Abstract

Dates are considered high energy nutritional fruits as they are packed with plenty of minerals, vitamins and sugars. Among various options available for processing and value addition, dry dates are one of the best possible alternatives to convert doka/khalal stage fruit into a high value product. However, the technology for their production is limited to a few traditional date growing countries and research is limited in the countries with expanding areas. Thus, the protocol for development of dry dates was standardised and the effect of different blanching intervals (5, 10 and 15 min) on the drying and quality parameters were studied. The rate of drying, dehydration ratio and rehydration ratio were found to increase with increasing hot water dipping durations while a 10 min hot water dip was found to be best for retaining the best sensory parameters of taste, colour/appearance and flavour. The total colour difference (ΔE) was also maximal (71.10) in the date fruits exposed to a 10 min dip treatment. The reducing sugars decreased and non-reducing sugars increased with increasing hot water dipping periods while there was no significant variation in the total sugar content of the treated dates. The tannins responsible for acrid taste were also reduced to a minimum (1.43%) compared to control (2.52%) fruits. Thus, the fruits of date cv. Medjool being bulky and fibrous with more dry matter content are well suited for dry date preparation.

1. Introduction

Dates are grown in hot, dry regions of the world and are an essential subsistence crop in the majority of desert regions. Due to its beneficial properties, the date palm is widely regarded as the most promising fruit crop for the irrigated dry arid zones of developing nations such as India. The area and production of date palm is currently dominated by Middle Eastern and African countries while in India, it is cultivated majorly in the Kachchh district of Gujarat followed by a few pockets in Rajasthan and Punjab. Lately, date farming has been extended to the dry pockets of southern India with promising results [1].

In India, date fruits are usually required to be picked at the khalal/doka stage of maturity due to unfavourable weather factors, such as the occurrence of seasonal rains during July and August, when the fruits are about to reach the dang and pind stages, causing fungal growth over the fruit surface due to high moisture and humidity. Thus, in order to prevent damage resulting from poor weather circumstances, these fruits must be harvested at the doka/khalal stage of maturity to prevent spoiling [2]. The khalal (doka) stage harvested fruits have varying degrees of astringency based on the cultivar and hence all the varieties are not suitable for fresh fruit consumption. The date fruit cultivars best suited for table purpose/fresh consumption at doka stage include Halawy, Barhee, Chip-chap, Khadrawy and Kuneizi. Since the doka stage date fruits are rich in sugars and water that could trigger fermentation during storage under ambient conditions, they must be consumed soon after harvesting, since they would only last a few days without cold storage [3].

Given the significant potential for date palm cultivation in India, the world’s largest importer of these fruits, the government has chosen to promote its cultivation systematically in the huge tracts of arid regions merging within three key states, namely Rajasthan, Gujarat and Punjab. This public-private partnership (PPP) has achieved substantial progress within a brief period of time for translating its date palm idea via mission mode projects and has transformed wastelands into vegetation with this highly productive and widely recognized crop. So far, date fruits produced in India are being consumed as fresh dates in local markets. With on-going expansion, higher date production is expected in the future and there is a need for efficient postharvest handling, marketing and processing to have a greater influence on the economic, social and cultural life of farmers with small and marginal land holdings [4,5].

Since fresh doka stage date fruits are highly perishable under ambient storage, currently they cannot be transported over longer distances and are sold in local markets primarily and in neighbouring states to a certain extent. Thus, there is a need to develop and establish a proper cold chain network for increasing the niche area for marketing of these healthy fruits [6]. In other countries, where there are no climatic barriers such as seasonal rains during fruit ripening stages, they are harvested at full ripe stage (i.e., pind) and dried to remove excess moisture prior to packing for sale. These pind stage date fruits are highly suitable for preparation of value added products such as date jam, date paste, date syrup, date sugar and date wine [7]. Unlike these pind dates, the doka stage date fruits have limited options for processing and value addition. Some of the options available for utilization of the surplus production include dry date (chhuhara) making, dry date bits and powder preparation which could be incorporated into various confectionary products. The dry dates are having very good market scope in a populous country such as India, where they are being used in most of the religious rituals and are currently being imported from neighbouring countries such as Pakistan in significant quantities.

In most of the date growing countries, the fruits are picked when the influx of sugars is maximum (i.e., khalal (doka) dates) and boiled for a certain time period to remove the astringent components such as tannins and phenols and to deactivate enzymes. The blanching time is standardised for most of the commercial varieties grown in other countries such as Zariek, Halo, Chibchaap [8], Halawy, Samran and Khadrawy [9]. In India, the date cultivars that are being promoted commercially include Barhee, Halawy, Medjool and Khunaizi. Among these, Medjool cannot be consumed in fresh form at the doka stage of maturity due to its high tannin and phenolic contents. Though the fruits are sweeter and edible at the pind stage, being a late maturing variety, its ripening coincides with the onset of monsoons resulting in their spoilage. However, research work on the protocol development for dry date preparation from doka dates is limited and thus the current work was proposed to standardise the blanching time and study its effect on drying efficiency and quality of the dry dates during storage.

2. Materials and Methods

2.1. Plant Material Preparation

The fresh fruits of date cv. Medjool were procured from the experimental research block of date palms located in the ICAR-Central Institute for Arid Horticulture at Bikaner, Rajasthan, India (28°11′ N latitude and 73°34′ E longitude). The fruit bunches are harvested upon attainment of their maximum size and bright yellowish orange colour (characteristic of that variety). The bunches are harvested along with their peduncles and strands are separated carefully using secateurs before transporting them to the post-harvest laboratory where they are stripped ensuring intactness of their calyx. The fruits are sorted to remove spoiled/damaged fruits and cleaned under running water for removal of any external dirt and inert materials.

2.2. Treatments

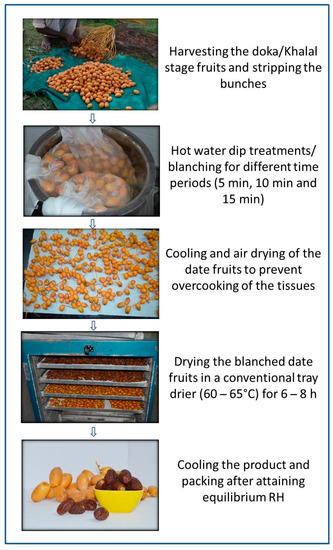

Three kilograms of stripped clean dates were taken in each treatment and replicated four times for processing into dry dates. The sampled date fruits were blanched (hot water treatment-HWT) for three different time periods (5, 10 and 15 min) by placing them in a boiling water pot (85 ± 2 °C) with the help of muslin cloth bags. Later, the fruits were cooled by dipping in cold water to avoid over cooking, drained of excess water and air dried under a fan for 5–10 min before spreading over the drying trays. The fruits were dried at 60 ± 5 °C for a period of 8–10 h (Figure 1) in an electrical tray/cabinet drier (Make: CM Envirosystems Pvt. Ltd., Bengaluru, India, Model: TD-24A). The fruits were spread in a single layer to facilitate the faster drying process and to attain a desired moisture content of 7–8%.

Figure 1.

Process protocol for dry date preparation.

2.3. Estimation of Drying Parameters

The dry date recovery was calculated as a percentage of the initial fresh weight of the sample taken for processing. The drying rate (Dr) was calculated using the formula Dr (g/min) = initial weight − final weight/time interval. Dehydration ratio (DR) was estimated by taking the ratio of the product weight placed for drying to that of the final dried product [DR = Initial product weight/Final dried product]. Rehydration ratio (RR) was measured as a ratio of the mass of the rehydrated and drained fruit material to the mass of the original dry fruit taken [RR = Mass of drained rehydrated fruit/Mass of dried fruit]. Pulp to stone ratio was calculated by dividing their respective weights after separation [3,10]. All the data were recorded in five replicates.

2.4. Estimation of Quality Parameters

The quality parameter surface colour was measured using a portable handheld colorimeter (Make: Color Reader, CR-10, Konica Minolta, Japan) and expressed as L*, a*, b*, Hue (h°) and Chroma (C*) values. The colour readings for each date fruit were taken at three random places and their mean values were taken as the average colour value for each of the four replications [11]. The fresh fruit surface colour (L*, a*, b*) values were taken as reference values for calculating the total colour difference (ΔE) using the formula mentioned below [12]:

The sugars including reducing, non-reducing and total sugars were estimated using the standard procedures of the Lane and Eynon method [13] with slight modifications. From each treatment, four replicate samples were taken for analysis. For the estimation of reducing sugars, a 10 g of sample was homogenised in 25 mL of distilled water using a high speed homogeniser at 1000 rpm (Make and Model: IKA® T25 Digital Ultra Turrax, Kengeri, India) and later the volume was set at 150 mL with distilled water prior to filtration with Whatman No. 1 filter paper. The filtrate was then used to titrate 10 mL of the boiling Fehling’s solution mixture (A + B) using methylene blue indicator to develop a brick red colour as the end point of titration. While for estimation of total sugars, 25 mL of the filtrate was hydrolysed with 1:1 HCl for 24 h and neutralised there after using 20% NaOH before setting the volume to 25 mL with distilled water. The resulting solution was used again for titrating 10 mL of the boiling Fehling’s mixture (A + B) using methylene blue indicator.

The ascorbic acid content was estimated using the standard 2, 6-dichlorophenol indophenol visual titration method [14]. Five grams of sample from each quadruplicate sample were homogenised using 0.4% oxalic acid with volume set at 50 mL using the same solution prior to filtration with Whatman No. 1 filter paper. Two ml of filtrate added to an equal quantity of 0.4% oxalic acid was titrated against the standard dye solution where the end point was indicated by persistence of a light pink colour developed for 10 s.

The non-enzymatic browning (NEB) was estimated by measuring the absorbance of alcoholic extract at 420 nm. Two grams of dry date samples from all four replicates were soaked overnight in an 80% alcohol solution and the extract was filtered through Whatman no. 41 filter paper. The OD of the filtrate was measured using a UV-Vis spectrophotometer (Make: Shimizu, New Delhi, India, Model: UV-2550) [3].

Tannin content was estimated using spectrophotometry through the measurement of blue tint generated by the reduction of phosphotungstomolybdic acid with tannin-like molecules in a high pH solution [14]. Sample extracts from the four replicate samples of each treatment were prepared by boiling 5 g of dry date in 400 mL of distilled water for 30 min, and the volume was set to 500 mL using distilled water in a volumetric flask. The solution was filtered through Whatman No. 01 filter paper and the aliquot of the filtrate was used for the estimation of tannins. One ml of the filtered aliquot was taken to which 5 mL of Folin-Denis reagent and 10 mL of saturated sodium carbonate were added. The volume set to 100 mL by the addition of distilled water, mixed well and incubated for 30 min. The colour development was measured at 760 nm against a reagent blank adjusted to 0 absorbance in an UV Spectrophotometer (Make: Shimizu, Model: UV-2550). Tannic acid standard solution containing 0.1 mg of tannic acid per ml was used for standard curve preparation (0, 2, 4, 6, 8 and 10 mL) and tannin content was expressed as % tannic acid [13].

2.5. Sensory Analysis

A team of fifteen trained panellists have evaluated the sensory attributes of the dried date fruits using a nine-point hedonic scale. All the panellists were males and were in the age group range of 25–45 years. The products were evaluated for their appearance/colour, taste/flavour, texture/mouthfeel and overall quality/acceptability. Product samples with an overall sensory score of ≥7 were deemed to be acceptable, while those with a score ≤7 were deemed undesirable. The sensory analysis of best treatment fruits was performed at tri-monthly intervals for a period of 9 months during storage at ambient conditions (35 ± 2 °C and 55% RH).

2.6. Mineral Analysis

The mineral analysis was performed in triplicate for the best treatment samples finalized through sensory analysis. The mineral composition of the dried fruit samples was examined after digesting 0.2 g of finely grounded samples with a mixture of strong nitric acid (69–72%) and perchloric acid (60%) (9:4). Later, the digested samples were fed into the Microwave Plasma Atomic Emission Spectrometer (Model: AGILENT 4210 MP-AES, Bengaluru, India) for judging the concentration of mineral elements such as phosphorous, potassium, calcium, magnesium, copper, boron, iron, manganese, molybdenum, zinc and selenium as described by Preethi et al. [11,15].

2.7. Statistical Analysis

The significance of hot water treatment periods on the drying efficiency as well as for quality was analysed with an online SAS program (version 9.3). The Fisher’s Least Significant Difference and analysis of variance (ANOVA) were used to assess the level of significance at 5% (p = 0.05). The data represented in the table are the mean values of three replicates with standard deviation. The mean value followed by alphabets represents the rate of significance at a 95% confidence level.

3. Results

3.1. Effect on Drying Parameters

The varying periods of hot water treatment had differential effects on the drying parameters as well as on the sensory and biochemical quality of the dry dates. However, there was no significant difference in the recovery percentage, drying rate and pulp to stone ratio of the dry dates (Table 1). Though the recovery percentage of dry dates decreased with increasing hot water dip time periods, the difference was not statistically significant. The rate of drying (Dr) has shown a positive correlation with the increasing hot water treatment periods but with less or no significance for the difference values [8]. The dehydration ratio (DR) value has increased with increasing the time period of blanching with the maximum dehydration ratio (2.79) for 15 min HWT while this was minimum for the control dried date fruits with no water dip treatment (Table 1). Similarly, an increase in the DR of the blanched immature dates was observed by Kulkarni et al. [3]. The rehydration ratio (RR) was also found to have a positive correlation with increasing blanching periods with a maximum RR (1.42) for the 15 min blanched dry dates. Though the pulp to stone ratio was found to be at maximum (5.72) in 5 min blanched fruits which was on par with that of 10 min and 15 min blanch treatments (Table 1). However, a few instances of blistering involving separation of skin from pulp were observed in a few cases of hot water treatments [16].

Table 1.

Effect of different hot water dip periods on the drying characteristics of dry dates cv. Medjool.

3.2. Effect on Surface Colour Characteristics

Surface colour of the dry dates is one of the major characteristics determining their market value. Though the surface colour is largely dependent on the varietal characteristics, to a certain extent it is also determined by the enzymatic and non-enzymatic browning reactions occurring in the fruit epidermis [17]. The L* (lightness) values are significantly higher (38.40) in the control treatment compared to the hot water dip treatments and the minimum (29.43) was observed in dry dates exposed to 10 min blanching. The a* and b* values are observed to be high (12.40 and 12.53) in the control fruits while minimum a* and b* values were observed in fruits exposed to 10 and 15 min of blanching. The intensity of colour Chroma (C*) values indicates higher intensities in the control (18.46) and 5 min hot water dip (16.53) treatments while the intensity appeared to be lower in the fruits exposed to 10 and 15 min of blanching (Table 2). The better fruit colour development and higher sensory perception could be attributed to the regulation of metabolic enzymes and activation of heat shock proteins [18]. The hue angle (h°) value indicates the colour hue of the fruit surface whereby the control fruits are more yellowish (52.53°), and with increasing the period of blanching the fruits attained a reddish-brown tinge (33.67–37.50°). Likewise, estimation of total colour difference (ΔE) indicated that more significant colour changes were observed in date fruits exposed to HWT 10 min (71.10) and 15 min (69.55), followed by the treatments HWT 5 min (62.30) and control (59.65) fruits which were on par (Table 2).

Table 2.

Effect of different hot water dip periods on the surface colour characteristics of dry dates cv. Medjool.

3.3. Effect on Biochemical Parameters

Tannins are the major phytochemicals present in the mature date fruits (doka/khalal stage) responsible for their typical acrid taste. The main purpose of the hot water treatment was to reduce the tannin content in addition to softening the fruit tissues. Compared to the control fruits (2.52%), the tannin content was significantly reduced in the blanched date fruits which could be due to leaching of tannins into the hot water during the boiling process [19]. Moreover, the drop in tannin content was in proportion to the time period or interval of hot water dip executed (Table 3). Though no specific trend was observed in the retention of vitamin C content of the dry dates, maximum vitamin C content (3.83 mg/100 g) was observed in fruits exposed for 5 min blanching followed by 10 min blanching (3.53 mg/100 g). The minimum vitamin C content (2.20 mg/100 g) was observed in dates treated for 15 min of blanching and this could be due to the heat sensitive nature of vitamin C which could have been destroyed by longer exposure to heat [20,21]. Consistent with our results, a significant reduction in the vitamin C content of hot water treated vegetables including spinach leaves [22] and bitter melon [23] was observed. Moreover, the loss of vitamin C during HWT of date fruits could be associated with greater moisture loss and accelerated metabolic activities.

Table 3.

Effect of different hot water dip periods on the quality characteristics of dry dates cv. Medjool.

Among sugars, there is no significant difference among the total sugar content of different treatments (Table 3). However, the reducing sugars are high (25.79%) in the control fruits and their content reduced gradually with the increasing time period of blanching consisting of 22.81, 20.79 and 18.32%, respectively. Conversely, the non-reducing sugars were low in the control fruits (45.34%) and increased gradually with the increasing blanching period consisting of 52.44, 55.40 and 56.30%, respectively (Table 3). This could be due to accelerated inhibition of the enzymes related to sugar conversion from non-reducing to reducing sugars by the hot water dip treatments [24,25]. Similar accumulation of sugar content and improved palatability of the citrus fruits with HWT was reported by Holland et al. [26].

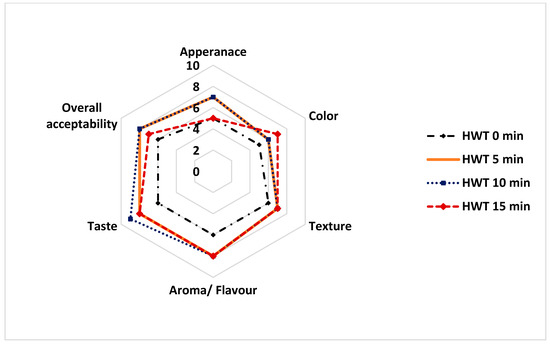

3.4. Effect on Sensory Characteristics

The analysis of sensory scores given by the semi-trained panel has indicated that all the hot water dip treatments are superior to the control dates dried without hot water blanching (Figure 2). Among different hot water dip intervals, the best taste score was achieved by 10 min dipping while maximum flavour, best appearance and overall acceptability were scored by fruits exposed to 5 and 10 min of hot water dipping (Figure 2). In a similar context, Li et al. [27] documented higher overall best sensory attributes in dry dates exposed to 3 min HWT (cv. Hillawi) and 5 min HWT (cv. Khadrawi). Considering the 10 min HWT as the best treatment, mineral analysis was done for those fruits (Table 4) and they were stored for six months to study the changes in their sensory parameters at monthly intervals (Table 5). Though the taste was retained throughout the storage period, there was significant degradation in the colour/appearance of dry dates during storage [9].

Figure 2.

Sensory analysis (n = 15) of the dry dates prepared with different blanching periods (HWT—Hot Water Treatment).

3.5. Mineral Composition of the Dry Dates

Mineral analysis of the best treatment consisting of 10 min hot water dipped dry dates were analysed and the detected mineral profile was Potassium (4.08%), Calcium (20.71 mg/g), Magnesium (3.40 mg/g), Iron (3.99 mg/g), Copper (7.55 mg/g), Zinc (4.26 mg/g), Manganese (474.75 ppm), Molybdenum (526.62 ppb), Selenium (75.41 ppm) and Sodium (3.57 mg/g), respectively (Table 4). This indicates that dry dates act as a rich source of minerals including Ca, Fe, Mn and Mo [28] and have the potential to be used in the process of value addition processes such as extrusion [15].

Table 4.

Mineral composition of the dry dates prepared through the developed protocol.

Table 4.

Mineral composition of the dry dates prepared through the developed protocol.

| Element/Mineral | Quantity |

|---|---|

| Potassium (%) | 4.08 ± 0.16 |

| Calcium (mg/g) | 20.71± 0.87 |

| Magnesium (mg/g) | 3.40 ± 0.13 |

| Iron (mg/g) | 3.99 ± 0.14 |

| Copper (mg/g) | 7.55 ± 0.15 |

| Zinc (mg/g) | 4.26 ± 0.11 |

| Manganese (ppm) | 474.75 ± 1.27 |

| Molybdenum (ppb) | 526.62 ± 6.22 |

| Selenium (ppm) | 75.41 ± 7.23 |

| Sodium (mg/g) | 3.57 ± 0.18 |

Data represented are the triplicate mean ± standard deviation values.

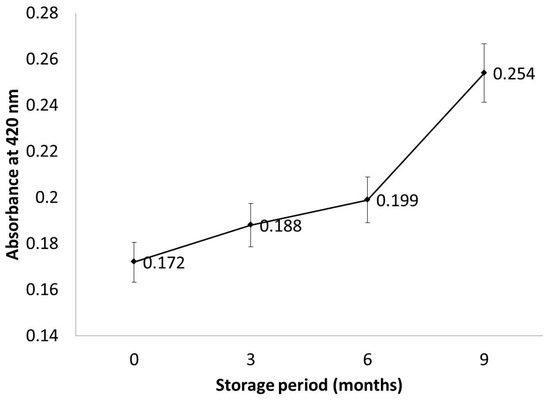

3.6. Qualitative and Sensory Changes during Storage of Prepared Dry Dates

The chhuhara prepared with the best treatment consisting of a 10 min hot water dip were packed in a 100 gauge polythene bag and stored under ambient conditions (35 ± 2 °C and 55% RH) for 9 months. The stored fruits were sampled at tri-monthly intervals for their qualitative and sensory acceptance during storage. Sensory studies over the storage period have revealed that the appearance and colour parameters have shown significant negative changes with storage, while the texture, flavour and taste were retained to a greater extent until the end of the storage period (Table 5). The significant loss of colour perception during storage could be due to the darkening of the dry dates caused by non-enzymatic browning (NEB) reactions occurring in the dried fruit tissues [29]. Quantification of the NEB reactions have revealed that the fruit tissue browning was gradual in the initial months of storage until 6 months and later it accelerated until the end of the storage period of 9 months (Figure 3). The development of brown pigments consisting of melanoidins could be due to the reaction of amino groups of proteins with the carbonyl groups in the reducing sugars resulting in the production of some intermediaries which further polymerise to form brown coloured melanoidins [30].

Figure 3.

Non enzymatic browning (NEB) of the dry dates during storage under ambient conditions.

Table 5.

Changes in the sensory scores of the dry dates during storage under ambient conditions.

Table 5.

Changes in the sensory scores of the dry dates during storage under ambient conditions.

| Storage (Months) | Appearance | Colour | Texture/MouthFeel | Aroma/Flavour | Taste | Overall Acceptability |

|---|---|---|---|---|---|---|

| 0 months | 7.46 ± 0.27 a | 7.32 ± 0.19 a | 8.76 ± 0.13 a | 8.85 ± 0.07 a | 8.92 ± 0.07 a | 8.85 ± 0.06 a |

| 3 months | 7.21 ± 0.10 b | 6.87 ± 0.12 b | 8.65 ± 0.10 a | 8.54 ± 0.21 b | 8.86 ± 0.11 a | 8.64 ± 0.11 ab |

| 6 months | 7.10 ± 0.24 b | 6.32 ± 0.23 c | 7.86 ± 0.13 b | 7.76 ± 0.12 c | 8.52 ± 0.11 b | 8.42 ± 0.22 b |

| 9 months | 6.76 ± 0.22 b | 5.42 ± 0.20 d | 7.74 ± 0.18 b | 7.21 ± 0.12 d | 8.24 ± 0.17 c | 7.89 ± 0.23 c |

Data represented are the triplicate mean ± standard deviation values. Mean data values with different alphabets indicate significant difference at p < 0.05.

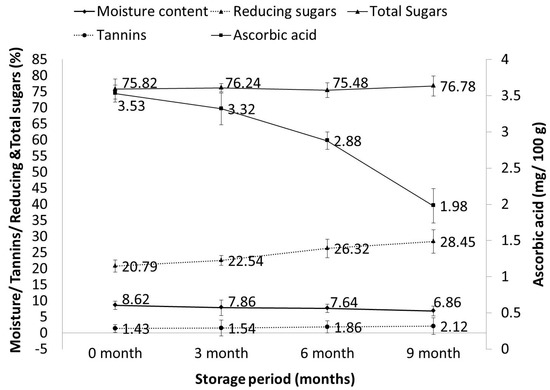

Study of the biochemical changes during storage of the freshly prepared dry dates (chhuhara) has indicated that the moisture content has reduced gradually during storage under ambient conditions until the end of the storage period (9 months). The reducing sugar content has increased substantially with storage while the total sugar content has remained constant (Figure 4). This increase in the reducing sugar content could be due to conversion of the non-reducing sugars such as sucrose into reducing sugars such as glucose and fructose during storage under ambient conditions [31,32]. The increase in sugar content with HWT could be ascribed to the activation of glucosidase, galactosidase and arabinose enzymes due to their higher catabolism [27]. A slight increase was observed in the amount of tannins present in the dried date fruits which could be due to polymerisation of the polyphenols present in them. The ascorbic acid content has shown a slight reduction in the initial periods of storage up to 3 months and then accelerated reduction was observed. Similar increases in tannin composition and decreases in vitamin C content were observed by Kulkarni et al. [3] in dried immature dates.

Figure 4.

Changes in moisture content, tannins, reducing and total sugars and ascorbic acid content of the dry dates during storage under ambient conditions.

4. Conclusions

Considering the increase in crop area and the surplus of date production each year in India, these efforts for the development of protocols for the preparation of dry dates were successful, and among the different hot water dip intervals sampled, 10 min was found to be effective in improving their sensory score, especially for taste and appearance. The tannins responsible for the acrid taste of the doka/khalal stage fruits were also reduced to a minimum with the imposed hot water treatments. Ultimately, the fruits of date cv. Medjool being bulky and fibrous with more dry matter content are well suited for dry date preparation. However, the fruits exhibited characteristics of non-enzymatic browning during storage at ambient conditions (35 ± 2 °C and 55% RH). Thus, there is a need for standardisation of some pre-treatments for the reduction of browning reactions during the storage of dry dates.

Author Contributions

Conceptualization, S.V.R.R. and R.S.S.; methodology, S.V.R.R. and R.M.; software, validation, and formal analysis, P.P.; investigation, M.K.B. and S.V.R.R.; resources and data curation, D.K.S.; writing—original draft preparation, S.V.R.R.; writing—review and editing, P.P. and D.K.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research is carried out under institute funded project of ICAR-CIAH, Bikaner and received no external funding by any agency.

Data Availability Statement

Data available on request.

Acknowledgments

The authors also gratefully acknowledge the instrumental support for colour estimation by DV Sudhakar Rao, and Deep Lata, ICAR-IIHR, Bengaluru. The authors also wish to thank Samshudeen M, ICAR-DCR, Puttur for support in conducting biochemical analysis.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Al-Farsi, M.A.; Lee, C.Y. Nutritional and functional properties of dates: A review. Crit. Rev. Food Sci. Nutr. 2008, 48, 877–887. [Google Scholar] [CrossRef] [PubMed]

- Jawanda, J.S. Prospect of date cultivation in dry regions. Indian Hortic. 1974, 19, 31–35. [Google Scholar]

- Kulkarni, S.G.; Vijayanand, P.; Aksha, M.; Reena, P.; Ramana, K.V.R. Effect of dehydration on the quality and storage stability of immature dates (Pheonix dactylifera). LWT 2008, 41, 278–283. [Google Scholar] [CrossRef]

- Iliyasu, R.; Muhammad, A.S.; Dundago, M.A.; Jibril, H. Date Fruit Processing and Composition. Ann. Food Sci. Technol. 2021, 22, 274–284. [Google Scholar]

- Oladzad, S.; Fallah, N.; Mahboubi, A.; Afsham, N.; Taherzadeh, M.J. Date fruit processing waste and approaches to its valorization: A review. Bioresour. Technol. 2021, 340, 125625. [Google Scholar] [CrossRef]

- Lallouche, A.; Kolodyaznaya, V.; Boulkrane, M.S.; Baranenko, D. Low temperature refrigeration as an alternative anti-pest treatment of dates. Environ. Clim. Technol. 2017, 20, 24–35. [Google Scholar] [CrossRef]

- Aleid, S.M. Date Fruit Processing and Processed Products; Siddiq, M., Aleid, S.M., Kader, A.A., Eds.; Dates: Postharvest Science, Processing Technology and Health Benefits; Wiley-Blackwell: West Sussex, UK, 2013; pp. 171–202. [Google Scholar]

- Kalra, S.K.; Munshi, S.K.; Jawanda, J.S. Studies on the preparation of dry dates (chhoharas). J. Food Sci. Technol. 1978, 15, 43–46. [Google Scholar]

- Godara, R.K.; Pareek, O.P. Effect of Dehydration Methods and Boiling Water Dip Treatments on the Recovery and Quality of Chhuhara From Doka Fruits of Halawy, Khadrawy and Shamran Date Palm Cultivars. Indian J. Hortic. 1985, 42, 199–205. [Google Scholar]

- Kanevce, G.H.; Kanevce, L.P.; Mitrevski, V.B.; Dulikravich, G.S. Estimation of drying parameters including moisture diffusivity by using temperature measurements. Comput. Methods Exp. Meas. 2011, 51, 111. [Google Scholar]

- Preethi, P.; Shamsudheen, M.; Thanushree, K.; Reddy, S.V.R.; Pandiselvam, R.; Ramesh, S.V.; Sachin, A.J.; Manikantan, M.R.; Veena, G.L. Synergistic effect of powdered cashew sprout cum cotyledon and cereals on improving the biochemical and physical properties of extrudates. J. Food Process. Preserv. 2022, 46, e16938. [Google Scholar] [CrossRef]

- Reddy, S.V.R.; Sharma, R.R.; Srivastava, M.; Kaur, C. Effect of pre-harvest application of Salicylic acid on the postharvest behavior of ‘Amrapali’ mango fruits during storage. Indian J. Hortic. 2016, 73, 405–409. [Google Scholar] [CrossRef]

- Ranganna, S. Hand Book of Analysis and Quality Control for Fruits and Vegetables, 2nd ed.; McGraw-Hill Publishing Co. Ltd.: New Delhi, India, 1986. [Google Scholar]

- AOAC. Official Methods of Analysis, 17th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 2000. [Google Scholar]

- Preethi, P.; Mangalassery, S.; Shradha, K.; Pandiselvam, R.; Manikantan, M.R.; Reddy, S.V.R.; Devi, S.R.; Nayak, M.G. Cashew apple pomace powder enriched the proximate, mineral, functional and structural properties of cereal based extrudates. LWT 2021, 139, 110539. [Google Scholar] [CrossRef]

- Kalra, S.K.; Jawanda, J.S.; Munshi, S.K. Studies on the curing of dates (Phoenix dactylifera) by hot water treatment. Indian J. Hortic. 1976, 33, 146–151. [Google Scholar]

- Haider, M.S.; Rauf, M.; Saleem, N.; Jamil, K.; Mukhtar, O. Studies on ripening of dates from rutab stage to ripe dehydrated dates. J. Biochem. Mol. Biol. 2012, 45, 31–34. [Google Scholar]

- Wang, C.Y. Heat treatment affects postharvest quality of kale and collard, but not of brussels sprouts. HortScience 1998, 33, 881–883. [Google Scholar] [CrossRef]

- Kunyanga, C.N.; Imungi, J.K.; Okoth, M.; Momanyi, C.; Biesalski, H.K.; Vadivel, V. Antioxidant and antidiabetic properties of condensed tannins in acetonic extract of selected raw and processed indigenous food ingredients from Kenya. J. Food Sci. 2011, 76, C560–C567. [Google Scholar] [CrossRef]

- Santos, P.H.S.; Silva, M.A. Retention of vitamin C in drying processes of fruits and vegetables—A review. Dry. Technol. 2008, 26, 1421–1437. [Google Scholar] [CrossRef]

- Amin, I.; Lee, W.Y. Effect of different blanching times on antioxidant properties in selected cruciferous vegetables. J. Sci. Food Agric. 2005, 85, 314–2320. [Google Scholar] [CrossRef]

- Tincheva, P.A. The effect of heating on the vitamin C content of selected vegetables. World J. Adv. Res. Rev. 2019, 3, 27–32. [Google Scholar]

- Ng, Z.X.; Kuppusamy, U.R. Effects of different heat treatments on the antioxidant activity and ascorbic acid content of bitter melon, Momordica charantia. Braz. J. Food Technol. 2019, 22, 1–12. [Google Scholar] [CrossRef]

- Chohan, G.S.; Jawanda, J.S.; Bakhshi, J.C. Studies on the curing of dates at Abohar. Punjab Hortic. J. 1972, 12, 46–53. [Google Scholar]

- Pedreschi, F.; Travisany, X.; Reyes, C.; Troncoso, E.; Pedreschi, R. Kinetics of extraction of reducing sugar during blanching of potato slices. J. Food Eng. 2009, 91, 443–447. [Google Scholar] [CrossRef]

- Holland, N.; Menezes, H.C.; Lafuente, M.T. Carbohydrates as related to the heat-induced chilling tolerance and respiratory rate of ‘Fortune’ mandarin fruit harvested at different maturity stages. Postharvest Biol. Technol. 2002, 25, 181–191. [Google Scholar] [CrossRef]

- Li, J.; Hussain, I.; Azam, M.; Khan, M.A.; Akram, M.T.; Naveed, K.; Asif, M.; Anjum, N.; Zeng, J.; Zhang, J.; et al. Hot water treatment improves date drying and maintains phytochemicals and fruit quality characteristics of date palm (Phoenix dactylifera). Foods 2023, 12, 2405. [Google Scholar] [CrossRef]

- Anwar-Shinwari, M. Iron content of date fruits. J. Coll. Sci.-King-Saud-Univ. 1987, 18, 5–13. [Google Scholar]

- Sabry, Z.I. Food discoloration, browning in dried fruit products: Nonenzymatic browning and its effect on the carotenoids in qamareddeen, a dried apricot pulp. J. Agric. Food Chem. 1961, 9, 53–55. [Google Scholar] [CrossRef]

- Al-Amrani, M.; Al-Alawi, A.; Al-Marhobi, I. Assessment of enzymatic browning and evaluation of antibrowning methods on dates. Int. J. Food Sci. 2020, 2020, 8380461. [Google Scholar] [CrossRef]

- Balasubramanian, P.; Sivakumar, V.; Balakrishnamoorthy, G.; Balakumbahan, R. Impact of dehydration on biochemical changes of stored dehydrated product of bhendi. Plant Arch. 2011, 11, 417–422. [Google Scholar]

- Dumitru, M.G. Biochemical changes of dried fruit of Figs (Ficus carica L.) during Storage. Rev. De Chim. 2018, 69, 3605–3610. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).