Experimental and Numerical Analyses of a Novel Magnetostatic Force Sensor for Defect Inspection in Ferromagnetic Materials

Abstract

1. Introduction

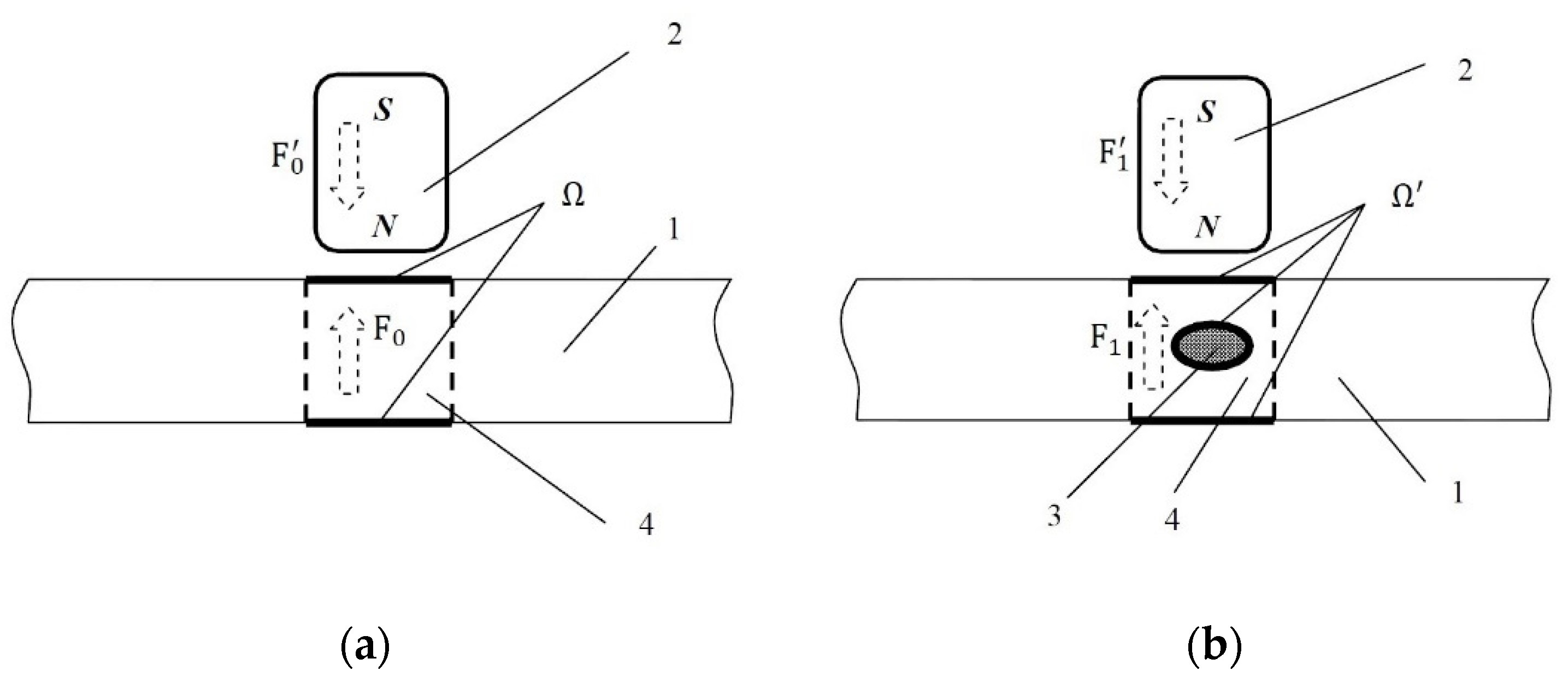

2. Measurement Principle

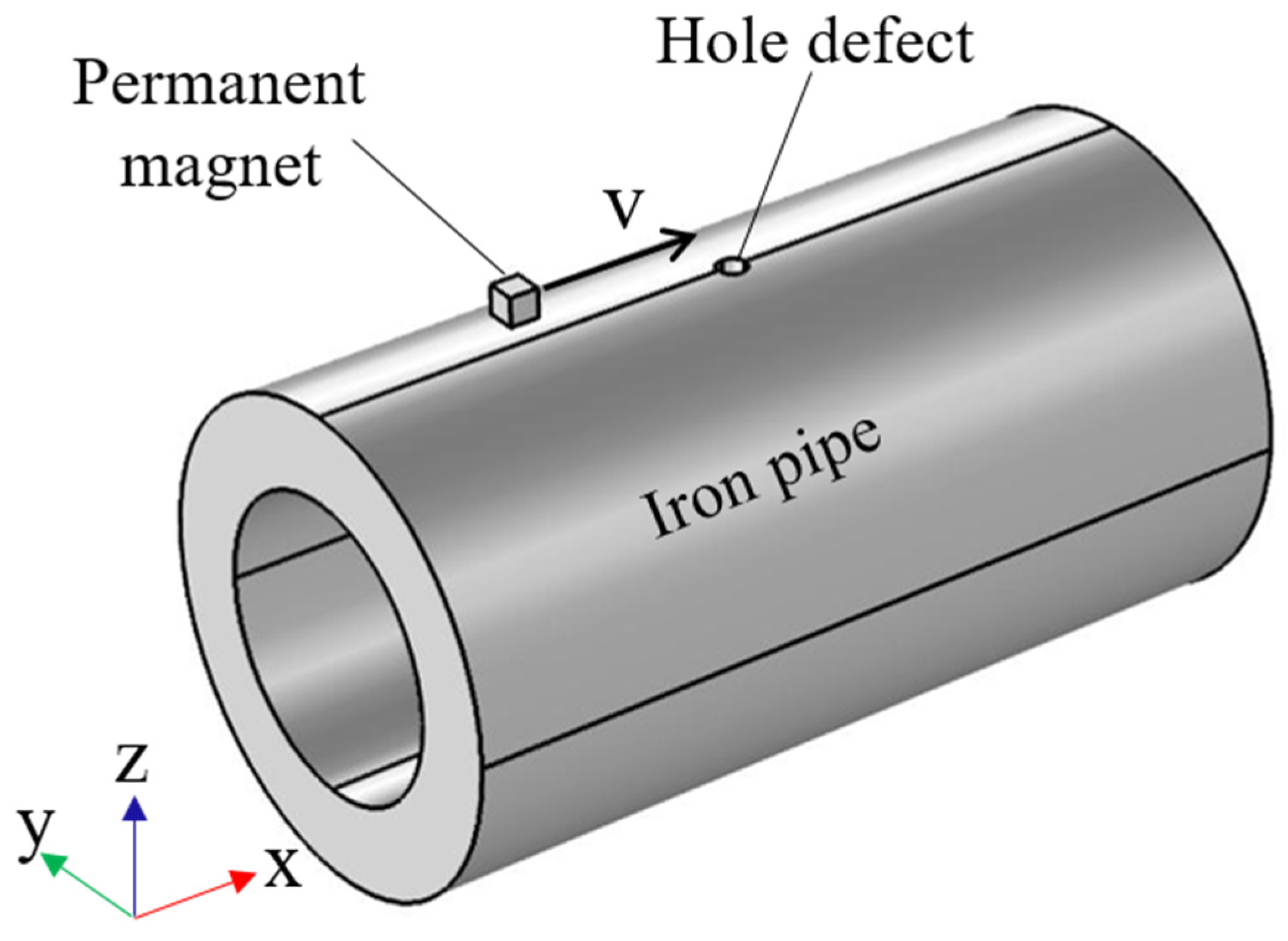

3. Experimental Prototype

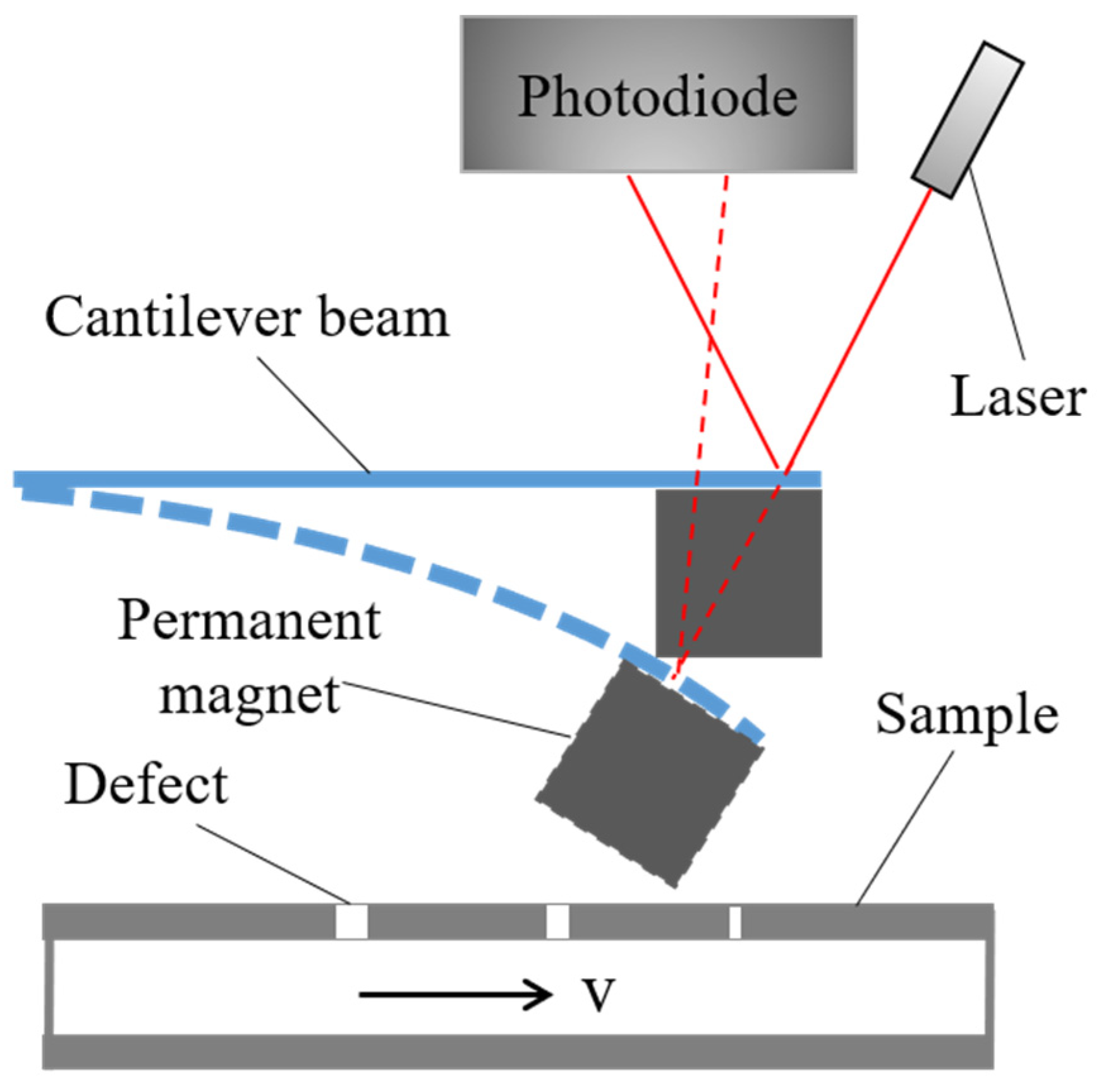

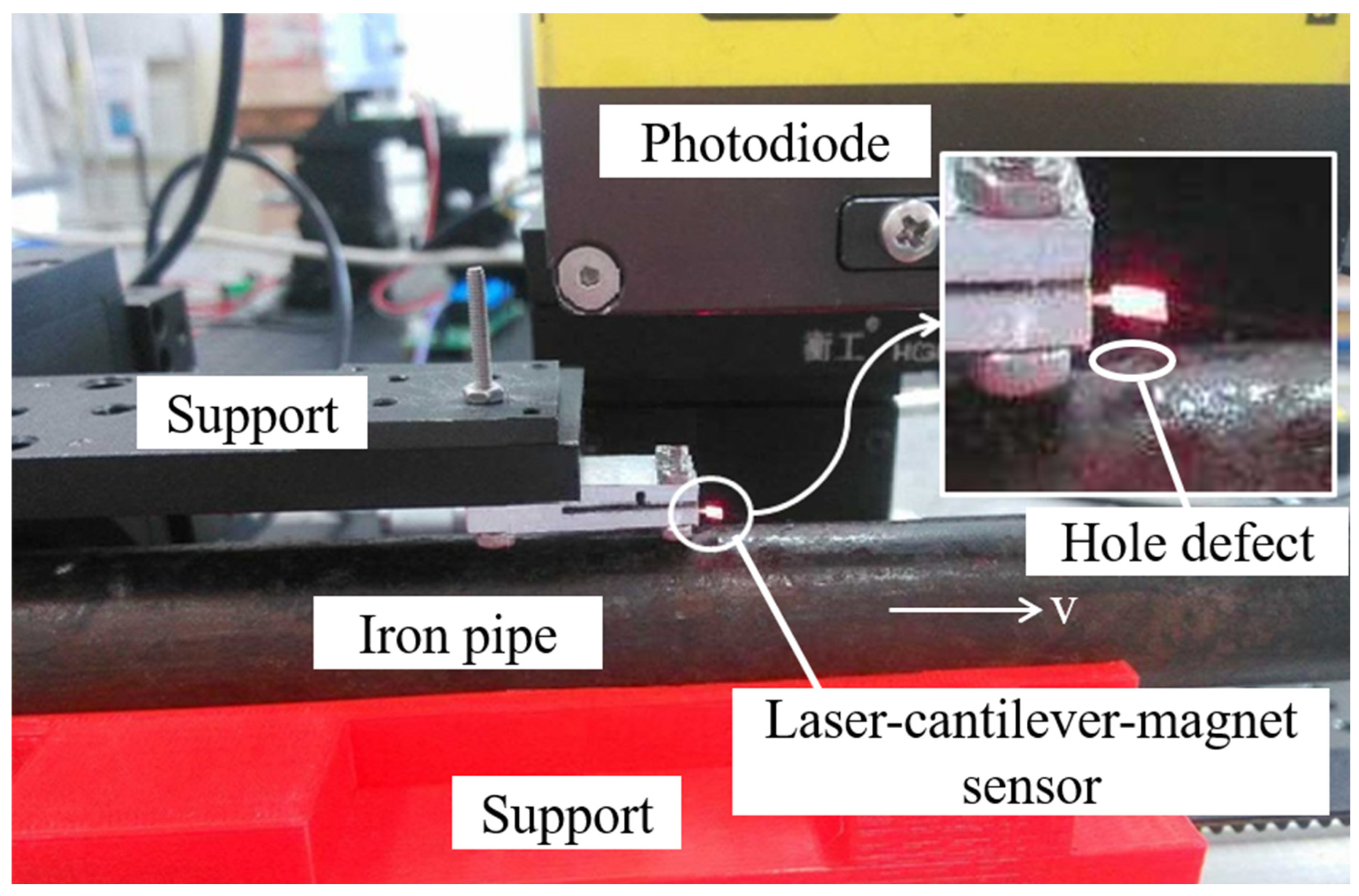

3.1. Design of the Experimental Device

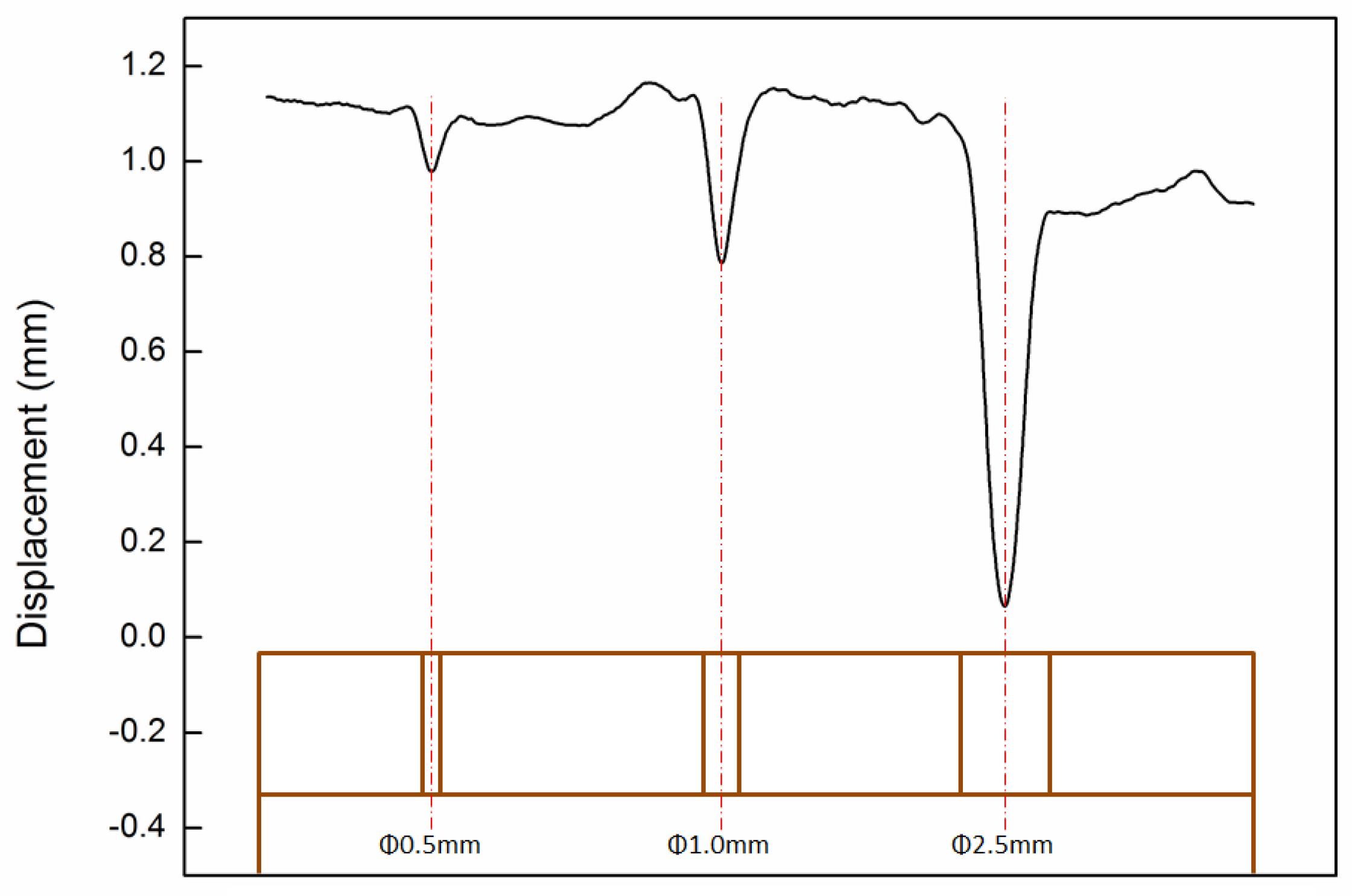

3.2. Experimental Detection of Pipe Defects

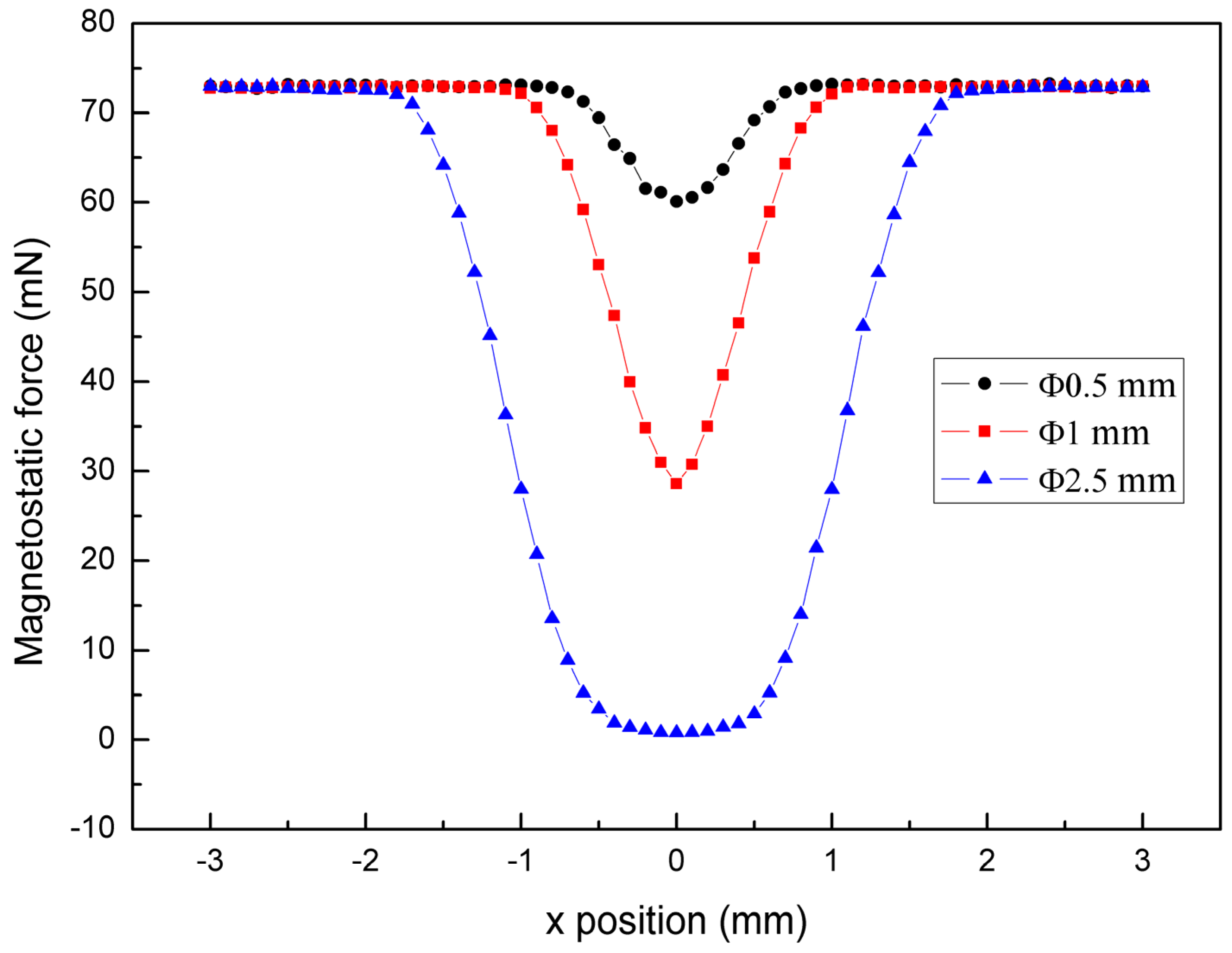

3.3. Depth Detection of Slot Defects

4. Numerical Models and Results

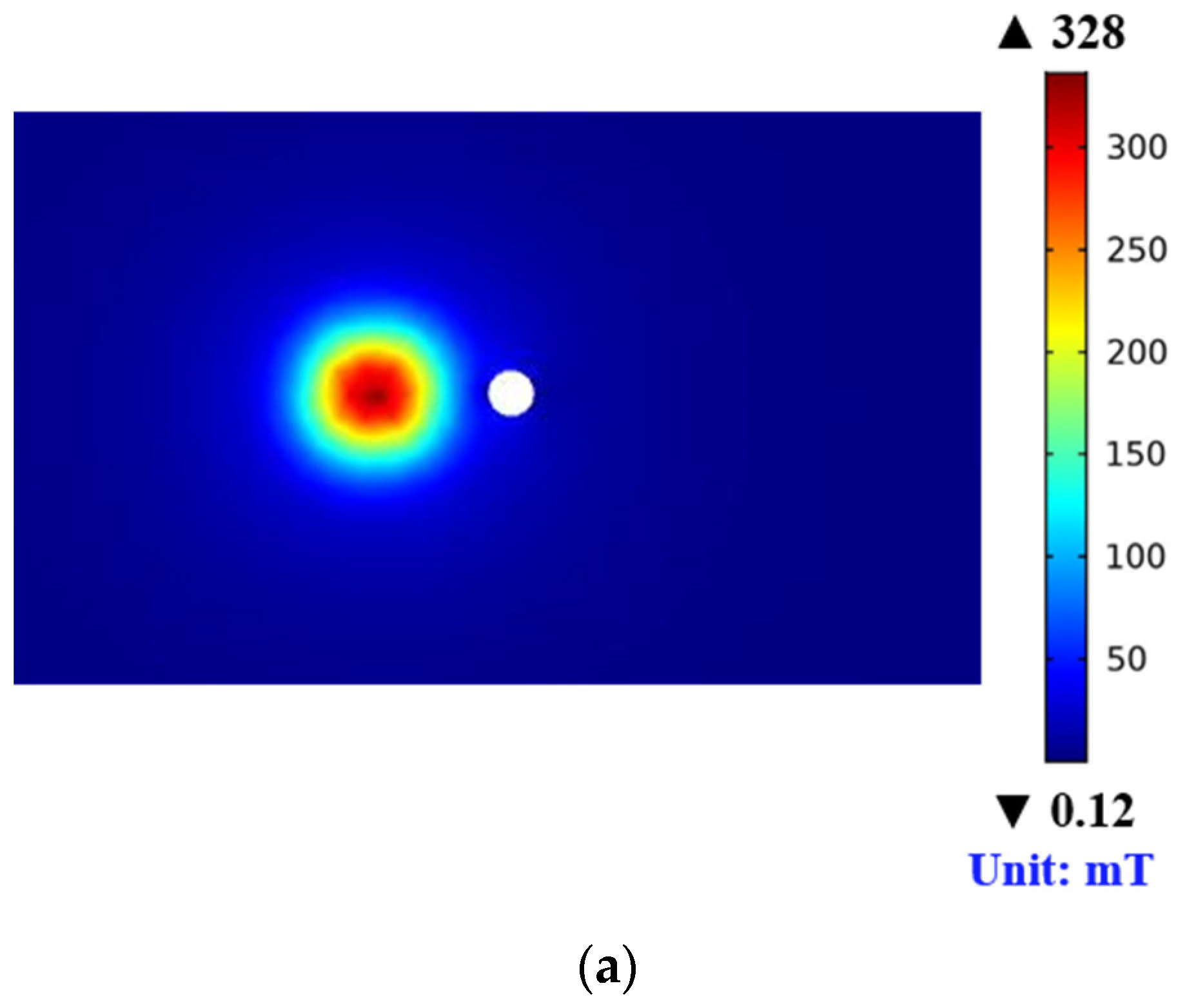

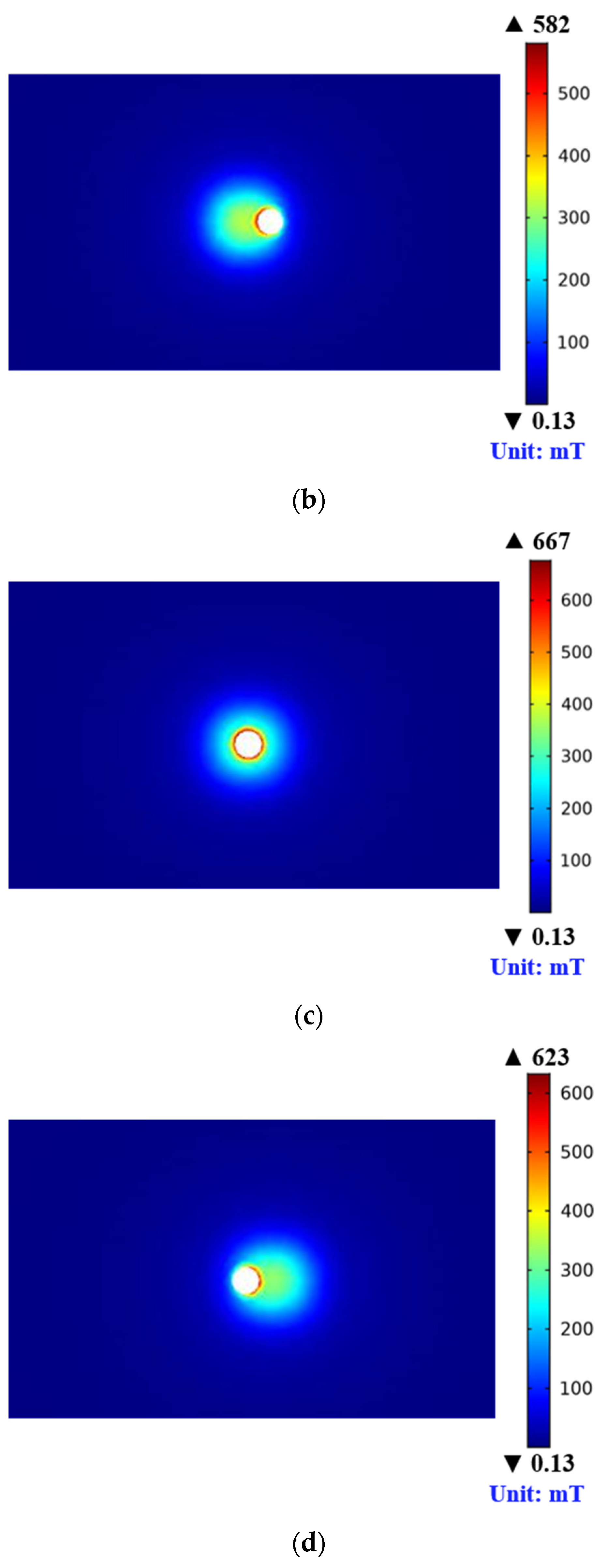

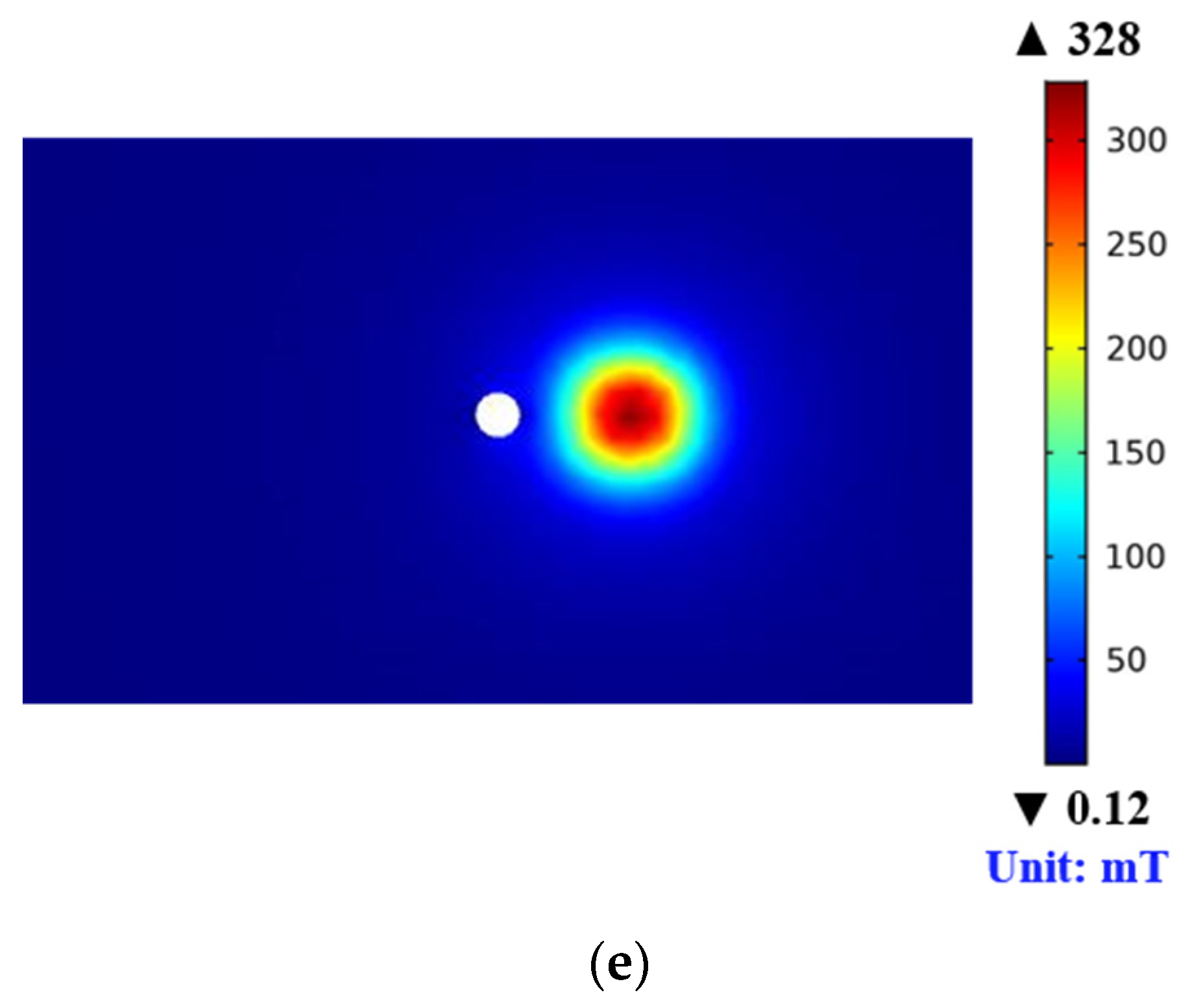

4.1. Numerical Analysis of Magnetostatic Force

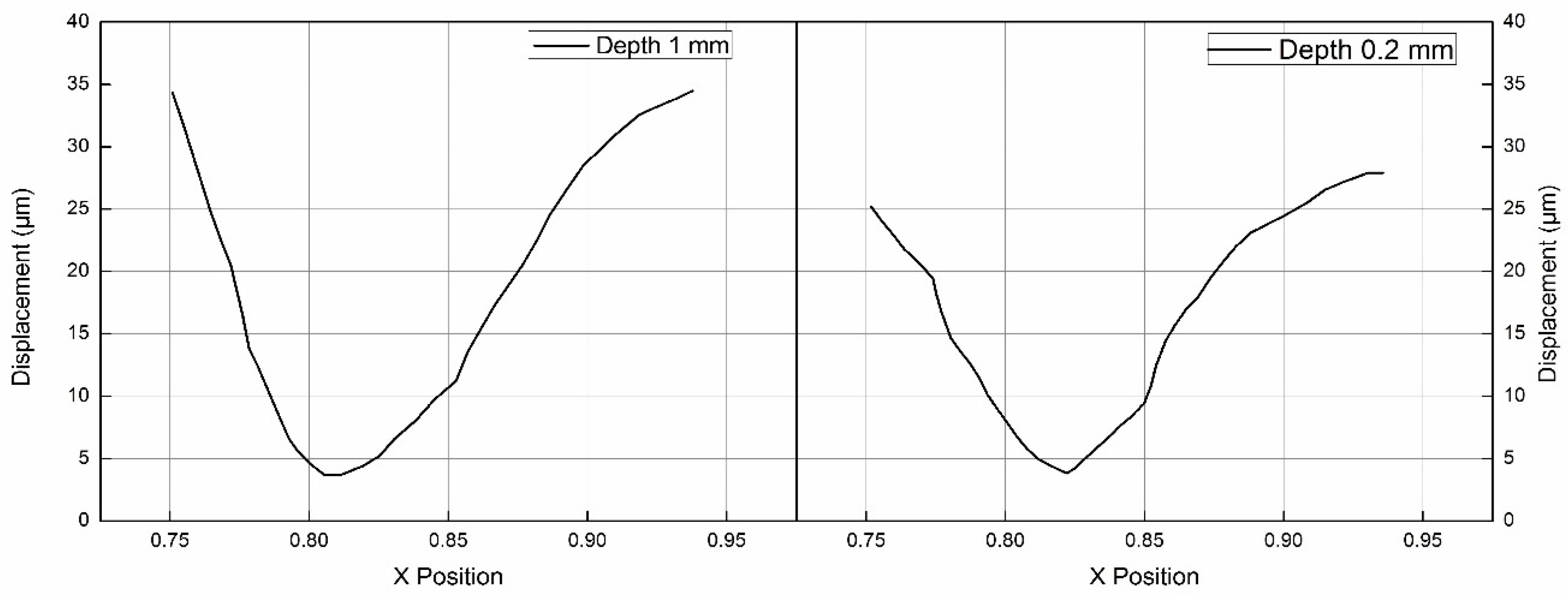

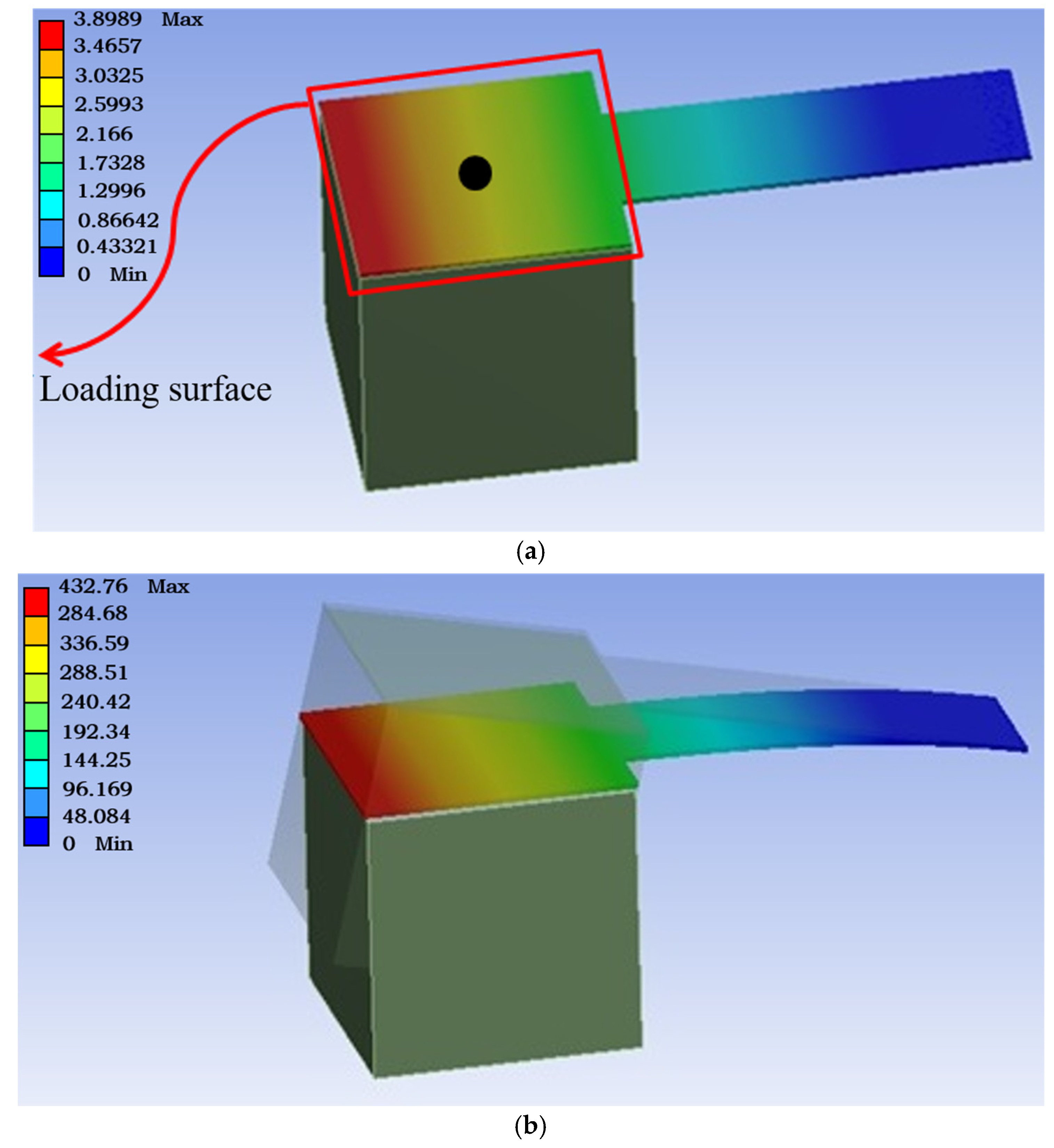

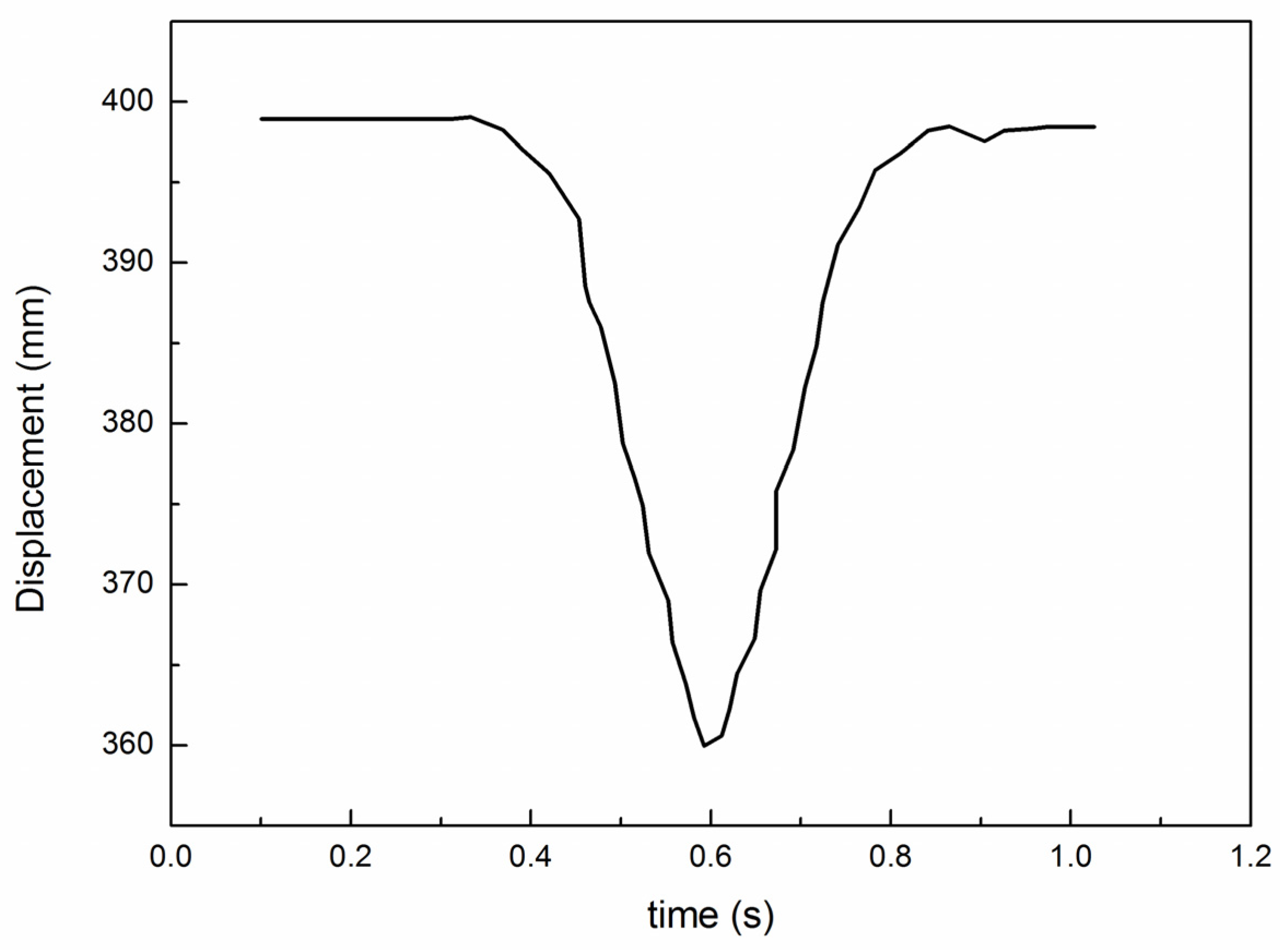

4.2. Numerical Analysis of the Cantilever Beam Displacement

5. Conclusions and Perspective

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saguy, H.; Rittel, D. Flaw detection in metals by the ACPD technique: Theory and experiments. NDT E Int. 2007, 40, 505–509. [Google Scholar]

- Zhang, W.; Wang, G.; Zhang, Y.; Cheng, G.; Zhan, Z. Formation Mechanism and Improvement of Magnetic Particle Inspection Defects in Cr5 Backup Roller Forged Ingot. Metals 2022, 12, 295. [Google Scholar] [CrossRef]

- Rosado, L.S.; Santos, T.G.; Piedade, M.; Ramos, P.M.; Vilaça, P. Advanced technique for non-destructive testing of friction stir welding of metals. Measurement 2010, 43, 1021–1030. [Google Scholar] [CrossRef]

- Williams, C.; Borigo, C.; Rivière, J.; Lissenden, C.J.; Shokouhi, P. Nondestructive Evaluation of Fracture Toughness in 4130 Steel Using Nonlinear Ultrasonic Testing. J. Nondestruct. Eval. 2022, 41, 13. [Google Scholar] [CrossRef]

- Zhao, M.; Nie, Z.; Wang, K.; Liu, P.; Zhang, X. Nonlinear ultrasonic test of concrete cubes with induced crack. Ultrasonics 2019, 97, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Kim, F.H.; Pintar, A.L.; Obaton, A.F.; Fox, J.C.; Tarr, J.; Donmez, A.M. Merging experiments and computer simulations in X-ray Computed Tomography probability of detection analysis of additive manufacturing flaws. NDT E Int. 2021, 119, 102416. [Google Scholar]

- Cotter, D.J.; Koenigsberg, W.D. Improving Probability of Flaw Detection in Ceramics by X-ray Imaging Energy level Optimization. J. Am. Ceram. Soc. 1990, 73, 1763–1765. [Google Scholar] [CrossRef]

- Chen, W.; Wu, D.; Wang, X.; Wang, T. A self-frequency-conversion eddy current testing method. Measurement 2022, 195, 111129. [Google Scholar] [CrossRef]

- Gong, Z.; Yang, S. Metamaterial-Core Probes for Nondestructive Eddy Current Testing. IEEE Trans. Instrum. Meas. 2021, 70, 3505209. [Google Scholar] [CrossRef]

- Zhao, Y.; Wei, G.; Han, J.; Cai, W.; Chen, H.E.; Chen, Z. Enhancement of crack reconstruction through inversion of eddy current testing signals with a new crack model and a deterministic optimization method. Meas. Sci. Technol. 2022, 33, 055011. [Google Scholar] [CrossRef]

- Drinkwater, B.W.; Wilcox, P.D. Ultrasonic arrays for non-destructive evaluation: A review. NDT E Int. 2006, 39, 525–541. [Google Scholar]

- Sumarto, S.; Yulianti, I.; Addawiyah, A.; Setiawan, R. Optimization of exposure factors for X-ray radiography non-destructive testing of pearl oyster. J. Phys. Conf. Ser. 2018, 983, 012004. [Google Scholar]

- Zhang, H.; Wang, Y.; Wang, H.O.; Huo, D.X.; Tan, W.S. Room-temperature magnetoresistive and magnetocaloric effect in La1−xBaxMnO3 compounds: Role of Griffiths phase with ferromagnetic metal cluster above Curie temperature. J. Appl. Phys. 2022, 131, 043901. [Google Scholar] [CrossRef]

- Wang, Z.; Yu, Y. Traditional Eddy Current–Pulsed Eddy Current Fusion Diagnostic Technique for Multiple Micro-Cracks in Metals. Sensors 2018, 18, 2909. [Google Scholar] [CrossRef]

- Shkatov, P. Combining eddy-current and magnetic methods for the defectoscopy pf ferromagnetic materials. Nondestruct. Test. Eval. 2013, 28, 155–165. [Google Scholar] [CrossRef]

- Schmidt, R.; Otterbach, J.M.; Ziolkowski, M.; Brauer, H.; Toepfer, H. Portable Lorentz Force Eddy Current Testing System with Rotational Motion. IEEE Trans. Magn. 2018, 54, 6200504. [Google Scholar] [CrossRef]

- Uhlig, R.P.; Zec, M.; Brauer, H.; Thess, A. Lorentz Force Eddy Current Testing: A Prototype Model. J. Nondestruct. Eval. 2012, 31, 357–372. [Google Scholar] [CrossRef]

- Otterbach, J.M.; Schmidt, R.; Brauer, H.; Ziolkowski, M.; Töpfer, H. Comparison of defect detection limits in Lorentz force eddy current testing and classical eddy current testing. J. Sens. Sens. Syst. 2018, 7, 453–459. [Google Scholar] [CrossRef]

- Weise, K.; Schmidt, R.; Carlstedt, M.; Ziolkowski, M.; Brauer, H.; Toepfer, H. Optimal Magnet Design for Lorentz Force Eddy-Current Testing. IEEE Trans. Magn. 2015, 51, 6201415. [Google Scholar] [CrossRef]

- Chen, X.Y.; Wang, X.D.; Ren, Z.M.; Tao, Z.; Na, X.Z.; Wang, E.G. A magnetostatic force inspection method for monitoring the oscillation marks of continuous casting. Meas. Sci. Technol. 2015, 26, 115601. [Google Scholar] [CrossRef]

- Tao, Z.; Wang, X.D.; Chen, X.Y.; Na, X.Z. Theory of Magnetostatic Force Inspection Method for Monitoring the Oscillation Marks of Continuous Casting. Exp. Tech. 2016, 40, 1539–1547. [Google Scholar] [CrossRef]

- Binnig, G.; Quate, C.F.; Gerber, C. Atomic Force Microscope. Phys. Rev. Lett. 1986, 56, 930–933. [Google Scholar] [CrossRef] [PubMed]

- Sajid, N. Topography of Schwann cell with atomic force microscope. Chin. J. Phys. 2020, 68, 381–386. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Moving velocity of permanent magnet (mm/s) | 15 |

| Diameter of the through-hole defect (mm) | 0.5/1/2.5 |

| Outer diameter of the iron pipe (mm) | 16 |

| Inner diameter of the iron pipe (mm) | 10 |

| Length of the iron pipe (mm) | 30 |

| Size of the cubic permanent magnet (mm) | 1 |

| Distance between the permanent magnet and the iron pipe (mm) | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Zhang, S.; Chen, X.; Wang, F.; Xu, B. Experimental and Numerical Analyses of a Novel Magnetostatic Force Sensor for Defect Inspection in Ferromagnetic Materials. Magnetochemistry 2022, 8, 182. https://doi.org/10.3390/magnetochemistry8120182

Wang B, Zhang S, Chen X, Wang F, Xu B. Experimental and Numerical Analyses of a Novel Magnetostatic Force Sensor for Defect Inspection in Ferromagnetic Materials. Magnetochemistry. 2022; 8(12):182. https://doi.org/10.3390/magnetochemistry8120182

Chicago/Turabian StyleWang, Bo, San Zhang, Xinyue Chen, Fujie Wang, and Baohui Xu. 2022. "Experimental and Numerical Analyses of a Novel Magnetostatic Force Sensor for Defect Inspection in Ferromagnetic Materials" Magnetochemistry 8, no. 12: 182. https://doi.org/10.3390/magnetochemistry8120182

APA StyleWang, B., Zhang, S., Chen, X., Wang, F., & Xu, B. (2022). Experimental and Numerical Analyses of a Novel Magnetostatic Force Sensor for Defect Inspection in Ferromagnetic Materials. Magnetochemistry, 8(12), 182. https://doi.org/10.3390/magnetochemistry8120182