3.1. Self-Similarity Definition

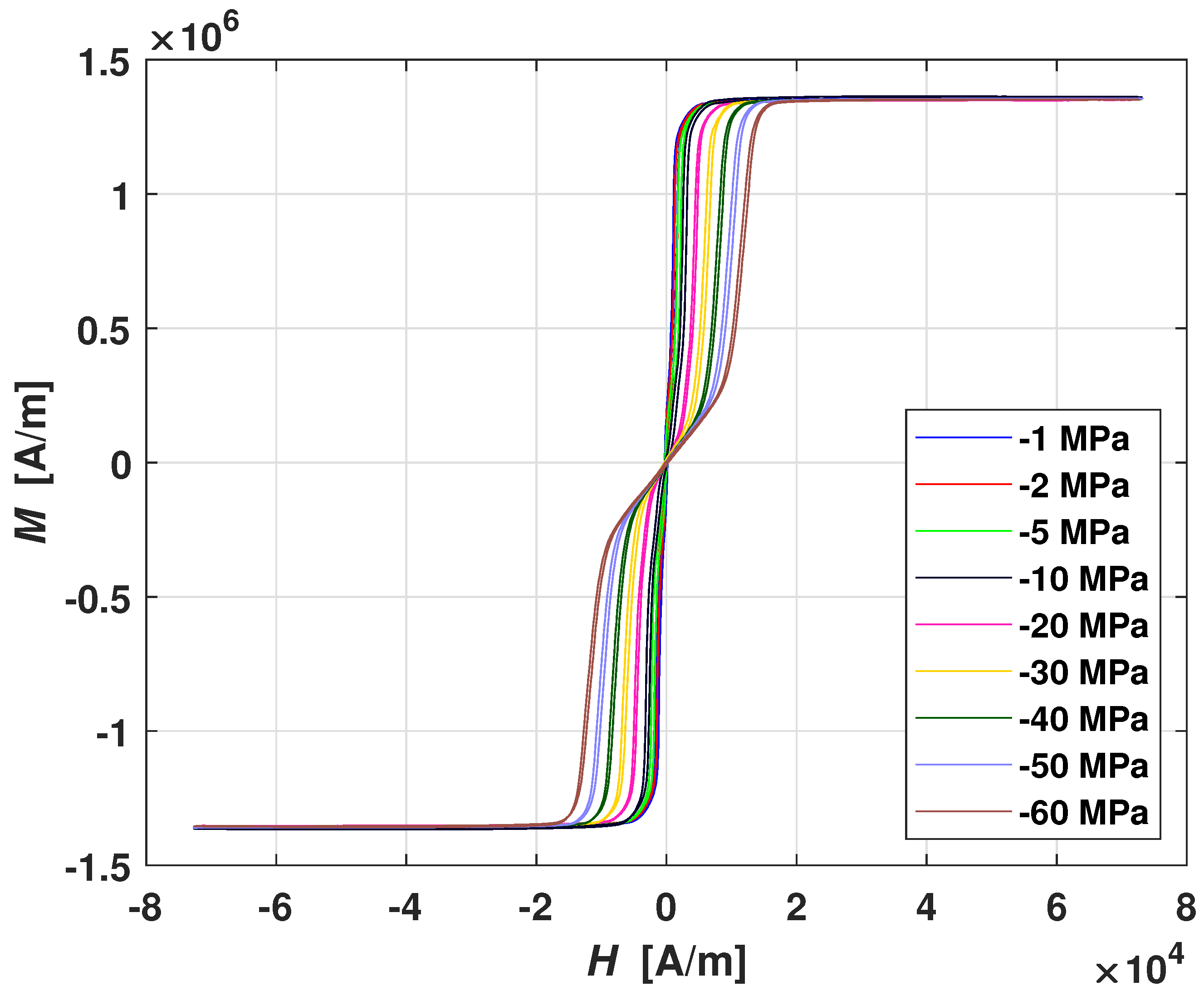

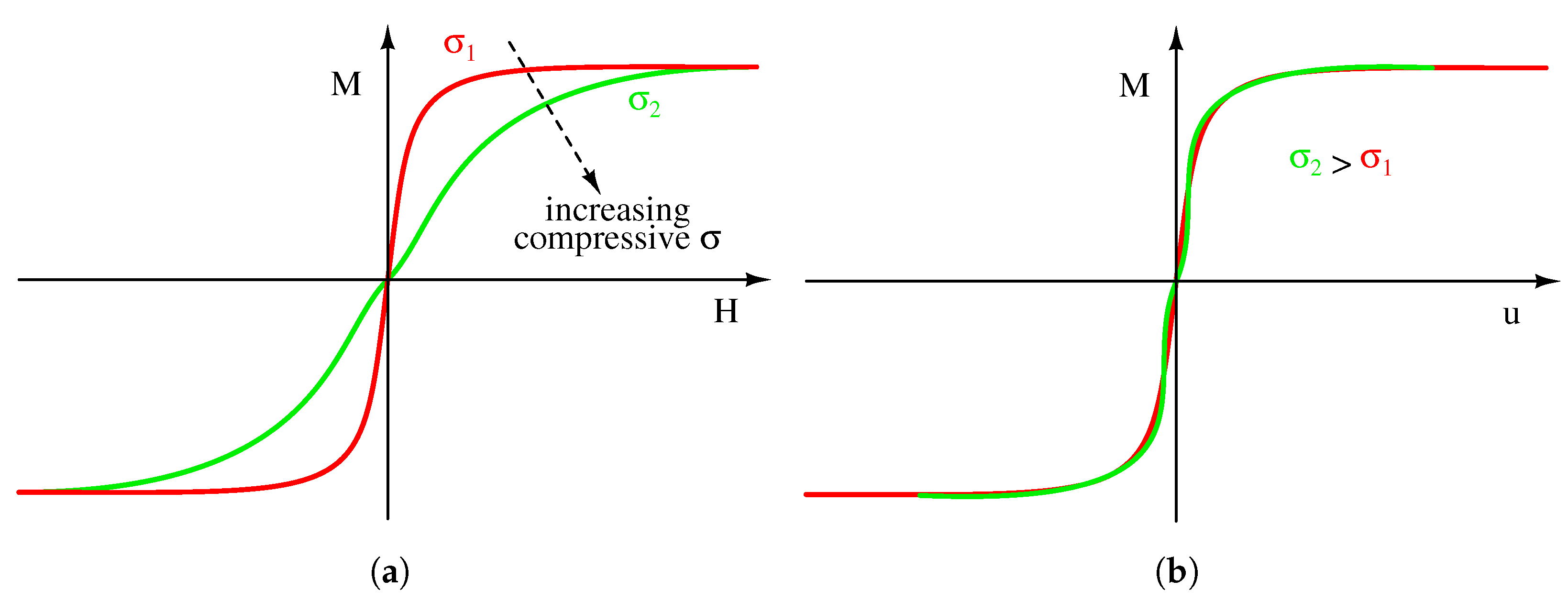

Figure 3a shows the typical qualitative magnetization characteristics of a NSA Galfenol sample at different stresses (hysteresis is neglected). There and in the following, it is assumed that all the involved physical quantities are aligned and uniform (e.g., the magnetostrictive sample has a regular and constant cross sectional area

S, with stress

, where

F is the applied force, and the magnetic field

H is directed along its longitudinal axis). Those curves can be represented as two general implicit relationships:

Indeed, from the practical point of view, it would be more convenient to solve explicitly the implicit Equations (

4) with respect to

and

M and write them in the form:

which clearly distinguishes between the input and output quantities.

It can be observed that the

M-

H curves at different constant applied stresses (

) have similar shapes, and the stress appears as a scaling parameter. Therefore, it is possible to introduce a new state variable

that is function of the magnetic field and stress, in such a way that all

M-

u curves overlap, and reformulate Equations (

5) as:

as shown in the illustration of

Figure 3b. This behavior would be an experimental evidence of the

self-similarity property of magnetostrictive materials, with

u as

self-similar variable. It is worth pointing out that the variable

u, as shown in the following, appears to be substantial in modeling magnetostriction. Indeed, a suitable choice of

u allows for building up an analytical phenomenological description of the most common magnetostrictive behavior, as reported in Reference [

12]. Moreover, in this paper, we show this particular viewpoint of the self-similarity property, based on the experimental measurements, similar to what was done in Reference [

8,

9] for magnetocaloric materials with ferro-to-paramagnetic phase transitions.

One of the questions that this paper deals with is: can self-similarity be formally quantified for the most common magnetostrictive materials? This would be very beneficial for the mathematical modeling of the materials. Let us note that this approach has already been considered in modeling, even though not fully explicited and exploited. For example, in Reference [

13,

14], thermodynamic constraints led to the following expression for

u:

where the function

described the influence of different applied stresses on the magnetic characteristics of magnetostrictives.

In view of the mathematical modeling, the variable

u defined as in Equation (

7) may not be able to fully mimic the experimental magnetic and magnetostrictive behaviors of MMs at a very low magnetic field (near-zero

H), as the ones reported in Reference [

15,

16,

17]. It is, therefore, appropriate to modify the simple definition of

u of Equation (

7) in the form:

where the term

represents the

feedback, the influence of which may become dominant at very low magnetic fields. Moreover, as suggested in Reference [

18,

19,

20], the term

can be seen as the

effective magnetic field,

. The formulation of

u as reported in Equation (

8) helps to take into account, in the modeling of MMs, the experimental behavior at a very low field, such as the residual magnetization and the inverse magnetostriction effect (Villari effect) at no field applied, i.e.,

. Finally, it is worth noting that Equation (

8) inserted in Equations (

6) would be a simplified expression of Equation (

4). Nevertheless, if

is sufficiently small,

is sufficiently large, and

is a continuously differentiable function, then the relations reported in Equations (

6) and (

8) implicitly define a constitutive law

. The problem of analytical representation of the function

is generally difficult. We propose to use the self-similar character of the experimental curves and reduce the complexity of the problem by representing the constitutive function

of two variables by means of four functions of one variable:

,

,

, and

.

Once the expression of

u has been considered, the three functions,

,

, and

, must be identified. The most simple and robust method to identify if and how much two or more different continuous curves are similar among them is to compute the difference of the areas under the curves, with respect to the abscissa

u. The smaller this difference, the stronger the similarity. In the case of magnetic characteristics, because of the odd symmetry, this property can be checked by considering only the first quadrant and can be written as:

where

is the area under the

M-

u curve at the minimum applied stress, i.e.,

while

is the area under of the

M-

u curve at the maximum applied stress, i.e.

This minimization is computed with respect to the parameters of the functions

,

, and

. Once the minimum of Equation (

9) is obtained, the output parameters are available to be used in modeling of MMs.

It is noticeable that it could be possible to use the

-

H curve also, i.e., the first of Equation (

6), in order to test the self-similar character. Nevertheless, it is proven in the literature that both magnetic and magnetostrictive characteristics are analytically correlated by the principles of thermodynamics [

14,

21], and, then, out of experimental errors, the self-similarity concept applies to both at the same extent. However, contrary to the magnetic curves, the magnetostrictive ones would need a much higher magnetic field to reach saturation [

3,

22], and, nevertheless, magnetostrictive curves show different saturation values, with respect to the applied stress. Thus, magnetic curves were preferred in this experimental analysis, and the verification of the correlation is left to future works.

The choice of the functions

,

, and

is indeed different for different materials. In this manuscript, we considered three different MMs: two twin samples of Galfenol, wherein one is non-stress annealed, and the other is stress-annealed; and a sample of Terfenol-D. The samples were manufactured by the company

Vib, LLC (Boone, IA, USA); see Reference [

23].

3.2. NSA Galfenol

Galfenol is an Iron-Gallium alloy (Fe

Ga

), and it is textured polycrystalline, grown with free-standing zone melt (FSZM) technique by

Vib. It has good magnetic, mechanical, and magnetostrictive properties. In particular, it does not show very large magnetostriction values (about 200–250 ppm) in comparison with other MMs but has better magnetic characteristics (about 1.8–2 T magnetic saturation) than Terfenol-D (about 0.9–1 T magnetic saturation; see

Section 3.4 for further details). As a consequence, it is particularly suitable for sensing and energy harvesting use [

22]. The Galfenol samples adopted for the experimental measurements are both 30 mm long with a diameter of 5 mm.

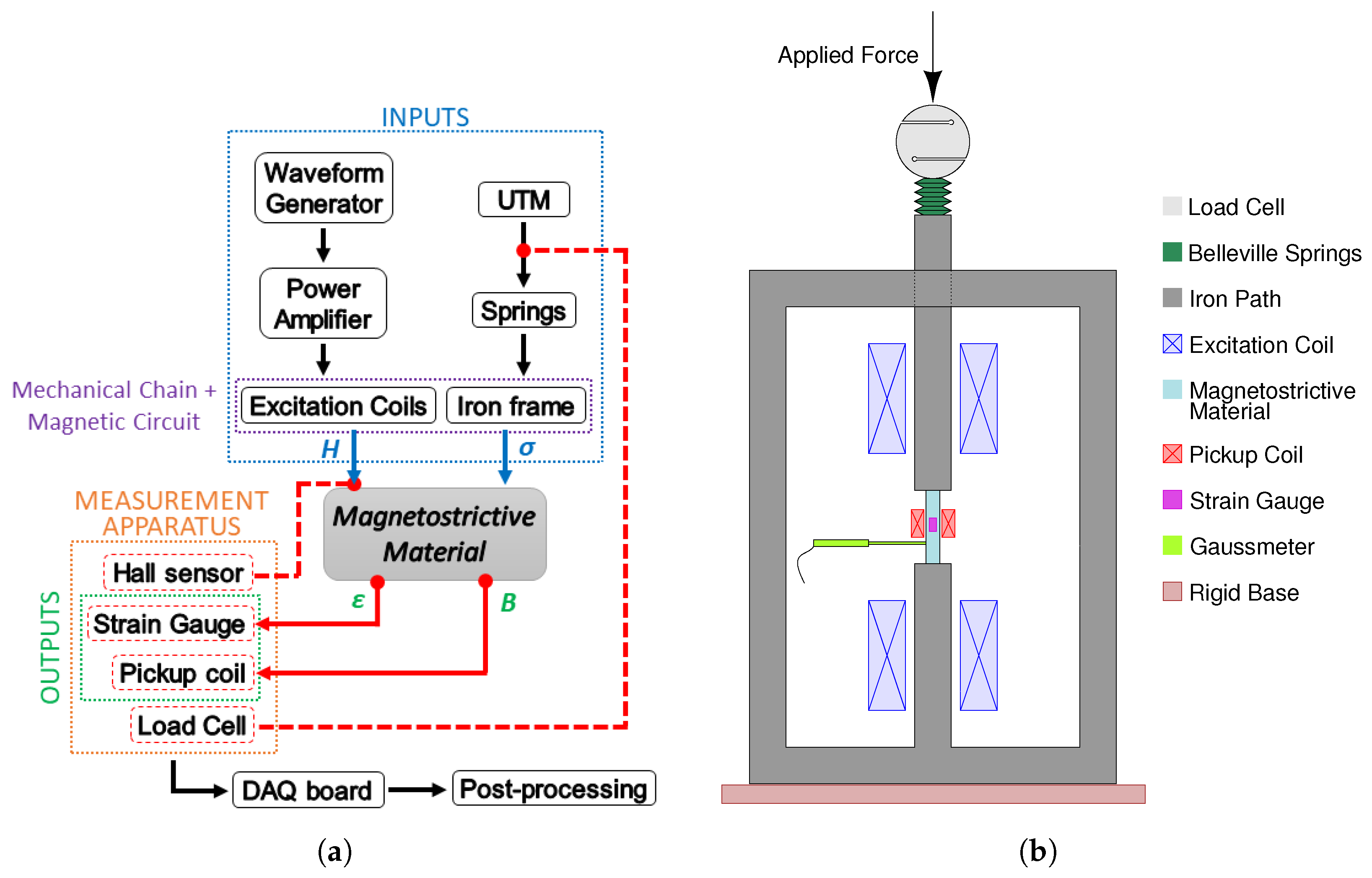

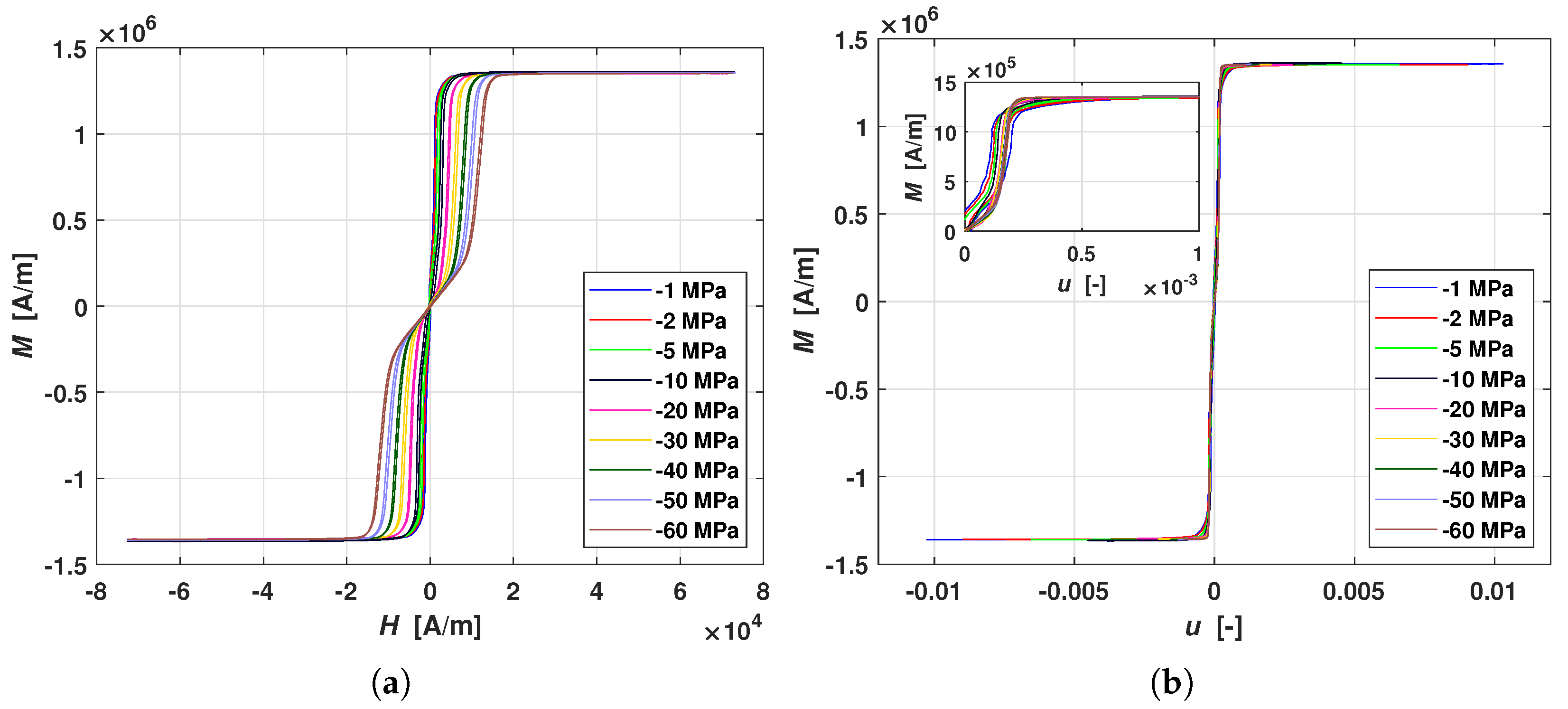

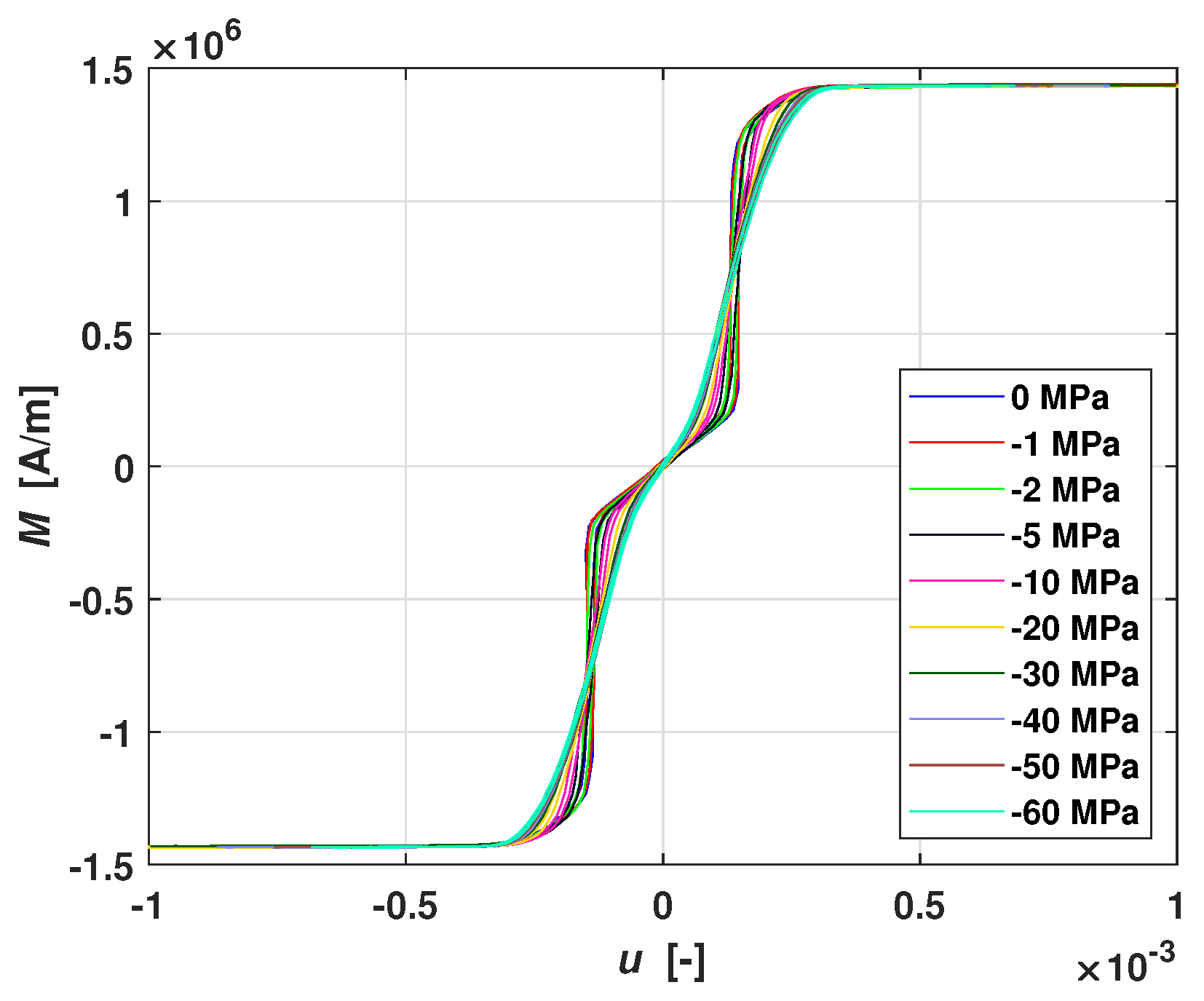

The magnetic characteristics of NSA Galfenol at different constant applied stresses are shown in

Figure 4a. It is possible to note a very narrow hysteresis loop, low coercive field, low saturation field, and high saturation magnetization. Moreover, it is noticeable that, by increasing the compressive stress, the initial magnetic permeability decreases. These experimental data suggest to use a simple definition of the feedback term and

, reported in Equation (

8). In particular,

is a constant parameter

, and

is the magnetization itself, while

is a linear function of the applied

, i.e.,

where

has a mere meaning of a dimensional scaling factor, and, in this case, because compressive stress has been defined as negative, it is equal to −1, while

is another constant parameter. The self-similarity problem can be computed by solving the Equation (

9) with respect to

and

parameters.

The whole problem is described as follows:

From the computational point of view, the minimization problem in the set of Equations (

13)–(

16) has been performed by considering only the average curve of each hysteresis loop of the experimental data shown in

Figure 4a. Moreover, in principle, the minimization problem could be extended to all the experimental data, i.e., all the mechanical stress-range curves. However, this is not necessary because, by minimizing the area between the

M-

u curves at minimum and maximum stress, the areas computed for the other stress are just included, due to intrinsic magnetostrictive behaviors.

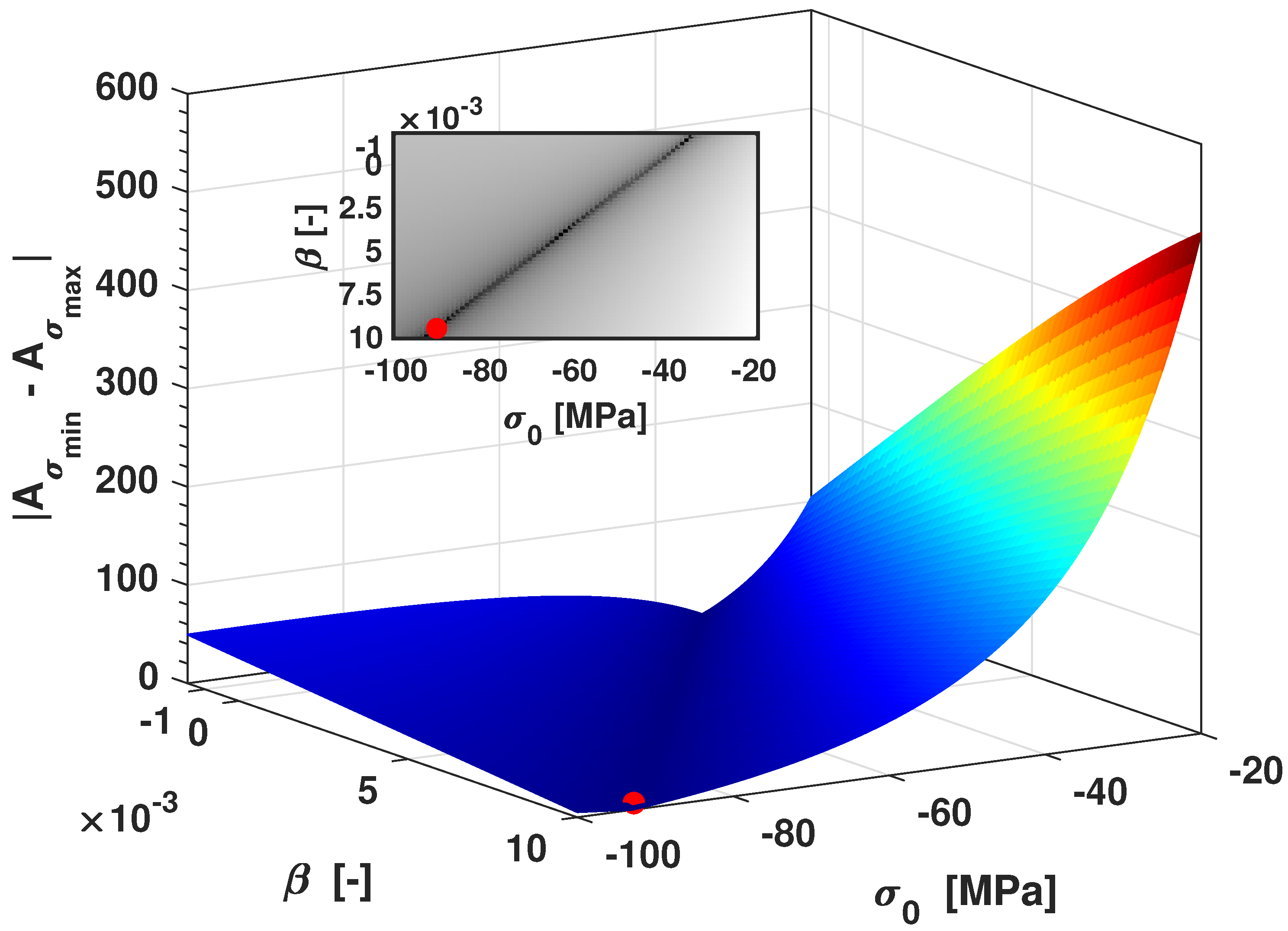

In

Figure 5, the minimization problem as reported in the set of Equations (

13)–(

16) for NSA Galfenol is shown. The minimum of the areas difference is obtained for

and

MPa.

Figure 4b shows the

M-

u curves at different applied stresses, where

u has been computed according to Equation (

16) with the aforementioned

and

parameters values. Note that all the curves almost overlap, which confirms that Equation (

12) describes self-similarity in an appropriate way. Furthermore, in

Figure 5, we see a zone, as in the dark gray river bed of the inset, where

is very small. This means that it would be an almost linear combination of

and

that minimizes the difference of the areas, and where the self-similarity is observable. However, the red dot shows the minimum of the surface in the considered range of values.

3.3. SA Galfenol

SA Galfenol differs from NSA ones because a built-in stress has been “frozen” into the material, during a post-manufacturing process. The built-in stress value is not provided with the sample characteristics. However, it essentially consists of a combination of magnetic field, high temperature, and mechanical stress applied to the material, for some time. Following that, a built-in stress remains in the magnetostrictive sample, which generates an uniaxial anisotropy that avoids the need for an external pre-stress mechanism [

24,

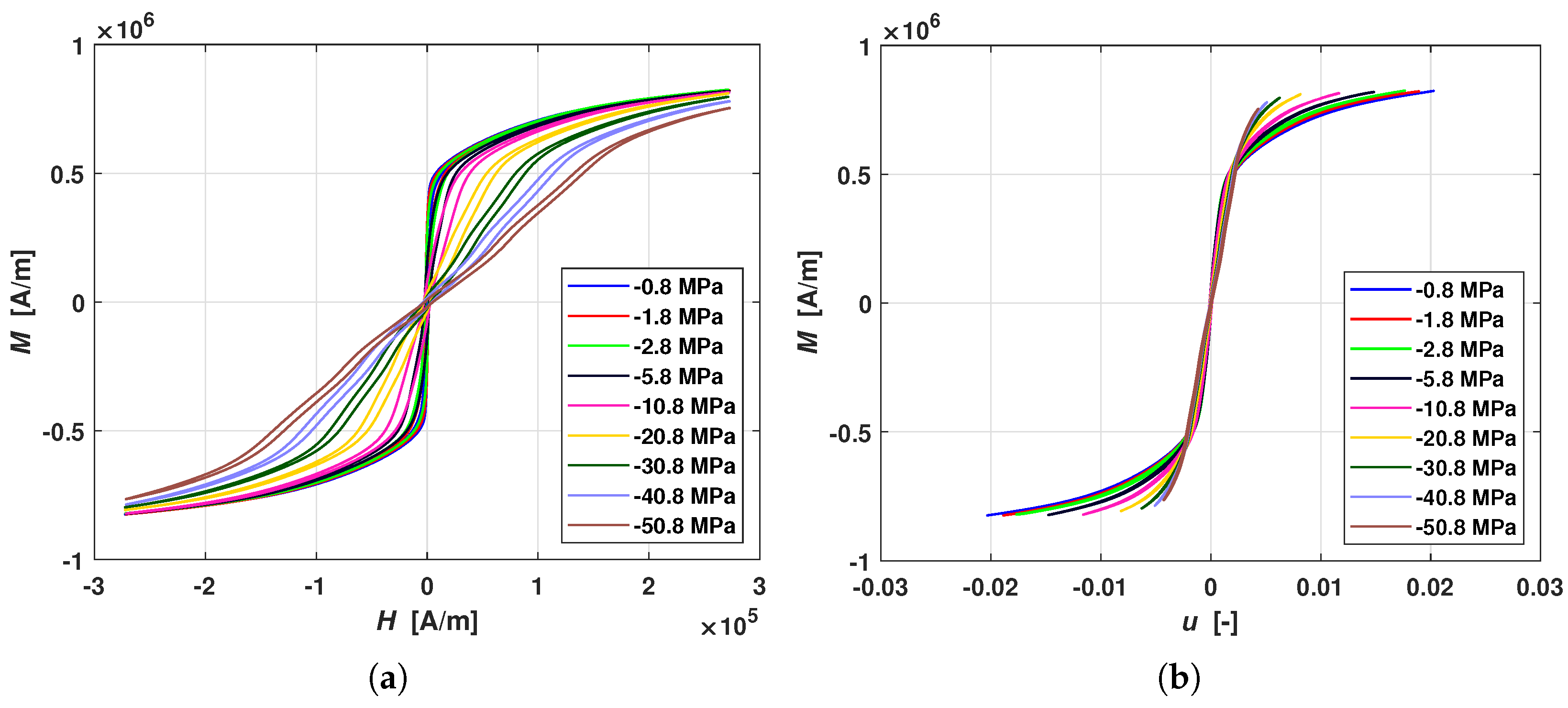

25]. This is visible in

Figure 6a, where SA Galfenol magnetic characteristics at different applied stresses are shown. It is observable that, in this case, all the curves show the same initial magnetic permeability (linear behavior at low

H), which is similar to the ones shown in

Figure 4a at high compressive stress. Indeed, the built-in stress acts in the material as an external applied pre-stress.

The minimization problem for SA Galfenol is exactly the same of NSA ones, i.e., the set of Equations (

13)–(

16).

Figure 7 shows the minimization results for SA Galfenol. In particular, the red dot indicates the minimum of the area difference that is obtained at

and

MPa. In

Figure 6b, we represent the

M-

u curves at different applied stresses, where

u has been computed according to Equation (

16) with the aforementioned

and

parameter values. We see that all the curves almost overlap, so that they be quite accurately interpreted as a single curve. As for NSA Galfenol, also in

Figure 7, we see a zone (dark gray) where

is very small. This means that it is an almost linear combination of

and

that minimizes the difference of the areas.

As reported previously, the term

(in the numerator in Equation (

12)) represents the magnetic feedback and can be identified as an effective field

. Moreover, it is worth noting that, from a numerical point of view, the parameter

can have any positive or slightly negative values. Indeed, for large negative values, the curves would be S-shaped crossing the second quadrant of the graph, so that

M cannot be represented by a function of

u any longer. On the other hand, from a physical point of view, small negative values of

can be interpreted as a demagnetizing factor. Finally, the term

is dimensionally compatible with a constant pre-stress, and then, physically, it could be seen as a stress “frozen” in the material due to its annealing post-manufacturing process. As expected, this value for NSA Galfenol has been found to be low. On the other hand, for SA Galfenol, this value has been found to be quite high. This is due to the fact the the surface in

Figure 7 shows different local minima (blue/green “river bed”) because an almost linear combination of

and

minimizes the areas difference. These minima correspond to positive values of

, while, if we allow

to be negative, then, the values of

are between −34 and −41 MPa.

These values of the pre-stress are compatible with “built-in stress” values reported in Reference [

26]. For the sake of clarity,

Figure 8 shows the self-similar curves

M-

u for SA Galfenol with minima of the areas difference found in the negative range of

and for its corresponding

. It is noticeable that a certain similarity is still visible.

3.4. Terfenol-D

Terfenol-D is a Terbium, Dysprosium, and Iron alloy, and its chemical composition is Tb

Dy

Fe

, where the commonly adopted concentrations are

and

[

27]. It produces the largest elongation at room temperature among all MMs for a relatively low

H. In particular, it exhibits a maximum strain of about 1000–1500 ppm at room temperature and magnetic saturation of about 1 T [

28]. This makes Terfenol-D particularly suitable for micro-positioning and actuating purposes. In addition, it is often used as active element in energy harvesting device [

29]. The sample used in our experimental measurements is 20 mm long with a square section of 25 mm

.

In

Figure 9a, the magnetic characteristics for Terfenol-D at different applied constant stresses are reported. It is noticeable that saturation is reached at higher magnetic fields with respect to Galfenol. Indeed, the considered material is magnetically harder than Galfenol with stronger hysteresis effects. Moreover, the magnetic permeability decreases when the applied stress increases and exhibits a self-similar behavior typical also for Iron-Gallium alloys.

The overall minimization problem can be assumed as follows:

where, in this case, the function

has been defined to be a hyperbolic function of

and the scaling parameter

still equal to −1. The choice of a nonlinear function

, instead of a constant parameter as for Galfenol, allows for identifying the feedback term more efficiently and obtaining a better fit with experimental data, by minimizing again the area difference.

Figure 10 illustrates the minimization problem for Terfenol-D. In particular, the red dot indicates the minimum of the area difference within the given range, which is reached for

and

MPa. In

Figure 9b, the

M-

u curves at different applied stresses are reported, where

u has been computed as reported in Equation (

20) with the aforementioned

k and

parameters values. It is worth noting that the curves almost overlap near the origin with a linear-like behavior, while they slightly deviate in the knee area approaching the saturation. This is also related to the fact that, in experiments, it is difficult to reach complete saturation, and a part of the information necessary for the minimization procedure is missing. With the aim to improve the minimization algorithm, the average curve of the Terfenol hysteresis loops has been extrapolated according to the Law of Approach to Saturation (LAS), reported in Reference [

30], up to 1000 kA/m. Still, due to the lack of experimental information about the large field asymptotics of the loops, the identification results are not optimal.

As reported for Galfenol, also in

Figure 10, we see a zone (dark gray) where the surface

shows different minima. In particular, there would be a nonlinear combination of

k and

that minimizes the difference of the areas. However, the red dot shows the global minimum in the considered parameters range.

The value of

k obtained from minimization is relatively high, but, as described for Galfenol, what is important in the feedback term is that the value of

remains small.

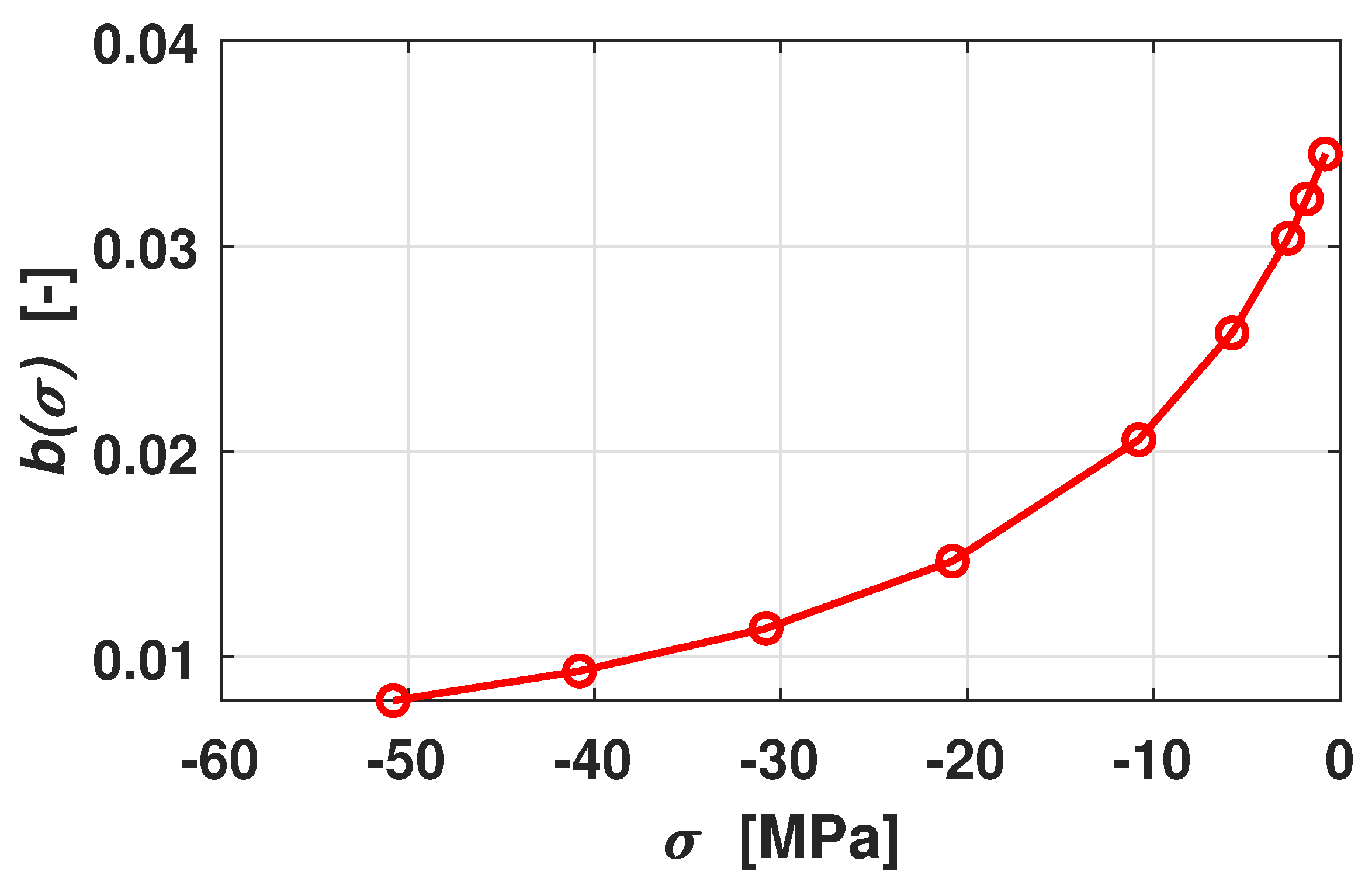

Figure 11 shows how

depends on

, for the

k and

parameters obtained from minimization. It is noticeable that, for increasing compressive stress, the function goes to zero (hyperbolic function of

), while it is bounded from above by the value 0.04. From the experimental point of view, the value of

MPa obtained from minimization procedure can be reasonably interpreted as a pre-stress frozen in the material due to its manufacturing process. Indeed, the Terfenol-D sample under consideration has no stress-annealing [

31], while much larger built-in compressive stress of about hundreds of MPa have been reported for SA samples [

32].