In Operando Health Monitoring for Lithium-Ion Batteries in Electric Propulsion Using Deep Learning

Abstract

1. Introduction

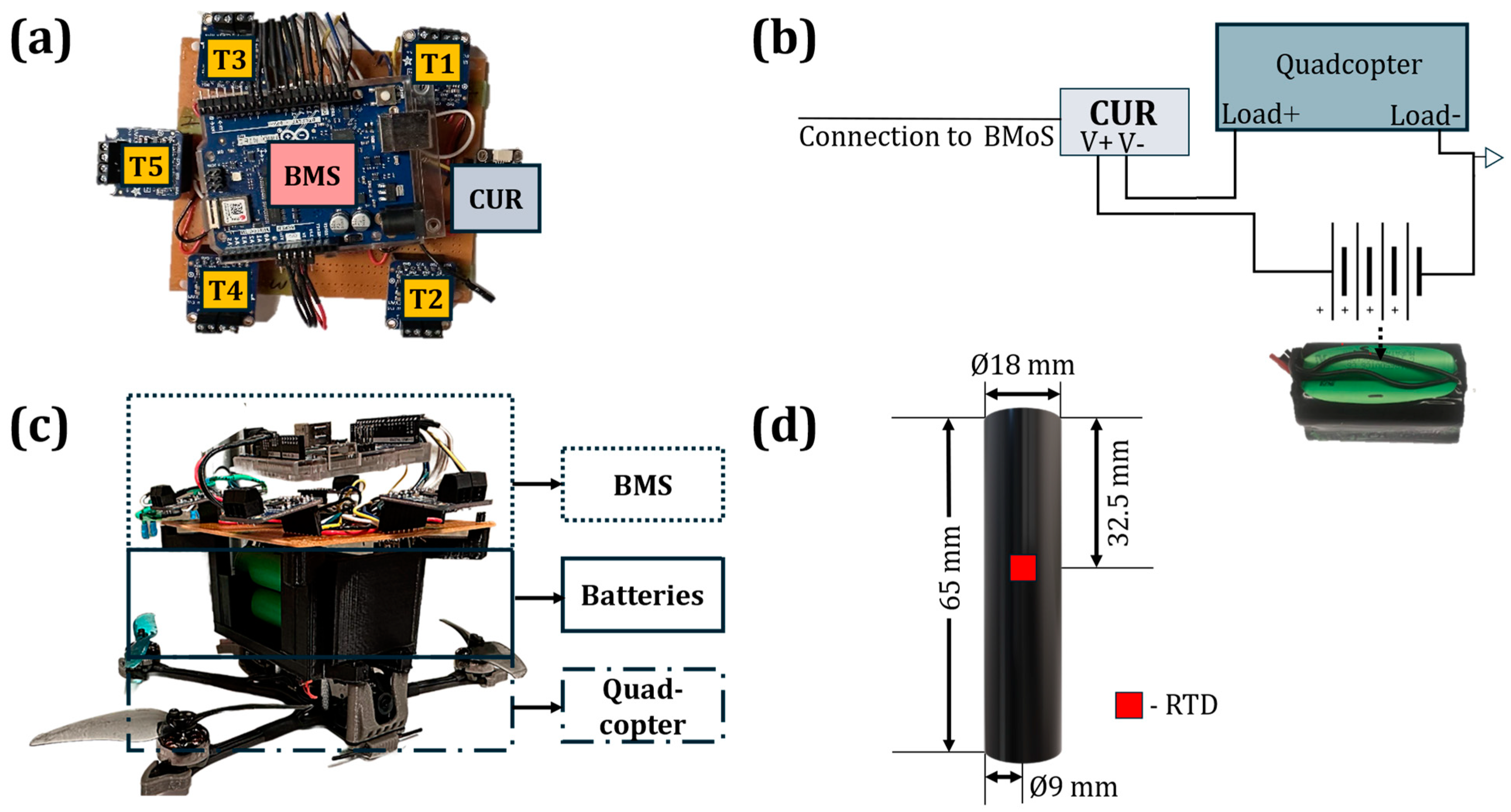

2. Development of BMS

2.1. Sensor Measurement

2.1.1. Current and Voltage Measurement

2.1.2. Temperature Measurement

2.2. Device Control

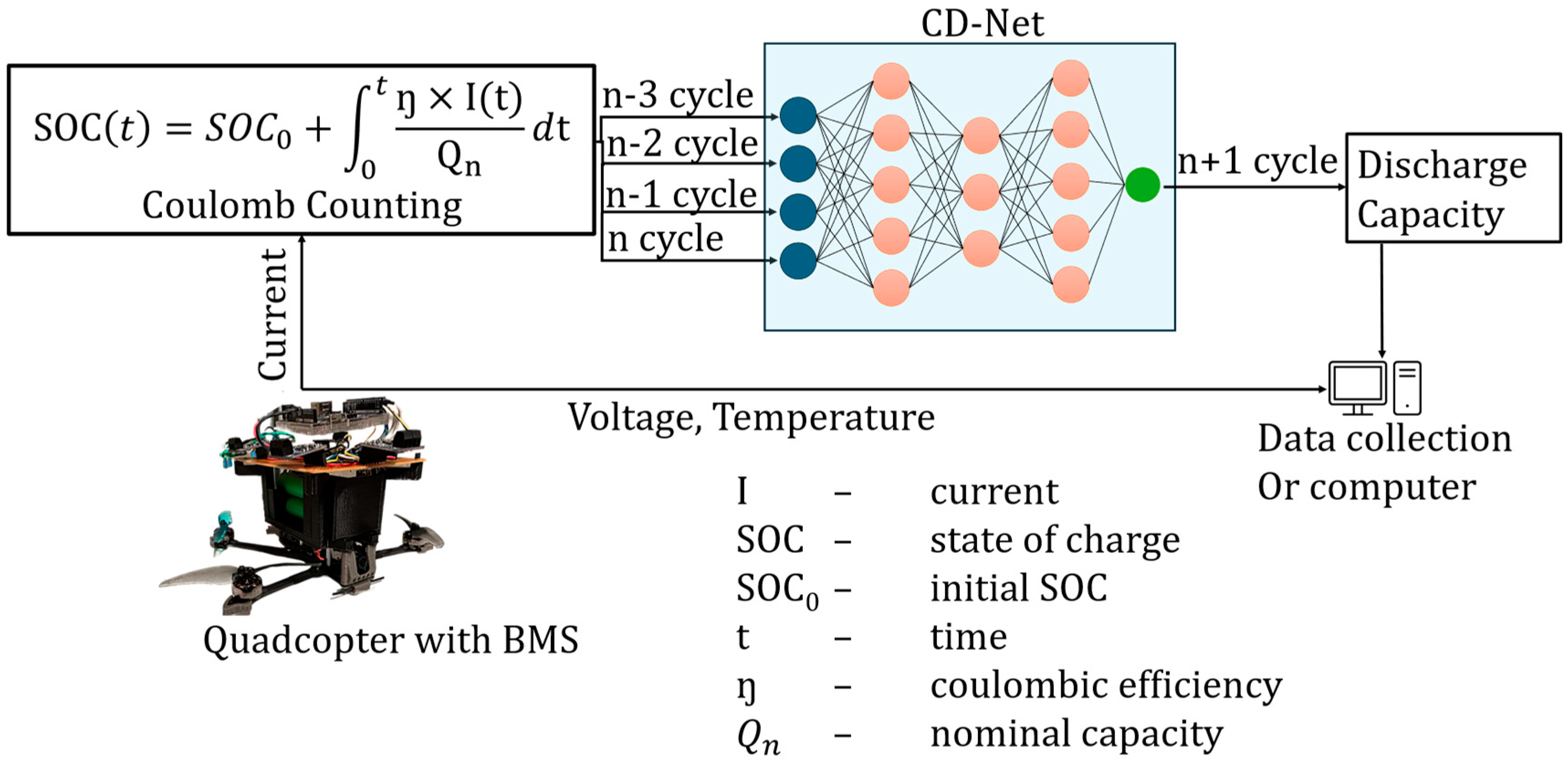

2.3. SOH Estimation on BMS

3. Experimental Setup

3.1. On-Ground Testing

3.2. In-Air Testing

4. Results and Discussion

4.1. On-Ground Voltage Profile Measurements

4.2. On-Ground Current Profile Measurements

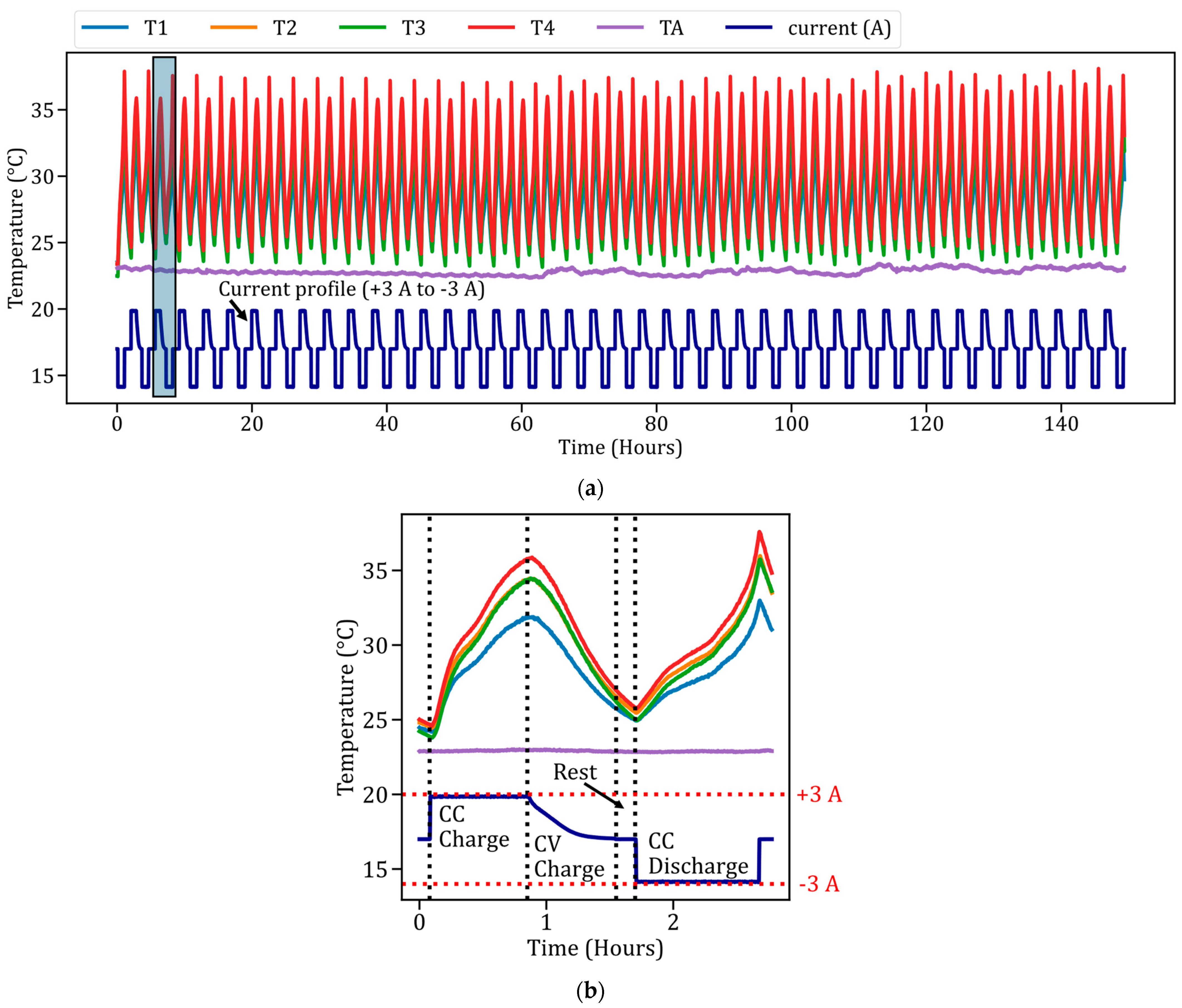

4.3. On-Ground Temperature Profile Measurements

4.4. In-Air Current and Voltage Profile Measurements

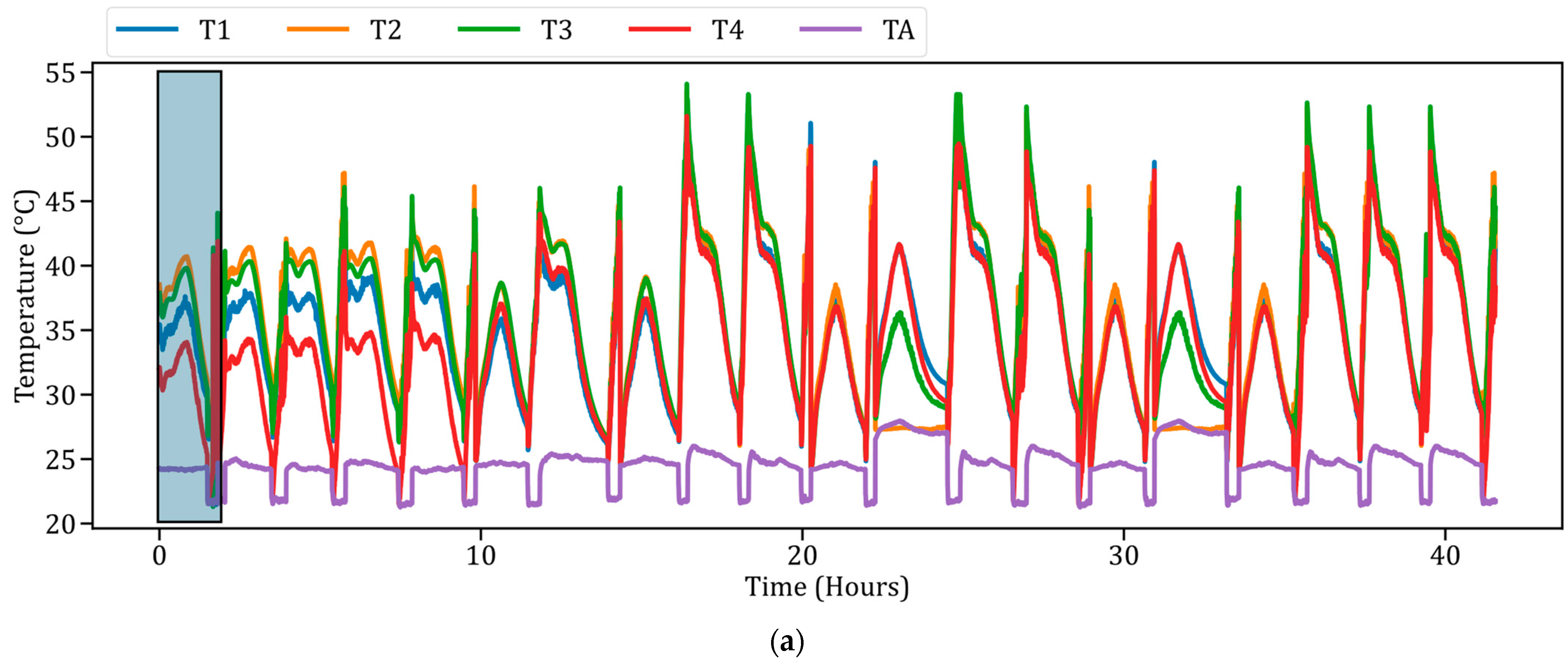

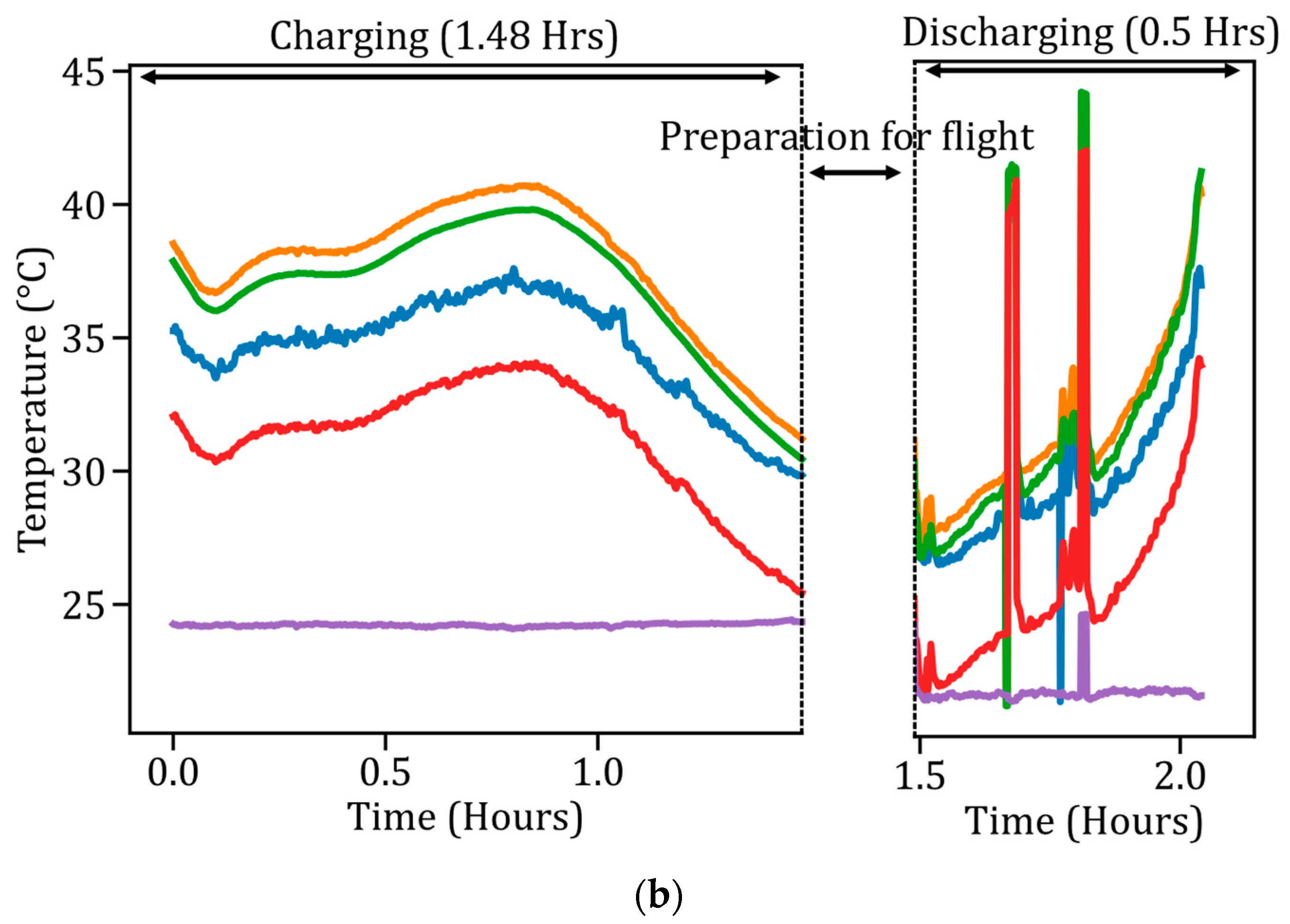

4.5. In-Air Temperature Profile Measurements

4.6. Deep Learning Integration with BMS

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Scrosati, B.; Garche, J. Lithium batteries: Status, prospects and future. J. Power Sources 2010, 195, 2419–2430. [Google Scholar] [CrossRef]

- Tarascon, J.M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 2001, 414, 359–367. [Google Scholar] [CrossRef]

- Xiong, R.; Li, L.; Tian, J. Towards a smarter battery management system: A critical review on battery state of health monitoring methods. J. Power Sources 2018, 405, 18–29. [Google Scholar] [CrossRef]

- Pradhan, S.K.; Chakraborty, B. Battery management strategies: An essential review for battery state of health monitoring techniques. J. Energy Storage 2022, 51, 104427. [Google Scholar] [CrossRef]

- Peng, P.; Jiang, F. Thermal safety of lithium-ion batteries with various cathode materials: A numerical study. Int. J. Heat. Mass. Transf. 2016, 103, 1008–1016. [Google Scholar] [CrossRef]

- Vezzini, A. Lithium-Ion Battery Management. In Lithium-Ion Batteries; Elsevier: Amsterdam, The Netherlands, 2014; pp. 345–360. [Google Scholar]

- Lelie, M.; Braun, T.; Knips, M.; Nordmann, H.; Ringbeck, F.; Zappen, H.; Sauer, D.U. Battery Management System Hardware Concepts: An Overview. Appl. Sci. 2018, 8, 534. [Google Scholar] [CrossRef]

- Hasib, S.A.; Islam, S.; Chakrabortty, R.K.; Ryan, M.J.; Saha, D.K.; Ahamed, M.H.; Moyeen, S.I.; Das, S.K.; Ali, M.F.; Islam, M.R.; et al. A Comprehensive Review of Available Battery Datasets, RUL Prediction Approaches, and Advanced Battery Management. IEEE Access 2021, 9, 86166–86193. [Google Scholar] [CrossRef]

- Kunz, M.R.; Dufek, E.J.; Yi, Z.; Gering, K.L.; Shirk, M.G.; Smith, K.; Chen, B.; Wang, Q.; Gasper, P.; Bewley, R.L.; et al. Early Battery Performance Prediction for Mixed Use Charging Profiles Using Hierarchal Machine Learning. Batter. Supercaps 2021, 4, 1186–1196. [Google Scholar] [CrossRef]

- Huang, Z.; Best, M.; Knowles, J.; Fly, A. Adaptive Piecewise Equivalent Circuit Model with SOC/SOH Estimation Based on Extended Kalman Filter. IEEE Trans. Energy Convers. 2023, 38, 959–970. [Google Scholar] [CrossRef]

- Gasper, P.; Schiek, A.; Smith, K.; Shimonishi, Y.; Yoshida, S. Predicting battery capacity from impedance at varying temperature and state of charge using machine learning. Cell Rep. Phys. Sci. 2022, 3, 101184. [Google Scholar] [CrossRef]

- Smith, K.; Gasper, P.; Colclasure, A.M.; Shimonishi, Y.; Yoshida, S. Lithium-Ion Battery Life Model with Electrode Cracking and Early-Life Break-in Processes. J. Electrochem. Soc. 2021, 168, 100530. [Google Scholar] [CrossRef]

- Raijmakers, L.H.J.; Danilov, D.L.; Eichel, R.A.; Notten, P.H.L. A review on various temperature-indication methods for Li-ion batteries. Appl. Energy 2019, 240, 918–945. [Google Scholar] [CrossRef]

- Rao, Z.; Lyu, P.; Du, P.; He, D.; Huo, Y.; Liu, C. Thermal safety and thermal management of batteries. Battery Energy 2022, 1, 20210019. [Google Scholar] [CrossRef]

- Tran, M.K.; Panchal, S.; Khang, T.D.; Panchal, K.; Fraser, R.; Fowler, M. Concept Review of a Cloud-Based Smart Battery Management System for Lithium-Ion Batteries: Feasibility, Logistics, and Functionality. Batteries 2022, 8, 19. [Google Scholar] [CrossRef]

- Li, B.; Jones, C.M.; Tomar, V. Overdischarge Detection and Prevention with Temperature Monitoring of Li-Ion Batteries and Linear Regression-Based Machine Learning. J. Electrochem. Energy Convers. Storage 2021, 18, 040905. [Google Scholar] [CrossRef]

- Jones, C.; Sudarshan, M.; Tomar, V. Predicting the discharge capacity of a lithium-ion battery after nail puncture using a Gaussian process regression with incremental capacity analysis. Energy 2023, 285, 129364. [Google Scholar] [CrossRef]

- Jia, J.; Liang, J.; Shi, Y.; Wen, J.; Pang, X.; Zeng, J. SOH and RUL Prediction of Lithium-Ion Batteries Based on Gaussian Process Regression with Indirect Health Indicators. Energies 2020, 13, 375. [Google Scholar] [CrossRef]

- Nizam, M.; Maghfiroh, H.; Rosadi, R.A.; Kusumaputri, K.D.U. Battery management system design (BMS) for lithium ion batteries. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2020; p. 030157. [Google Scholar]

- Patil, M.A.; Tagade, P.; Hariharan, K.S.; Kolake, S.M.; Song, T.; Yeo, T.; Doo, S. A novel multistage Support Vector Machine based approach for Li ion battery remaining useful life estimation. Appl. Energy 2015, 159, 285–297. [Google Scholar] [CrossRef]

- Wang, S.; Jin, S.; Deng, D.; Fernandez, C. A Critical Review of Online Battery Remaining Useful Lifetime Prediction Methods. Front. Mech. Eng. 2021, 7, 719718. [Google Scholar] [CrossRef]

- Shen, S.; Sadoughi, M.; Li, M.; Wang, Z.; Hu, C. Deep convolutional neural networks with ensemble learning and transfer learning for capacity estimation of lithium-ion batteries. Appl. Energy 2020, 260, 114296. [Google Scholar] [CrossRef]

- Tian, J.; Xiong, R.; Shen, W.; Lu, J.; Sun, F. Flexible battery state of health and state of charge estimation using partial charging data and deep learning. Energy Storage Mater. 2022, 51, 372–381. [Google Scholar] [CrossRef]

- Sudarshan, M.; Serov, A.; Jones, C.; Ayalasomayajula, S.M.; García, R.E.; Tomar, V. Data-driven autoencoder neural network for onboard BMS Lithium-ion battery degradation prediction. J. Energy Storage 2024, 82, 110575. [Google Scholar] [CrossRef]

- Saxena, S.; Xing, Y.; Kwon, D.; Pecht, M. Accelerated degradation model for C-rate loading of lithium-ion batteries. Int. J. Electr. Power Energy Syst. 2019, 107, 438–445. [Google Scholar] [CrossRef]

- Sripad, S.; Bills, A.; Viswanathan, V. A review of safety considerations for batteries in aircraft with electric propulsion. MRS Bull. 2021, 46, 435–442. [Google Scholar] [CrossRef]

- Li, M.; Feng, M.; Luo, D.; Chen, Z. Fast Charging Li-Ion Batteries for a New Era of Electric Vehicles. Cell Rep. Phys. Sci. 2020, 1, 100212. [Google Scholar] [CrossRef]

- Tomaszewska, A.; Chu, Z.; Feng, X.; O’Kane, S.; Liu, X.; Chen, J.; Ji, C.; Endler, E.; Li, R.; Liu, L.; et al. Lithium-ion battery fast charging: A review. eTransportation 2019, 1, 100011. [Google Scholar] [CrossRef]

- Ouyang, D.; Chen, M.; Liu, J.; Wei, R.; Weng, J.; Wang, J. Investigation of a commercial lithium-ion battery under overcharge/over-discharge failure conditions. RSC Adv. 2018, 8, 33414–33424. [Google Scholar] [CrossRef] [PubMed]

- Selvabharathi, D.; Muruganantham, N. Experimental analysis on battery based health monitoring system for electric vehicle. Mater. Today Proc. 2021, 45, 1552–1558. [Google Scholar] [CrossRef]

- Jinasena, A.; Spitthoff, L.; Wahl, M.S.; Lamb, J.J.; Shearing, P.R.; Strømman, A.H.; Burheim, O.S. Online Internal Temperature Sensors in Lithium-Ion Batteries: State-of-the-Art and Future Trends. Front. Chem. Eng. 2022, 4, 804704. [Google Scholar] [CrossRef]

- Maroșan, A.; Constantin, G.; Gîrjob, C.E.; Chicea, A.L.; Crenganis, M. Real Time Data Acquisition of Low-Cost Current Sensors Acs712-05 and Ina219 Using Raspberry Pi, Daqcplate and Node-Red. Proc. Manuf. Syst. 2023, 18, 51–59. [Google Scholar]

- Setiawan, B.J. Design and Build Voltage and Current Monitoring Parameters Device of Rechargeable Batteries in Real-Time Using the INA219 GY-219 Sensor. J. Energy Mater. Instrum. Technol. 2023, 4, 58–71. [Google Scholar] [CrossRef]

- Li, B.; Jones, C.M.; Adams, T.E.; Tomar, V. Sensor based in-operando lithium-ion battery monitoring in dynamic service environment. J. Power Sources 2021, 486, 229349. [Google Scholar] [CrossRef]

- Anjali, R.; Deepak, Y. Evaluating Wiring Configurations for RTD Sensor in Temperature Measurement. I-Manager’s J. Electron. Eng. 2019, 10, 1. [Google Scholar] [CrossRef]

- Sarkar, S. Platinum RTD sensor based multi-channel high-precision temperature measurement system for temperature range −100 °C to +100 °C using single quartic function. Cogent Eng. 2018, 5, 1558687. [Google Scholar] [CrossRef]

- Gridling, G.; Weiss, B. Introduction to Microcontrollers; Vienna University of Technology Institute of Computer Engineering Embedded Computing Systems Group: Vienna, Austria, 2007. [Google Scholar]

- Movassagh, K.; Raihan, A.; Balasingam, B.; Pattipati, K. A Critical Look at Coulomb Counting Approach for State of Charge Estimation in Batteries. Energies 2021, 14, 4074. [Google Scholar] [CrossRef]

- Duh, Y.S.; Sun, Y.; Lin, X.; Zheng, J.; Wang, M.; Wang, Y.; Lin, X.; Jiang, X.; Zheng, Z.; Zheng, S.; et al. Characterization on thermal runaway of commercial 18650 lithium-ion batteries used in electric vehicles: A review. J. Energy Storage 2021, 41, 102888. [Google Scholar] [CrossRef]

- Cameron, Z.; Kulkarni, C.S.; Luna, A.G.; Goebel, K.; Poll, S. A battery certification testbed for small satellite missions. In Proceedings of the 2015 IEEE AUTOTESTCON, National Harbor, MD, USA, 2–5 November 2015; pp. 162–168. [Google Scholar]

- Perreault, M.; Behdinan, K. Delivery Drone Driving Cycle. IEEE Trans. Veh. Technol. 2021, 70, 1146–1156. [Google Scholar] [CrossRef]

- Chin, K.B.; Brandon, E.J.; Bugga, R.V.; Smart, M.C.; Jones, S.C.; Krause, F.C.; West, W.C.; Bolotin, G.G. Energy Storage Technologies for Small Satellite Applications. Proc. IEEE 2018, 106, 419–428. [Google Scholar] [CrossRef]

- Huang, D.; Becerra, V.; Ma, H.; Simandjuntak, S.; Fraess-Ehrfeld, A. An Intelligent BMS for Drone-Based Inspection of Offshore Wind Turbines. In Proceedings of the 2022 International Conference on Unmanned Aircraft Systems (ICUAS), Dubrovnik, Croatia, 21–24 June 2022; pp. 1210–1218. [Google Scholar]

- Ruan, H.; He, H.; Wei, Z.; Quan, Z.; Li, Y. State of Health Estimation of Lithium-Ion Battery Based on Constant-Voltage Charging Reconstruction. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 4393–4402. [Google Scholar] [CrossRef]

- Fleischer, C.; Sauer, D.U.; Barreras, J.V.; Schaltz, E.; Christensen, A.E. Development of software and strategies for Battery Management System testing on HIL simulator. In Proceedings of the 2016 Eleventh International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 6–8 April 2016. pp. 1–12.

- Chen, Y.S.; Hu, C.C.; Li, Y.Y. The importance of heat evolution during the overcharge process and the protection mechanism of electrolyte additives for prismatic lithium ion batteries. J. Power Sources 2008, 181, 69–73. [Google Scholar] [CrossRef]

- Spitthoff, L.; Shearing, P.R.; Burheim, O.S. Temperature, Ageing and Thermal Management of Lithium-Ion Batteries. Energies 2021, 14, 1248. [Google Scholar] [CrossRef]

- Pesaran, A.A. Battery Thermal Management in EVs and HEVs: Issues and Solutions. Battery Man 2001, 43, 34–49. [Google Scholar]

- Alipour, M.; Ziebert, C.; Conte, F.V.; Kizilel, R. A Review on Temperature-Dependent Electrochemical Properties, Aging, and Performance of Lithium-Ion Cells. Batteries 2020, 6, 35. [Google Scholar] [CrossRef]

- Li, W.; Rentemeister, M.; Badeda, J.; Jöst, D.; Schulte, D.; Sauer, D.U. Digital twin for battery systems: Cloud battery management system with online state-of-charge and state-of-health estimation. J. Energy Storage 2020, 30, 101557. [Google Scholar] [CrossRef]

- Johnson, C.S.; Li, N.; Lefief, C.; Thackeray, M.M. Anomalous capacity and cycling stability of xLi2MnO3·(1−x)LiMO2 electrodes (M = Mn, Ni, Co) in lithium batteries at 50 °C. Electrochem. Commun. 2007, 9, 787–795. [Google Scholar] [CrossRef]

- Shi, D.; Zhao, J.; Eze, C.; Wang, Z.; Wang, J.; Lian, Y.; Burke, A.F. Cloud-Based Artificial Intelligence Framework for Battery Management System. Energies 2023, 16, 4403. [Google Scholar] [CrossRef]

- Ng, K.S.; Moo, C.S.; Chen, Y.P.; Hsieh, Y.C. Enhanced coulomb counting method for estimating state-of-charge and state-of-health of lithium-ion batteries. Appl. Energy 2009, 86, 1506–1511. [Google Scholar] [CrossRef]

- Krishna, T.N.V.; Kumar, S.V.S.V.P.D.; Srinivasa Rao, S.; Chang, L. Powering the Future: Advanced Battery Management Systems (BMS) for Electric Vehicles. Energies 2024, 17, 3360. [Google Scholar] [CrossRef]

| Type | Connection | Use |

|---|---|---|

| Power and Serial | USB | 5 V power supply as well as serial communication to the main CPU |

| Ground | GND | Common star ground for every component in the sensor network |

| Shunt V+ | Current Sensor V+ | Positive Kelvin connection from current shunt to battery positive |

| Shunt V− | Current Sensor V− | Negative Kelvin connection from current shunt to load positive |

| Arduino Pins | ||

| SCLK | Arduino Pin 13 | Clock line for SPI |

| SDO | Arduino Pin 12 | Serial Data Output for SPI |

| SDI | Arduino Pin 11 | Serial Data Input for SPI |

| CS1 | Arduino Pin 10 | Chip Select Temperature Sensor 1 |

| CS2 | Arduino Pin 9 | Chip Select Temperature Sensor 2 |

| CS3 | Arduino Pin 8 | Chip Select Temperature Sensor 3 |

| CS4 | Arduino Pin 7 | Chip Select Temperature Sensor 4 |

| CS5 | Arduino Pin 6 | Chip Select Temperature Sensor 5 |

| SCLK | Arduino Pin SCLK | Serial Data Clock for I2C |

| SDO | Arduino Pin SDO | Serial Data Address for I2C |

| Purpose | Sensors Used | Operating Voltage | Maximum Supply Current |

|---|---|---|---|

| Pack voltage and current sensor | Adafruit INA219 | 3.0–5.5 V | 1 mA |

| Battery surface temperature sensors | Adafruit PT100 MAX31865 | 3.0–3.6 V | 3 mA |

| Ambient temperature sensor | Adafruit PT100 MAX31865 | 3.0–3.6 V | 3 mA |

| Characteristic | Value |

|---|---|

| Cell chemistry | NCA |

| Cell form factor | 18650 |

| Nominal capacity | 3120 mAh |

| Nominal voltage | 3.6 V |

| Standard charge | CCCV, 1 C, 4.2 V |

| Standard discharge | Constant charge, 1 C, 2.5 V |

| Weight | 46.4 ± 1.5 g |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vajja, J.V.R.; Serov, A.; Sudarshan, M.; Singh, M.; Tomar, V. In Operando Health Monitoring for Lithium-Ion Batteries in Electric Propulsion Using Deep Learning. Batteries 2024, 10, 355. https://doi.org/10.3390/batteries10100355

Vajja JVR, Serov A, Sudarshan M, Singh M, Tomar V. In Operando Health Monitoring for Lithium-Ion Batteries in Electric Propulsion Using Deep Learning. Batteries. 2024; 10(10):355. https://doi.org/10.3390/batteries10100355

Chicago/Turabian StyleVajja, Jaya Vikeswara Rao, Alexey Serov, Meghana Sudarshan, Mahavir Singh, and Vikas Tomar. 2024. "In Operando Health Monitoring for Lithium-Ion Batteries in Electric Propulsion Using Deep Learning" Batteries 10, no. 10: 355. https://doi.org/10.3390/batteries10100355

APA StyleVajja, J. V. R., Serov, A., Sudarshan, M., Singh, M., & Tomar, V. (2024). In Operando Health Monitoring for Lithium-Ion Batteries in Electric Propulsion Using Deep Learning. Batteries, 10(10), 355. https://doi.org/10.3390/batteries10100355