From Sun to Snack: Different Drying Methods and Their Impact on Crispiness and Consumer Acceptance of Royal Gala Apple Snacks

Abstract

1. Introduction

2. Materials and Methods

2.1. Apples and Drying Process

2.2. Crispiness Evaluation

2.3. Sound Measurements Apparatus

2.4. X-Ray Diffraction

2.5. Sensorial Analyses

2.6. Statistical Analysis

3. Results and Discussion

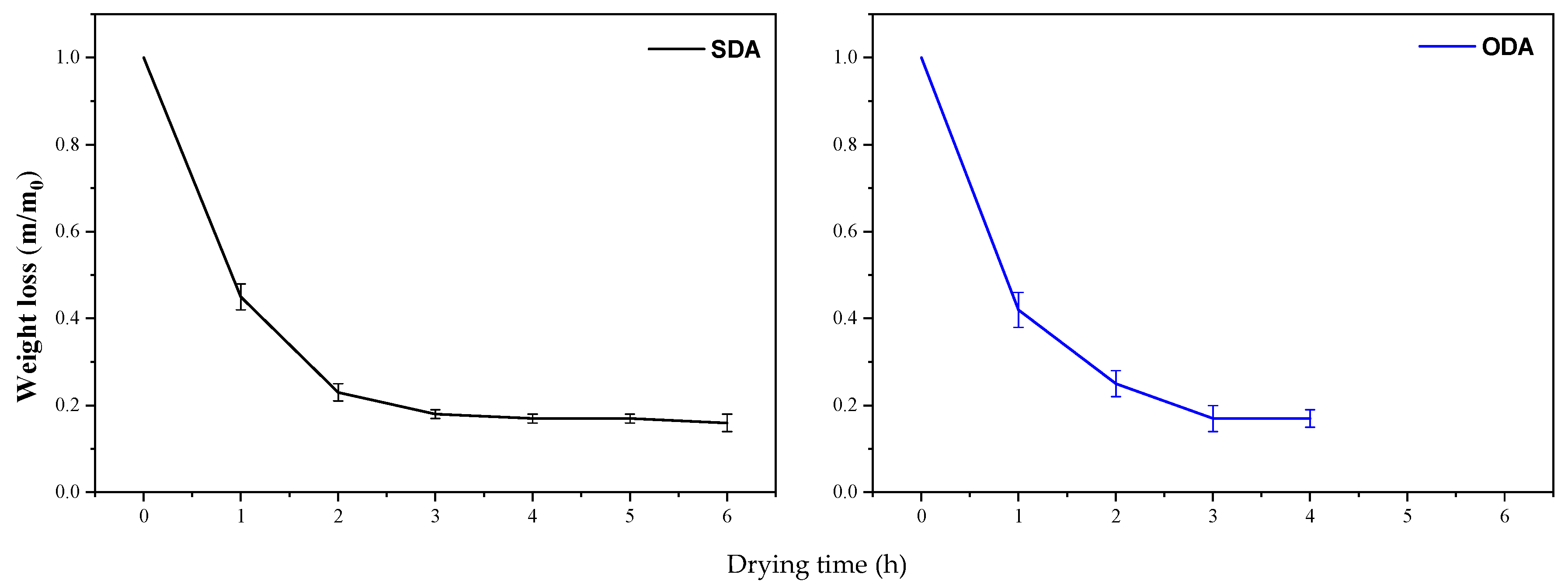

3.1. Drying Kinetics

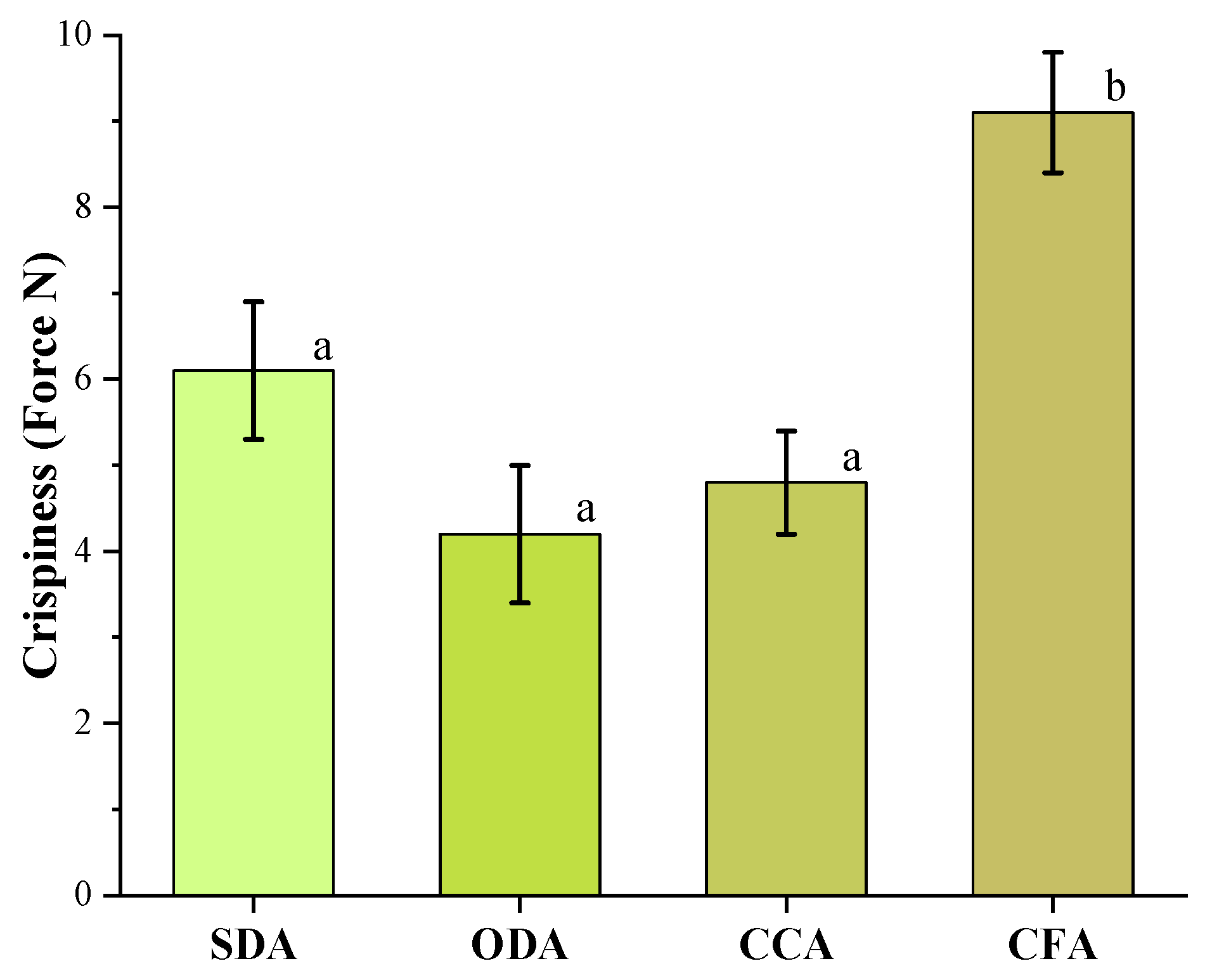

3.2. Crispiness

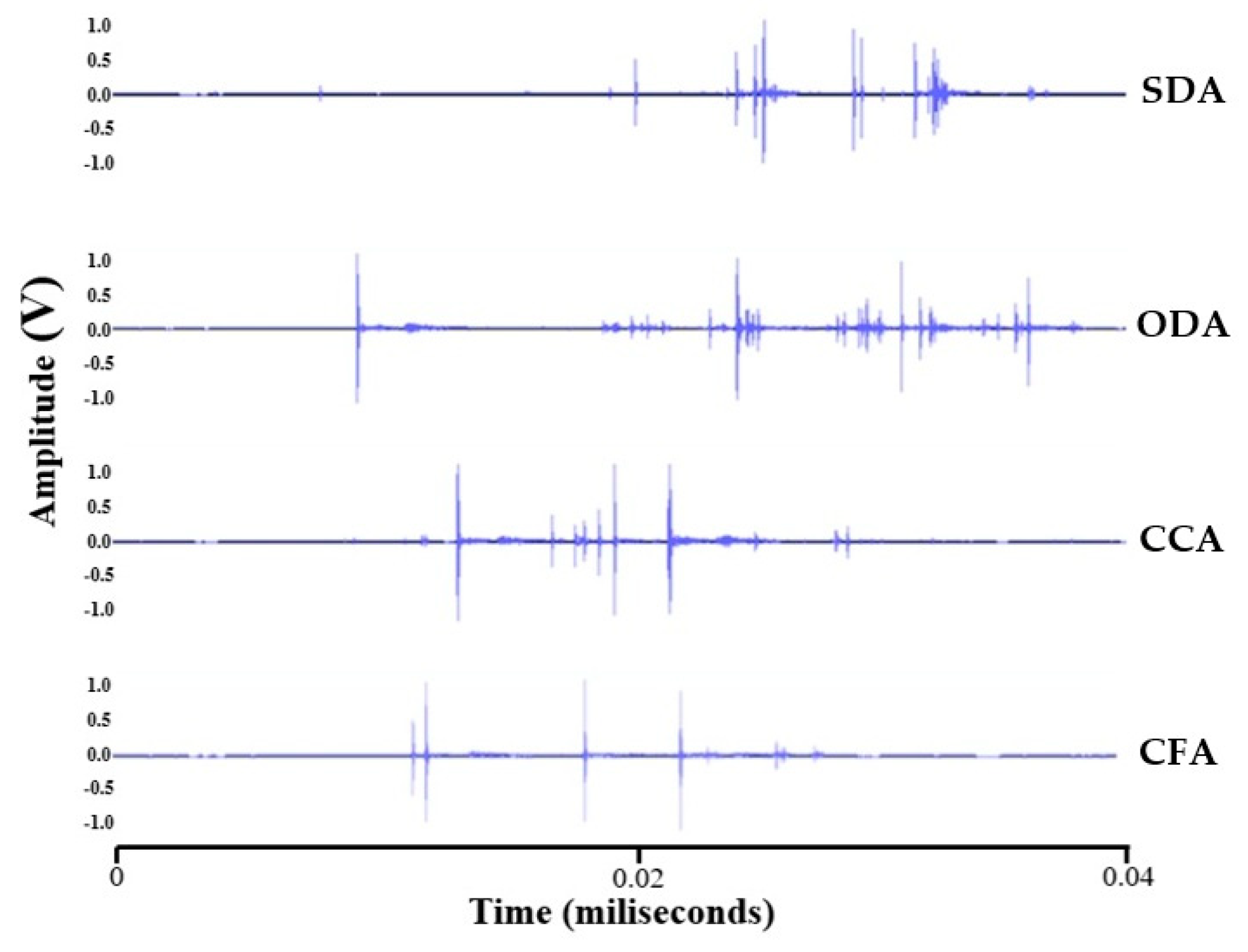

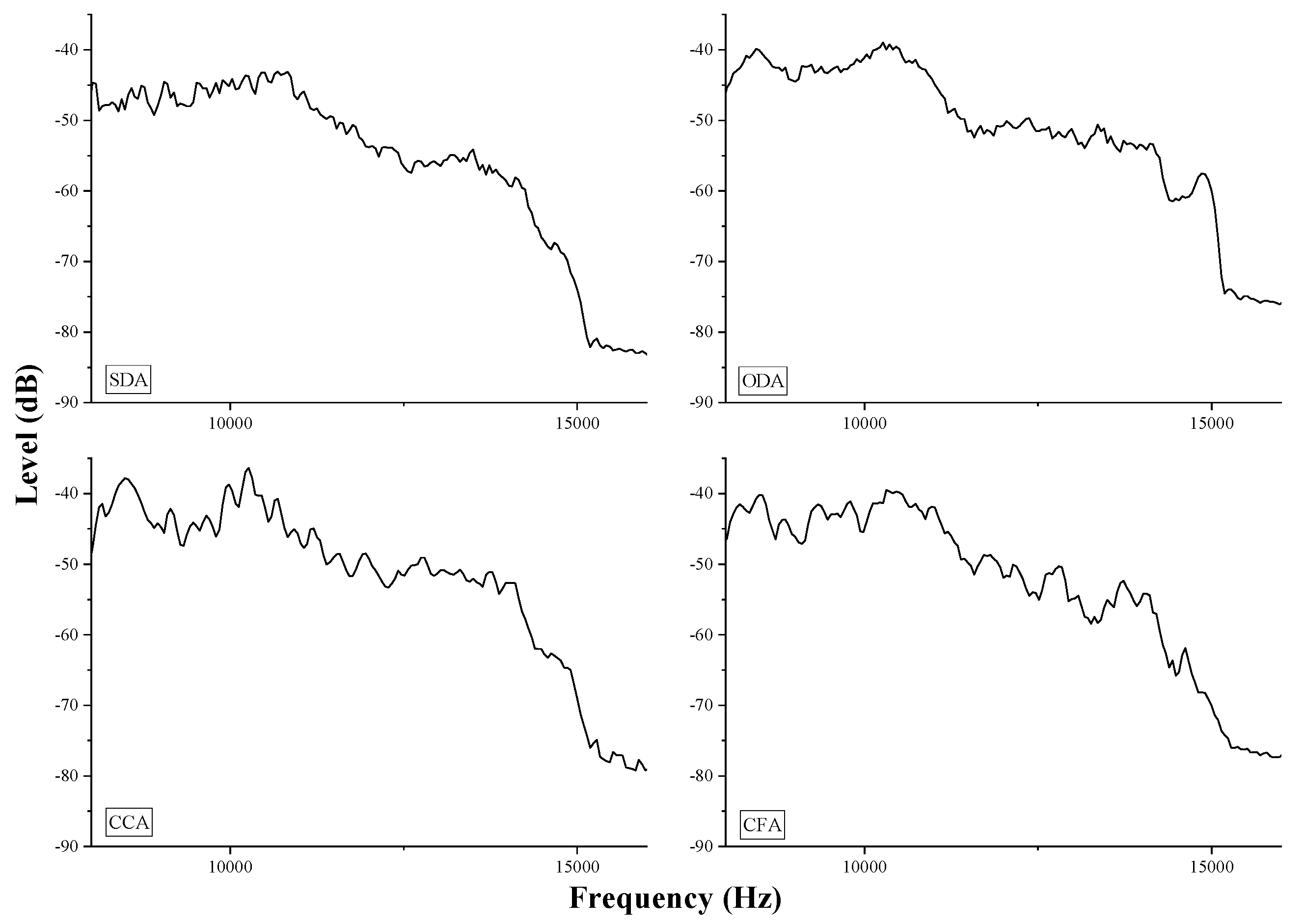

3.3. Sound Emission Analyses

3.3.1. Sound Amplitude

3.3.2. Sound Frequency

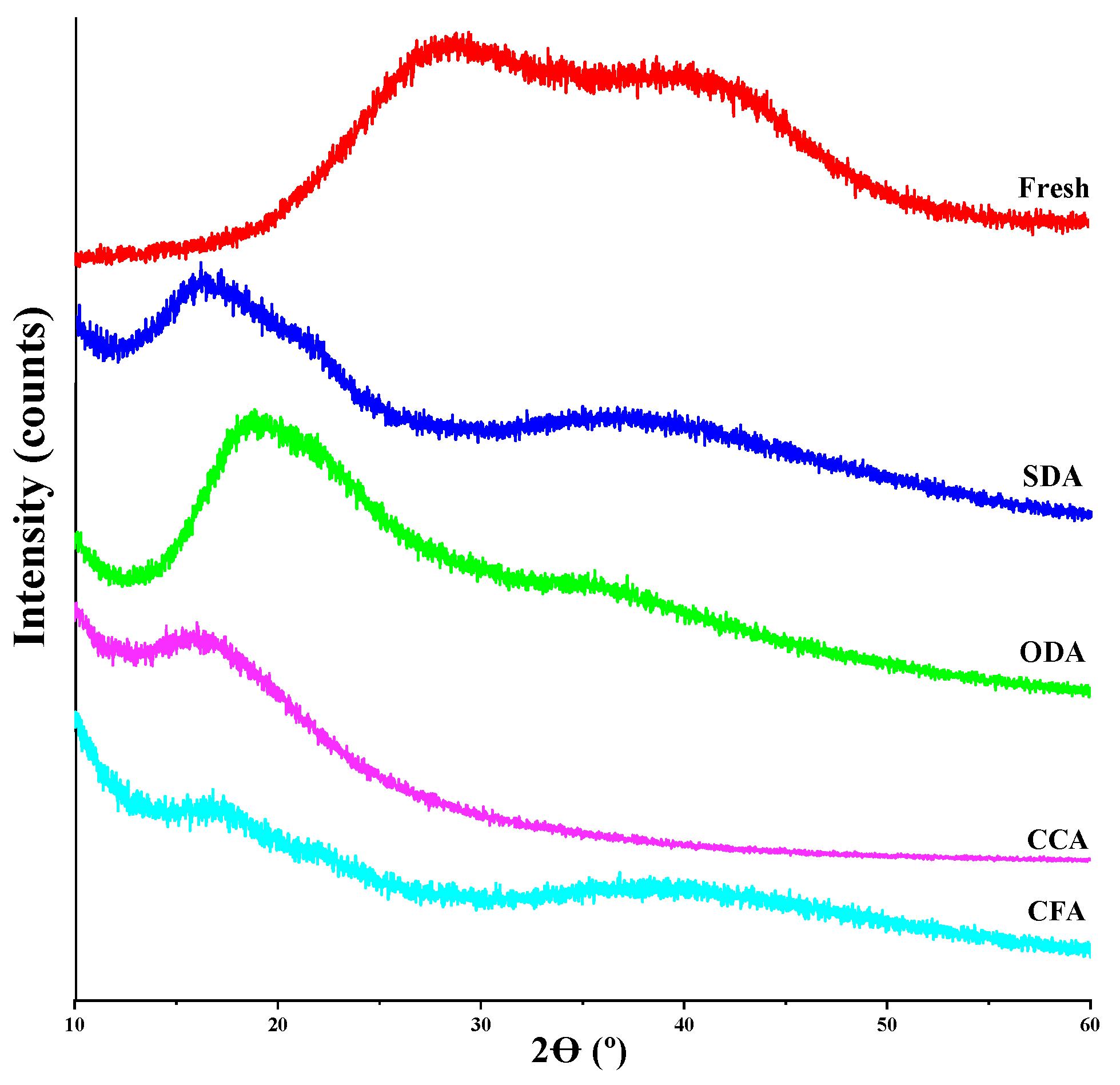

3.4. X-Ray Analyses

3.5. Relation Between Crispiness, Sound and X-Ray Diffraction

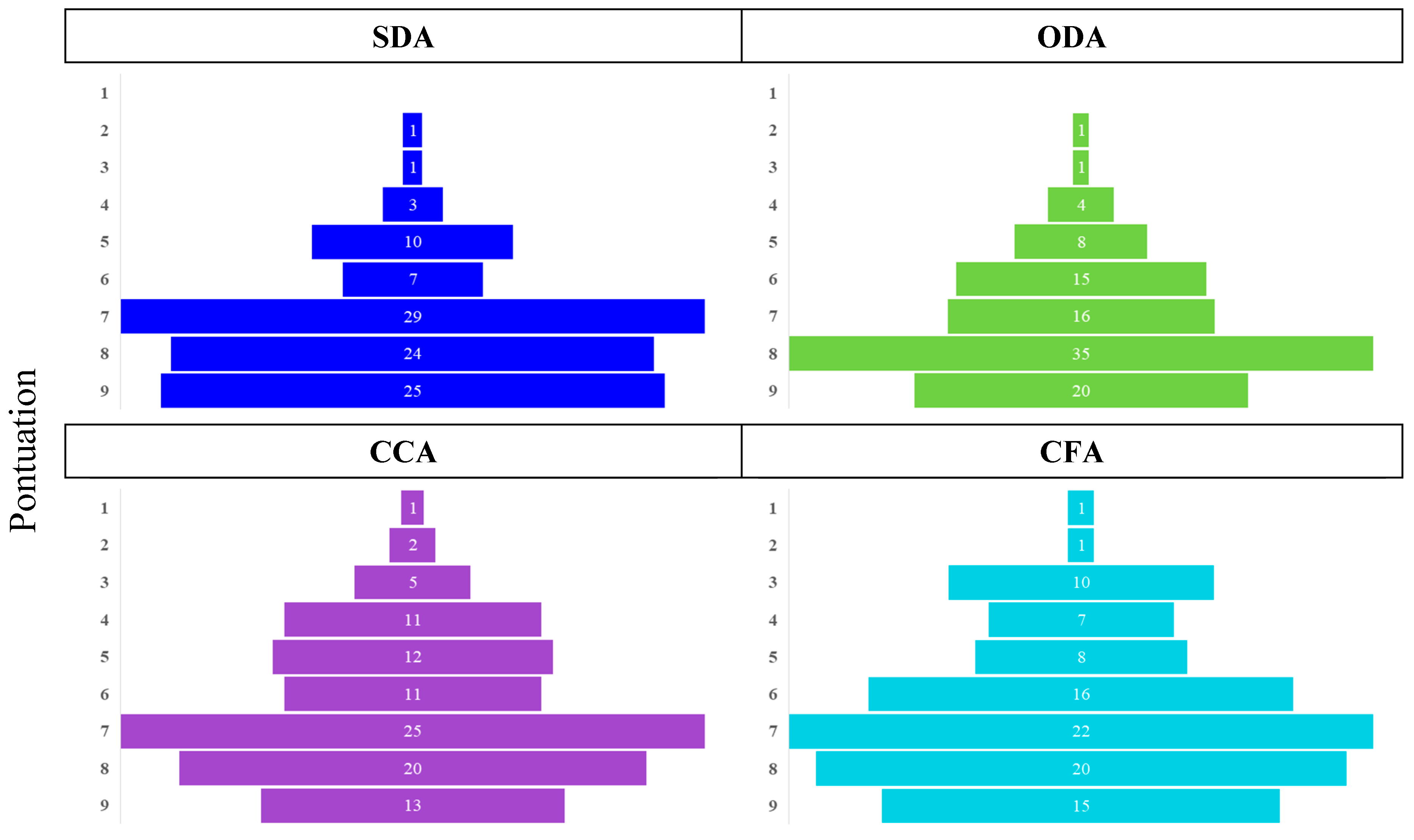

3.6. Sensory Analyses: CATA Tests, Quality and Acceptance

3.6.1. CATA Test

3.6.2. Texture Evaluation

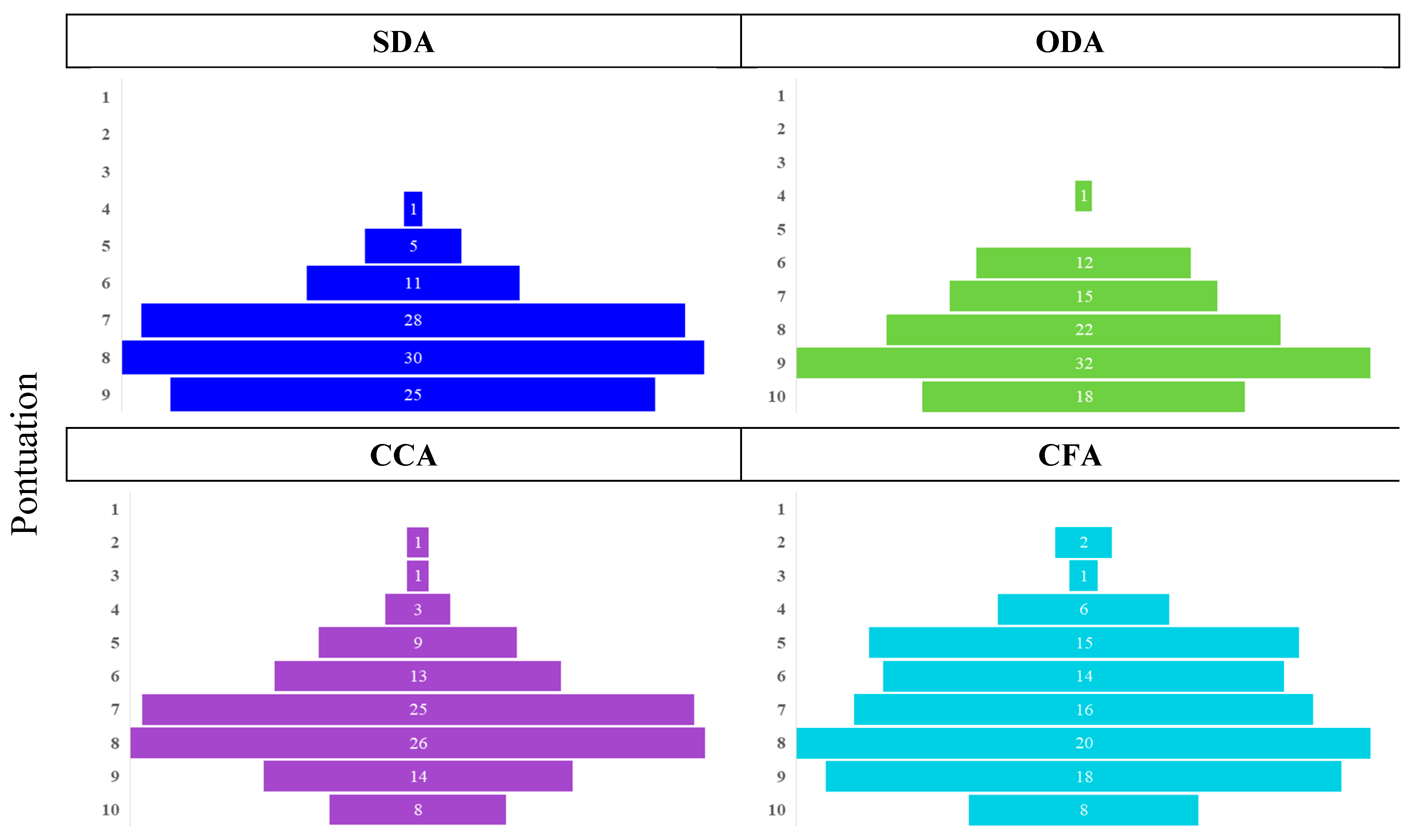

3.6.3. Overall Quality

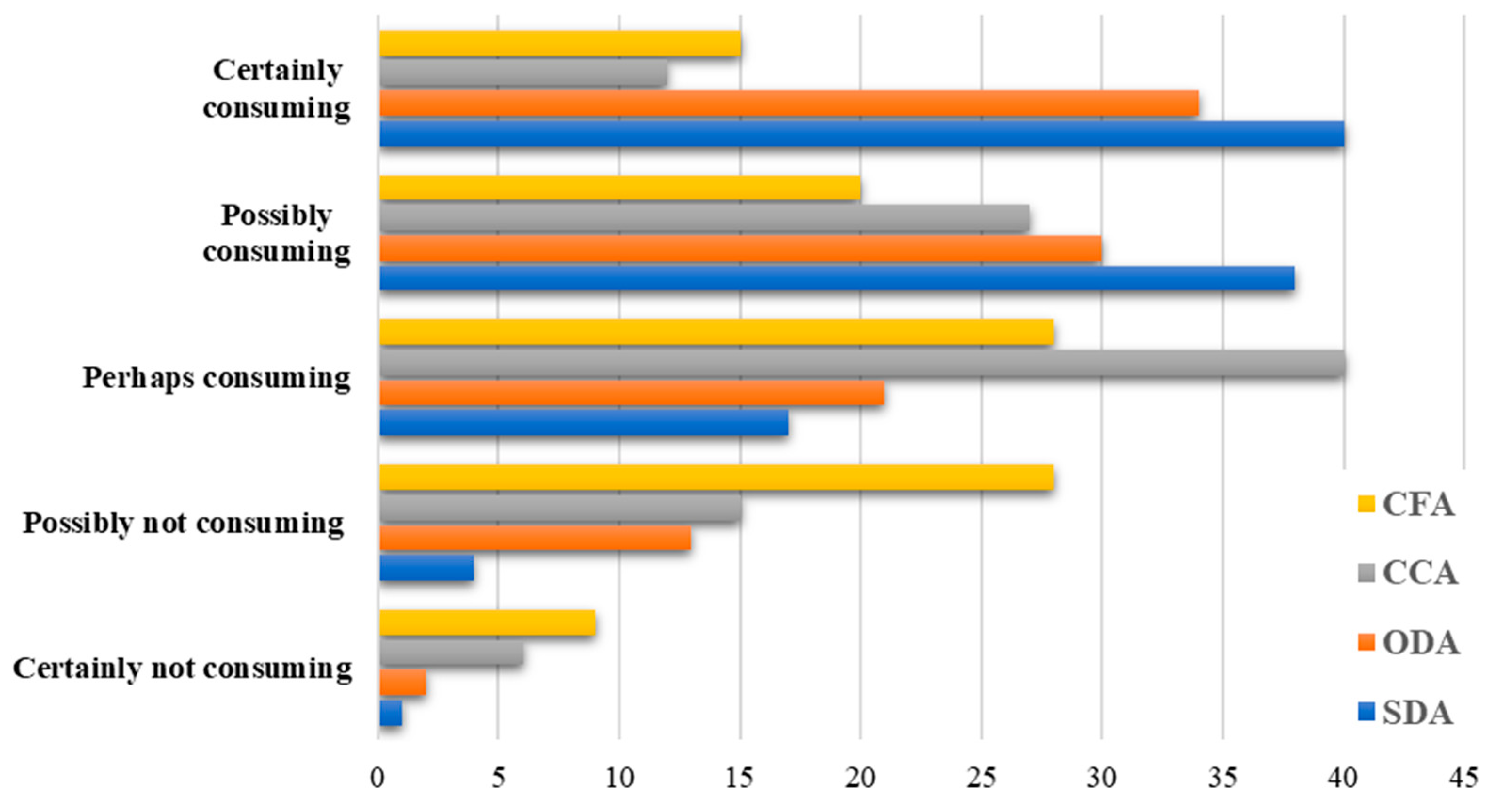

3.6.4. Acceptance of the Snacks Under Study

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, L.; Wang, X.; Bi, J.; Liu, X.; Yi, J.; Wu, X. Effect of different moisture equilibration process on the quality of apple chips dried by instant controlled pressure drop (dic)-assisted hot air drying. J. Food Process. Preserv. 2017, 42, e13316. [Google Scholar] [CrossRef]

- Pateiro, M.; Vargas-Ramella, M.; Franco, D.; da Cruz, A.G.; Zengin, G.; Kumar, M.; Dhama, K.; Lorenzo, J.M. The role of emerging technologies in the dehydration of berries: Quality, bioactive compounds, and shelf life. Food Chem. X 2022, 16, 100465. [Google Scholar] [CrossRef]

- Sablani, S.S. Drying of fruits and vegetables: Retention of nutritional/functional quality. Dry. Technol. 2006, 24, 123–135. [Google Scholar] [CrossRef]

- Fernandes, L.; Tavares, P.B. A Review on Solar Drying Devices: Heat Transfer, Air Movement and Type of Chambers. Solar 2024, 4, 15–42. [Google Scholar] [CrossRef]

- Guiné, R.P.F. The Drying of Foods and Its Effect on the Physical-Chemical, Sensorial and Nutritional Properties. ETP Int. J. Food Eng. 2018, 4, 93–100. [Google Scholar] [CrossRef]

- Siddiqui, S.A.; Ucak, I.; Jain, S.; Elsheikh, W.; Redha, A.A.; Kurt, A.; Toker, O.S. Impact of drying on techno-functional and nutritional properties of food proteins and carbohydrates—A comprehensive review. Dry. Technol. 2024, 42, 592–611. [Google Scholar] [CrossRef]

- Omolola, A.O.; Jideani, A.I.O.; Kapila, P.F. Quality properties of fruits as affected by drying operation. Crit. Rev. Food Sci. Nutr. 2015, 57, 95–108. [Google Scholar] [CrossRef]

- Ghinea, C.; Prisacaru, A.E.; Leahu, A. Physico-Chemical and Sensory Quality of Oven-Dried and Dehydrator-Dried Apples of the Starkrimson, Golden Delicious and Florina Cultivars. Appl. Sci. 2022, 12, 2350. [Google Scholar] [CrossRef]

- Radojčin, M.; Pavkov, I.; Kovačević, D.B.; Putnik, P.; Wiktor, A.; Stamenković, Z.; Kešelj, K.; Gere, A. Effect of selected drying methods and emerging drying intensification technologies on the quality of dried fruit: A review. Processes 2021, 9, 132. [Google Scholar] [CrossRef]

- Fernandes, L.; Fernandes, J.R.; Nunes, F.M.; Tavares, P.B. Effect of drying temperature and storage time on the crispiness of homemade apple snacks. J. Sci. Food Agric. 2023, 104, 916–931. [Google Scholar] [CrossRef]

- El-Mesery, H.S.; El-Seesy, A.I.; Hu, Z.; Li, Y. Recent developments in solar drying technology of food and agricultural products: A review. Renew. Sustain. Energy Rev. 2022, 157, 112070. [Google Scholar] [CrossRef]

- Margarita, C.T.; Beatriz, C.T.; Viviana, M.M.E.; Carlos, O.S.J. Technical and Experimental Study of the Solar Dehydration of the Moringa Leaf and Its Potential Integration to the Sustainable Agricultural Industry. Eur. J. Sustain. Dev. 2018, 7, 65–73. [Google Scholar] [CrossRef]

- Petikirige, J.; Karim, A.; Millar, G. Effect of drying techniques on quality and sensory properties of tropical fruits. Int. J. Food Sci. Technol. 2022, 57, 6963–6979. [Google Scholar] [CrossRef]

- Fernandes, L.; Fernandes, J.R.; Tavares, P.B. Design of a Friendly Solar Food Dryer for Domestic Over-Production. Solar 2022, 2, 495–508. [Google Scholar] [CrossRef]

- Appiani, M.; Cattaneo, C.; Laureati, M. Sensory properties and consumer acceptance of plant-based meat, dairy, fish and eggs analogs: A systematic review. Front. Sustain. Food Syst. 2023, 7, 1268068. [Google Scholar] [CrossRef]

- Jeltema, M.; Beckley, J.; Vahalik, J. Model for understanding consumer textural food choice. Food Sci. Nutr. 2015, 3, 202–212. [Google Scholar] [CrossRef]

- Saeleaw, M.; Schleining, G. A review: Crispness in dry foods and quality measurements based on acoustic-mechanical destructive techniques. J. Food Eng. 2011, 105, 387–399. [Google Scholar] [CrossRef]

- Kahraman, O.; Malvandi, A.; Vargas, L.; Feng, H. Drying characteristics and quality attributes of apple slices dried by a non-thermal ultrasonic contact drying method. Ultrason. Sonochem. 2021, 73, 105510. [Google Scholar] [CrossRef]

- Drake, M.; Watson, M.; Liu, Y. Sensory Analysis and Consumer Preference: Best Practices. Annu. Rev. Food Sci. Technol. 2023, 14, 427–448. [Google Scholar] [CrossRef]

- Zampini, M.; Spence, C. Assessing the role of sound in the perception of food and drink. Chemosens. Percept. 2010, 3, 57–67. [Google Scholar] [CrossRef]

- Michel, M.; Eldridge, A.L.; Hartmann, C.; Klassen, P.; Ingram, J.; Meijer, G.W. Benefits and challenges of food processing in the context of food systems, value chains and sustainable development goals. Trends Food Sci. Technol. 2024, 153, 104703. [Google Scholar] [CrossRef]

- Kamei, M.; Nishibe, M.; Araki, R.; Kohyama, K.; Kusakabe, Y. Effect of texture preference on food texture perception: Exploring the role of matching food texture and preference. Appetite 2023, 192, 107078. [Google Scholar] [CrossRef] [PubMed]

- Arimi, J.; Duggan, E.; O’sullivan, M.; Lyng, J.; O’riordan, E. Crispiness of a microwave-expanded imitation cheese: Mechanical, acoustic and sensory evaluation. J. Food Eng. 2012, 108, 403–409. [Google Scholar] [CrossRef]

- Maruyama, T.T.; Arce, A.I.C.; Ribeiro, L.P.; Costa, E.J.X. Time-frequency analysis of acoustic noise produced by breaking of crisp biscuits. J. Food Eng. 2008, 86, 100–104. [Google Scholar] [CrossRef]

- Sanz, T.; Primo-Martín, C.; van Vliet, T. Characterization of crispness of French fries by fracture and acoustic measurements, effect of pre-frying and final frying times. Food Res. Int. 2007, 40, 63–70. [Google Scholar] [CrossRef]

- Piazza, L.; Gigli, J.; Benedetti, S. Study of structure and flavour release relationships in low moisture bakery products by means of the acoustic-mechanical combined technique and the electronic nose. J. Cereal Sci. 2008, 48, 413–419. [Google Scholar] [CrossRef]

- Grimi, N.; Mamouni, F.; Lebovka, N.; Vorobiev, E.; Vaxelaire, J. Impact of apple processing modes on extracted juice quality: Pressing assisted by pulsed electric fields. J. Food Eng. 2011, 103, 52–61. [Google Scholar] [CrossRef]

- Costa, F.; Cappellin, L.; Fontanari, M.; Longhi, S.; Guerra, W.; Magnago, P.; Gasperi, F.; Biasioli, F. Texture dynamics during postharvest cold storage ripening in apple (Malus×domestica Borkh.). Postharvest Biol. Technol. 2012, 69, 54–63. [Google Scholar] [CrossRef]

- Shmulevich, I.; Galili, N.; Howarth, M. Nondestructive dynamic testing of apples for firmness evaluation. Postharvest Biol. Technol. 2003, 29, 287–299. [Google Scholar] [CrossRef]

- Spence, C. Eating with our ears: Assessing the importance of the sounds of consumption on our perception and enjoyment of multisensory flavour experiences. Flavour 2015, 4, 3. [Google Scholar] [CrossRef]

- Reinoso-Carvalho, F.; Janice Wang, Q. Extrinsic Auditory Contributions to Food Perception. Multisens. Res. 2019, 32, 275–318. [Google Scholar]

- Aboonajmi, M.; Jahangiri, M.; Hassan-Beygi, S.R. A Review on Application of Acoustic Analysis in Quality Evaluation of Agro-food Products. J. Food Process. Preserv. 2015, 39, 3175–3188. [Google Scholar] [CrossRef]

- Dias-Faceto, L.S.; Salvador, A.; Conti-Silva, A.C. Acoustic settings combination as a sensory crispness indicator of dry crispy food. J. Texture Stud. 2019, 51, 232–241. [Google Scholar] [CrossRef] [PubMed]

- JECFA; FAO; WHO. Combined Compendium of Food Additive Specifications—Analytical Methods, Test Procedures and Laboratory Solutions Used by and Referenced in the Food Additive Specification; Food & Agriculture Org.: Rome, Italy, 2005; Volume 4.

- Murugan, P.; Dhanushkodi, S.; Sudhakar, K.; Wilson, V.H. Industrial and small-scale biomass dryers: An overview. Energy Eng. J. Assoc. Energy Eng. 2021, 118, 435–446. [Google Scholar] [CrossRef]

- Yudhistira, B.; Adi, P.; Mulyani, R.; Chang, C.; Gavahian, M.; Hsieh, C. Achieving sustainability in heat drying processing: Leveraging artificial intelligence to maintain food quality and minimize carbon footprint. Com. Rev. Food Sci. Food Saf. 2024, 23, e13413. [Google Scholar] [CrossRef]

- Lewicki, P.P. Design of hot air drying for better foods. Trends Food Sci. Technol. 2006, 17, 153–163. [Google Scholar] [CrossRef]

- Liu, Y.-X.; Cao, M.-J.; Liu, G.-M. Texture Analyzers for Food Quality Evaluation; Elsevier Inc.: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Dooley, L.; Lee, Y.-S.; Meullenet, J.-F. The application of check-all-that-apply (CATA) consumer profiling to preference mapping of vanilla ice cream and its comparison to classical external preference mapping. Food. Qual. Prefer. 2010, 21, 394–401. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, S.; Zhu, B.; Wang, C.; Li, J.; Liu, Y.; Jia, Y.; Zhu, L. Relationship between consumer acceptance, sensory characteristics, and physicochemical characteristics of ‘Fuji’ apples from different origins. J. Food Sci. 2024, 89, 7944–7957. [Google Scholar] [CrossRef]

- Massei, A.; Falco, N.; Fissore, D. NIR-Based Real-Time Monitoring of Freeze-Drying Processes: Application to Fault and Endpoint Detection. Processes 2025, 13, 452. [Google Scholar] [CrossRef]

- Zeng, Z.; Han, C.; Wang, Q.; Yuan, H.; Zhang, X.; Li, B. Analysis of drying characteristic, effective moisture diffusivity and energy, exergy and environment performance indicators during thin layer drying of tea in a convective-hot air dryer. Front. Sustain. Food Syst. 2024, 8, 1371696. [Google Scholar] [CrossRef]

- Veleșcu, I.D.; Rațu, R.N.; Arsenoaia, V.-N.; Roșca, R.; Cârlescu, P.M.; Țenu, I. Research on the Process of Convective Drying of Apples and Apricots Using an Original Drying Installation. Agriculture 2023, 13, 820. [Google Scholar] [CrossRef]

- Pinheiro, M.C.; Castro, L.M. Effective moisture diffusivity prediction in two Portuguese fruit cultivars (Bravo de Esmolfe apple and Madeira banana) using drying kinetics data. Heliyon 2023, 9, e17741. [Google Scholar] [CrossRef] [PubMed]

- Segura-Ponce, L.A.; Soto-Pardo, V.A.; Guzmán-Meza, M.F. Characterization of apples (Granny Smith) dried in industrial equipment and the relationship with drying mechanisms. Food Struct. 2019, 21, 100119. [Google Scholar] [CrossRef]

- Sharabiani, V.R.; Kaveh, M.; Abdi, R.; Szymanek, M.; Tanaś, W. Estimation of moisture ratio for apple drying by convective and microwave methods using artificial neural network modeling. Sci. Rep. 2021, 11, 9155. [Google Scholar] [CrossRef]

- Linke, M.; Praeger, U.; Neuwald, D.A.; Geyer, M. Measurement of Water Vapor Condensation on Apple Surfaces during Controlled Atmosphere Storage. Sensors 2023, 23, 1739. [Google Scholar] [CrossRef]

- Rashvand, M.; Nadimi, M.; Paliwal, J.; Zhang, H.; Feyissa, A.H. Effect of Pulsed Electric Field on the Drying Kinetics of Apple Slices during Vacuum-Assisted Microwave Drying: Experimental, Mathematical and Computational Intelligence Approaches. Appl. Sci. 2024, 14, 7861. [Google Scholar] [CrossRef]

- de Ayala, A.; Foudi, S.; Solà, M.d.M.; López-Bernabé, E.; Galarraga, I. Consumers’ preferences regarding energy efficiency: A qualitative analysis based on the household and services sectors in Spain. Energy Effic. 2021, 14, 3. [Google Scholar] [CrossRef]

- Mari, A.; Parisouli, D.N. Exploring Osmotic Dehydration for Food Preservation: Methods, Modelling, and Modern Applications. Foods 2024, 13, 2783. [Google Scholar] [CrossRef]

- Mazumder, P.; Roopa, B.; Bhattacharya, S. Textural attributes of a model snack food at different moisture contents. J. Food Eng. 2007, 79, 511–516. [Google Scholar] [CrossRef]

- Szczesniak, A.S. Texture is a sensory property. Food Qual. Prefer. 2002, 13, 215–225. [Google Scholar] [CrossRef]

- Zdunek, A.; Konopacka, D. Crispiness and Crunchiness Judgement of Apples Based on Contact Acoustic Emission. J. Texture Stud. 2010, 41, 75–91. [Google Scholar] [CrossRef]

- Duizer, L. A review of acoustic research for studying the sensory perception of crisp, crunchy and crackly textures. Trends Food Sci. Technol. 2001, 12, 17–24. [Google Scholar] [CrossRef]

- Bleha, T.; Cifra, P. Force-displacement relations at compression of dsDNA macromolecules. J. Chem. Phys. 2019, 151, 014901. [Google Scholar] [CrossRef] [PubMed]

- Lucas, P.; Prinz, J.; Agrawal, K.; Bruce, I. Food texture and its effect on ingestion, mastication and swallowing. J. Texture Stud. 2004, 35, 159–170. [Google Scholar] [CrossRef]

- Piazza, L.; Giovenzana, V. Instrumental acoustic-mechanical measures of crispness in apples. Food Res. Int. 2015, 69, 209–215. [Google Scholar] [CrossRef]

- Rizzolo, A.; Vanoli, M.; Cortellino, G.; Spinelli, L.; Contini, D.; Herremans, E.; Bongaers, E.; Nemeth, A.; Leitner, M.; Verboven, P.; et al. Characterizing the tissue of apple air-dried and osmo-air-dried rings by X-CT and OCT and relationship with ring crispness and fruit maturity at harvest measured by TRS. Innov. Food Sci. Emerg. Technol. 2014, 24, 121–130. [Google Scholar] [CrossRef]

- Banaszak, J.; Pawłowski, A. Influence of ultrasound assist during hot air drying on properties of dried apple crisps. Chem. Process Eng. Inz. Chem. I Proces. 2018, 39, 263–270. [Google Scholar] [CrossRef]

- Marzec, A.; Kowalska, H.; Zadrożna, M. Analysis of instrumental and sensory texture attributes of microwave-convective dried apples. J. Texture Stud. 2010, 41, 417–439. [Google Scholar] [CrossRef]

- Bechar, A.; Mizrach, A.; Barreiro, P.; Landahl, S. Determination of mealiness in apples using ultrasonic measurements. Biosyst. Eng. 2005, 91, 329–334. [Google Scholar] [CrossRef]

- Taniwaki, M.; Sakurai, N. Evaluation of the internal quality of agricultural products using acoustic vibration techniques. J. Jpn. Soc. Hortic. Sci. 2010, 79, 113–128. [Google Scholar] [CrossRef]

- Marzec, A.; Kowalska, H.; Pasik, S. Mechanical and Acoustic Properties of Dried Apples. J. Fruit Ornam. Plant Res. 2009, 17, 127–137. [Google Scholar]

- Suman, S.; Khan, M.K.; Pathak, M. Performance enhancement of solar collectors—A review. Renew. Sustain. Energy Rev. 2015, 49, 192–210. [Google Scholar] [CrossRef]

- De Belie, N.; Harker, F.; De Baerdemaeker, J. Crispness judgement of Royal Gala apples based on chewing sounds. Biosyst. Eng. 2002, 81, 297–303. [Google Scholar] [CrossRef]

- Zampini, M.; Spence, C. The role of auditory cues in modulating the perceived crispness and staleness of potato chips. J. Sens. Stud. 2004, 19, 347–363. [Google Scholar] [CrossRef]

- Endo, H.; Ino, S.; Fujisaki, W. The effect of a crunchy pseudo-chewing sound on perceived texture of softened foods. Physiol. Behav. 2016, 167, 324–331. [Google Scholar] [CrossRef]

- Chen, J. Surface texture of foods: Perception and characterization. Crit. Rev. Food Sci. Nutr. 2007, 47, 583–598. [Google Scholar] [CrossRef]

- Imanov, A.; Kozhas, A.; Mukhamejanova, A.; Nazarova, A.; Kazhimkanuly, D. Experimental study of sound wave propagation patterns. Technobius 2024, 4, 0057. [Google Scholar] [CrossRef]

- Demattè, M.L.; Pojer, N.; Endrizzi, I.; Corollaro, M.L.; Betta, E.; Aprea, E.; Charles, M.; Biasioli, F.; Zampini, M.; Gasperi, F. Effects of the sound of the bite on apple perceived crispness and hardness. Food Qual. Prefer. 2014, 38, 58–64. [Google Scholar] [CrossRef]

- van der Sman, R.; Schenk, E. Causal factors concerning the texture of French fries manufactured at industrial scale. Curr. Res. Food Sci. 2024, 8, 100706. [Google Scholar] [CrossRef]

- Khodayari, A.; Hirn, U.; Spirk, S.; Ogawa, Y.; Seveno, D.; Thielemans, W. Advancing plant cell wall modelling: Atomistic insights into cellulose, disordered cellulose, and hemicelluloses—A review. Carbohydr. Polym. 2024, 343, 122415. [Google Scholar] [CrossRef]

- Biswas, R.K.; Khan, P.; Mukherjee, S.; Mukhopadhyay, A.K.; Ghosh, J.; Muraleedharan, K. Study of short range structure of amorphous Silica from PDF using Ag radiation in laboratory XRD system, RAMAN and NEXAFS. J. Non. Cryst. Solids 2018, 488, 1–9. [Google Scholar] [CrossRef]

- Boudina, I.; Delalonde, M.; Koegel, L.; Maraval, I.; Forestier-Chiron, N.; Domingo, R.; Ricci, J.; Sharkawi, T.; Rondet, E. Mechanical approach for the evaluation of the crispiness of food granular products. J. Texture Stud. 2023, 54, 633–645. [Google Scholar] [CrossRef] [PubMed]

- Tunick, M.H.; Onwulata, C.I.; Thomas, A.E.; Phillips, J.G.; Mukhopadhyay, S.; Sheen, S.; Liu, C.-K.; Latona, N.; Pimentel, M.R.; Cooke, P.H. Critical evaluation of crispy and crunchy textures: A review. Int. J. Food Prop. 2013, 16, 949–963. [Google Scholar] [CrossRef]

- Garvey, C.J.; Parker, I.H.; Simon, G.P. On the interpretation of X-ray diffraction powder patterns in terms of the nanostructure of cellulose I fibres. Macromol. Chem. Phys. 2005, 206, 1568–1575. [Google Scholar] [CrossRef]

- Bhat, I.M.; Wani, S.M.; Mir, S.A.; Naseem, Z. Effect of microwave-assisted vacuum and hot air oven drying methods on quality characteristics of apple pomace powder. Food Prod. Process. Nutr. 2023, 5, 26. [Google Scholar] [CrossRef]

- Qadri, T.; Naik, H.R.; Hussain, S.Z.; Naseer, B.; Bhat, T.; Vijaykumar; Wani, F.J. Spray dried apple powder: Qualitative, rheological, structural characterization and its sorption isotherm. Lwt 2022, 165, 113694. [Google Scholar] [CrossRef]

| Peak 1 | Peak 2 | Peak 3 | Peak 4 | Crystallite Size | |||||

|---|---|---|---|---|---|---|---|---|---|

| Sample | (2Ꝋ) | d (Å) | (2Ꝋ) | d (Å) | (2Ꝋ) | d (Å) | (2Ꝋ) | d (Å) | (Å) |

| Fresh | 27.74° | 3.214 | 39.22° | 2.295 | 72.51° | 1.303 | - | - | 7 ± 2 |

| SDA | 16.43° | 5.389 | 20.60° | 4.308 | 37.83° | 2.376 | 43.90° | 2.061 | 18 ± 2 |

| ODA | 17.58° | 5.040 | 20.36 | 4.359 | 25.08 | 3.548 | 34.75° | 2.579 | 16 ± 4 |

| CCA | 16.17° | 5.476 | 19.55° | 4.536 | - | - | - | - | 18 ± 2 |

| CFA | 17.46° | 5.075 | 21.66° | 4.097 | 38.16° | 2.357 | 44.86° | 2.019 | 24 ± 4 |

| Acoustic Signal | Acoustic Analyses | X-Ray | |

|---|---|---|---|

| SDA | low amplitude and short duration signal; weak and brief sound | sound energy concentrated at lower frequencies, with little energy at higher frequencies | increase in crystallinity, comparing to fresh |

| ODA | moderate amplitude and short duration signal; louder than SDA, but still relatively weak sound | sound energy like SDA, but slightly more concentrated at low frequencies | increase in crystallinity, comparing to fresh |

| CCA | moderately high amplitude and prolonged duration signal; more intense and long-lasting sound | more distributed sound energy, with significant peaks at mid-high frequencies | increase in crystallinity, comparing to fresh |

| CFA | high amplitude and long duration signal; very intense and prolonged sound | greater energy at high frequencies, with well-defined peaks | highest increase in crystallinity, comparing to fresh and other drying processes |

| Principal Conclusions | crispness is directly related to the intensity and duration of the acoustic signal | crispness is related to the presence of high frequency components in the sound spectrum | crispiness is associated with crystallinity, but it is largely influenced by drying process |

| SDA | ODA | CCA | CFA | ||

|---|---|---|---|---|---|

| Texture | Dry | 30 | 35 | 41 | 51 |

| Crispy | 73 | 84 | 63 | 80 | |

| Soft/elastic | 14 | 9 | 24 | 10 | |

| Hard | 20 | 29 | 22 | 31 | |

| Firm | 34 | 36 | 26 | 27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernandes, L.; Tavares, P.B.; Gonçalves, C. From Sun to Snack: Different Drying Methods and Their Impact on Crispiness and Consumer Acceptance of Royal Gala Apple Snacks. Horticulturae 2025, 11, 610. https://doi.org/10.3390/horticulturae11060610

Fernandes L, Tavares PB, Gonçalves C. From Sun to Snack: Different Drying Methods and Their Impact on Crispiness and Consumer Acceptance of Royal Gala Apple Snacks. Horticulturae. 2025; 11(6):610. https://doi.org/10.3390/horticulturae11060610

Chicago/Turabian StyleFernandes, Lisete, Pedro B. Tavares, and Carla Gonçalves. 2025. "From Sun to Snack: Different Drying Methods and Their Impact on Crispiness and Consumer Acceptance of Royal Gala Apple Snacks" Horticulturae 11, no. 6: 610. https://doi.org/10.3390/horticulturae11060610

APA StyleFernandes, L., Tavares, P. B., & Gonçalves, C. (2025). From Sun to Snack: Different Drying Methods and Their Impact on Crispiness and Consumer Acceptance of Royal Gala Apple Snacks. Horticulturae, 11(6), 610. https://doi.org/10.3390/horticulturae11060610