1. Introduction

In 2018, 19,919 hectares (49,220 ac) of strawberries were harvested in the United States of America. California harvested 72.7% of the total area with 14,488 hectares (35,800 ac), followed by Florida (19.9%). Oregon, Washington, North Carolina, and New York accounted for approximately 7.4% of total strawberry production with 1465 hectares (3620 ac) [

1]. South Atlantic states (Alabama, Georgia, North Carolina, South Carolina, and Virginia) collectively produce strawberries on 948 hectares (2342 ac) [

2]. In the Commonwealth of Virginia, strawberries occupied about 158 hectares (391 ac) in 2017 [

3].

Strawberry yield varies depending on the production region. In 2018, the total national utilized yield was 1,295,049 mt (fresh equivalent), which generated approximately

$2,670,523,000 revenue. The average strawberry yield was 10.66 mt per hectare (29.03 t ac

−1) fresh equivalent, and yields ranged from 90.4 metric tons per hectare (40.3 t ac

−1) in California to 5.5 metric tons per hectare (2.5 t ac

−1) in New York [

1]. The main reason for the yield differences across different states is climate conditions. California weather allows it to produce strawberries all year round, resulting in higher yields. At the same time, other states are limited to short growing seasons with harvest lasting approximately one to five months [

3]. The short production season in states with colder climates is associated with lower prices received by growers. The retail price of strawberries is usually higher during the off-season and can even double in December. However, this gap has declined due to improved trade and increased year-round supply [

4].

The demand for strawberries has increased drastically in the past decades. Consumption per capita increased from approximately 0.9 kg (2 lbs) per year in 1980 to 3.6 kg (7.9 lbs) per year in 2013. This increase is due to the awareness of strawberries’ health benefits and increased strawberry availability all year round due to increased domestic production and increased imports [

5]. In addition to the increase in per capita strawberry consumption, there is an upward trend in consumers’ demand for locally grown food, presenting an opportunity for local producers to receive premium prices. Between 1994 and 2014, farmers’ markets increased from 1755 to 8284 [

6].

Most strawberries grown in the mid-south US are sold directly to local markets and contribute to agritourism activities. In a survey conducted by Virginia Cooperative Extension, 79% of strawberry growers stated that they sell their berries through pre-pick retail and U-pick outlets [

7]. In the City of Virginia Beach, the highest producer of strawberries in Virginia, an estimated 20% of the yield is sold pre-picked at farmers’ markets, and the remaining portion of the harvest is sold through U-Pick [

8].

An increase in local food demand is an opportunity for strawberry producers to adopt technology such as high tunnels that help expand their production and extend their season. High tunnels are unheated, polyethylene-cover, greenhouse-like structures [

9]. They offer protection from unfavorable weather conditions such as high wind, frost, hail, and precipitation, and they are reported to extend the harvest season for many crops, allowing the growers to gain early entry into the market when consumers are most excited about berry consumption and picking [

9]. A study in Utah reported that high tunnels advanced June-bearing strawberry production by 4 to 5 weeks [

10]. The noted benefits from high tunnels, coupled with their low installation costs compared to other protected structures, have stimulated interest among high-value crop growers [

11].

Previous analyses of high tunnel vs. open-field production have yielded mixed results. Some studies in North America reported the role of high tunnels in improving the productivity and quality of high-value crops and the possibility of allowing producers to access offseason premium prices [

12,

13,

14,

15]. However, a study in Tennessee [

16] reported lower net revenue from strawberries produced under a high tunnel compared to open- field production. An Arkansas study of primocane-fruiting blackberries found that open- field production was more profitable than high tunnel production [

17]. A Michigan study of high tunnel and open-field raspberry production found higher insect pest pressure under high tunnels compared to open-field [

18]. Another study [

19] notes that while increased strawberry yield would not justify the cost of a high tunnel, growers point out that the main advantage of a high tunnel is the reliability of production regardless of rain events during harvest. Further research is needed to determine how strawberry net revenues in the southeastern U.S. are affected by high tunnel production and what factors contribute to the change in net revenues. As strawberry producers explore alternatives to conventional open-field production to expand their growing season, little is known as to whether high tunnel benefits observed in other regions can be translated to the southeastern U.S. and whether potentially higher yields and price premiums obtained during the offseason would increase the revenue enough to cover initial installation costs. The effect of different strawberry cultivars on high tunnel versus open-field comparison is also unknown. We conducted this study with the primary objective of learning whether there are additional returns from strawberry cultivars grown in high tunnels compared to those in open-fields in the Southeast and specifically Virginia and what factors contribute to the change in net returns from high tunnel production. Secondly, we were interested in learning and identifying the interaction of strawberry cultivars with the high tunnel versus open-field economic returns. Finally, we were interested in learning the sensitivity of additional returns to the market price.

2. Materials and Methods

2.1. Horticultural Design

The horticultural study was conducted at Virginia Tech’s Hampton Roads Agricultural Research and Extension Center (AREC) in Virginia Beach, Virginia, during the 2019/20 season. The soil was tetotum loam with a non-amended pH of 5.9 and 5.1 for the land with and without strawberry history, respectively. Lime was applied at a rate of 2241 kg ha

−1 (2000 lb ac

−1) to land with strawberry history and 5043 kg ha

−1 (4500 lb ac

−1) to land without strawberry history to adjust the pH of both land types to a 6.2 level. Eight strawberry cultivars were evaluated in a randomized complete block. Five cultivars were short-day (June bearing), and three were day-neutral (spring and fall-bearing). The June-bearing cultivars were ‘Rocco’ [

20], ‘Ruby June’ [

21], ‘Camino Real’ and ‘Merced’ [

22], and ‘Chandler’ [

23]. The day-neutral cultivars were ‘San Andreas’ [

22], ‘Sweet Ann’ (Lassen Canyon Nursery; 2009), and ‘Albion’ [

22].

The strawberry plugs of all cultivars were ordered from the same nursery. They were planted in the first week of October 2019 and transplanted in annual hill plasticulture beds with 36 cm (14 in) in-row spacing in a staggered manner. A total of 8 rows 21 m (70 ft) long and 1.8 m (6 ft) center were planted. Four rows were inside a 9 × 45 m (30 × 148 ft) high tunnel, and four others were outside in the open-field. Each cultivar was planted on a 2 m2 (21 ft2) block and replicated four times in both high tunnel and open-field. The total area used for the trials in each environment was 195.1 m2 (2100 ft2). The planted area was 78 m2 (840 ft2), another 78 m2 was for the alley-ways, and the remaining 49 m2 (420 ft2) was the buffer area used to separate cultivars in the trial. We ignored this buffer area in our analysis because it would not be present on a commercial operation. Therefore, we considered the area used for the trials in each environment to be 156 m2 (1680 ft2).

Temperature and plant health were monitored throughout the study. Temperature probes were placed at canopy levels and 15.2 cm (6 in) depth under the soil (root zone) in each bed row. Plant runner counts were recorded monthly for each replicate using a rating from 1 to 5, 1 being for rare runners and 5 for the most runners. Similarly, plant health rating was done on a monthly basis using a rating from 0 to 10, 0 meaning all plants dead in a replicate, and 10 meaning extremely vigorous and healthy appearing plants in a replicate. Strawberry plant development was monitored by measuring plant canopy diameter early in the growing season, mid-season, and toward the end of the growing season. Field plots were harvested two to three times per week by project personnel.

2.2. Economic Analysis

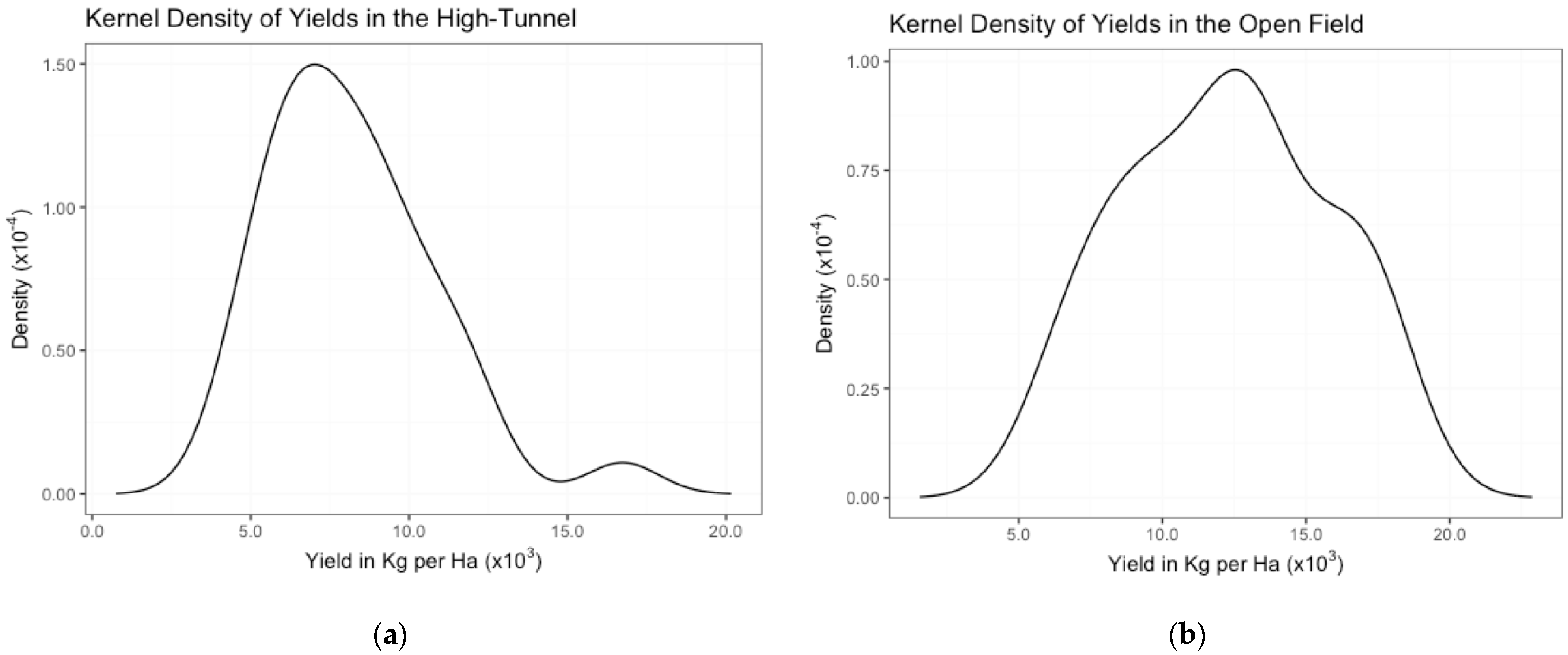

Marketable and nonmarketable yields per block were recorded by harvest date for each cultivar in both high tunnel and open-field environments. We added monthly marketable yield from each of the four blocks of the same cultivar in each environment to obtain the monthly yield per cultivar. Then, we extrapolated the yield to a per hectare basis.

For each cultivar, we calculated total costs, gross revenues, and net returns (revenue generated minus production cost) per hectare for three marketing strategies in both high tunnel and open-field. In the first strategy, producers pre-pick their berries and sell them at a wholesale market (pre-pick-wholesale). In the second, they pre-pick and retail berries (pre-pick-retail); in the third strategy, consumers pick the berries for themselves (U-pick).

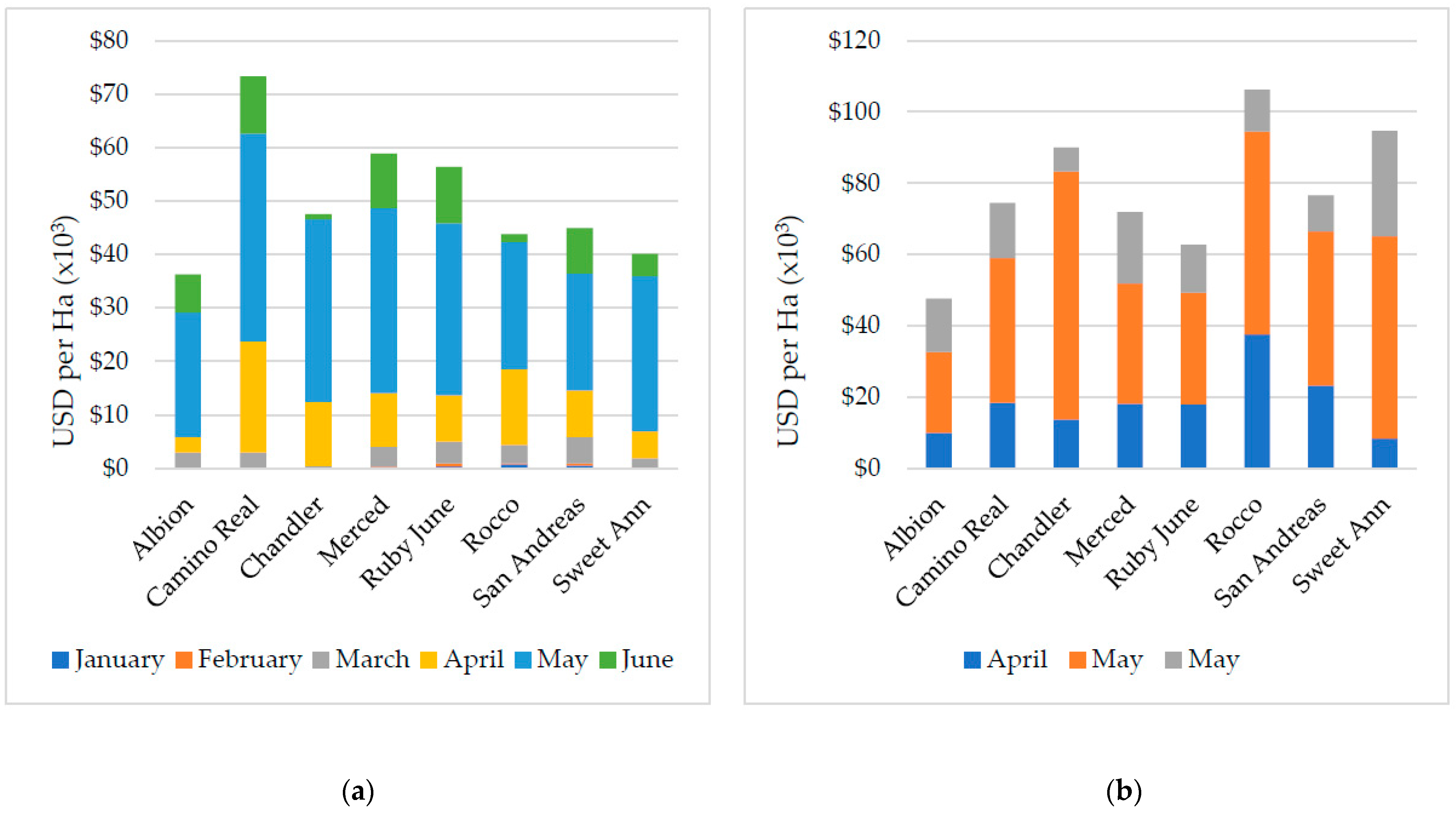

2.2.1. Gross Revenue

To calculate the seasonal gross revenue, we added the products of monthly marketable yield per cultivar in kilograms and the estimated monthly price per kilogram during the 2019–2020 harvest season. Estimated monthly prices differ by marketing strategy. The same monthly price is used for all cultivars with high tunnel or open-field production, except that January, February, and March monthly prices are not used for open-field production as there are no yields in those months. To account for inflation, all prices were expressed in terms of the purchasing power of money in 2020 (2020 dollars) using U.S. GDP implicit price deflators obtained from the Federal Reserve Bank of St Louis website (

https://fred.stlouisfed.org, accessed on 3 March 2021). To convert dollars for a cost or revenue item from a given quarter and year to 2020 dollars, we find the ratio of the deflator for the second quarter of 2020 and the deflator of the quarter in the year under consideration. This ratio is multiplied by a price reported in that year to convert it to 2020 dollars. The result was a set of prices expressed in 2020 dollars.

To estimate the monthly price received by producers in the southeastern US at the wholesale market, we found the 4-year average North Carolina strawberry prices (expressed in 2020 dollars) at the Baltimore Terminal Market (2017–2020). The terminal market price dataset was obtained from the USDA (AMS) website (

https://www.marketnews.usda.gov, accessed on 3 March 2021). This dataset reported weekly low, high, mostly low, and mostly high prices per flat 8 0.45 kg (1 lb) container with a lid. We took the average of the mostly high and mostly low prices for each month and converted these average prices to 2020 dollars, as described above. We took the average of the mostly high and mostly low prices in order to capture the range of prices observed without being overly influenced by outliers that might have been introduced with inclusion of the high and low price categories.

The USDA dataset for Baltimore Terminal Market price contained only information on April through June prices. We obtained a dataset of monthly southeastern US retail prices per kilogram for five years (2016–2020) from the USDA website (

https://www.marketnews.usda.gov, accessed on 4 March 2021). We converted all prices to 2020 dollars as described above and then used the average price for each month over the five years to estimate wholesale prices for January through March. First, we calculated the average percent retail margin over the terminal market price for April through June. The resulting average percent retail margin was used to estimate the average wholesale terminal market price for January, February, and March based on the retail prices for each month.

Prices for pre-pick retail and U-pick operations were obtained by finding an average of prices reported by local Virginia producers who responded to an online survey administered in 2021. Respondents market their berries via pre-pick retail or U-pick outlets. Survey respondents were asked to report their prices as dollars per pound or dollars per 4-quart basket.

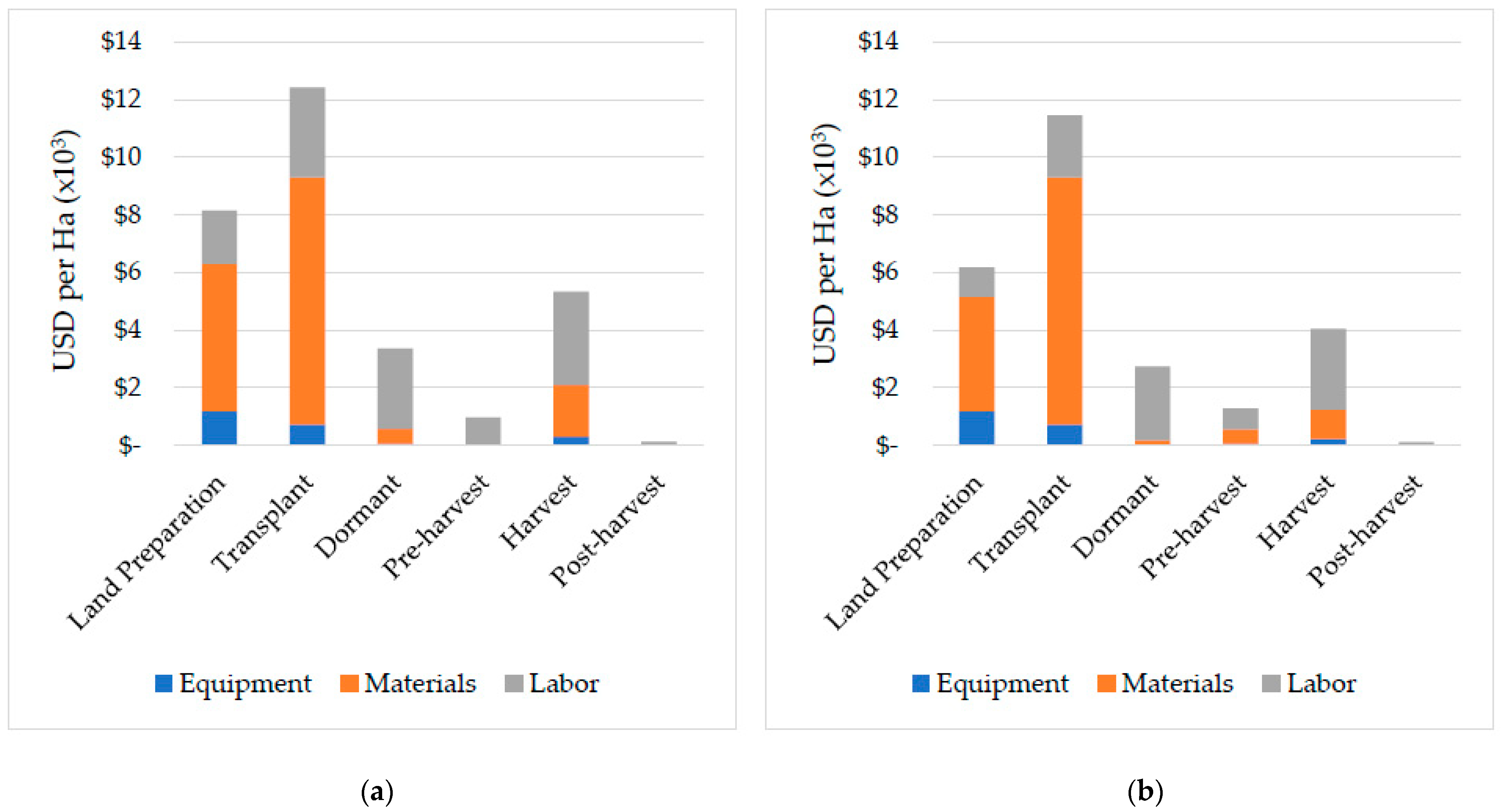

2.2.2. Cost

We used the costs recorded in trials at the AREC in Virginia Beach. Since the trials were conducted on a 156 m

2 (1680 ft

2) area with eight cultivars under high tunnel and open-field, we extrapolated the costs to a per-hectare basis. Some production labor costs were based on North Carolina State extension budgets, rather than experimental observations, to more accurately reflect production conditions on a commercial operation [

24]. In addition, other supplementary cost information was also obtained from the North Carolina extension budgets [

24]. All costs were expressed in 2020 dollars using the procedure described above for prices.

Costs are divided into production and overhead. Production costs were reported by strawberry production stages: land preparation, transplant, dormant, harvest, and post-harvest. Except for the harvest stage, all production stages started and ended around the same time in the open-field and the high tunnel. Costs for all activities that occurred between the first and the last harvest days were classified in the harvest production stage except the labor cost spent for the actual picking of the berries, which was classified in a separate harvest labor category.

For each production stage, reported production costs include labor, materials, and machinery variable costs. Production costs of the high tunnel differ from those of the open-field. Cultivars grown within the open-field (high tunnel) have the same costs with the exception of harvest labor costs, which vary by yield and by the marketing strategy. We used harvest labor reported in the trials for the pre-pick wholesale and retail operations, and we assumed the U-pick harvest labor to be 20% of the pre-pick harvest labor.

Overhead costs include interest, depreciation, and repairs for all irrigation, machinery, and high tunnel infrastructure. Overhead costs differ between the high tunnel and open-field but are the same for all cultivars within the open-field (high tunnel). The high tunnel structure cost was depreciated for ten years based on the Internal Revenue Services’ 2012 Farmers Tax Guide, which states that horticultural structures’ lifetime is ten years [

25]. Maintenance and interest costs were, respectively, four and five percent of the average costs of the structure.

2.2.3. Net Revenues

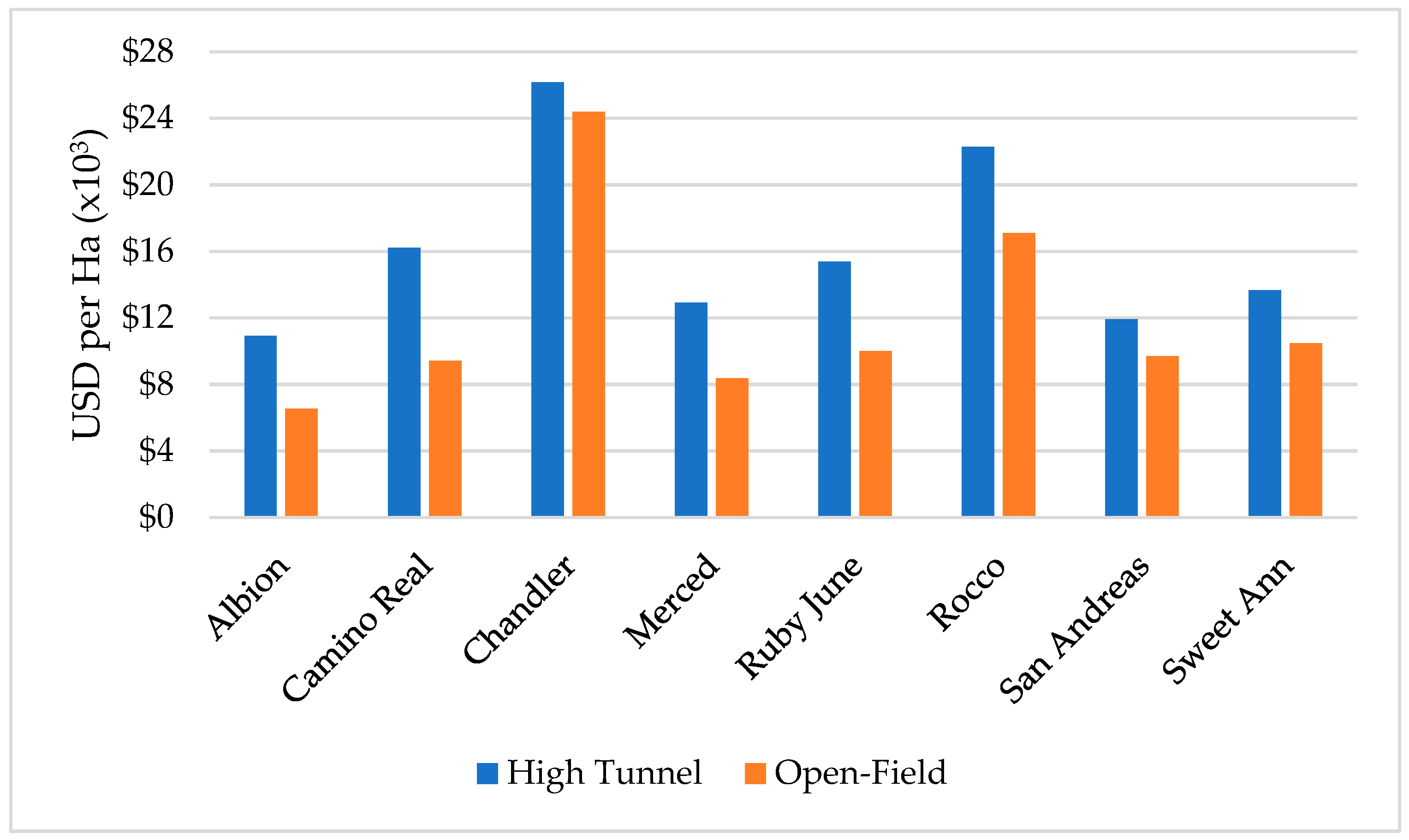

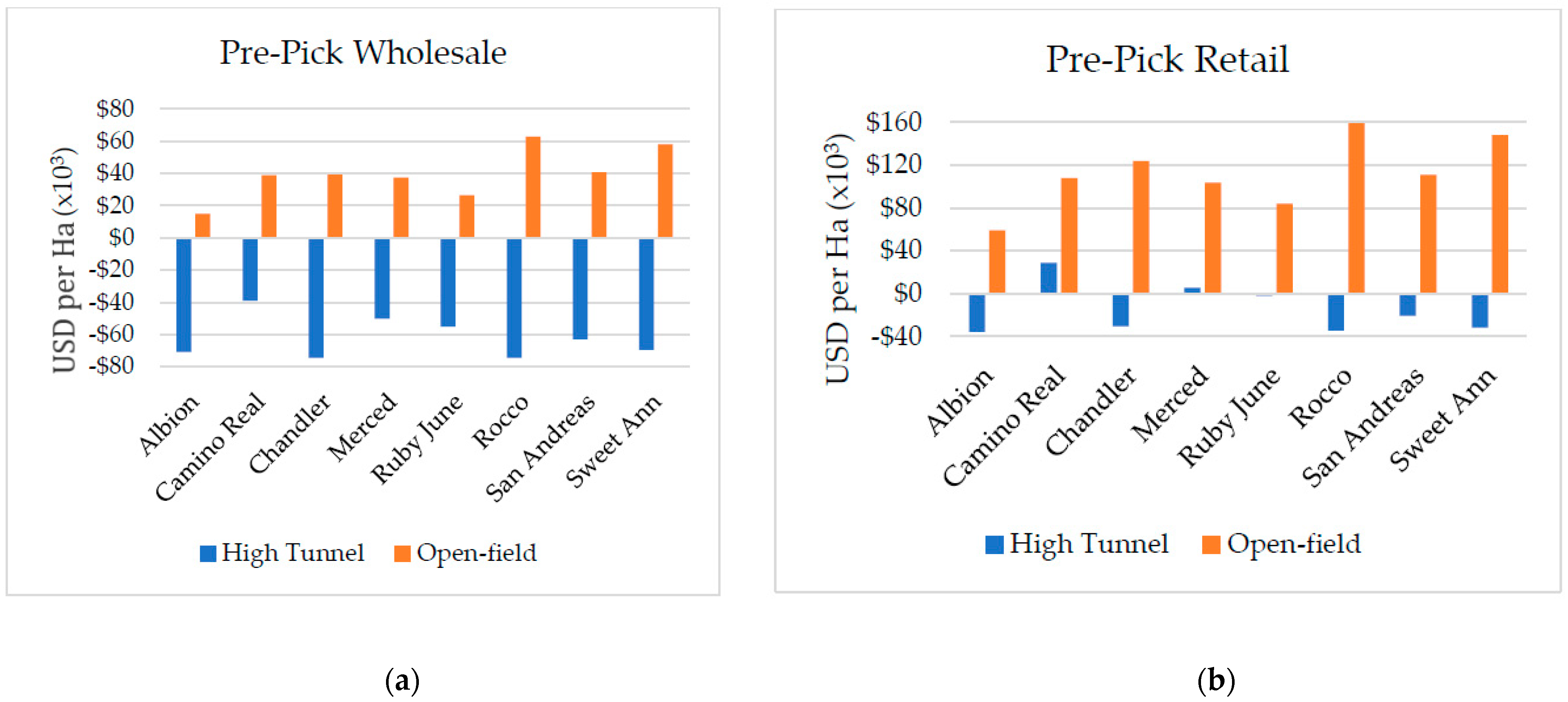

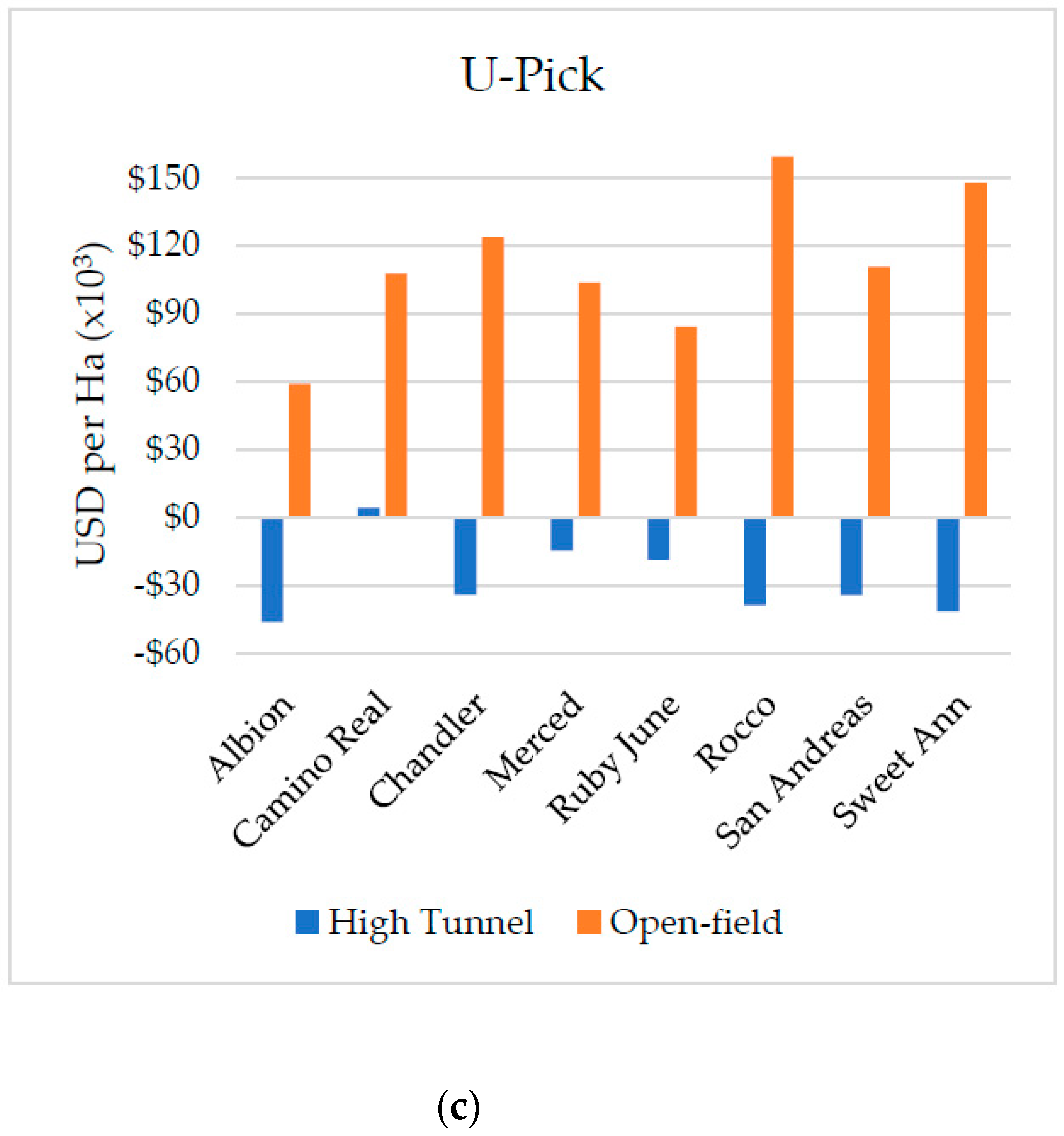

Net revenues per hectare from eight strawberry cultivars under each marketing strategy and under open-field and high tunnel production were estimated by subtracting the total per hectare cost from gross revenues.

4. Discussion

Several studies conducted in different regions in North America reported higher net revenues from producing fruits and vegetables in high tunnels compared to the open-field [

26]. High tunnels extended the harvest season and increased marketable yields resulting in higher net returns. In contrast, our study finds lower net returns from high tunnel production for all marketing strategies. Lower net returns in the high tunnel compared to the open-field can be attributed to two main reasons. First, the high tunnel production cost was higher than the cost of the open-field cultivars, as discussed in the previous section (

Table A2). A major reason for the higher cost is the overhead cost of the high tunnel structure, which makes up almost half of the total cost of high tunnel production. Second, as a result, the early season strawberry yields and revenues generated from high tunnel production compared to open-field production were not enough to offset the higher cost of owning the high tunnel structure for any of the three marketing prices used in this study. In fact, average yields from the high tunnel were lower than from the open-field (

Table 1 and

Table 2).

The lower yields in the high tunnel compared to the open-field corroborates the findings from a Tennessee study that spring-bearing open-field strawberries produced higher yields than winter and spring-bearing high-tunnel strawberries [

16]. One possible reason for lower high tunnel yields during our trials is herbicide and disease damage resulting from cooler conditions in winter and warmer conditions in spring. Early fruiting in the high tunnel when conditions were cooler favored the development of diseases in the high tunnel at the time when there were no fruits in the open-field. Forcing strawberries to bear fruit during the winter months can be a drawback as yield is reduced compared to traditional spring production [

27].

The warm conditions in the high tunnel during the spring compared to the open-field environment favored pests and led to lower yields. This is similar to what Martin reported that warm winter temperatures provided insects an overwintering location in the high tunnel and caused more damage to the berries during winter and spring production [

16]. Leach and Isaacs [

18] also reported higher pest pressure in high tunnel raspberries compared to open-field production while Ingwell et al. [

28] also observed a higher pest prevalence in high tunnels compared to open-field plots in a study of tomatoes, cucumbers, and broccoli. Rodents are also attracted to warm conditions in the high tunnel during winter and feed on high tunnel crops [

29]. Overhead irrigation was used in our study to protect the plants from frost, insect damage, and diseases, but it is clear that the yield loss was enlarged compared to open-field production.

Galitano and Miles [

11] also reported a lower profit from lettuce produced in the high tunnel than in the open-field. The net revenue from lettuce produced in the high tunnel was 30% less per square meter than the net revenue from producing in the open-field. The higher yield from the high tunnel observed in their study was insufficient to offset the increased costs. This finding suggests that even higher yields in the high tunnel would not have been a sufficient condition to guarantee higher net revenues at a low wholesale price, but it might have at higher prices for other marketing strategies. Results from previous studies as well as this study suggest greater attention needs to be given to managing strawberry production under high tunnels especially with respect to pest management.

Focusing on the open-field, where net-revenues were always positive, ‘Rocco’ and ‘Sweet Ann’ would be the best choices for U-pick and pre-pick retail due to higher net revenues (

Figure 5b,c). Their yields are higher than ‘Chandler’ yields although the differences are not statistically significant (

Table 1). However, these cultivars are not suitable for shipping making them less suited to pre-pick wholesale operations. Additionally, although data from research and on-farm trials shows that yield from ‘Rocco’ is similar to that of ‘Chandler’, it is still a new cultivar [

20]. ‘Sweet Ann’ does not tolerate rain events very well due to its thin fruit skin. It did well in the outdoor environment in our trial because low rain events and intensity were recorded this season. During harvest seasons when there are high rainfall events and intensity, this cultivar may not yield the same amount of marketable yield. ‘Chandler’, which ranked third in open-field net revenues for pre-pick retail and U-pick, has been grown by southeastern growers for a long time, and it has been among the top cultivars with high yields [

30] making it favorable for U-pick and pre-pick retail operations. ‘Camino Real’ ranked fifth in open-field net revenues. Previous studies reported that it can yield as well or better than ‘Chandler’ in different regions of Eastern Virginia [

31]. The high yield potential, rain resistance, ease of picking, and good shipping ability makes ‘Camino Real’ a favorable cultivar for pre-pick wholesale.

5. Conclusions

In this paper, we study and compare cost, revenues, and net revenues from eight strawberry cultivars produced under a high tunnel and in the open-field in the Commonwealth of Virginia. We find that producing in the high tunnel was not profitable for three marketing strategies: pre-pick with wholesale marketing, pre-pick with retail marketing, and U-pick whereby consumers pick strawberries.

The total production cost (including harvest, ownership, and administrative costs) for the high tunnel averaged $112,223 ($45,415 ac−1) and $99,276 ($40,175 ac−1) for pre-pick and U-pick, respectively, and for the open-field averaged $38,204 ($15,460 ac−1) and $28,608 ($11,577 ac−1) for pre-pick and U-pick, respectively. Revenues from all eight cultivars were lower in the high tunnel than in the open-field, regardless of whether strawberries were sold at a wholesale, retail, or U-pick price. This is a result of lower marketable yields from the high tunnel compared to the open-field. High tunnel net revenues were negative for all cultivars and marketing strategies, except for ‘Camino Real’ and ‘Merced’. The net revenue from ‘Camino Real’ was positive at pre-pick-retail and U-pick prices, and the net revenue from ‘Merced’ was positive at a pre-pick retail price. In contrast, net revenues from open-field were positive for all cultivars and marketing strategies. On average, net revenue was $101,893, $127,253, and $109,788 ha−1 ($41,235, $51,498, and $44,430 ac−1) higher in the open-field than in the high tunnel for pre-pick wholesale, pre-pick retail, and U-pick marketing, respectively.

Study results imply that growers should focus on open-field production of strawberries rather than under a high tunnel. The most promising cultivars in terms of net returns from open-field production are ‘Rocco’, ‘Sweet Ann’, ‘Chandler’, and ‘Camino Real’. However, ‘Rocco’ has limitations for shipping and ‘Sweet Ann’ has limitations due to sensitivity to damage from rain events. A limitation to this study was that the economic data was run on a field trial based on a single growing season, i.e., 2019–2020 growing season. Replicating the study might provide additional insights into the effects of growing season conditions on the differences in yields from high tunnel and open-field production.

Further research is also warranted to develop an improved production system for strawberries under high tunnels. Disease and insect pest management methods need to be adapted to the high tunnel production environment in order to produce the increased yields needed to offset the overhead costs of the high tunnel structure. Harvest costs reported in this study may be higher than those realized by commercial growers because of experimental methods used to record our harvest labor. Labor inputs were reported for small plots, and experiment workers harvested all berries, including non-marketable yields. Harvest workers on a commercial operation may be more efficient, resulting in lower harvest labor costs, which could be corroborated with further research. Additionally, further research is needed to evaluate the relative profitability of the three marketing strategies: U-pick, retail, and wholesale. Such study should consider all marketing costs for each marketing strategy.