Growth and Characterisation of Antiferromagnetic Ni2MnAl Heusler Alloy Films

Abstract

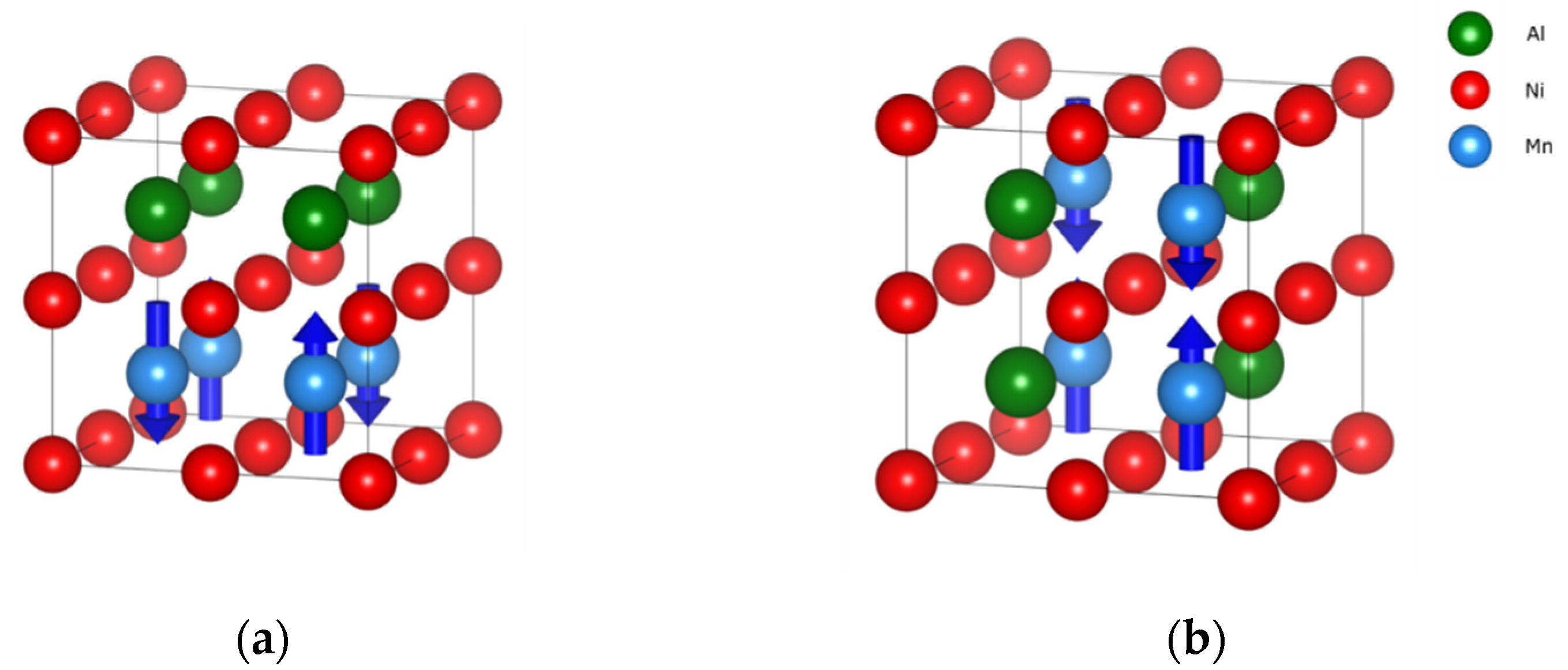

1. Introduction

2. Experimental Procedures

3. Results and Discussion

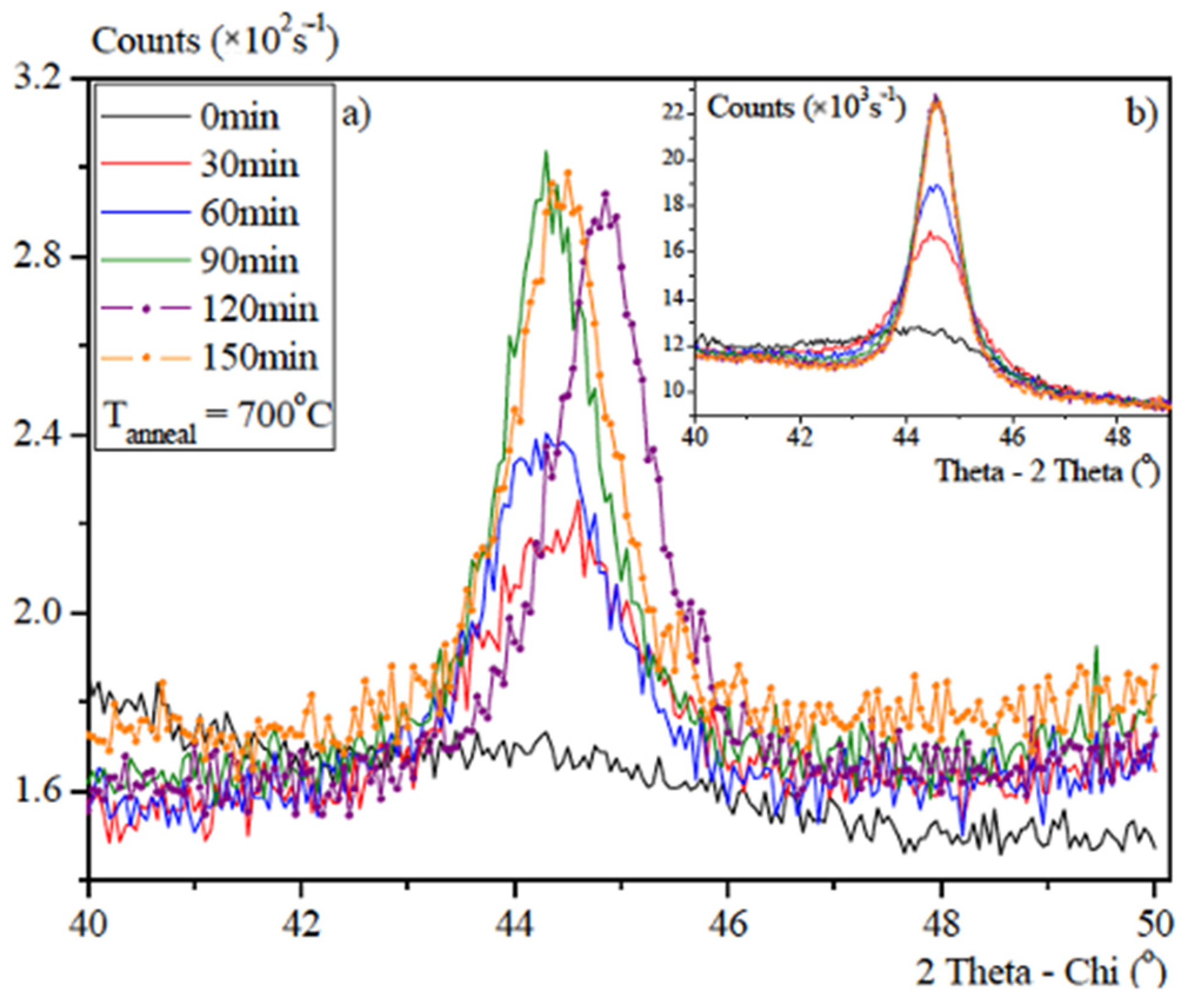

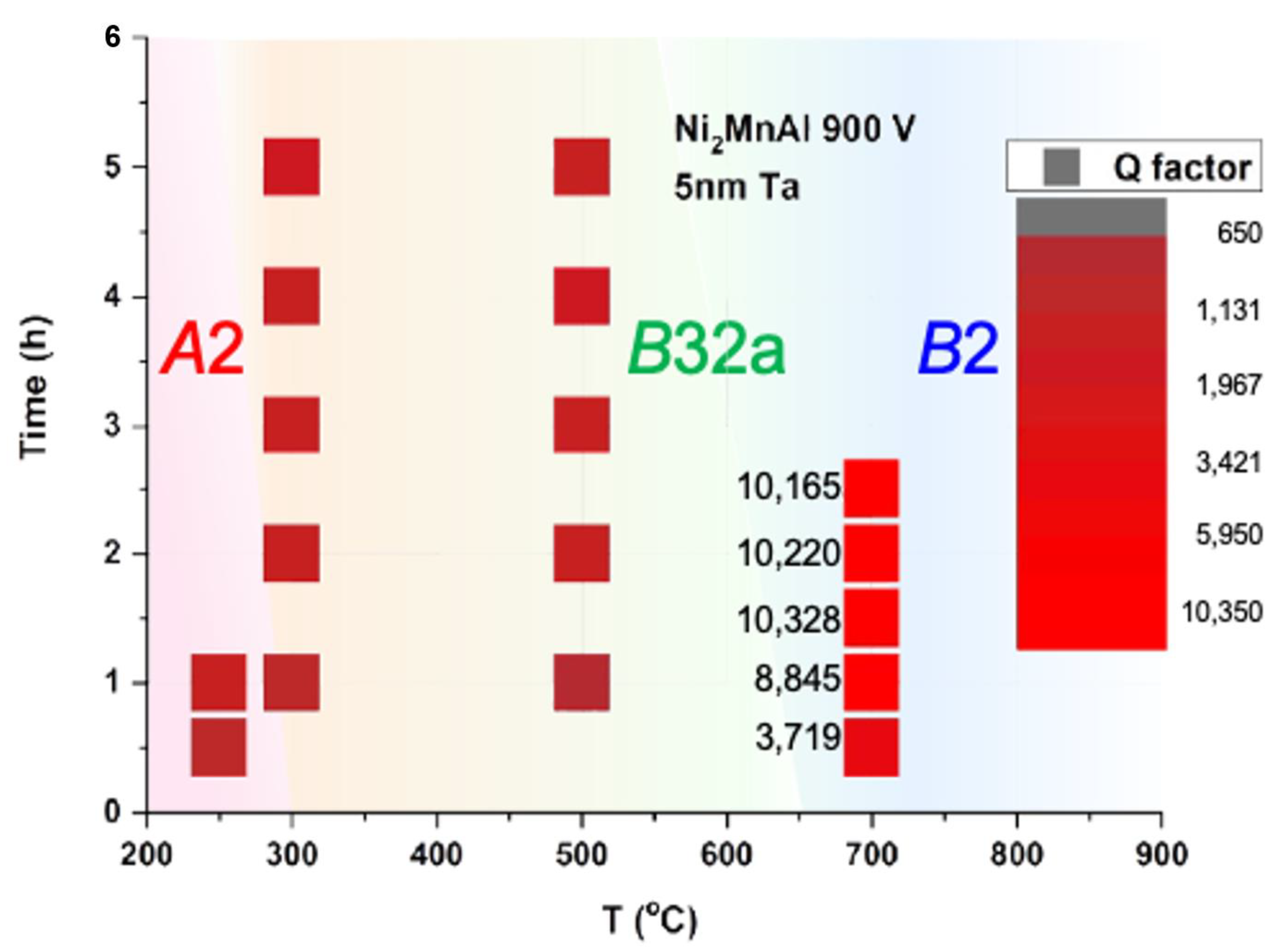

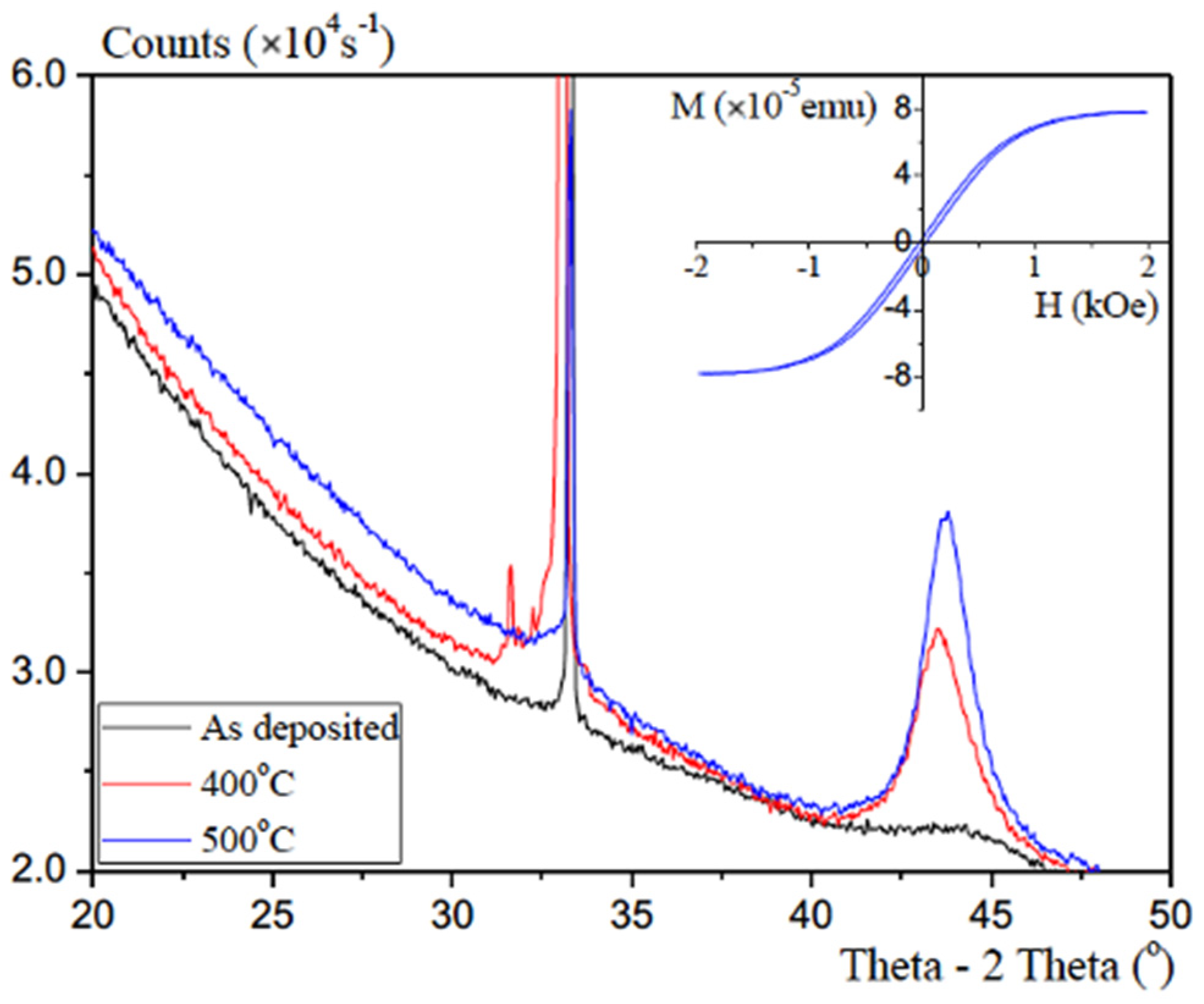

3.1. Ni2MnAl Films

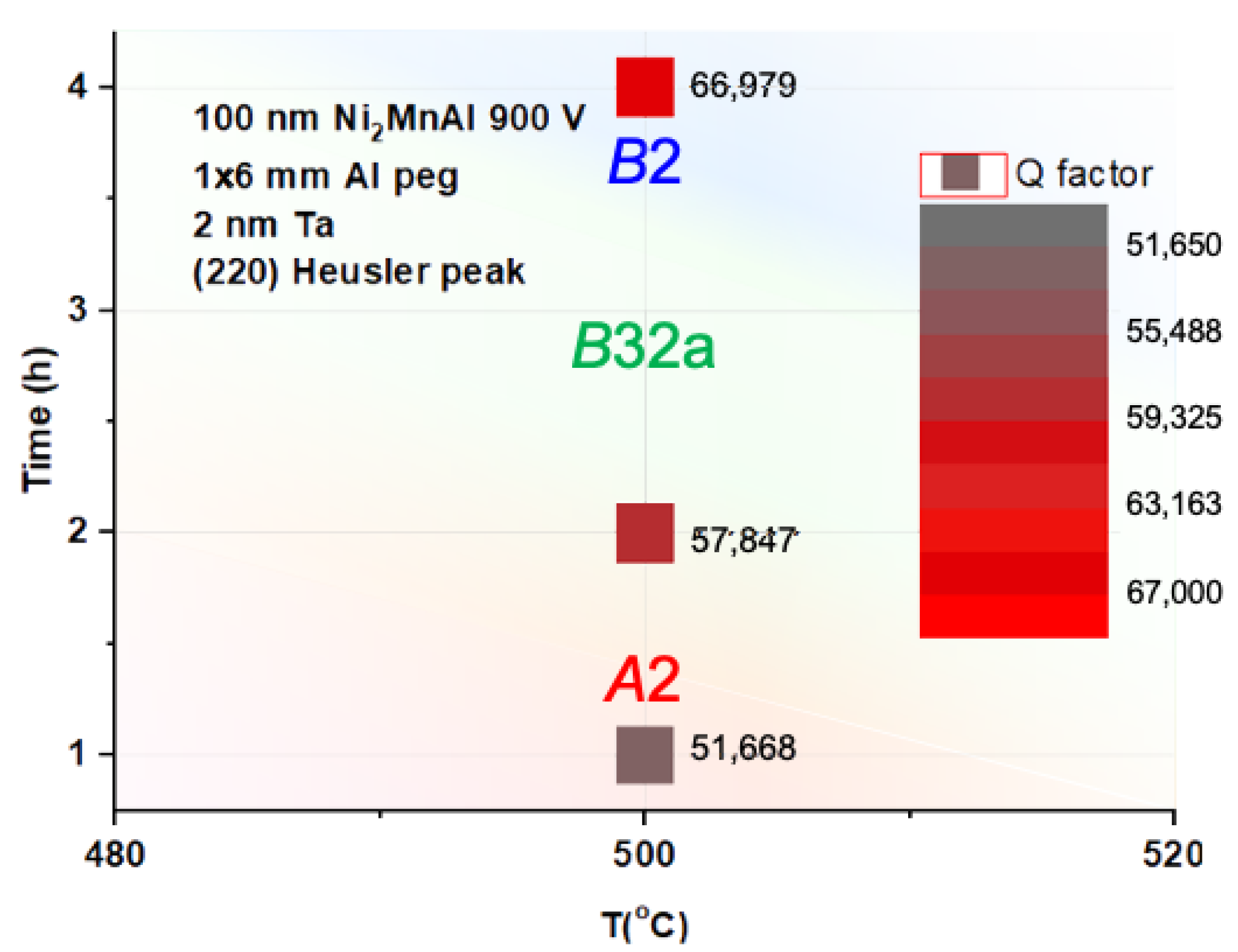

3.2. Ni2MnAl Films with Atomic Substitutions by Al

3.3. Ni2MnAl Films with Atomic Substitutions by Fe

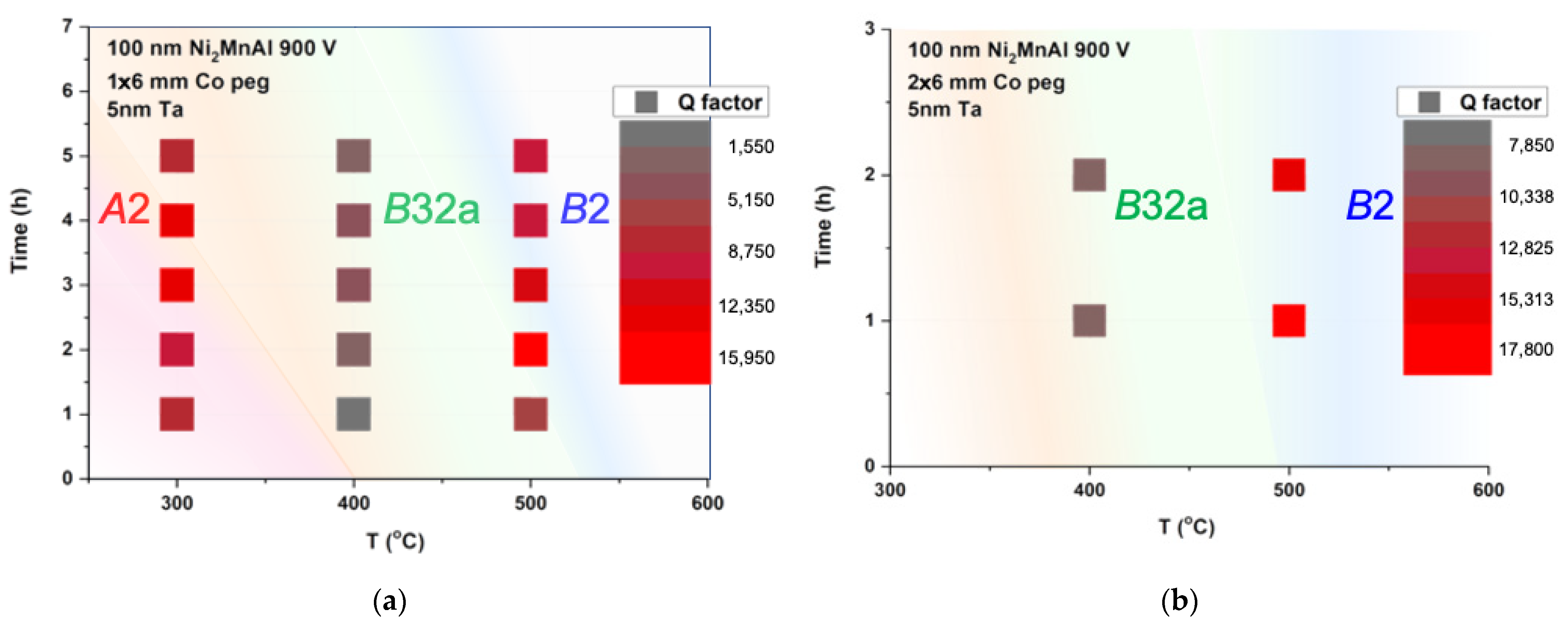

3.4. Ni2MnAl Films with Atomic Substitutions by Co

4. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jungwirth, T.; Marti, X.; Wadley, P.; Wunderlich, J. Antiferroagnetic spintronics. Nat. Nanotech. 2016, 11, 231–241. [Google Scholar] [CrossRef] [PubMed]

- Hirohata, A.; Huminiuc, T.; Sinclair, J.; Wu, H.; Samiepour, M.; Vallejo-Fernandez, G.; O’Grady, K.; Balluf, J.; Meinert, M.; Reiss, G.; et al. Development of antiferromagnetic Heusler alloys for the replacement of iridium as a critically raw material. J. Phys. D Appl. Phys. 2017, 50, 443001. [Google Scholar] [CrossRef]

- Singh, S.; D’Souza, W.; Suard, E.; Chapon, L.; Senyshyn, A.; Petricek, V.; Skourski, Y.; Nicklas, M.; Felser, C.; Chadov, S. Room-temperature tetragonal non-collinear Heusler antiferromagnet Pt2MnGa. Nat. Commun. 2016, 7, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Acet, M.; Duman, E.; Wassermann, E.F. Coexisting ferro- and antiferromagnetism in Ni2MnAl Heusler alloys. J. Appl. Phys. 2002, 92, 3867–3871. [Google Scholar] [CrossRef]

- Galanakis, I.; Şaşıoğlu, E. Structural-induced antiferromagnetism in Mn-based full Heusler alloys: The case of Ni2MnAl. Appl. Phys. Lett. 2011, 98, 102514. [Google Scholar] [CrossRef][Green Version]

- Wu, H.; Vallejo-Fernandez, G.; Hirohata, A. Magnetic and structural properties of antiferromagnetic Mn2VSi alloy films grown at elevated temperatures. J. Phys. D Appl. Phys. 2017, 50, 375001. [Google Scholar] [CrossRef]

- Singh, D.J.; Mazin, I. Electronic structure, local moments, and transport in Fe2VAl. Phys. Rev. B 1998, 57, 14352. [Google Scholar] [CrossRef]

- Nayak, A.K.; Nicklas, M.; Chadov, S.; Khuntia, P.; Shekhar, C.; Kalache, A.; Baenitz, M.; Skourski, Y.; Guduru, V.K.; Puri, A.; et al. Design of compensated ferrimagnetic Heusler alloys for giant tunable exchange bias. Nat. Mater. 2015, 14, 679–684. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.Y.; Dong, J.W.; Xie, J.Q.; Shih, T.C.; McKernan, S.; Leighton, C.; Palmstrøm, C.J. Growth temperature controlled magnetism in molecular beam epitaxially grown Ni2MnAl Heusler alloy. J. Cryst. Growth 2003, 254, 384–389. [Google Scholar] [CrossRef]

- Tsuchiya, T.; Kubota, T.; Sugiyama, T.; Huminiuc, T.; Hirohata, A.; Takanashi, K. Exchange bias effects in Heusler alloy Ni2MnAl/Fe bilayers. J. Phys. D Appl. Phys. 2016, 49, 235001. [Google Scholar] [CrossRef]

- Huminiuc, T.; Whear, O.; Takahashi, T.; Kim, J.-Y.; Vick, A.; Vallejo-Fernandez, G.; O’Grady, K.; Hirohata, A. Growth and characterisation of ferromagnetic and antiferromagnetic Fe2+xVyAl Heusler alloy films. J. Phys. D Appl. Phys. 2018, 51, 325003. [Google Scholar] [CrossRef]

- Elphick, K.; Frost, W.; Samiepour, M.; Kubota, T.; Takanashi, K.; Sukegawa, H.; Mitani, S.; Hirohata, A. Heusler alloys for spintronic devices: Review on recent development and future perspectives. Sci. Technol. Adv. Mater. 2021, 22, 235–271. [Google Scholar] [CrossRef] [PubMed]

- Kanomata, T.; Kikuchi, M.; Yamauchi, H. Magnetic properties of Heusler alloys Ru2MnZ (Z = Si, Ge, Sn and Sb). J. Alloys Compd. 2006, 414, 1–7. [Google Scholar] [CrossRef]

- Ishida, S.; Kashiwagi, S.; Fujii, S.; Asano, S. Magnetic and half-metallic properties of new Heusler alloys Ru2MnZ (Z = Si, Ge, Sn and Sb). Phys. B 1995, 210, 140–148. [Google Scholar] [CrossRef]

- Sagar, J.; Fleet, L.R.; Walsh, M.; Lari, L.; Boyes, E.D.; Whear, O.; Huminiuc, T.; Vick, A.; Hirohata, A. Over 50% reduction in the formation energy of Co-based Heusler alloy films by two-dimensional crystallisation. Appl. Phys. Lett. 2014, 105, 032401. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huminiuc, T.; Whear, O.; Vick, A.J.; Lloyd, D.C.; Vallejo-Fernandez, G.; O’Grady, K.; Hirohata, A. Growth and Characterisation of Antiferromagnetic Ni2MnAl Heusler Alloy Films. Magnetochemistry 2021, 7, 127. https://doi.org/10.3390/magnetochemistry7090127

Huminiuc T, Whear O, Vick AJ, Lloyd DC, Vallejo-Fernandez G, O’Grady K, Hirohata A. Growth and Characterisation of Antiferromagnetic Ni2MnAl Heusler Alloy Films. Magnetochemistry. 2021; 7(9):127. https://doi.org/10.3390/magnetochemistry7090127

Chicago/Turabian StyleHuminiuc, Teodor, Oliver Whear, Andrew J. Vick, David C. Lloyd, Gonzalo Vallejo-Fernandez, Kevin O’Grady, and Atsufumi Hirohata. 2021. "Growth and Characterisation of Antiferromagnetic Ni2MnAl Heusler Alloy Films" Magnetochemistry 7, no. 9: 127. https://doi.org/10.3390/magnetochemistry7090127

APA StyleHuminiuc, T., Whear, O., Vick, A. J., Lloyd, D. C., Vallejo-Fernandez, G., O’Grady, K., & Hirohata, A. (2021). Growth and Characterisation of Antiferromagnetic Ni2MnAl Heusler Alloy Films. Magnetochemistry, 7(9), 127. https://doi.org/10.3390/magnetochemistry7090127