Abstract

Cool season vegetables require adequate soil moisture to assure that maximum yield and quality are achieved. On California’s central coast, where the majority of cool season vegetables are produced in the US, long-term overpumping of irrigation water has reduced groundwater levels and led to environmental degradation. Two evapotranspiration (ET) based irrigation field trials were performed near Salinas CA (USA) to determine if ET-based irrigation scheduling could conserve water while producing romaine lettuce (cv. Sun Valley) of commercially viable yield. Sprinklers were used for seed germination and crop establishment. Four drip irrigation treatments were then imposed using a randomized complete block design with six replications. The CropManage decision-support model was used to estimate the full (100%) crop water requirement based mainly on ET replacement. Other treatments included 50% 75% and 150% of the full water requirement. The 100% treatment received 185 mm of water in 2015 and 247 mm in 2016, both of which were well below prior guidance and grower reports. Yields from the 100% and 150% treatments were not significantly different and were similar to industry average, while yields were significantly lower for the 50% and 75% treatments. The 100% treatment had the highest water use efficiency, and the 100% and 150% treatments together had the highest nitrogen recovery efficiency. Irrigation of romaine near the 100% ET replacement level can potentially reduce environmental impacts associated with nitrate leaching and surface runoff.

1. Introduction

A majority of US lettuce (Lactuca sativa L.) is produced in the coastal valleys of California between March and November, where a mild Mediterranean climate is ideal for cool season vegetable production. Attainment of satisfactory lettuce yield depends on adequate water supply [1]. Irrigation is required most of the growing season as rainfall is concentrated during the winter months. The combination of frequent droughts and increased pumping of wells for supplying water to agriculture and urban areas has resulted in declining groundwater levels and accelerated seawater intrusion into aquifers near the coast. Local groundwater management agencies were recently established to implement state regulations intended to reduce groundwater over-drafting [2]. Since agriculture accounts for 80–90% of annual pumping in most central coast aquifers, growers will need to adopt conservation practices that contribute to sustainable groundwater management.

Intensive production of cool season vegetables has also resulted in nitrate contamination of the underground aquifers [3]. Nitrate concentration of many agricultural wells in vegetable production areas of the central coast significantly exceeds the drinking water standard of 10 mg L−1 NO3-N [4]. Water quality regulations administered by the Central Coast Regional Water Quality Control Board require that vegetable growers annually report total fertilizer nitrogen applied to fields and implement practices that will limit nitrate leaching losses. Prior monitoring of 30 cool season vegetable fields (broccoli, cabbage, cauliflower) found that central coast growers applied an average water volume near 200% of crop evapotranspiration (ETc), potentially leading to significant nitrate losses through leaching [5]. More recent monitoring has similarly found that many irrigators may be applying more than 180% of ETc in commercial lettuce [6].

Improved irrigation management of lettuce and other cool season vegetables could both conserve groundwater supplies and reduce nitrate loss. Although soil moisture monitoring has been shown to be an effective tool to optimize water management of vegetables, it has not been widely adopted for lettuce production in the region. Most large-scale vegetable operations on the central coast manage one to two thousand ha of vegetables per season. Since lettuce production is characterized by short crop cycles (60–70 days), and small fields (<4 ha), in various stages of maturity, it is challenging for farm managers to use soil moisture sensors for even a small fraction of their fields. In contrast, an ET-based approach can be used in lettuce without the necessity to install, maintain, and remove equipment. Various studies involving ET-based irrigation management have examined lettuce water requirement at sites in Turkey, Lebanon, Myanmar, and Arizona USA [7,8,9,10]. A prior field experiment on the central coast (Salinas Valley) investigated relationships among biomass accumulation, soil water extraction, and partitioning between evaporation and transpiration under sprinkler irrigation [11]. To provide added guidance for ET-based irrigation scheduling, a recent campaign used eddy covariance instruments to measure seasonal ET of low desert lettuce fields in Arizona [12].

The California Irrigation Management and Information System (CIMIS), operated by the Department of Water Resources, is a statewide network of weather stations that monitor daily grass-based reference evapotranspiration (ETo) [13]. Six stations are located throughout the main microclimatic zones of the central coast. CIMIS also offers a satellite-based product that estimates ETo at 2-km spatial resolution based on data from the Geostationary Operational Environmental Satellite [14]. Although daily ETo data are readily obtained from the CIMIS website or automatically delivered by email, relatively few farm managers use ETo for irrigation scheduling of lettuce and other cool season vegetables. One reason is the complexity involved with determining appropriate crop coefficient (Kc) values to relate ETo to ETc at various development stages, then adjusting for irrigation interval, application uniformity, leaching fraction and precipitation, and ultimately converting water volume to irrigation system runtime.

Various decision-support models have been developed to mitigate computational issues and time constraints associated with ET based scheduling [15,16,17,18,19]. One such model is the CropManage (CM) application developed by the University of California, Cooperative Extension [20,21]. ET-based irrigation recommendations are made by integrating ETo with soil, plant, irrigation system, and salinity information. Empirical equations modelling canopy development are used to formulate daily Kc values based on the planting and expected harvest dates. An intuitive user-interface supports rapid determination of irrigation schedules and maintenance of applied water records for multiple fields and farms. Despite the improved usability of ET data for irrigation scheduling, some growers may be reluctant to adopt online tools such as CM without direct evidence that the guidance is accurate and reliable over multiple crops and seasons for a given crop type of interest.

A prior two-year (2012–2013) set of trials in the central coast region of the Salinas Valley evaluated the use of CM for irrigation scheduling of broccoli and iceberg lettuce using an ET based approach [22]. Applied water for broccoli was an average of 33% lower than a grower standard treatment while maintaining yield. Applied water for iceberg was reduced by an average of 24% relative to the grower standard without a significant difference in carton yield during either year or in cored-product yield during the final study year. The significantly lower cored-product yield observed during the initial year still exceeded the local industry average.

Demand for romaine lettuce has steadily increased during the past 20 years and now represents approximately 40% of California lettuce production. Romaine is a high-value crop grown on over 12,000 ha and generating around $500 million USD in annual revenues from Monterey County alone [23]. As with iceberg, romaine is harvested as trimmed whole heads, and cored product that is chopped and bagged for salads. Physically however, romaine has a more upright and open leaf structure than iceberg and has distinct water demand characteristics and somewhat higher ETc [11]. The study objectives were to describe relationships of applied water with romaine yield, water use efficiency (WUE) and nitrogen recovery, and to further evaluate the use of CM for guidance of ET-based irrigation scheduling of cool season vegetables under drip irrigation.

2. Materials and Methods

2.1. Irrigation Trials

Field trials were conducted at the US Department of Agriculture research farm in Salinas California (36.6280° N, −121.5415° W) during spring of 2015 (trial 1) and 2016 (trial 2). The site is located at an elevation of approximately 45 m above sea level within CIMIS Zone 3, which has mean annual ETo of 1175 mm and is characterized as an agricultural area primarily growing salad crops and strawberries [24]. Cumulative ETo was 273 mm and 302 mm during trials 1 and 2, respectively. Soils are Chualar sandy loam (fine-loamy, mixed, superactive, thermic Typic Argixerolls with 70% sand, 27.4% silt and 2.6% clay, pH of 7 and organic matter of 1.5%). A total of 336 kg ha−1 of 6N-20P-20K fertilizer was incorporated into the soil before bed-shaping. Romaine lettuce (Lactuca sativa L. var. Longifolia) (cv. Sun Valley) was seeded at a six mm depth in two rows spaced 0.3 m apart on 1 m wide raised beds. Planting dates were 29 April 2015 and 3 May 2016 for trials 1 and 2, respectively. Irrigation began two to three days later after a pre-emergent weed herbicide (Pronamide) and an anti-crustant combination of phosphoric and sulfuric acids and urea were sprayed as bands over the seed lines. The crop was germinated and established using overhead sprinklers (20JH Rainbird, Azusa, CA, USA) on 7.6-cm diameter aluminum pipe spaced 10-m apart with 9-m inline spacing between sprinkler heads. The trial was irrigated with well water with an electrical conductivity of 0.6 dS m−1 and pH of 7.6. A flowmeter (Seametrics AG1000, Kent, WA, USA) measured the water volume applied by sprinklers during crop establishment. The crop was manually thinned to a population of approximately 72,000 plants ha−1 and cultivated for weeds before transitioning to drip irrigation. Drip tape (16 mm diameter, emitter discharge rate = 1 L h−1, emitter spacing = 30 cm) was placed on the surface of the beds midway between plant rows approximately 25 and 20 days after planting (DAP) for trials 1 and 2, respectively. A manifold fitted with a disk filter and pressure regulator diverted irrigation water from the mainline into four separate 7.6 cm diameter submains made of layflat hose, each with a flowmeter (Netafim 36WST3F, Fresno, CA, USA) for measuring the applied water volumes of the irrigation treatments.

Upon crop establishment, 24 study plots were arranged in a randomized complete block design with six replications. The individual plots measured 6 m (6 beds) × 41 m. Irrigation treatments used drip tape to supply 50%, 75%, 100%, or 150% of the full water requirement specified by CropManage. The crop was irrigated two to three times per week. Daily reference ET from CIMIS station 214, located onsite at the USDA research farm, was used to support ETc calculation. Canopy cover images were collected using a digital camera (Rebel T5i 700D 18 MP; Canon Inc., Melville, NY, USA), modified to take normalized difference vegetated index photographs (LDP-LLC MaxMax Inc., Carlstadt, NJ, USA). Images were taken at 3 m height on 4–5 dates beginning at 20 DAP and analyzed for fractional cover using PixelWrench II software (Tetracam Inc., Chatsworth, CA, USA). Tensiometers (Irrometer, Riverside, CA USA) were installed in the plant row at 30 cm depth in two replications per treatment and read immediately before each irrigation during trial 2.

Fertilizer nitrogen was applied equally among treatments but differed between years, depending on the residual mineral N level of the soil. After crop establishment, nitrate was periodically evaluated in the top 30 cm of soil in all treatments to assure that mineral N was not limiting crop growth. Soil NO3-N values varied from 3 to 48 ppm depending on the date and treatment. A 20 ppm NO3-N threshold was used to determine if fertilizer N was needed [25]. A total of 134 and 209 kg N ha−1 was applied in trials 1 and 2, respectively. Ammonium-nitrate fertilizer was applied through the drip system at a rate of 33.6 kg N ha−1 at 28 DAP followed by subsequent applications of 33.6 kg N ha−1 of urea-ammonium-nitrate at 40, 50 and 57 DAP during trial 1. Urea-ammonium-nitrate was applied by drip at rates of 44.4, 44.8, 67.3, and 52.6 kg N ha−1 at 23, 38, 49, and 56 DAP, respectively for trial 2. A total of 57 kg K ha−1 in the form of potassium thiosulfate (0-0-25-17) was also applied equally to all treatments through the drip system at 47, 49, 54 DAP for trial 1 and 35 and 42 DAP for trial 2.

2.2. CropManage Calculations

Prior studies [26,27] have shown that Kc for lettuce and other vegetable crops is strongly related to fractional canopy cover (Fc). After [26], Fc is modeled by CM as:

where Cmax is the expected maximum percent cover of the canopy, A and B are fitted parameters that are specific to crop type and planting configuration, and Maxday is total days between planting and harvest. Maxday can be adjusted to account for crop cycle variation due to time of year, and is a number typically known to growers with reasonable certainty for specific varieties and planting dates. Equation (1) coefficients for this study were determined from prior Fc monitoring in ten commercial romaine fields planted with the same bed configuration as here, using a boom-mounted digital camera modified for capture of color infrared photographs. Values for Cmax, A, B, and Maxday were empirically determined as 80%, 6.2, −11.5, and 64, respectively.

Fc = Cmax/(1 + exp(A + B × DAP/Maxday))/100,

The model converts canopy cover to a transpiration coefficient (T):

T = −0.39Fc2 + 1.5Fc.

This equation derives from a relationship between field crop daily transpiration rate and solar radiation interception, which is strongly related to Fc, as proposed in [26]. For reference, a T value of 0.95 is associated with the Cmax value for this study. A soil evaporation coefficient (Ke) represents the daily soil evaporation component of ETc. For sprinkler irrigation and rainfall, which wet the entire field surface, Ke is set to 1.0 on the day of the event, 0.4 the following day, 0.05 two days post-event, and zero thereafter. For surface drip irrigation, which wets less than 30% of the soil surface, Ke values are 0.3 on day of the event, 0.1 the following day, 0.05 two days post-event, and 0 thereafter. As a simplification, CM then sets daily Kc to the greater of T and Ke:

Kc = max(T,Ke).

Total crop ET (ΣETc) since the last irrigation event is calculated as:

where ETo avg is average daily CIMIS reference ET since last event, Kc_avg is average Kc since last event, and ndays is number of days since last event. For a specific irrigation event, the applied water depth (AW) representing the crop water requirement is:

where DU is distribution uniformity, LR is leaching requirement, and P is precipitation since last event. The AW is calculated in terms of water depth (in.) but is optionally conveyed in terms of system runtime to the nearest 0.1 h, based on system application rate. In this study, DU of 0.75 was assumed for sprinklers used for crop establishment, and subsequently 0.85 for the surface drip irrigation system. Leaching fraction was set to zero. Scant precipitation (16 mm) was received during trial 1 and none during trial 2.

ΣETc = ETo_avg × Kc_avg × ndays,

AW = ΣETc/(DU × (1 − LR)) − P,

2.3. Crop Evaluation

Final population of marketable plants, biomass and carton yield were evaluated for each plot when the crop reached maturity at 62 and 63 DAP for trials 1 and 2, respectively. Forty heads were randomly selected from the middle 4 m × 23 m area of the plots. Biomass yield was calculated from the average untrimmed weight of the 40 heads multiplied by the final plant population. The outer leaves of eight of these heads were trimmed to market standards and reweighed to determine the ratio of trimmed to untrimmed weight. The ratio was used to calculate the carton yield from the biomass yield. An additional four whole plants from each plot were longitudinally sliced into quarters. One quarter of each plant was combined into one sample for determination of dry matter and total nitrogen content. Plant tissue was dried at 60 °C for 48 h, then ground and analyzed for N by the combustion method. Four whole plants per plot were evaluated for number of leaves, core height, and maximum circumference.

Cored product yield (CPY) of trial 1 was evaluated in four replications of the 100% and 150% treatments by a commercial harvesting team at 63 DAP. The 50% and 75% treatments of trial 1 were harvested at 70 DAP to provide extra time for the plants to gain size. Cored product yield of trial 2 was evaluated in four replications of the 75%, 100%, and 150% treatments at 63 DAP; the 50% treatment was not harvested because the plants were smaller than the market standard. All marketable plants were harvested from the center four beds of each plot. The CPY of each plot was determined as plant weight divided by harvested area.

Nitrogen recovery efficiency (NRE) was calculated per plot as:

where N content is average N content of the plant tissue (%), Y is dry biomass yield (kg ha−1), and N_fert is total applied fertilizer N (kg ha−1). Water use efficiencies based on carton and biomass yields were calculated for each plot by dividing yield (kg ha−1) by applied water (mm).

NRE = N_content × Y/N_fert,

2.4. Comparative Water Use

For comparative purposes, a survey of water use data for lettuce produced in the region from 2015–2017 was obtained from the Central Coast Regional Water Quality Control Board (CCRWQCB) through a public information request. A total of nearly 1500 farms were included in the analysis. The dataset was sorted by lettuce type and year, and summarized using the frequency analysis function in Excel Office (Microsoft, Redmond, WA, USA). Data from each farm represents the average reported water volume applied to romaine lettuce for the corresponding year.

2.5. Statistical Analysis

Yield differences among irrigation treatments, between years, and interaction between years, were evaluated for statistical significance by general linear model procedures using SAS 9.4 (SAS Institute Inc., Cary, NC, USA). Multiple means comparisons were performed when main effects were found to be significantly different at the p ≤ 0.05 level using the protected Fisher’s Test, 2-tailed (p < 0.05). Student t-test contrasts were also performed to determine if 100% and 150% treatments were statistically different at the p ≤ 0.05 level.

3. Results

Canopy cover and applied water volumes for the sprinkler and drip phases of the 100% treatment are shown in Figure 1. Total applied water across treatments ranged from 133–235 mm (plus 16 mm rainfall) in 2015, and 173–321 mm across treatments in 2016 (Table 1). By comparison, average applied water reported by regional romaine growers to the CCRWQCB ranged from 435–458 mm during 2015–2017. The U.C. Division of Agriculture and Natural Resources Division (UCANR) estimates the typical central coast water application for leaf lettuce at 12–18 inches (300–450 mm) under drip irrigation, and up to 24 inches (610 mm) for sprinkler irrigation [28].

Figure 1.

Measured canopy cover of the irrigation treatments (top) and applied water volumes of the 100% treatment (bottom) for trials 1 and 2. No rainfall occurred during trial 2. Treatments are 50–150% of crop water requirement.

Table 1.

Applied water for trials 1 (2015) and 2 (2016). Treatments are 50–150% of crop water requirement.

Main effects of irrigation treatment and year were statistically significant for most measured variables. Mean values of treatment and year main effects are presented for data pooled from both trials, except for when interaction effects between treatment and year were significant at p < 0.05 level, in which case treatment means are presented by year.

For both trials, above ground fresh and dry biomass yield, carton yield, and cored product yield were highest in the 100% and 150% treatments (Table 2, Figure 2). Student t-test contrasts confirmed that marketable and biomass yield between the 100% and 150% treatments were not significantly different in most cases, demonstrating that the addition of extra water applied with the 150% treatment did not result in more growth and yield. Carton yields were near 50,000 kg/ha and CPY near 32,000 kg/ha. For comparison, average reported commercial CPY was near 27,000 kg/ha during the trial 1 harvest period, and near 30,000 kg/ha at the time of the trial 2 harvest. Yields were significantly reduced in the lower water treatments. Trimmed and untrimmed plant weights were also highest for the 100% and 150% treatments. Plant population averaged 69,294 plants ha−1 at harvest and did not vary significantly among treatments either year, suggesting that greater yields for 100% and 150% treatments were not due to a higher plant population but rather due to more growth relative to the lower water treatments. Average above ground biomass and carton yields were higher in 2016 than in 2015 (Table 2).

Table 2.

Average biomass, dry matter, carton yield, plant weights, and head size of irrigation treatments from trials 1 and 2. Treatments are 50–150% of crop water requirement. Means with different letters are statistically different at the p < 0.05 confidence level.

Figure 2.

Average cored product yield per treatment from pooled 2015 and 2016 data. Treatments are 50–150% of crop water requirement. Irrigation treatments means with different letters are statistically different at the p < 0.05 confidence level. Error bars represent standard deviation of treatment means.

Plant weight, circumference, and leaf count were greatest for the 100% and 150% treatments and least for the 50% treatment (Table 2 and Table 3). These measures indicated that the 100% and 150% treatments produced larger plants compared to the lower water treatments. The 50% and 75% treatments also had a shorter core (Table 3), which in general is a desirable quality characteristic since a greater portion of the plant can be harvested as marketable product. In this case, however, the advantage was more than offset by smaller plant size. Canopy cover was also reduced for the lower water treatments near harvest (Figure 1).

Table 3.

Average leaf count and core height of untrimmed romaine heads from trials 1 and 2 (combined data across irrigation treatments), and of irrigation treatments (combined data from both trials). Treatments are 50–150% of crop water requirement. Means with different letters are statistically different at the p < 0.05 confidence level.

Tensiometer data collected during trial 2 indicated that the 50% and 75% treatments did not receive adequate water to meet crop needs. Soil tension at 30 cm depth for these treatments increased to more than 60 kPa at 45 DAP while the soil tension in the 100% and 150% treatments typically remained below 20 kPa (Figure 3). Prior studies have reported that maintaining soil moisture tension less than 20 kPa optimizes lettuce yield [29,30].

Figure 3.

Soil water tension at 30 cm depth during trial 2. Symbols are an average of two replications. Higher values indicate drier soils. Treatments are 50–150% of crop water requirement.

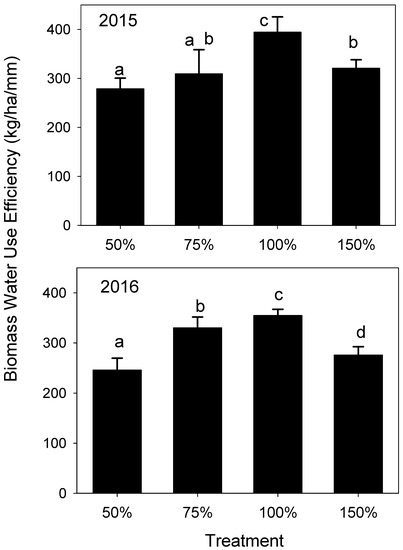

Aboveground crop nitrogen uptake and nitrogen fertilizer recovery were greatest in the 100% and 150% treatments and significantly less in the lower water treatments (Table 4). Water use efficiency with respect to carton yield was highest in the 100% treatment during both seasons (Figure 4). There was no significant difference among the 50%, 75%, and 150% treatments of trial 1, but during trial 2 all treatments were significantly different and the 50% treatment lowest. Water use efficiency for biomass yield also showed that the 100% treatment was highest both years, and 50% was lowest (Figure 5).

Table 4.

Average tissue N content, aboveground crop N uptake, and nitrogen recovery efficiency of irrigation for both trials (data pooled across treatments) and of irrigation treatments (data pooled for both trials). Treatments are 50–150% of crop water requirement. Means with different letters are statistically different at the p < 0.05 confidence level.

Figure 4.

Water use efficiency of irrigation treatments for both trials, based on carton yields. Treatments are 50–150% of crop water requirement. Treatment means with different letters (a–d) are statistically different at the p < 0.05 confidence level. Error bars represent standard deviations of treatment means.

Figure 5.

Water use efficiency of irrigation treatments for both trials, based on above ground biomass yields. Treatments are 50–150% of crop water requirement. Treatment means with different letters (a–d) are statistically different at the p < 0.05 confidence level. Error bars represent standard deviations of treatment means.

4. Discussion

Two seasons of field trials demonstrated an ET based approach to scheduling irrigations of romaine lettuce with respect to biomass, carton, and cored product yield, as well as WUE and nitrogen recovery. Crop water requirement for the post-establishment period was 119 mm in 2015 and 165 mm in 2016. These values compare reasonably well with the post-establishment total of 137 mm applied by sprinkler in an earlier Salinas Valley study [11]. Applying water in excess of the 100% treatment had no significant effect on yield or nitrogen recovery efficiency, and served to reduce water use efficiency. Irrigating at less than the full water requirement limited yield, water use efficiency, and nitrogen recovery. The yield observations are broadly consistent with prior studies reporting yield or biomass maximization under irrigation volumes approximating the crop water requirement [7,8,31,32]. The WUE outcome of the present study differs from an earlier Salinas Valley effort that reported similar lettuce WUE across irrigation treatments [11], and contradicts studies from various locations reporting inverse relationships between WUE and applied water [7,9,33]. In the current study, the 50% and 75% treatments received an average of 62 and 31 mm less water than the 100% treatment, respectively, across the two years. However, the applied water reduction was more than offset by decreased biomass production. Similar to present results, decreased nitrogen use efficiency has been observed under deficit irrigation in lettuce [8]. While the current study found no significant difference between NRE of the 100% and 150% treatments, decreased N utilization has been previously linked to excess irrigation [30].

Although direct measurements of crop ET were not performed, various metrics indicated that CM reasonably estimated ETc during the drip phase. Canopy cover, plant weight, and leaf count measurements for the 100% treatment significantly exceeded those of the lower water treatments and did not significantly differ from the 150% treatment. Soil moisture tension of the 100% and 150% treatments was also maintained in the same range (20 to 30 kPa) according to data collected in trial 2. A recent measurement campaign using eddy covariance instrumentation for the autumn-winter lettuce crop in the low desert (Yuma Valley, Arizona) found seasonal ET values ranging from 234–314 mm for season length of 63–107 days across multiple sites [12]. These data somewhat exceed the crop water requirement of 185–247 mm found in the current study, likely due to use of furrow irrigation in the post-establishment period.

Though soil moisture monitoring is useful in determining when to schedule irrigations for lettuce, it is a less reliable method than using ET for determining how much water to apply. A previous study [34] found that applying enough water to return the soil to field capacity served to maximize lettuce yield. However, determining the volume of water to apply for field capacity can be difficult to implement in a commercial vegetable operation due to the number of fields and variety of soil types on a farm. In contrast, the use of an evapotranspiration approach facilitated by online software that can be easily accessed with a smartphone or tablet computer in the field can provide growers with a quick and simple method to determine how much to irrigate as well as the optimal irrigation interval without the need to install soil sensors.

Surveys on best management practices implemented by growers on the central coast show that ET based scheduling is not one of the top ten practices employed to conserve irrigation water [35]. While CM has been a well-received management tool with a reasonably large userbase at present, the reluctance of vegetable growers to more widely implement ET based irrigation scheduling technology may be due to lingering concerns about reliability of the general approach. The field trials reported here demonstrate the effectiveness of ET based scheduling and, combined with availability of a convenient web-application for decision support, may help to expand such practice on the central coast and elsewhere.

During both trials the 100% and 150% treatments attained an average maximum canopy cover of approximately 73% at harvest which was somewhat below the 80% value used for Cmax in Equation (1). The smaller canopy cover may have been caused by cooler than normal conditions that slowed crop growth as well as disease that held back growth or killed plants. Approximately 3 to 5% of plants had disease symptoms several days before harvest in trial 2 (data not presented). The difference between measured and modeled canopy resulted in CM slightly overestimating water demand during the drip phase. Thus, it is possible that the crop water requirement indicated by the 100% treatment, though well below typical commercial practice, may be somewhat lower still.

Evapotranspiration based irrigation scheduling guided by CM could substantially conserve water and reduce potential leaching losses of nitrate to groundwater. The average applied water volume reported to the CCRWQCB by romaine growers (approximately 450 mm) was about double that of the 100% treatment. More than 87% of responding farms reported applying more than 300 mm, which exceeds the volume of the 150% treatment during trial 1 (235 mm) and is just below the amount applied by the high water treatment in trial 2 (321 mm). Although some central coast areas may experience higher reference ET, most coastal valleys where lettuce is produced have similar summertime ET conditions and water requirement as the location where the trials were conducted. Exceptions would be locations farther inland with warmer temperatures, or sites with saline irrigation water that would require a greater leaching fraction to maintain yields. Additional study is recommended for those areass.

Relatively high water use in some commercial operations may be due to use of sprinklers for the entire season, which usually results in more water applied than with drip [28,34,36]. However, use of drip during the post-establishment period has become the predominant method of irrigation on the central coast over the past ten years and represented approximately 70% of Monterey County vegetable-farm area as of 2019 [35].

Water use reported by commercial romaine growers suggests that management could be improved. Many operators still operate their drip systems using practices employed for sprinklers or furrow, such as irrigating infrequently and for long periods. During these field trials the crop was drip irrigated 11 to 12 times during the 35 to 40-day post-establishment phase. In contrast, most commercial lettuce fields are drip irrigated only 6 or 7 times during the same period. A prior study [37] in the California’s San Joaquin Valley (USA) observed lower yield in autumn-planted lettuce irrigated once per week compared to twice weekly drip irrigations. To compensate for the longer intervals between irrigations, growers tend to apply extra water per event to fully saturate the soil. Some growers water less frequently to reduce labor costs associated with irrigation system operation. Growers may also allow soils to dry out to accommodate tractor-mounted spray operations, a practice that can serve to lengthen the irrigation interval.

5. Conclusions

Evapotranspiration based irrigation trials were performed on romaine lettuce in the Salinas Valley during 2015 and 2016. The CropManage decision-support application estimated crop water requirement based primarily on ET replacement (Equation (5)), and served as a basis for irrigation scheduling across treatments. Results suggest that irrigation at 100% of the crop water requirement was adequate to produce commercially viable yields of carton and cored product at the study site. Irrigation at 150% of the water requirement did not affect yield, while yield penalties were associated with lower applied water levels (50%, 75% of water requirement). The 100% treatment had the highest water use efficiency. Nitrogen recovery efficiencies of the 100% and 150% treatments were not significantly different and were above the 50% and 75% treatments. Crop water requirement represented by the 100% treatment was in the range of 185–247 mm, which is approximately 35–50% below the typical water application for drip-irrigated leaf lettuce on the central coast according to UCANR [28] and direct grower reports. Such improvements in irrigation practice have the potential to maintain central coast agricultural production by helping to preserve groundwater levels and associated water quality. Further monitoring of commercial vegetable fields in the region, to include collection of ET data by ground-based [12] or satellite-based methods [38], may serve to further enhance CM model performance and user acceptance.

Author Contributions

Conceptualization, M.D.C., L.F.J. and S.D.B.; Methodology, M.D.C., L.F.J. and S.D.B.; Software, M.D.C.; Validation, M.D.C. and L.F.J.; Formal Analysis, M.D.C. and L.F.J.; Investigation, M.D.C., L.F.J. and S.D.B.; Resources, M.D.C., L.F.J. and S.D.B.; Data Curation, M.D.C. and L.F.J.; Writing—Original Draft Preparation, M.D.C.; Writing—Review and Editing, L.F.J. and S.D.B.; Visualization, M.D.C.; Supervision, M.D.C., L.F.J. and S.D.B.; Project Administration, L.F.J.; Funding Acquisition, L.F.J. All authors have read and agreed to the published version of the manuscript.

Funding

This project was supported by the Specialty Crop Block Grant Program at the U.S. Department of Agriculture (USDA) through grant 14-SCBGP-CA-0006. Its contents are solely the responsibility of the authors and do not necessarily represent the official views of the USDA.

Data Availability Statement

Data are available at UC Cooperative Extension, 1432 Abbott St., Salinas CA, 93901 (USA).

Acknowledgments

The authors are grateful to Tom Lockhart, Isabel Zaragoza, Laura Murphy, Ivy Lurz, Michael Hang, Ashley Quackenbush, David Lara, Gerry Ochoa, Armando Lopez Tayum, and Valeriano Hernandez for fieldwork support. Richard Smith contributed guidance on nutrient management. Forrest Melton assisted with project conceptualization and staff management. Plant tissue analysis was performed by the UC Davis Analytical Lab. Donations in kind were provided by Fresh Express, Sakata, and Wilbur-Ellis.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Shock, C.; Pereira, A.; Hanson, B.; Cahn, M. Vegetable Irrigation. In Irrigation of Agricultural Crops, 2nd ed.; Lascano, R., Sojka, R., Eds.; American Society of Agronomy: Madison, WI, USA, 2007; pp. 535–604. [Google Scholar]

- California Department of Water Resources. Sustainable Groundwater Management Act (SGMA). Available online: https://water.ca.gov/programs/groundwater-management/sgma-groundwater-management (accessed on 17 August 2022).

- Harter, T.; Lund, J.R. Addressing Nitrate in California’s Drinking Water with a Focus on Tulare Lake Basin and Salinas Valley Groundwater; Report for the State Water Resources Control Board Report to the Legislature; Center for Watershed Sciences, University of California: Davis, CA, USA, 2012; Available online: https://ucanr.edu/sites/groundwaternitrate/ (accessed on 17 August 2022).

- Central Coast Regional Water Quality Control Board. General Waste Discharge Requirements for Discharges from Irrigated Lands. Attachment A: Findings. 2021. Available online: https://www.waterboards.ca.gov/centralcoast/water_issues/programs/ilp/docs/ag_order4/2021/ao4_att_a.pdf (accessed on 17 August 2022).

- Smith, R.; Cahn, M.; Hartz, T.; Love, P.; Farrara, B. Nitrogen dynamics of cole crop production: Implications for fertility management and environmental protection. HortSciences 2016, 51, 1586–1591. [Google Scholar] [CrossRef]

- Cahn, M.D. (U.C. Cooperative Extension). Unpublished data.

- Bozkurt, S.; Mansuroglu, G.; Kara, M.; Onder, S. Responses of lettuce to irrigation levels and nitrogen forms. Afr. J. Agric. Res. 2009, 4, 1171–1177. [Google Scholar]

- Karam, F.; Mounzer, O.; Sarkis, F.; Lahoud, R. Yield and nitrogen recovery of lettuce under different irrigation regimes. J. Appl. Hort. 2002, 4, 70–76. [Google Scholar] [CrossRef]

- Michelon, N.; Pennisi, G.; Myint, N.; Orsini, F.; Gianquinto, G. Strategies for improved water use efficiency (WUE) of field-grown lettuce (Lactuca sativa L.) under a semi-arid climate. Agronomy 2020, 10, 668. [Google Scholar] [CrossRef]

- Sanchez, C. Response of lettuce to water and nitrogen on sand and the potential for leaching of nitrate-N. HortScience 2000, 35, 73–77. [Google Scholar] [CrossRef]

- Gallardo, M.; Jackson, L.; Schulbach, K.; Snyder, R.; Thompson, R.; Wyland, L. Production and water use in lettuces under variable water supply. Irrig. Sci. 1996, 16, 125–137. [Google Scholar] [CrossRef]

- Dhungel, R.; Anderson, R.; French, A.; Saber, M.; Sanchez, C.; Scudiero, E. Assessing evapotranspiration in a lettuce crop with a two-source energy balance model. Irrig. Sci. 2022. [Google Scholar] [CrossRef]

- Temesgen, B.; Eching, S.; Davidoff, B.; Frame, K. Comparison of some reference evapotranspiration equations for California. J. Irrig. Drain. Eng. 2005, 131, 73–84. [Google Scholar] [CrossRef]

- Hart, Q.; Brugnach, M.; Temesgen, B.; Rueda, C.; Ustin, S.; Frame, K. Daily reference evapotranspiration for California using satellite imagery and weather station measurement interpolation. Civ. Engrg. Environ. Syst. 2009, 26, 19–33. [Google Scholar] [CrossRef]

- Ventura, F.; Faber, B.; Bali, K.; Snyder, R.; Spano, D.; Duce, P.; Schulbach, K. Model for estimating evaporation and transpiration from row crops. J. Irrig. Drain. Engrg. 2001, 127, 339–345. [Google Scholar] [CrossRef]

- Snyder, R.; Geng, S.; Orang, M.; Sarreshteh, S. Calculation and simulation of evapotranspiration of applied water. J. Integr. Agric. 2012, 11, 489–501. [Google Scholar] [CrossRef]

- Miras-Avalos, J.; Rubio-Asensio, J.; Ramirez-Cuesta, J.; Maestre-Valero, J.; Intrigliolo, D. Irrigation-Advisor—A decision support system for irrigation of vegetable crops. Water 2019, 11, 2245. [Google Scholar] [CrossRef]

- Gallardo, M.; Elia, A.; Thompson, R. Decision support systems and models for aiding irrigation and nutrient management of vegetable crops. Agric. Water Manag. 2020, 240, 106209. [Google Scholar] [CrossRef]

- Zinkernagel, J.; Maestre-Valero, J.; Sereste, S.; Intrigliolo, D. New technologies and practical approaches to improve irrigation management of open field vegetable crops. Agric. Water Manag. 2020, 242, 106404. [Google Scholar] [CrossRef]

- Cahn, M.; Smith, R.; Hartz, T.; Farrara, B.; Johnson, L.; Melton, F. Irrigation and nitrogen management decision support tool for cool season vegetables and berries. In Proceedings of the US Committee on Irrigation and Drainage, Water Management Conference, Sacramento, CA, USA, 4–7 March 2014. [Google Scholar]

- Cahn, M.; Johnson, L. New approaches to irrigation scheduling of vegetables. Special issue: Refining irrigation strategies in horticultural production. Horticulturae 2017, 3, 28. [Google Scholar] [CrossRef]

- Johnson, L.; Cahn, M.; Martin, F.; Melton, F.; Benzen, S.; Farrara, B.; Post, K. Evapotranspiration-based irrigation scheduling of lettuce and broccoli. HortSciences 2016, 51, 935–940. [Google Scholar] [CrossRef]

- Monterey County Agricultural Commission. Monterey County 2020 Crop Report. Available online: https://www.co.monterey.ca.us/home/showpublisheddocument/103876 (accessed on 17 August 2022).

- California Irrigation Management Information System. Available online: https://cimis.water.ca.gov/ (accessed on 17 August 2022).

- Breschini, S.; Hartz, T. Presidedress soil nitrate testing reduces nitrogen fertilizer use and nitrate leaching hazard in lettuce production. HortSciences 2002, 37, 1061–1064. [Google Scholar] [CrossRef]

- Gallardo, M.; Snyder, R.; Schulbach, K.; Jackson, L. Crop growth and water use model for lettuce. J. Irrig. Drain. Eng. 1996, 122, 354–359. [Google Scholar] [CrossRef]

- Bryla, D.; Trout, T.; Ayars, J. Weighing lysimeters for developing crop coefficients and efficient practices for vegetable crops. HortSciences 2010, 45, 1597–1604. [Google Scholar] [CrossRef]

- Smith, R.; Cahn, M.; Daugovish, O.; Koike, S.; Natwick, E.; Smith, H.; Subbarao, K.; Takele, E.; Turini, T.; Leaf lettuce production in California. UC Agricultural and Natural Resources, Publication No. 7216, 2011. Available online: https://anrcatalog.ucanr.edu/pdf/7216.pdf (accessed on 17 August 2022).

- Sammis, T. Comparison of sprinkler, trickle, subsurface, and furrow irrigation methods for row crops. Agron. J. 1980, 72, 701–704. [Google Scholar] [CrossRef]

- Thompson, T.; Doerge, T. Nitrogen and water rates for subsurface trickle-irrigated romaine lettuce. HortSciences 1995, 30, 1233–1237. [Google Scholar] [CrossRef]

- Kuslu, Y.; Dursun, A.; Sahin, U.; Kiziloglu, F.; Turan, M. Effect of deficit irrigation on curly lettuce grown under semiarid conditions. Span. J. Agric. Res. 2008, 6, 714–719. [Google Scholar] [CrossRef]

- Russo, D. Lettuce yield-irrigation water quality and quantity relationships in a gypsiferous desert soil. Agron. J. 1987, 79, 8–14. [Google Scholar] [CrossRef]

- Capra, A.; Consoli, S.; Russo, A.; Scicoloni, B. Intregrated agro-economic approach to deficit irrigation on lettuce crops. J. Irrig. Drain. Eng. 2008, 134, 437–445. [Google Scholar] [CrossRef]

- Sutton, B.; Merit, N. Maintenance of lettuce root zone at field capacity give best yields with drip irrigation. Sci. Hortic. 1993, 56, 1–11. [Google Scholar] [CrossRef]

- Monterey County Water Resources Agency. Monterey County Groundwater Extraction Summary Report. Available online: https://www.co.monterey.ca.us/home/showpublisheddocument/105304/637677507531170000 (accessed on 17 August 2022).

- Hanson, B.; Schwankl, L.; Schulbach, K.; Pettygrove, G. A comparison of furrow, surface drip, and subsurface drip irrigation on lettuce yield and applied water. Agric. Water Manag. 1997, 33, 139–157. [Google Scholar] [CrossRef]

- Hanson, B.; May, D.; Schwankl, L. Effect of irrigation frequency on subsurface drip irrigated vegetables. HortTechnology 2003, 13, 115–120. [Google Scholar] [CrossRef]

- Melton, F.; Huntington, J.; Grimm, R.; Herring, J.; Hall, M.; Rollison, D.; Erickson, T.; Allen, R.; Anderson, M.; Fisher, J.; et al. OpenET: Filling a critical data gap in water management for the western United States. J. Am. Water Resour. Assn. 2021. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).