Non-Destructive Evaluation of White-Flesh Dragon Fruit Decay with a Robot

Abstract

:1. Introduction

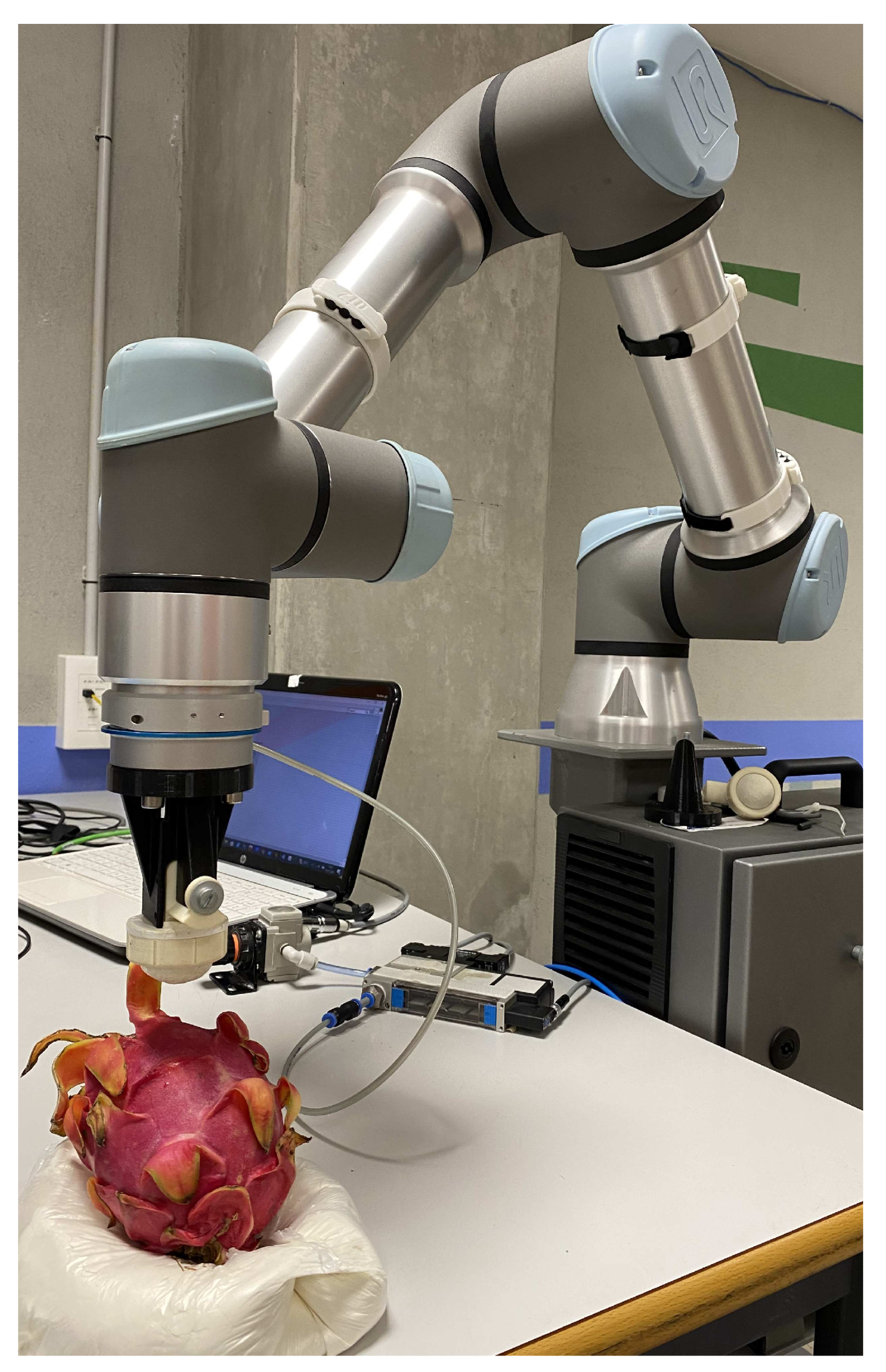

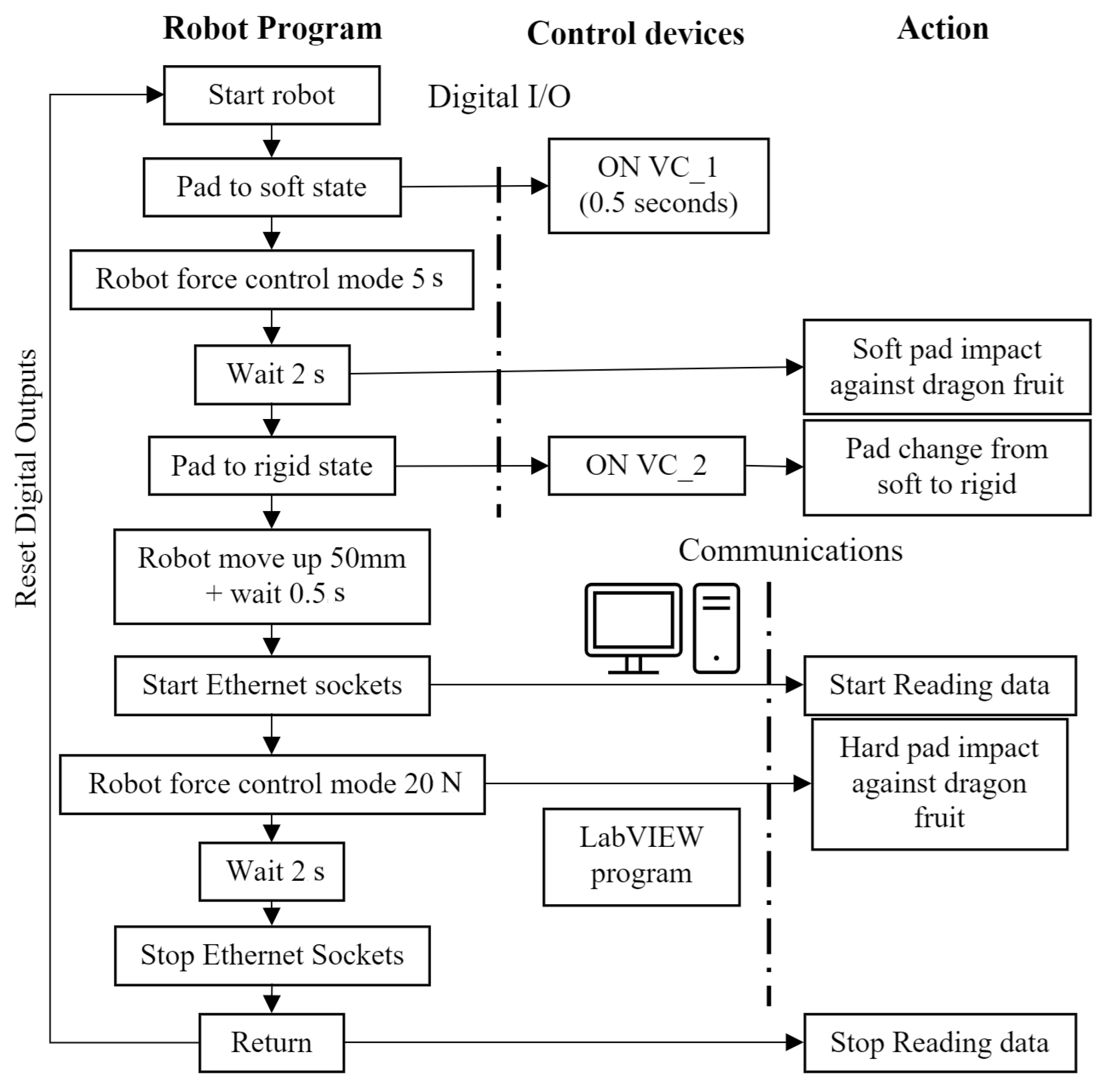

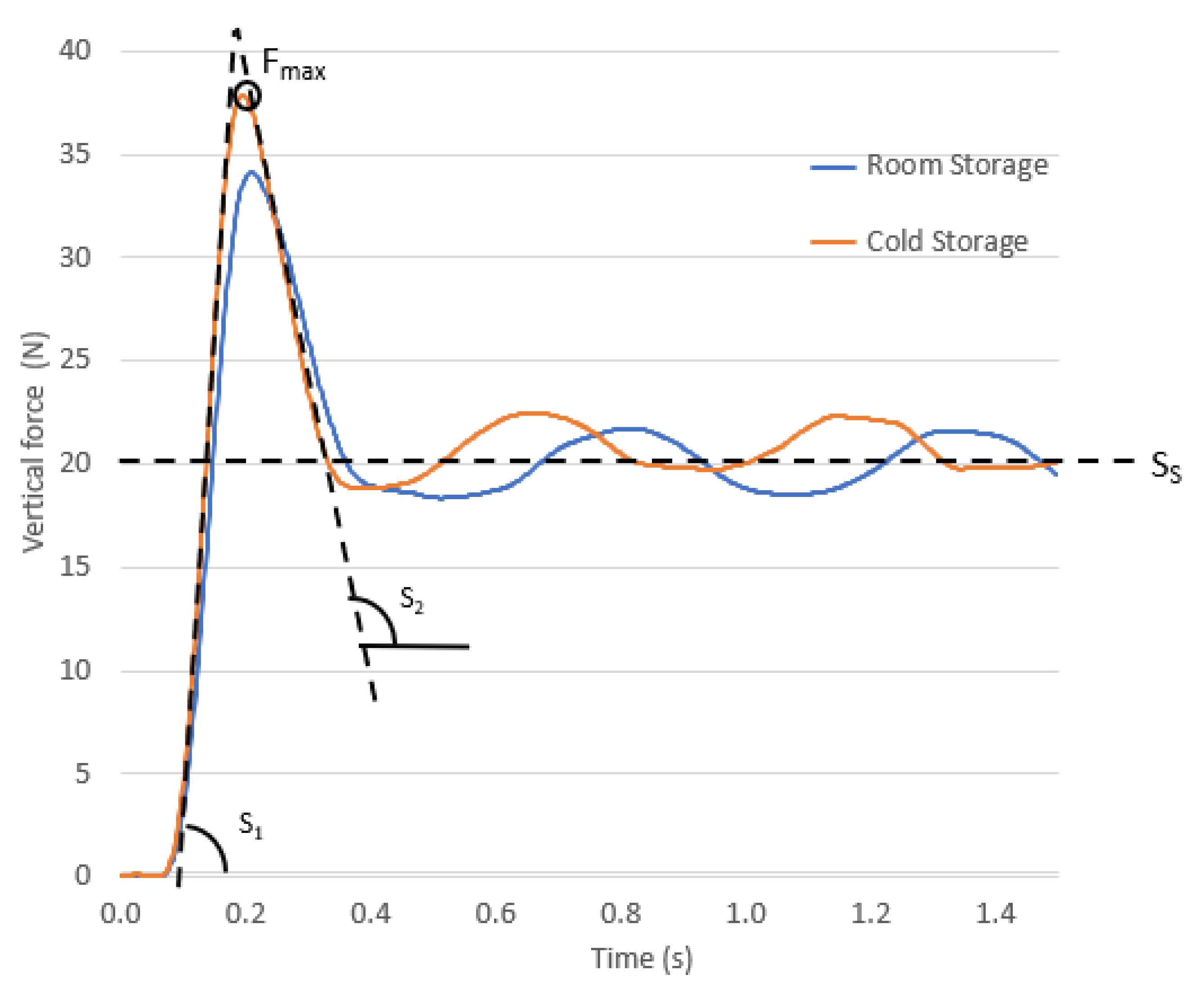

2. Materials and Methods

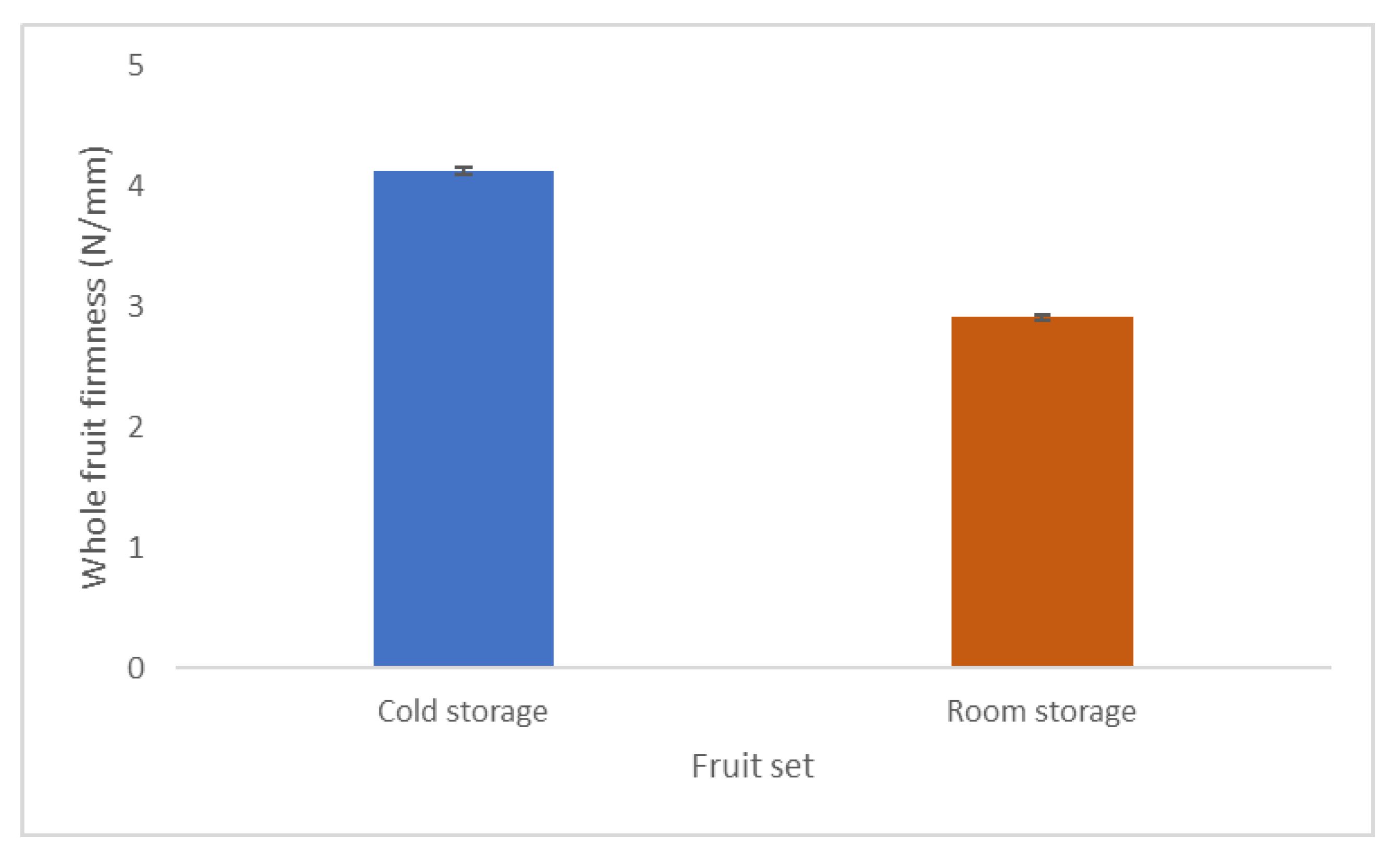

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Magalhães, D.S.; da Silva, D.M.; Ramos, J.D.; Pio, L.A.S.; Pasqual, M.; Vilas Boas, E.V.B.; Galvão, E.C.; de Melo, E.T. Changes in the physical and physico-chemical characteristics of red-pulp dragon fruit during its development. Sci. Hortic. 2019, 253, 180–186. [Google Scholar] [CrossRef]

- Verona-Ruiz, A.; Urcia-Cerna, J.; Paucar-Menacho, L.M. Pitahaya (Hylocereus spp.): Culture, physicochemical characteristics, nutritional composition, and bioactive compounds. Sci. Agropecu. 2020, 11, 439–453. [Google Scholar] [CrossRef]

- Hossain, F.M.; Numan, S.M.N.; Akhtar, S. Cultivation, nutritional value, and health benefits of Dragon Fruit (Hylocereus spp.): A Review. Int. J. Hortic. Sci. Technol. 1988, 8, 259–269. [Google Scholar]

- Pérez, A.L.D.Á.; Garay, A.V.A.; Gutiérrez, R.G.R.; Rangel, P.P. Elements to improve the management and commercialization of dragon fruit (Hylocereus undatus (Haworth) DR Hunt). Agro Product. 2023, 2, 129–135. [Google Scholar] [CrossRef]

- Moser, R.; Raffaelli, R.; Thilmany, D.D. Consumer preferences for fruit and vegetables with credence-based attributes: A review. Int. Food Agribus. Manag. Rev. 2011, 14, 121–142. [Google Scholar]

- Omar, A.F.; MatJafri, M.Z. Principles, methodologies and technologies of fresh fruit quality assurance. Qual. Assur. Saf. Crop. Foods 2013, 5, 257–271. [Google Scholar] [CrossRef]

- Abbott, J.A. Quality measurement of fruit and vegetables. Postharvest Biol. Technol. 1999, 15, 207–225. [Google Scholar] [CrossRef]

- Kyriacou, M.C.; Rouphael, Y. Towards a new definition of quality for fresh fruits and vegetables. Sci. Hortic. 2018, 234, 463–469. [Google Scholar] [CrossRef]

- Cortés, V.; Blasco, J.; Aleixos, N.; Cubero, S.; Talens, P. Monitoring strategies for quality control of agricultural products using visible and near-infrared spectroscopy: A review. Trends Food Sci. Technol. 2019, 85, 138–148. [Google Scholar] [CrossRef]

- Magwaza, L.S.; Opara, U.L. Analytical methods for determination of sugars and sweetness of horticultural products—A review. Sci. Hortic. 2015, 184, 179–192. [Google Scholar] [CrossRef]

- Magwaza, L.S.; Opara, U.L.; Nieuwoudt, H.; Cronje, P.J.; Saeys, W.; Nicolaï, B. NIR spectroscopy applications for internal and external quality analysis of citrus fruit—A review. Food Bioprocess Technol. 2012, 5, 425–444. [Google Scholar] [CrossRef]

- Wieme, J.; Mollazade, K.; Malounas, I.; Zude-Sasse, M.; Zhao, M.; Gowen, A.; Van Beek, J. Application of hyperspectral imaging systems and artificial intelligence for quality assessment of fruit, vegetables and mushrooms: A review. Biosyst. Eng. 2022, 222, 156–176. [Google Scholar] [CrossRef]

- Lu, Y.; Saeys, W.; Kim, M.; Peng, Y.; Lu, R. Hyperspectral imaging technology for quality and safety evaluation of horticultural products: A review and celebration of the past 20-year progress. Postharvest Biol. Technol. 2022, 170, 111318. [Google Scholar] [CrossRef]

- Mei, M.; Li, J. An overview on optical non-destructive detection of bruises in fruit: Technology, method, application, challenge and trend. Comput. Elect. Agric. 2023, 213, 108195. [Google Scholar] [CrossRef]

- Wanitchang, J.; Terdwongworakul, A.; Wanitchang, P.; Noypitak, S. Maturity sorting index of dragon fruit: Hylocereus polyrhizus. J. Food Eng. 2010, 100, 409–416. [Google Scholar] [CrossRef]

- Singh, A.; Swami, S.; Panwar, N.R.; Kumar, M.; Shukla, A.K.; Rouphael, Y.; Kumar, P. Development changes in the physicochemical composition and mineral profile of red-fleshed dragon fruit grown under semi-arid conditions. Agronomy 2022, 12, 355. [Google Scholar] [CrossRef]

- Tavarini, S.; Degl’innocenti, E.; Remorini, D.; Massai, R.; Guidi, L. Polygalacturonase and B-galactosidase activities in Hayward kiwifruit as affected by light exposure, maturity stage and storage time. Sci. Hortic. 2009, 120, 342–347. [Google Scholar] [CrossRef]

- Huang, M.; Zhao, J. Recent advances in postharvest storage and preservation technology of pitaya (dragon fruit). J. Hortic. Sci. Biotechnol. 2023, 1–15. [Google Scholar] [CrossRef]

- Woolf, A.; Hien, D.M.; Hoa, T.T.; Jackman, R.; Clark, C. HortResearch and SOFRI. Dragon Fruit Assessment Manual; SOFRI: Tien Giang, Vietnam, 2006; ISBN 0-478-06839-5. [Google Scholar]

- Tian, S.; Xu, H. Mechanical-based and optical-based methods for nondestructive evaluation of fruit firmness. Food Rev. Int. 2023, 39, 4009–4039. [Google Scholar] [CrossRef]

- Ortiz, C.; Blanes, C.; Mellado, M. An ultra-low pressure pneumatic jamming impact device to non-destructively assess cherimoya firmness. Biosyst. Eng. 2019, 180, 161–167. [Google Scholar] [CrossRef]

- Mandil, W.; Rajendran, V.; Nazari, K.; Ghalamzan-Esfahani, A. Tactile-Sensing Technologies: Trends, Challenges and Outlook in Agri-Food Manipulation. Sensors 2023, 23, 7362. [Google Scholar] [CrossRef] [PubMed]

- Blanes, C.; Mellado, M.; Beltrán, P. Tactile sensing with accelerometers in prehensile grippers for robots. Mechatronics 2016, 33, 1–12. [Google Scholar] [CrossRef]

- Ribeiro, P.; Cardoso, S.; Bernardino, A.; Jamone, L. Fruit quality control by surface analysis using a bio-inspired soft tactile sensor. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 25–29 October 2020. [Google Scholar]

- Zhang, J.; Lai, S.; Yu, H.; Wang, E.; Wang, X.; Zhu, Z. Fruit Classification Utilizing a Robotic Gripper with Integrated Sensors and Adaptive Grasping. Math. Probl. Eng. 2021, 2021, 7157763. [Google Scholar] [CrossRef]

- Rizzolo, A.; Vanoli, M.; Spinelli, L.; Torricelli, A. Sensory characteristics, quality and optical properties measured by time-resolved reflectance spectroscopy in stored apples. Postharvests Biol. Technol. 2010, 58, 1–12. [Google Scholar] [CrossRef]

- Pourdarbani, R.; Sabzi, S.; Kalantari, D.; Karimzadeh, R.; Ilbeygi, E.; Arribas, J.I. Automatic non-destructive video estimation of maturation levels in Fuji apple (Malus Malus pumila) fruit in orchard based on colour (Vis) and spectral (NIR) datag. Biosyst. Eng. 2020, 195, 136–151. [Google Scholar] [CrossRef]

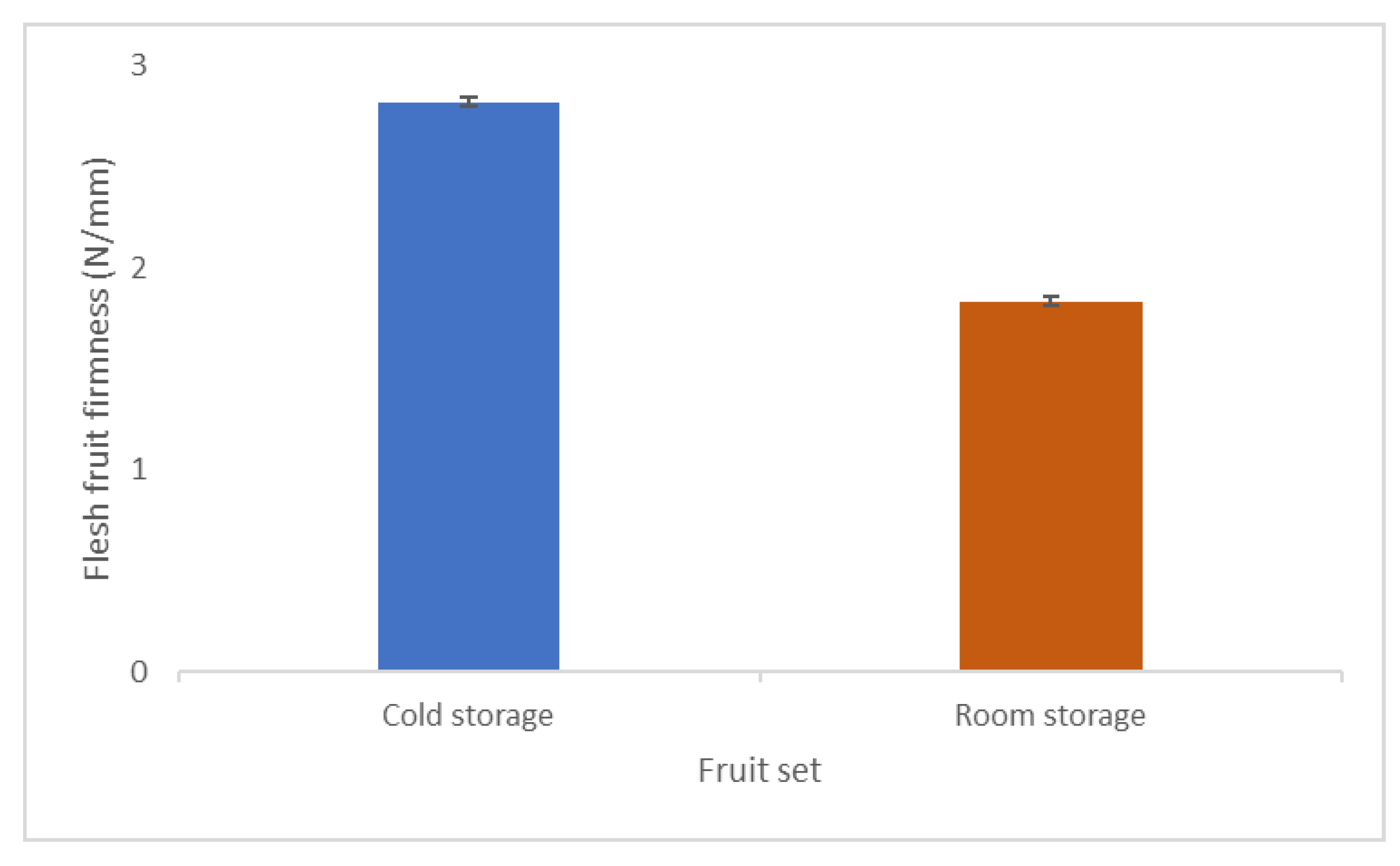

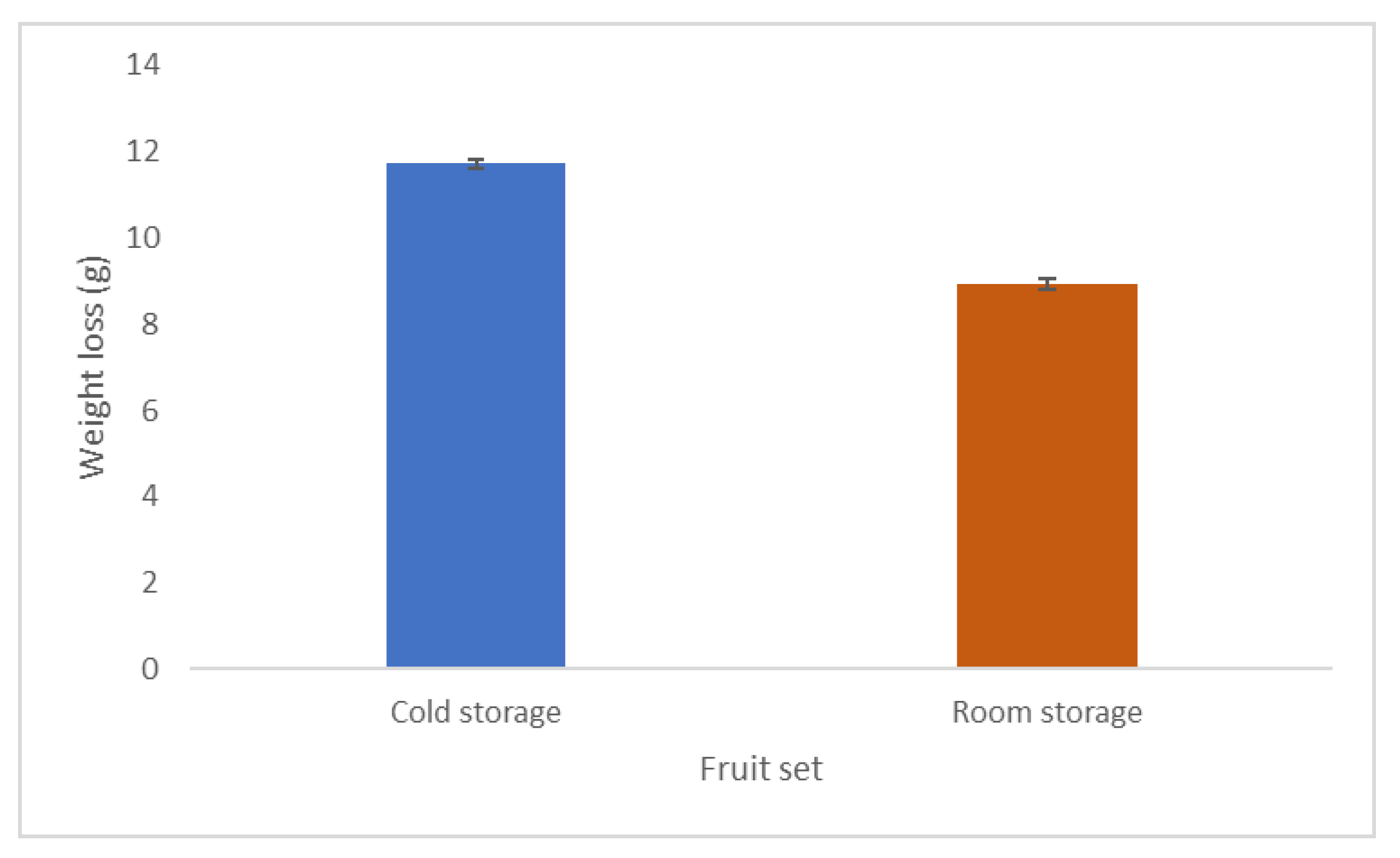

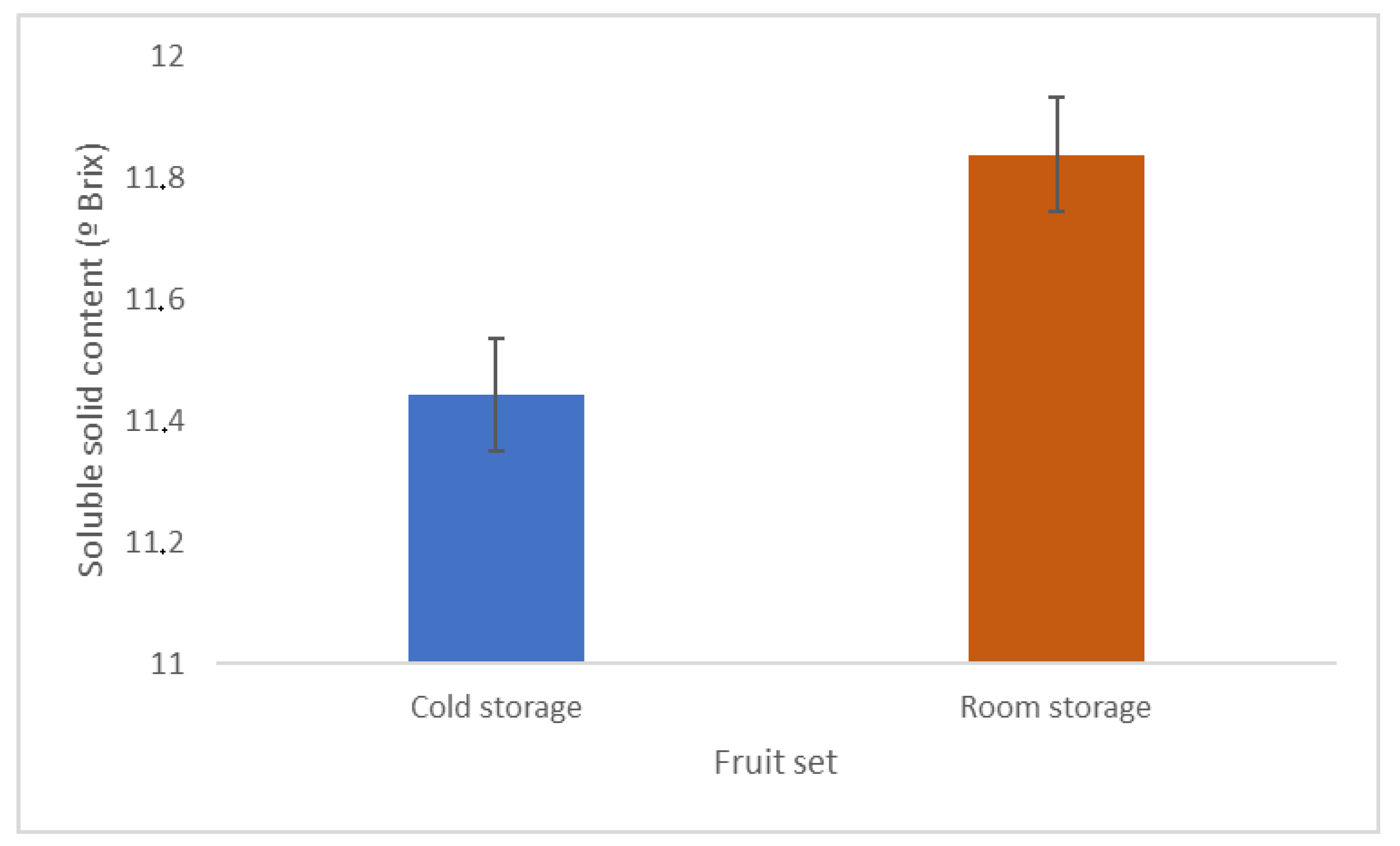

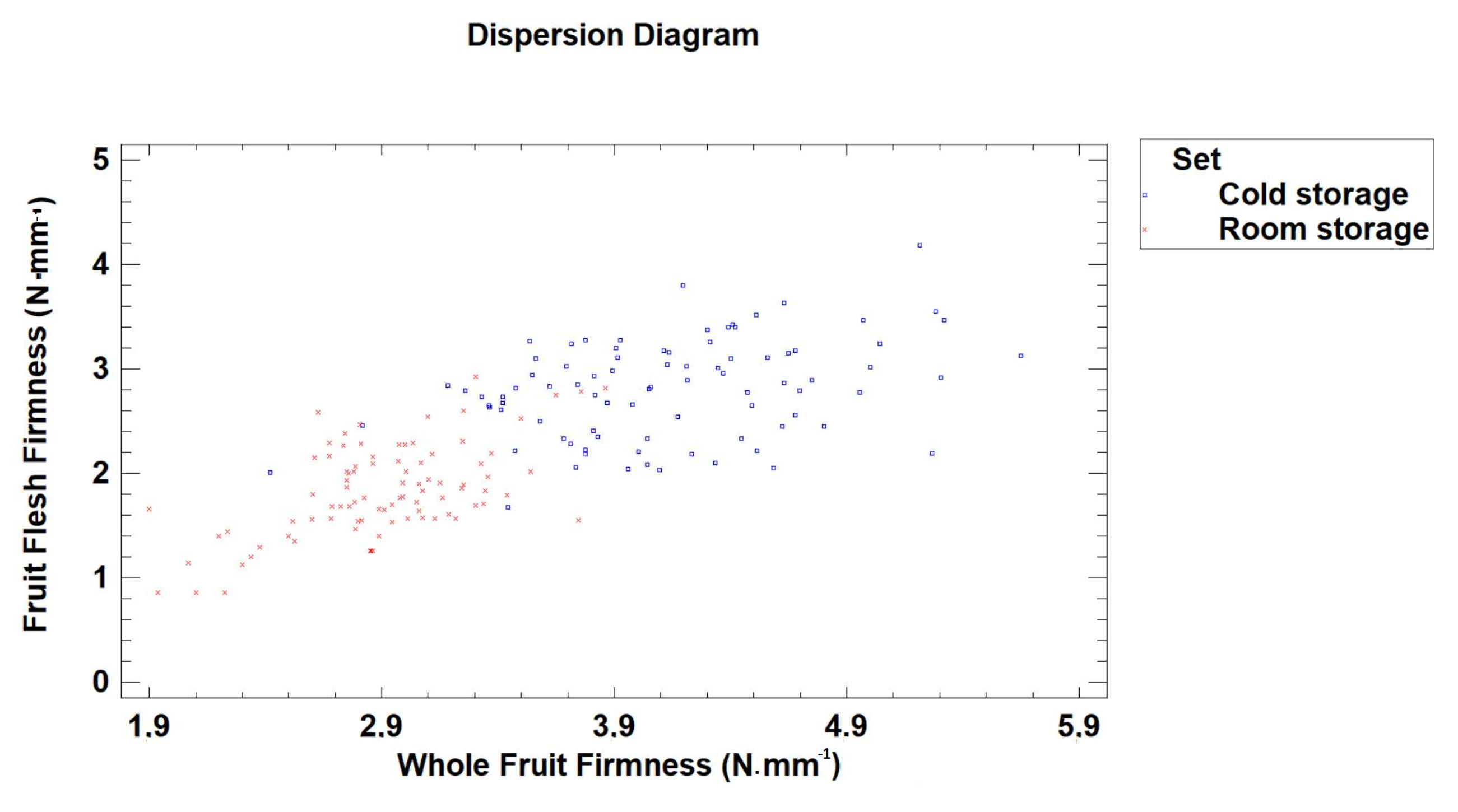

| Variable | F-Ratio | p-Value |

|---|---|---|

| Whole Fruit Firmness (N mm) | 260.04 | 0.0000 |

| Fruit Flesh Firmness (N mm) | 211.36 | 0.0000 |

| Weight loss | 70.39 | 0.0000 |

| Soluble Solid Content (Brix) | 2.54 | 0.1126 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortiz, C.; Blanes, C.; Gonzalez-Planells, P.; Rovira-Más, F. Non-Destructive Evaluation of White-Flesh Dragon Fruit Decay with a Robot. Horticulturae 2023, 9, 1286. https://doi.org/10.3390/horticulturae9121286

Ortiz C, Blanes C, Gonzalez-Planells P, Rovira-Más F. Non-Destructive Evaluation of White-Flesh Dragon Fruit Decay with a Robot. Horticulturae. 2023; 9(12):1286. https://doi.org/10.3390/horticulturae9121286

Chicago/Turabian StyleOrtiz, Coral, Carlos Blanes, Pablo Gonzalez-Planells, and Francisco Rovira-Más. 2023. "Non-Destructive Evaluation of White-Flesh Dragon Fruit Decay with a Robot" Horticulturae 9, no. 12: 1286. https://doi.org/10.3390/horticulturae9121286

APA StyleOrtiz, C., Blanes, C., Gonzalez-Planells, P., & Rovira-Más, F. (2023). Non-Destructive Evaluation of White-Flesh Dragon Fruit Decay with a Robot. Horticulturae, 9(12), 1286. https://doi.org/10.3390/horticulturae9121286