Excellent Microwave Absorption Properties in the C Band for the Nitrided Y2Fe12Co4Si/Paraffin Composites

Abstract

1. Introduction

2. Materials and Methods

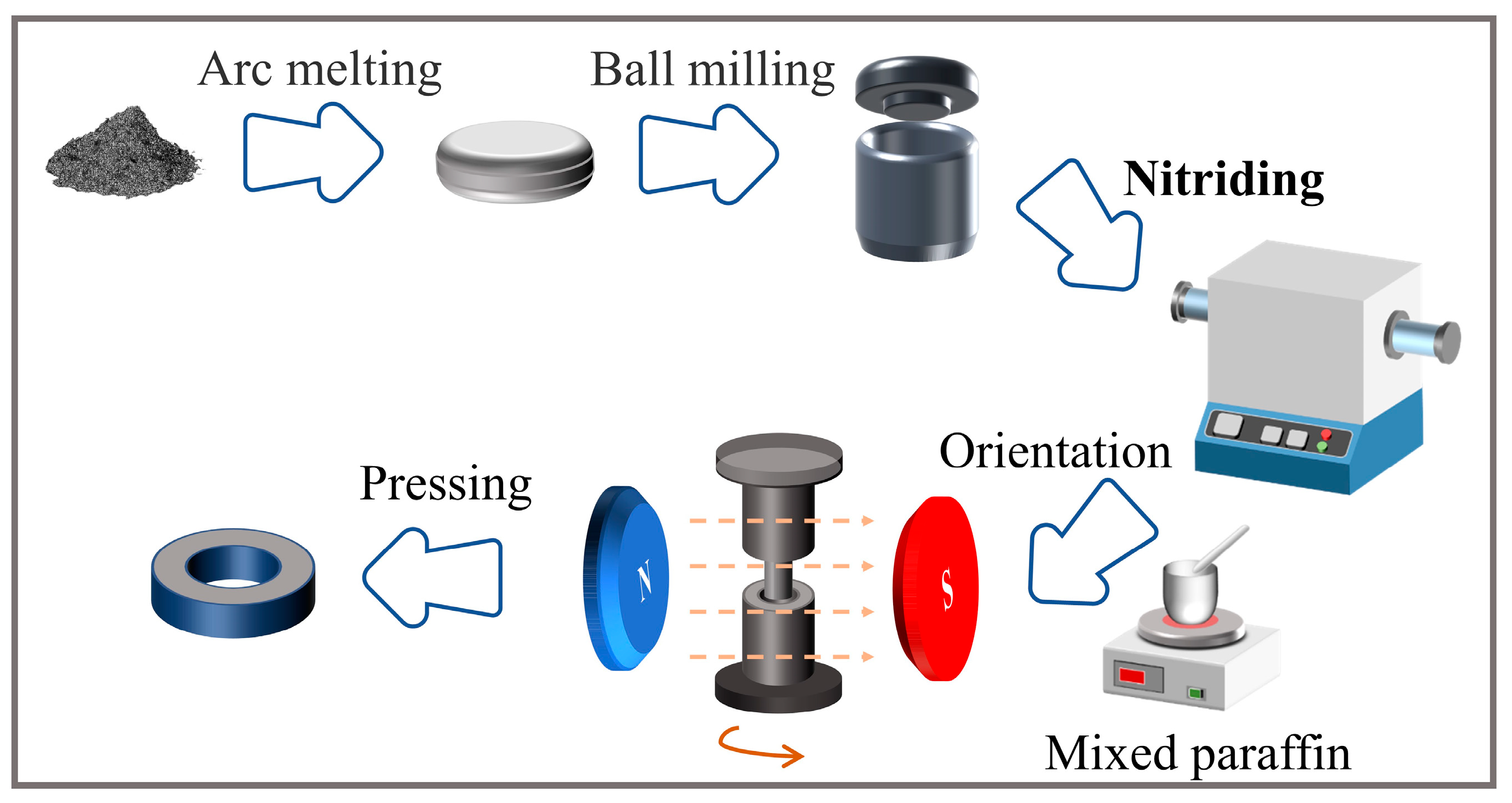

2.1. Sample Preparation

2.2. Properties and Characterization

3. Results

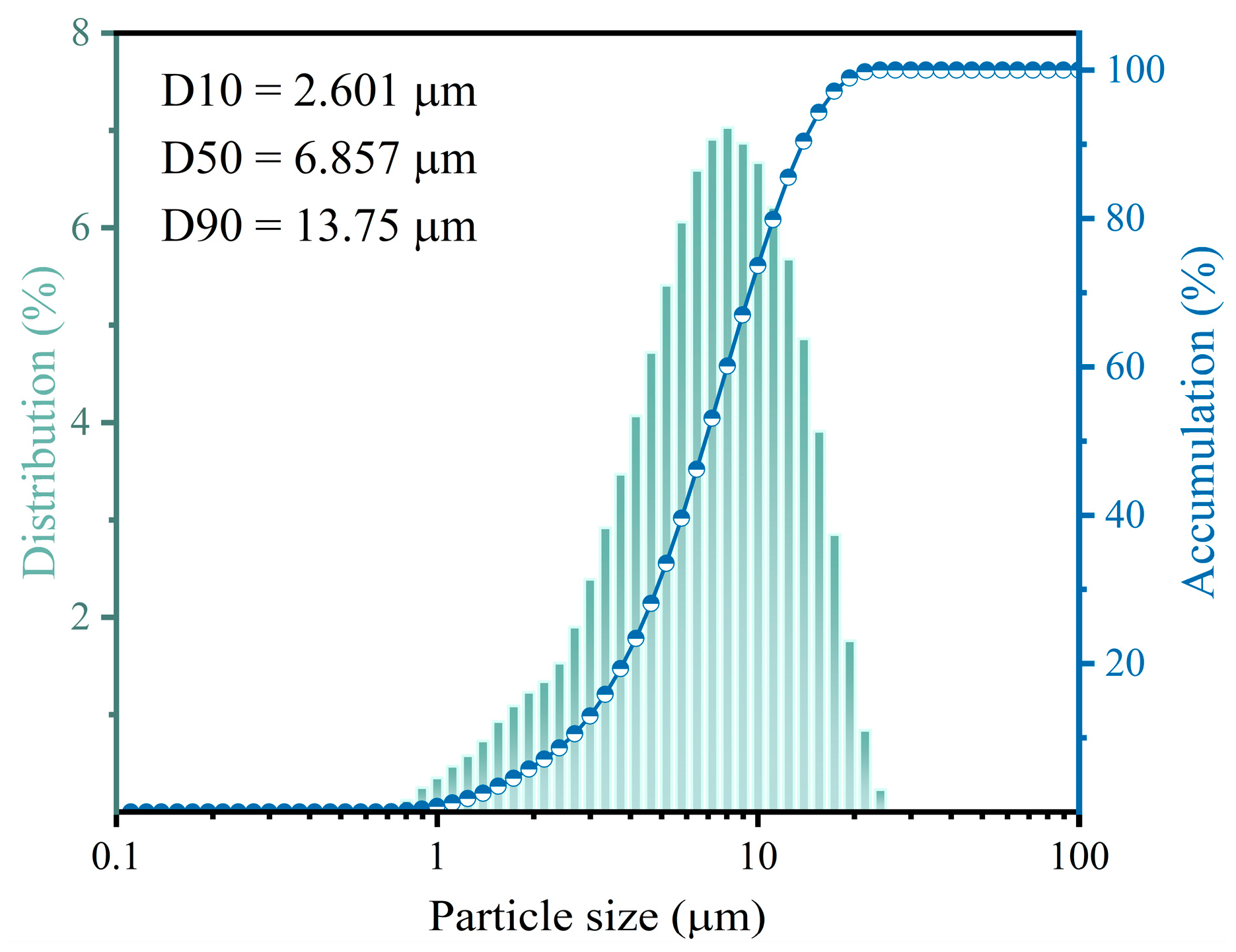

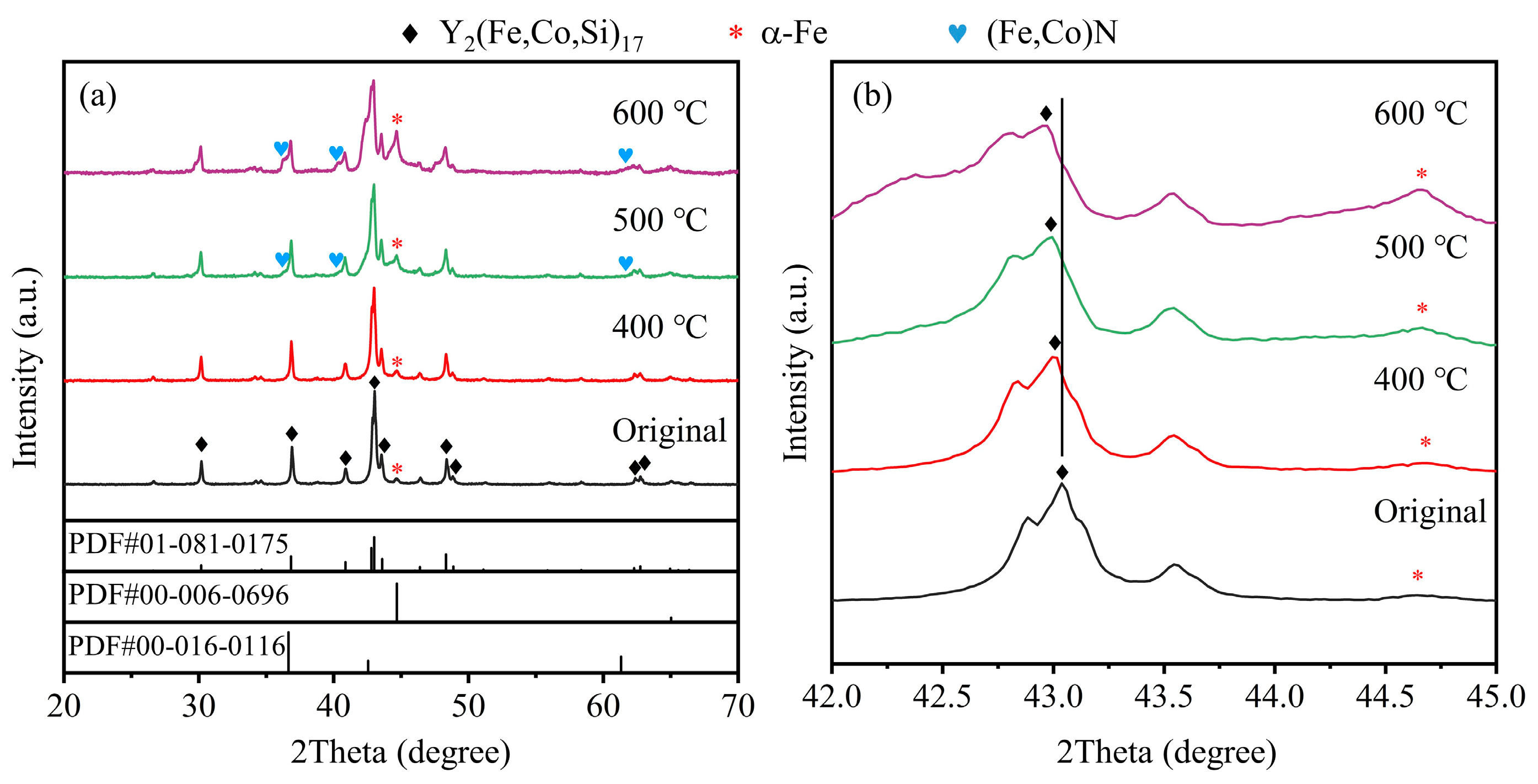

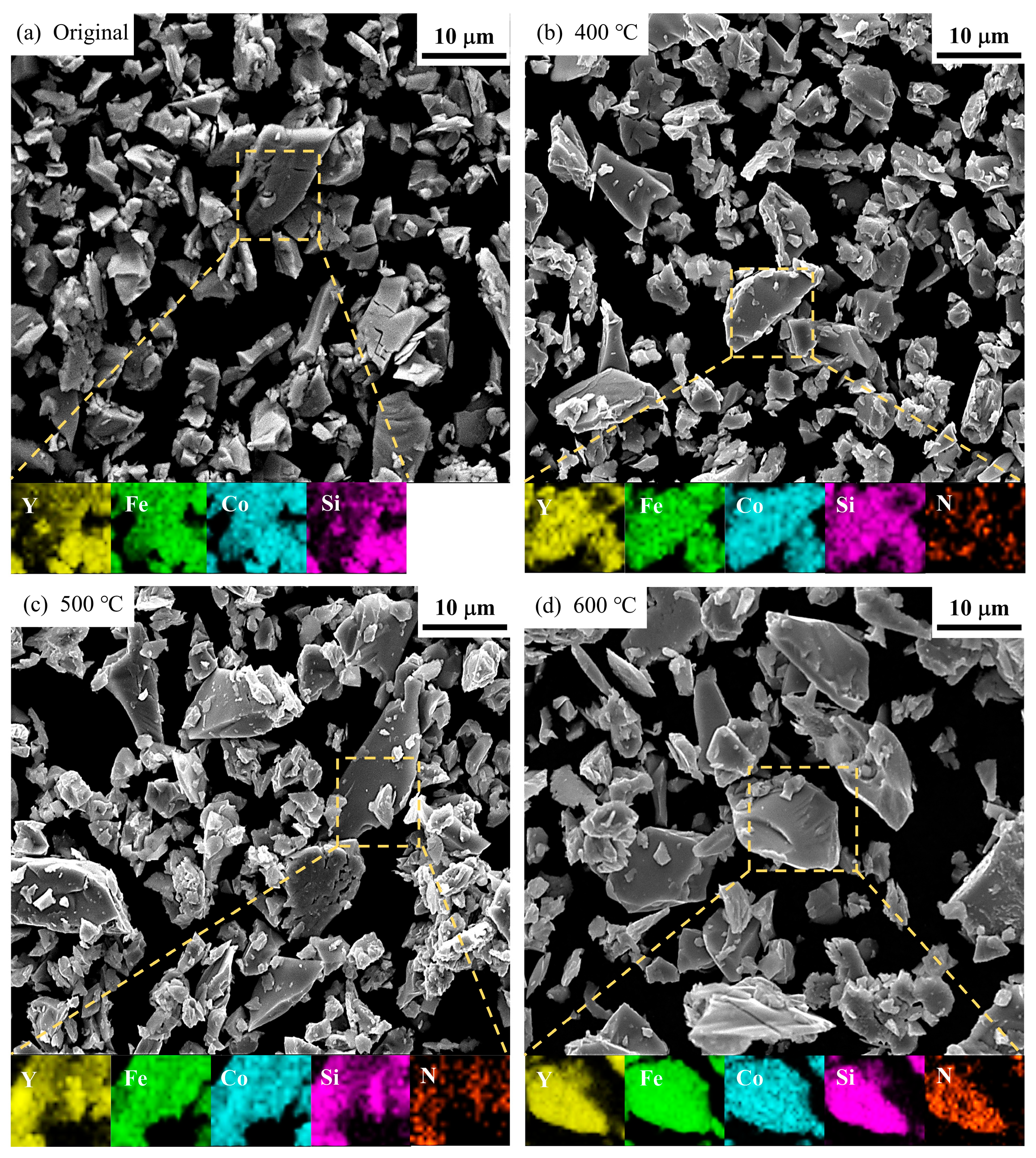

3.1. Phase Composition and Morphology

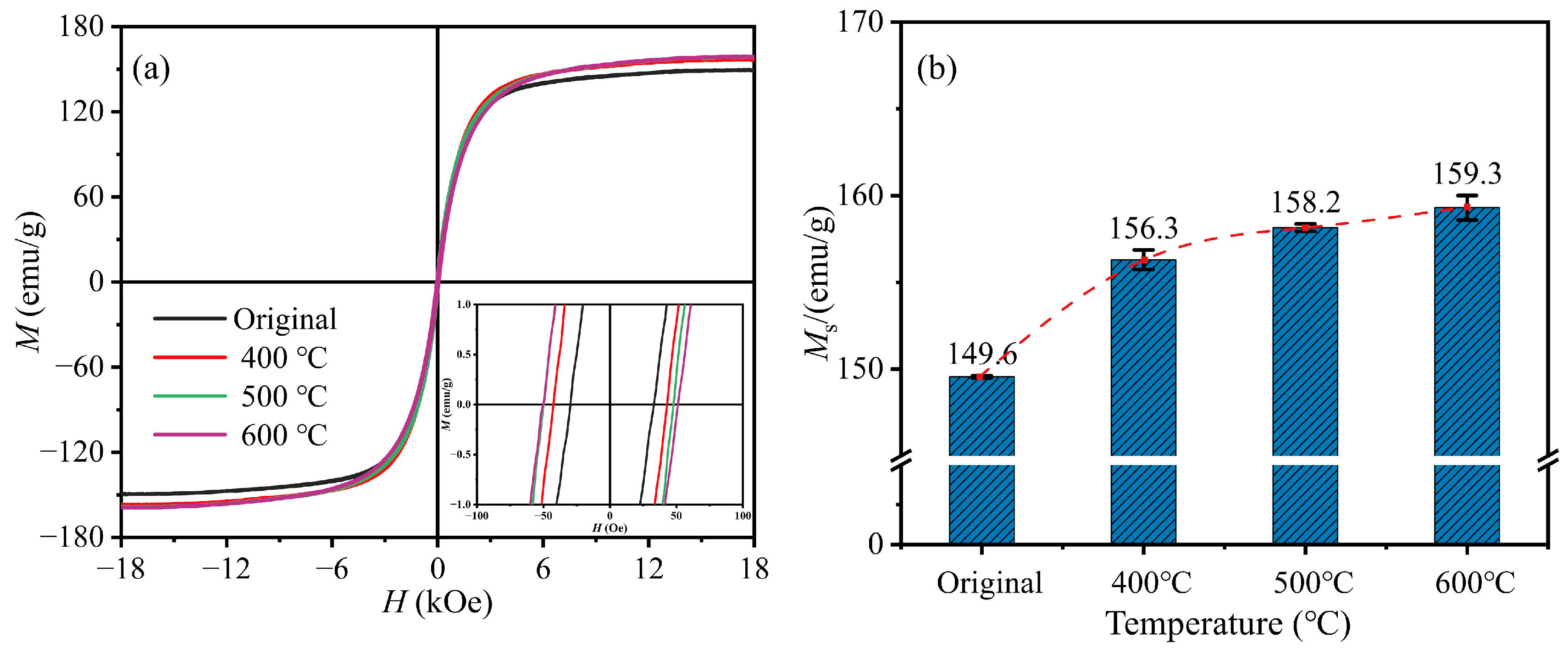

3.2. Static Magnetic Properties

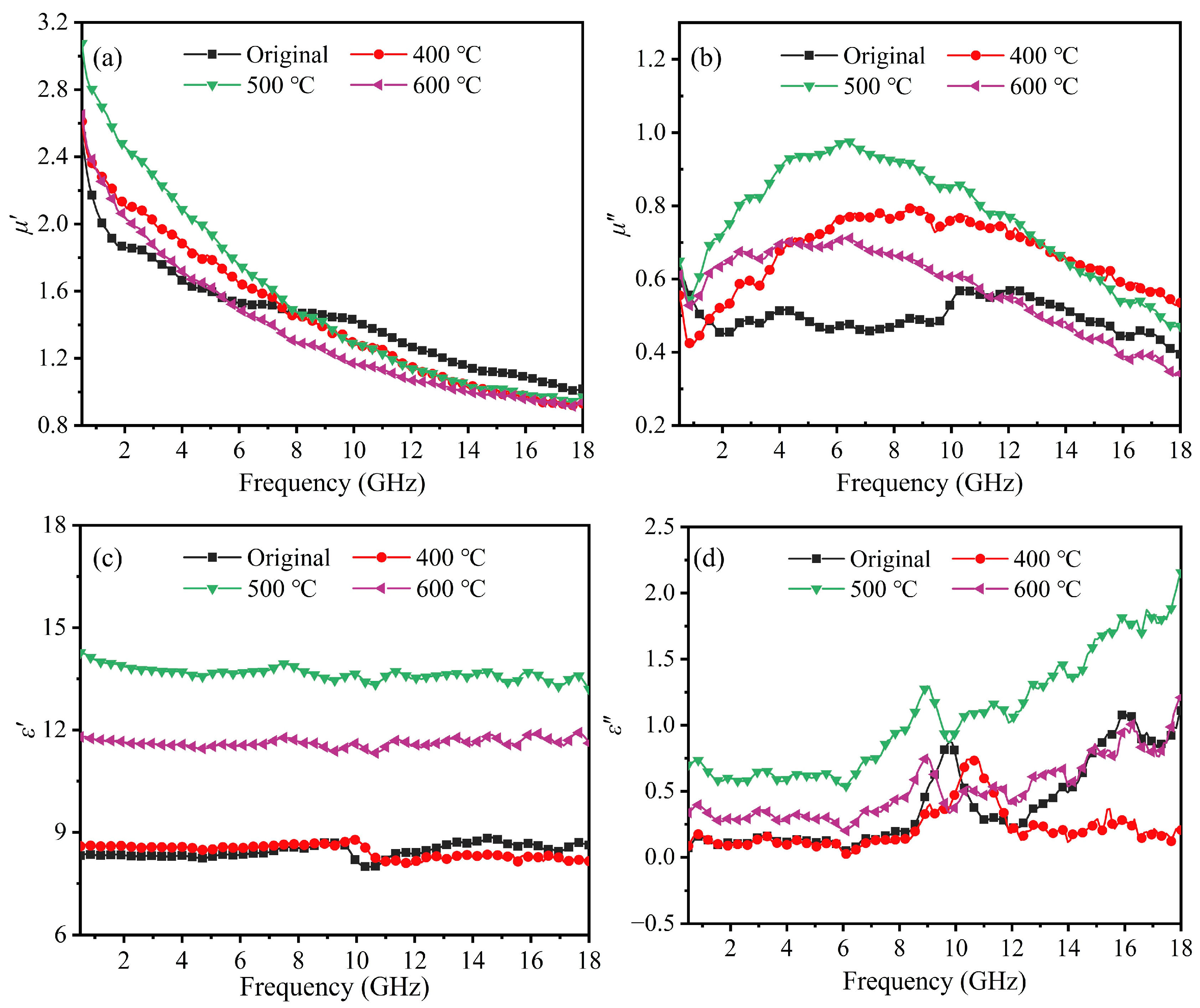

3.3. Electromagnetic Parameters

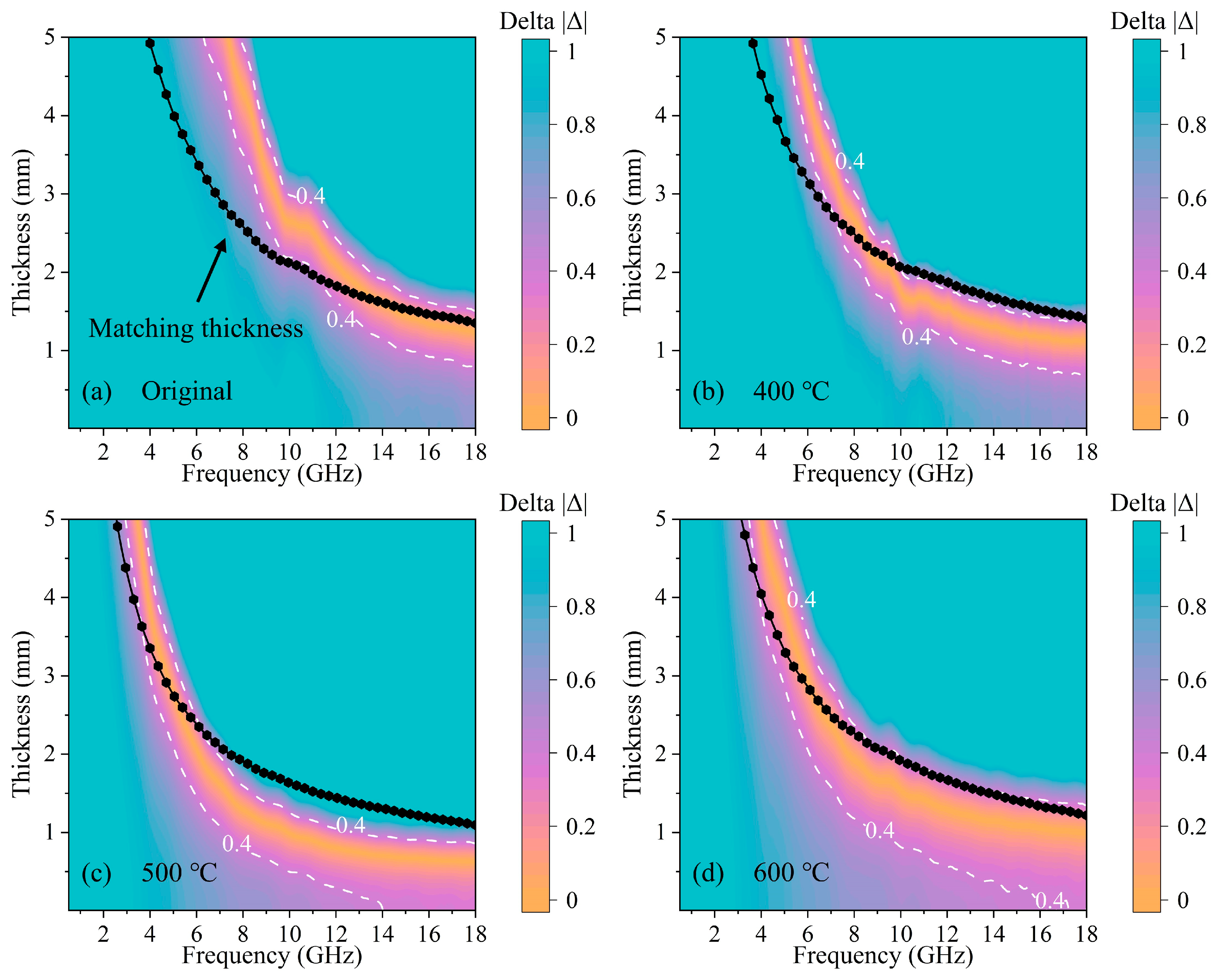

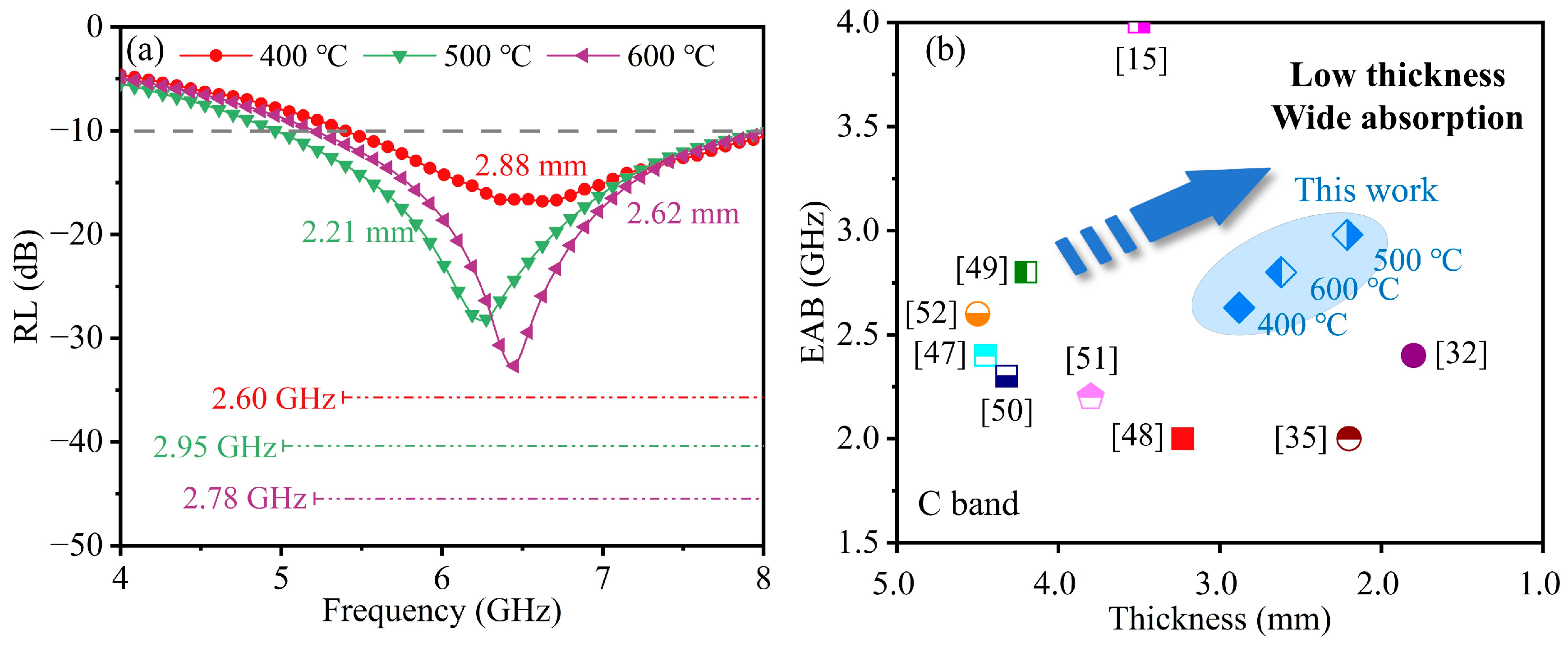

3.4. Microwave Absorption Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, J.Y.; Zhang, H.B.; Ning, M.Q.; Raza, H.S.; Zhang, D.Q.; Zheng, G.P.; Zheng, Q.B.; Che, R.C. Emerging materials and designs for low- and multi-band electromagnetic wave absorbers: The search for dielectric and magnetic synergy? Adv. Funct. Mater. 2022, 32, 12. [Google Scholar] [CrossRef]

- Elmahaishi, M.F.; Azis, R.S.; Ismail, I.; Muhammad, F.D. A review on electromagnetic microwave absorption properties: Their materials and performance. J. Mater. Res. Technol. JmrT 2022, 20, 2188–2220. [Google Scholar] [CrossRef]

- Jin, E.S. Analysis of the harm of electromagnetic wave pollution and its protection strategies. In Proceedings of the 2020 Cross Strait Radio Science & Wireless Technology Conference (CSRSWTC), Fuzhou, China, 13–16 December 2020; p. 2. [Google Scholar] [CrossRef]

- Mathews, S.A.; Babu, D.R. Analysis of the role of M-type hexaferrite-based materials in electromagnetic interference shielding. Curr. Appl. Phys. 2021, 29, 39–53. [Google Scholar] [CrossRef]

- Zheng, W.; Ye, W.X.; Yang, P.; Wang, D.S.; Xiong, Y.T.; Liu, Z.Y.; Qi, J.D.; Zhang, Y.X. Recent progress in iron-based microwave absorbing composites: A review and prospective. Molecules 2022, 27, 23. [Google Scholar] [CrossRef] [PubMed]

- Zhong, X.C.; Zhang, H.N.; He, N.; Hu, J.W.; Xu, H.X.; Liao, X.F.; Zhou, Q.; Liu, Z.W.; Ramanujan, R.V. Superior microwave absorption properties of carbon-coated FeSiCr micro flakes. J. Alloys Compd. 2024, 989, 11. [Google Scholar] [CrossRef]

- He, N.; Ju, W.B.; Hu, J.W.; Wu, Y.; Zhao, L.Z.; Zhong, X.C.; Liu, Z.W. Magnetic needles enable tunable microwave absorption from S to Ku band via collective orientation. J. Alloys Compd. 2024, 979, 9. [Google Scholar] [CrossRef]

- Jang, D.; Kim, B.J.; Nam, I.W. A comprehensive study on EMI shielding performance of carbon nanomaterials-embedded CFRP or GFRP composites. Polymers 2022, 14, 5224. [Google Scholar] [CrossRef]

- Gunwant, D.; Vedrtnam, A. Microwave absorbing properties of carbon fiber based materials: A review and prospective. J. Alloys Compd. 2021, 881, 23. [Google Scholar] [CrossRef]

- Jia, X.S.; Wang, Z.W.; Zhang, H.; Liu, F.; Yi, Q.J.; Li, C.L.; Wang, X.; Piao, M.X. Structural design of FeCo/C magnetic nanocomposites: Implications toward C-band electromagnetic wave absorption. Acs Appl. Nano Mater. 2024, 7, 19602–19618. [Google Scholar] [CrossRef]

- Fang, G.; Liu, C.Y.; Yang, Y.; Peng, K.S.; Cao, Y.F.; Jiang, T.; Zhang, Y.T.; Zhang, Y.J. Regulating percolation threshold via dual conductive phases for high-eEfficiency microwave absorption performance in C and X bands. Acs Appl. Mater. Interfaces 2021, 13, 37507–37516. [Google Scholar] [CrossRef]

- Han, Y.X.; He, M.K.; Hu, J.W.; Liu, P.B.; Liu, Z.W.; Ma, Z.L.; Ju, W.B.; Gu, J.W. Hierarchical design of FeCo-based microchains for enhanced microwave absorption in C band. Nano Res. 2023, 16, 1773–1778. [Google Scholar] [CrossRef]

- Lv, H.L.; Yang, Z.H.; Pan, H.G.; Wu, R.B. Electromagnetic absorption materials: Current progress and new frontiers. Prog. Mater. Sci. 2022, 127, 74. [Google Scholar] [CrossRef]

- Ma, Y.Y.; Jiang, Y.H.; Wang, C.Y.; Kang, S.B.; Chen, G.Q.; Zhong, B. Microwave absorption performance enhancement of NiFe2O4/GNs composite with hollow hexagonal-like structure. J. Magn. Magn. Mater. 2023, 565, 11. [Google Scholar] [CrossRef]

- Liu, X.L.; Sun, H.L.; Yan, W.W.; Yang, S.T.; Jiang, X.S. Effect of Gd addition on the microwave absorption properties of FeSiAl composite. Vacuum 2024, 219, 11. [Google Scholar] [CrossRef]

- Xiang, Z.C.; Song, Z.; Wang, T.S.; Feng, M.H.; Zhao, Y.J.; Zhang, Q.T.; Hou, Y.; Wang, L.X. Bead-like flexible ZIF-67-derived Co@Carbon composite nanofibre mat for wideband microwave absorption in C-band. Carbon 2024, 216, 10. [Google Scholar] [CrossRef]

- Zhang, H.N.; Zhong, X.C.; Hu, J.W.; He, N.; Xu, H.X.; Liao, X.F.; Zhou, Q.; Liu, Z.W.; Ramanujan, R.V. Graphite/epoxy-coated flaky FeSiCr powders with enhanced microwave absorption. Metals 2023, 13, 12. [Google Scholar] [CrossRef]

- Min, D.D.; Zhou, W.C.; Qing, Y.C.; Luo, F.; Zhu, D.M. Greatly enhanced microwave absorption properties of highly oriented flake carbonyl iron/epoxy resin composites under applied magnetic field. J. Mater. Sci. 2017, 52, 2373–2383. [Google Scholar] [CrossRef]

- Houbi, A.; Aldashevich, Z.A.; Atassi, Y.; Telmanovna, Z.B.; Saule, M.; Kubanych, K. Microwave absorbing properties of ferrites and their composites: A review. J. Magn. Magn. Mater. 2021, 529, 17. [Google Scholar] [CrossRef]

- Yang, J.B.; Yang, W.Y.; Li, F.S.; Yang, Y.C. Research and development of high-performance new microwave absorbers based on rare earth transition metal compounds: A review. J. Magn. Magn. Mater. 2020, 497, 11. [Google Scholar] [CrossRef]

- Yan, L.; Zhang, Y.J.; Zhang, Y.L.; Liu, R.; Liu, C.Y.; Wu, F.; Xu, F. Progress of rare earth-transition metal alloys and their compounds for electromagnetic wave absorption. J. Magn. Magn. Mater. 2024, 597, 12. [Google Scholar] [CrossRef]

- Xue, D.S.; Li, F.S.; Fan, X.L.; Wen, F.S. Bianisotropy picture of higher permeability at higher frequencies. Chin. Phys. Lett. 2008, 25, 4120–4123. [Google Scholar] [CrossRef]

- Yang, W.Y.; Hu, Q.W.; Qiao, G.Y.; Zha, L.; Liu, S.Q.; Han, J.Z.; Du, H.L.; Zhang, Y.; Yang, Y.C.; Wang, C.S. Tuning effect of silicon substitution on magnetic and high frequency electromagnetic properties of R2Fe17 and their composites. J. Rare Earths 2019, 37, 1102–1107. [Google Scholar] [CrossRef]

- Yang, W.Y.; Zhang, Y.F.; Qiao, G.Y.; Lai, Y.F.; Liu, S.Q.; Wang, C.S.; Han, J.Z.; Du, H.L.; Zhang, Y.; Yang, Y.C.; et al. Tunable magnetic and microwave absorption properties of Sm1.5Y0.5Fe17-xSix and their composites. Acta Mater. 2018, 145, 331–336. [Google Scholar] [CrossRef]

- Wei, H.Y.; Zhang, Z.P.; Hussain, G.; Zhou, L.S.; Li, Q.; Ostrikov, K. Techniques to enhance magnetic permeability in microwave absorbing materials. Appl. Mater. Today 2020, 19, 13. [Google Scholar] [CrossRef]

- Zhong, J.P.; Tan, G.G.; Man, Q.K.; Ning, M.Q.; Gao, Y.; Liu, X.C.; Pan, J. Optimisation of microwave absorption properties of Fe-substituted Y2Co17-xFex soft-magnetic composites. J. Mater. Sci. Mater. Electron. 2021, 32, 27849–27859. [Google Scholar] [CrossRef]

- Andreev, A.V.; Tereshina, E.A.; Gorbunov, D.I.; Santavá, E.; Sebek, J.; Zácek, M.; Danis, S.; Pospisil, J.; Havela, L. Influence of Ru on magnetic properties of Y2T17 (T = Fe, Co) and Y2Fe16Si single crystals. J. Alloys Compd. 2015, 621, 415–422. [Google Scholar] [CrossRef]

- Lin, Z.C.; Tian, G.; Zhang, P.Y.; Hu, Q.W.; Xia, Y.H.; Qiao, L.; Wu, R.; Wang, M.K.; Liu, Z.; Wang, Y.K.; et al. Interstitial nitrogen-modified Y2Fe16SiNy compounds towards enhanced high-frequency magnetic properties. Acta Mater. 2024, 264, 9. [Google Scholar] [CrossRef]

- Wu, P.; Zhang, Y.D.; Hao, H.B.; Qiao, L.; Liu, X.; Wang, T.; Li, F.S. Effects of nitriding and Ni doping for the frequency of domain wall resonance peak and high-frequency magnetic performance of easy-plane Y2Fe17. J. Magn. Magn. Mater. 2022, 549, 7. [Google Scholar] [CrossRef]

- He, Y.; Pan, S.K.; Yu, J.J. Magnetic and microwave absorbing properties of Ce-Co-based alloy powders driven with lanthanum content. J. Rare Earths 2020, 38, 749–754. [Google Scholar] [CrossRef]

- Li, Y.W.; Liu, Z.; Wu, H.C.; Wang, F.; Zhu, C.Q.; Tan, D.L.; Liu, Y.; Yang, Y.; Zhang, M.X.; Chen, R.J.; et al. Phase structure evolution and its effect on magnetic and mechanical properties of B-doped Sm2Co17-type magnets with high Fe content. Chin. Phys. B 2024, 33, 7. [Google Scholar] [CrossRef]

- Liu, Y.H.; Pan, S.K.; Cheng, L.C.; Yu, J.J.; Huang, L. Effect of misch-metal content on microwave absorption property of Ce2Co17 alloy. J. Mater. Sci. Mater. Electron. 2020, 31, 11204–11210. [Google Scholar] [CrossRef]

- Tabata, T.; Asari, Y.; Nojima, M.; Terada, S. Process development for synthesizing FeCoN-based magnetic materials. In Proceedings of the 2024 IEEE International Magnetic Conference—Short Papers (INTERMAG Short Papers), Rio de Janeiro, Brazil, 5–10 May 2024; pp. 1–2. [Google Scholar] [CrossRef]

- Kutepov, A.V.; Tarasov, V.P.; Ignatov, A.S. Optimization of nitriding regimes for Sm2Fe17 alloy powder. Metallurgist 2017, 60, 1262–1266. [Google Scholar] [CrossRef]

- Zhuang, X.H.; Tan, G.G.; Ning, M.Q.; Qi, C.Y.; Ge, X.J.; Yang, Z.; Man, Q.K. Boosted microwave absorbing performance of Ce2Fe17N3-δ@SiO2 composite with broad bandwidth and low thickness. J. Alloys Compd. 2021, 883, 160835–160843. [Google Scholar] [CrossRef]

- Ma, Z.; Monalisha, P.; Tan, Z.W.; Pellicer, E.; Liedke, M.O.; Butterling, M.; Attallah, A.G.; Hirschmann, E.; Wagner, A.; Ibrahim, F.; et al. Optimizing magneto-ionic performance in structure/composition-engineered ternary nitrides. J. Mater. 2024, 10, 870–879. [Google Scholar] [CrossRef]

- Arabczyk, W.; Skulmowska, K.; Pelka, R.; Lendzion-Bielun, Z. Oscillatory mechanism of α-Fe(N)⇆γ’-Fe4N phase transformations during nanocrystalline iron nitriding. Materials 2022, 15, 9. [Google Scholar] [CrossRef]

- Zhong, X.C.; Xu, H.X.; Hu, J.W.; He, N.; Zhang, H.N.; Wu, Z.Y.; Liao, X.F.; Liu, Z.W.; Ramanujan, R.V. Superior microwave absorption properties of anisotropic Y2Fe16-xCoxSi/ paraffin composites by orientation tuning. Mater. Res. Bull. 2024, 177, 11. [Google Scholar] [CrossRef]

- Xu, H.X.; Zhong, X.C.; Hu, J.W.; He, N.; Zhang, H.N.; Wu, Z.Y.; Ma, L.; Liu, Z.W.; Ramanujan, R.V. Excellent microwave absorption of Y2Fe15.5Co0.5Si/paraffin composites by tuning powder particle size. J. Magn. Magn. Mater. 2024, 590, 9. [Google Scholar] [CrossRef]

- Capehart, T.W.; Mishra, R.K.; Pinkerton, F.E. X-ray-absorption fine structure of selected R2Fe17 nitrides. J. Appl. Phys. 1994, 75, 7018–7020. [Google Scholar] [CrossRef]

- Coey, J.M.D.; Lawler, J.F.; Hong, S.; Allan, J.E.M. Nitrogenation of R2Fe17 compounds: R=rare earth. J. Appl. Phys. 1991, 69, 3007–3010. [Google Scholar] [CrossRef]

- Park, S.J.; Kim, S.; Lee, S.; Khim, Z.G.; Char, K.; Hyeon, T. Synthesis and magnetic studies of uniform iron nanorods and nanospheres. J. Am. Chem. Soc. 2000, 122, 8581–8582. [Google Scholar] [CrossRef]

- Xu, X.C.; Li, Y.Q.; Ma, Z.H.; Zhuge, Y.T.; Teng, Y.; Zhang, Y.; Zhang, H.G.; Zhang, D.T.; Yue, M. Tuning the morphology of soft magnetic phase to optimize the microstructure of SmCo5/α-Fe nanocomposites. Mater. Charact. 2021, 172, 6. [Google Scholar] [CrossRef]

- Tyunina, M.; Rusevich, L.L.; Savinov, M.; Kotomin, E.A.; Dejneka, A. Dielectric behaviour of nitrogen doped perovskite SrTiO3-δNδ films. J. Mater. Chem. C 2023, 11, 16689–16698. [Google Scholar] [CrossRef]

- Wang, S.P.; Zhang, M.; Liu, Q.C.; Zhang, P.; Zhang, K.Y.; Kong, X.K. Synthesis of chain-like α-Fe/Fe3O4 core/shell composites exhibiting enhanced microwave absorption performance in high-frequency under an ultrathin matching thickness. J. Mater. Sci.-Mater. Electron. 2018, 29, 21040–21050. [Google Scholar] [CrossRef]

- Ma, Z.; Cao, C.T.; Liu, Q.F.; Wang, J.B. A new method to calculate the degree of electromagnetic impedance matching in one-layer microwave absorbers. Chin. Phys. Lett. 2012, 29, 4. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhao, Y.; Zhao, H.Q.; Lv, H.L.; Qi, X.D.; Cao, J.M.; Ji, G.B.; Du, Y.W. Engineering morphology configurations of hierarchical flower-like MoSe2 spheres enable excellent low-frequency and selective microwave response properties. Chem. Eng. J. 2019, 372, 390–398. [Google Scholar] [CrossRef]

- Yang, H.L.; Shen, Z.J.; Peng, H.L.; Xiong, Z.Q.; Liu, C.B.; Xie, Y. 1D-3D mixed-dimensional MnO2@nanoporous carbon composites derived from Mn-metal organic framework with full-band ultra-strong microwave absorption response. Chem. Eng. J. 2021, 417, 128087–128099. [Google Scholar] [CrossRef]

- Zhao, H.Q.; Cheng, Y.; Liu, W.; Yang, Z.H.; Zhang, B.S.; Ji, G.B.; Du, Y.W. The flaky porous Fe3O4 with tunable dimensions for enhanced microwave absorption performance in X and C bands. Nanotechnology 2018, 29, 295603–295613. [Google Scholar] [CrossRef]

- Ouyang, J.; He, Z.L.; Zhang, Y.; Yang, H.M.; Zhao, Q.H. Trimetallic FeCoNi@C nanocomposite hollow spheres derived from metal-organic frameworks with superior electromagnetic wave absorption ability. Acs Appl. Mater. Interfaces 2019, 11, 39304–39314. [Google Scholar] [CrossRef]

- Cui, Y.H.; Wu, F.; Wang, J.Q.; Wang, Y.B.; Shah, T.; Liu, P.; Zhang, Q.Y.; Zhang, B.L. Three dimensional porous MXene/CNTs microspheres: Preparation, characterization and microwave absorbing properties. Compos. Part A Appl. Sci. Manuf. 2021, 145, 106378–106389. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Gao, Y.; Zhang, Z.K.; Zhang, G.H.; Kang, B.J.; Jia, R.R.; Ge, J.Y.; Cao, S.X.; Zhang, J.C.; Feng, Z.J. Microstructure-tuned amorphous Co2FeGe nanoflakes for enhanced microwave absorption via mechanical alloying. Phys. Status Solidi A Appl. Mater. Sci. 2024, 221, 2400317. [Google Scholar] [CrossRef]

| Sample | Chemical Composition of Y2Fe12Co4Si Alloy (at.%) | ||||

|---|---|---|---|---|---|

| Y | Fe | Co | Si | N | |

| Original | 8.19 | 66.40 | 22.06 | 3.35 | — |

| 400 °C | 9.74 | 61.52 | 19.70 | 3.90 | 5.14 |

| 500 °C | 8.43 | 62.31 | 19.00 | 3.23 | 7.03 |

| 600 °C | 8.50 | 61.21 | 19.31 | 3.20 | 7.78 |

| Sample | Ha1 (kOe) | Ha2 (kOe) | Ha1/Ha2 | Ms (emu/g) | ||

|---|---|---|---|---|---|---|

| Original | 11.21 | 3.88 | 2.89 | 147 | 166.57 | 2.53 |

| 400 °C | 9.69 | 4.08 | 2.38 | 156 | 160.27 | 2.61 |

| 500 °C | 9.19 | 3.63 | 2.53 | 158 | 167.59 | 3.07 |

| 600 °C | 8.29 | 3.43 | 2.42 | 159 | 164.79 | 2.65 |

| Composite | Loading | RLmin (dB) | RL < −10 dB | Ref. | |

|---|---|---|---|---|---|

| EAB (GHz) | Thickness (mm) | ||||

| MnO2@NPC/paraffin | 50 wt.% | −54.96 | 2.00 (6.00–8.00) | 3.23 | [48] |

| FeSiAl-3Gd | sinter | −54.60 | 4.00 (4.00–8.00) | 3.50 | [15] |

| MoSe2/paraffin | 50 wt.% | −51.60 | 2.40 (4.40–6.80) | 4.45 | [47] |

| Flaky porous Fe3O4/paraffin | 60 wt.% | −22.50 | 2.80 (4.80–7.60) | 4.20 | [49] |

| MXene@CNTs /paraffin | 30 vol.% | −29.90 | 2.20 (5.80–8.00) | 3.80 | [51] |

| FeCoNi@MOF/paraffin | 38 wt.% | −27.70 | 2.30 (5.70–8.00) | 4.23 | [50] |

| Ce2Fe17N3-δ/paraffin | 30 vol.% | −34.40 | 2.00 (4.00–7.00) | 2.20 | [35] |

| Co2FeGe nanoflakes/paraffin | 70 wt.% | −48.60 | 2.60 (4.00–6.60) | 4.50 | [52] |

| Ce1.2MM0.8Co1.7/paraffin | 80 wt.% | −31.98 | 2.40 (5.80–8.00) | 1.80 | [32] |

| Y2Fe12Co4Si/paraffin * | 60 wt.% | −55.90 | 2.95 (5.05–8.00) | 2.46 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, W.; Xu, H.; Zhong, X.; He, N.; Liu, Z.; Ramanujan, R.V. Excellent Microwave Absorption Properties in the C Band for the Nitrided Y2Fe12Co4Si/Paraffin Composites. Magnetochemistry 2025, 11, 54. https://doi.org/10.3390/magnetochemistry11070054

Tang W, Xu H, Zhong X, He N, Liu Z, Ramanujan RV. Excellent Microwave Absorption Properties in the C Band for the Nitrided Y2Fe12Co4Si/Paraffin Composites. Magnetochemistry. 2025; 11(7):54. https://doi.org/10.3390/magnetochemistry11070054

Chicago/Turabian StyleTang, Wenjian, Hanxing Xu, Xichun Zhong, Na He, Zhongwu Liu, and Raju V. Ramanujan. 2025. "Excellent Microwave Absorption Properties in the C Band for the Nitrided Y2Fe12Co4Si/Paraffin Composites" Magnetochemistry 11, no. 7: 54. https://doi.org/10.3390/magnetochemistry11070054

APA StyleTang, W., Xu, H., Zhong, X., He, N., Liu, Z., & Ramanujan, R. V. (2025). Excellent Microwave Absorption Properties in the C Band for the Nitrided Y2Fe12Co4Si/Paraffin Composites. Magnetochemistry, 11(7), 54. https://doi.org/10.3390/magnetochemistry11070054