; Gera, P.; Jha, M.K.; Bhaskar, T. Chapter 8—Thermochemical Route for Biohydrogen Production. In Biohydrogen, 2nd ed.; Pandey, A., Mohan, S.V., Chang, J.-S., Hallenbeck, P.C., Larroche, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 187–218. [Google Scholar]

- Zhang, G.W.; He, Y.Q.; Feng, Y.; Wang, H.F.; Zhang, T.; Xie, W.N.; Zhu, X.N. Enhancement in liberation of electrode materials derived from spent lithium-ion battery by pyrolysis. J. Clean. Prod. 2018, 199, 62–68. [Google Scholar] [CrossRef]

- Chen, Y.L.; Hu, Y.; Shao, J.Z.; Shen, Z.; Chen, R.Z.; Zhang, X.W.; He, X.; Song, Y.Z.; Xing, X.L. Pyrolytic carbon-coated silicon/carbon nanofiber composite anodes for high-performance lithium-ion batteries. J. Power Sources 2015, 298, 130–137. [Google Scholar] [CrossRef]

- Yang, Z.W.; Yang, Y.; Guo, H.J.; Wang, Z.X.; Li, X.H.; Zhou, Y.; Wang, J.X. Compact structured silicon/carbon composites as high-performance anodes for lithium ion batteries. Ionics 2018, 24, 3405–3411. [Google Scholar] [CrossRef]

- Hu, J.Z.; Wang, M.; Meyer, A.W.; Huang, X.S.; Cheng, Y.T. Oxidative Pyrolysis of Si/Polyacrylonitrile Composites as an Unconventional Approach to Fabricate High Performance Lithium Ion Battery Negative Electrodes. J. Electrochem. Soc. 2019, 166, A3716–A3722. [Google Scholar] [CrossRef]

- Su, M.R.; Wang, Z.X.; Guo, H.J.; Li, X.H.; Huang, S.L.; Gan, L. Silicon, flake graphite and phenolic resin-pyrolyzed carbon based Si/C composites as anode material for lithium-ion batteries. Adv. Powder Technol. 2013, 24, 921–925. [Google Scholar] [CrossRef]

- Wang, M.S.; Fan, L.Z. Silicon/carbon nanocomposite pyrolyzed from phenolic resin as anode materials for lithium-ion batteries. J. Power Sources 2013, 244, 570–574. [Google Scholar] [CrossRef]

- Campbell, H.R.; Alsharif, F.M.; Marsac, P.J.; Lodder, R.A. The Development of a Novel Pharmaceutical Formulation of D-Tagatose for Spray-Drying. J. Pharm. Innov. 2022, 17, 194–206. [Google Scholar] [CrossRef]

- Sosnik, A.; Seremeta, K.P. Advantages and challenges of the spray-drying technology for the production of pure drug particles and drug-loaded polymeric carriers. Adv. Colloid Interface Sci. 2015, 223, 40–54. [Google Scholar] [CrossRef]

- Pan, Q.R.; Zuo, P.J.; Lou, S.F.; Mu, T.S.; Du, C.Y.; Cheng, X.Q.; Ma, Y.L.; Gao, Y.Z.; Yin, G.P. Micro-sized spherical silicon@carbon@graphene prepared by spray drying as anode material for lithium-ion batteries. J. Alloys Compd. 2017, 723, 434–440. [Google Scholar] [CrossRef]

- Lai, J.; Guo, H.J.; Wang, Z.X.; Li, X.H.; Zhang, X.P.; Wu, F.X.; Yue, P. Preparation and characterization of flake graphite/silicon/carbon spherical composite as anode materials for lithium-ion batteries. J. Alloys Compd. 2012, 530, 30–35. [Google Scholar] [CrossRef]

- Su, M.R.; Liu, S.; Tao, L.; Tang, Y.P.; Dou, A.C.; Lv, J.; Liu, Y.J. Silicon@graphene composite prepared by spray-drying method as anode for lithium ion batteries. J. Electroanal. Chem. 2019, 844, 86–90. [Google Scholar] [CrossRef]

- Paireau, C.; Jouanneau, S.; Ammar, M.R.; Simon, P.; Béguin, F.; Raymundo-Piñero, E. Si/C composites prepared by spray drying from cross-linked polyvinyl alcohol as Li-ion batteries anodes. Electrochim. Acta 2015, 174, 361–368. [Google Scholar] [CrossRef]

- Wang, D.S.; Gao, M.X.; Pan, H.G.; Liu, Y.F.; Wang, J.H.; Li, S.Q.; Ge, H.W. Enhanced cycle stability of micro-sized Si/C anode material with low carbon content fabricated via spray drying and in situ carbonization. J. Alloys Compd. 2014, 604, 130–136. [Google Scholar] [CrossRef]

- Shi, Q.T.; Zhou, J.H.; Ullah, S.; Yang, X.Q.; Tokarska, K.; Trzebicka, B.; Ta, H.Q.; Rümmeli, M.H. A review of recent developments in Si/C composite materials for Li-ion batteries. Energy Storage Mater. 2021, 34, 735–754. [Google Scholar] [CrossRef]

- Ren, J.; Zhang, Y.; Li, J.; Tian, S.; Fei, T.; Li, H. Effects of deposition temperature and time on HfC nanowires synthesized by CVD on SiC-coated C/C composites. Ceram. Int. 2016, 42, 5623–5628. [Google Scholar] [CrossRef]

- Shukrullah, S.; Mohamed, N.; Shaharun, M.; Saheed, M.; Irshad, M. Effect of CVD process temperature on activation energy and structural growth of MWCNTs. Metall. Mater. Trans. A 2016, 47, 1413–1424. [Google Scholar] [CrossRef]

- Wang, W.; Kumta, P.N. Nanostructured Hybrid Silicon/Carbon Nanotube Heterostructures: Reversible High-Capacity Lithium-Ion Anodes. ACS Nano 2010, 4, 2233–2241. [Google Scholar] [CrossRef]

- Fu, K.; Xue, L.G.; Yildiz, O.; Li, S.L.; Lee, H.; Li, Y.; Xu, G.J.; Zhou, L.; Bradford, P.D.; Zhang, X.W. Effect of CVD carbon coatings on Si@CNF composite as anode for lithium-ion batteries. Nano Energy 2013, 2, 976–986. [Google Scholar] [CrossRef]

- Jin, H.C.; Sun, Q.; Wang, J.T.; Ma, C.; Ling, L.C.; Qiao, W.M. Preparation and electrochemical properties of novel silicon-carbon composite anode materials with a core-shell structure. New Carbon Mater. 2021, 36, 390–398. [Google Scholar] [CrossRef]

- Liu, B.; Huang, P.; Xie, Z.Y.; Huang, Q.Z. Large-Scale Production of a Silicon Nanowire/Graphite Composites Anode via the CVD Method for High-Performance Lithium-Ion Batteries. Energy Fuels 2021, 35, 2758–2765. [Google Scholar] [CrossRef]

- Yu, J.L.; Yang, J.; Feng, X.J.; Jia, H.; Wang, J.L.; Lu, W. Uniform Carbon Coating on Silicon Nanoparticles by Dynamic CVD Process for Electrochemical Lithium Storage. Ind. Eng. Chem. Res. 2014, 53, 12697–12704. [Google Scholar] [CrossRef]

- Chen, W.L.; Dave, R.N.; Pfeffer, R.; Walton, O. Numerical simulation of Mechanofusion system. Powder Technol. 2004, 146, 121–136. [Google Scholar] [CrossRef]

- Alonso, M.; Satoh, M.; Miyanami, K. Mechanism of the combined coating-mechanofusion processing of powders. Powder Technol. 1989, 59, 45–52. [Google Scholar] [CrossRef]

- Tubtimkuna, S.; Danilov, D.L.; Sawangphruk, M.; Notten, P.H.L. Review of the Scalable Core-Shell Synthesis Methods: The Improvements of Li-Ion Battery Electrochemistry and Cycling Stability. Small Methods 2023, 7, e2300345. [Google Scholar] [CrossRef]

- Kim, S.J.; Ha, S.J.; Lee, J.U.; Jeon, Y.P.; Hong, J.Y.; Bedia, J.; Vedyagin, A.A. Preparation of Silicon Oxide-Carbon Composite with Tailored Electrochemical Properties for Anode in Lithium-Ion Batteries. C-J. Carbon Res. 2023, 9, 114. [Google Scholar] [CrossRef]

- Cao, Y.D.; Hatchard, T.D.; Dunlap, R.A.; Obrovac, M.N. Mechanofusion-derived Si-alloy/graphite composite electrode materials for Li-ion batteries. J. Mater. Chem. A 2019, 7, 8335–8343. [Google Scholar] [CrossRef]

- Jiang, H.R.; Salehabadi, M.; Yasmin, S.; Wang, J.; Obrovac, M.N. Nano-Si Filled Graphite Anode Particles by Mechanofusion. J. Electrochem. Soc. 2023, 170, 120511. [Google Scholar] [CrossRef]

- Wutthiprom, J.; Phattharasupakun, N.; Tomon, C.; Sawangphruk, M. Scalable solvent-free mechanofusion and magnesiothermic reduction processes for obtaining carbon nanospheres-encapsulated crystalline silicon anode for Li-ion batteries. Electrochim. Acta 2020, 352, 136457. [Google Scholar] [CrossRef]

| Synthesis Method | Advantages | Disadvantages | Materials | Capacity | Ref. |

|---|---|---|---|---|---|

| Ball milling | Large-scale production | Non-uniform particles | Si/CNT | 1760 mAh/g after 100 cycles | [76] |

| Pyrolysis | High yield | High energy | Si/C | 1555 mAh/g after 100 cycles | [86] |

| Spray Drying | Spherical particle, simple process | Bulky equipment | Si/C | 1041 mAh/g after 50 cycles | [91] |

| CVD | Uniform particle, various particle design | Expensive process | pSi-CNF | 848 mAh/g after 100 cycles | [101] |

| Mechanofusion | Spherical particle | Expensive process | Si/C | 600 mAh/g after 1000 cycles | [109] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, I.; Lee, H.; Chae, O.B. Synthesis Methods of Si/C Composite Materials for Lithium-Ion Batteries. Batteries 2024, 10, 381. https://doi.org/10.3390/batteries10110381

Park I, Lee H, Chae OB. Synthesis Methods of Si/C Composite Materials for Lithium-Ion Batteries. Batteries. 2024; 10(11):381. https://doi.org/10.3390/batteries10110381

Chicago/Turabian StylePark, Inkyu, Hanbyeol Lee, and Oh B. Chae. 2024. "Synthesis Methods of Si/C Composite Materials for Lithium-Ion Batteries" Batteries 10, no. 11: 381. https://doi.org/10.3390/batteries10110381

APA StylePark, I., Lee, H., & Chae, O. B. (2024). Synthesis Methods of Si/C Composite Materials for Lithium-Ion Batteries. Batteries, 10(11), 381. https://doi.org/10.3390/batteries10110381