Abstract

One suitable solution to achieve sustainable development goals (SDGs) is to utilize methane fermentation residue obtained from food waste. However, methane fermentation residue compost is often difficult to use due to its inhibitory properties and pungent smell. To evaluate chemical parameters and plant growth, we examined the use of methane-fermented food waste residue compost (FWM), three types of animal manure, namely, horse manure (HM), cow manure (CWM), and chicken manure (CKM). Our results revealed that mixing food waste compost with cow and horse manure reduced the inhibition of Komatsuna germination, however, chicken manure blending limited inhibition reduction. The improvement of GI in the combination of FWM and animal manure was obtained at a ratio 1:4 with an improvement in GI of 20.8%, 16.8%, and 3.8% for combination FWM + HM, FWM + CWM, and FWM + CKM, respectively. The ratio of the combination of FWM + HM could be increased to a ratio of 2:3 with an improvement of 14.7%. Additionally, for Komatsuna growth, FWM with cow and horse manure mixer considerably enhanced plant growth and yield. Furthermore, the combination of FWM + HM and FWM + CWM could improve the ratio of NUE compost/NUE FWM with the values being 12.0 and 11.1, respectively. Therefore, combining FWM with CWM and HM increases the utility value of methane fermentation residues obtained from food waste as compost for maintaining soil fertility, while reducing the use of chemical fertilizer.

1. Introduction

Improving soils for better crops is one of the most practical approaches to enhance sustainable agriculture through soil management. As we confront a future of peak oil, climate change, and depleted freshwater resources, restoring soil health is more imperative than ever [1]. Excessive use of nitrogen in planetary bio ecology, flow, and human health requires us to pay attention to the agricultural sector to reduce the use of chemicals continuously or reduce them periodically, replacing them with the use of natural materials, such as the use of organic materials. However, the use of organic materials as a substitute for fertilizers had several setbacks, necessitating various innovations to improve it and see if it could be more perfect. This is observed from various kinds of technological advances that develop products still considered impossible to do, one of which is the utilization of residual waste for both energy material and organic fertilizer.

Considering that 30% of food produced globally is wasted [2] and that food production is one of the main activities causing environmental damage [3]. Currently, the use of methane fermentation residue is a solution proposed by developed countries. Methane fermentation residue derived from food waste (FWM) will be an appropriate solution to achieve the sustainable development goals (SDGs) for soil health preservation by utilizing this residue as organic fertilizer.

Methane is a biogas that can be converted into electricity. Anaerobic digestion primarily degrades food waste into energy. Raw material characteristics, including 70% moisture content, the energy content of 1500–3000 btu/lb., and density of 2000 pounds per cubic yard, reactor design, and operating conditions play a major role in gas bioproduction and anaerobic digestion processes [4]. Food waste treatment and conversion to biogas are performed separately. Anaerobic digestion is a two-phase process in which microorganisms break down biodegradable materials in the absence of oxygen [4,5]. Commercial food waste is a relatively high-quality raw material available for landfill supplies to biological treatment. Currently, the use of FWM has received little attention from farmers, probably because FWM obtained from food scraps still has several shortcomings, one of which is the high ammonia content, resulting in a less desirable fertilizer odor [6].

Methane fermentation residue compost is often hard to use due to its inhibitor and considerable smell. However, if those are improved, FWM could gain traction among farmers. Those composts would also be of sufficient quality, contributing to soil health, increasing the production of plants that have good quality nutrients, and are environmentally friendly to develop the farm-to-table recycling system. Therefore, this study evaluates FWM characteristics that directly use methane anaerobic digestion residue without the decomposition process, investigates its potential to compare with cow manure, chicken manure, and horse manure, and the mixing of FWM with animal manure to improve compost quality.

2. Materials and Methods

2.1. Site Description and Experimental Design

The FWM fertilization test on Komatsuna was conducted from April–July 2021 at the International Field Agricultural Center, Faculty of Agriculture, Ibaraki University. The experiment consisted of two parts. The first part was the evaluation of FWM characteristics on Komatsuna germination, and the second part was improving FWM for Komatsuna production. The evaluation of FWM characteristics was conducted in the laboratory using a randomized complete design with three replications. The treatment consists of the combination of FWM extract with animal manure extracts, such as horse manure (HM), cow manure (CWM), and chicken manure (CKM) with five different ratios, namely, 0:5 (0% of FWM and 100% of animal manure), 1:4 (20% of FWM and 80% of animal manure), 2:3 (40% of FWM and 60% of animal manure), 3:2 (60% of FWM and 40% of animal manure), 4:1 (80% of FWM and 20% of animal manure), 5:0 (100% of FWM and 0% of animal manure), and control (CT, distilled water).

The FWM improvement for Komatsuna was performed in the greenhouse pot experiment. The experiment was conducted using a split-plot randomized complete block design with two treatment factors in three replications. The first factor was the compost dose that consists of 25 g pot−1, 50 g pot−1, and 100 g pot−1 and the second factor was the compost type that consists of FWM, HM, CWM, CKM, and the combinations of FWM with HM (FWM + HM, 1:1), FWM with CWM (FWM + CWM, 1:1), FWM with CKM (FWM + CKM, 1:1), and control (CT, no compost addition).

2.2. Compost Material and Procedure

Hitachi Cement Industry gathered garbage (food waste) from residents and markets daily for methane gas fermentation (MGF) or Biogas plant at Ibaraki Prefecture, Japan (36°07′06.9″ N 140°12′56.4″ E). Before being used in the biogas plant, the garbage was screened to remove unnecessary materials, such as plastic bottles, metals, and glass. Following the screening process, the garbage materials were shredded into small particles and then the organic matter was added to fermenter tanks containing methanogenic bacteria.

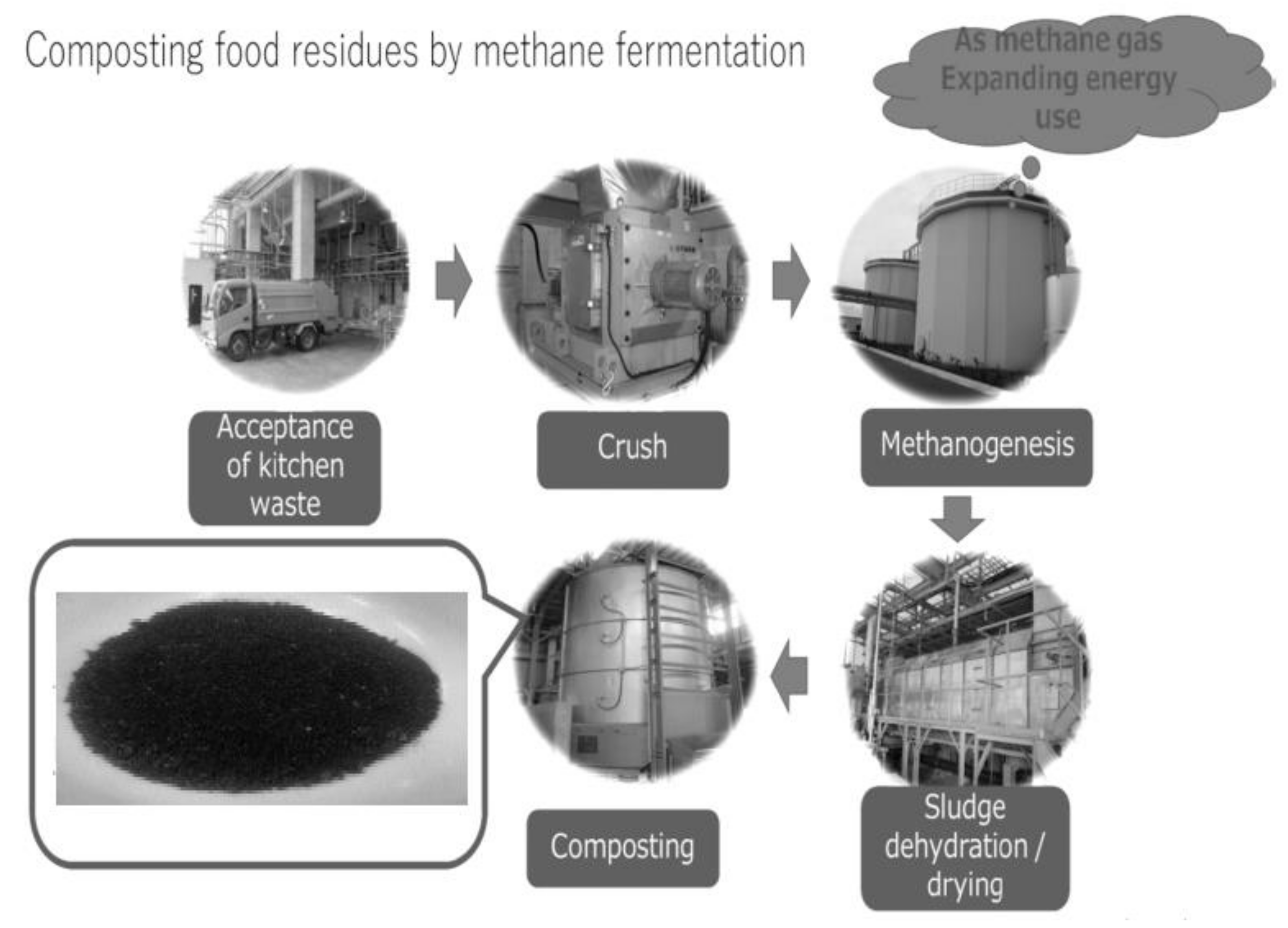

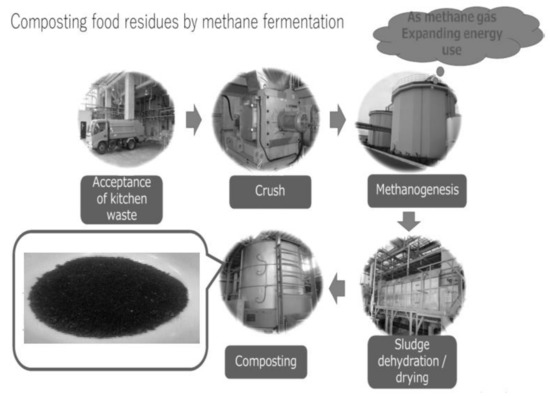

The methane gas (biogas) was generated by burning the garbage in the cement plants. The sludge was dehydrated and dewatered after methane gas fermentation, as shown in Figure 1. For the drying process, steam was used to dry compost, after which the compost was suitable for plant application [7].

Figure 1.

The production process of methane fermentation residues compost and biogas from local residence garbage. Methane fermentation residue component: total nitrogen 5.7%, phosphorus 2.2%, and total amount of potash 0.6% (Quoted from Hitachi Cement HP, 2016).

Animal manure used in this study consisted of HM, CWM, and CKM in solid form. This animal manure was obtained from the commercial market with the nutrient content described in Table 1. Then, this animal manure was mixed with FWM according to their respective treatments.

Table 1.

The nutrient content in the different manure.

2.3. Evaluation of FWM Characteristics on Komatsuna Germination

A Komatsuna germination test was performed using hot water extracts of FWM mixed with animal manure, such as horse manure (HM), cow manure (CWM), and chicken manure (CKM), with five different ratios, namely, 0:5, 1:4, 2:3, 3:2, 4:1, and 5:0. A total of 20 g of each fertilizer (FWM, HM, CWM, and CKM) was weighed and placed in a 200 mL volumetric flask container. Following this, 200 mL hot water was added and stirred for half an hour. Filtration was performed using a suction pump vacuum, and the extraction was placed in the 50 mL Corning centrist container. Then, the extract solution was refrigerated. The pH and EC were measured using a handheld pH and EC meter immediately. The pH was measured using a personal pH/oxidation–reduction potential meter (model PH72-S2.01; Yokogawa, Japan). The EC was measured using the B-173 conductivity meter (Horiba, Japan).

The Komatsuna seed was planted in a Petri dish with 50 seeds, and each Petri dish received a liquid extract compost of up to 2 mL at filter paper substrate. For the control treatment, the Komatsuna seed was planted in distilled water at the filter paper substrate. The Komatsuna seed was cultivated in an incubator at 23 °C. The germination percentage and the radicle length were measured two days after planting. The germination percentage was calculated based on the number of seeds that germinated and the total number of seeds with the following formula:

We also calculated the germination index according to [6] with the following formula:

We also analyzed the improvement of germination index in each treatment based on the GI percentage different between the combination FWM and animal manure with the single FWM.

2.4. FWM Improvement for Komatsuna Production

2.4.1. Komatsuna Cultivation Test

Komatsuna cultivation tests were conducted at a greenhouse in the compost media containing FWM, HM, CWM, CKM, a mixture of FWM and animal manure compost in different doses, and CT. The cultivation test was conducted for one month in a Wagner pot (17 cm in diameter and 20 cm in height) with kousitu kanumatuti soil (medium and large granules) soil as much as 4.3 kg/pot.

Before seed sowing, the planting media was prepared as the treatment and placed in each pot, with five planting holes with three seeds in each hole. The Komatsuna was ready for harvesting after one month. Harvesting was performed by cutting the rootstock of vegetables and then weighing the plant base, after that it was oven-dried for three days at 30 °C, and then the oven-dried plant base was weighed. The Komatsuna yield was calculated based on the fresh and dry yield of Komatsuna per pot.

2.4.2. Carbon and Nitrogen Analysis of Komatsuna

The carbon (C) and nitrogen (N) content of Komatsuna were measured using a CN analyzer (JM 3000, J-science lab, Japan) with dry combustible techniques. About 100–200 mg of ground Komatsuna was inputted in the board before analysis. Following the completion of combustion, the total carbon (TC) and total nitrogen (TN) were obtained. Then, nitrogen (N) uptake, and nitrogen use efficiency (NUE) were calculated.

N uptake was calculated using the following formula, N uptake = N (%) × dried biomass content of Komatsuna. Then, NUE was calculated as the ratio of Komatsuna yield to the applied N, with the following formula, NUE = ; Yield a = yield in certain compost, Yield 0 = yield in the control treatment, Input N = the amount of nitrogen input on the plant.

2.4.3. Data Analysis

The data were analyzed using Stat View for Windows, version 5 (SAS Institute, Cary, NC, USA). Analysis of variance (ANOVA) followed by Tukey–Kramer significant test at 0.05 significance level was performed to analyze the differences of germination and radicle-length of the Komatsuna seeds. The chemical properties and yield of Komatsuna were performed using ANOVA followed by the Tukey–Kramer significance test at 0.05 significance level.

3. Results

3.1. Evaluation of FWM Characteristics on Komatsuna Germination

3.1.1. pH and EC in the Combination of FWM and Animal Manure

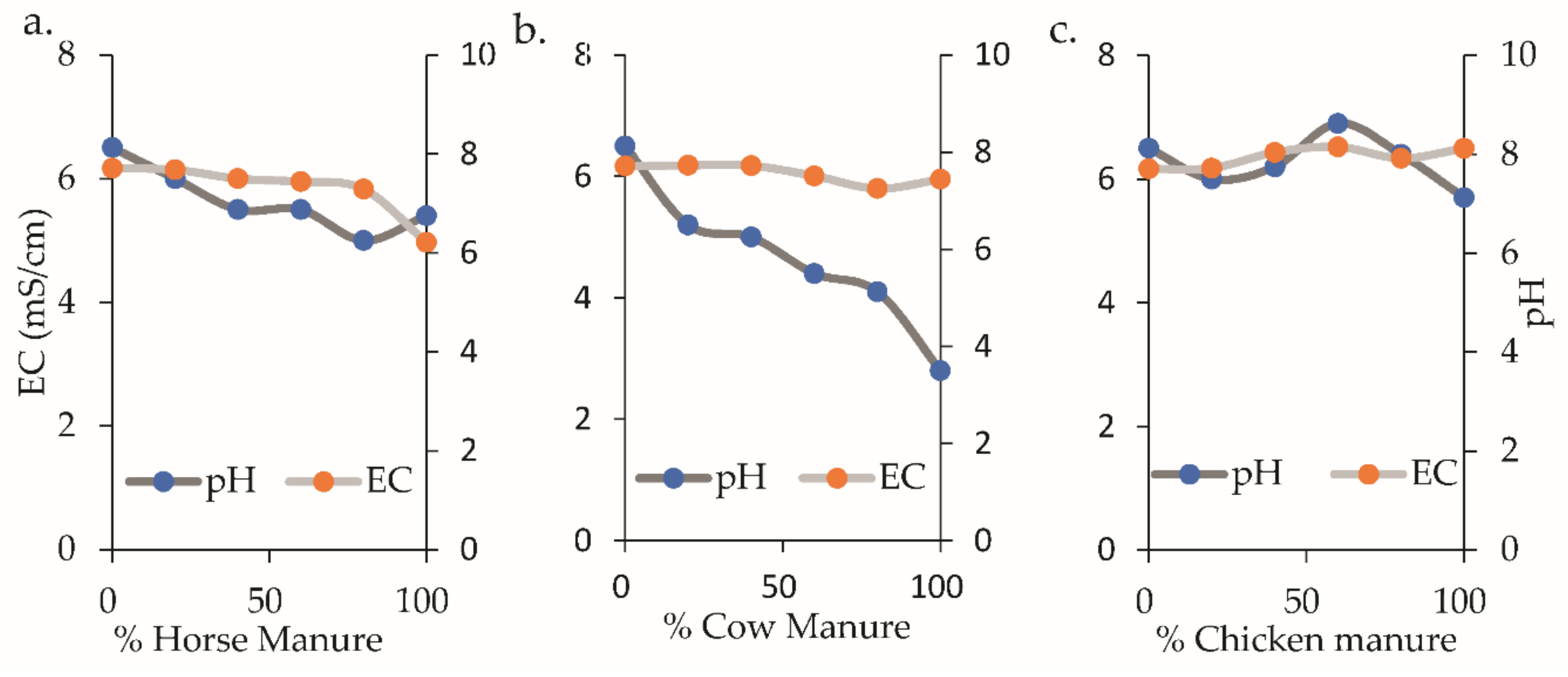

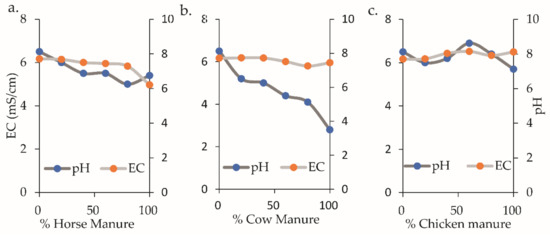

Figure 2 depicts the pH and EC in the combination of food waste compost and animal manure. In a combination of FWM and HM (Figure 2a), the use of 0% HM and 100% FWM fertilizers contained the highest pH, with a pH value of 6.5, whereas the use of 40% or more of HM in that combination shifted the pH value to the optimum for plant growth (5–5.5). The EC value in the 100% FWM also had the highest value, 7.71 mS cm−1. The addition of horse manure reduced the compost’s EC value by about 40% or more.

Figure 2.

pH and EC in the combination of food waste manure and animal manure: (a), food waste manure and horse manure; (b), food waste manure and cow manure; and (c), food waste manure, and chicken manure.

Similar to what was observed in the combination of FWM and CWM (Figure 2b), the addition of CWM to the FWM decreased the pH value. However, the addition of FWM did not affect the EC value of the compost. The EC value remained high in the range 7.7 mS cm−1. Conversely, the combination of FWM with CKM produced a different outcome (Figure 2c). The addition of CKM did not affect the changes in pH and EC, where changes occurred only in the addition of 20% and 40% CKM, increasing the pH and EC value. Based on this result, the addition of animal manure maintained the pH value in the optimum range for plant growth, but the addition of animal manure did not affect the EC value.

3.1.2. The Germination, Radicle Length, and Germination Index of KOMATSUNA

Based on Table 2, the combination ratio of FWM and animal manure influenced the germination percentage, radicle length, and GI of Komatsuna seeds. A single animal manure (HM, CKM, or CWM) gave the highest result in germination percentage, radicle length, and GI of Komatsuna seed that was not significantly different with the CT. Meanwhile, in the combination of FWM and animal manure, the best ratio for germination percentage, radicle length, and GI was found at 1:4; however, it can be increased to a ratio of 2:3.

Table 2.

Germination, radicle-length, and germination index of komatsuna affected by different compost ratios.

The improvement in GI of the combination of FWM and animal manure was obtained at a ratio 1:4 with an improvement in GI of 20.8%, 16.8%, and 3.8% for combination FWM + HM, FWM + CWM, and FWM + CKM, respectively. The ratio of combination of FWM + HM could be increased to a ratio of 2:3 with an improvement of 14.7

3.2. FWM Improvement for Komatsuna Production

3.2.1. Komatsuna Yield

There were significant differences in the Komatsuna yield under different doses and compost (Table 3). The highest yield was found in the 100 g pot−1 with the value being 90.79 g pot−1 of fresh weight.

Table 3.

Yield and nitrogen uptake of komatsuna under different doses and compost.

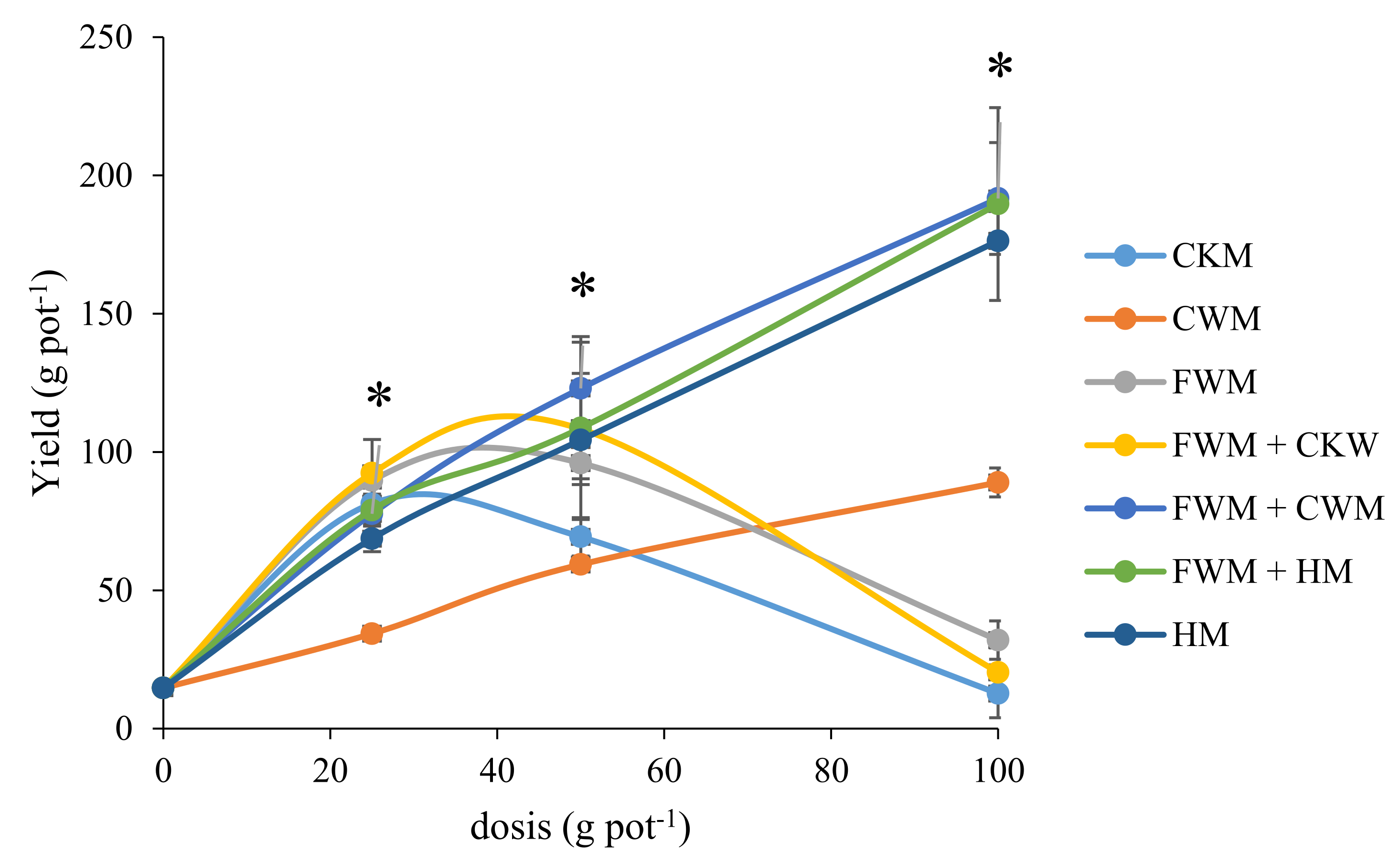

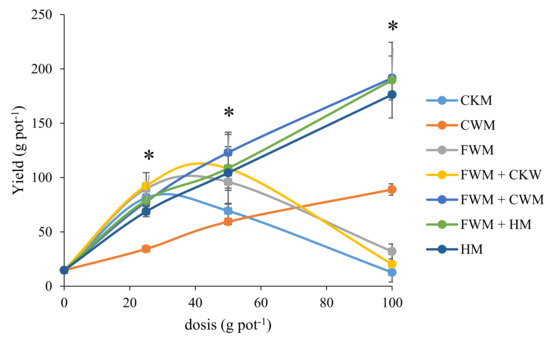

There were no differences between 100 g pot−1 and 50 g pot−1 of compost. The combination between FWM and CWM also gave the highest Komatsuna yield, with the value being 130.78 g pot−1 followed by the combination of FWM and HM with the value being 125.78 g pot−1. Furthermore, the highest fresh yield was obtained at the interaction between 100 g pot−1 of compost and FWM + CWM, FWM + HM, or HM (Figure 3).

Figure 3.

The Komatsuna yield affected by different dose rates and compost. HM = horse manure; CKM = chicken manure; CWM = cow manure; FWM = foot waste manure; FWM + HM = food waste manure compost combined with horse manure; FWM + CKM = food waste manure compost combined with chicken manure; and FWM + CWM = food waste manure compost combined with cow manure. * above the standard error indicates a significant difference at each dose rate based on Tukey–Kramer test (p < 0.05).

However, the dry weight yield of Komatsuna was not significantly different under the different compost doses, but HM was the highest value of dry weight yield. However, there was no significant difference between HM with FWM + HM and FWM + CWM. A single FWM did not give a good yield, but if FWM was combined with animal manure, it gave a good Komatsuna yield.

3.2.2. Total Carbon and Nitrogen of Komatsuna

Based on Table 4, there was a significant difference in the combination of FWM and animal manure on the TC of Komatsuna. The highest TC content was obtained at a dose of 25 g pot−1 with a value of 38.8%, while the lowest TC content was at a dose of 50 g pot−1 with 37.2% TC. The type of compost also had a significant effect on TC. The highest TC was obtained in the control with the value being 4.0%, but it was not significantly different from the application of FWM. The lowest TC was obtained in the treatment with CKM with a TC amount of 36.2%. Also, there was an interaction between dose and type of compost with a significant effect on the TC of Komatsuna.

Table 4.

Total carbon (TC) and total nitrogen (TN) ratios of komatsuna under different doses and compost.

The dose and type of compost influenced the nitrogen content of Komatsuna. The 100 g pot−1 of compost had the highest nitrogen content with the value of 4.5% compared to 50 g pot−1 and 25 g pot−1 of compost. The use of CKM had the highest N content with a value of 5.4%, but this result was not significantly different from the use of FWM. With a TN of 1.4%, the treatment in the CWM had the lowest TN content. There was also an interaction between the dose and type of compost on Komatsuna’s TN content.

3.2.3. Nitrogen Uptake of Komatsuna

There was a significant difference in N uptake of Komatsuna (Table 3). The dose of compost influenced the N uptake of Komatsuna. The highest N uptake was obtained in the 100 g pot−1. The type of compost also influenced the N uptake of Komatsuna. The highest N uptake was obtained in the combination of FWM and CWM with a value of 21.64 g pot−1. There was also an interaction between dose and compost on N uptake of Komatsuna.

3.2.4. Nitrogen Use Efficiency (NUE) of Komatsuna

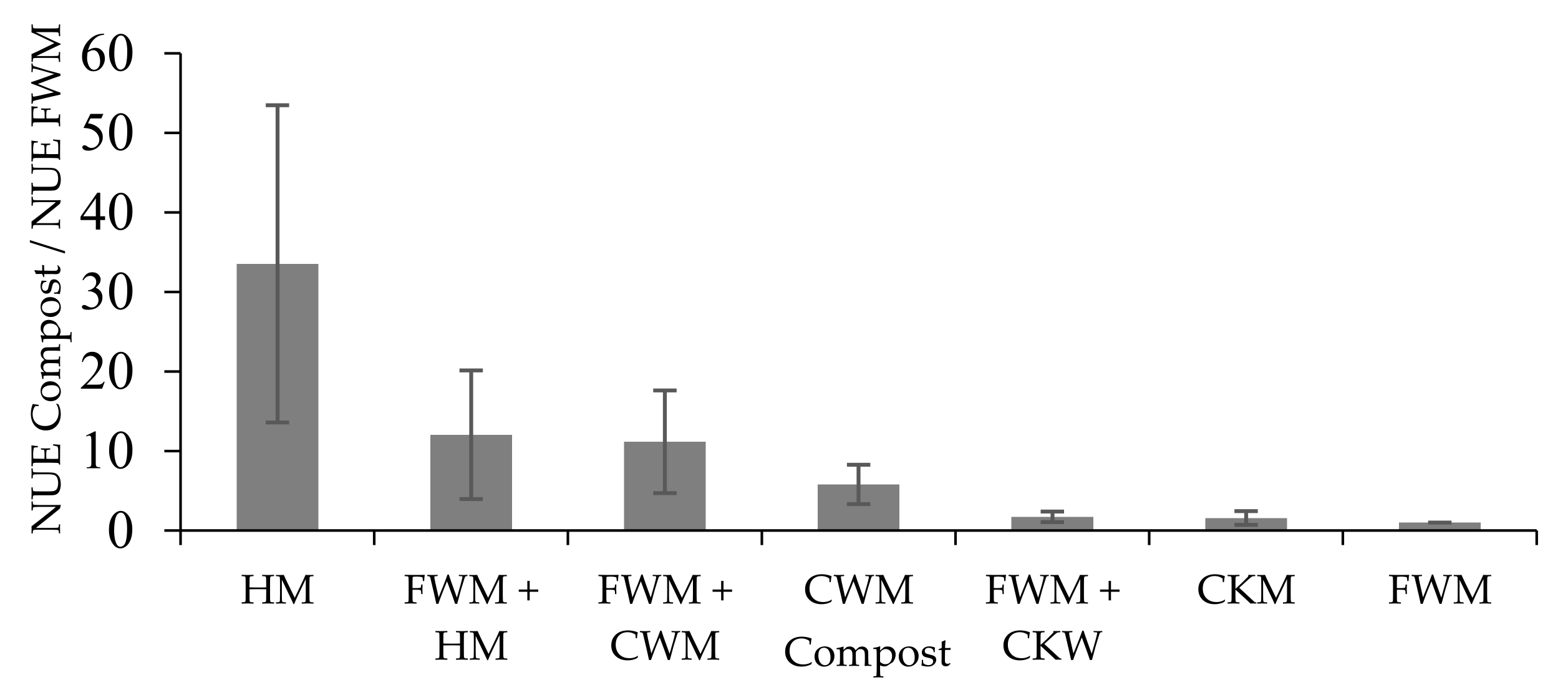

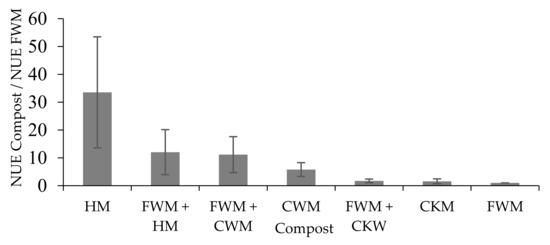

There was a significant difference in the nitrogen use efficiency of Komatsuna. The dose of compost affected the efficiency of nitrogen use in Komatsuna (Table 5). The maximum NUE was obtained at 25 g pot−1 dose of compost. The type of compost also affected the NUE of Komatsuna. The highest NUE was obtained at HM usage with a value of 186.2 and the lowest NUE was obtained at FWM usage with a value of 28.37. There was also a significant interaction between dose and compost on NUE Komatsuna. The addition of HM in the FWM resulted in the highest enhancement of FWM followed by CWM (Figure 4). Meanwhile, the CKM provided no considerable improvement to the FWM.

Table 5.

Nitrogen use efficiency (NUE) of Komatsuna under different doses and compost.

Figure 4.

NUE improvement of FWM combined with animal manure. HM = horse manure; CKM = chicken manure; CWM = cow manure; FWM = foot waste manure; FWM + HM = food waste manure compost combined with horse manure; FWM + CKM = food waste manure compost combined with chicken manure; and FWM + CWM = food waste manure compost combined with cow manure.

4. Discussion

4.1. Evaluation of FWM Characteristics on Komatsuna Germination

Compost quality, such as stability and maturity, should be assessed before compost application on land. The unstable and/or immature compost can have adverse effects on seed germination, plant growth, and soil environment due to the decreased supply of oxygen and/or available nitrogen or the presence of phytotoxic compounds [8]. Compost stability and maturity are evaluated using compost respiration and humification indices, respectively [9]. However, there exists the possibility for unexpected factors that are not considered for analysis. Furthermore, there is a lack of analytical procedures for evaluating the combined effect of toxic substances in compost. Consequently, the seed germination test attracted a lot of interest as a bioassay to overcome these limitations [10].

The seed germination index (GI) was first proposed by [11] who used cress seeds in the germination test for evaluating compost toxicity. Later, the GI is still used for the compost maturity evaluation with a newly proposed index based on a germination test using Komatsuna (Brassica rapa Var. Peruviridis) seeds [12,13]. GI is calculated using the radicle length and germination percentage of the seeds in the sample (compost extract) compared to that in the control (e.g., deionized water). GI is correlated with other biological and chemical indices for evaluating compost quality. Therefore, the seed germination test has been broadly accepted for evaluating compost quality [6]. In this study, the extract of FWM had the lowest GI. The addition of animal manure, particularly HM and CWM improves the GI of FWM. This indicates that the addition of animal manure to the FWM reduced the FWM toxicity.

The Komatsuna seed germination test has been widely employed in compost [13]. Seed germination as the critical initial stage of plant growth has its performance against seedling growth, such as susceptibility to environmental pollution and a short period without photosynthesis. The seed germination test is an effective and economical bioassay for evaluating compost potential toxicity before it is used [10]. This speculation partly supports a viewpoint that seed germination can be used to examine high-toxicity compost and radicle growth to examine low-toxicity compost [10,11]. The results of the percentage germination of Komatsuna seeds indicated that using animal manure produced by three types of compost had almost the same germination percentage as using FWM (Table 2). The germination percentage of animal manure was higher than that of FWM. This might be due to the absence of toxicity events in the animal manure, except in the CKM. Our study demonstrated that a single FWM was toxic to Komatsuna seed germination. The combination of FWM with animal manure, such as HM and CWM enhances the germination rate and the radicle length of Komatsuna seeds. Based on this result, the FWM can be mixed with animal manure in the ratio of 1:4 or 2:3. Therefore, the evaluation of compost maturity can properly rely on germination tests, which are not time-consuming [12].

Morphologically, the seed germination process consists of three phases. The first phase is imbibition, the second phase is radicle emergence, and the last phase is radicle elongation. This process takes several days, depending on the seed type and the suitable condition [14]. The major process of seed germination during the first phase is water uptake, which could be negatively affected by high compost salinity. In this study, the EC value in the combination compost remains high, this could inhibit germination. During the second phase, the low molecular weight of organic acids in compost could be the primary inhibitor of radicle emergence after testa rupture. Ammonia (NH4+–N) could inhibit radicle elongation during the third phase [10]. The FWM had the shortest radicle length compared to other animal manure in our study, indicating that the radicle elongation is controlled by compost salinity. Thus, adding animal manure to FWM could enhance the radicle elongation of the Komatsuna seed.

4.2. FWM Improvement for Komatsuna Production

In this study, we discovered that combining FWM and animal manure enhances the Komatsuna yield. This is observed in the peak of Komatsuna yield when FWM and CWM or HM is combined. The combination of FWM with animal manure improves FWM quality as shown in Figure 3. The higher the use of FWM, the lower the yield compared to the compost combination. Conversely, the combination of FWM and CKM resulted in the lowest yield of Komatsuna. In this study, the N uptake of Komatsuna in the combination of FWM and CWM or HM was higher than those in the CKM.

Compared with another compost, the application of HM resulted in the highest NUE followed by CWM. Therefore, the Komatsuna yield in the combination of FWM and HM or CWM resulted in a higher yield compared to other compost. This indicates that the performance of FWM could be improved by the combination with animal manure, particularly with HM and CWM.

The nutritional content of each animal manure is different. The age and type of food an animal consumes determine its characteristics [15]. The animal manure used in this study was influenced by the type of food given to the livestock. The urine of herbivorous, or plant-eating, livestock, such as cows and horses, significantly influences the content of compost produced. Hence, yielding good results on the quality of the compost produced. This can be seen in Figure 3, where the production of Komatsuna that was observed based on yields increased in the results of FWM combination with animal manure but reduced in the results of FWM combination with chicken manure. This might be because CKM has excess calcium (Ca), which inhibits plant growth. High Ca causes high pH, resulting in micronutrient deficiencies [16].

The combination of compost with animal manure improves the imbalance in the nutrient content of FWM. The CWM and HM were giving the best blends of animal manure in this study, as shown in Figure 4. This shows that the weakness of FWM is improved by combining it with other organic materials, particularly CWM and HM. This approach will be effective for the appropriate use of methane fermentation residue from food waste as compost.

5. Conclusions

FWM was discovered to have a growth inhibitory effect on Komatsuna germination. The germination significantly improved in the FWM mixed with animal manure at the ratio of 1:4 or 2:3. Additionally, for Komatsuna growth, FWM with cow and horse manure mixer considerably enhanced plant growth and yield. Furthermore, the combination of FWM + HM and FWM + CWM could improve the ratio of NUE compost/NUE FWM, with the value being 12.04 and 11.15, respectively. Therefore, the combination of FWM with CWM and HM increases the utility value of methane fermentation residues derived from food waste as compost for maintaining soil fertility with the reduction of chemical fertilizer use.

Author Contributions

Conceptualization, M.K., N.S., Y.S., T.I. and H.S.; methodology, M.K.; validation, M.K.; formal analysis, N.S.; writing—original draft preparation, N.S.; writing—review and editing, R.K.D.; visualization, N.S. and R.K.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the grants from Hitachi Cement Co., Ltd.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This work was supported by Hitachi Cement Co., Ltd. and Life Earth Agriculture Future Co., Ltd.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Fred, M.; Harold, V.E. Building Soil for Better Crops Sustainable Soil Management. In The Sustainable Agriculture Research and Education (SARE) Program, with Funding from the National Institute of Food and Agriculture, U.S. Department of Agriculture, 3rd ed.; University of Maryland: College Park, MD, USA; University of Vermont: Burlington, VT, USA, 2009; pp. 3–294. [Google Scholar]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; Otterdijk, V.R. Global Food Losses and Food Waste; Extent, Causes and Prevention; Swedish Institute for Food and Biotechnology (SIK) and Food and Agriculture Organization of the United Nations: Gothenburg, Sweden; Rome, Italy, 2011. [Google Scholar]

- Rockström, J.; Steffen, W.; Noone, K.; Persson, A.; Chapin, S.F.; Lambin, E.F.; Lenton, T.M.; Scheffer, M.; Folke, C.; Hans, P.K.; et al. A safe operating space for humanity. Nature 2009, 461, 447. Available online: http://tinyurl.com/boundariesblog (accessed on 27 September 2021). [CrossRef] [PubMed]

- OjikutuAbimbola, O.; Osokoya, O. Evaluation of biogas production from food waste. Int. J. Eng. Sci. (IJES) 2014, 3, 1–7. [Google Scholar]

- Oliveira, F.; Doelle, K. Anaerobic digestion of food waste to produce biogas: A comparison of bioreaction to increase methane content. J. Food Process Technol. 2015, 6, 2157–7110. [Google Scholar] [CrossRef]

- Levis, J.W.; Morton, A.B. What is the most environmentally beneficial way to treat commercial food waste? Environ. Sci. Technol. 2011, 45, 7438–7444. [Google Scholar] [CrossRef] [PubMed]

- Ismail, M.M. Appropriate Compost Management Using for Fallen Leaves and Methane Fermentation Residues. Master’s Thesis, Universitas Ibaraki, Ami City, Ibaraki Prefecture, Japan, September 2017. [Google Scholar]

- Bernal, M.P.; Alburquerque, J.A.; Moral, R. Composting of animal manures and chemical criteria for compost maturity assessment. Bioresour. Technol. 2009, 100, 5444–5453. [Google Scholar] [CrossRef] [PubMed]

- Komilis, D.; Kanellos, D.A. Modified dynamic respiration test to assess compost stability: Effect of sample size and air flowrate. Bioresour. Technol. 2012, 117, 300–309. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Liang, J.; Zeng, G.; Chen, M.; Mo, D.; Li, G.; Zhang, D. Seed germination test for toxicity evaluation of compost: Its roles, problems and prospects. Waste Manag. 2018, 71, 109–114. [Google Scholar] [CrossRef] [PubMed]

- Zucconi, F.; Monaco, A.; Debertoldi, M. Biological evaluation of compost maturity. Biocycle 1981, 22, 27–29. [Google Scholar]

- Cesaro, A.; Belgiorno, V.; Guida, M. Compost from organic solid waste: Quality assessment and Europeanregulations for its sustainable use. Resour. Conserv. Recycl. 2015, 94, 72–79. [Google Scholar] [CrossRef]

- Hase, T.; Kawamura, K. Evaluating compost maturity with a newly proposed index based on a germination test using Komatsuna (Brassica rapa Var. Peruviridis) seeds. J. Mater. Cycles Waste Manag. 2012, 14, 220–227. [Google Scholar] [CrossRef]

- Bewley, J.D. Seed germination and dormancy. Sci. Hortic. 2019, 82, 415–420. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- dan La Sarido, A. Uji empat jenis pupuk kandang terhadap pertumbuhan dan hasil tanaman cabai keriting (Capsicum annum L.). J. Agrifor 2013, 12, 22–29. [Google Scholar]

- Barbara, J.B. Nutrient deficiency symptoms. Mercer City. Hortic. 2010, 10, 1–8. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).