Abstract

Induction in pineapples requires the targeted delivery of specific chemical solutions into the plant’s central core to enable batch management, a task currently reliant on manual operation. This study addressed this challenge by analyzing the physical characteristics of pineapple plants and establishing a perception-based mathematical model for core position localization. An integrated hardware–software system was developed, complemented by a human–machine interface for real-time operational monitoring. Comprehensive experiments were conducted to evaluate the spraying accuracy, nozzle response time, and prototype performance. The results demonstrate that the actuation system—comprising solenoid valves, pumps, and flowmeters—achieved an average spraying error of 2.72%. The average nozzle opening/closing time was 0.111 s; with a standard operating speed of 0.5 m/s, a delay compensation distance of 55.5 mm was implemented. In human–machine comparative trials, the automated system outperformed manual spraying in both efficiency and stability, with average errors of 7.1% and 6.4%, respectively. The system reduced chemical usage by over 67,500 mL per hectare while maintaining a miss-spray rate of 5–6%. Both two-tailed tests revealed extremely significant differences (p < 0.001). These findings confirm that the developed solution meets the operational requirements for pineapple floral induction, offering significant improvements in precision and resource efficiency.

1. Introduction

As a vital tropical economic crop, pineapple ranks fourth globally in cultivation area and sixth in production volume [1], serving significant roles in fresh consumption and processing industries while being renowned as the “King of Canned Fruits” [2,3]. The Food and Agriculture Organization of the United Nations (FAO) 2023 statistics indicate that global pineapple production reached approximately 30 million metric tons in 2022, with China contributing 2.003 million metric tons (7% of global output) [4,5]. Despite China’s leading production scale, field management technologies remain relatively underdeveloped. Pineapple growth is particularly susceptible to environmental factors and cultivar variations, often resulting in non-uniform natural flowering that compromises fruit quality and yield consistency, ultimately causing substantial economic losses [6,7,8]. Therefore, during the pineapple seedling stage, the application of appropriate boron levels proves crucial as it significantly enhances D-leaf development, improves stress resistance, and contributes to flowering induction [9,10].

When pineapple plants reach specific growth phases, the application of plant growth regulators, such as ethephon and gibberellins, into the central whorl becomes necessary for synchronized flowering [11,12]. Traditional pineapple flower induction relies entirely on manual chemical spraying, which involves intensive labor input. Implementing mechanized approaches could effectively alleviate workers’ physical strain while reducing production costs. However, traditional pineapple flower forcing-spraying relies very heavily on manual labor, which has great labor intensity, in order to reduce the labor volume of workers and reduce production costs. There are many studies on the spraying machine abroad, and the technology is relatively advanced, but it is primarily used for bulk crops, orchards and facility agriculture; there are few reports on the research into pineapple flower forcing-spraying. Chinese scholars have made some progress in this regard. For example, Cai, Y.B. [13] disclosed an auxiliary artificial pineapple flower-inducing device, which can slowly spray the flower-inducing liquid into the heart of pineapple plants by operating the push rod button of the guide valve switch of the liquid storage tank and the push rod button of the valve cover at the outlet of the quantitative cylinder, respectively, which can conveniently and accurately complete the flower inducing process of pineapple; Zhang, R.H. et al. [14] developed a self-propelled pineapple flower forcing machine with a high gap. The whole machine is controlled by a Programmable Logic Controller (PLC). Its spraying system adapts to the row spacing of pineapple planting by adjusting the horizontal and vertical distances and sprays in combination with setting the spraying interval time. However, the machine is only suitable for structured pineapple planting areas and cannot automatically adapt to the change in row spacing, so the nozzle distance needs to be manually adjusted; Liu, H.T. et al. [15] designed an automatic pineapple flower forcing robot and flower forcing method. Machine vision technology was used to obtain pineapple images, find the pineapple anchor basket position coordinates, and then make confidence judgments. Finally, the data were run to realize the automatic flower forcing and spraying operation. This method is easily affected by light in the natural environment, and there are also problems such as blade occlusion, which may reduce the recognition accuracy.

In another year, Zhang, R.H. et al. [16] built a hybrid network model based on the yolov4 target recognition algorithm. Under the conditions of dense and sparse pineapple plants, the recognition accuracy was 94.7% and 95.5%, respectively. The real-time recognition speed could reach 27 frames/s, and the average detection time of each image was 72 ms, which was 23% shorter than that of the conventional YOLOV4 model. To a certain extent, the balance among detection speed, recognition accuracy and model size was achieved; Wang, B.B. [17] designed a device that can be used for pineapple field spraying. During operation, the spraying gasoline engine provides power for the liquid pesticide pump, and the liquid pesticide pipeline connects the pesticide box, liquid pesticide pump and spray rod to form a liquid pesticide flow path. The spray pressure of the spray rod spray assembly is adjustable from 0.3 MPa to 1.5 MPa, which can obtain a wide range of spray volume adjustment without replacing the nozzle. It is folded in a “U” shape when not in operation. The spray rod spray operation width is 900 cm, the average operation speed is 2.0 km/h, and the operation efficiency can reach 1.67 hm2/h; Zhang, Z.J. [18] adaptively corrected the uneven illumination of the night image through the gamma function based on the HSV(Hue, Saturation, Value) color space, and then used the yolov8 target detection algorithm to realize the rapid recognition of pineapple flower core, and obtained the predicted coordinates of the flower core Then, the depth estimation of the prediction frame is realized based on the depth information of the rgbd image. Finally, the spatial coordinates of the flower core are obtained through coordinate transformation. The accuracy of flower core recognition is 94.9%; Pan, K.Y. [19] proposed a yolo-cmst and intermediate domain transform Improved Dense Trajectory (IDT) algorithm model, which can adapt to pineapple images under different lighting conditions and ensure that the position of the pineapple core is consistent with the original image. The algorithm model is deployed to the self-propelled pineapple flower sprayer. The experimental results show that the algorithm has the characteristics of fast response, low cost, high spraying reliability and efficiency, and the accuracy is improved by more than 7% compared with other YOLO algorithms.

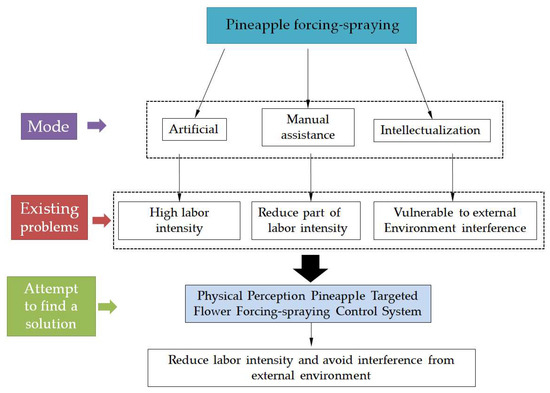

Most of the above research on pineapple automatic and intelligent flower-inducing and spraying technology is still in the laboratory stage or still needs manual assistance. However, the pineapple flower-inducing robot developed by Zhang [20] can carry out pineapple flower-inducing and spraying operations in the actual scene, but its flower core recognition accuracy is obtained in the night environment, and the accuracy is unknown under the interference of natural light in the daytime. In this regard, this paper uses the physical perception method, skillfully uses the pineapple plant morphology, and designs a perception mechanism combined with the control system to realize the function of an automatic targeted flower forcing and spraying under the unstructured but suitable mechanized pineapple planting mode in the field scene. The dosage is adjusted by controlling the time, which provides a certain reference for the research of automatic and intelligent flower inducement and spraying in pineapple field management, as shown in Figure 1.

Figure 1.

Schematic diagram of research ideas.

2. Methodology

2.1. Analysis of Pineapple Plant Morphology at Flowering Forcing Stage

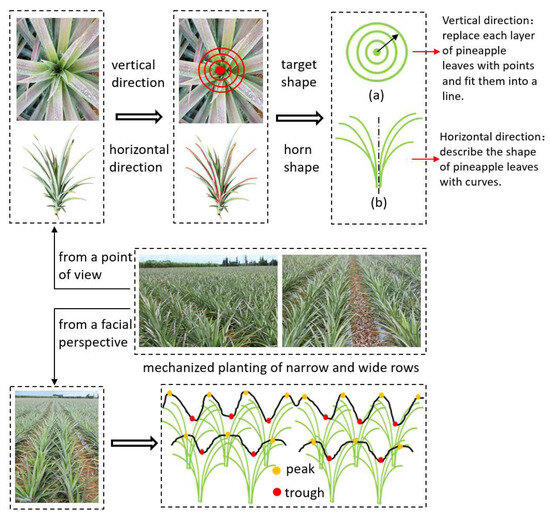

This study took “Tainong 16” (Xuwen, China) as the research object and carried out morphological analysis. The variety has narrow and long leaves, dark green leaves, leaf edge without thorns, purplish red on the middle axis of the leaf surface, with raised stripes and green edges. It generally grows to the fourth, fifth or sixth circle from inside to outside when the leaf length is more than 50 cm and the leaf width is 5–6 cm, and the flower-inducing effect is excellent [19,20,21]. The growth of plants in the pineapple field is similar, and the leaves bend and spread around. From the perspective of a single plant, the layered growth of pineapple leaves can be compared to the “target shape” from the vertical angle of the ground. The leaf tip in the horizontal direction is at the highest position, and the core is at the lowest position, similar to the “horn shape”. From the analysis of the whole row of plants, on the same horizontal plane, the whole row of pineapples circulates along the leaf tip to the core and then to the leaf tip, forming a parabola with N openings upward, with the characteristics of peak and trough, as shown in Figure 2. To sum up, we can find the regular pattern: suppose an object is used to make an appeal cycle on the whole row of pineapple plants, when it moves to the trough, we can know the position of the pineapple plant core, or we can also determine the position of the pineapple plant core by converting the change in height difference between the wave crest and wave trough.

Figure 2.

Analysis of physical characteristics of pineapple plants.

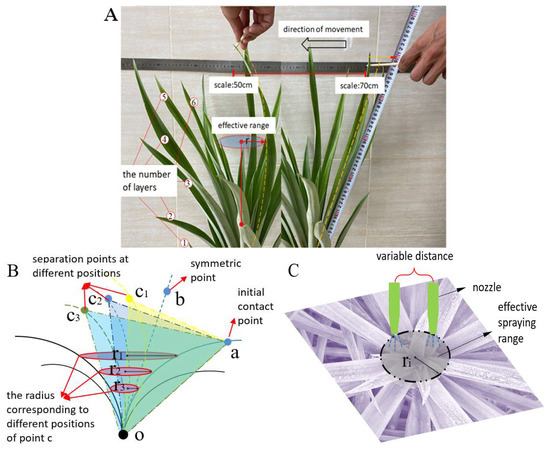

Among them, some key physical characteristic parameters of pineapple plants during the flower forcing were measured, such as the height of the pineapple plant being 45–55 cm, as shown in Figure 3A. The effective range of pineapple leaves from natural bending to reverse bending, namely the straight-line distance from point A to point C (including C1, C2, C3, etc.), as shown in Figure 3B, is 0–40 cm. The maximum effective spraying range of the medicinal solution is the circle with a radius r of 7 cm directly above the plant core, as shown in Figure 3C; the closer it is to the core position, the more accurate it is, and the more effective the utilization rate of the medicinal solution. For example, the vertical projections of points C1, C2, and C3 are all within a circle with radius r1, indicating that the medicinal solution can be sprayed into or flow into the core of the plant along the leaves.

Figure 3.

Analysis of physical characteristic parameters of pineapple plants. (A) Measurement of physical characteristics of typical pineapple plants. (B) The range of bending changes in pineapple leaves. (C) Effective range of drug spray.

2.2. Structure and Principle Design of Flower Forcing–Spraying System

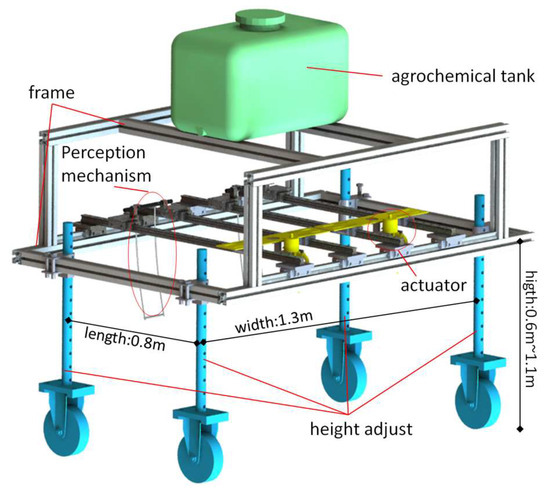

2.2.1. Overall Structure

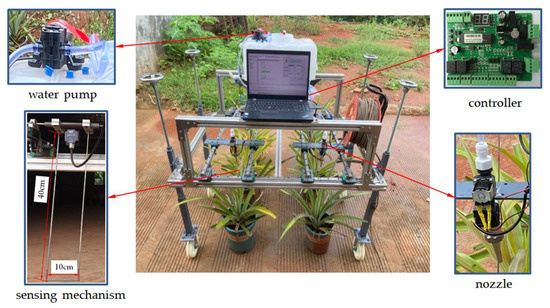

Based on the morphological analysis of pineapple plants above, a physical perception-based pineapple-targeted flower forcing and spraying system was designed. The overall structure is shown in Figure 4 and includes a frame, control unit, sensing mechanism, actuator, and pesticide box. The actuator is composed of solenoid valves, flow meters, water pumps, etc. The overall size of the machine was designed according to the existing Tainong agricultural variety’s “narrow and wide double row ridge planting” agronomic model [2,21,22]. It is divided into upper and lower layers, with a length × width of 1.3 m × 0.8 m, and a height adjustable within the range of 0.6–1.1 m for adaptation to the growth height of the pineapple during the flower forcing period. The sensing mechanism (size: length × width 40 cm × 10 cm) and solenoid valve each have two groups on the same horizontal plane in the lower layer, with the sensing mechanism in front and the solenoid valve and flow meter in the rear relative to the direction of the machine’s movement. The pesticide box, power supply, and control unit are placed at the top of the rack, and the bottom of the pesticide box is equipped with an outlet connected to a small water pump, solenoid valve, and flow meter through hoses.

Figure 4.

Schematic diagram of the structure of the flower forcing-spraying system.

2.2.2. Theoretical Analysis

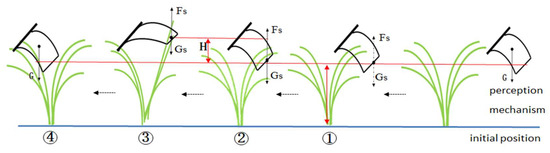

The working principle of the system is shown in Figure 5: the sensing mechanism gradually moves to the left from the initial state to state ➀, and the pineapple leaves pass through the middle of the sensing mechanism and move to state ➁, at which point the pineapple leaves come into contact with the sensing mechanism. When the acting force Fs > Gs, the sensing mechanism is forced to rotate upward by a certain angle to state ➂, and the pineapple leaves are forced to straighten. Continuing forward, due to the toughness of pineapple leaves, they will bend in the opposite direction until the sensing mechanism crosses over the pineapple leaves, and the pineapple leaves will return to their natural bending state. Under the action of gravity, even if Fs < Gs, the sensing mechanism will also return to its initial state ➃. During the movement from ➁ to ➃, the sensing mechanism will generate a height difference change. This height difference will be converted into an angle signal through an angle sensor to determine the position information of the sensing mechanism. The signal will be transmitted to the control unit to control the opening and closing time of the solenoid valve to quantitatively spray the pesticide, thus forming a physical perception-based pineapple plant-targeted flowering spraying method.

Figure 5.

Decomposition of the motion process of the perception mechanism.

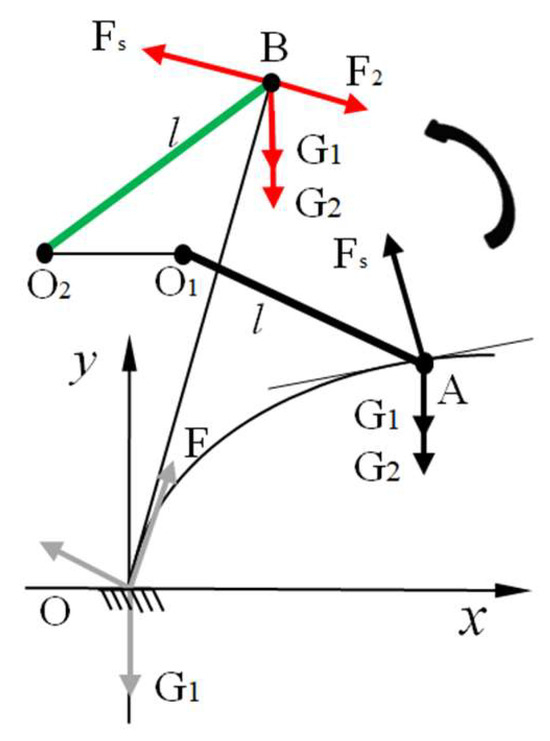

The specific analysis of the acting force Fs and gravity Gs generated during the motion of ➁ and ➂ is shown in Figure 6. Point A is the moment when the sensing mechanism first contacts the pineapple leaf, and point B is the point where the pineapple leaf is straightened. The acting force Fs is the resultant force obtained by subtracting the interaction force between the sensing mechanism (l) and the pineapple leaf, as well as the sum of their gravity forces G1 and G2, from the component force of the traction force in the x- and y-axis directions. The component force in the x-axis direction causes the pineapple leaf to move upward to point B, while the component force in the y-axis direction causes the sensing mechanism to rotate around point O1 (a fixed point at one end of the sensing mechanism). This point undergoes horizontal translational motion with the advancement of the machine. Next, the sensing mechanism performs a rotational translational compound motion relative to point O. After the sensing mechanism crosses point B, the combination of Fs causes the pineapple leaves to bend in the opposite direction, generating an anti-bending force F2, until the sensing mechanism separates from the pineapple leaves and disappears, and both return to their initial state.

Figure 6.

Force analysis of the interaction between the perception mechanism and pineapple leaves.

2.3. Key Components and Mathematical Models

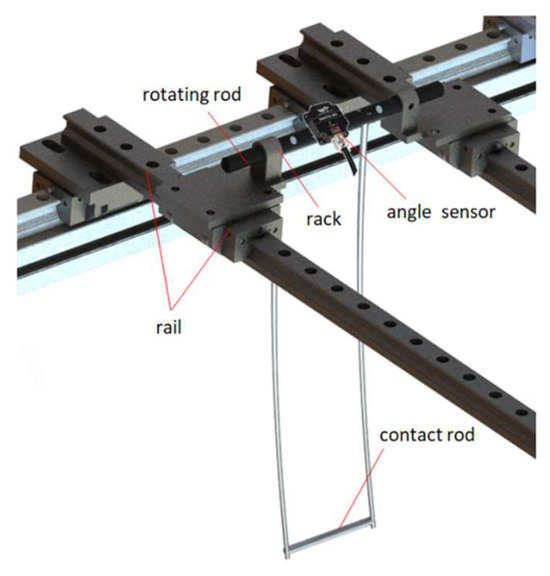

In order to effectively locate the core position of pineapple plants, we designed a sensing mechanism. Due to the small bending deformation force of pineapple leaves and the need for the sensing mechanism to rotate, lightweight aluminum material was used and the shape was designed in a “mouth” shape, with one end fixed and the other end rotating around a fixed point and in contact with the pineapple leaves, as shown in Figure 7. In addition, if the sensing mechanism is too long or too short, it may lead to large positioning errors in the plant core. Therefore, the external dimensions of the sensing mechanism are determined by actual measurements of pineapple plant height, leaf length, and other key physical parameters during the flower forcing period.

Figure 7.

Schematic diagram of perception mechanism structure.

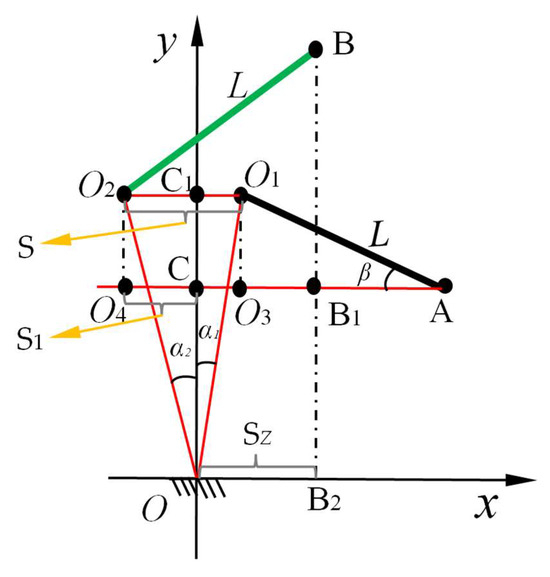

By analyzing the motion process of the perception mechanism and calculating its distance from the plant core, the position of the plant core was located to provide theoretical support for flower forcing-spraying. The specific analysis and calculation are as follows: In Figure 8, the pineapple plant core is the coordinate origin, the forward direction of the perception mechanism is the x-axis, and the vertical direction is the y-axis. A plane coordinate system is established, and it can be seen from the previous analysis that the perception mechanism performs a planar compound motion. Point A is the initial position, and point B is the highest point state of the perception mechanism. At this time, the distance between the vertical projection point B2 and the origin O, namely OB2, is the distance Sz between the plant core, O1O2 is the horizontal motion distance S, and assuming CO4 is S1, this is the case.

Figure 8.

Schematic diagram of pineapple plant core positioning calculation.

This transforms into the following:

Namely:

S is the forward movement distance of the implement. L is the length of the sensing mechanism. α is the rotation angle of the sensing mechanism. β is the initial angle of the sensing mechanism.

Based on this, a perceptual mathematical model for locating the cores of pineapple plants is established, laying the foundation for the subsequent design of the flowering and spraying control system.

2.4. Control System Design

2.4.1. System Hardware Composition

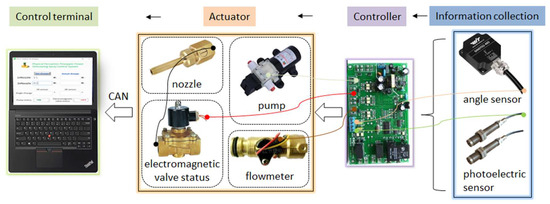

The overall hardware composition of the flower forcing–spraying control system is based on STM32 as the core processor, and the overall system framework is shown in Figure 9. It is mainly divided into three modules: The data acquisition module collects the rotation angle signal of the sensing mechanism through angle sensors. The data processing module processes the original angle signal to obtain displacement data, and further processes the displacement data into trigger signals. The actuator starts spraying pesticide upon receiving the trigger signal. All data are transmitted to the computer through CAN communication.

Figure 9.

Overall block diagram of control system.

A STM32F103C8 chip (Zhanjiang, China) was selected for the overall system core controller to implement various functions. The chip uses Cortex-M3 as the hardware architecture, powered by a DC5 V voltage, with 512 kB of Flash memory, 64 kB of RAM, a maximum clock frequency of 72 MHz, 37 input/output ports, and multiple external interfaces to meet the system design requirements. In the data acquisition module, the SINDT01 angle sensor produced by China Weite Intelligent Co., Ltd. was selected as the angle sensor, with an angle measurement range of ±180° and an accuracy of 0.2°, which could enable the monitoring of small angle changes. The speed sensor selected was the CZ480 speed sensor produced by Shanghai Chuanzhen Electronic Technology Co., Ltd., in China, with a measurement accuracy of 0.5%. In the execution mechanism, we uesd the DP-521 micro diaphragm water pump produced by China Fengqing Pump Industry Co., Ltd., with a maximum flow rate of 3.5 L/min and a maximum pressure of 0.48 MPa, which was able to mobilize the required amount of liquid pesticide.

2.4.2. System Software Design

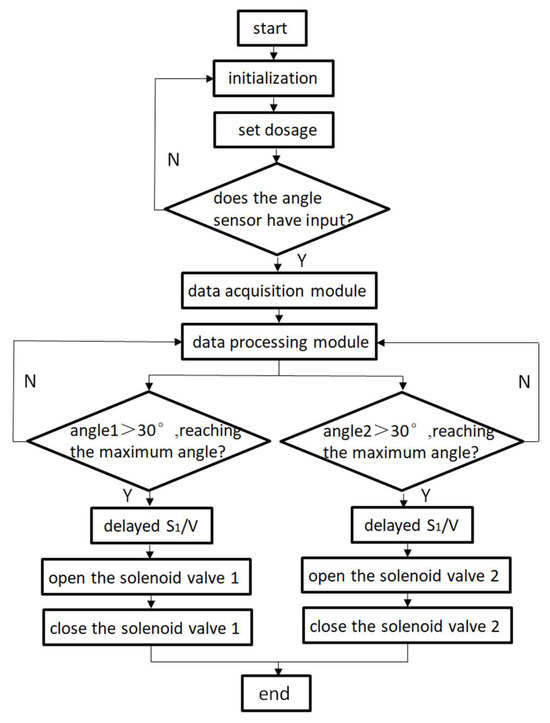

Based on the overall scheme and functional block diagram of the physical perception targeted flower forcing–spraying control system, combined with hardware module design, the main program flow of the control system was established, as shown in Figure 10.

Figure 10.

Control system program flowchart.

The system mainly includes three aspects: collecting the forward speed of the equipment and sensing changes in the angle of the mechanism, converting and processing the collected data, and sending signals from the controller to adjust the opening/closing status of the solenoid valve. After the main program of the control system is started, the serial port initialization and hardware module initialization stages are carried out first, and the corresponding system parameters are set. After initialization is completed, the forward speed V and angle sensor signal changes of the equipment are fed back and collected through the speed sensor to determine whether the angle change is greater than 30°. If it is greater than 30° and the angle change reaches its maximum, the delayed opening time of the solenoid valve is calculated based on the known distance between the sensing mechanism and the solenoid valve arrangement and the speed V. After the expected dosage is reached, the solenoid valve is closed and the program ends, thus achieving automatic quantitative spraying. The system parameters can be adjusted according to the actual field operation conditions; the main control procedures are shown in Algorithm 1.

| Algorithm 1 Partial programs and algorithms |

| void control_valve2(void) word_union angle_temp2; angle_temp2.Byte[0]= modbus_2m.RxData[4]; angle_temp2.Byte[1]= modbus_2m.RxData[3]; angle2 = angle_temp2.Word*1800/32,768; if(angle2>30) Set_PB6; if(pulseCount2> t=LCOSβ-S(1−Δα)){ Clear_PB6; pulseCount2=0; void control pump(void) if((HAL_GPIO_ReadPin(GPIOB,GPIO_PIN_5)==1)||(HAL_GPIO_ReadPin(GPIOB, GPIO_PIN_6)==1)) |

2.4.3. Communication Protocol

If independent control of N nozzles is required according to the requirements, the execution mechanism in this study can be expanded to N (N = 1, 2, 3…) groups, and the control instructions will be relatively complex. To standardize the pineapple flower forcing–spraying operation, the communication protocol was developed using the ISO 11783 serial control and communication data network bus standard [23].

For the targeted flower forcing–spraying control system, because a single data frame can contain up to 8 bytes of data, and considering the transmission requirements for subsequent multi-source information expansion, according to ISO 11783-3:2014 regulations [24], this protocol adopted a multi-packet message approach to divide the data information of the message (parameter group N., PGN), including the job speed, angle changes, and real-time flow rate, into packets for transmission. Among them, the first byte of each packet data field was defined as the packet sequence number and sent in ascending order. Due to the ability to allocate up to 255 serial numbers, it can meet the information expansion requirements for pineapple flower forcing–spraying operations. Referring to the provisions of ISO 11783-7:2015 for the application layer of tool messages [25], we formulated messages for the relevant parameters of the control system, as shown in Table 1. For example, we defined the PGN for the start-stop control of spraying operations as 00F401, with an update cycle of 100 ms and a byte length of 8 bytes. Among them, bytes 1 and 2 represent job speed verification instructions. Bytes 3 and 4 represent the instruction to start the job. Bytes 5 and 6 represent stop job instructions. The remaining undefined bits were reserved.

Table 1.

CAN communication protocol.

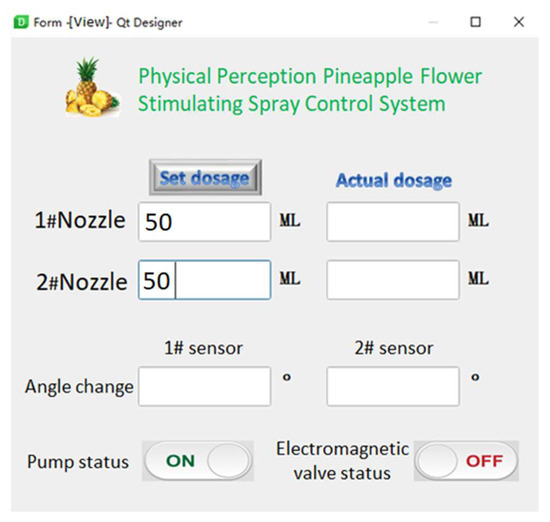

2.4.4. Human–Computer Interaction Interface Design

After the main program design is completed, QT (The version 5.12.10) software is used on the computer terminal to design the human–computer interaction interface, as shown in Figure 11. The operator sets the target spraying amount of the corresponding nozzle through the physical sensing-targeted flower forcing–spraying control system terminal interface, which can receive data collected by sensing devices to display the status on a real-time status display. It also makes it easy for the operator to control the working status of the spraying system at any time.

Figure 11.

PC interface.

3. Experiments

3.1. Spray Rate Accuracy Test

To evaluate the accuracy of the system’s spraying amount, a spraying amount accuracy test was designed. During the experiment, a turbine flowmeter (ZJ-LCD-M type, Zhongjiang Energy saving Electronics Co., Ltd., Foshan, China) was used to record the amount of pesticide added to the pesticide box. The nozzle spray control valve was adjusted to the maximum opening, and the spraying was carried out. After the spraying was completed, the spraying amount data displayed on the computer monitoring terminal was read. Five sets of experiments were designed according to different dosage gradients, and the experimental results are shown in Table 2. It can be seen that the maximum error in monitoring the spraying amount was 4.36%, and the average monitoring error was 2.72%. The calculation accuracy for the spraying amount was high, so the waste of liquid pesticide could be minimized by achieving the appropriate spraying amount for pineapple flower stimulation.

Table 2.

Test results of calculation accuracy of spray volume.

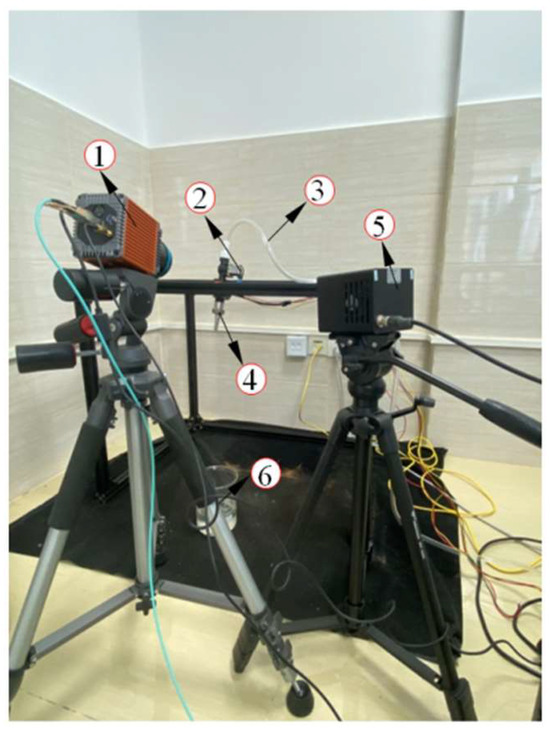

3.2. Measurement of Nozzle Opening and Closing Time

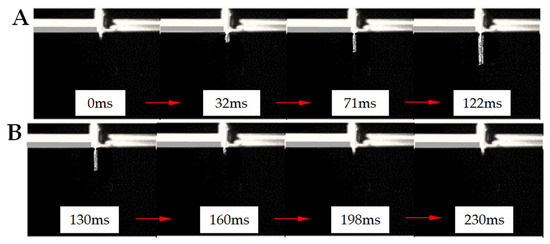

When spraying on the target, there is a delay in the opening and closing of the nozzle, which affects the accuracy of target control. To measure the opening and closing time of the nozzle in a real spraying environment, a single nozzle spraying system was built in the laboratory, as shown in Figure 12.

Figure 12.

Measurement tests of nozzle opening and closing times. 1. High-speed camera; 2. fill-in light; 3. nozzle; 4. solenoid valve; 5. intercepting bottle; 6. jet line.

For the spraying system, we adopted a DP-521 micro diaphragm pump, with a maximum flow rate of 3.5 L/min and a maximum pressure of 0.48 MPa. The opening and closing of the nozzle were repeated 3 times in each experiment, and the FRCAM HX high-resolution high-speed camera from China Yuan’ao Company (Tianjin, China) was used to capture the opening and closing of the nozzle (500 frames/s). After the shooting was completed, the supporting software was used to analyze the opening and closing of the nozzle [26], capturing the entire process of the nozzle from closing to fully opening and from opening to closing. We analyzed and calculated the nozzle opening and closing times, as shown in Figure 13. The nozzle started to close at 0.122 s, and the water flow noticeably decreased at 0.130 s, until the nozzle was completely closed at 0.230 s. The final analysis showed that the nozzle opening time was 0.122 s and the nozzle closing time was 0.10 s. Delay compensation was added to the target spraying control system based on the nozzle opening and closing times. The average opening and closing time of the nozzle (0.111 s) was taken as the delay compensation time. The conventional operating speed for pineapple flower spraying is generally set to 0.5 m/s, so the delay compensation distance is 55.5 mm.

Figure 13.

Nozzle opening and closing process. (A) Nozzle opening process. (B) Nozzle closing process.

3.3. Prototype Testing

The prototype test was conducted at a pineapple planting test base in China. The test materials included the prototype, a potted pineapple, water (as a substitute for pesticide), a tape measure, a 100 mL liquid measuring tool, and a timer. The prototype is shown in Figure 14.

Figure 14.

The prototype physical image.

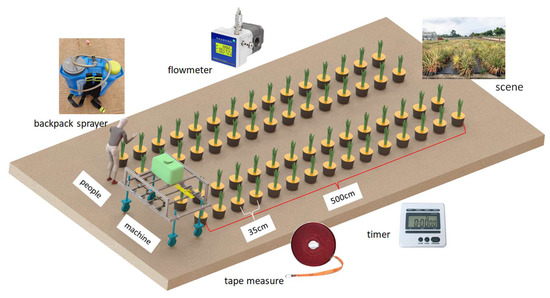

To evaluate the prototype’s chemical-saving performance while maintaining spraying efficacy, we conducted comparative trials between manual and automated spraying operations. The experiment comprised two parallel groups: Manual Group A (A-A) vs. Machine Group A (M-A), and Manual Group B (A-B) vs. Machine Group B (M-B). Each group treated 200 pineapple plants during the floral induction phase, with the parameters set to a 50 mL spray dosage per plant and a machine forward speed of 0.5 m/s. Identical environmental conditions and a total chemical volume of 12,000 mL were maintained across all trials (the experimental setup is illustrated in Figure 15).

Figure 15.

The schematic diagram of experimental plan.

This dual-group comparative design enabled the following:

- (1)

- Dose Consistency Verification: Fixed total volume allocation controlled for chemical consumption variables.

- (2)

- Operational Efficiency Benchmarking: Quantitative comparison of human vs. machine performance under matched parameters.

- (3)

- System Robustness Assessment: Repeated trials (Groups A/B) to evaluate prototype reliability.

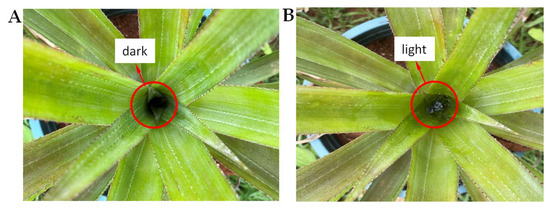

Manual spraying operations were quantitatively monitored using high-precision flowmeters to record the per-plant chemical consumption. Post-trial analysis for each experimental group focused on three key performance metrics: operational duration, chemical conservation efficiency, and miss-spray rate. Spraying accuracy validation employed an optical detection protocol based on core luminosity analysis. The plant core exhibits distinct spectral reflectance characteristics when treated with chemical solutions: untreated cores maintain a dark appearance (Figure 16A) due to light absorption (Figure 16B), while successfully treated cores demonstrate measurable brightness enhancement through specular reflection.

Figure 16.

Comparison of pesticide before and after spraying. (A) Before spraying. (B) After spraying.

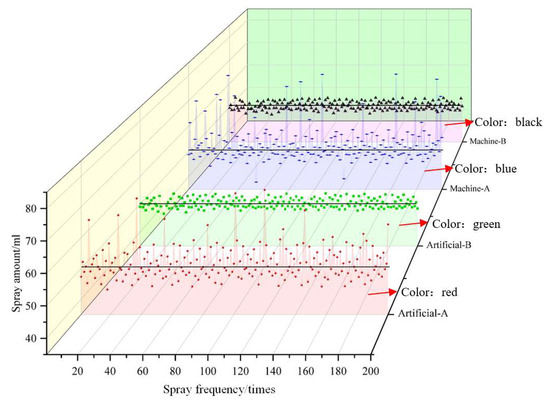

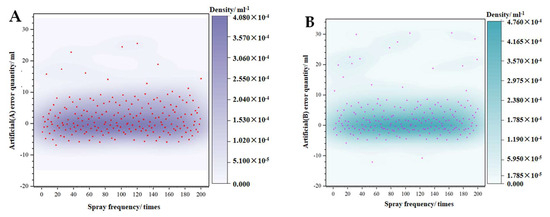

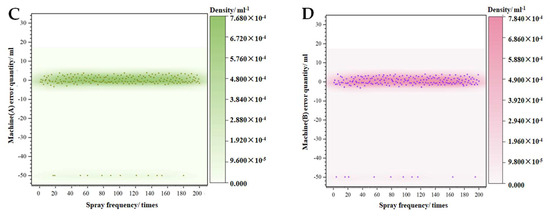

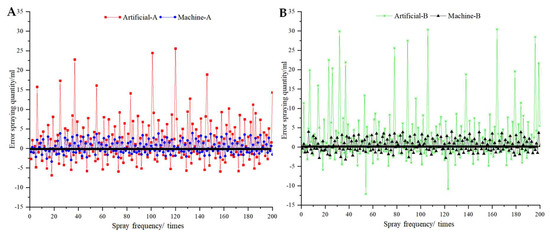

The experimental results of each group are shown in Figure 17.

Figure 17.

Experimental results of each control group.

As demonstrated in Figure 17, Figure 18 and Figure 19 and Table 3, the mean dosages were deviated from for experimental groups A-A, A-B, M-A, and M-B and were quantified as 20.6%, 18.4%, 7.1%, and 6.4%, respectively. Manual spraying operations exhibited significant dosage fluctuations with non-uniform distribution patterns, where excessive chemical application risks phytotoxicity in pineapple plants [27]. Notably, the prototype achieved a 12.7% improvement in operational efficiency compared to manual methods while conserving over 300 mL of chemicals per 200 treated plants (excluding missed targets). Scaled to standard planting density (45,000 plants/hectare), this translates to a minimum chemical saving of 67,500 mL/hectare. Furthermore, the system maintained comparable throughput rates (0.5 m/s forward speed) to human operators.

Figure 18.

Distribution of experimental errors for each control group. (A) A-A error distribution. (B) A-B error distribution. (C) M-A error distribution. (D) M-B error distribution.

Figure 19.

Comparison of error amount of two groups of test results. (A) Comparison of error of control test results in group A. (B) Comparison of error of control test results in group B.

Table 3.

The test result.

The results presented in Table 4 demonstrate statistically significant differences between the two comparative experimental groups, with t-values of 3.570 and 4.342, respectively. Both two-tailed tests revealed extremely significant differences (p < 0.001), accompanied by mean differences of 1.515 and 2.276, and standard errors of 0.424 and 0.524. The 95% confidence intervals for the mean differences ranged from 0.681 to 2.349 and from 1.245 to 3.307, respectively. Since the significance levels (Sig.) were both <0.001, these results conclusively indicate a statistically profound disparity between manual and machine spraying approaches. Specifically, the machine spraying method demonstrated superior stability in pesticide application quantity, as evidenced by the narrower confidence intervals and higher t-values reflecting greater precision in operational consistency.

Table 4.

Test data analysis results.

The formulas for calculating the average error and coefficient of variation are as follows:

Xi is single data point. is the data mean. n is the amount of data.

σ is the standard deviation.

A critical limitation emerged in the form of prototype miss-spray rates (10–13%), primarily attributable to the following:

- (1)

- Vegetative Occlusion: Leaf interference during core targeting.

- (2)

- Dynamic Response Lag: Mechanical delay in nozzle actuation.

- (3)

- Morphological Variability: Plant-to-plant structural differences.

These findings underscore the system’s operational advantages in precision and resource efficiency while identifying key areas for mechatronic optimization in subsequent iterations.

4. Discussion

This study developed a targeted spraying system based on the physical characteristics of pineapple leaves, effectively addressing the technical challenge of precise chemical delivery to the meristem core during floral induction. By leveraging the unique biomechanical properties of pineapple plants during the flowering phase, the mechatronic system achieved 93.2% targeting accuracy in field trials (Table 3), representing a significant advancement in agricultural automation for this specialty crop.

Existing mechanized solutions exhibit fundamental limitations. Although Zhang, R.H. et al. [14] developed a high-clearance vehicular platform that prevents plant damage during field operations, their system lacks targeted delivery mechanisms for floral induction chemicals. The computer vision approach proposed by Liu et al. [15] demonstrates 87% meristem recognition accuracy under controlled conditions, but suffers from performance degradation (≤72% accuracy) under variable illumination and canopy occlusion— a critical drawback given the frequent cloud cover in tropical pineapple-growing regions. Drone-based applications prove particularly unsuitable due to aerodynamic interference caused by the spiral phyllotaxis of the pineapple leaves during low-altitude spraying.

Our physics-driven methodology introduces three key innovations: (1) mathematical modeling correlating flowering-phase leaf stiffness variations with meristem positioning, (2) a non-visual localization algorithm based on mechanical resistance profiling, and (3) an embedded real-time control architecture maintaining a 69 ms response latency under agricultural electromagnetic interference. This integrated approach ensures stable operation across diverse lighting conditions (coefficient of variation (CV) = 4.75% vs. 11.7% in [13]) while eliminating sensor fouling risks inherent to optical systems. The automated system outperformed manual spraying in both efficiency and stability, with average errors of 7.1% and 6.4%, respectively. The system reduced chemical usage by over 67,500 mL per hectare while maintaining a miss-spray rate of 5–6%. Both two-tailed tests revealed extremely significant differences (p < 0.001), showing that the error and stability of mechanical spraying are better than those of manual spraying.

Two technical limitations require emphasis. First, operational speeds exceeding 0.8 m/s result in 5–6% target miss rates (Table 3), primarily attributable to servo actuator latency in the current prototype. At the same time, the CV coefficient is high. Second, the system’s parameter adjustment process (10–15 min per field) for different agronomic configurations presents scalability challenges for non-standardized plantations. These limitations guide future improvements, particularly the integration of adaptive speed control and LiDAR-based row detection modules.

Future research should prioritize the following: (1) dynamic viscosity compensation mechanisms for diverse chemical formulations, (2) multi-robot coordination algorithms for large-scale plantations, and (3) the investigation of leaf-bending characteristics across pineapple cultivars. The developed framework shows promising extensibility to other rosette-type crops requiring meristem-specific targeting, such as artichokes and selected bromeliads, demonstrating significant technological transfer potential.

5. Conclusions

- (1)

- By analyzing the physical and mechanical characteristics of pineapple plants, a method for locating the core of pineapple plants is proposed. The contact motion process between the sensing mechanism and pineapple leaves was analyzed, and a mathematical model was established to provide theoretical support for the design of targeted spraying control systems.

- (2)

- We designed the control logic, scheme, and key components of the entire system, selected the hardware reasonably, used STM32 embedded technology to program the system software, and used QT software to design the human–computer interaction interface. We connected the computer terminal through CAN bus communication technology, collected and analyzed data, and displayed them in real-time for operators to observe the operation status.

- (3)

- We conducted tests on spraying accuracy, measurements of nozzle opening and closing times, and evaluations of prototype performance. The experimental results indicated an average error of 2.72% in spraying accuracy and an average nozzle opening and closing time of 0.111 s. At the conventional operational speed for pineapple flowering induction spraying, the delay compensation distance amounted to 55.5 mm. The average errors associated with machine spraying were 7.1% and 6.4%, respectively, which were lower than those of manual spraying, exhibiting higher stability. Additionally, operational efficiency was enhanced, resulting in savings of over 67,500 mL of pesticide per hectare. However, there were instances of missed spraying, with a rate of 5% to 6%. Overall, the performance was satisfactory and capable of meeting the requirements for pineapple flowering induction spraying operations.

Author Contributions

Conceptualization, S.Z. (Shuang Zheng) and Y.D.; methodology, S.Z. (Shuang Zheng), Y.D., and S.Z. (Shuang Zheng); software, G.D.; validation, G.L. and Z.C.; formal analysis, Z.C. and L.L.; investigation, L.L. and X.W.; resources, S.Z. (Sili Zhou) and Y.D.; data curation, S.Z. (Sili Zhou) and Y.D.; writing—original draft preparation, S.Z. (Sili Zhou), Y.D. and F.H.; writing—review and editing, S.Z. (Sili Zhou), Y.D., and B.Y.; visualization, S.Z. (Shuang Zheng) and S.Q.; supervision, Z.L. and P.C.; project administration, S.Z. (Sili Zhou) and Y.L.; funding acquisition, G.D. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Foundation for Innovative Research Groups of the National Natural Science Foundation of China (Grant NO. 52405300); the Hainan Provincial Natural Science Foundation Youth Fund (Grant NO. 323QN284); and the Central Government Public Welfare Basic Scientific Research Operating Funds (Grant NO. 1630012025402).

Institutional Review Board Statement

The research presented in this study was conducted in accordance with ethical standards and guidelines for research involving technology and agricultural practices. No human or animal subjects were involved in this study. The research methodologies used, including data collection and analysis, were carried out with full respect for the environment and agricultural practices in the study area.

Data Availability Statement

Data is contained within the article.

Acknowledgments

We confirm that neither the manuscript nor any parts of its content are currently under consideration for publication with or published in another journal. All authors have approved the manuscript and agree with its submission to Horticulturae. The authors wish to thank the anonymous reviewers for their useful comments on this paper.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Liu, Q.; Zhou, S.L.; Deng, G.R.; Li, Q.Y.; Huang, Q.Y.; Li, G.J. The current situation and countermeasures of industrial development in the main pineapple producing areas of China. Mod. Agric. Equip. 2024, 45, 11–15+20. [Google Scholar]

- He, G.Y.; Huang, J.J.; Wu, W.; Zhang, J.; Wang, Z. Analysis and promotion strategy for the comparative advantage of pineapple production in Hainan province. Chin. J. Trop. Agric. 2024, 44, 39–44. [Google Scholar]

- Liu, T.H.; Cheng, Y.F.; Li, J.Y.; Chen, S.; Lai, J.; Liu, Y.; Qi, L.; Yang, X. Feeding-type harvesting mechanism with the rotational lever for pineapple fruit. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2023, 39, 27–38. [Google Scholar]

- Wang, G.R. China Rural Statistical Yearbook; 7-33 (Fruit production by Region); China Statistics Press: Beijing, China, 2024. [Google Scholar]

- FAO. Available online: https://www.fao.org/statistics/zh/ (accessed on 6 March 2025).

- Cai, Z.Y.; Wang, X.M.; Dong, L.; Liu, Y.Q.; Fang, W.K.; Deng, B.; Xu, J.; Ren, H.; Qiu, W.W.; Su, W.Q.; et al. Effects of natural flowering and ethephon induction on fruit and quality of 7 pineapple varieties. Mol. Plant Breed. 2022, 20, 7902–7913. [Google Scholar]

- Zhang, J.Z.; Yan, C.M.; Li, B.S.; Shi, W.Q.; Liu, Y.N. Investigation and analysis of leaf yellowing of pineapple plants in the dry season. Chin. J. Trop. Agric. 2012, 32, 16–19. [Google Scholar]

- Liu, S.H.; Yang, Y.M.; Zhu, Z.Y.; Sun, W.S.; Wu, Q.S.; Sun, G.M. The influence of planting period on the natural flowering and fruiting of “MD-2” pineapple. South China Fruits 2014, 43, 89–91. [Google Scholar]

- Chen, J.; Zeng, H.; Zhang, X.M. Integrative transcriptomic and metabolomic analysis of D-leaf of seven pineapple varieties differing in N-P-K% contents. BMC Plant Biol. 2021, 21, 550. [Google Scholar] [CrossRef]

- Santos, M.P.; Maia, V.M.; Oliveira, F.S.; Pegoraro, R.F.; Santos, S.R.D.; Aspiazú, I. Estimation of total leaf area and D leaf area of pineapple from biometric characteristics. Rev. Bras. Frutic. 2018, 40, 1–5. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, C.H.; Fan, C.; Wu, J.F.; Dai, H.F.; Chen, J.R. Influence of exogenous GA3 application on growth and chemical quality of pineapple fruits. Guangdong Agric. Sci. 2012, 39, 42–43. [Google Scholar]

- Pu, Y.; Lin, W.Q.; Liu, C.Y.; Liu, S.H.; Wu, Q.S.; Sun, W.S.; Lu, X.H.; Gao, X.Y.; He, J.J. Effects of ethephonon flower bud initiation and fruit quality of five pineapple varieties. J. Fruit Sci. 2012, 41, 505–516. [Google Scholar]

- Cai, Y.; Yang, X.Y.; Li, M.; Chen, T.; Li, J.; Huang, Q.; Tan, Q.; Qin, X.; Tang, X.; Zhou, J. A Drone Uniform Sprayer Suitable for Pineapple Flower Stimulation. Guangxi Zhuang Autonomous Region Subtropical Crop Research Institute. Patent 201921245364.0, 22 May 2020. [Google Scholar]

- Zhang, R.H.; Zhang, Q.; Ou, J.S.; He, K.J.; Wang, Z.W.; Lu, D.X. Design and control of self-propelled pineapple flower induction machine with high gap. Mech. Electr. Eng. Technol. 2022, 51, 18–21. [Google Scholar]

- Liu, H.T.; Zhu, J.H.; Mai, Q.Q. An Automatic Flower Forcing Robot for Pineapple and Its Flower Forcing Inducing Method. Patent CN202310253502.4, 12 April 2024. [Google Scholar]

- Zhang, R.H.; Ou, J.S.; Li, X.M.; Ling, X.; Zhu, Z.; Hou, B.F. Lightweight algorithm for pineapple plant center detection based on improved an YOLOv4 model. Trans. Chin. Soc. Agric. Eng. 2023, 39, 135–143. [Google Scholar]

- Wang, B.B.; Liu, W.; Deng, W.P.; Chen, Z.W. A multifunctional field management machine based on pineapple mechanized field management technology design and testing. China South. Agric. Mach. 2024, 55, 1–5+25. [Google Scholar]

- Zhang, Z.J.; Huang, C.H.; Lan, J.H. Flower core recognition and location of pineapple flower inducing robot based on RGBD. Control. Theory Appl. 2025, 42, 281–288. [Google Scholar]

- Pan, K.Y.; Lin, W.J.; Chen, J.W.; Lin, Y.H. YOLO-CMST: Towards accurate pineapple flowering induction using YOLO-based models with the Cross Multi-Style Translator. Comput. Electron. Agric. 2025, 235, 110315. [Google Scholar] [CrossRef]

- Liu, W.; Dong, W.; Ye, Z.L.; Xie, Y.L.; Zhang, X.H.; Li, R.X.; Liu, G.H. Effects of different flower forcing methods on flowering and fruit quality of pineapple ‘Tainong 16’. J. Trop. Biol. 2024, 15, 315–322. [Google Scholar]

- Wang, L.; Li, Y.; Jin, X. Floral transcriptomes reveal gene networks in pineapple floral growth and fruit development. Commun. Biol. 2020, 3, 500. [Google Scholar] [CrossRef]

- Jin, F.L.; Zhang, M.Q.; Hu, X.Z.; He, F.G.; Cui, Z.D.; Deng, G.R. Test analysis of ridge double-row pineapple transplanting machine. Mod. Agric. Equip. 2023, 44, 18–23. [Google Scholar]

- Liu, C.H.; He, H.; Zhou, C.P.; Wu, X.M.; Qiu, R.B.; Yang, M.; Wei, Y.R. High-quality and high-efficiency cultivation model of “one fertilizer-two prevention-three reduction” for pineapple production. China Trop. Agric. 2024, 10, 72–75. [Google Scholar]

- Gao, Y.Y.; Wang, X.; Yang, S.; Zhai, C.Y.; Zhao, X.G.; Zhao, C.J. Development of CAN-based sowing depth monitoring and evaluation system. Trans. Chin. Soc. Agric. Mach. 2019, 50, 23–32. [Google Scholar]

- Okajima, J.; Kato, M.; Hayakawa, A. Investigation of bimodal characteristics of the droplet size distribution in condensation spray. Sci. Rep. 2023, 13, 12006. [Google Scholar]

- Wang, Z.; Zhang, Z.; Wang, Q. A nasal spray vaccination device based on Laval nozzle and its experimental test. Sci. Rep. 2023, 13, 6267. [Google Scholar]

- Zhou, L.; Matsumoto, T.; Tan, H.W. Developing single nucleotide polymorphism markers for the identification of pineapple (Ananas comosus) germplasm. Hortic. Res. 2015, 13, 15056. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).